WO2020031789A1 - Construction machine - Google Patents

Construction machine Download PDFInfo

- Publication number

- WO2020031789A1 WO2020031789A1 PCT/JP2019/029842 JP2019029842W WO2020031789A1 WO 2020031789 A1 WO2020031789 A1 WO 2020031789A1 JP 2019029842 W JP2019029842 W JP 2019029842W WO 2020031789 A1 WO2020031789 A1 WO 2020031789A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- attachment

- controller

- pressure

- variable relief

- relief valve

- Prior art date

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02F—DREDGING; SOIL-SHIFTING

- E02F9/00—Component parts of dredgers or soil-shifting machines, not restricted to one of the kinds covered by groups E02F3/00 - E02F7/00

- E02F9/20—Drives; Control devices

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B11/00—Servomotor systems without provision for follow-up action; Circuits therefor

- F15B11/02—Systems essentially incorporating special features for controlling the speed or actuating force of an output member

- F15B11/028—Systems essentially incorporating special features for controlling the speed or actuating force of an output member for controlling the actuating force

Definitions

- the present invention relates to a construction machine such as a hydraulic excavator, and more particularly to a construction machine having a controller that sets a relief pressure of a variable relief valve and outputs a command current corresponding to the set value to the variable relief valve.

- a hydraulic excavator which is one of construction machines, includes a self-propelled lower traveling body, an upper revolving body rotatably provided above the lower traveling body, and a working device coupled to the upper revolving body.

- the working device includes a boom rotatably connected to the upper swing body, an arm rotatably connected to a tip of the boom, and an attachment rotatably connected to the tip of the arm.

- the boom, the arm, and the attachment are rotated by a boom cylinder, an arm cylinder, and an attachment rotation cylinder, respectively.

- the hydraulic excavator can be equipped with an optional attachment instead of the standard attachment bucket.

- Some optional attachments include an actuator for driving the attachment.

- a grapple which is one of the specific examples, includes an attachment driving actuator that opens and closes a claw.

- the operating pressure of the attachment drive actuator differs depending on the type and specifications of the attachment. Therefore, for example, in the related art described in Patent Literature 1, an electromagnetic variable relief valve that limits the operating pressure (circuit pressure) of an attachment driving actuator to a relief pressure or less, and a variable relief valve that operates in accordance with the operation of a dial switch. A controller that sets a relief pressure and outputs a command current corresponding to the set value to the variable relief valve.

- variable relief valve is configured so that the relief pressure increases according to a decrease in the current from the controller. Have been.

- the variable relief valve is configured such that the relief pressure decreases in accordance with an increase in current from the controller.

- the controller When the controller is started according to the instruction of the start switch, the controller increases the output current to the variable relief valve from zero so that the command current corresponds to the set value of the relief pressure of the variable relief valve. At this time, if the output current is increased significantly, a surge current exceeding the command current may occur, during which the relief pressure of the variable relief valve may drop below the set value and fall below the holding pressure of the attachment drive actuator. There is. Therefore, the attachment may malfunction due to its own weight.

- the present invention has been made in view of the above circumstances, and an object of the present invention is to provide a construction machine capable of preventing generation of a surge current and preventing malfunction of an attachment.

- the present invention provides a hydraulic pump driven by a prime mover, an attachment mounted on a tip side of a working device, and an attachment incorporated in the attachment and operated by pressure oil from the hydraulic pump.

- a driving actuator for limiting the operating pressure of the attachment driving actuator to a relief pressure or less, and a relief pressure for the variable relief valve, wherein a command current corresponding to the set value is set to the variable relief valve.

- a start switch for instructing activation of the controller, wherein the controller is configured to activate the variable relief valve until a predetermined time elapses after activation according to the instruction of the activation switch. Current so that the rate of change is less than a predetermined value.

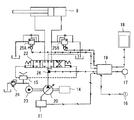

- FIG. 2 is a circuit diagram illustrating a configuration related to an attachment driving actuator in the configuration of the hydraulic shovel driving device according to the embodiment of the present invention.

- FIG. 2 is a block diagram illustrating a functional configuration of a controller related to control of the variable relief valve according to the embodiment of the present invention.

- FIG. 4 is a diagram for describing filter processing of a controller according to an embodiment of the present invention.

- FIG. 1 is a side view illustrating the structure of the hydraulic shovel according to the present embodiment.

- the hydraulic shovel according to the present embodiment includes a lower traveling body 1 that is capable of self-propelling, and an upper revolving body 2 that is rotatably provided above the lower traveling body. Make up the body.

- the lower traveling body 1 travels by a traveling motor (not shown), and the upper revolving body 2 turns by a turning motor (not shown).

- a working device 3 is connected to the front side of the upper swing body 2.

- the working device 3 includes a boom 4 rotatably connected to the upper swing body 2 in the up-down direction, an arm 5 rotatably connected to the tip of the boom 4 in the up-down direction, and a tip end of the arm 5. And an attachment that is connected to be rotatable in the vertical direction.

- the boom 4, the arm 5, and the attachment are respectively rotated by a boom cylinder 6, an arm cylinder 7, and an attachment rotation cylinder (not shown).

- the hydraulic excavator shown in FIG. 1 is equipped with a grapple 8 as an optional attachment instead of the bucket as the standard attachment.

- the grapple 8 includes a support frame, a plurality of claws provided on the support frame so as to be openable and closable, and an attachment driving actuator 9 (see FIG. 2 described later) for opening and closing these claws.

- the upper revolving superstructure 2 is disposed at a rear end of the revolving frame 10, a cab (cab) 12 disposed at a front portion of the revolving frame 10 via a pedestal 11, and a rear end of the revolving frame 10. And a counter weight 13.

- a machine room is formed between the pedestal portion 11 and the counterweight 13, and equipment including an engine 14 (see FIG. 2 described later) is mounted in the machine room.

- An operating device (not shown) for instructing driving of the traveling motor and an operating device (not shown) for instructing driving of the swing motor, the boom cylinder 6, the arm cylinder 7, and the attachment rotating cylinder are provided in the cab 12.

- an operation device 15 for instructing driving of the attachment driving actuator 9 are provided.

- the key switch 16 (start switch) can be operated to the ON position, thereby instructing the start of the display device 18 and the controller 19 (see FIG. 2 described later).

- the key switch 16 can be operated to the START position, thereby instructing the start of the engine 14.

- the key switch 16 can be operated to the OFF position, thereby instructing the stop of the engine 14 and the stop of the display device 18 and the controller 19.

