WO2021128951A1 - 一种新型焦炉结构及其分段加热燃烧方法 - Google Patents

一种新型焦炉结构及其分段加热燃烧方法 Download PDFInfo

- Publication number

- WO2021128951A1 WO2021128951A1 PCT/CN2020/114457 CN2020114457W WO2021128951A1 WO 2021128951 A1 WO2021128951 A1 WO 2021128951A1 CN 2020114457 W CN2020114457 W CN 2020114457W WO 2021128951 A1 WO2021128951 A1 WO 2021128951A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- gas

- coke oven

- air

- hole

- regenerator

- Prior art date

Links

- 239000000571 coke Substances 0.000 title claims abstract description 60

- 238000010438 heat treatment Methods 0.000 title claims abstract description 28

- 238000009841 combustion method Methods 0.000 title claims abstract description 8

- 239000007789 gas Substances 0.000 claims abstract description 115

- 238000002485 combustion reaction Methods 0.000 claims abstract description 69

- 238000003763 carbonization Methods 0.000 claims abstract description 39

- 239000003245 coal Substances 0.000 claims abstract description 12

- 206010022000 influenza Diseases 0.000 claims abstract description 11

- 239000000779 smoke Substances 0.000 claims description 12

- 238000004939 coking Methods 0.000 claims description 10

- 230000000630 rising effect Effects 0.000 claims description 5

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 claims description 3

- 239000011449 brick Substances 0.000 claims description 3

- 239000003546 flue gas Substances 0.000 claims description 3

- 239000002912 waste gas Substances 0.000 claims description 3

- 230000009467 reduction Effects 0.000 claims description 2

- 238000013461 design Methods 0.000 abstract description 5

- 238000005338 heat storage Methods 0.000 abstract description 4

- IJGRMHOSHXDMSA-UHFFFAOYSA-N nitrogen Substances N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 abstract description 4

- 229910052757 nitrogen Inorganic materials 0.000 abstract description 4

- 239000003034 coal gas Substances 0.000 abstract description 2

- 230000007246 mechanism Effects 0.000 abstract description 2

- 238000004891 communication Methods 0.000 abstract 2

- 230000001174 ascending effect Effects 0.000 abstract 1

- 239000002010 green coke Substances 0.000 abstract 1

- MWUXSHHQAYIFBG-UHFFFAOYSA-N nitrogen oxide Inorganic materials O=[N] MWUXSHHQAYIFBG-UHFFFAOYSA-N 0.000 description 18

- 238000005516 engineering process Methods 0.000 description 9

- 238000000034 method Methods 0.000 description 4

- 238000011161 development Methods 0.000 description 3

- 238000012546 transfer Methods 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000010531 catalytic reduction reaction Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 239000000428 dust Substances 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000001301 oxygen Substances 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- 239000013589 supplement Substances 0.000 description 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000005336 cracking Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 230000002401 inhibitory effect Effects 0.000 description 1

- 230000009916 joint effect Effects 0.000 description 1

- 230000035800 maturation Effects 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 238000005192 partition Methods 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 238000006722 reduction reaction Methods 0.000 description 1

- 239000011819 refractory material Substances 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 238000012827 research and development Methods 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10B—DESTRUCTIVE DISTILLATION OF CARBONACEOUS MATERIALS FOR PRODUCTION OF GAS, COKE, TAR, OR SIMILAR MATERIALS

- C10B49/00—Destructive distillation of solid carbonaceous materials by direct heating with heat-carrying agents including the partial combustion of the solid material to be treated

- C10B49/02—Destructive distillation of solid carbonaceous materials by direct heating with heat-carrying agents including the partial combustion of the solid material to be treated with hot gases or vapours, e.g. hot gases obtained by partial combustion of the charge

Definitions

- the present invention relates to the technical field of coke ovens, in particular to a novel coke oven structure capable of realizing the generation of low nitrogen oxides and a segmented heating and combustion method thereof.

- the height of the coking chamber of the coke oven has been developed from less than 2.8 meters to 7.65 meters, and the 8.43 meter test furnace of Uhde, Germany has also been put into operation for many years.

- the development of new coke ovens has approached the limit in the research direction of increasing the height and volume of the coking chamber.

- the design of the coke oven combustion system is still at the stage of simple segmented combustion and imitating foreign advanced technology.

- the main problem is how to set the structure of the vertical fire channel, the position of each air outlet section and the flow rate to reduce the generation of nitrogen oxides. It uses the existing mature low-nitrogen combustion technology and non-selective catalytic reduction technology to reduce nitrogen oxide emissions.

- the bottom surface of the combustion chamber and the bottom surface of the coking chamber corresponding to the chute mouth in the traditional coke oven are both located at The same level, so there is a risk of coke formation in the lower part of the coking chamber of the coke oven.

- the invention provides a new type of coke oven structure and its segmented heating and combustion method.

- the combustion process under a variety of low-nitrogen combustion mechanisms is realized, and the bottom surface of the coking chamber is higher than the combustion chamber.

- the new design of the bottom surface eliminates the risk of coke formation due to insufficient heat supply at the bottom of the coking chamber due to segmented combustion.

