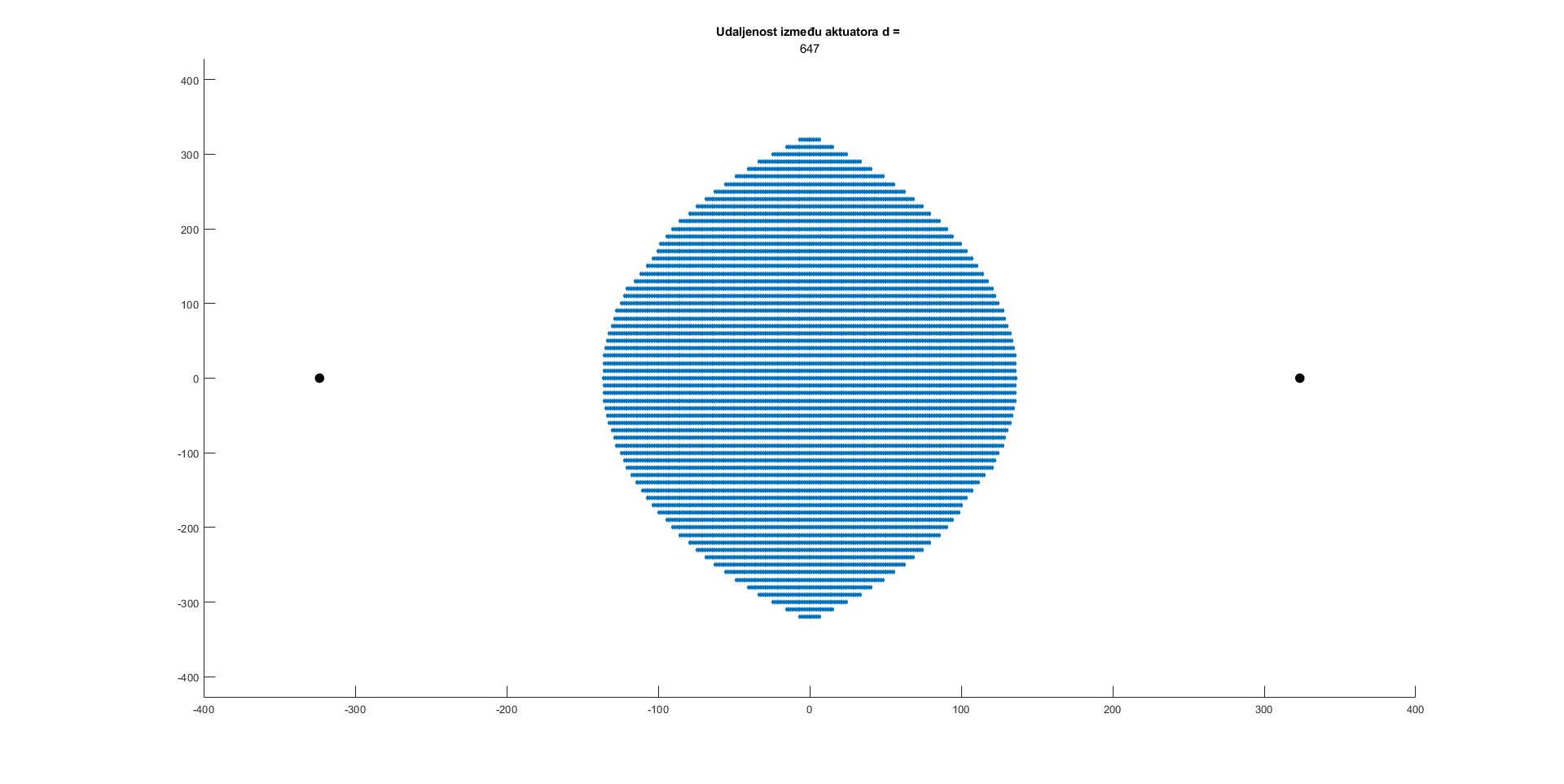

In this project, a planar parallel mechanism with two degrees of freedom is described. The inverse kinematics procedure was used to obtain expressions for the rotation angles of the actuator depending on the given position of the tooltip. Furthermore, the problem of determining the working space with the set requirements of centroid vectorization is described. The obtained conclusions were tested on the made model of the mechanism. Although the control of systems using planar parallel mechanisms is already widely used in various fields, the use for the centroid vectoring by controlling the position of the center of mass of the system is a new concept under investigation. In the next steps, it is necessary to create the mechanism control and then implement it on real robots in order to examine the advantages and disadvantages of the control of the stabilization of robots with a floating base compared to the currently used methods.

Sketch for inverse kinematics calculation:

optimal_bar_lengths.m

seminar.m

At the end of the project, a real-life model of the mechanism was made. The mechanism was made using a 3D printer and the control of the mechanism was done using a Dynamixel motors. The mechanism was controlled using the inverse kinematics calculations and the working space of the mechanism was tested. The mechanism was able to move the tooltip in the desired direction and the working space was tested for the given requirements.

Contributors names and contact info

| Author | GitHub | |

|---|---|---|

| Enio Krizman | @kr1zzo | [email protected] |

| Mentors | |

|---|---|

| Izv. Prof. Dr. Sc. Matko Orsag | [email protected] |