- the controller 19 has an arithmetic control unit (for example, CPU) for executing arithmetic processing and control processing based on a program, and a storage unit (for example, ROM, RAM) for storing the program and the result of the arithmetic processing.

- arithmetic control unit for example, CPU

- ROM read only memory

- RAM random access memory

- the display device 18 displays the engine speed, the temperature of the engine cooling water, the remaining fuel amount, and the like on the basic screen.

- the dial switch 17 can perform a rotating operation and a pressing operation. By pressing the dial switch 17, switching from the basic screen of the display device 18 to the setting screen can be performed, and thereafter, setting input can be performed by rotating and pressing the dial switch 17.

- FIG. 2 is a circuit diagram illustrating a configuration related to the attachment driving actuator 9 in the configuration of the hydraulic shovel driving device according to the present embodiment.

- the drive device includes an engine 14 (motor), a variable displacement hydraulic pump 20 driven by the engine 14, an electromagnetic regulator 21 that variably controls the displacement of the hydraulic pump 20, and a hydraulic pump 20.

- a directional control valve 22 for controlling the flow of pressurized oil to the attachment driving actuator 9, a fixed displacement pilot pump 23 driven by the engine 14, a pilot relief valve 24 for regulating the discharge pressure of the pilot pump 23,

- the operation device 15 includes, for example, an operation pedal that can be operated by foot movement, and a pilot valve.

- the pilot valve uses the discharge pressure of the pilot pump 23 as a source pressure, generates a pilot pressure corresponding to the operation amount of one side of the operation pedal, and outputs the pilot pressure to the pressure receiving unit on the left side of the direction control valve 22 in the drawing. Thereby, the direction control valve 22 is switched to the switching position on the left side in the figure. As a result, pressure oil from the hydraulic pump 20 is supplied to the bottom side of the attachment driving actuator 9, and the attachment driving actuator 9 is extended.

- the pilot valve generates a pilot pressure corresponding to the operation amount of the other side of the operation pedal by using the discharge pressure of the pilot pump 23 as the original pressure, and outputs the pilot pressure to the pressure receiving portion on the right side of the direction control valve 22 in the drawing.

- the direction control valve 22 is switched to the right switching position in the figure.

- the pressure oil from the hydraulic pump 20 is supplied to the rod side of the actuator 9 for driving the attachment, and the actuator 9 for driving the attachment is shortened.

- the controller 19 sets the capacity of the hydraulic pump 20 and outputs a command current corresponding to the set value to the regulator 21.

- the regulator 21 changes the tilt angle of the swash plate of the hydraulic pump 20 (that is, the capacity of the hydraulic pump 20) according to the current from the controller 19.

- the controller 19 sets the relief pressure of the variable relief valves 25A and 25B, and outputs a command current corresponding to the set value to the variable relief valves 25A and 25B.

- the variable relief valves 25A and 25B are configured so that the relief pressure decreases in accordance with an increase in the current from the controller 19.

- the display device 18 switches to an attachment selection screen (not shown) in accordance with the pressing operation of the dial switch 17.

- the attachment selection screen has a plurality of different attachment buttons depending on the type and specification of the attachment.

- the controller 19 stores in advance the required flow rate and required pressure of the attachment driving actuator corresponding to each attachment, acquires the required flow rate and required pressure of the attachment driving actuator according to the input attachment, and based on this, To set the displacement of the hydraulic pump 20 and the relief pressure of the variable relief valves 25A, 25B, and store those set values.

- the display device 18 switches to a relief pressure adjustment screen (not shown) in response to the pressing operation of the dial switch 17.

- the relief pressure adjustment screen displays the required pressure of the attachment driving actuator acquired as described above and the operating pressure of the attachment driving actuator detected by the pressure sensor 26, and displays a relief pressure adjustment cursor and adjustment. Has an ending item.

- the controller 19 When the display device 18 is displaying the relief pressure adjustment screen, the controller 19 outputs to the regulator 21 a command current corresponding to the capacity of the hydraulic pump 20 set as described above. In the initial stage, a command current corresponding to the relief pressure of the variable relief valves 25A, 25B set as described above is output to the variable relief valves 25A, 25B. Then, when the attachment driving actuator is operated by operating the operation device 15, the operating pressure of the attachment driving actuator is detected by the pressure sensor 26 and displayed on the relief pressure adjustment screen.

- the controller 19 When the cursor on the relief pressure adjustment screen is moved by rotating the dial switch 17, a correction value of the relief pressure corresponding to the amount of movement is input to the controller 19. Then, the controller 19 outputs a command current corresponding to the correction value of the relief pressure to the variable relief valves 25A and 25B. Along with this, the operating pressure of the attachment driving actuator displayed on the relief pressure adjustment screen also changes. Therefore, the driver can adjust the relief pressure so that the required pressure of the attachment driving actuator and the operating pressure match. Thereafter, when the dial switch 17 is pressed in a state where the adjustment end item is selected by the rotation operation of the dial switch 17, the controller 19 updates the set value of the relief pressure to the adjusted value and stores it.

- the controller 19 when the controller 19 is started according to the instruction of the key switch 16, the controller 19 changes the output current to the variable relief valves 25A and 25B so that the command current corresponds to the set value of the relief pressure of the variable relief valves 25A and 25B. Increase from zero. At this time, if the output current is significantly increased, a surge current exceeding the command current may be generated.

- the controller 19 changes the current flowing to the variable relief valves 25A and 25B to a predetermined value (for example, 600 mA / sec) until a predetermined time (for example, one second) elapses after the controller 19 is activated according to the instruction of the key switch 16. Seconds). Details of this control will be described with reference to FIG.

- FIG. 3 is a block diagram illustrating a functional configuration of the controller 19 related to the control of the variable relief valves 25A and 25B in the present embodiment.

- the controller 19 has a command current calculation unit 27, a switching unit 28, and a filter 29 as a functional configuration related to the control of the variable relief valves 25A and 25B.

- the command current calculation unit 27 has a calculation table indicating the relationship between the set values (or adjustment values) of the relief pressures of the variable relief valves 25A and 25B and the command current.

- the command current is calculated from the set value (or adjustment value) of the relief pressure of the valves 25A, 25B.

- the switching unit 28 determines whether a predetermined time has elapsed since the controller 19 was started. If the controller 19 has been activated but the predetermined time has not elapsed, the command current calculated by the command current calculator 27 is output to the variable relief valves 25A and 25B via the filter 29.