- a new type of coke oven structure including furnace roof, combustion chamber, carbonization chamber, chute area, regenerator and small flue; the combustion chamber and the carbonization chamber are arranged alternately, and the combustion chamber is connected to the regenerator through the chute, and the combustion chamber It is composed of multiple double-joint fire passages.

- the top of the double-joint fire passage is connected through cross holes, and the bottom is connected through exhaust gas circulation holes; the lower part of each regenerator is provided with a small flue to the outside through an exchange switch

- the flue gas ducts are connected; the furnace roof above each vertical fire channel is equipped with a fire hole; the furnace roof above each carbonization chamber is equipped with coal loading ports/smoke holes and rising pipe holes; the vertical flame channel is provided with multiple sections along the height direction With gas outlet and multi-stage air outlet, the bottom surface of the carbonization chamber is higher than the bottom surface of the combustion chamber corresponding to the ramp mouth.

- the first-stage gas outlet is higher than the first-stage air outlet, and compared with the two, the first-stage gas outlet is far away from the exhaust gas circulation hole; each middle-stage gas outlet It is arranged staggered with the air outlets of each middle section, and the air outlet of the last section is higher than the gas outlet of the last section.

- the bottom surface of the carbonization chamber is higher than the upper edge of the exhaust gas circulation hole, but lower than the first-stage gas outlet elevation.

- the combustion chamber is surrounded by a combustion chamber furnace wall, and the combustion chamber furnace wall extends obliquely toward the carbonization chamber at the lower part of the corresponding carbonization chamber, so that the cross section of the lower part of the carbonization chamber is an isosceles trapezoid.

- the furnace roof above the vertical fire channel is also provided with compensation holes, which are used to pass supplementary waste gas or mixed low partial pressure reducing gas into the vertical fire channel.

- the regenerator is provided with a compartment structure, that is, the air regenerator is divided into a plurality of air compartment regenerators along the height direction, and the gas regenerator is divided into a plurality of gas compartment regenerators along the height direction; the first section The gas outlet alone corresponds to one gas compartmentalized regenerator, and the other sections of gas outlets correspond to one or more gas compartmentalized regenerators; the first section of air outlet alone corresponds to an air compartmentalized regenerator, and the remaining sections of air outlets correspond to one to Multiple air compartment regenerators; correspondingly, the small flue is also connected to each air compartment regenerator/gas compartment regenerator along the high-direction compartment as a plurality of small flues or cluster small flues.

- a plurality of manual adjustment gates are arranged at the connection between the small flue and the exhaust gas switch.

- the main body of the coke oven is built with refractory bricks, and the positions corresponding to the coal charging port/smoke hole, riser hole, fire hole, compensation hole, and chute adopt castable prefabricated blocks, and the coal charging port/smoke hole , Riser pipe hole, fire hole, compensation hole and chute are respectively set in the corresponding castable prefabricated block.

- the chute area of the coke oven is provided with a plurality of supplementary heating holes on the front of the coke oven, and the supplementary heating holes are respectively connected with the corresponding gas chute and air chute.

- a new type of stepped heating and combustion method of coke oven structure The amount of gas flowing out of the first stage gas outlet does not exceed 90% of the total gas supply, and the amount of air flowing out of the first stage air outlet does not exceed the total air supply. 90%, the amount of coal gas at each stage of the gas outlet and the amount of air at each stage of the air outlet are controlled according to the excess air coefficient of the updraft deviating from 1, and the amount of gas in the updraft after the last stage of gas outlet is excessive.

- a more reasonable application method is provided to realize the low nitrogen oxide combustion of the coke oven combustion chamber vertical flue structure.

- the heating of the coal cake at the bottom of the coking chamber is completed by the joint action of the two furnace walls and the bottom of the coking chamber.

- the section heating technology disperses and raises the flame in the vertical flame channel.

- the present invention raises the bottom of the carbonization chamber, which can enhance the heat transfer of the vertical flame channel to the bottom of the carbonization chamber, indirectly increases the heat transfer in the carbonization chamber, and solves the problem of segmented heating coke ovens. , Especially in coke ovens where a section of the gas outlet is not at the bottom of the vertical fire channel, and the bottom of the carbonization chamber is not heated enough and is easy to appear defects;

- the lower part of the carbonization chamber is an isosceles trapezoid with a wide upper mouth and a narrow lower mouth, making the carbonization chamber structure With higher strength and more wear resistance, it also facilitates heat transfer and accelerates the maturation speed of the bottom of the coke cake;

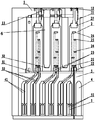

- Fig. 1 is a schematic diagram of the structure of a novel coke oven according to the present invention.

- Figure 2 is a schematic diagram of the relative positional relationship between the bottom surface of the carbonization chamber and the bottom surface of the combustion chamber of the present invention.

- the novel coke oven structure of the present invention includes a furnace roof 1, a combustion chamber 2, a carbonization chamber, a chute area 3, a regenerator 4 and a small flue 5; a combustion chamber 2 and a carbonization chamber 6-phase arrangement, the combustion chamber 2 is connected to the regenerator 4 through the chute of the chute area 3.

