CN101966566A - Rotary outlet type submerged nozzle for continuous casting - Google Patents

Rotary outlet type submerged nozzle for continuous casting Download PDFInfo

- Publication number

- CN101966566A CN101966566A CN 201010511760 CN201010511760A CN101966566A CN 101966566 A CN101966566 A CN 101966566A CN 201010511760 CN201010511760 CN 201010511760 CN 201010511760 A CN201010511760 A CN 201010511760A CN 101966566 A CN101966566 A CN 101966566A

- Authority

- CN

- China

- Prior art keywords

- continuous casting

- submerged nozzle

- submersed nozzle

- rotary outlet

- molten steel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Carbon Steel Or Casting Steel Manufacturing (AREA)

- Continuous Casting (AREA)

Abstract

The invention provides a rotary outlet type submerged nozzle for continuous casting, which comprises a submerged nozzle body and a water inlet and a water outlet which are mutually orthogonal, wherein the bottom surface of the submerged nozzle is provided with at least two diversion ports, and the diversion ports are arranged in a spiral way. The invention has the main advantage that the rotary outlet type submerged nozzle for continuous casting can enable the temperature of molten steel to be more uniform, better control the dissolving of crystallizer protecting slag, reduce the generation possibility of eddy current, improve the quality of molten steel, replace the electromagnetic stirring effect to a certain extent and save the energy.

Description

Technical field

The present invention relates to a kind of continuous casting rotary outlet submersed nozzle.

Background technology

Continuous casting is the important production process of modern steel metallurgy, and the effect of submersed nozzle is that metallic solution is incorporated into the crystallizer from tundish.Submersed nozzle is steel mill's continuous casting requisite parts of equipment, and it is except having the steel of guiding stream, and main is control and improves the flow regime of steel stream in crystallizer, and the interior liquid level of maintenance crystallizer is stable.

As shown in Figure 1, general submersed nozzle for routine, the inwall of its submersed nozzle body 1 is through-type, molten steel enters from water inlet 11, by through-type passage from flowing out with the vertically disposed delivery ports 12 of water inlet 11, the flow-guiding mouth that the bottom surface 3 of delivery port 12 is offered is straight flow-guiding mouth 31, and the generation of eddy current is arranged when causing molten steel to enter mould, influences the quality of molten steel.

Summary of the invention

The objective of the invention is to solve above-mentioned technical problem, a kind of continuous casting rotary outlet submersed nozzle is provided.

Purpose of the present invention is achieved through the following technical solutions:

A kind of continuous casting rotary outlet submersed nozzle comprises submersed nozzle body, mutual vertically disposed water inlet and delivery port, is provided with two flow-guiding mouths on the bottom surface of wherein said submersed nozzle at least, and described flow-guiding mouth is the spiral setting.

Further, above-described continuous casting rotary outlet submersed nozzle, relative formation one up/down steps in wherein said flow-guiding mouth bottom surface with delivery port bottom surface, bottom center position.

Beneficial effect of the present invention is mainly reflected in: continuous casting can make the more uniform temperature of molten steel with the rotary outlet submersed nozzle; the better dissolving of crystallization control device covering slag reduces the generation of eddy current, improves the quality of molten steel; and can replace the use of electromagnetic agitation to a certain extent, save the energy.

Description of drawings

Below in conjunction with accompanying drawing technical solution of the present invention is described further:

Fig. 1: common submersed nozzle generalized section of the prior art.

Fig. 2: common submersed nozzle of the prior art is along the cutaway view of A-A.

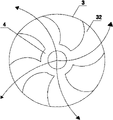

Fig. 3: submersed nozzle of the present invention is along the cutaway view of A-A.

Wherein:

1 submersed nozzle body, 11 water inlets, 12 delivery ports

3 bottom surfaces, 31 straight flow-guiding mouth 32 flow-guiding mouths

4 steps

The specific embodiment

The present invention has disclosed a kind of continuous casting rotary outlet submersed nozzle, as shown in Figure 2, comprises submersed nozzle body 1, mutual vertically disposed water inlet 11 and delivery port 12, is provided with the flow-guiding mouth 32 that two spirals are provided with on the bottom surface 3 of submersed nozzle at least.Simultaneously, form a up/down steps 4 in flow-guiding mouth 32 bottom surfaces and delivery port bottom surface, 3 center, bottom surface, step 4 has played the effect of buffering when molten steel flows out.

The present invention compared with prior art has the following advantages: continuous casting can make the more uniform temperature of molten steel with the rotary outlet submersed nozzle; the better dissolving of crystallization control device covering slag; because flow-guiding mouth 32 adopts the spiral setting; reduce the generation of eddy current; improve the quality of molten steel; and can replace the use of electromagnetic agitation to a certain extent, save the energy.

The present invention still has multiple concrete embodiment, and all employings are equal to replacement or equivalent transformation and all technical schemes of forming, all drop within the scope of protection of present invention.