- the switching unit 28 outputs the command current calculated by the command current calculation unit 27 to the variable relief valves 25A and 25B as it is when a predetermined time has elapsed since the start of the controller 19.

- the controller 19 changes the current to the variable relief valves 25A and 25B until the predetermined time elapses from the start in response to the instruction of the key switch 16 and the rate of change of the current to the variable relief valves 25A and 25B is equal to or less than the predetermined value. Restrict to be. Therefore, generation of surge current can be prevented, and malfunction of the attachment can be prevented.

- the controller 19 outputs the current to the variable relief valves 25A and 25B in a stepwise manner so that the rate of change is equal to or less than a predetermined value.

- the present invention is not limited to this, and the output may be continuously increased.

- the driving device includes two variable relief valves that limit the operating pressure of the attachment driving actuator to a relief pressure or less has been described as an example.

- the present invention is not limited thereto. May be provided alone.

- the hydraulic shovel has been described as an example to which the present invention is applied.

- the present invention is not limited to this and may be applied to other construction machines (specifically, for example, a wheel loader).

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Mechanical Engineering (AREA)

- Mining & Mineral Resources (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Operation Control Of Excavators (AREA)

- Fluid-Pressure Circuits (AREA)

Abstract

Provided is a construction machine capable of preventing the generation of surge currents and the malfunction of an attachment. In the present invention, a hydraulic shovel is provided with: an attachment driving actuator which is embedded in a grapple and operated by hydraulic oil from a hydraulic pump; a variable relief valve which prevents the operation pressure of the attachment driving actuator from exceeding a relief pressure; and a controller which sets the relief pressure of the variable relief valve and outputs a command current corresponding to the set value to the variable relief valve. The controller starts in response to an instruction of a start switch, and thereafter restricts the current to the variable relief valve, so that the rate of change of the current does not exceed a predetermined value until a predetermined time elapses.

Description

本発明は、油圧ショベル等の建設機械に係わり、特に、可変リリーフ弁のリリーフ圧を設定すると共に、その設定値に対応する指令電流を可変リリーフ弁に出力するコントローラを備えた建設機械に関する。

The present invention relates to a construction machine such as a hydraulic excavator, and more particularly to a construction machine having a controller that sets a relief pressure of a variable relief valve and outputs a command current corresponding to the set value to the variable relief valve.

建設機械の一つである油圧ショベルは、自走可能な下部走行体と、下部走行体の上側に旋回可能に設けられた上部旋回体と、上部旋回体に連結された作業装置とを備えている。作業装置は、上部旋回体に回動可能に連結されたブームと、ブームの先端部に回動可能に連結されたアームと、アームの先端部に回動可能に連結されたアタッチメントとを備えている。ブーム、アーム、及びアタッチメントは、ブームシリンダ、アームシリンダ、及びアタッチメント回動用シリンダによってそれぞれ回動する。

A hydraulic excavator, which is one of construction machines, includes a self-propelled lower traveling body, an upper revolving body rotatably provided above the lower traveling body, and a working device coupled to the upper revolving body. I have. The working device includes a boom rotatably connected to the upper swing body, an arm rotatably connected to a tip of the boom, and an attachment rotatably connected to the tip of the arm. I have. The boom, the arm, and the attachment are rotated by a boom cylinder, an arm cylinder, and an attachment rotation cylinder, respectively.

油圧ショベルは、標準装備のアタッチメントであるバケットに代えて、オプション装備のアタッチメントを装着可能である。オプション装備のアタッチメントは、アタッチメント駆動用アクチュエータを備えたものがある。具体例の一つであるグラップルは、爪を開閉させるアタッチメント駆動用アクチュエータを備えている。

The hydraulic excavator can be equipped with an optional attachment instead of the standard attachment bucket. Some optional attachments include an actuator for driving the attachment. A grapple, which is one of the specific examples, includes an attachment driving actuator that opens and closes a claw.

アタッチメント駆動用アクチュエータの作動圧は、アタッチメントの種類や仕様に応じて異なる。そこで、例えば特許文献1に記載の従来技術では、アタッチメント駆動用アクチュエータの作動圧(回路圧)をリリーフ圧以下に制限する電磁式の可変リリーフ弁と、ダイヤルスイッチの操作に応じて可変リリーフ弁のリリーフ圧を設定すると共に、その設定値に対応する指令電流を可変リリーフ弁に出力するコントローラとを備えている。

作 動 The operating pressure of the attachment drive actuator differs depending on the type and specifications of the attachment. Therefore, for example, in the related art described in Patent Literature 1, an electromagnetic variable relief valve that limits the operating pressure (circuit pressure) of an attachment driving actuator to a relief pressure or less, and a variable relief valve that operates in accordance with the operation of a dial switch. A controller that sets a relief pressure and outputs a command current corresponding to the set value to the variable relief valve.

特許文献1には記載されていないものの、例えば断線発生時にアタッチメント駆動用アクチュエータの作動を確保する等の理由から、可変リリーフ弁は、コントローラからの電流の減少に応じてリリーフ圧が上がるように構成されている。言い換えれば、可変リリーフ弁は、コントローラからの電流の増大に応じてリリーフ圧が下がるように構成されている。

Although not described in Patent Document 1, for example, in order to ensure the operation of the attachment driving actuator when a disconnection occurs, the variable relief valve is configured so that the relief pressure increases according to a decrease in the current from the controller. Have been. In other words, the variable relief valve is configured such that the relief pressure decreases in accordance with an increase in current from the controller.

コントローラは、起動スイッチの指示に応じて起動すると、可変リリーフ弁のリリーフ圧の設定値に対応する指令電流となるように、可変リリーフ弁への出力電流をゼロから上昇させる。このとき、出力電流を著しく上昇させれば、指令電流を超えるサージ電流が発生する可能性があり、その間、可変リリーフ弁のリリーフ圧が設定値より下がり、アタッチメント駆動用アクチュエータの保持圧を下回る可能性がある。したがって、アタッチメントが自重によって誤作動する可能性がある。

(4) When the controller is started according to the instruction of the start switch, the controller increases the output current to the variable relief valve from zero so that the command current corresponds to the set value of the relief pressure of the variable relief valve. At this time, if the output current is increased significantly, a surge current exceeding the command current may occur, during which the relief pressure of the variable relief valve may drop below the set value and fall below the holding pressure of the attachment drive actuator. There is. Therefore, the attachment may malfunction due to its own weight.