- the combustion chamber 2 is composed of multiple double-joint fire passages, and the top of the double-joint fire passage passes through the cross hole 27

- the bottom of each regenerator 4 is connected through the exhaust gas circulation hole 23; the lower part of each regenerator 4 is provided with a small flue 5 connected to the external flue gas channel through an exchange switch; the top of each vertical fire channel is provided with a fire hole 12;

- the furnace roof above the carbonization chamber 6 is equipped with coal loading/smoke holes 13 and rising pipe holes; the vertical fire channel is provided with multi-section gas outlets and multi-section air outlets along the high direction, and the bottom surface 32 of the carbonization chamber is higher than the combustion corresponding to the chute opening.

- the bottom surface of the chamber 31 (as shown in Figure 2).

- the first-stage gas outlet 21 is higher than the first-stage air outlet 22, and compared with the two, the first-stage gas outlet 21 is far away from the exhaust gas circulation hole 23; each The gas outlet 24 of the middle section is staggered with the air outlets of each middle section, and the air outlet 26 of the last section is higher than the gas outlet 25 of the last section.

- the bottom surface 32 of the carbonization chamber is higher than the upper edge of the exhaust gas circulation hole 23, but lower than the level of the first-stage gas outlet 21.

- the combustion chamber 2 is surrounded by a combustion chamber furnace wall 28, and the combustion chamber furnace wall 28 extends obliquely into the carbonization chamber 6 at the lower part of the corresponding carbonization chamber 6, so that the cross section of the lower part of the carbonization chamber 6 is an isosceles trapezoid.

- the furnace roof 1 above the vertical fire channel is also provided with a compensation hole 11 for passing supplementary waste gas or mixed low partial pressure reducing gas into the vertical fire channel.

- the regenerator 4 is provided with a grid structure.

- the grid structure is not only the regenerator compartment along the horizontal direction of the combustion chamber and corresponds to a pair or several opposite fire channels on it, but also can be along the height of the regenerator 4

- the regenerator 4 is arranged side by side and divided into cells, and each small cell can be further subdivided according to the needs of multi-stage heating.

- the first section of gas outlet 21 corresponds to a single gas compartmentalized regenerator 41, so that the gas flowing through the compartment is discharged from one section of gas outlet 21, and the remaining sections of gas outlets correspond to one or more gas compartmentalized regenerators.

- Each compartment regenerator can be subdivided into two parts to communicate with the other sections of the outlet; the multi-stage air outlet is similar to the compartment regenerator, the first section of the air outlet 22 is connected to a single air compartment regenerator Correspondingly, the other sections of air outlets correspond to one or more air compartmentalized regenerators, and each compartmentalized regenerator can be subdivided into two parts to communicate with other sections of outlets; accordingly, the small flue 5 is also arranged side by side

- the compartments are connected to each air compartment regenerator/gas compartment regenerator 41 as a plurality of small flues 51 or cluster small flues.

- connection between the small flue 5 and the exhaust gas switch is provided with multiple manual adjustment gates, which cooperate with the adjustment function of the regenerator grate plate, and can appropriately adjust the gas/air flowing through each compartment of the heat storage according to the type of heating gas Or the flow of exhaust gas, so as to adjust the high-direction heating of the combustion chamber.

- the main body of the coke oven is built with refractory bricks, and the positions corresponding to the coal loading port/smoke hole 13, rising pipe hole, fire hole 12, compensation hole 11, and chute 33 are made of castable prefabricated blocks, and the coal loading port /The smoke guide hole 13, the rising pipe hole, the fire hole 12, the compensation hole 11, and the chute 33 are respectively arranged in the corresponding castable prefabricated block.

- the chute zone 1 of the coke oven is provided with a plurality of supplementary heating holes on the front of the coke oven, and the supplementary heating holes are respectively connected with the corresponding gas chute and air chute.

- a new type of coke oven structure segmented heating and combustion method the amount of gas flowing out of the first stage gas outlet 21 does not exceed 90% of the total gas supply, and the amount of air flowing out of the first stage air outlet 22 does not exceed the total air supply 90% of the gas volume, the gas volume at each stage of the gas outlet and the air volume at each stage of the air outlet are controlled according to the excess air coefficient of the updraft deviating from 1, and the amount of gas in the updraft after the last stage of gas outlet 25 is excessive.

- the novel coke oven structure of the present invention adopts a new chute zone structure in which the elevation of the bottom 32 of the coking chamber is higher than the elevation of the bottom 31 of the combustion chamber corresponding to the chute opening, and the first section of the gas outlet 21 at the bottom of the combustion chamber 2 is higher than the first Sectional heating structure of section air outlet 22.

- each vertical fire channel there is also a compensation hole 11 above each vertical fire channel.

- the compensation hole 11 can supplement the exhaust gas of the combustion chamber 2 through the external pipeline of the coke oven or the low partial pressure after mixing Reduction gas operation. This operation can be used to reduce the temperature of the exhaust gas in the combustion chamber 2 or to supplement the heating of the exhaust gas in the combustion chamber 2 to achieve the purpose of adjusting the temperature of the head space of the carbonization chamber.

