CN101394025B - Terminal crimping structure onto aluminum electric-wire and producing method of alminum electric-wire with terminal - Google Patents

Terminal crimping structure onto aluminum electric-wire and producing method of alminum electric-wire with terminal Download PDFInfo

- Publication number

- CN101394025B CN101394025B CN2008101747810A CN200810174781A CN101394025B CN 101394025 B CN101394025 B CN 101394025B CN 2008101747810 A CN2008101747810 A CN 2008101747810A CN 200810174781 A CN200810174781 A CN 200810174781A CN 101394025 B CN101394025 B CN 101394025B

- Authority

- CN

- China

- Prior art keywords

- crimping

- electric wire

- aluminium

- terminal

- wire

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 229910052782 aluminium Inorganic materials 0.000 title claims abstract description 578

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 title claims abstract description 540

- 238000002788 crimping Methods 0.000 title claims abstract description 443

- 238000000034 method Methods 0.000 title abstract description 27

- 239000004020 conductor Substances 0.000 claims abstract description 205

- 238000004519 manufacturing process Methods 0.000 claims abstract description 22

- 239000011810 insulating material Substances 0.000 claims abstract description 11

- 239000004411 aluminium Substances 0.000 claims description 564

- 238000007906 compression Methods 0.000 claims description 178

- 230000006835 compression Effects 0.000 claims description 176

- 238000000576 coating method Methods 0.000 claims description 32

- 238000012423 maintenance Methods 0.000 claims description 19

- 238000013459 approach Methods 0.000 claims description 18

- 150000001398 aluminium Chemical class 0.000 claims description 8

- 230000000694 effects Effects 0.000 abstract description 5

- 238000010301 surface-oxidation reaction Methods 0.000 abstract 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 31

- 229910052802 copper Inorganic materials 0.000 description 31

- 239000010949 copper Substances 0.000 description 31

- 238000012360 testing method Methods 0.000 description 29

- 230000007613 environmental effect Effects 0.000 description 12

- 238000009826 distribution Methods 0.000 description 11

- 238000002360 preparation method Methods 0.000 description 10

- 230000015572 biosynthetic process Effects 0.000 description 8

- 239000011248 coating agent Substances 0.000 description 8

- 230000000630 rising effect Effects 0.000 description 8

- 238000005452 bending Methods 0.000 description 6

- 239000000463 material Substances 0.000 description 6

- 230000001351 cycling effect Effects 0.000 description 5

- 230000006378 damage Effects 0.000 description 5

- 230000005540 biological transmission Effects 0.000 description 4

- 230000035939 shock Effects 0.000 description 4

- 241001269238 Data Species 0.000 description 3

- 238000000465 moulding Methods 0.000 description 3

- 239000011347 resin Substances 0.000 description 3

- 229920005989 resin Polymers 0.000 description 3

- 230000035882 stress Effects 0.000 description 3

- 229910000838 Al alloy Inorganic materials 0.000 description 2

- 235000014676 Phragmites communis Nutrition 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 230000005611 electricity Effects 0.000 description 2

- 239000004519 grease Substances 0.000 description 2

- 230000007774 longterm Effects 0.000 description 2

- 230000003647 oxidation Effects 0.000 description 2

- 238000007254 oxidation reaction Methods 0.000 description 2

- 210000004243 sweat Anatomy 0.000 description 2

- 241000931705 Cicada Species 0.000 description 1

- 230000032683 aging Effects 0.000 description 1

- 238000000137 annealing Methods 0.000 description 1

- 230000004087 circulation Effects 0.000 description 1

- 230000000052 comparative effect Effects 0.000 description 1

- 238000009795 derivation Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 210000002445 nipple Anatomy 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

Images

Landscapes

- Connections Effected By Soldering, Adhesion, Or Permanent Deformation (AREA)

- Manufacturing Of Electrical Connectors (AREA)

Abstract

The present invention discloses a method for manufacturing a terminal crimping structure onto aluminum electric-wire and aluminum electric-wires with terminal. In the terminal crimping structure, the terminal is provided with an aluminum electric-wire covered portion crimping insulating sleeve composed of insulating material for crimping the aluminum electric-wire covered portion, an aluminum electric-wire conductive crimping sleeve for destroying the aluminum electric-wire surface oxidation film, and an aluminum electric-wire holding crimping sleeve for holding the aluminum electric-wire conductive portion; the aluminum electric-wire conductive crimping sleeve and the aluminum electric-wire holding crimping sleeve are integrated with a conductor sleeve, wherein the lower region of the conductor sleeve is relative to the aluminum electric-wire conductive crimping sleeve from the terminal crimping direction under the crimping condition of the terminal, and the higher region is relative to the aluminum electric-wire holding crimping sleeve. When the terminal is crimped onto the aluminum electric-wire, the invention may maintain the electronic characteristics of the connecting portion without the effect of the circumstance change.

Description

The present invention is that application number is 200410059075.3, the applying date is on July 27th, 2004, denomination of invention is divided an application for the Chinese invention patent application of " to the manufacturing approach of terminal crimping structure and the terminal crimping method and the sub-aluminium electric wire of band edge of aluminium electric wire ".

Invention field

The present invention relates to be crimped onto the terminal that uses on the aluminium electric wire, specially refer to and be assemblied in the manufacturing approach of the interior terminal of connector terminal crimping structure and the terminal crimping method and the sub-aluminium electric wire of band edge of aluminium electric wire.

Background technology

At first first problem of the present invention is explained.Originally, distribution generally adopted the copper electric wire in the car, did not almost use the relatively poor aluminium electric wires of characteristic (physical property) such as conductivity and intensity.Yet, in recent years,, the requirement of using the aluminium electric wire is being improved gradually in view of the lighting and the recirculation property of vehicle.In addition, between distribution and distribution or vehicle-mounted instrument and the distribution, generally use electrical cnnector to connect.This electrical cnnector is by mutual chimeric connector case, and is inserted in these connector cases, and a plurality of crimp type terminals that are connected with the distribution crimping constitute.

Though the shape that constitutes the clamped nipple pressure contact portion of crimp type terminal has open type and enclosed two kinds.But owing to consider that from the viewpoint that improves machinability that generally adopt is the former.In addition; Also consider decision: promptly represent with the ratio of the wire conductor portion sectional area before the wire conductor portion sectional area/crimping of crimping part from following viewpoint; The compression ratio of defined (also claiming the cross section slip, hereinafter to be referred as " compression ratio ") is in contact resistance is stablized the field; Vibration can not cause the generation of breaking; Have enough electric wires and be close to power etc.

The compression ratio in the wire conductor cross section during as for existing terminal crimping, though different by manufacturer or wire size, all stipulate and be controlled in 75%~95% scope (referring to patent documentation 1).

Patent documentation 1: No. 3005065 communique of Japan's utility model registration (the 5th~6 page, Fig. 6)

Terminal crimping method in the past, be terminal is crimped onto the copper electric wire by compression ratio recited above wire conductor portion still.According to such compression ratio terminal is crimped onto on the copper electric wire, does not influence the mechanical property and the electrical characteristic of copper electric wire, and function upper terminal and copper electric wire be connected also no problem.The copper electric wire that connects this terminal, using does not as before have any problem yet.

But the fusing-off temperature of aluminium electric wire is lower than copper electric wire, and each the root twisted wire that constitutes electric wire also forms oxide-film easily, and causes current only flows through indivedual twisted wires, is easy to produce lumped resistance, and troubling this lumped resistance can cause fusing or conduct electricity bad.

Take the condition identical to aluminium electric wire and the actual result who carries out crimping of terminal with the copper electric wire; The variation of environment such as high temperatureization or low temperatureization; The resistance of terminal pressure contact portion is risen, and it is bad to have produced conduction, causes and can not keep the good state that is electrically connected between terminal and the electric wire.Therefore, it is unsuitable taking above-mentioned compression ratio to carry out crimping to the terminal crimping structure of aluminium electric wire.