本発明は、上記事柄に鑑みてなされたものであり、その目的は、サージ電流の発生を防ぎ、アタッチメントの誤作動を防止することができる建設機械を提供することにある。

The present invention has been made in view of the above circumstances, and an object of the present invention is to provide a construction machine capable of preventing generation of a surge current and preventing malfunction of an attachment.

上記目的を達成するために、本発明は、原動機によって駆動される油圧ポンプと、作業装置の先端側に取付けられたアタッチメントと、前記アタッチメントに組込まれ、前記油圧ポンプからの圧油によって作動するアタッチメント駆動用アクチュエータと、前記アタッチメント駆動用アクチュエータの作動圧をリリーフ圧以下に制限する可変リリーフ弁と、前記可変リリーフ弁のリリーフ圧を設定すると共に、その設定値に対応する指令電流を前記可変リリーフ弁に出力するコントローラと、前記コントローラの起動を指示する起動スイッチとを備えた建設機械において、前記コントローラは、前記起動スイッチの指示に応じて起動してから所定時間が経過するまで、前記可変リリーフ弁への電流をその変化率が所定値以下となるように制限する。

In order to achieve the above object, the present invention provides a hydraulic pump driven by a prime mover, an attachment mounted on a tip side of a working device, and an attachment incorporated in the attachment and operated by pressure oil from the hydraulic pump. A driving actuator, a variable relief valve for limiting the operating pressure of the attachment driving actuator to a relief pressure or less, and a relief pressure for the variable relief valve, wherein a command current corresponding to the set value is set to the variable relief valve. And a start switch for instructing activation of the controller, wherein the controller is configured to activate the variable relief valve until a predetermined time elapses after activation according to the instruction of the activation switch. Current so that the rate of change is less than a predetermined value. To.

本発明によれば、サージ電流の発生を防ぎ、アタッチメントの誤作動を防止することができる。

According to the present invention, it is possible to prevent generation of surge current and prevent malfunction of the attachment.

本発明の一実施形態を、図面を参照しつつ説明する。

An embodiment of the present invention will be described with reference to the drawings.

図1は、本実施形態における油圧ショベルの構造を表す側面図である。

FIG. 1 is a side view illustrating the structure of the hydraulic shovel according to the present embodiment.

本実施形態の油圧ショベルは、自走可能な下部走行体1と、下部走行体の上側に旋回可能に設けられた上部旋回体2とを備えており、下部走行体1及び上部旋回体2が車体を構成している。下部走行体1は、走行モータ(図示せず)によって走行し、上部旋回体2は、旋回モータ(図示せず)によって旋回する。

The hydraulic shovel according to the present embodiment includes a lower traveling body 1 that is capable of self-propelling, and an upper revolving body 2 that is rotatably provided above the lower traveling body. Make up the body. The lower traveling body 1 travels by a traveling motor (not shown), and the upper revolving body 2 turns by a turning motor (not shown).

上部旋回体2の前側には作業装置3が連結されている。作業装置3は、上部旋回体2に上下方向に回動可能に連結されたブーム4と、ブーム4の先端部に上下方向に回動可能に連結されたアーム5と、アーム5の先端部に上下方向に回動可能に連結されたアタッチメントとを備えている。ブーム4、アーム5、及びアタッチメントは、ブームシリンダ6、アームシリンダ7、及びアタッチメント回動用シリンダ(図示せず)によってそれぞれ回動する。

作業 A working device 3 is connected to the front side of the upper swing body 2. The working device 3 includes a boom 4 rotatably connected to the upper swing body 2 in the up-down direction, an arm 5 rotatably connected to the tip of the boom 4 in the up-down direction, and a tip end of the arm 5. And an attachment that is connected to be rotatable in the vertical direction. The boom 4, the arm 5, and the attachment are respectively rotated by a boom cylinder 6, an arm cylinder 7, and an attachment rotation cylinder (not shown).

図1で示す油圧ショベルは、標準装備のアタッチメントであるバケットに代えて、オプション装備のアタッチメントであるグラップル8を装着している。グラップル8は、支持フレームと、この支持フレームに開閉可能に設けられた複数の爪と、これらの爪を開閉させるアタッチメント駆動用アクチュエータ9(後述の図2参照)とを備えている。

油 圧 The hydraulic excavator shown in FIG. 1 is equipped with a grapple 8 as an optional attachment instead of the bucket as the standard attachment. The grapple 8 includes a support frame, a plurality of claws provided on the support frame so as to be openable and closable, and an attachment driving actuator 9 (see FIG. 2 described later) for opening and closing these claws.

上部旋回体2は、基礎構造体をなす旋回フレーム10と、旋回フレーム10の前部に台座部11を介して配置された運転室(キャブ)12と、旋回フレーム10の後端に配置されたカウンタウエイト13とを備えている。台座部11とカウンタウエイト13の間には機械室が形成されており、この機械室内には、エンジン14(後述の図2参照)を含む機器が搭載されている。

The upper revolving superstructure 2 is disposed at a rear end of the revolving frame 10, a cab (cab) 12 disposed at a front portion of the revolving frame 10 via a pedestal 11, and a rear end of the revolving frame 10. And a counter weight 13. A machine room is formed between the pedestal portion 11 and the counterweight 13, and equipment including an engine 14 (see FIG. 2 described later) is mounted in the machine room.

運転室12内には、走行モータの駆動を指示する操作装置(図示せず)と、旋回モータ、ブームシリンダ6、アームシリンダ7、及びアタッチメント回動用シリンダの駆動を指示する操作装置(図示せず)と、アタッチメント駆動用アクチュエータ9の駆動を指示する操作装置15(後述の図2参照)とが設けられている。

An operating device (not shown) for instructing driving of the traveling motor and an operating device (not shown) for instructing driving of the swing motor, the boom cylinder 6, the arm cylinder 7, and the attachment rotating cylinder are provided in the cab 12. ) And an operation device 15 (see FIG. 2 described later) for instructing driving of the attachment driving actuator 9 are provided.