Claims (2)

1. continuous casting rotary outlet submersed nozzle, comprise submersed nozzle body (1), mutual vertically disposed water inlet (11) and delivery port (12), it is characterized in that: be provided with two flow-guiding mouths (32) on the bottom surface of described submersed nozzle (3) at least, described flow-guiding mouth (32) is the spiral setting.

2. continuous casting rotary outlet submersed nozzle according to claim 1 is characterized in that: described flow-guiding mouth (32) bottom surface and bottom surface (3) relative formation one up/down steps in delivery port bottom surface, center (4).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201010511760 CN101966566A (en) | 2010-10-19 | 2010-10-19 | Rotary outlet type submerged nozzle for continuous casting |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201010511760 CN101966566A (en) | 2010-10-19 | 2010-10-19 | Rotary outlet type submerged nozzle for continuous casting |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN101966566A true CN101966566A (en) | 2011-02-09 |

Family

ID=43545822

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN 201010511760 Pending CN101966566A (en) | 2010-10-19 | 2010-10-19 | Rotary outlet type submerged nozzle for continuous casting |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN101966566A (en) |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN2607214Y (en) * | 2003-02-19 | 2004-03-24 | 鞍山钢铁集团公司 | Immersed nozzle for continuous casting mould |

| CN201008964Y (en) * | 2007-03-16 | 2008-01-23 | 宝山钢铁股份有限公司 | Immersed water gap of bakie |

| CN201082465Y (en) * | 2007-08-28 | 2008-07-09 | 宝山钢铁股份有限公司 | Immersion water gap for continuous casting |

| CN201470878U (en) * | 2009-07-13 | 2010-05-19 | 河北钢铁股份有限公司 | Thin-slab continuous casting tundish submerged nozzle |

| CN201823930U (en) * | 2010-10-19 | 2011-05-11 | 维苏威高级陶瓷(苏州)有限公司 | Submerged nozzle with rotary outlet for continuous casting |

-

2010

- 2010-10-19 CN CN 201010511760 patent/CN101966566A/en active Pending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN2607214Y (en) * | 2003-02-19 | 2004-03-24 | 鞍山钢铁集团公司 | Immersed nozzle for continuous casting mould |

| CN201008964Y (en) * | 2007-03-16 | 2008-01-23 | 宝山钢铁股份有限公司 | Immersed water gap of bakie |

| CN201082465Y (en) * | 2007-08-28 | 2008-07-09 | 宝山钢铁股份有限公司 | Immersion water gap for continuous casting |

| CN201470878U (en) * | 2009-07-13 | 2010-05-19 | 河北钢铁股份有限公司 | Thin-slab continuous casting tundish submerged nozzle |

| CN201823930U (en) * | 2010-10-19 | 2011-05-11 | 维苏威高级陶瓷(苏州)有限公司 | Submerged nozzle with rotary outlet for continuous casting |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR102455602B1 (en) | Flow-controllable tundish structure that can filter the inclusions in molten steel | |

| CN105965003B (en) | A kind of mouth of a river whirlwind generator and mouth of a river eddy flow continuous cast method | |

| CN101733373A (en) | Submerged nozzle for sheet billet continuous casting crystallizer | |

| CN110125379A (en) | A kind of submersed nozzle reducing nozzle blocking | |

| CN102958629A (en) | Submerged entry nozzle | |

| CN204770627U (en) | Packing is put in middle of single current passageway formula induction heating bend pipe type passageway | |

| CN201823930U (en) | Submerged nozzle with rotary outlet for continuous casting | |

| CN201082465Y (en) | Immersion water gap for continuous casting | |

| CN205496560U (en) | Prevent bias flow immersion nozzle structure | |

| CN202479461U (en) | Immersion type rotational-flow water gap for continuous casting | |

| CN201136054Y (en) | Submerged type pouring head for continuous casting jobbing sheet blank | |

| CN108436071B (en) | Spin-flow long nozzle for continuous casting | |

| CN201565600U (en) | Immersion type water opening used for thin plate blank continuous casting crystallizer | |

| CN207026437U (en) | A kind of roll-casting of magnesium alloy case before tilting casting and rolling machine-lip system | |

| CN201815639U (en) | Submerged nozzle with cascade inner wall for continuous casting | |

| CN101966566A (en) | Rotary outlet type submerged nozzle for continuous casting | |

| CN204799939U (en) | Immersion nozzle structure | |

| CN209736576U (en) | Novel rotational flow downward casting device | |

| CN201026526Y (en) | High molten steel flux submerged type pouring head for continuous casting thin sheet blank | |

| CN201198030Y (en) | Flat immersion water inlet for continuous casting of special-shaped billet | |

| CN101966565A (en) | Continuous casting ladder inner wall submersed nozzle | |

| CN203209685U (en) | Quasi-four-hole immersed nozzle for FTSC thin slab continuous casting crystallizer | |

| CN102950275B (en) | Multi-hole continuous-casting submersed nozzle for square and round billets | |

| CN203292440U (en) | Continuous casting submerged nozzle capable of reducing molten steel impact | |

| CN203184640U (en) | Electromagnetism rotational flow water gap for continuous casting |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication |

Application publication date: 20110209 |