- the vertical fire channel in the combustion chamber 2 adopts the structure of simultaneous segmented heating of gas and air, wherein the first section of gas outlet 21 is higher than the first section of air outlet 22 and the relative position is far from the exhaust gas circulation hole 23, and the middle section of the gas outlet 24 The position is staggered with the positions of the air outlets of each middle section, and the air outlet 26 of the last section is the highest. This ensures that the air at the bottom of the standing fire channel first passes through the combustion-supporting gas diluted by the exhaust gas circulation, and then burns with the gas. After the air is first diluted, the partial pressure of oxygen in the air can be significantly reduced, thereby reducing the intensity of combustion, and inhibiting the combustion process. The nitrogen oxides are generated.

- the updraft after one stage of combustion is diluted by the gas or air supplied by multiple stages, thereby realizing deviated combustion. Control the excess amount of gas in the updraft after the gas outlet in the last stage of the combustion process.

- the reducing atmosphere of the high-temperature exhaust gas can be used to partially reduce the generated NOx to N2, thereby reducing the production of NOx during the combustion process.

- the chute area 3 corresponding to the front of the coke oven can be provided with supplementary heating holes connected to the gas chute and the air chute for supplementary heating of the burner flame, thereby increasing the temperature of the burner flame.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Combustion & Propulsion (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Coke Industry (AREA)

Abstract

一种新型焦炉结构及其分段加热燃烧方法,所述新型焦炉结构包括炉顶、燃烧室、炭化室、斜道区、蓄热室及小烟道;燃烧室通过斜道与蓄热室相连,燃烧室由多个双联立火道组成,组成双联立火道的立火道顶部通过跨越孔连通,底部通过废气循环孔连通;每个蓄热室下部设小烟道;每个立火道上方的炉顶设看火孔;每个炭化室上方的炉顶设装煤口/导烟孔及上升管孔;所述立火道内沿高向设置多段煤气出口及多段空气出口,炭化室底面高于斜道口对应的燃烧室底面。本发明通过改进焦炉燃烧室立火道结构,实现多种低氮燃烧机理下的燃烧过程,同时采用炭化室底面高于燃烧室底面的全新设计,消除因分段燃烧造成炭化室底部供热不足出现生焦的风险。

Description

本申请要求于2019年12月27日提交中国专利局、申请号为201911376204.4、发明名称为“一种新型焦炉结构及其分段加热燃烧方法”的中国专利申请的优先权,其全部内容通过引用结合在本申请中。

本发明涉及焦炉技术领域,尤其涉及一种能够实现低氮氧化物生成的新型焦炉结构及其分段加热燃烧方法。

随着机装焦炉整体工艺技术的不断发展,焦炉炭化室高度已经由原先不足2.8米发展至7.65米,而德国伍德的8.43米试验炉也投产多年。目前,新型焦炉开发在炭化室高度增加和容积增大的研究方向上已经接近极限。

随着环境保护要求的呼声日益强烈,焦炉技术的发展又走向了新的方向。在焦炉生产过程中,如何有效降低烟尘的无组织排放和有组织排放已经越来越受到重视,从源头治理污染已经成为焦炉装备工艺研发的新课题。

目前,焦炉燃烧系统设计还停留在简单的分段燃烧和模仿国外先进技术的阶段,针对如何设置立火道结构、各气流出口段位置及流量,以达到降低氮氧化物生成的问题,主要是应用现有成熟的低氮燃烧技术以及非选 择催化还原技术降低氮氧化物的排放。

另外,对于采用分段燃烧技术的焦炉,由于其改变了原有焦炉设计中底部加热量远大于顶部的加热方式,而传统焦炉中对应斜道口的燃烧室底面和炭化室底面均处于同一水平面,因此存在焦炉炭化室下部出现生焦的风险。

发明内容

本发明提供了一种新型焦炉结构及其分段加热燃烧方法,通过改进焦炉燃烧室立火道结构,实现多种低氮燃烧机理下的燃烧过程,同时采用炭化室底面高于燃烧室底面的全新设计,消除因分段燃烧造成炭化室底部供热不足出现生焦的风险。

为了达到上述目的,本发明采用以下技术方案实现:

一种新型焦炉结构,包括炉顶、燃烧室、炭化室、斜道区、蓄热室及小烟道;燃烧室与炭化室相间设置,燃烧室通过斜道与蓄热室相连,燃烧室由多个双联立火道组成,组成双联立火道的立火道顶部通过跨越孔连通,底部通过废气循环孔连通;每个蓄热室下部设小烟道通过交换开闭器与外部烟气道相连;每个立火道上方的炉顶设看火孔;每个炭化室上方的炉顶设装煤口/导烟孔及上升管孔;所述立火道内沿高向设置多段煤气出口及多段空气出口,炭化室底面高于斜道口对应的燃烧室底面。

所述多段煤气出口、多段空气出口中,自下而上,第一段煤气出口高于第一段空气出口,且两者相比,第一段煤气出口远离废气循环孔;各中间段煤气出口与各中间段空气出口交错设置,且最后一段空气出口高于最 后一段煤气出口。

