CN101981328B - 金属材料部件和复合材料部件间的组装方法 - Google Patents

金属材料部件和复合材料部件间的组装方法 Download PDFInfo

- Publication number

- CN101981328B CN101981328B CN2009801116977A CN200980111697A CN101981328B CN 101981328 B CN101981328 B CN 101981328B CN 2009801116977 A CN2009801116977 A CN 2009801116977A CN 200980111697 A CN200980111697 A CN 200980111697A CN 101981328 B CN101981328 B CN 101981328B

- Authority

- CN

- China

- Prior art keywords

- inserting member

- diameter

- parts

- metallic material

- insert

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000002131 composite material Substances 0.000 title claims abstract description 60

- 238000000034 method Methods 0.000 title claims abstract description 43

- 239000007769 metal material Substances 0.000 title claims abstract description 27

- 229910052751 metal Inorganic materials 0.000 claims abstract description 53

- 239000002184 metal Substances 0.000 claims abstract description 53

- 230000000694 effects Effects 0.000 claims description 7

- 229910000831 Steel Inorganic materials 0.000 claims description 3

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 claims description 3

- 239000010959 steel Substances 0.000 claims description 3

- 239000010936 titanium Substances 0.000 claims description 3

- 229910052719 titanium Inorganic materials 0.000 claims description 3

- 229910001374 Invar Inorganic materials 0.000 claims description 2

- 229910045601 alloy Inorganic materials 0.000 claims description 2

- 239000000956 alloy Substances 0.000 claims description 2

- 230000008878 coupling Effects 0.000 claims description 2

- 238000010168 coupling process Methods 0.000 claims description 2

- 238000005859 coupling reaction Methods 0.000 claims description 2

- 239000000835 fiber Substances 0.000 description 4

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 2

- 208000037656 Respiratory Sounds Diseases 0.000 description 2

- 230000032798 delamination Effects 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 229910002804 graphite Inorganic materials 0.000 description 2

- 239000010439 graphite Substances 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 229910000838 Al alloy Inorganic materials 0.000 description 1

- 239000004593 Epoxy Substances 0.000 description 1

- 230000000712 assembly Effects 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 230000002452 interceptive effect Effects 0.000 description 1

- 210000001503 joint Anatomy 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 238000005728 strengthening Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21J—FORGING; HAMMERING; PRESSING METAL; RIVETING; FORGE FURNACES

- B21J15/00—Riveting

- B21J15/10—Riveting machines

- B21J15/14—Riveting machines specially adapted for riveting specific articles, e.g. brake lining machines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21J—FORGING; HAMMERING; PRESSING METAL; RIVETING; FORGE FURNACES

- B21J15/00—Riveting

- B21J15/02—Riveting procedures

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21J—FORGING; HAMMERING; PRESSING METAL; RIVETING; FORGE FURNACES

- B21J15/00—Riveting

- B21J15/10—Riveting machines

- B21J15/14—Riveting machines specially adapted for riveting specific articles, e.g. brake lining machines

- B21J15/147—Composite articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23P—METAL-WORKING NOT OTHERWISE PROVIDED FOR; COMBINED OPERATIONS; UNIVERSAL MACHINE TOOLS

- B23P9/00—Treating or finishing surfaces mechanically, with or without calibrating, primarily to resist wear or impact, e.g. smoothing or roughening turbine blades or bearings; Features of such surfaces not otherwise provided for, their treatment being unspecified

- B23P9/02—Treating or finishing by applying pressure, e.g. knurling

- B23P9/025—Treating or finishing by applying pressure, e.g. knurling to inner walls of holes by using axially moving tools

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/56—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using mechanical means or mechanical connections, e.g. form-fits

- B29C65/562—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using mechanical means or mechanical connections, e.g. form-fits using extra joining elements, i.e. which are not integral with the parts to be joined

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/05—Particular design of joint configurations

- B29C66/10—Particular design of joint configurations particular design of the joint cross-sections

- B29C66/11—Joint cross-sections comprising a single joint-segment, i.e. one of the parts to be joined comprising a single joint-segment in the joint cross-section

- B29C66/112—Single lapped joints

- B29C66/1122—Single lap to lap joints, i.e. overlap joints

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/05—Particular design of joint configurations

- B29C66/20—Particular design of joint configurations particular design of the joint lines, e.g. of the weld lines