また、運転室12内には、後述の図2で示す、キースイッチ16、ダイヤルスイッチ17、及び表示装置18が設けられている。キースイッチ16(起動スイッチ)は、ON位置に操作可能とし、これによって表示装置18及びコントローラ19(後述の図2参照)の起動を指示する。また、キースイッチ16は、START位置に操作可能とし、これによってエンジン14の起動を指示する。また、キースイッチ16は、OFF位置に操作可能とし、これによってエンジン14の停止を指示すると共に、表示装置18及びコントローラ19の停止を指示する。

{Circle around (2)} A key switch 16, a dial switch 17, and a display device 18 shown in FIG. The key switch 16 (start switch) can be operated to the ON position, thereby instructing the start of the display device 18 and the controller 19 (see FIG. 2 described later). The key switch 16 can be operated to the START position, thereby instructing the start of the engine 14. The key switch 16 can be operated to the OFF position, thereby instructing the stop of the engine 14 and the stop of the display device 18 and the controller 19.

コントローラ19は、プログラムに基づいて演算処理や制御処理を実行する演算制御部(例えばCPU)と、プログラムや演算処理の結果を記憶する記憶部(例えばROM、RAM)等を有するものである。

The controller 19 has an arithmetic control unit (for example, CPU) for executing arithmetic processing and control processing based on a program, and a storage unit (for example, ROM, RAM) for storing the program and the result of the arithmetic processing.

表示装置18は、基本画面上で、エンジン回転数、エンジン冷却水の温度、及び燃料の残量等を表示する。ダイヤルスイッチ17は、回転操作と押し操作が行えるものである。そして、ダイヤルスイッチ17の押し操作によって、表示装置18の基本画面から設定画面への切替えが行え、その後、ダイヤルスイッチ17の回転操作及び押し操作によって、設定入力が行えるようになっている。

The display device 18 displays the engine speed, the temperature of the engine cooling water, the remaining fuel amount, and the like on the basic screen. The dial switch 17 can perform a rotating operation and a pressing operation. By pressing the dial switch 17, switching from the basic screen of the display device 18 to the setting screen can be performed, and thereafter, setting input can be performed by rotating and pressing the dial switch 17.

上述した走行モータ、旋回モータ、ブームシリンダ6、アームシリンダ7、アタッチメント回動用シリンダ、及びアタッチメント駆動用アクチュエータ9は、油圧ショベルに備えられた駆動装置によって駆動される。図2は、本実施形態における油圧ショベルの駆動装置の構成のうち、アタッチメント駆動用アクチュエータ9に係わる構成を表す回路図である。

The driving motor, the turning motor, the boom cylinder 6, the arm cylinder 7, the attachment rotating cylinder, and the attachment driving actuator 9 described above are driven by a drive device provided in the hydraulic shovel. FIG. 2 is a circuit diagram illustrating a configuration related to the attachment driving actuator 9 in the configuration of the hydraulic shovel driving device according to the present embodiment.

本実施形態の駆動装置は、エンジン14(原動機)と、エンジン14によって駆動される可変容量型の油圧ポンプ20と、油圧ポンプ20の容量を可変制御する電磁式のレギュレータ21と、油圧ポンプ20からアタッチメント駆動用アクチュエータ9への圧油の流れを制御する方向制御弁22と、エンジン14によって駆動される固定容量型のパイロットポンプ23と、パイロットポンプ23の吐出圧を規定するパイロットリリーフ弁24と、方向制御弁22を操作する操作装置15と、アタッチメント駆動用アクチュエータ9と方向制御弁22の間に設けられ、アタッチメント駆動用アクチュエータ9の作動圧をリリーフ圧以下に制限する電磁式の可変リリーフ弁25A,25Bと、レギュレータ21及び可変リリーフ弁25A,25Bを制御するコントローラ19とを備えている。

The drive device according to the present embodiment includes an engine 14 (motor), a variable displacement hydraulic pump 20 driven by the engine 14, an electromagnetic regulator 21 that variably controls the displacement of the hydraulic pump 20, and a hydraulic pump 20. A directional control valve 22 for controlling the flow of pressurized oil to the attachment driving actuator 9, a fixed displacement pilot pump 23 driven by the engine 14, a pilot relief valve 24 for regulating the discharge pressure of the pilot pump 23, An operation device 15 for operating the directional control valve 22, and an electromagnetic variable relief valve 25A provided between the attachment driving actuator 9 and the directional control valve 22 to limit the operating pressure of the attachment driving actuator 9 to a relief pressure or less. , 25B, the regulator 21 and the variable relief valves 25A, 25 And a controller 19 for controlling.

操作装置15は、例えば、足動操作可能な操作ペダルと、パイロット弁とを備えている。パイロット弁は、パイロットポンプ23の吐出圧を元圧として、操作ペダルの一方側の操作量に対応したパイロット圧を生成して方向制御弁22の図中左側の受圧部へ出力する。これにより、方向制御弁22が図中左側の切換位置に切換えられる。その結果、油圧ポンプ20からの圧油がアタッチメント駆動用アクチュエータ9のボトム側に供給されて、アタッチメント駆動用アクチュエータ9が伸長する。

The operation device 15 includes, for example, an operation pedal that can be operated by foot movement, and a pilot valve. The pilot valve uses the discharge pressure of the pilot pump 23 as a source pressure, generates a pilot pressure corresponding to the operation amount of one side of the operation pedal, and outputs the pilot pressure to the pressure receiving unit on the left side of the direction control valve 22 in the drawing. Thereby, the direction control valve 22 is switched to the switching position on the left side in the figure. As a result, pressure oil from the hydraulic pump 20 is supplied to the bottom side of the attachment driving actuator 9, and the attachment driving actuator 9 is extended.

また、パイロット弁は、パイロットポンプ23の吐出圧を元圧として、操作ペダルの他方側の操作量に対応したパイロット圧を生成して方向制御弁22の図中右側の受圧部へ出力する。これにより、方向制御弁22が図中右側の切換位置に切換えられる。その結果、油圧ポンプ20からの圧油がアタッチメント駆動用アクチュエータ9のロッド側に供給されて、アタッチメント駆動用アクチュエータ9が縮短する。

The pilot valve generates a pilot pressure corresponding to the operation amount of the other side of the operation pedal by using the discharge pressure of the pilot pump 23 as the original pressure, and outputs the pilot pressure to the pressure receiving portion on the right side of the direction control valve 22 in the drawing. Thereby, the direction control valve 22 is switched to the right switching position in the figure. As a result, the pressure oil from the hydraulic pump 20 is supplied to the rod side of the actuator 9 for driving the attachment, and the actuator 9 for driving the attachment is shortened.