Secondly, next problem of the present invention is explained.Here, according to the terminal crimping structure of copper electric wire, the crimping process when being crimped onto this terminal on the aluminium electric wire for hypothesis is explained.Shown in Figure 1 for being crimped onto the terminal in the past on the copper electric wire.As shown in Figure 1; Terminal 580 is made up of connecting portion 580a between terminal and electric wire connecting portion 580b, electric wire connecting portion 580b by the perpendicular direction of the court of terminal have the wire socket 581 of length to a certain degree and therewith the insulating sleeve 585 that is crimped into copper electric wire coatings portion of adjacency constitute.Fig. 2 is or not the copper electric wire with this terminal 580 but is crimped onto the operation sketch map on the aluminium electric wire 501.Show like this figure, during this terminal of crimping, use corresponding with the wire socket 581 of terminal 580 with insulating sleeve 585 difference, sub-pressure contact portion 681 of band edge and 685 ladder crimping anchor clamps 680.Crimping anchor clamps 680 are seen in order to make most advanced and sophisticated perpendicular side from crimp type terminal, are inverted V-shaped to the most advanced and sophisticated direction tortuous (bending) of squeezing bushing, are also forming the crimp groove of M font.And, let these crimping anchor clamps 680 move (the figure) downwards from the top of terminal 580 referring to the arrow X that shows terminal crimping direction, make each sleeve pipe 581 and 585 the inverted v-shaped groove faces (referring to Fig. 2 B and Fig. 2 C) of terminal 580 along anchor clamps 680.Because the V word tip of the inverted v-shaped groove face of anchor clamps 680 is the M word, let further extruding terminals 580 of anchor clamps 680, the end that makes each sleeve pipe 581 and 585 with the direction at outlet sleeve tip towards aluminium electric wire 501 bendings (complications).Conductor portion 501a and the 501b of lining portion with each sleeve pipe 581,585 crimping electric wire of falling aluminium 501 goes up (referring to Fig. 2 C and Fig. 3 A) like this.After terminal 580 firmly is crimped onto aluminium electric wire 501, the Y direction of crimping anchor clamps 680 in figure promoted, finish the terminal crimping process.

In addition, wire socket except that as above-mentioned terminal 580 by a sleeve pipe constitute, known have several kinds of terminals with the structure that is made up of a plurality of sleeve pipes.(referring to patent documentation 2 to patent documentation 4)

Patent documentation 2: real (the 4-5 page in flat 6-36215 communiques of opening of Japan; Fig. 2)

Patent documentation 3: real (the 4-5 page in flat 6-36216 communiques of opening of Japan; Fig. 2)

Patent documentation 4: real (the 3-4 page in flat 11-297375 communiques of opening of Japan; Fig. 1)

Then, next problem of the present invention is explained.

Under the method for attachment of copper electric wire and terminal, though terminal 580 does not all contact with each twisted wire that constitutes the copper electric wire, because the mechanical property and the electrical characteristic of copper electric wire, terminal can be connected to the copper electric wire, does not have what problem.

Yet the mechanical strength of aluminium electric wire or fusing-off temperature are lower than the copper electric wire, and each the root twisted wire that constitutes electric wire also has the characteristic of easy formation oxide-film.For this reason, electric current only flows through indivedual twisted wires, is easy to produce lumped resistance, and troubling this lumped resistance can cause fusing or conduct electricity bad.

Its concrete manifestation is in the oxide-film that destroys each twisted wire; Brute force is carried out crimping; Make between each twisted wire when being close to as far as possible, though electric energising characteristic reaches the degree that can bear environmental tests such as cold cycling, because the terminal pressure contact portion is because of excessive stress is arranged with wire socket; Extremely reduce the electric wire hold facility sometimes, thereby can not use as the syndeton of terminal and electric wire.

Fig. 3 be on such aluminium electric wire 1 crimping the plane graph (Fig. 3 A) and the side view (Fig. 3 B, C) of state of terminal 580.In addition, among Fig. 3 B,, see the pressure contact portion of wire socket 581 the same height (referring to the height H e among the figure) when having with in the past copper electric wire crimp from terminal crimping direction for the conductor portion 501a of aluminium electric wire 1.Fig. 3 C has shown and has taked the state of high compression rate (cross section slip) when terminal 580 is crimped onto aluminium electric wire 501, sees that from terminal crimping direction aspect ratio Fig. 3 B of the terminal 580 that is crimped is low.(referring to the height H f among the figure).

With the identical crimped status of copper electric wire in the past shown in Fig. 3 B; Though it is no problem that terminal crimp strength (electric wire confining force) goes up; But can not fully destroy the oxide-film on each twisted wire surface of conductor portion 501a, in addition, in environmental tests such as cold cycling; Contact resistance can rise, and reduces conductive characteristic.And shown in Fig. 3 C; Take high compression rate (cross section slip) when terminal 580 is crimped onto aluminium electric wire 501, can obtain enough conductions, but because the stress of the terminal pressure contact portion of electric wire is big; Reduce the electric wire confining force, can not obtain the needed terminal crimp strength of each wire size.

Patent documentation 2 to patent documentation 4 described terminals have the structure that is formed by insulating sleeve and a plurality of wire socket; But; These wire sockets all are indivedual formation the in line footpath to the electric wire that carries out crimping; Structure not open when being adapted to the aluminium electric wire with the footpath to it, carry out the crimping of aluminium wire conductor portion with different compression ratios (cross section slip).

Summary of the invention

The object of the present invention is to provide when terminal is crimped onto the aluminium electric wire, do not receive the influence of environmental change, can keep the manufacturing approach to terminal crimping structure and the terminal crimping method and the sub-aluminium electric wire of band edge of aluminium electric wire of the electrical characteristic of connecting portion.

When another object of the present invention is to provide terminal is crimped onto the aluminium electric wire, guarantee enough conductive characteristics of aluminium electric wire and terminal, and have the terminal structure of needed terminal crimp strength (the electric wire confining force of terminal).

In order to solve first above-mentioned problem; The described terminal crimping structure to the aluminium electric wire of first aspect of the present invention is the terminal crimping structure to the aluminium electric wire of direct crimp type terminal on the aluminium electric wire that the lining portion by a plurality of twisted wires and this twisted wire of coating constitutes; It is characterized in that: terminal has the wire socket that is crimped on aluminium wire conductor portion; Compression ratio when utilizing the direct crimping aluminium of wire socket wire conductor portion; Ratio with the aluminium wire conductor portion sectional area before the aluminium wire conductor portion sectional area/crimping of crimping part is represented, in 50~70% scopes.

In addition; The described terminal crimping structure to the aluminium electric wire of second aspect of the present invention is the terminal crimping structure to the aluminium electric wire of direct crimp type terminal on the aluminium electric wire that the lining portion by a plurality of twisted wires and this twisted wire of coating constitutes; It is characterized in that: terminal has the wire socket that is crimped on aluminium wire conductor portion, and the sectional area that carries out the aluminium wire conductor portion of crimping has 1.5mm

2More than, the compression ratio when utilizing the direct crimping aluminium of wire socket wire conductor portion is represented with the ratio of the aluminium wire conductor portion sectional area before the aluminium wire conductor portion sectional area/crimping of crimping part, in 40~70% scopes.

In addition; The described terminal crimping structure to the aluminium electric wire of the third aspect of the invention is the terminal crimping structure to the aluminium electric wire of direct crimp type terminal on the aluminium electric wire that the lining portion by a plurality of twisted wires and this twisted wire of coating constitutes; It is characterized in that: terminal has the wire socket that is crimped on aluminium wire conductor portion, and the sectional area that carries out the aluminium wire conductor portion of crimping has 1.5mm

2More than; Compression ratio when utilizing the direct crimping aluminium of wire socket wire conductor portion; Ratio with the aluminium wire conductor portion sectional area before the aluminium wire conductor portion sectional area/crimping of crimping part is represented; The higher limit that makes this compression ratio is 70%, and its lower limit is to make the terminal crimp strength become the compression ratio of 100N.