- B29C66/21—Particular design of joint configurations particular design of the joint lines, e.g. of the weld lines said joint lines being formed by a single dot or dash or by several dots or dashes, i.e. spot joining or spot welding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/40—General aspects of joining substantially flat articles, e.g. plates, sheets or web-like materials; Making flat seams in tubular or hollow articles; Joining single elements to substantially flat surfaces

- B29C66/41—Joining substantially flat articles ; Making flat seams in tubular or hollow articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/40—General aspects of joining substantially flat articles, e.g. plates, sheets or web-like materials; Making flat seams in tubular or hollow articles; Joining single elements to substantially flat surfaces

- B29C66/41—Joining substantially flat articles ; Making flat seams in tubular or hollow articles

- B29C66/45—Joining of substantially the whole surface of the articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/72—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the structure of the material of the parts to be joined

- B29C66/721—Fibre-reinforced materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/74—Joining plastics material to non-plastics material

- B29C66/742—Joining plastics material to non-plastics material to metals or their alloys

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/54—Component parts, details or accessories; Auxiliary operations, e.g. feeding or storage of prepregs or SMC after impregnation or during ageing

- B29C70/545—Perforating, cutting or machining during or after moulding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/71—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the composition of the plastics material of the parts to be joined

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/72—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the structure of the material of the parts to be joined

- B29C66/721—Fibre-reinforced materials

- B29C66/7212—Fibre-reinforced materials characterised by the composition of the fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2305/00—Use of metals, their alloys or their compounds, as reinforcement

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16B—DEVICES FOR FASTENING OR SECURING CONSTRUCTIONAL ELEMENTS OR MACHINE PARTS TOGETHER, e.g. NAILS, BOLTS, CIRCLIPS, CLAMPS, CLIPS OR WEDGES; JOINTS OR JOINTING

- F16B5/00—Joining sheets or plates, e.g. panels, to one another or to strips or bars parallel to them

- F16B5/04—Joining sheets or plates, e.g. panels, to one another or to strips or bars parallel to them by means of riveting

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49826—Assembling or joining

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49826—Assembling or joining

- Y10T29/49908—Joining by deforming

- Y10T29/49938—Radially expanding part in cavity, aperture, or hollow body

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Composite Materials (AREA)

- Connection Of Plates (AREA)

Abstract

本发明涉及一种金属材料部件(1)和复合材料部件(2)间的组装方法,所述部件间的组装是借助于固定构件(11)来实现的,其特征在于所述方法包括如下步骤,其中:-在这两个部件中进行预钻孔,以便在金属材料部件(1)中和在复合材料部件(2)中形成具有直径D1的镂空(6),-在所述镂空(6)中在部件的厚度的方向上放置直径可变的插入件(9),所述插入件包括空心主体(12)和至少一个凸缘(10),该凸缘(10)至少有一部分紧贴一个部件的外表面(101),所述插入件(9)用于接纳固定构件(11),-通过利用外径与插入件的内径匹配的扩孔工具(7)进行的径向扩孔,在插入件的内壁上沿着插入件(9)的周缘在两个部件的至少一个区域中产生残余压应力,-对插入件的主体(12)的镂空再镗孔,使得插入件的最终内径D最终明显大于固定构件(11)的外径,以在插入件的内壁和固定构件的外表面之间留出间隙,以及-将固定构件(11)放入插入件中,以将金属部件和复合部件保持为一体。

Description

技术领域

本发明涉及金属材料部件(例如,金属支座)和复合材料部件(例如,夹层结构板)间的组装方法。

背景技术

一般来说,本发明可应用于需要组装至少一个金属材料部件与复合材料部件的情况,尤其针对要承受相当多的机械应力的组装。更特别地,本发明可应用于组装方法可能影响航空结构的疲劳寿命和安全性的航空领域。本发明还可应用于陆上车辆的领域,以组装用于形成轻质结构的部件。

在后续说明中,“金属材料部件”和“复合材料部件”被分别表述为“金属部件”和“复合部件”。

已知可使用扩大镗孔以及干涉安装固件的方法来增加两个金属部件间的组件的疲劳寿命。这些扩孔和干涉方法导致在镗孔表面处以及在镂空周围在部件中的残余压应力。这些应力会产生如下效果:在紧挨着镗孔的镗孔周围减缓疲劳裂纹的触发和扩展。从而增加了疲劳寿命。

