CN101182112B - Collapsar furnace for manufacturing fibre-optical prefabricated rod - Google Patents

Collapsar furnace for manufacturing fibre-optical prefabricated rod Download PDFInfo

- Publication number

- CN101182112B CN101182112B CN 200710168318 CN200710168318A CN101182112B CN 101182112 B CN101182112 B CN 101182112B CN 200710168318 CN200710168318 CN 200710168318 CN 200710168318 A CN200710168318 A CN 200710168318A CN 101182112 B CN101182112 B CN 101182112B

- Authority

- CN

- China

- Prior art keywords

- air

- graphite

- furnace

- ring

- overcoat

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03B—MANUFACTURE, SHAPING, OR SUPPLEMENTARY PROCESSES

- C03B37/00—Manufacture or treatment of flakes, fibres, or filaments from softened glass, minerals, or slags

- C03B37/01—Manufacture of glass fibres or filaments

- C03B37/012—Manufacture of preforms for drawing fibres or filaments

- C03B37/014—Manufacture of preforms for drawing fibres or filaments made entirely or partially by chemical means, e.g. vapour phase deposition of bulk porous glass either by outside vapour deposition [OVD], or by outside vapour phase oxidation [OVPO] or by vapour axial deposition [VAD]

- C03B37/018—Manufacture of preforms for drawing fibres or filaments made entirely or partially by chemical means, e.g. vapour phase deposition of bulk porous glass either by outside vapour deposition [OVD], or by outside vapour phase oxidation [OVPO] or by vapour axial deposition [VAD] by glass deposition on a glass substrate, e.g. by inside-, modified-, plasma-, or plasma modified- chemical vapour deposition [ICVD, MCVD, PCVD, PMCVD], i.e. by thin layer coating on the inside or outside of a glass tube or on a glass rod

- C03B37/01861—Means for changing or stabilising the diameter or form of tubes or rods

- C03B37/01869—Collapsing

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Geochemistry & Mineralogy (AREA)

- Manufacturing & Machinery (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Manufacture, Treatment Of Glass Fibers (AREA)

Abstract

The invention relates to a melting-contracting furnace device used for the manufacturing of an optical fiber perform rod, which includes a graphite heating furnace. One end of one lateral of the graphite heating furnace is equipped with an air-curtain sealing device and an airflow scouring device, corresponding to a graphite bush. The furnace is characterized in that the air-curtain sealing device and the airflow scouring device consist of a cover respectively, which is matched with a front bush and a back bush, wherein, a ring shaped split is formed at a connection end of the front and the back bush. Relative to the ring shaped split, a ring shaped air chamber is arranged in an inner hole of the cover. An air guide damping ring is arranged in the ring shaped air chamber to form the air-curtain sealing device. The back bush is equipped with a radial ventilation hole along the circumferential direction. Corresponding to an air outlet of the radial ventilation hole, the back bush is equipped with an axial air guide port. Corresponding to the radial ventilation hole, a ring shaped air chamber is arranged in the inner hole of the cover. An air guide damping ring is arranged in the back ring shaped air camber to form the airflow scouring device. The invention has the advantages of simple structure, reasonable arrangement and processing convenience. The arrangement of the air guide damping ring results in the even distribution of sealed airflow. The air-tightness of the melting-contracting furnace is further improved.

Description

Technical field

The present invention relates to a kind of molten furnace apparatus that contracts that is used for the preform manufacturing, is to the further improvement of the existing molten furnace apparatus that contracts, and belongs to the preform technical field of processing equipment.

Background technology

Preform is made by plug and glass bushing usually, wherein the making of plug comprises that elder generation carries out pure silicon dioxide or doped silica vitreous state deposition with Plasma Enhanced Chemical Vapor Deposition (PECVD) or other chemical Vapor deposition process at the silica tube inwall, molten shorten it into rod again after deposition finishes, be optical fiber prefabricated rod mandrel.The molten furnace apparatus that contracts is the molten processing units that shortens plug into of sedimentary silica tube.Optical fiber prefabricated rod mandrel the molten furnace apparatus that contracts mainly is made of graphite heater furnace and the graphite bushing that is installed in the graphite heater furnace middle part, is installed on air curtain tightness system and air-flow flushing device at an end of graphite bushing.The air curtain tightness system of the existing molten furnace apparatus that contracts and air-flow flushing device be by in metal lining, offer circumferential aperture and or annular finedraw constitute, because the aperture is little, annulus is thin, so complex structure of part, processing and assembly difficulty are big, the processing requirement height, otherwise will influence homogeneity and the air-tightness that air-flow distributes; And the interface between its parts connect to be difficult to guarantees the isolation between different gas circuits, under high-temperature work environment, isolates destroyed easily and causes and collaborate; This structural metal lining is at high temperature worked in addition, easily deformable and damage, and work-ing life is short.

Summary of the invention

Technical problem to be solved by this invention is the deficiency that exists at above-mentioned prior art and provide a kind of structure that comparatively advantages of simple is set, and good manufacturability, is easy to make and the molten furnace apparatus that contracts that is used for the preform manufacturing that air-tightness is good.

The present invention for the technical scheme that problem adopted of the above-mentioned proposition of solution is: include graphite heater furnace and the graphite bushing 4 that is installed in the graphite heater furnace middle part, be provided with air curtain tightness system and air-flow flushing device at corresponding graphite bushing one end of a side of graphite heater furnace, before its difference is that described air curtain tightness system and air-flow flushing device are by overcoat 7 configurations, back bush 6,8 constitute, wherein preceding, the cohesive end head of back bush is formed with annular finedraw 19, at the overcoat endoporus ring-shaped air chamber 16 is set corresponding to annular finedraw, ring-shaped air chamber and inlet mouth 18 join, in ring-shaped air chamber, be provided with air guide damping ring 17 between annular finedraw and the inlet mouth, constitute the air curtain tightness system; Circumferentially offer radial direction through hole 15 in back bush 8 upper edges, on back bush, offer axial air guide port 11 corresponding to the radial direction through hole air outlet, at the overcoat endoporus back ring-shaped air chamber 12 is set corresponding to radial direction through hole, back ring-shaped air chamber and inlet mouth 14 conductings, in the ring-shaped air chamber of back, radially be provided with air guide damping ring 13 between through hole and the inlet mouth, constitute the airflow scouring device.

Press such scheme, it is conical that described annular finedraw 19 is, and tilts laterally, constitutes the air curtain tightness system of outwards blowing.

Press such scheme, the axial air guide port of offering on the described back bush 8 11 is the ring shaped axial air guide port, is provided with the water conservancy diversion conical surface 20 at the back bush endoporus corresponding to axial air guide port.

Press such scheme, described overcoat 7 rear ends are clutch disk, and cooling trough 9 is set in clutch disk, and two of cooling trough is communicated with water-in 21 and water outlet 22 respectively, constitute the water-cooling structure of overcoat, and the working temperature of overcoat is reduced.

When the present invention uses, the silica tube that deposition is finished passes the intermediate throughholes that graphite melts the stove that contracts, the working temperature of the molten stove that contracts of graphite reaches about 2000 ℃ during molten contracting, the molten stove that contracts of graphite slowly moves back and forth, at high temperature with the silica tube 10 molten solid bars that shorten into, this moment, the silica tube upstream end in molten stove one side that contracts of graphite blew out rare gas element formation sealing air curtain by the air curtain tightness system, stop outside air to enter the high-temperature zone of graphite furnace from left end, avoid the silica tube surface to form new zone of oxidation, meanwhile blow out the rare gas element of certain flow rate by the airflow scouring device, with between graphite bushing pipe and the silica tube since silicon-carbide particle that high temperature produced blow away rapidly with the surperficial evaporable silicon-dioxide of silica tube, and stop outside air to enter the high-temperature zone of graphite furnace from right-hand member, contract thereby the silica tube under the realization anaerobic state is molten, guarantee the processing quality of optical fiber prefabricated rod mandrel.

Beneficial effect of the present invention is: 1, adopts the front and rear bushings structure to form air curtain tightness system and air-flow flushing device, can not only form effective seal, and also simple in structure, be provided with rationally, be convenient to processing; Especially by flow and the flow velocity that the air guide damping ring comes adjustments of gas is set, can make the slit of annular finedraw and relative increasing the in aperture of radial direction through hole, the manufacturability of workpiece processing is improved greatly, made being evenly distributed of sealing air-flow simultaneously, further improve air-tightness; 2, be provided with the water conservancy diversion conical surface corresponding to axial air guide port, can make and wash away air-flow and further quicken, reach better surface erosion effect; 3, on overcoat and terminal pad that graphite furnace links to each other, cooling trough is set, can effectively reduces the working temperature of containment member, prevent deformation of members and oxidation, effectively prolong the work-ing life of member.

Description of drawings

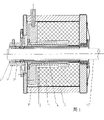

Fig. 1 is the positive sectional structure chart of one embodiment of the invention.

Fig. 2 is the positive sectional structure chart of one embodiment of the invention air curtain tightness system and air-flow flushing device.

Fig. 3 is the right view of Fig. 2.

Embodiment

Further specify embodiments of the invention below in conjunction with accompanying drawing, include graphite heater furnace, described graphite heater furnace comprises graphite heater 2 and copper conductive electrode 1, periphery at graphite heater is surrounded with graphite thermofin 3, the graphite thermofin is the molten stove outer covering 5 that contracts outward, in the graphite heater at graphite heater furnace middle part, be installed on piped graphite bushing 4, graphite bushing runs through the heating zone of whole graphite heater furnace, corresponding graphite bushing one end in the left side of graphite heater furnace be installed on overcoat 7 and with overcoat endoporus phase configuration before, back bush 6,8, constitute air curtain tightness system and air-flow flushing device, wherein preceding, the linking termination of back bush is formed with annular finedraw 19 by Control Shaft to spacer, the finedraw gap is 0.5 ± 0.1mm, the annular finedraw is conical, tilt laterally, constitute the air curtain tightness system of outwards blowing, at overcoat 7 endoporus ring-shaped air chamber 16 is set corresponding to annular finedraw, ring-shaped air chamber and inlet mouth 18 join, be provided with air guide damping ring 17 in ring-shaped air chamber between annular finedraw and the inlet mouth, constitute the air curtain tightness system thus; Circumferentially be evenly equipped with radial direction through hole 15 in back bush 8 upper edges, the aperture of radial direction through hole is 0.8 ± 0.2mm, on back bush, offer the axial air guide port 11 of annular corresponding to the radial direction through hole air outlet, axially place, the air outlet of air guide port disposes the water conservancy diversion conical surface 20, at the overcoat endoporus back ring-shaped air chamber 12 is set corresponding to the radial direction through hole inlet end, back ring-shaped air chamber and inlet mouth 14 conductings radially are provided with air guide damping ring 13 between through hole and the inlet mouth in the ring-shaped air chamber of back, constitute the airflow scouring device.Described overcoat 7 rear ends are the bigger clutch disk of diameter, cooling trough 9 is set in clutch disk, and cooling trough is the large semicircle arc, and circular arc two is communicated with water-in 21 and water outlet 22 respectively, constitute the water-cooling structure of overcoat, the working temperature of overcoat is descended greatly.

Claims (7)

1. molten furnace apparatus that contracts that is used for the preform manufacturing, include graphite heater furnace and the graphite bushing (4) that is installed in the graphite heater furnace middle part, be provided with air curtain tightness system and air-flow flushing device at corresponding graphite bushing one end of a side of graphite heater furnace, before it is characterized in that described air curtain tightness system and air-flow flushing device are by overcoat (7) configuration, back bush (6,8) constitute, wherein preceding, the cohesive end head of back bush is formed with annular finedraw (19), at the overcoat endoporus ring-shaped air chamber (16) is set corresponding to annular finedraw, ring-shaped air chamber and inlet mouth (18) join, in ring-shaped air chamber, be provided with air guide damping ring (17) between annular finedraw and the inlet mouth, constitute the air curtain tightness system; Circumferentially offer radial direction through hole (15) in back bush (8) upper edge, on back bush, offer axial air guide port (11) corresponding to the radial direction through hole air outlet, at the overcoat endoporus back ring-shaped air chamber (12) is set corresponding to radial direction through hole, back ring-shaped air chamber and inlet mouth (14) conducting, in the ring-shaped air chamber of back, radially be provided with air guide damping ring (13) between through hole and the inlet mouth, constitute the airflow scouring device.

2. by the described molten furnace apparatus that contracts that is used for the preform manufacturing of claim 1, it is characterized in that described annular finedraw (19) is conical, tilt laterally, constitute the air curtain tightness system of outwards blowing.

3. by claim 1 or the 2 described molten furnace apparatus that contract that are used for the preform manufacturing, it is characterized in that the axial air guide port of offering on the described back bush (11) is the ring shaped axial air guide port, be provided with the water conservancy diversion conical surface (20) corresponding to axial air guide port at the back bush endoporus.

4. by claim 1 or the 2 described molten furnace apparatus that contract that are used for the preform manufacturing, it is characterized in that described overcoat (7) rear end is a clutch disk, cooling trough (9) is set in clutch disk, two of cooling trough is communicated with water-in (21) and water outlet (22) respectively, constitutes the water-cooling structure of overcoat.

5. by claim 1 or the 2 described molten furnace apparatus that contract that are used for the preform manufacturing, it is characterized in that described graphite heater furnace comprises graphite heater (2) and copper conductive electrode (1), periphery at graphite heater is surrounded with graphite thermofin (3), the graphite thermofin is the molten stove outer covering (5) that contracts outward, in the graphite heater at graphite heater furnace middle part, be installed on piped graphite bushing (4), graphite bushing runs through the heating zone of whole graphite furnace, corresponding graphite bushing one end in the left side of graphite heater furnace be installed on overcoat (7) and with overcoat endoporus phase configuration before, back bush (6,8), constitute air curtain tightness system and air-flow flushing device.

6. by claim 1 or the 2 described molten furnace apparatus that contract that are used for the preform manufacturing, it is characterized in that described annular finedraw gap is 0.5 ± 0.1mm.

7. by claim 1 or the 2 described molten furnace apparatus that contract that are used for the preform manufacturing, it is characterized in that described radial direction through hole aperture is 0.8 ± 0.2mm.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 200710168318 CN101182112B (en) | 2007-11-09 | 2007-11-09 | Collapsar furnace for manufacturing fibre-optical prefabricated rod |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 200710168318 CN101182112B (en) | 2007-11-09 | 2007-11-09 | Collapsar furnace for manufacturing fibre-optical prefabricated rod |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN101182112A CN101182112A (en) | 2008-05-21 |

| CN101182112B true CN101182112B (en) | 2010-12-22 |

Family

ID=39447555

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN 200710168318 Active CN101182112B (en) | 2007-11-09 | 2007-11-09 | Collapsar furnace for manufacturing fibre-optical prefabricated rod |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN101182112B (en) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104710106B (en) * | 2015-03-09 | 2017-12-12 | 烽火通信科技股份有限公司 | A kind of induction furnace for preform collapsing |

| CN107793017B (en) * | 2016-09-06 | 2022-03-25 | 秦文隆 | Airtight cavity heat-insulating layer of moulding three-dimensional glass continuous forming device |

| CN106430941B (en) * | 2016-09-09 | 2019-06-28 | 长飞光纤光缆股份有限公司 | A kind of HEC optical fiber production stove water cooling gas ring device |

| CN111621755A (en) * | 2019-02-28 | 2020-09-04 | 广东汉能薄膜太阳能有限公司 | Air curtain isolation device and air curtain isolation cavity |

| CN111018337B (en) * | 2019-10-24 | 2021-04-02 | 长飞光纤光缆股份有限公司 | HEC optical fiber collapsing furnace gas path system and gas sealing method |

| CN114965158B (en) * | 2021-01-14 | 2023-12-08 | 深圳市大成精密设备股份有限公司 | Air curtain mechanism and measuring device |

| CN113716859B (en) * | 2021-07-22 | 2023-07-07 | 山东企赢盈网络科技有限公司 | Optical fiber prefabricated core rod fusion shrinkage processing sectional detection and stretching integrated equipment |

| CN115536261A (en) * | 2022-11-10 | 2022-12-30 | 江苏亨通光纤科技有限公司 | Optical fiber preform manufacturing apparatus and optical fiber preform manufacturing method |

| CN116062983B (en) * | 2023-02-17 | 2024-08-20 | 长飞光纤光缆股份有限公司 | Deposition cavity with stable air flow field |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4666487A (en) * | 1984-10-31 | 1987-05-19 | Compagnie Lyonnaise De Transmissions Optiques, Sa | Apparatus for removing dust from the atmosphere around a tube |

| US4915622A (en) * | 1986-08-28 | 1990-04-10 | Witmer Warner H | Fluid barrier curtain system |

| CN1354371A (en) * | 2001-12-07 | 2002-06-19 | 中国科学院上海技术物理研究所 | Super narrow bandpass optical film filter and film layer thickness generation method |

| CN1500754A (en) * | 2002-11-13 | 2004-06-02 | ס�ѵ�����ҵ��ʽ���� | Method of drawing optical fiber and apparatus for implementing the method |

| CN1665749A (en) * | 2002-04-30 | 2005-09-07 | 康宁股份有限公司 | Methods and apparatus for thermal treatment of a glass optical fiber during drawing |

| CN1854098A (en) * | 2005-04-29 | 2006-11-01 | 波克股份有限公司 | Preform consolidation process |

| CN1876588A (en) * | 2005-06-10 | 2006-12-13 | 日立电线株式会社 | Optical fiber drawing apparatus, sealing mechanism for the same, and method for drawing an optical fiber |

| CN2898010Y (en) * | 2005-11-17 | 2007-05-09 | 江苏亨通光纤科技有限公司 | Gas sealing device for optical fiber drawing furnace |

| CN201132815Y (en) * | 2007-11-09 | 2008-10-15 | 长飞光纤光缆有限公司 | Fusion Shrinking furnace for preparing optical fiber preform |

-

2007

- 2007-11-09 CN CN 200710168318 patent/CN101182112B/en active Active

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4666487A (en) * | 1984-10-31 | 1987-05-19 | Compagnie Lyonnaise De Transmissions Optiques, Sa | Apparatus for removing dust from the atmosphere around a tube |

| US4915622A (en) * | 1986-08-28 | 1990-04-10 | Witmer Warner H | Fluid barrier curtain system |

| CN1354371A (en) * | 2001-12-07 | 2002-06-19 | 中国科学院上海技术物理研究所 | Super narrow bandpass optical film filter and film layer thickness generation method |

| CN1665749A (en) * | 2002-04-30 | 2005-09-07 | 康宁股份有限公司 | Methods and apparatus for thermal treatment of a glass optical fiber during drawing |

| CN1500754A (en) * | 2002-11-13 | 2004-06-02 | ס�ѵ�����ҵ��ʽ���� | Method of drawing optical fiber and apparatus for implementing the method |

| CN1854098A (en) * | 2005-04-29 | 2006-11-01 | 波克股份有限公司 | Preform consolidation process |

| CN1876588A (en) * | 2005-06-10 | 2006-12-13 | 日立电线株式会社 | Optical fiber drawing apparatus, sealing mechanism for the same, and method for drawing an optical fiber |

| CN2898010Y (en) * | 2005-11-17 | 2007-05-09 | 江苏亨通光纤科技有限公司 | Gas sealing device for optical fiber drawing furnace |

| CN201132815Y (en) * | 2007-11-09 | 2008-10-15 | 长飞光纤光缆有限公司 | Fusion Shrinking furnace for preparing optical fiber preform |

Also Published As

| Publication number | Publication date |

|---|---|

| CN101182112A (en) | 2008-05-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101182112B (en) | Collapsar furnace for manufacturing fibre-optical prefabricated rod | |

| CN201132815Y (en) | Fusion Shrinking furnace for preparing optical fiber preform | |

| CN104477885B (en) | A kind of vertical sense of continuity answers high temperature graphitization stove | |

| WO2012133897A1 (en) | Vacuum degassig apparatus, apparatus for producing glassware, and method for producing glassware | |

| CN106653557A (en) | Focused anode layer ion source device | |

| CN102303950A (en) | Method for drawing optical fibers by using large-size optical fiber prefabricated rod and auxiliary device thereof | |

| CN208304130U (en) | It rotates air pressure and protects fine plasma burning torch | |

| CN109111087A (en) | For manufacturing the Dan Na pipe and method of glass tube or glass bar | |

| CN105222597A (en) | A kind of horizontal diffusion furnace fast cooling body of heater | |

| CN110698052B (en) | A wire drawing bushing for basalt fiber processing | |

| CN206898566U (en) | A kind of plasma cutting-torch electrode tip holder and apply its plasma cutting-torch | |

| CN211946806U (en) | Optical fiber perform melts graphite stove that contracts | |

| CN202625256U (en) | Electric heater for screw shaft | |

| CN203411468U (en) | Glass fiber forming centrifugal machine | |

| CN102485649B (en) | Polysilicon hydrogenation furnace | |

| CN201301359Y (en) | Step progressive baffle jacket of polysilicon reduction furnace | |

| CN113896412B (en) | Plasma heating furnace for optical fiber preform rod fusion shrinkage | |

| CN111018337B (en) | HEC optical fiber collapsing furnace gas path system and gas sealing method | |

| CN211352482U (en) | Silicon carbide spiral heating pipe and heating device for overflow downdraw method | |

| CN202107632U (en) | Rotary seal chuck of optical fiber perform depositing lathe | |

| CN203399335U (en) | Electrode cooling water sleeve | |

| CN101543753A (en) | Embedded type cylindrical blast cap | |

| CN102225835A (en) | Process gas distributive ring for fiber prefabricated rod melting furnace | |

| CN205088107U (en) | Gas smelts a tub combustor | |

| CN213388316U (en) | Rectangular carpet type heating glass all-electric melting furnace |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C56 | Change in the name or address of the patentee |

Owner name: YANGTZE OPTICAL FIBRE AND CABLE CO., LTD Free format text: FORMER NAME: CHANGFEI FIBRE-OPTICAL + OPTICAL CABLE CO., LTD. |

|

| CP01 | Change in the name or title of a patent holder |

Address after: 430073 Hubei city of Wuhan province Wuchang two Guanshan Road No. four Patentee after: Yangtze Optical Fibre and Cable Co., Ltd Address before: 430073 Hubei city of Wuhan province Wuchang two Guanshan Road No. four Patentee before: Changfei Fibre-Optical & Optical Cable Co., Ltd. |