In addition; The described terminal crimping method to the aluminium electric wire of fourth aspect of the present invention is the terminal crimping method to the aluminium electric wire of direct crimp type terminal on the aluminium electric wire that the lining portion by a plurality of twisted wires and this twisted wire of coating constitutes; It is characterized in that: when preparing the aluminium electric wire; Preparation has the terminal of the wire socket that is crimped on aluminium wire conductor portion; Compression ratio when utilizing the direct crimping aluminium of wire socket wire conductor portion is represented with the ratio of the aluminium wire conductor portion sectional area before the aluminium wire conductor portion sectional area/crimping of crimping part, in 50~70% scopes, terminal directly is crimped onto on the aluminium electric wire.

In addition; The described terminal crimping method to the aluminium electric wire in the 5th aspect of the present invention is the terminal crimping method to the aluminium electric wire of direct crimp type terminal on the aluminium electric wire that the lining portion by a plurality of twisted wires and this twisted wire of coating constitutes, and it is characterized in that: the sectional area that the wire conductor portion of crimping is carried out in preparation has 1.5mm

2In the time of above aluminium electric wire; Preparation has the terminal of the wire socket that is crimped on aluminium wire conductor portion; Compression ratio when utilizing the direct crimping aluminium of wire socket wire conductor portion; Ratio with the aluminium wire conductor portion sectional area before the aluminium wire conductor portion sectional area/crimping of crimping part is represented, in 40~70% scopes, terminal directly is crimped onto on the aluminium electric wire.

In addition; The described terminal crimping method to the aluminium electric wire in the 6th aspect of the present invention is the terminal crimping method to the aluminium electric wire of direct crimp type terminal on the aluminium electric wire that the lining portion by a plurality of twisted wires and this twisted wire of coating constitutes, and it is characterized in that: the sectional area that the wire conductor portion of crimping is carried out in preparation has 1.5mm

2In the time of above aluminium electric wire; Preparation has the terminal of the wire socket that is crimped on aluminium wire conductor portion; Compression ratio when utilizing the direct crimping aluminium of wire socket wire conductor portion; Ratio with the aluminium wire conductor portion sectional area before the aluminium wire conductor portion sectional area/crimping of crimping part representes that the higher limit that makes this compression ratio is 70%, and its lower limit is the terminal crimp strength to be become in the scope of compression ratio of 100N terminal directly is crimped onto on the aluminium electric wire.

Be controlled at above-mentioned higher limit through the compression ratio with the aluminium electric wire, sample at high temperature or in the environmental test under the low temperature, the resistance that the sub-aluminium electric wire of band edge can not take place rises, and can keep stable being electrically connected.

Be controlled at above-mentioned lower limit through the compression ratio with the aluminium electric wire, the crimp strength of aluminium electric wire can significantly not reduce.Therefore, mechanical failure such as electric wire fracture can not take place in aluminium electric wire crimp portion.

And, when the sectional area of aluminium wire conductor portion has 1.5mm

2When above, exactly compression ratio is controlled to above-mentioned lower limit, the crimp strength of aluminium electric wire can significantly not reduce yet.Therefore, mechanical failure such as electric wire fracture can not take place in aluminium electric wire crimp portion.

In addition; The manufacturing approach of the sub-aluminium electric wire of the described band edge in the 7th aspect of the present invention be on the aluminium electric wire that constitutes by a plurality of twisted wires and the lining portion that coats this twisted wire directly crimp type terminal with the manufacturing approach of the sub-aluminium electric wire of band edge of making the sub-aluminium electric wire of band edge; It is characterized in that: when preparing the aluminium electric wire; Preparation has the terminal of the wire socket that is crimped on aluminium wire conductor portion; Compression ratio when utilizing the direct crimping aluminium of wire socket wire conductor portion; Ratio with the aluminium wire conductor portion sectional area before the aluminium wire conductor portion sectional area/crimping of crimping part is represented, in 50~70% scopes, terminal directly is crimped onto on the aluminium electric wire, to make the sub-aluminium electric wire of band edge.

In addition; The manufacturing approach of the sub-aluminium electric wire of the described band edge of eight aspect of the present invention is that crimp type terminal is with the manufacturing approach of the sub-aluminium electric wire of band edge of the sub-aluminium electric wire of manufacturing band edge on the aluminium electric wire that the lining portion by a plurality of twisted wires and this twisted wire of coating constitutes, and it is characterized in that: the sectional area that the wire conductor portion of crimping is carried out in preparation has 1.5mm

2In the time of above aluminium electric wire; Preparation has the terminal of the wire socket that is crimped on aluminium wire conductor portion; Compression ratio when utilizing the direct crimping aluminium of wire socket wire conductor portion; Ratio with the aluminium wire conductor portion sectional area before the aluminium wire conductor portion sectional area/crimping of crimping part is represented, in 40~70% scopes, terminal is crimped onto on the aluminium electric wire, to make the sub-aluminium electric wire of band edge.

In addition; The manufacturing side of the sub-aluminium electric wire of the described band edge in the 9th aspect of the present invention is that crimp type terminal is with the manufacturing approach of the sub-aluminium electric wire of band edge of the sub-aluminium electric wire of manufacturing band edge on the aluminium electric wire that the lining portion by a plurality of twisted wires and this twisted wire of coating constitutes, and it is characterized in that: the sectional area that the wire conductor portion of crimping is carried out in preparation has 1.5mm

2In the time of above aluminium electric wire; Preparation has the terminal of the wire socket that is crimped on aluminium wire conductor portion; Compression ratio when utilizing the direct crimping aluminium of wire socket wire conductor portion representes that with the ratio of the aluminium wire conductor portion sectional area before the aluminium wire conductor portion sectional area/crimping of crimping part the higher limit that makes this compression ratio is 70%; Its lower limit is the terminal crimp strength to be become in the scope of compression ratio of 100N terminal is crimped onto on the aluminium electric wire, to make the sub-aluminium electric wire of band edge.

Through making the sub-aluminium electric wire of such band edge, resistance can not take place in the environmental test that needs high temperature or low temperature to rise, can keep outside stable being electrically connected, can also obtain the sub-aluminium electric wire of band edge that mechanical failure such as electric wire fracture do not take place in electric wire crimp portion.

In addition; The described terminal crimping structure to the aluminium electric wire in the tenth aspect of the present invention is that terminal is crimped onto the terminal crimping structure to the aluminium electric wire on the aluminium electric wire; This terminal has the aluminium electric wire coatings portion crimping of the crimping aluminium electric wire coatings portion that is made up of insulating material and uses insulating sleeve; And the aluminium wiring conductive with the surface film oxide that destroys the aluminium electric wire keeps using crimping sleeve with crimping sleeve and the aluminium electric wire that keeps aluminium wire conductor portion; It is characterized in that: the aluminium wiring conductive keeps using crimping sleeve with crimping sleeve and aluminium electric wire; Form an integral body as wire socket; Under the state that terminal is crimped when terminal crimping direction is seen, the low area of this wire socket height is corresponding with crimping sleeve with the aluminium wiring conductive of the surface film oxide that destroys the aluminium electric wire, and the high zone of its height is corresponding with crimping sleeve with aluminium electric wire maintenance of maintenance aluminium wire conductor portion.

Keeping high terminal crimp region with the aluminium electric wire with the corresponding height of crimping sleeve; Keeping the aluminium electric wire with the same compression ratio (cross section slip) of in the past copper electric wire, with the low area of aluminium wiring conductive with the corresponding height of crimping sleeve, with high compression rate (cross section slip) crimping aluminium electric wire; Destroy the dielectric oxide film of twisted wire; And be close to as far as possible, can guarantee to carry out crimping under the conductive characteristic like this.

In addition; The described terminal crimping structure to the aluminium electric wire of the tenth one side of the present invention is according to the described terminal crimping structure to the aluminium electric wire in the tenth aspect; It is characterized in that: the compression ratio of the aluminium wire conductor portion of the low area of the wire socket height after the terminal crimping; Ratio with the aluminium wire conductor portion sectional area before the aluminium wire conductor portion sectional area/crimping of crimping part is represented, in 50~70% scopes.