图1A示出了被称为“干涉安装”的一种已知方法,该方法用于两个金属部件1a、1b间的组装。该方法在于在这两个金属部件中实现孔眼4,孔眼的直径D孔眼小于固件直径D固件(固件直径D固件是固件杆的直径)。在固定孔眼中插入固件3时在孔眼周围直接产生压应力。

图1B示意性地示出了被称为“扩孔方法”的一种已知方法的另一示例,该方法用于在金属部件1a与第二金属部件1b的组装中在固定孔眼4周围局部地产生残余压应力。使用扩孔工具7。该方法包括如下步骤:

-通过传统的镗孔工具在两个金属部件中实现固定孔眼,选择孔眼的直径以使其适合于扩孔工具7的直径,即孔眼的直径D孔眼必须略小于扩孔工具的直径;

-然后,使被称为“抛光器”的扩孔工具7穿过在前一步骤中实现的孔眼,该工具包括橄榄形的扩孔头701,该扩孔头701具有大于固定孔眼的直径D孔眼的直径D扩大,在扩孔工具7穿过孔眼时将在孔眼的内壁上施加径向作用,因此在孔眼周围在两个部件中产生残余压应力,以及最后

-对固定孔眼再镗孔以使孔眼直径适合于固件杆的直径,然后安装该固件用于保持两部件的组装。

现有的两种方法允许产生应力以便增加在工作区域处的疲劳寿命,由于裂纹起源于荷载区域中,因此这种应力至关重要。

在金属部件和复合部件间的组装范畴内,不能再应用存在严重损坏复合部件的风险的如上所述的方法。

复合材料部件在抗机械疲劳方面表现出优良的特性,并且具有很强的刚性,同时赋予结构相当小的质量。这种部件尤其应用在航空工业中(在航空工业中,这种部件被包含在高强度荷载的结构中)。然而,相比于金属部件的情况,这种复合部件的组装带来了特别的问题。

实际上,复合部件由通过浸渍树脂的纤维(例如,浸渍环氧树脂的碳纤维)的层叠而获得的结构构成。这种复合部件在纤维层的平面上具有有利的结构特性,但在垂直于这些平面的方向上(也就是说,在部件厚度的方向上,使用该方向来放置固件)易于受起鳞现象的影响。

由固定装置施加的压迫作用可能在孔眼处造成起鳞现象。按照用来避免起鳞现象的一般方式,必须使得在固定区域处(即在固定孔眼的内壁和固定构件之间的界面处)产生的应力最小化。为此,与将金属部件与另一金属部件组装的情况相反,通常实现直径略大于固件直径的固定孔眼,以便在孔眼内壁和固件的外表面之间留出足够的间隙以避免干涉。

在航空结构中,金属部件和复合部件的共存导致经常要对金属部件与复合部件进行组装。这可能涉及到不同结构的两块板之间的接合、或者涉及到局部加固,例如复合板上的金属加强肋或加固件。

在这样的组装中,或者选择在孔眼壁和固件之间包含间隙的组装,因此这种安装在疲劳寿命上对于金属部件不利;或者选择利用干涉的组装,而这种安装存在损坏复合部件的风险。

一种解决方案在于,在金属部件中以及在复合部件(这两个部件是分开的)中独立地实现用于固定的孔眼,然后在没有复合部件的情况下在金属部件中产生残余压应力,然后在第二时段中将复合部件对着金属部件放置以进行组装。该解决方案并不令人满意,实际上,在这种情况下,必须预先精确地确定孔眼的位置从而在组装时将孔眼对准以使固件穿过。这种对准在工业上是不可实现的。

一个未公开的在先申请中提出另一种解决方案,该方案在于在金属部件中和在复合部件中实现固定孔眼,然后在复合部件一侧的孔眼中进行新的镗孔,以便获得比扩孔工具的直径大的内径。因此,在固定孔眼中存在两个内径使得能够只在金属部件中产生残余压应力。

但是,该解决方案必须具有在复合部件侧的入口,甚至每侧都必须具有入口。

发明内容

因此,本发明的目的在于,寻求在不对金属部件的疲劳寿命造成损失并且不损害复合部件的情况下借助于固件来解决金属部件和复合部件间的组装问题。

本发明的另一目的是能够提出一种即便在只有金属部件侧的一个入口的情况下也能够应用的解决方案。

为此,本发明旨在一种金属材料部件和复合材料部件间的组装方法,所述部件间的组装是借助于固定构件来实现的。

根据本发明,该方法包括如下步骤,其中:

-在两个部件中进行预钻孔,以便在金属材料部件中和在复合材料部件中形成具有直径D1的镂空,

-在所述镂空中在部件的厚度的方向上放置直径可变的插入件,所述插入件包括空心主体和至少一个凸缘,该凸缘至少有一部分紧贴部件的外表面,所述插入件用于接纳固定构件,

-通过利用外径与插入件的内径匹配的扩孔工具进行的径向扩孔,在插入件的内壁上沿着插入件的周缘在两个部件的至少一个区域中产生残余压应力,

-对插入件的主体的镂空再镗孔,使得插入件的最终内径D最终明显大于固定构件的外径,以在插入件的内壁和固定构件的外表面之间留出间隙,以及

-将固定构件置入插入件中,以将金属部件和复合部件保持为一体。

本发明还涉及使用如上所述的用于实现将复合材料部件(例如夹层结构板)固定在金属材料部件(例如板的支座)上的方法来实现飞行器结构。

附图说明

通过阅读随后的描述并参照附图将更好地理解本发明。这些附图是作为示例给出的,而绝非限制本发明。这些附图表示:

-图1A是实施根据现有技术的干涉安装方法的两个金属部件间的组件的截面图;

-图1B是实施根据现有技术的另一方法的两个金属部件间的组件的截面图;

-图2A、图2B、图2C、图2D和图2E示出根据本发明第一实施方式的金属部件和复合部件间的组装方法的各个步骤;

-图3A、图3B、图3C、图3D示出根据本发明第二实施方式的金属部件和复合部件间的组装方法的各个步骤。

具体实施方式

一般来说,根据本发明的方法可应用于金属部件1和复合部件2间的组装,金属部件1和复合部件2是两个分开的部件并且通过固定构件(该固定构件被放置在在所述部件中实现的镗孔中)来保持这个两个部件对置。

本发明的主要设想是能够在金属部件和复合部件间的组装之前先通过扩孔方法在镗孔周围在金属部件中产生应力而不损害复合部件。应力的存在使得能够增加金属部件中的疲劳寿命并减缓裂纹的扩展。

为此,必须在没有与复合部件的干涉的情况下实现扩孔方法的步骤,以避免在复合部件内部产生会损害复合部件的应力。

此外,即便在只有金属部件侧的一个入口的情况下也应该能够实施该扩孔方法。

图2A、图2B、图2C、图2D和图2E中示出了根据本发明第一实施方式的扩孔方法的各个步骤,所述第一实施方式针对通过固定构件11的金属部件1和复合部件2间的组装。固定构件11是由钢或者钛制成的螺栓。

作为示例,金属部件1可以用铝合金来制造,而复合部件2可以用包括由树脂固定的纤维(例如碳纤维)的复合材料来制造。

作为示例,金属材料部件1是金属支座,而复合材料部件2是夹层结构板。

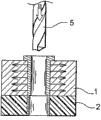

在两个部件1、2中进行预钻孔以便在金属材料部件1和复合材料部件2中形成具有直径D1的镂空6(图2A)。通过传统的镗孔工具5实现该预钻孔。

然后,将直径可变的插入件9在部件厚度的方向上放入该镂空6中(图2B)。插入件包括用于使固定构件11穿过的空心主体12和与两个部件中的一个的外表面101紧贴的凸缘10。在图2B中示出的示例中,凸缘紧贴金属部件1的外表面。优选地,可以在凸缘和金属部件的外表面之间布置粘合层,以确保插入件在镂空中的固定。

在本发明的变型中,在组件的每一侧均具有入口,插入件可以在空心主体的两端均包含紧贴部件外表面的凸缘。

该插入件的功能在于实现扩孔工具和两个部件的对接。

在本发明的第一实施方式中,当插入件被放置在所述镂空6中时,该插入件9包含下部和上部,下部具有对应于复合材料部件2的内径D2,上部具有对应于金属材料部件1的内径D3。插入件的下部的内径D2介于镂空的直径D1和插入件的上部的内径D3之间。