所述炭化室底面高于废气循环孔的上沿,但低于第一段煤气出口标高。

所述燃烧室由燃烧室炉墙围设而成,燃烧室炉墙在对应炭化室下部向炭化室内倾斜延伸,使炭化室下部横截面呈等腰梯形。

所述立火道上方的炉顶还设有补偿孔,用于向立火道内通入补充废气或掺混后的低分压还原气。

所述蓄热室设分格结构,即空气蓄热室沿高向分为多个空气分格蓄热室,煤气蓄热室沿高向分为多个煤气分格蓄热室;第一段煤气出口单独对应一个煤气分格蓄热室,其余各段煤气出口对应一至多个煤气分格蓄热室;第一段空气出口单独对应一个空气分格蓄热室,其余各段空气出口对应一至多个空气分格蓄热室;相应地,小烟道也沿高向分格作为复数小烟道或集束小烟道与各个空气分格蓄热室/煤气分格蓄热室相连。

所述小烟道与废气开闭器连接处设置多道手动调节闸板。

所述焦炉的本体采用耐火砖砌筑,对应设置装煤口/导烟孔、上升管孔、看火孔、补偿孔、斜道的部位采用浇注料预制块,装煤口/导烟孔、上升管孔、看火孔、补偿孔、斜道分别设于对应的浇注料预制块中。

所述焦炉的斜道区在焦炉正面设置多个补充加热孔,补充加热孔分别与对应的煤气斜道、空气斜道相连。

一种新型焦炉结构的分段加热燃烧方法,自第一段煤气出口流出的煤气量不超过煤气总供应量的90%,自第一段空气出口流出的空气量不超过空气总供应量的90%,其后各段煤气出口的煤气量、各段空气出口的空气量都按照使上升气流的空气过剩系数偏离1控制,并且最后一段煤气出口 后上升气流中煤气的量过剩。

与现有技术相比,本发明的有益效果是:

1)为实现低氮氧化物燃烧的焦炉燃烧室立火道结构提供了一种更为合理的应用方式,炭化室底部煤饼的加热是通过两边炉墙和炭化室底共同作用完成,分段加热技术使立火道内火焰分散且升高,本发明将炭化室底部抬高,可加强立火道对炭化室底的传热,间接增加了炭化室内热量传递,解决了分段加热焦炉,尤其是采用一段煤气出口不在立火道底面的分段加热方式的焦炉中,炭化室底部加热不足而容易出现的缺陷;

2)炭化室底面增高后,能够避开燃烧室底部开设废气循环孔的区域,使燃烧室炉墙更加坚固耐用;炭化室下部呈上口宽、下口窄的等腰梯形,使炭化室结构强度更高,更耐磨的同时,还有利于传热,加快焦饼底部的成熟速度;

3)能够从真正意义上实现废气循环、浓淡燃烧、深度低氧燃烧等多种低氮燃烧技术的集合,通过蓄热室高向分格、小烟道端部闸板的设置与蓄热室箅子板的配置,可精确控制立火道内可燃气与助燃气的分配,从而成为一种全新的焦炉加热系统;

4)在炉顶部位还设置有补偿孔,可通过通入不同温度、不同种类的补偿气达到控制炉顶空间温度和非选择性催化还原氮氧化物的目的,其作为一种补偿手段,在焦炉设计上也是全新的;

5)将浇注料预制块应用于炉顶、斜道区等部位,可减少焦炉机械碾压、反复推焦等操作带来的震动和位移,避免因耐材之间震裂而造成的炉内气体窜漏,减少烟尘的无组织排放。

图1是本发明所述一种新型焦炉结构的结构示意图。

图2是本发明所述炭化室底面与燃烧室底面相对位置关系示意图。

图中:1.炉顶 2.燃烧室 3.斜道区 4.蓄热室 5.小烟道 6.炭化室 11.补偿孔 12.看火孔 13.装煤口/导烟孔 21.第一段煤气出口 22.第一段空气出口 23.废气循环孔 24.中间段煤气出口 25.最后一段煤气出口 26.最后一段空气出口 27.跨越孔 28.燃烧室炉墙 31.斜道口对应的燃烧室底面 32.炭化室底面 33.斜道 41.空气分格蓄热室/煤气分格蓄热室 51.复数小烟道

下面结合附图对本发明的具体实施方式作进一步说明:

如图1所示,本发明所述一种新型焦炉结构,包括炉顶1、燃烧室2、炭化室、斜道区3、蓄热室4及小烟道5;燃烧室2与炭化室6相间设置,燃烧室2通过斜道区3的斜道与蓄热室4相连,燃烧室2由多个双联立火道组成,组成双联立火道的立火道顶部通过跨越孔27连通,底部通过废气循环孔23连通;每个蓄热室4下部设小烟道5通过交换开闭器与外部烟气道相连;每个立火道上方的炉顶设看火孔12;每个炭化室6上方的炉顶设装煤口/导烟孔13及上升管孔;所述立火道内沿高向设置多段煤气出口及多段空气出口,炭化室底面32高于斜道口对应的燃烧室底面31(如图2所示)。

所述多段煤气出口、多段空气出口中,自下而上,第一段煤气出口21 高于第一段空气出口22,且两者相比,第一段煤气出口21远离废气循环孔23;各中间段煤气出口24与各中间段空气出口交错设置,且最后一段空气出口26高于最后一段煤气出口25。