In addition; The described terminal crimping structure to the aluminium electric wire in the 12 aspect of the present invention is according to the described terminal crimping structure to the aluminium electric wire in the tenth aspect, it is characterized in that: with the sectional area of the aluminium wire conductor portion of crimping sleeve institute crimping 1.5mm is arranged with the aluminium wiring conductive

2More than, the compression ratio of the aluminium wire conductor portion of the low area of the wire socket height after the terminal crimping is represented with the ratio of the aluminium wire conductor portion sectional area before the aluminium wire conductor portion sectional area/crimping of crimping part, in 40~70% scopes.

In addition; The described terminal crimping structure to the aluminium electric wire in the 13 aspect of the present invention is according to the described terminal crimping structure to the aluminium electric wire in the tenth aspect, it is characterized in that: with the sectional area of the aluminium wire conductor portion of crimping sleeve institute crimping 1.5mm is arranged with the aluminium wiring conductive

2More than; The compression ratio of the aluminium wire conductor portion of the low area of the wire socket height after the terminal crimping; Ratio with the aluminium wire conductor portion sectional area before the aluminium wire conductor portion sectional area/crimping of crimping part is represented; The higher limit that makes this compression ratio is 70%, and its lower limit is to make the terminal crimp strength become the compression ratio of 100N.

Low area through the wire socket height after the terminal crimping; The compression ratio of aluminium wire conductor portion is controlled at above-mentioned higher limit; Sample at high temperature or in the environmental test under the low temperature, the resistance that the sub-aluminium electric wire of band edge can not take place rises, and can keep stable being electrically connected.

Through this compression ratio is controlled at above-mentioned lower limit, the crimp strength of aluminium electric wire can significantly not reduce.Therefore, mechanical failure such as electric wire fracture can not take place in aluminium electric wire crimp portion.

And, when the sectional area of aluminium wire conductor portion has 1.5mm

2When above, exactly this compression ratio is controlled to above-mentioned lower limit, the crimp strength of aluminium electric wire can significantly not reduce yet.Therefore, mechanical failure such as electric wire fracture can not take place in aluminium electric wire crimp portion.

In addition; The described terminal crimping structure to the aluminium electric wire in the 14 aspect of the present invention is that terminal is crimped onto the terminal crimping structure to the aluminium electric wire on the aluminium electric wire; This terminal has the aluminium electric wire coatings portion crimping of the crimping aluminium electric wire coatings portion that is made up of insulating material and uses insulating sleeve; And the aluminium wiring conductive with the surface film oxide that destroys the aluminium electric wire keeps using crimping sleeve with crimping sleeve and the aluminium electric wire that keeps aluminium wire conductor portion; It is characterized in that: when on being adjacent to the position of insulating sleeve, having formed the aluminium electric wire and keep with crimping sleeve; Keep having formed the aluminium wiring conductive tossing about of insulating sleeve to this aluminium electric wire and use crimping sleeve, be crimped under the state on the aluminium electric wire, when terminal crimping direction is seen at two crimping sleeves with crimping sleeve; Destroy the aluminium wiring conductive of the surface film oxide of aluminium electric wire and use crimping sleeve, keep being crimped on this aluminium electric wire with the height of crimping sleeve to be lower than the aluminium electric wire that keeps aluminium wire conductor portion.

Because the aluminium wiring conductive keeps with sleeve pipe near electric wire most advanced and sophisticated (terminal is inboard) than aluminium electric wire with the crimping of sleeve pipe; So be exactly that conduction is not too strong with the terminal crimp strength of cannula portion; Also because the maintenance at rear with the effect of sleeve pipe, the confining force aspect of terminal and electric wire does not have problem.In addition; Because the maintenance at rear is keeping electric wire well with sleeve pipe, through using sleeve pipe, destroy the dielectric oxide film of aluminium electric wire forwardly with high compression rate (cross section slip) crimping conduction; And be close to as far as possible, can between terminal and aluminium electric wire, obtain enough electrical characteristics.

In addition; The described terminal crimping structure to the aluminium electric wire in the 15 aspect of the present invention is according to the described terminal crimping structure to the aluminium electric wire in the 14 aspect, it is characterized in that: the aluminium wiring conductive keeps with forming a slit between the crimping sleeve with crimping sleeve and aluminium electric wire.

Form this slit, crimping aluminium wiring conductive keeps using crimping sleeve with crimping sleeve and aluminium electric wire individually.Like this; The aluminium electric wire keeps can carrying out crimping by the compression ratio (cross section slip) of in the past copper electric wire with crimping sleeve and keeps the aluminium electric wire, and the energising of aluminium electric wire can be taked high compression rate (cross section slip) with crimping sleeve, the destruction dielectric oxide film; And crimping as far as possible closely, guarantee conductive characteristic.

In addition; The described terminal crimping structure to the aluminium electric wire in the 16 aspect of the present invention is that insulating sleeve is used in the aluminium electric wire coatings portion crimping with the crimping aluminium electric wire coatings portion that is made up of insulating material; And have the different conductor crimping of anterior and posterior height (length) and be crimped onto the terminal crimping structure on the aluminium electric wire the aluminium electric wire with the terminal of sleeve pipe; It is characterized in that: formed aforementioned conductor crimping on the position of insulating sleeve and use sleeve pipe being adjacent to; This conductor crimping is that (the place ahead is high for the incline structure that gets up to the direction of leaving insulating sleeve (terminal the place ahead) height with the height of sleeve pipe before crimp type terminal; The structure that the rear is low), when this terminal being crimped onto on the aforementioned aluminium electric wire, low clearance part (rear part) shallow entering aluminium electric wire carries out crimping and keeps aluminium wire conductor portion; High altitude part (the place ahead part) gets into aforementioned aluminium electric wire deeply and carries out the surface film oxide that crimping destroys the aluminium electric wire; With the exposure level of each heart yearn that constitutes the aluminium electric wire and the difference (the place ahead part is many, and the rear part is few) of compression ratio, all in the perpendicular direction of the terminal of aluminium electric wire.

During with the aluminium electric wire crimp; The conductor crimping is with the shallow entering aluminium electric wire in rear (part that casing length is low) of sleeve pipe; Firmly keep electric wire; The conductor crimping enters the center of aluminium electric wire deeply with the place ahead (part that casing length is high) of sleeve pipe, can with the contacting of each heart yearn (twisted wire) of the formation aluminium electric wire of majority, guarantee stable energising.

In addition; The manufacturing approach of the sub-aluminium electric wire of the described band edge in the 17 aspect of the present invention; It is characterized in that: insulating sleeve is used in the aluminium electric wire coatings portion crimping that will have the crimping aluminium electric wire coatings portion that is made up of insulating material; And the aluminium wiring conductive with the surface film oxide that destroys the aluminium electric wire is when being crimped onto on the aluminium electric wire with crimping sleeve and the aluminium electric wire maintenance that keeps aluminium wire conductor portion with the terminal of crimping sleeve; Keep with crimping sleeve and aluminium electric wire being crimped under the state on the aluminium electric wire at the aluminium wiring conductive and see from terminal crimping direction with crimping sleeve; Aluminium wiring conductive with the surface film oxide that destroys the aluminium electric wire keeps the aluminium electric wire of aluminium wire conductor portion to keep being crimped onto on the aluminium electric wire with the low height of crimping sleeve with crimping sleeve, thereby makes the aluminium electric wire that this terminal in crimping.

In addition; The manufacturing approach of the sub-aluminium electric wire of the described band edge of the tenth eight aspect of the present invention is characterized in that: insulating sleeve is used in the aluminium electric wire coatings portion crimping that will have the crimping aluminium electric wire coatings portion that is made up of insulating material, and the different conductor crimping of height before and after having is when being crimped onto on the aluminium electric wire with the terminal of sleeve pipe; Formed the crimping of aluminium wire conductor on the position of insulating sleeve and used sleeve pipe being adjacent to; This conductor crimping is that the height before crimp type terminal is the incline structure that gets up to the direction height that leaves insulating sleeve, when being crimped onto this terminal on the aluminium electric wire with the sleeve pipe employing; The shallow entering aluminium of low clearance part electric wire carries out crimping and keeps aluminium wire conductor portion; High altitude part is dark to get into aforementioned aluminium electric wire and carries out the surface film oxide that crimping destroys the aluminium electric wire, makes and the exposure level of each heart yearn that constitutes the aluminium electric wire and the difference of compression ratio, all in the perpendicular direction of the terminal of aluminium electric wire; Like this this terminal is crimped onto on the aluminium electric wire aluminium electric wire of this terminal of having made crimping.