根据本发明的第一实施方式,插入扩孔工具7,扩孔工具7的扩孔直径D4大于插入件的内径D2和D3(图2C)。因此,当将扩孔工具7插入到插入件的空心主体12中时,该工具对插入件内壁在整体上施加径向作用,从而在插入件周围在金属部件中和在复合部件中同时产生残余压应力。由于直径D2很轻微地小于直径D4,因此,金属部件中的扩孔率高于复合部件中的扩孔率。

因此,通过直径在部件厚度方向上变化的插入件,能够控制扩孔方法,尤其是能够优先考虑金属部件中的扩孔率,以改善疲劳寿命同时防止复合部件可能的起鳞。

在两个部件间的组装之前先在两个部件中实现残余压应力,这使得能够在金属部件中实现直径大于固定构件的直径的钻孔,以便能与制造公差兼容并且在可能的情况下允许部件的互换性。

在最终步骤(图2D和图2E)中,对插入件的主体12的镂空再镗孔,以使插入件的最终内径D最终明显大于固定构件11的外径,以在插入件的内壁和固定构件的外表面之间留出间隙,并且将固定构件11放置在插入件中以将金属部件和复合部件保持为一体以实现组装。

插入件9为金属材料制成的整体部件,其弹性模量和塑性屈服应力大于组件的金属部件的弹性模量和塑性屈服应力。优选地,插入件9由钢、钛或因瓦合金制成。

扩孔工具7包括管状主体702和扩孔头701,管状主体702的外径D5小于插入件的内径D2和D3,并且在该实施方式中扩孔头701的外径D4同时大于插入件的内径D3和直径D4。

图3A、图3B、图3C和图3D示出本发明的第二实施方式,其中,为了在复合部件中避免所有起鳞的风险,本发明的方法使得能够不对复合部件扩孔而仅对金属部件扩孔,也就是说,只在插入件周围在金属部件中产生残余压应力。

为此,使用具有扩孔直径D4的扩孔工具7,扩孔直径D4既大于内径D3而又小于内径D2。因此,当该工具穿过插入件的空心主体11时,其仅对插入件内壁的与金属材料部件1对应的上部施加径向作用,从而仅在金属材料部件中产生残余压应力。

基于金属部件(例如金属支座)和复合部件(例如夹层结构板)间的组装,上述方法可被用于制造所有类型的飞行器结构100或所有类型的陆上车辆。

Claims (9)

1.一种金属材料部件(1)和复合材料部件(2)间的组装方法,所述部件间的组装是借助于固定构件(11)来实现的,其特征在于所述方法包括如下步骤,其中:

-在这两个部件中进行预钻孔,以便在所述金属材料部件(1)中和在所述复合材料部件(2)中形成具有直径D1的镂空(6),

-在所述镂空(6)中在所述部件的厚度的方向上放置直径能够变化的插入件(9),所述插入件包括空心主体(12)和至少一个凸缘(10),所述凸缘(10)至少有一部分紧贴所述两个部件(1,2)中的一个的外表面(101),所述插入件(9)用于接纳所述固定构件(11),

-通过利用外径与所述插入件的内径匹配的扩孔工具(7)进行的径向扩孔,在所述插入件内壁上沿着所述插入件(9)的周缘在所述两个部件的至少一个区域中产生残余压应力,

-对所述插入件的所述主体(12)的所述镂空再镗孔,使得所述插入件的最终内径D最终明显大于所述固定构件(11)的外径,以在所述插入件的内壁和所述固定构件的外表面之间留出间隙,以及

-将所述固定构件(11)放入所述插入件中,以将所述金属材料部件和所述复合材料部件保持为一体。

2.根据权利要求1所述的方法,其特征在于,当所述插入件被放置在所述镂空(6)中时,所述插入件(9)包括下部和上部,所述下部具有对应于所述复合材料部件(2)的内径D2,所述上部具有对应于所述金属材料部件(1)的内径D3,所述内径D2大于D3并介于所述镂空的直径D1和所述插入件(9)的上部的内径D3之间。

3.根据权利要求2所述的方法,其特征在于,所述扩孔工具(7)具有大于所述插入件(9)的内径D2和D3的扩孔直径D4,以使所述工具对所述插入件的内壁在整体上施加径向作用,从而在所述金属材料部件中和在所述复合材料部件中产生残余压应力,所述金属材料部件中的扩孔率高于所述复合材料部件中的扩孔率。