所述炭化室底面32高于废气循环孔23的上沿,但低于第一段煤气出口21标高。

所述燃烧室2由燃烧室炉墙28围设而成,燃烧室炉墙28在对应炭化室6下部向炭化室6内倾斜延伸,使炭化室6下部横截面呈等腰梯形。

所述立火道上方的炉顶1还设有补偿孔11,用于向立火道内通入补充废气或掺混后的低分压还原气。

所述蓄热室4设分格结构,该分格结构不仅是沿燃烧室横排方向蓄热室分格并与其上一对或数对立火道相对应,也可以是沿蓄热室4高向设置的隔墙,使蓄热室4并排分格,且每一个小格还可按照多段加热的需要再细分。第一段煤气出口21与单独一个煤气分格蓄热室41对应,使流经该格的煤气从一段煤气出口21中排出,其余各段煤气出口与一至多个煤气分格蓄热室对应,各分格蓄热室可以再细分成两部分分别与其它几段出口联通;空气多段出口与分格蓄热室的联通设置类似,第一段空气出口22与单独一个空气分格蓄热室对应,其余各段空气出口于一至多个空气分格蓄热室对应,各分格蓄热室可以再细分成两部分分别与其它几段出口联通;相应地,小烟道5也做并排分格作为复数小烟道51或集束小烟道与各个空气分格蓄热室/煤气分格蓄热室41相连。

所述小烟道5与废气开闭器连接处设置多道手动调节闸板,配合蓄热室箅子板调节作用,可根据加热煤气的种类适当调节流经各分格蓄热内煤 气\空气或废气的流量,从而达到调节燃烧室高向加热的作用。

所述焦炉的本体采用耐火砖砌筑,对应设置装煤口/导烟孔13、上升管孔、看火孔12、补偿孔11、斜道33的部位采用浇注料预制块,装煤口/导烟孔13、上升管孔、看火孔12、补偿孔11、斜道33分别设于对应的浇注料预制块中。

所述焦炉的斜道区1在焦炉正面设置多个补充加热孔,补充加热孔分别与对应的煤气斜道、空气斜道相连。

一种新型焦炉结构的分段加热燃烧方法,自第一段煤气出口21流出的煤气量不超过煤气总供应量的90%,自第一段空气出口22流出的空气量不超过空气总供应量的90%,其后各段煤气出口的煤气量、各段空气出口的空气量都按照使上升气流的空气过剩系数偏离1控制,并且最后一段煤气出口25后上升气流中煤气的量过剩。

本发明所述一种新型焦炉结构,采用炭化室底面32标高高于斜道口对应的燃烧室底面31标高的新型斜道区结构,以及燃烧室2底部第一段煤气出口21高于第一段空气出口22的分段加热结构。

炉顶1除设有看火孔12外,还在各立火道上方设有补偿孔11,补偿孔11可通过焦炉外设管线对燃烧室2进行补充废气或掺混后的低分压还原气操作。该操作可用于降低燃烧室2内的废气温度或者补充加热燃烧室2内的废气,达到调节炭化室顶部空间温度的目的。

燃烧室2中的立火道采用煤气和空气同时分段加热的结构,其中第一段煤气出口21高于第一段空气出口22且相对位置远离废气循环孔23,各 中间段煤气出口24的位置与各中间段空气出口的位置错开,最后一段空气出口26最高。从而保证立火道底部的空气先经过废气循环稀释的助燃气,然后与煤气燃烧,空气先经过稀释后,可明显降低空气中的氧气分压,从而降低燃烧的剧烈程度,达到抑制燃烧过程中的氮氧化物生成。一段燃烧后的上升气流被多段供入的煤气或者空气冲淡,从而实现偏离燃烧。控制燃烧过程中最后一段煤气出口后上升气流中煤气的量过剩。而且可利用高温废气的还原性气氛使已生成的NOx部分还原为N2,从而降低燃烧过程中NOx的生成。

对应焦炉正面的斜道区3可开设与煤气斜道、空气斜道相连的补充加热孔,用于炉头火道的补充加热,从而提高炉头火道的温度。

以上所述,仅为本发明较佳的具体实施方式,但本发明的保护范围并不局限于此,任何熟悉本技术领域的技术人员在本发明揭露的技术范围内,根据本发明的技术方案及其发明构思加以等同替换或改变,都应涵盖在本发明的保护范围之内。

Claims (13)

- 一种新型焦炉结构,包括炉顶、燃烧室、炭化室、斜道区、蓄热室及小烟道;燃烧室与炭化室相间设置,燃烧室通过斜道与蓄热室相连,燃烧室包括立火道,其特征在于,所述立火道内沿高向设置多段煤气出口及多段空气出口,炭化室底面高于斜道口对应的燃烧室底面。

- 根据权利要求1所述的一种新型焦炉结构,其特征在于,所述多段煤气出口、多段空气出口中,自下而上,第一段煤气出口高于第一段空气出口,且两者相比,第一段煤气出口远离废气循环孔;各中间段煤气出口与各中间段空气出口交错设置,且最后一段空气出口高于最后一段煤气出口。

- 根据权利要求1所述的一种新型焦炉结构,其特征在于,所述炭化室底面高于废气循环孔的上沿,但低于第一段煤气出口标高。

- 根据权利要求1所述的一种新型焦炉结构,其特征在于,所述燃烧室由燃烧室炉墙围设而成,燃烧室炉墙在对应炭化室下部向炭化室内倾斜延伸,使炭化室下部横截面呈等腰梯形。

- 根据权利要求1所述的一种新型焦炉结构,其特征在于,所述立火道上方的炉顶还设有补偿孔,用于向立火道内通入补充废气或掺混后的低分压还原气。

- 根据权利要求1所述的一种新型焦炉结构,其特征在于,所述蓄热室设分格结构;第一段煤气出口单独与一个煤气分格蓄热室对应,其余各段煤气出口与一至多个煤气分格蓄热室对应;第一段空气出口单独与一个 空气分格蓄热室对应,其余各段空气出口与一至多个空气分格蓄热室对应。

- 根据权利要求6所述的一种新型焦炉结构,其特征在于,所述空气蓄热室沿高向分为多个空气分格蓄热室,所述煤气蓄热室沿高向分为多个煤气分格蓄热室。

- 根据权利要求6所述的一种新型焦炉结构,其特征在于,小烟道沿高向或横排分格作为复数小烟道或集束小烟道,与各个空气分格蓄热室/煤气分格蓄热室相连。

- 根据权利要求1所述的一种新型焦炉结构,其特征在于,所述小烟道与废气开闭器连接处设置多道手动调节闸板。

- 根据权利要求1所述的一种新型焦炉结构,其特征在于,所述焦炉的本体采用耐火砖砌筑,对应设置装煤口/导烟孔、上升管孔、看火孔、补偿孔、斜道的部位采用浇注料预制块,装煤口/导烟孔、上升管孔、看火孔、补偿孔、斜道分别设于对应的浇注料预制块中。

- 根据权利要求1所述的一种新型焦炉结构,其特征在于,所述焦炉的斜道区在焦炉正面设置多个补充加热孔,补充加热孔分别与对应的煤气斜道、空气斜道相连。

- 根据权利要求1-11任一项所述的一种新型焦炉结构,其特征在于,所述燃烧室由多个双联立火道组成,组成双联立火道的立火道顶部通过跨越孔连通,底部通过废气循环孔连通;每个蓄热室下部设小烟道通过交换开闭器与外部烟气道相连;每个立火道上方的炉顶设看火孔;每个炭化室上方的炉顶设装煤口/导烟孔及上升管孔。

- 基于权利要求1-11任一项所述一种新型焦炉结构的分段加热燃烧 方法,其特征在于,自第一段煤气出口流出的煤气量不超过煤气总供应量的90%,自第一段空气出口流出的空气量不超过空气总供应量的90%,其后各段煤气出口的煤气量、各段空气出口的空气量都按照使上升气流的空气过剩系数偏离1控制,并且最后一段煤气出口后上升气流中煤气的量过剩。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911376204.4A CN110938447B (zh) | 2019-12-27 | 2019-12-27 | 一种焦炉结构及其分段加热燃烧方法 |

| CN201911376204.4 | 2019-12-27 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2021128951A1 true WO2021128951A1 (zh) | 2021-07-01 |

Family

ID=69913371

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/CN2020/114457 WO2021128951A1 (zh) | 2019-12-27 | 2020-09-10 | 一种新型焦炉结构及其分段加热燃烧方法 |

Country Status (2)

| Country | Link |

|---|---|

| CN (1) | CN110938447B (zh) |

| WO (1) | WO2021128951A1 (zh) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110938447B (zh) * | 2019-12-27 | 2024-06-11 | 中冶焦耐(大连)工程技术有限公司 | 一种焦炉结构及其分段加热燃烧方法 |

| CN112066399A (zh) * | 2020-09-08 | 2020-12-11 | 鞍钢股份有限公司 | 一种适用于焦炉的降氮装置及降氮工艺 |

| CN113150801A (zh) * | 2021-04-13 | 2021-07-23 | 新兴铸管股份有限公司 | 一种快速准确定位焦炉负压系统损漏位置的方法 |

| CN114276822A (zh) * | 2022-01-18 | 2022-04-05 | 中钢设备有限公司 | 一种焦炉斜道及燃烧室进气量调节方法 |

| CN114717014B (zh) * | 2022-03-16 | 2023-12-08 | 程相魁 | 一种高温低氮燃烧焦炉 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN201395570Y (zh) * | 2009-01-13 | 2010-02-03 | 贺建虎 | 清洁型立式热回收炼焦炉 |

| CN102517042A (zh) * | 2011-06-21 | 2012-06-27 | 中冶焦耐(大连)工程技术有限公司 | 一种可控制多段燃烧的焦炉加热方法 |

| CN202465585U (zh) * | 2012-03-01 | 2012-10-03 | 北京众联盛化工工程有限公司 | 一种燃烧室分段加热、蓄热室分格可调式捣固焦炉 |

| JP2019035024A (ja) * | 2017-08-16 | 2019-03-07 | 株式会社メガテック | コークス炉の燃焼室を補修するための一体成形煉瓦、およびそれを用いた補修方法 |

| CN110938447A (zh) * | 2019-12-27 | 2020-03-31 | 中冶焦耐(大连)工程技术有限公司 | 一种新型焦炉结构及其分段加热燃烧方法 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB431825A (en) * | 1933-10-25 | 1935-07-16 | Fours A Coke Systems Lecocq S | Improvements in or relating to processes of, and coke ovens for producing semi-coke in lumps |

| JP2006070188A (ja) * | 2004-09-03 | 2006-03-16 | Jfe Steel Kk | コークス炉及びコークス炉炭化室上部のカーボン付着抑制方法 |

| JP5020656B2 (ja) * | 2007-02-15 | 2012-09-05 | 新日本製鐵株式会社 | コークス炉の燃焼方法および燃焼装置 |

| CN201301298Y (zh) * | 2008-11-13 | 2009-09-02 | 武汉科技大学 | 一种双联下喷废气循环捣固焦炉 |

| CN106190184A (zh) * | 2016-08-12 | 2016-12-07 | 湖南千盟智能信息技术有限公司 | 一种降低NOx生成的焦炉加热方法及装置 |

| CN107033926B (zh) * | 2017-06-20 | 2019-08-27 | 中冶焦耐(大连)工程技术有限公司 | 实现低氮氧化物燃烧的焦炉燃烧室立火道结构 |

| CN211946909U (zh) * | 2019-12-27 | 2020-11-17 | 中冶焦耐(大连)工程技术有限公司 | 一种新型焦炉结构 |

-

2019

- 2019-12-27 CN CN201911376204.4A patent/CN110938447B/zh active Active

-

2020

- 2020-09-10 WO PCT/CN2020/114457 patent/WO2021128951A1/zh active Application Filing

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN201395570Y (zh) * | 2009-01-13 | 2010-02-03 | 贺建虎 | 清洁型立式热回收炼焦炉 |

| CN102517042A (zh) * | 2011-06-21 | 2012-06-27 | 中冶焦耐(大连)工程技术有限公司 | 一种可控制多段燃烧的焦炉加热方法 |

| CN202465585U (zh) * | 2012-03-01 | 2012-10-03 | 北京众联盛化工工程有限公司 | 一种燃烧室分段加热、蓄热室分格可调式捣固焦炉 |

| JP2019035024A (ja) * | 2017-08-16 | 2019-03-07 | 株式会社メガテック | コークス炉の燃焼室を補修するための一体成形煉瓦、およびそれを用いた補修方法 |

| CN110938447A (zh) * | 2019-12-27 | 2020-03-31 | 中冶焦耐(大连)工程技术有限公司 | 一种新型焦炉结构及其分段加热燃烧方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110938447B (zh) | 2024-06-11 |

| CN110938447A (zh) | 2020-03-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2021128951A1 (zh) | 一种新型焦炉结构及其分段加热燃烧方法 | |

| CN1084782C (zh) | 联体式炼焦炉及其炼焦方法 | |

| CN101585524B (zh) | 一种罐式炭素煅烧炉挥发份和预热空气通道结构 | |

| CN108277022B (zh) | 一种顶装捣固一体化焦炉炉体结构及其调节方法 | |

| CN2505478Y (zh) | 热回收焦炉的炉体 | |

| CN108728126B (zh) | 一种高向加热均匀性随时可调的焦炉加热系统及调节方法 | |

| CN211946909U (zh) | 一种新型焦炉结构 | |

| CN108728125B (zh) | 加热高度可变的富煤气加热焦炉加热系统及其调节方法 | |

| CN108728127B (zh) | 采用富煤气加热的低氮排放焦炉加热系统及其调节方法 | |

| CN218262368U (zh) | 一种加热油式焦炉 | |

| CN214571689U (zh) | 一种可组合调节的富煤气加热焦炉 | |

| CN208649219U (zh) | 加热高度可变的富煤气加热焦炉加热系统 | |

| CN106675584A (zh) | 一种上部协同下部调节焦炉长向气流分配的结构及方法 | |

| JPS6137313B2 (zh) | ||

| RU2811610C1 (ru) | Новая конструкция коксовой печи и способ её горения с секционным нагревом | |

| CN113122283A (zh) | 一种复热式多段加热焦炉加热系统的调节方法 | |

| CN112538359B (zh) | 一种富煤气焦炉加热系统及组合调节方法 | |

| CN220618811U (zh) | 一种强化加热的焦炉加热系统 | |

| CN112538360B (zh) | 一种可组合调节的富煤气加热焦炉 | |

| CN220393609U (zh) | 一种用于复热式焦炉的废气开闭器 | |

| CN114702971B (zh) | 一种焦炉的废气分配装置及其工作方法 | |

| CN217230610U (zh) | 一种高热效率的热回收焦炉主墙结构 | |

| CN201206124Y (zh) | 单热式单侧烟道焦炉 | |

| CN214528832U (zh) | 一种富煤气焦炉加热系统 | |

| CN220485610U (zh) | 一种高效的焦炉加热系统 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 20904705 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2022102926 Country of ref document: RU |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 20904705 Country of ref document: EP Kind code of ref document: A1 |