アタッチメント駆動用アクチュエータ9の要求流量は、アタッチメントの種類や仕様に応じて異なる。そのため、コントローラ19は、油圧ポンプ20の容量を設定すると共に、その設定値に対応する指令電流をレギュレータ21に出力する。レギュレータ21は、コントローラ19からの電流に応じて油圧ポンプ20の斜板の傾転角(すなわち、油圧ポンプ20の容量)を変化させるようになっている。

要求 The required flow rate of the attachment driving actuator 9 differs depending on the type and specification of the attachment. Therefore, the controller 19 sets the capacity of the hydraulic pump 20 and outputs a command current corresponding to the set value to the regulator 21. The regulator 21 changes the tilt angle of the swash plate of the hydraulic pump 20 (that is, the capacity of the hydraulic pump 20) according to the current from the controller 19.

アタッチメント駆動用アクチュエータ9の要求圧力は、アタッチメントの種類や仕様に応じて異なる。そのため、コントローラ19は、可変リリーフ弁25A,25Bのリリーフ圧を設定すると共に、その設定値に対応する指令電流を可変リリーフ弁25A,25Bに出力する。可変リリーフ弁25A,25Bは、コントローラ19からの電流の増大に応じてリリーフ圧が下がるように構成されている。

要求 The required pressure of the attachment driving actuator 9 differs depending on the type and specification of the attachment. Therefore, the controller 19 sets the relief pressure of the variable relief valves 25A and 25B, and outputs a command current corresponding to the set value to the variable relief valves 25A and 25B. The variable relief valves 25A and 25B are configured so that the relief pressure decreases in accordance with an increase in the current from the controller 19.

次に、本実施形態における油圧ポンプ20の容量と可変リリーフ弁25A,25Bのリリーフ圧の設定方法について詳述する。

Next, a method of setting the displacement of the hydraulic pump 20 and the relief pressure of the variable relief valves 25A and 25B in the present embodiment will be described in detail.

表示装置18は、ダイヤルスイッチ17の押し操作に応じて、アタッチメント選択画面(図示せず)に切替わる。アタッチメント選択画面は、アタッチメントの種類や仕様に応じて異なる複数のアタッチメントボタンを有している。ダイヤルスイッチ17の回転操作によって複数のアタッチメントボタンのうちのいずれか1つが選択された状態で、ダイヤルスイッチ17の押し操作が行われると、選択したアタッチメントがコントローラ19に入力される。

The display device 18 switches to an attachment selection screen (not shown) in accordance with the pressing operation of the dial switch 17. The attachment selection screen has a plurality of different attachment buttons depending on the type and specification of the attachment. When the dial switch 17 is pressed while any one of the plurality of attachment buttons is selected by the rotation operation of the dial switch 17, the selected attachment is input to the controller 19.

コントローラ19は、各アタッチメントに対応するアタッチメント駆動用アクチュエータの要求流量及び要求圧力を予め記憶しており、入力されたアタッチメントに応じてアタッチメント駆動用アクチュエータの要求流量及び要求圧力を取得し、これに基づいて油圧ポンプ20の容量及び可変リリーフ弁25A,25Bのリリーフ圧を設定し、それらの設定値を記憶する。

The controller 19 stores in advance the required flow rate and required pressure of the attachment driving actuator corresponding to each attachment, acquires the required flow rate and required pressure of the attachment driving actuator according to the input attachment, and based on this, To set the displacement of the hydraulic pump 20 and the relief pressure of the variable relief valves 25A, 25B, and store those set values.

表示装置18は、ダイヤルスイッチ17の押し操作に応じて、リリーフ圧調整画面(図示せず)に切替わる。リリーフ圧調整画面は、上述のようにして取得されたアタッチメント駆動用アクチュエータの要求圧力と、圧力センサ26で検出されたアタッチメント駆動用アクチュエータの作動圧を表示すると共に、リリーフ圧調整用のカーソル及び調整終了項目を有している。

The display device 18 switches to a relief pressure adjustment screen (not shown) in response to the pressing operation of the dial switch 17. The relief pressure adjustment screen displays the required pressure of the attachment driving actuator acquired as described above and the operating pressure of the attachment driving actuator detected by the pressure sensor 26, and displays a relief pressure adjustment cursor and adjustment. Has an ending item.

表示装置18がリリーフ圧調整画面を表示しているときに、コントローラ19は、上述のようにして設定された油圧ポンプ20の容量に対応する指令電流をレギュレータ21に出力する。また、初期段階では、上述のようにして設定された可変リリーフ弁25A,25Bのリリーフ圧に対応する指令電流を可変リリーフ弁25A,25Bに出力する。そして、操作装置15の操作によってアタッチメント駆動用アクチュエータが作動すれば、アタッチメント駆動用アクチュエータの作動圧が圧力センサ26で検出されてリリーフ圧調整画面に表示される。

When the display device 18 is displaying the relief pressure adjustment screen, the controller 19 outputs to the regulator 21 a command current corresponding to the capacity of the hydraulic pump 20 set as described above. In the initial stage, a command current corresponding to the relief pressure of the variable relief valves 25A, 25B set as described above is output to the variable relief valves 25A, 25B. Then, when the attachment driving actuator is operated by operating the operation device 15, the operating pressure of the attachment driving actuator is detected by the pressure sensor 26 and displayed on the relief pressure adjustment screen.

ダイヤルスイッチ17の回転操作によってリリーフ圧調整画面のカーソルが移動すると、その移動量に対応するリリーフ圧の補正値がコントローラ19に入力される。そして、コントローラ19は、リリーフ圧の補正値に対応する指令電流を可変リリーフ弁25A,25Bに出力する。これに伴い、リリーフ圧調整画面で表示されるアタッチメント駆動用アクチュエータの作動圧も変動する。したがって、運転者は、アタッチメント駆動用アクチュエータの要求圧力と作動圧が一致するようにリリーフ圧を調整することが可能である。その後、ダイヤルスイッチ17の回転操作によって調整終了項目が選択された状態で、ダイヤルスイッチ17の押し操作が行われると、コントローラ19は、リリーフ圧の設定値を調整値に更新して記憶する。

When the cursor on the relief pressure adjustment screen is moved by rotating the dial switch 17, a correction value of the relief pressure corresponding to the amount of movement is input to the controller 19. Then, the controller 19 outputs a command current corresponding to the correction value of the relief pressure to the variable relief valves 25A and 25B. Along with this, the operating pressure of the attachment driving actuator displayed on the relief pressure adjustment screen also changes. Therefore, the driver can adjust the relief pressure so that the required pressure of the attachment driving actuator and the operating pressure match. Thereafter, when the dial switch 17 is pressed in a state where the adjustment end item is selected by the rotation operation of the dial switch 17, the controller 19 updates the set value of the relief pressure to the adjusted value and stores it.

ところで、コントローラ19は、キースイッチ16の指示に応じて起動すると、可変リリーフ弁25A,25Bのリリーフ圧の設定値に対応する指令電流となるように、可変リリーフ弁25A,25Bへの出力電流をゼロから上昇させる。このとき、仮に、出力電流を著しく上昇させれば、指令電流を超えるサージ電流が発生する可能性がある。

By the way, when the controller 19 is started according to the instruction of the key switch 16, the controller 19 changes the output current to the variable relief valves 25A and 25B so that the command current corresponds to the set value of the relief pressure of the variable relief valves 25A and 25B. Increase from zero. At this time, if the output current is significantly increased, a surge current exceeding the command current may be generated.

そこで、コントローラ19は、キースイッチ16の指示に応じて起動してから所定時間(例えば1秒)が経過するまで、可変リリーフ弁25A,25Bへの電流をその変化率が所定値(例えば600mA/秒)以下となるように制限する。この制御の詳細を、図3を用いて説明する。

Therefore, the controller 19 changes the current flowing to the variable relief valves 25A and 25B to a predetermined value (for example, 600 mA / sec) until a predetermined time (for example, one second) elapses after the controller 19 is activated according to the instruction of the key switch 16. Seconds). Details of this control will be described with reference to FIG.

図3は、本実施形態における可変リリーフ弁25A,25Bの制御に係わるコントローラ19の機能的構成を表すブロック図である。

FIG. 3 is a block diagram illustrating a functional configuration of the controller 19 related to the control of the variable relief valves 25A and 25B in the present embodiment.

コントローラ19は、可変リリーフ弁25A,25Bの制御に係わる機能的構成として、指令電流演算部27、切換部28、及びフィルタ29を有している。指令電流演算部27は、図示のように、可変リリーフ弁25A,25Bのリリーフ圧の設定値(又は調整値)と指令電流の関係を示す演算テーブルを有し、この演算テーブルを用いて可変リリーフ弁25A,25Bのリリーフ圧の設定値(又は調整値)から指令電流を演算する。

The controller 19 has a command current calculation unit 27, a switching unit 28, and a filter 29 as a functional configuration related to the control of the variable relief valves 25A and 25B. As shown in the figure, the command current calculation unit 27 has a calculation table indicating the relationship between the set values (or adjustment values) of the relief pressures of the variable relief valves 25A and 25B and the command current. The command current is calculated from the set value (or adjustment value) of the relief pressure of the valves 25A, 25B.

切換部28は、コントローラ19が起動してから所定時間が経過したか否かを判定する。そして、コントローラ19が起動しているものの、所定時間が経過していなければ、指令電流演算部27で演算された指令電流を、フィルタ29を介して可変リリーフ弁25A,25Bに出力する。フィルタ29は、可変リリーフ弁25A,25Bへの電流をその変化率が所定値以下となるように、図4で示すようにステップ状に増加させて(例えば、指令電流に達するまで、ΔT=0.25秒毎に、ΔI=150mAずつ増加させて)出力する。

The switching unit 28 determines whether a predetermined time has elapsed since the controller 19 was started. If the controller 19 has been activated but the predetermined time has not elapsed, the command current calculated by the command current calculator 27 is output to the variable relief valves 25A and 25B via the filter 29. The filter 29 increases the current to the variable relief valves 25A and 25B in a stepwise manner as shown in FIG. 4 so that the rate of change is equal to or less than a predetermined value (for example, ΔT = 0 until the command current is reached). .25 seconds, increasing ΔI = 150 mA).

切換部28は、コントローラ19が起動してから所定時間が経過すれば、指令電流演算部27で演算された指令電流をそのまま可変リリーフ弁25A,25Bに出力する。

The switching unit 28 outputs the command current calculated by the command current calculation unit 27 to the variable relief valves 25A and 25B as it is when a predetermined time has elapsed since the start of the controller 19.

以上のように本実施形態において、コントローラ19は、キースイッチ16の指示に応じて起動してから所定時間が経過するまで、可変リリーフ弁25A,25Bへの電流をその変化率が所定値以下となるように制限する。したがって、サージ電流の発生を防ぎ、アタッチメントの誤作動を防止することができる。

As described above, in the present embodiment, the controller 19 changes the current to the variable relief valves 25A and 25B until the predetermined time elapses from the start in response to the instruction of the key switch 16 and the rate of change of the current to the variable relief valves 25A and 25B is equal to or less than the predetermined value. Restrict to be. Therefore, generation of surge current can be prevented, and malfunction of the attachment can be prevented.

なお、上記一実施形態において、コントローラ19は、可変リリーフ弁25A,25Bへの電流をその変化率が所定値以下となるように、ステップ状に増加させて出力する場合を例にとって説明したが、これに限られず、連続的に増加させて出力してもよい。

In the above-described embodiment, the case where the controller 19 outputs the current to the variable relief valves 25A and 25B in a stepwise manner so that the rate of change is equal to or less than a predetermined value has been described as an example. The present invention is not limited to this, and the output may be continuously increased.

また、上記一実施形態において、駆動装置は、アタッチメント駆動用アクチュエータの作動圧をリリーフ圧以下に制限する可変リリーフ弁を2つ備えた場合を例にとって説明したが、これに限られず、可変リリーフ弁を1つだけ備えてもよい。

Further, in the above-described embodiment, the case where the driving device includes two variable relief valves that limit the operating pressure of the attachment driving actuator to a relief pressure or less has been described as an example. However, the present invention is not limited thereto. May be provided alone.

なお、以上においては、本発明の適用対象として油圧ショベルを例にとって説明したが、これに限られず、他の建設機械(詳細には、例えばホイールローダ等)に適用してもよい。

In the above description, the hydraulic shovel has been described as an example to which the present invention is applied. However, the present invention is not limited to this and may be applied to other construction machines (specifically, for example, a wheel loader).

3 作業装置

8 グラップル(アタッチメント)

9 アタッチメント駆動用アクチュエータ

14 エンジン

16 キースイッチ(起動スイッチ)

19 コントローラ

20 油圧ポンプ

25A,25B 可変リリーフ弁 3 Workingdevice 8 Grapple (attachment)

9Attachment drive actuator 14 Engine 16 Key switch (start switch)

19Controller 20 Hydraulic pump 25A, 25B Variable relief valve

8 グラップル(アタッチメント)

9 アタッチメント駆動用アクチュエータ

14 エンジン

16 キースイッチ(起動スイッチ)

19 コントローラ

20 油圧ポンプ

25A,25B 可変リリーフ弁 3 Working

9

19

Claims (2)

- 原動機によって駆動される油圧ポンプと、作業装置の先端側に取付けられたアタッチメントと、前記アタッチメントに組込まれ、前記油圧ポンプからの圧油によって作動するアタッチメント駆動用アクチュエータと、前記アタッチメント駆動用アクチュエータの作動圧をリリーフ圧以下に制限する可変リリーフ弁と、前記可変リリーフ弁のリリーフ圧を設定すると共に、その設定値に対応する指令電流を前記可変リリーフ弁に出力するコントローラと、前記コントローラの起動を指示する起動スイッチとを備えた建設機械において、

前記コントローラは、前記起動スイッチの指示に応じて起動してから所定時間が経過するまで、前記可変リリーフ弁への電流をその変化率が所定値以下となるように制限することを特徴とする建設機械。 A hydraulic pump driven by a prime mover, an attachment attached to a distal end side of a working device, an attachment driving actuator incorporated in the attachment and operated by pressurized oil from the hydraulic pump, and an operation of the attachment driving actuator A variable relief valve that limits the pressure to a relief pressure or less, a controller that sets a relief pressure of the variable relief valve, and outputs a command current corresponding to the set value to the variable relief valve, and instructs activation of the controller. In a construction machine having a start switch and

The controller limits the current to the variable relief valve so that its rate of change is equal to or less than a predetermined value until a predetermined time elapses after the controller is started according to the instruction of the start switch. machine. - 請求項1に記載の建設機械において、

前記コントローラは、前記起動スイッチの指示に応じて起動してから所定時間が経過するまで、前記可変リリーフ弁への電流をその変化率が所定値以下となるようにステップ状に増加させて出力することを特徴とする建設機械。 The construction machine according to claim 1,

The controller increases and outputs the current to the variable relief valve in a stepwise manner so that the rate of change is equal to or less than a predetermined value until a predetermined time elapses after the controller is started according to the instruction of the start switch. A construction machine characterized by the above.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018-147841 | 2018-08-06 | ||

| JP2018147841A JP2020023793A (en) | 2018-08-06 | 2018-08-06 | Construction machine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2020031789A1 true WO2020031789A1 (en) | 2020-02-13 |

Family

ID=69414128

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2019/029842 WO2020031789A1 (en) | 2018-08-06 | 2019-07-30 | Construction machine |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP2020023793A (en) |

| WO (1) | WO2020031789A1 (en) |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH03122322A (en) * | 1989-10-04 | 1991-05-24 | Hitachi Constr Mach Co Ltd | Hydraulic driving device for civil engineering and construction machine |

| JPH0449336A (en) * | 1990-06-18 | 1992-02-18 | Kobe Steel Ltd | Pressure controller for working machine |

| JPH07127604A (en) * | 1993-11-05 | 1995-05-16 | Uchida Yuatsu Kiki Kogyo Kk | Slewing control device |

| JP2010242375A (en) * | 2009-04-06 | 2010-10-28 | Hitachi Constr Mach Co Ltd | Hydraulic circuit device for hydraulic shovel |

| JP2012141705A (en) * | 2010-12-28 | 2012-07-26 | Caterpillar Sarl | Fluid pressure circuit controlling device and operating machine |

| JP2013053740A (en) * | 2011-09-06 | 2013-03-21 | Sumitomo (Shi) Construction Machinery Co Ltd | Construction machine |

-

2018

- 2018-08-06 JP JP2018147841A patent/JP2020023793A/en active Pending

-

2019

- 2019-07-30 WO PCT/JP2019/029842 patent/WO2020031789A1/en active Application Filing

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH03122322A (en) * | 1989-10-04 | 1991-05-24 | Hitachi Constr Mach Co Ltd | Hydraulic driving device for civil engineering and construction machine |

| JPH0449336A (en) * | 1990-06-18 | 1992-02-18 | Kobe Steel Ltd | Pressure controller for working machine |

| JPH07127604A (en) * | 1993-11-05 | 1995-05-16 | Uchida Yuatsu Kiki Kogyo Kk | Slewing control device |

| JP2010242375A (en) * | 2009-04-06 | 2010-10-28 | Hitachi Constr Mach Co Ltd | Hydraulic circuit device for hydraulic shovel |

| JP2012141705A (en) * | 2010-12-28 | 2012-07-26 | Caterpillar Sarl | Fluid pressure circuit controlling device and operating machine |

| JP2013053740A (en) * | 2011-09-06 | 2013-03-21 | Sumitomo (Shi) Construction Machinery Co Ltd | Construction machine |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2020023793A (en) | 2020-02-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5192367B2 (en) | Work vehicle and control method of work vehicle | |

| JP6474908B2 (en) | Hydraulic system of work machine | |

| JP6676827B2 (en) | Work machine | |

| JP6955524B2 (en) | Battery-powered work machine | |

| US11746497B2 (en) | Shovel | |

| JP6013389B2 (en) | Hydraulic system of work machine | |

| JP6860519B2 (en) | Construction machinery | |

| JP2020169707A (en) | Operation control device for work vehicle | |

| JP5562285B2 (en) | Work machine display | |

| JP2011085159A (en) | Hydraulic driving device of working machine | |

| JP6695620B2 (en) | Construction machinery | |

| WO2017061220A1 (en) | Construction machinery | |

| JP6691482B2 (en) | Work vehicle and operation control method | |

| WO2020031789A1 (en) | Construction machine | |

| WO2003001067A1 (en) | Hydraulic driving unit for working machine, and method of hydraulic drive | |

| JP2019011690A (en) | Work machine | |

| JP6788733B2 (en) | Work machine | |

| JP2020169708A (en) | Operation control device for work vehicle | |

| JP7001572B2 (en) | Construction machinery | |

| JPH11303759A (en) | Hydraulic pump regulator | |

| EP3492664B1 (en) | Construction machine | |

| JP2008256048A (en) | Revolving work vehicle provided with elevatable operator cab | |

| JP6660907B2 (en) | Construction machinery | |

| EP4124694B1 (en) | Working control device in working vehicle | |

| KR102698835B1 (en) | work machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 19848629 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 19848629 Country of ref document: EP Kind code of ref document: A1 |