4.根据权利要求2所述的方法,其特征在于,所述扩孔工具(7)具有既大于所述内径D3而又小于所述内径D2的扩孔直径D4,以使所述工具仅对所述插入件内壁的与所述金属材料部件对应的上部施加径向作用,因此仅在所述金属材料部件中产生残余压应力。

5.根据权利要求2所述的方法,其特征在于,所述扩孔工具包括管状主体(702)和扩孔头(701),所述管状主体(702)的外径D5小于所述插入件的内径D2和D3,所述扩孔头(701)的外径D4大于所述插入件的内径D3。

6.根据权利要求1到5之一所述的方法,其特征在于,所述插入件是由金属材料制成的整体部件。

7.根据权利要求6所述的方法,其特征在于,构成所述插入件的所述金属材料选自:钢以及钛。

8.根据权利要求6所述的方法,其特征在于,构成所述插入件的所述金属材料为因瓦合金。

9.根据权利要求1到5之一所述的方法,其特征在于,所述金属材料部件(1)为金属支座,而所述复合材料部件(2)为夹层结构板。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0852016 | 2008-03-28 | ||

| FR0852016A FR2929352B1 (fr) | 2008-03-28 | 2008-03-28 | Procede d'assemblage entre une piece en materiau metallique et une piece en materiau composite |

| PCT/FR2009/050447 WO2009122092A1 (fr) | 2008-03-28 | 2009-03-18 | Procédé d'assemblage entre une pièce en matériau métallique et une pièce en matériau composite |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN101981328A CN101981328A (zh) | 2011-02-23 |

| CN101981328B true CN101981328B (zh) | 2012-08-08 |

Family

ID=39745636

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2009801116977A Expired - Fee Related CN101981328B (zh) | 2008-03-28 | 2009-03-18 | 金属材料部件和复合材料部件间的组装方法 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US8458885B2 (zh) |

| EP (1) | EP2271850B1 (zh) |

| CN (1) | CN101981328B (zh) |

| BR (1) | BRPI0909478A2 (zh) |

| CA (1) | CA2719149C (zh) |

| FR (1) | FR2929352B1 (zh) |

| WO (1) | WO2009122092A1 (zh) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2970203B1 (fr) * | 2011-01-12 | 2014-02-14 | Airbus Operations Sas | Procede d'amelioration des proprietes mecaniques d'un assemblage en materiau composite |

| US20120201999A1 (en) * | 2011-02-08 | 2012-08-09 | Woods Mark A | Methods and apparatus for mechanically joining metal components and composite components |

| DE102012009505A1 (de) * | 2012-05-14 | 2013-11-14 | Johnson Controls Gmbh | Bauteilanordnung, fahrzeugsitz und herstellungsverfahren |

| US9180509B2 (en) | 2013-10-24 | 2015-11-10 | The Boeing Company | Cold working holes in a composite and metal stack |

| FR3043349B1 (fr) * | 2015-11-09 | 2017-10-27 | Airbus Operations Sas | Bague d'expansion comprenant au moins deux bagues exterieures et procede d'expansion a froid utilisant ladite bague d'expansion |

| FR3043348B1 (fr) * | 2015-11-09 | 2018-03-02 | Airbus Operations | Bague d'expansion comprenant au moins deux portions cylindriques avec des proprietes mecaniques differentes, procede de fabrication d'une telle bague d'expansion et procede d'expansion a froid utilisant ladite bague d'expansion |

| FR3072322B1 (fr) * | 2017-10-13 | 2023-03-24 | Psa Automobiles Sa | Piece en materiau composite avec insert metallique |

| EP3622846A1 (fr) | 2018-09-14 | 2020-03-18 | Comadur S.A. | Procede d'assemblage d'au moins deux elements |

| US11892035B2 (en) * | 2021-04-23 | 2024-02-06 | Hamilton Sundstrand Corporation | Composite/metal joints |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2551147A1 (fr) * | 1983-08-22 | 1985-03-01 | Salter Larry | Procede et dispositif pour reduire les forces et les couts de montage dans un systeme a boulon conique |

| CN1847674A (zh) * | 2005-04-15 | 2006-10-18 | 斯奈克玛 | 安装两个部件的方法,至少一个部件由合成物制成,以及用于完成安装的插入物 |

| US7347641B2 (en) * | 2004-03-31 | 2008-03-25 | The Boeing Company | Methods and systems for joining structures |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3603626A (en) * | 1969-01-27 | 1971-09-07 | Standard Pressed Steel Co | High-strength joint and fastener assembly therefor |

| US4087896A (en) * | 1976-09-17 | 1978-05-09 | Paul R. Briles | Sleeve bolt installation nut |

| SE527876C2 (sv) * | 2004-11-26 | 2006-07-04 | Safetrack Infrasystems Sisab A | Metod och anordning för anslutning av en elektrisk ledare till en metallskena samt verktyg för fastsättning av en bussning i ett hål i en metallskena |