Through the 17 aspect of embodiment of the present invention or the manufacturing approach of the sub-aluminium electric wire of the described band edge of the tenth eight aspect; When can guarantee the needed terminal crimp strength of each wire size (hold facility of terminal and electric wire) of aluminium electric wire; Can obtain crimping and destroy the dielectric oxide film of aluminium electric wire; And be close to as far as possible, guarantee the aluminium electric wire of the terminal of electric energising property.

The simple declaration of accompanying drawing

Fig. 1 shows that in the past copper electric wire crimp is with the profile (Figure 1A) and the side view (Figure 1B) of terminal.

Fig. 2 shows copper electric wire crimp terminal shown in Figure 1 is crimped onto the operation sketch map on the aluminium electric wire.

Fig. 3 shows copper electric wire crimp terminal shown in Figure 1 is crimped onto the plane graph (Fig. 3 A) of the state on the aluminium electric wire and the side view (Fig. 3 C) of the side view (Fig. 3 B) of crimped status during with low-shrinkage (cross section slip) crimping and the crimped status during with high shrinkage (cross section slip) crimping.

Fig. 4 shows to use plane graph (Fig. 4 A) and the side view (Fig. 4 B) to the terminal of the terminal crimping structure of aluminium electric wire that relates to the embodiment of the invention 1.

Fig. 5 shows that order by Fig. 5 A to Fig. 5 D will be referred to the process chart to the terminal crimping method of aluminium electric wire of the embodiment of the invention 1.

Fig. 6 shows plane graph (Fig. 6 A) and the side view (Fig. 6 B) to the terminal crimping structure of aluminium electric wire relate to the embodiment of the invention 1.

Fig. 7 is the pressure contact portion profile (Fig. 7 B) of the terminal crimping structure beyond VIIA-VIIA profile (Fig. 7 A) and the scope of the invention among Fig. 6 A.

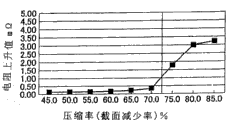

Fig. 8 is the test data figure that shows about the embodiment of embodiment 1 and variation 1 thereof, variation 2.

Fig. 9 is the pressure contact portion profile (Fig. 9 B) of the terminal crimping structure of IXA-IXA profile (Fig. 9 A) and the copper electric wire beyond the scope of the invention among Fig. 6 of variation 1 of relevant embodiment 1.

Figure 10 is the pressure contact portion profile (Figure 10 B) of the terminal crimping structure of XA-XA profile (Figure 10 A) and the copper electric wire beyond the scope of the invention among Fig. 6 of variation 1 of relevant embodiment 1.

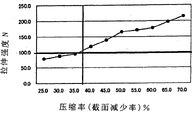

Figure 11 is the test data figure of embodiment 2 that shows the variation 1 of relevant embodiment 1.

Figure 12 is the test data figure of embodiment 3 that shows the variation 2 of relevant embodiment 1.

Figure 13 is plane graph (Figure 13 A) and the side view (Figure 13 B) that shows the aluminium electric wire crimp terminal of the relevant embodiment of the invention 2.

Figure 14 shows that order by Figure 14 A to Figure 14 D will be referred to the process chart to the terminal crimping method of aluminium electric wire of the embodiment of the invention 2.

Figure 15 is the plane graph (Figure 15 A) and the side view (Figure 15 B) of the state on the aluminium electric wire that aluminium electric wire crimp terminal is crimped onto shown in the displayed map.

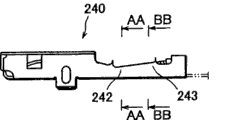

Figure 16 shows that the aluminium electric wire crimp terminal of the variation 1 that will be referred to embodiment 2 is crimped onto side view (Figure 16 A) and the AA-AA profile among Figure 16 A and the BB-BB profile (Figure 16 B) of the state on the aluminium electric wire.

Figure 17 is plane graph (Figure 17 A) and the side view (Figure 17 B) that shows the aluminium electric wire crimp terminal of the variation 2 that relates to embodiment shown in Figure 13 2.

Figure 18 is the operation sketch map that shows the crimping process of aluminium electric wire crimp terminal shown in Figure 17.

Figure 19 is plane graph (Figure 19 A) and the side view (Figure 19 B) that shows the state on the aluminium electric wire that aluminium electric wire crimp terminal shown in Figure 17 is crimped onto.

Figure 20 relates to the plane graph (Figure 20 A) and the side view (Figure 20 B) of aluminium electric wire crimp terminal of the variation 3 of embodiment 2.

Figure 21 shows that the process sequence by Figure 21 A to Figure 21 D is crimped onto the operation sketch map on this aluminium electric wire with aluminium electric wire crimp terminal shown in Figure 20.

Figure 22 is plane graph (Figure 22 A) and the side view (Figure 22 B) that shows the state on the aluminium electric wire that aluminium electric wire crimp terminal shown in Figure 20 is crimped onto.

Figure 23 is plane graph (Figure 23 A) and the unfolding state figure (Figure 23 C) of side view (Figure 23 B) and this crimp type terminal that shows the V electric wire crimp terminal of the variation 4 relate to embodiment 2.

Figure 24 be use aluminium electric wire crimp terminal crimping aluminium electric wire shown in Figure 23 state side view (Figure 24 A) with and show the CC-CC profile (Figure 24 A) and the DD-DD profile (Figure 24 B) of specified cross-section.

The optimised form that carries out an invention

On one side referring to accompanying drawing,, explain by scheming on one side to the manufacturing approach of relevant embodiments of the invention 1 and embodiment 2 to terminal crimping structure and the compression bonding method and the sub-aluminium electric wire of band edge of aluminium electric wire.

The terminal 101 that uses that relates to embodiments of the invention 1 to the terminal crimping structure of aluminium electric wire; As shown in Figure 4; Be made up of terminal connecting portion 110 and electric wire connecting portion 120, electric wire connecting portion 120 also has for the wire socket 121 of crimping conductor portion with together with the insulating sleeve 125 of resin molding crimping aluminium electric wire.In addition, the cross section of wire socket 121 is the U font, forms the terminal of so-called open type casing-type.

This terminal 101 is crimped on the aluminium electric wire 140 by following operation.At first, shown in Fig. 5 A, aluminium electric wire crimp terminal 101 is fixed on the base station 180, aluminium electric wire 140 is positioned the appropriate location of aluminium electric wire crimp terminal 101.The lining portion 142 that is aluminium electric wire 140 is positioned to be insulated the zone that sleeve pipe 125 is held under the arm, simultaneously the conductor portion 141 of aluminium electric wire 140 is positioned the zone of being held under the arm by wire socket 121.Under this state, let crimping anchor clamps 190 from the top of terminal near (referring to the arrow X of the demonstration terminal crimping direction of Fig. 5 A).Crimping anchor clamps 190 are formed with the pressure contact portion corresponding with wire socket 121 and insulating sleeve 125.Promptly form terminal pressure contact portion 191, form terminal pressure contact portion 195 in position corresponding to the insulating sleeve 125 of terminal 101 in position corresponding to the wire socket 121 of terminal 101.And these crimping anchor clamps 190 by not shown transmission device towards terminals side descend (referring to Fig. 5 B).This down maneuver makes the end of each sleeve pipe 121 and 125 crooked gradually along each crimp groove of the pressure contact portion of crimping anchor clamps 190, and at last at crimping anchor clamps 190 places, the end of each sleeve pipe will be to central axial direction distortion (bending) (referring to Fig. 5 C) of aluminium electric wire 140.

And the crimping anchor clamps 190 that descend again can push the wire socket tip in the twisted wire of conductor portion 141 of aluminium electric wire 140 more.Simultaneously, insulating sleeve 125 also is crimped in the lining portion 142 of aluminium electric wire 140.

When like this terminal 101 being crimped onto aluminium wire conductor portion 141; Though compression ratio (cross section slip) according to the aluminium wire conductor portion of the ratio defined of the aluminium wire conductor portion sectional area before the aluminium wire conductor portion sectional area/crimping of crimping part; Press the concrete compression ratio of wire size difference to some extent, but all in 50~70% scope, terminal 101 is crimped onto on the aluminium electric wire 140.This compression ratio scope, crimp type terminal is the scope that impossible have on general copper electric wire at present.After this terminal crimping operation is accomplished, promote the crimping anchor clamps, finish terminal crimping operation (referring to Fig. 5 D).

For the compression ratio of 101 pairs of aluminium electric wires 140 of terminal, be that evidence limits with many experimental datas.To this problem, intend following and after the embodiment hurdle stated explain.

The sub-aluminium electric wire of the band edge that relates to present embodiment that this terminal is crimped onto the state of aluminium electric wire is shown in plane graph (Fig. 6 A) and the side view (Fig. 6 B) of Fig. 6.In addition, Fig. 7 A has shown the crimping section of the VIIA-VIIA among Fig. 6.

In addition, Fig. 7 B has shown the profile of the terminal crimping structure that the scope of the invention is outer.

As in Fig. 7, representing that with the height value Ha that curls, Hb the crimp height of terminal is called curling height value, the compression ratio of terminal and electric wire (cross section slip) is generally with this curling height value control.

Cross section example A shown in Fig. 7 A, the height value that curls is little, and cross-sectional area of conductor is long-pending also little, with the compression state crimping.Otherwise, the cross section example B shown in Fig. 7 B, the height value that curls is big, and cross-sectional area of conductor is long-pending also big, with the low compression state crimping.

For example, the compression ratio of the cross section example A little as if the height value that curls is 70%, is equivalent to relate to the terminal crimping structure to the aluminium electric wire of present embodiment.And the compression ratio of the height value that curls (cross-sectional area of conductor is long-pending) the cross section example B bigger than cross section example A, numerical value will be equivalent to relevant terminal crimping structure to the copper electric wire of the present invention greater than 70%.

Be that compression ratio refers to: the cross section slip when the sectional area before the terminal crimping of wire conductor is 100%, what curling height value after the crimping or cross-sectional area of conductor were long-pending little then is high compression.Get over high compression, the numerical value of its compression ratio is more little.Be the little compression ratio of concrete numerical value of high compression rate finger pressure shrinkage, the big compression ratio of concrete numerical value of little compressible finger pressure shrinkage.

The terminal crimping structure to the copper electric wire in the past is actually with the curling height value control that becomes target compression.Though the kind of terminal or electric wire footpath are different, the result mostly is controlled in 75~95% atmosphere.

And say,, resistance can take place in the environmental test that needs high temperature or low temperature rise, can not keep stable being electrically connected if the aluminium electric wire is carried out crimping with existing controlling value.

But the inventor has carried out a large amount of experiments, be only limited to the aluminium electric wire with the scope of its Optimal Control value specific be 50~70%, passed through environmental test, successfully realized stable being electrically connected.To in the hurdle of embodiment, explain this.

As for the compression ratio more than 71% (cross section slip) be lower than 50% why not meet, it the reasons are as follows:

Compression ratio reaches 71% incongruent reason when above: from after also can see the embodiment hurdle stated because more than the crimping resistance rising 1.0m Ω before and after the environmental test (cold cycling), can not keep the stable state that is electrically connected.And compression ratio is lower than incongruent reason of 50% o'clock: because when the cross-sectional area of conductor after the terminal crimping overstock the long-pending high compression 1/2 below of the cross-sectional area of conductor be reduced to before the terminal crimping, and remarkable reduction crimp strength.

Then, in embodiment 1, explain having confirmed the result of the test that limits aforementioned compression ratio.

(embodiment 1)

Aluminium electric wire to wire conductor portion that various sectional areas are arranged; Take multiple compression ratio crimp type terminal; Aluminium electric wire to this band crimp type terminal carries out cold shock testing; Promptly carry out continuously repeatedly the test of low temperature environment (40 ℃) and hot environment (120 ℃), the outward appearance of the terminal pressure contact portion before and after the comparative test, and the resistance variations before and after the test of mensuration electric connection part etc.

This cold shock testing is suitable for assessing the switching performance of terminal pressure contact portion most.In addition, cold shock testing has carried out 1000 circulations.

The typical example of the resistance rising value guide look before and after the environmental test (cold shock testing) that so obtains is as shown in table 1.This pictorialization is as shown in Figure 8.

(table 1)

| Compression ratio (%) | 45.0 | 50.0 | 55.0 | 60.0 | 65.0 | 70.0 | 75.0 | 80.0 | 85.0 |

| Resistance rising value (m Ω) | 0.13 | 0.12 | 0.14 | 0.18 | 0.22 | 0.36 | 1.80 | 3.00 | 3.20 |

The inventor is according to the result of table 1, with the resistance rising value at 1.0m Ω with interior as the stable objects value, be set at the upper limit boundary line of compression ratio with 70%.

In addition, because chart shown in Figure 8 is a typical example, the material of various aluminium electric wires or line footpath be some difference all, but learnt that the scope of compression ratio 50%~70% is to stablize the field.As for lower limit, along with compression ratio diminishes, the resistance rising value also diminishes thereupon; But be lower than at 50% o'clock; Promptly for the conductor portion sectional area before the terminal crimping, when the conductor portion sectional area after the terminal crimping was 1/2 high compression, crimp strength can significantly descend; Damage the mechanical connection intensity of terminal pressure contact portion, therefore the lower limit with compression ratio is set at 50%.

Learn through above evaluation test, to aluminium electric wire crimp terminal, can not damage the intensity of terminal pressure contact portion in the scope of compression ratio 50%~70%, the stable conduction that can keep between aluminium electric wire and the terminal connects.

Then, for the manufacturing approach to terminal crimping structure and the terminal crimping method and the sub-aluminium electric wire of band edge of aluminium electric wire of the variation that relates to aforesaid embodiment 11, explain according to accompanying drawing.

And say that variation 1 is: the sectional area of aluminium wire conductor portion that carries out crimping is at 1.5mm

2More than, wire socket is represented the terminal crimping structure to the aluminium electric wire in 40~70% scopes to the compression ratio of aluminium wire conductor portion with the ratio of the aluminium wire conductor portion sectional area before the aluminium wire conductor portion sectional area/crimping of crimping part.

The terminal 101 that uses the terminal crimping structure of aluminium electric wire that relates to variation 1 has the formation identical with aforesaid embodiment; As shown in Figure 4; Be made up of terminal connecting portion 110 and electric wire connecting portion 120, electric wire connecting portion 120 also has for the wire socket 121 of crimping conductor portion with together with the insulating sleeve 125 of resin molding crimping aluminium electric wire.In addition, the cross section of wire socket 121 is the U font, forms the terminal of so-called open type casing-type.

This terminal 1 is identical with aforesaid embodiment 2, and the sectional area that is crimped into aluminium wire conductor portion by following operation is at 1.5mm

2On the above aluminium electric wire 140.At first, shown in Fig. 5 A, aluminium electric wire crimp terminal 101 is fixed on the base station 180, with the sectional area of conductor portion at 1.5mm

2Above aluminium electric wire 140 is positioned the appropriate location of aluminium electric wire crimp terminal 101.Be aluminium electric wire 140 lining portion 142 be insulated the zone that sleeve pipe 125 is held under the arm, simultaneously the conductor portion 141 of aluminium electric wire 140 is positioned the zone of being held under the arm by wire socket 121.Under this state, let the crimping anchor clamps 190 of seeing crimp groove from the perpendicular direction of terminal with special shape from the top of terminal near (referring to the arrow X of the demonstration terminal crimping direction of Fig. 5 A).Crimping anchor clamps 190 are formed with the pressure contact portion corresponding with wire socket 121 and insulating sleeve 125.Promptly form terminal pressure contact portion 191, form terminal pressure contact portion 195 in position corresponding to the insulating sleeve 125 of terminal 101 in position corresponding to the wire socket 121 of terminal 101.

And these crimping anchor clamps 190 by not shown transmission device towards terminals side descend (referring to Fig. 5 B).This down maneuver makes the end of each sleeve pipe 121 and 125 crooked gradually along each crimp groove of the pressure contact portion of crimping anchor clamps 190, and at last at crimping anchor clamps 190 places, the end of each sleeve pipe will be to central axial direction distortion (bending) (referring to Fig. 5 C) of aluminium electric wire 140.

And the crimping anchor clamps 190 that descend again can push the wire socket tip in the twisted wire of conductor portion 141 of aluminium electric wire 140 more.Simultaneously, insulating sleeve 125 also is crimped in the lining portion 142 of aluminium electric wire 140.

The sectional area that like this terminal 101 is crimped onto conductor portion is at 1.5mm

2In the above aluminium wire conductor portion 141.When carrying out this crimping; Though compression ratio (cross section slip) according to the aluminium wire conductor portion of the ratio defined of the aluminium wire conductor portion sectional area before the aluminium wire conductor portion sectional area/crimping of crimping part; Along with the concrete compression ratio of wire size difference to some extent, but all in 40~70% scope, terminal 101 is crimped onto on the aluminium electric wire 140.This compression ratio scope, crimp type terminal is the scope that impossible have on general copper electric wire at present.After this terminal crimping operation is accomplished, promote the crimping anchor clamps, finish terminal crimping operation (referring to Fig. 5 D).

For the compression ratio of 101 pairs of aluminium electric wires 140 of terminal, be that evidence limits with many experimental datas.To this problem, according to aforesaid embodiment 1 and after the embodiment 2 that states explain.

This terminal is crimped onto the sub-aluminium electric wire of the band edge that relates to present embodiment of the state of aluminium electric wire, identical with the plane graph (Fig. 6 A) of Fig. 6 with side view (Fig. 6 B).In addition, Fig. 9 A has shown the crimping cross section (IXA-IXA among Fig. 6) of the aluminium electric wire of present embodiment institute crimping.

In addition, Fig. 9 B has shown the profile of the general terminal crimping structure that the scope of the invention is outer.

For example, the compression ratio of the cross section example A ' little as if the height value that curls is 45%, is equivalent to relate to the terminal crimping structure to the aluminium electric wire of present embodiment 1.And the compression ratio of the height value that curls (cross-sectional area of conductor is long-pending) the cross section example B bigger than cross section example A ', numerical value will be equivalent to extraneous terminal crimping structure of the present invention greater than 70%.

As for greater than 70% compression ratio be lower than 40% why not meet, it the reasons are as follows:

Compression ratio surpasses incongruent reason of 70% o'clock: also can see from the content of aforesaid embodiment 1, because more than the crimping resistance rising 1.0m Ω before and after the environmental test (cold cycling), can not keep the stable state that is electrically connected.

In addition, the lower limit of compression ratio is made as 40%, is lower than incongruent reason of 40% o'clock: be reduced to 1/2 high compression because cross-sectional area of conductor overstock, can significantly reduce crimp strength, still, cross-sectional area of conductor amasss at 1.5mm

2The above original hot strength of electric wire is very high, from after the content of the embodiment 2 that states also can see, the lower limit of compression ratio is dropped to 40%, still can satisfy target strength.

Then, in embodiment 2, to having confirmed that aforementioned lower limit with compression ratio drops to 40% result of the test and explains.

(embodiment 2)

Embodiment 2 turns out to be any wire conductor portion sectional area at 1.5mm

2During crimp type terminal, can the lower limit of compression ratio be dropped to 40% embodiment on the above aluminium electric wire.

Specifically, along with the concrete numerical value of compression ratio diminishes, aforementioned resistance rising value diminishes too.And the sectional area of aluminium wire conductor portion is lower than 1.5mm

2The time, if compression ratio is lower than 50%, promptly for the conductor portion sectional area before the terminal crimping; When the conductor portion sectional area after the terminal crimping is 1/2 high compression; Crimp strength can significantly descend, and damages the mechanical connection intensity of terminal pressure contact portion, therefore thinks that the lower limit of compression ratio preferably should be set at 50%.But according to following result of the test, cicada when the sectional area of aluminium wire conductor portion at 1.5mm

2When above, can the lower limit of compression ratio be dropped to 40%.This reason is: as shown above, cross-sectional area of conductor is overstock when being reduced to 1/2 high compression, crimp strength can significantly descend, but since cross-sectional area of conductor amass at 1.5mm

2The above original hot strength of electric wire is very high, and the lower limit of compression ratio is dropped to 40%, still can satisfy target strength.

Explain in the face of this result of the test down.Say that again electric wire is exactly size (mm

2) identical, its structure (stranded mode/heart yearn number etc.) or material (various aluminium alloy), modified (admittedly melting processing, Ageing Treatment, annealing) etc. are different, and characteristic (intensity etc.) is also different.Therefore, the inventor at present embodiment with the sectional area of aluminium wire conductor portion at 1.5mm

2Be condition more than, taking minimum dimension is 1.5mm

2, have general employed structure or material, modified aluminium electric wire, investigated the compression ratio of aluminium electric wire and terminal and the relation of crimp strength.Its result such as table 2 are with shown in Figure 11.

(table 2)

| Compression ratio (%) | 25.0 | 30.0 | 35.0 | 40.0 | 45.0 | 50.0 | 55.0 | 60.0 | 65.0 | 70.0 |

| Terminal crimp strength (N) | 78.9 | 87.5 | 94.2 | 118.3 | 139.0 | 165.0 | 171.2 | 177.0 | 197.1 | 214.8 |

Though in order to prevent in hugging line or wiring operation etc. to take place breaking or breaking of electric wire and terminal, each electric wire manufacturer and user respectively have the regulation of pair desirable strength.But the inventor is according in the past experience, in the present embodiment, and with prevent that the desirable strength that breaks or break that electric wire and terminal take place is defined as 100N in hugging line or wiring operation etc.

Can know that from Ben Biao and figure (chart) compression ratio has more than 40%, then can obtain the above intensity of 100N.And because the sectional area of aluminium wire conductor portion at 1.5mm

2Minimum dimension 1.5mm under the above condition

2The time, the compression ratio that satisfies 100N is 40%, therefore the lower limit with compression ratio is set at 40%.

Result of the test according to above learns, to aluminium electric wire crimp terminal, can not damage the intensity of terminal pressure contact portion in the scope of compression ratio 40%~70%, and the stable conduction that can keep between aluminium electric wire and the terminal connects.

Then, for the manufacturing approach to terminal crimping structure and the terminal crimping method and the sub-aluminium electric wire of band edge of aluminium electric wire of the variation that relates to aforesaid embodiment 12, explain according to accompanying drawing.And say that this variation 2 is: the sectional area and the variation 1 of carrying out the aluminium wire conductor portion of crimping are at 1.5mm equally

2More than, but in the aforesaid variation 1, the compression ratio lower limit of aluminium wire conductor portion is 40%, and in this variation 2, the lower limit of the compression ratio of aluminium wire conductor portion is to make the terminal crimp strength become the embodiment of the compression ratio of 100N.

Maybe this terminal is crimped onto the concrete grammar on the aluminium electric wire because carry out the terminal shape of crimping, identical with embodiment 1 and variation 1 thereof, use symbol and the accompanying drawing identical, no longer detailed description here with embodiment 1 and variation thereof 1.

The employed terminal 101 of the terminal crimping structure to the aluminium electric wire of variation 2; The terminal that also is the open type casing-type is made up of terminal connecting portion shown in Figure 4 110 and electric wire connecting portion 120, and electric wire connecting portion 120 also has for the wire socket 121 of crimping conductor portion with together with the insulating sleeve 125 of resin molding crimping aluminium electric wire.

This terminal 101 is by the operation shown in aforesaid Fig. 5 A to Fig. 5 C, and the sectional area that is crimped into aluminium wire conductor portion is at 1.5mm

2On the above aluminium electric wire 140.

The sectional area of the aluminium wire conductor portion of this crimping is at 1.5mm

2More than, for example the sectional area of conductor portion is at 2.5mm

2Crimp type terminal on the above aluminium electric wire.At this moment; Higher limit with the compression ratio (cross section slip) of the aluminium wire conductor portion sectional area defined before the aluminium wire conductor portion sectional area/crimping of crimping part is 70%; The lower limit of compression ratio is the terminal crimp strength to be become in the scope of compression ratio of 100N, terminal 101 is crimped onto on the aluminium electric wire 140.This compression ratio scope, crimp type terminal is the scope that impossible have on general copper electric wire at present.After this terminal crimping operation is accomplished, shown in Fig. 5 D, promote the crimping anchor clamps, finish terminal crimping operation.

For the compression ratio of 101 pairs of aluminium electric wires 140 of terminal, be that evidence limits with many experimental datas.To this problem, according to aforesaid embodiment 1 and after the embodiment 3 that states explain.

The plane graph of the sub-aluminium electric wire of the band edge that relates to this variation of state that this terminal is crimped onto the aluminium electric wire is shown in Fig. 6 A, and side view is shown in Fig. 6 B.In addition, the crimping cross section (XA-XA among Fig. 6) according to the aluminium electric wire of embodiment institute crimping is shown in Figure 10 A.

In addition, the cross-section illustration of the general terminal crimping structure outside the scope of the invention is in Figure 10 B.

In variation 2, for example, from the curling height value Ha of comparison diagram 10A " and the curling height value Hb of Figure 10 B can know that cross-sectional area of conductor amasss at 2.5mm

2Above aluminium electric wire compression reach 30% compression ratio; Curling height value Ha with aforesaid variation 1 " relatively; the sectional area of the aluminium wire conductor portion after the terminal crimping littler (referring to the section A of Fig. 9 A ' and the section A of Figure 10 A " comparison), crimping gets compression state especially.

Sectional area as for wire conductor portion has 1.5mm

2During above aluminium electric wire; Compression ratio greater than 70% is incongruent reason why; Identical with the reason of embodiment 1 and variation 1, be because more than the crimping resistance rising 1.0m Ω before and after the environmental test (cold cycling), can not keep the stable state that is electrically connected.

In addition, the sectional area as aluminium wire conductor portion has 1.5mm

2During above aluminium electric wire; So that the terminal crimp strength becomes the compression ratio of 100N is that lower limit is such; Reason according to the lower limit of terminal crimp strength regulation compression ratio is: cross-sectional area of conductor is overstock when being reduced to 1/2 high compression, and crimp strength can significantly descend, but because wire size (sectional area of wire conductor portion) is big more; Hot strength is high more, though so 1.5mm

2The lower limit (limiting value) of the compression ratio of above electric wire is by each wire size difference to some extent, but compression ratio still can satisfy the hot strength of 100N when being lower than 50% (1/2).

Then, in embodiment 3, the result of the test of the lower limit that confirmed the aforementioned compression ratio that limits is explained.

(embodiment 3)

The inventor is at embodiment 3, with the sectional area of aluminium wire conductor portion at 1.5mm

2Be condition more than, taked larger-size 2.5mm

2Have general employed structure or material, a modified aluminium electric wire, investigated the compression ratio of aluminium electric wire and terminal and the relation of crimp strength.Its result such as table 3 are with shown in Figure 12.

(table 3)

| Compression ratio (%) | 25.0 | 30.0 | 35.0 | 40.0 | 45.0 | 50.0 | 55.0 | 60.0 | 65.0 | 70.0 |

| Terminal crimp strength (N) | 120.0 | 146.3 | 169.6 | 186.4 | 195.8 | 204.1 | 218.9 | 235.8 | 247.0 | 274.1 |

From then on result of the test can be known, cross-sectional area of conductor is overstock when being reduced to 1/2 high compression, and crimp strength can significantly descend, but because size (mm

2) big more, hot strength is high more, though so 1.5mm

2Above electric wire, when compression ratio was lower than 50% (1/2), the lower limit of compression ratio (limiting value) is difference to some extent, but can satisfy the crimp strength of 100N.

This situation can be seen from following.Be that the cross-sectional area of conductor shown in the embodiment 2 of Figure 11 amasss at 1.5mm

2Above aluminium electric wire, the limiting value of crimp strength 100N is a compression ratio 40%, and the cross-sectional area of conductor shown in the embodiment 3 of Figure 12 amasss at 2.5mm

2Above aluminium electric wire, compression ratio up to 25% still can satisfy 100N crimp strength.

Thus, the prescriptive procedure of the lower limit of the compression ratio of variation 2 is different with variation 1, is that the compression ratio that makes crimp strength become 100N is amassed at 1.5mm as cross-sectional area of conductor

2The above aluminium electric wire and the compression ratio lower limit of terminal.

Say that again connecting portion is the cloudy shape (reed structure) of terminal in the past between the terminal shown in the aforesaid embodiment, also the using of positive shape, no matter the structure of connecting portion between terminal is the new and old terminal that uses various structures.

In addition, terminal is crimped onto on the aluminium electric wire, can obtains enough conductive characteristics according to aforementioned compression ratio.But in order to prevent the terminal connecting portion, spread antirust grease etc. at terminal connecting portion or terminal pressure contact portion in addition, will obtain higher reliability because of air oxidation or cargo sweat.

Then, for the manufacturing approach that relates to embodiments of the invention 2, explain according to accompanying drawing to terminal crimping structure and the terminal crimping method and the sub-aluminium electric wire of band edge of aluminium electric wire.

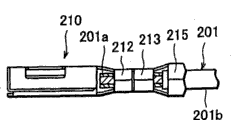

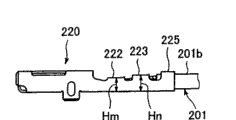

Here, 2 aluminium electric wire crimps of this embodiment terminal 230 is shown in Figure 13.Aluminium electric wire crimp terminal 230 is conductive casings 232 and the conductive casings 231 that keeps sleeve pipe 233 integrated formation.Be seamless between conductive casings 232 and the maintenance sleeve pipe 233.

Except that use the crimp type terminal that generally used so in the same old way in the past; Use special ladder crimping anchor clamps 310 (referring to Figure 14); Aluminium electric wire crimp terminal 230 is crimped onto on the aluminium electric wire 201, can be with conductive casings 232 and the crimping under the band stepped of the ladder that adapts to crimping anchor clamps 320 of maintenance sleeve pipe 233.Like this; Under the state of conductive casings 232 and maintenance sleeve pipe 233 integrated formation conductive casings 231; Use the crimping anchor clamps 310 of special shape to carry out crimping, can make under the state that aluminium electric wire crimp terminal 230 is crimped, see from terminal crimping direction; Highly low zone is corresponding with crimping sleeve (conductive casings 232) with the aluminium wiring conductive, and its highly high zone keeps corresponding with crimping sleeve (keeping sleeve pipe 233) with the aluminium electric wire.

Then, the operation that aluminium electric wire crimp terminal 230 is crimped onto on the aluminium electric wire 201 of present embodiment is explained.Shown in Figure 14 A, at first aluminium electric wire crimp terminal 230 is fixed on the base station 410, aluminium electric wire 201 is positioned the appropriate location of aluminium electric wire crimp terminal 230.The 201b of lining portion (referring to Figure 15 A) that is about to aluminium electric wire 201 is positioned to be insulated the zone that sleeve pipe 235 is held under the arm, and the conductor portion 201a (referring to Figure 15 A) with aluminium electric wire 201 is positioned respectively by conductive casings 232 and the zone that keeps sleeve pipe 233 to hold under the arm simultaneously.