-

2008

- 2008-03-28 FR FR0852016A patent/FR2929352B1/fr not_active Expired - Fee Related

-

2009

- 2009-03-18 WO PCT/FR2009/050447 patent/WO2009122092A1/fr active Application Filing

- 2009-03-18 EP EP09727393A patent/EP2271850B1/fr active Active

- 2009-03-18 CN CN2009801116977A patent/CN101981328B/zh not_active Expired - Fee Related

- 2009-03-18 CA CA2719149A patent/CA2719149C/fr active Active

- 2009-03-18 US US12/934,281 patent/US8458885B2/en not_active Expired - Fee Related

- 2009-03-18 BR BRPI0909478A patent/BRPI0909478A2/pt not_active IP Right Cessation

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2551147A1 (fr) * | 1983-08-22 | 1985-03-01 | Salter Larry | Procede et dispositif pour reduire les forces et les couts de montage dans un systeme a boulon conique |

| US7347641B2 (en) * | 2004-03-31 | 2008-03-25 | The Boeing Company | Methods and systems for joining structures |

| CN1847674A (zh) * | 2005-04-15 | 2006-10-18 | 斯奈克玛 | 安装两个部件的方法,至少一个部件由合成物制成,以及用于完成安装的插入物 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN101981328A (zh) | 2011-02-23 |

| FR2929352A1 (fr) | 2009-10-02 |

| EP2271850B1 (fr) | 2012-10-31 |

| CA2719149C (fr) | 2015-04-28 |

| US20110119891A1 (en) | 2011-05-26 |

| US8458885B2 (en) | 2013-06-11 |

| WO2009122092A1 (fr) | 2009-10-08 |

| FR2929352B1 (fr) | 2010-04-09 |

| EP2271850A1 (fr) | 2011-01-12 |

| BRPI0909478A2 (pt) | 2015-12-22 |

| CA2719149A1 (fr) | 2009-10-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101981328B (zh) | 金属材料部件和复合材料部件间的组装方法 | |

| CN101595314B (zh) | 用于复合材料的螺母板紧固件组件 | |

| US8656593B2 (en) | Method for assembling a part of a metal material and a part of a composite material using a fastener | |

| US10752377B2 (en) | Method and apparatus for preventing lightning strike damage to a structural component | |

| US8926263B2 (en) | Turbomachine casing assembly | |

| US9562559B2 (en) | Connecting arrangement and also a method | |

| EP3036445B1 (en) | Replacing an aperture with an annular bushing in a composite laminated composite component | |

| US7510372B2 (en) | Wedge repair of mechanically retained vanes | |

| RU2698039C2 (ru) | Ремонт сборной детали, содержащей основное тело и упрочняющий элемент | |

| EP3062990B1 (en) | Fastening structure | |

| US20120275913A1 (en) | External threaded mount attachment for fan case | |

| JP2012531341A (ja) | 胴体セグメント及び接合手段を含む胴体要素 | |

| US9523281B2 (en) | Blade for a wind turbine | |

| JP4947604B2 (ja) | 中空構造のロッドならびにその製造方法 | |

| JP2010241420A6 (ja) | ラダーストック | |

| CN103648906B (zh) | 纤维复合部件、小翼和具有纤维复合部件的飞行器 | |

| US9533383B2 (en) | Method for repairing a flange of a housing | |

| US9347752B2 (en) | Connecting element for a body made of composite material of a piercing projectile | |

| US8192575B2 (en) | Process for mounting a metal part in a composite material part | |

| GB2539604A (en) | Riveted assembly and associated production method | |

| CN204082799U (zh) | 工件连接装置以及安装组件 | |

| US20200276776A1 (en) | Method for repairing a composite profile | |

| EP3482917A1 (en) | Joining components | |

| WO2018177901A1 (en) | Wheel for a vehicle |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20120808 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |