WO2016159169A1 - めっき鋼板のスポット溶接方法 - Google Patents

めっき鋼板のスポット溶接方法 Download PDFInfo

- Publication number

- WO2016159169A1 WO2016159169A1 PCT/JP2016/060541 JP2016060541W WO2016159169A1 WO 2016159169 A1 WO2016159169 A1 WO 2016159169A1 JP 2016060541 W JP2016060541 W JP 2016060541W WO 2016159169 A1 WO2016159169 A1 WO 2016159169A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- welding

- plating

- spot welding

- electrode

- spot

- Prior art date

Links

- 238000003466 welding Methods 0.000 title claims abstract description 287

- 229910000831 Steel Inorganic materials 0.000 title claims abstract description 252

- 239000010959 steel Substances 0.000 title claims abstract description 252

- 238000000034 method Methods 0.000 title claims abstract description 59

- 238000007747 plating Methods 0.000 claims abstract description 145

- 238000005336 cracking Methods 0.000 claims abstract description 24

- 238000012360 testing method Methods 0.000 claims description 65

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 claims description 31

- 229910052725 zinc Inorganic materials 0.000 claims description 31

- 239000011701 zinc Substances 0.000 claims description 31

- 230000008569 process Effects 0.000 claims description 10

- 238000001704 evaporation Methods 0.000 claims description 9

- 230000008020 evaporation Effects 0.000 claims description 8

- 239000000853 adhesive Substances 0.000 claims description 7

- 230000001070 adhesive effect Effects 0.000 claims description 7

- 229910001338 liquidmetal Inorganic materials 0.000 abstract description 10

- 229910052751 metal Inorganic materials 0.000 description 34

- 239000002184 metal Substances 0.000 description 34

- 230000015572 biosynthetic process Effects 0.000 description 19

- 238000005260 corrosion Methods 0.000 description 13

- 230000007797 corrosion Effects 0.000 description 13

- 238000005246 galvanizing Methods 0.000 description 11

- 238000004519 manufacturing process Methods 0.000 description 10

- 229910001335 Galvanized steel Inorganic materials 0.000 description 9

- 239000008397 galvanized steel Substances 0.000 description 9

- 238000003825 pressing Methods 0.000 description 8

- 230000000630 rising effect Effects 0.000 description 8

- 230000000052 comparative effect Effects 0.000 description 6

- 101100284397 Oryza sativa subsp. japonica HAZ1 gene Proteins 0.000 description 5

- 239000013078 crystal Substances 0.000 description 5

- 230000008859 change Effects 0.000 description 4

- 238000012790 confirmation Methods 0.000 description 4

- 229910045601 alloy Inorganic materials 0.000 description 3

- 239000000956 alloy Substances 0.000 description 3

- 238000006664 bond formation reaction Methods 0.000 description 3

- 238000005520 cutting process Methods 0.000 description 3

- 230000007423 decrease Effects 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 230000001678 irradiating effect Effects 0.000 description 3

- 239000000203 mixture Substances 0.000 description 3

- 229910001209 Low-carbon steel Inorganic materials 0.000 description 2

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 2

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical compound [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 description 2

- 230000000712 assembly Effects 0.000 description 2

- 238000000429 assembly Methods 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 239000010949 copper Substances 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 2

- 238000009713 electroplating Methods 0.000 description 2

- 239000011521 glass Substances 0.000 description 2

- 238000000227 grinding Methods 0.000 description 2

- JEIPFZHSYJVQDO-UHFFFAOYSA-N iron(III) oxide Inorganic materials O=[Fe]O[Fe]=O JEIPFZHSYJVQDO-UHFFFAOYSA-N 0.000 description 2

- 229910052749 magnesium Inorganic materials 0.000 description 2

- 239000011777 magnesium Substances 0.000 description 2

- 230000013011 mating Effects 0.000 description 2

- 230000007246 mechanism Effects 0.000 description 2

- 239000000155 melt Substances 0.000 description 2

- 230000035515 penetration Effects 0.000 description 2

- 241001163841 Albugo ipomoeae-panduratae Species 0.000 description 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 229910000881 Cu alloy Inorganic materials 0.000 description 1

- 229910000794 TRIP steel Inorganic materials 0.000 description 1

- 238000002679 ablation Methods 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 238000005275 alloying Methods 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910001566 austenite Inorganic materials 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 238000009835 boiling Methods 0.000 description 1

- 239000010960 cold rolled steel Substances 0.000 description 1

- 230000008602 contraction Effects 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 230000003628 erosive effect Effects 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 230000000977 initiatory effect Effects 0.000 description 1

- 238000007689 inspection Methods 0.000 description 1

- 238000000608 laser ablation Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- 239000011780 sodium chloride Substances 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000009864 tensile test Methods 0.000 description 1

- 238000010998 test method Methods 0.000 description 1

- 238000009834 vaporization Methods 0.000 description 1

- 230000008016 vaporization Effects 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

- 239000013585 weight reducing agent Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K11/00—Resistance welding; Severing by resistance heating

- B23K11/34—Preliminary treatment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K11/00—Resistance welding; Severing by resistance heating

- B23K11/10—Spot welding; Stitch welding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K11/00—Resistance welding; Severing by resistance heating

- B23K11/10—Spot welding; Stitch welding

- B23K11/11—Spot welding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K11/00—Resistance welding; Severing by resistance heating

- B23K11/10—Spot welding; Stitch welding

- B23K11/11—Spot welding

- B23K11/115—Spot welding by means of two electrodes placed opposite one another on both sides of the welded parts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K11/00—Resistance welding; Severing by resistance heating

- B23K11/16—Resistance welding; Severing by resistance heating taking account of the properties of the material to be welded

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K11/00—Resistance welding; Severing by resistance heating

- B23K11/16—Resistance welding; Severing by resistance heating taking account of the properties of the material to be welded

- B23K11/163—Welding of coated materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K11/00—Resistance welding; Severing by resistance heating

- B23K11/16—Resistance welding; Severing by resistance heating taking account of the properties of the material to be welded

- B23K11/163—Welding of coated materials

- B23K11/166—Welding of coated materials of galvanized or tinned materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/36—Removing material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2101/00—Articles made by soldering, welding or cutting

- B23K2101/006—Vehicles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2101/00—Articles made by soldering, welding or cutting

- B23K2101/34—Coated articles, e.g. plated or painted; Surface treated articles

Definitions

- the present invention relates to a spot welding method for a plurality of steel plates including a plated steel plate, and particularly to a spot welding method suitable for a plurality of steel plates including a zinc-based plated high strength steel plate for automobiles.

- galvanized steel sheets have good corrosion resistance.

- zinc-based plated high-strength steel sheets using high-strength steel sheets as plating base plates are used in galvanized steel sheets used for automobiles.

- Spot welding is mainly used in the assembly of automobile bodies and parts.

- cracks may occur in the thickness direction from the outer surface of the steel plate in contact with the electrode for spot welding.

- FIG. 1 shows an outline of a crack at a spot welded spot when spot welding is performed on a zinc-based plated high-strength steel sheet.

- FIG. 1 is a cross section in the thickness direction.

- a crack 3 hereinafter referred to as “electrode-underside crack” that progresses from the surface of the steel plate 1 in contact with the electrode toward the melt-solidified portion 2 (nugget), or the steel plate 1

- a crack 5 hereinafter referred to as “shoulder crack” that propagates from the portion that contacts the shoulder of the electrode to the heat-affected zone 4

- a crack 6 that propagates from the outside of the location where the electrode and the steel plate 1 contact to the heat-affected zone 4

- Patent Document 1 adjusts the component composition of the steel sheet, makes the austenite phase generated during spot welding fine crystal grains, and has a metal structure that is complicated with the crystal grains of other phases. Therefore, it is disclosed that the diffusion and penetration path of molten zinc into the crystal grain boundary is complicated to make it difficult for molten zinc to penetrate and to prevent liquid metal embrittlement cracking during welding.

- Patent Document 2 teaches that the occurrence of cracks in the welded portion may not be sufficiently suppressed only by making the grain boundaries complicated by controlling the structure of the steel sheet.

- the grain boundary oxidation depth of the hot-rolled steel sheet is 5 ⁇ m or less, and the Fe-based electroplating treatment is performed on the cold-rolled steel sheet before the alloying hot-dip galvanizing treatment, thereby reducing the grain boundary erosion depth of the alloyed hot-dip galvanized steel sheet. It discloses that the occurrence of cracks in the welded portion of the alloyed hot-dip galvanized steel sheet is suppressed by setting it to 5 ⁇ m or less.

- FIG. 2 and FIG. 3 are outlines of cracks at a spot welded portion, and show a cross section in the plate thickness direction including a nugget.

- an object of the present invention is to provide a spot welding method that can easily prevent liquid metal embrittlement cracking in spot welding of a plated steel sheet.

- the inventors of the present invention investigated the relationship between the occurrence factors of liquid metal embrittlement cracks at the welded portions and found that they are likely to occur in the following cases (a) to (g).

- the inventors of the present invention have a location where the tensile stress is high at the crack generation position in the welding process, and the molten plated metal enters the crystal grain boundary of the steel plate at the location, thereby generating a crack. I thought that I was letting.

- the present inventors examined a means for preventing liquid metal embrittlement cracking.

- it is possible to prevent external cracking by removing the plating coated on the region inside the weld heat affected zone at least on the surface in contact with the electrode, and at least With plating coated on both sides of the overlapping surface of the steel plates, the outer periphery is the outer edge of the heat affected zone, and the inner periphery is covered with a ring-shaped region consisting of 0.8 times the nugget diameter

- the invention was completed with the idea of removing the plating to prevent internal cracks in the overlapping surface of the steel sheets.

- the present invention has been made on the basis of the above findings, and the gist thereof is as follows.

- a method of spot welding by sandwiching a plurality of superposed steel plates including one or more steel plates coated with plating on at least one surface of a welding spot, with opposing welding electrodes, Including the step of removing the plating prior to spot welding; In the step of removing the plating, the range in which the plating is removed is at least within a circle that is an outer edge of the welded heat affected zone formed on the welding electrode side of the plurality of steel plates with the outer circumferences superimposed. Spot welding method.

- Test spot welding was performed before removing the plating, and the presence or absence of cracks in the welded part was confirmed. When cracks on the welded electrode side of a plurality of stacked steel sheets were confirmed, cracks were confirmed.

- a method of spot welding by sandwiching a plurality of superposed steel plates including one or more steel plates coated with plating on at least one surface of the welded portion, with opposing welding electrodes, Including the step of removing the plating prior to spot welding; In the process of removing plating, the range where plating is removed, A spot welding method characterized in that the outer periphery of the welding heat-affected zone formed on the overlapping surface of a plurality of steel plates whose outer circumferences are overlapped is within a circle that is wider.

- a method of spot welding by sandwiching a plurality of superposed steel plates including one or more steel plates coated with plating on at least one surface of the welding spot, with opposing welding electrodes, Including the step of removing the plating prior to spot welding;

- the range where plating is removed It is the wider outer edge of the weld heat affected zone formed on the overlapping surface of multiple steel plates whose outer circumferences are overlapped,

- the inner circumference shares the center and the center of the nugget formed on the overlapped surface of the steel sheet, and is in an annulus that is a circle having a diameter that is 0.8 times the nugget diameter.

- Test spot welding is performed before removing the plating, and the presence or absence of cracks in the welded part is confirmed.

- the spot welding method according to the above (4), (5) or (6), wherein the plating on the overlapped surface of the steel plate overlapped with the generated surface is removed.

- the spot welding is performed by (a) welding with an angle at which the axis of the welding electrode is 3 ° or more perpendicular to the surface of the steel plate, (b) the axis of the welding electrode is the surface of the steel plate.

- welding is performed using an angled electrode that is at least 5 ° from the vertical, (c) a welding gun in which the axis of the electrode bends to 3 ° or more from the vertical to the surface of the steel plate during welding

- (d) welding is performed in a state where the relative misalignment of the axis of the opposing welding electrode is 0.5 mm or more, (e) the gap between the overlapping surfaces is 0.5 mm or more.

- the occurrence of liquid metal cracks can be easily prevented in spot welding.

- the spot welding method of the present invention (hereinafter referred to as “welding method of the present invention”) is performed before a spot welded to a plurality of steel plates including one or more steel plates coated with plating on one surface of the welded portion. This is a method of removing plating before spot welding when cracks are predicted to occur.

- the occurrence of cracks can be confirmed by performing test spot welding on a plurality of steel plates including one or more coated steel plates that are actually spot welded.

- test spot welding may be performed with the same plate set before actually performing spot welding and starting production. preferable.

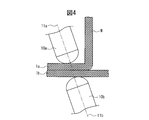

- FIG. 4 is welded with an angle at which the axis is 3 ° or more with respect to the surface of the steel plate. It is sectional drawing of the plate

- the member to be welded shown in FIG. 4 includes a steel plate 1a and a steel plate 1b.

- the steel plate 1a is a steel plate having a cross-sectional hat shape having a rising portion W.

- the electrodes 10a and 10b may be welded at an angle.

- the electrodes 10a and 10b have shaft axes 11a and 11b that are not perpendicular to the surfaces of the steel plates 1a and 1b.

- the spot welding electrode 10a is inclined in a direction away from the rising portion W.

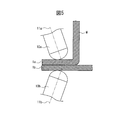

- FIG. 5 shows a state where welding is performed using the angled electrode. It is sectional drawing of the plate

- the member to be welded shown in FIG. 5 includes a steel plate 1a and a steel plate 1b.

- the steel plate 1a is a steel plate having a cross-sectional hat shape having a rising portion W.

- angled electrodes 10a and 10b are used.

- the angled electrodes 10a and 10b have axes 11a and 11b that are not perpendicular to the surfaces of the steel plates 1a and 1b.

- the spot welding electrode is inclined in a direction away from the rising portion W.

- FIG. 6 shows a welding gun that is easy to bend (the electrode is attached to the tip of the welding gun) It is sectional drawing of the plate

- the shaft cores 11a and 11b are not perpendicular to the surfaces of the steel plates 1a and 1b, and the tip surfaces are parallel to the surfaces of the steel plates 1a and 1b.

- a welding gun (not shown) bends due to pressurization by welding, the distal ends of the welding electrodes 10a and 10b are displaced away from a holder (not shown) that holds the welding electrodes.

- FIG. 7 shows welding with a relative misalignment of the axial core of the opposing welding electrode. It is sectional drawing of the plate

- the welding electrodes 10 a and 10 b may cause a relative displacement 12 (hereinafter referred to as “electrode displacement”) relative to the respective shaft cores 11 a and 11 b due to poor attachment of the electrode tips.

- electrode displacement a relative displacement 12 relative to the respective shaft cores 11 a and 11 b due to poor attachment of the electrode tips.

- FIG. 8 is a cross-sectional view in the plate thickness direction showing a state where the welded portion having a gap on the overlapping surface is welded.

- a gap 14 (hereinafter referred to as “plate gap”) is provided between the steel plates 1 a and 1 b on the overlapping surface of the welded portions. ) May occur.

- FIG. 9 shows that the position in the pressing direction of the welding electrode with respect to a plurality of steel plates remains inappropriate. It is a cross section of the plate

- spot welding in order to properly position the welding electrodes in the pressurizing direction with respect to a plurality of steel plates, the welding electrode on the fixed side is brought into contact with the steel plates and the robot is instructed to perform welding, or pressurization is performed.

- An equalizing mechanism is provided between a robot and a spot welding gun so as to freely move in a direction and welding is performed.

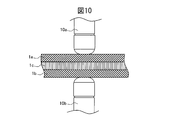

- FIG. 10 shows a state in which a mild steel plate is provided in the middle and a high-strength steel plate is provided at the top and bottom and welded. It is a cross section.

- spot welding three-layer welding is often performed.

- the middle mild steel plate having low strength is pushed out from directly under the electrode and is thickened around.

- tensile stress parallel to the steel sheet surface is generated on the surface of the high-strength steel sheet so as to push the upper and lower high-strength steel sheets up and down.

- a plurality of steel plates including at least one steel plate coated with at least a welded portion is prepared.

- two or more steel plates having a tensile strength of 780 MPa or more, a C content of 0.15 mass% or more, and a plate thickness of 0.5 to 3.0 mm, which are coated on both sides with zinc-based plating, are prepared.

- two or more steel plates are overlapped on both sides under conditions that include one or more of the crack generation factors (a) to (g) that occur in actual production.

- nugget and corona bond cut in the plate thickness direction through the center of the recess by spot welding, polish, and etch with chemicals such as nital.

- the plurality of spot-welded steel plates are not particularly limited as long as they are a plurality of steel plates including one or more steel plates that are coated with plating on at least one surface of the welded portion.

- a combination of steel plates coated with plating on the surface on the side where the steel plate and the electrode are in contact a combination of steel plates coated with plating on the surface on the side where the steel plate and the electrode are in contact with a steel plate not coated with plating

- Examples thereof include a combination of steel plates in which plating is coated on the surface on the side where the steel plate and the electrode are in contact with each other and the overlapping surface of the steel plates.

- the surface on the side where the steel plate and the electrode are in contact with each other and the overlapping surface of the steel plate are coated with plating.

- the welding method of the present invention is suitable for spot welding of steel sheets including zinc-based plated steel sheets and the like plated with an alloy containing zinc.

- an alloy containing zinc an alloy containing zinc.

- the plating coated on the steel plate to be welded is zinc-based

- the plating contains zinc.

- alloyed hot dip galvanizing, hot dip galvanizing, electrogalvanizing, and zinc / nickel electroplating are exemplified as plating types.

- zinc / aluminum / magnesium plating can be included.

- each steel plate to be spot welded is not particularly limited, and can be, for example, 0.5 to 3.0 mm.

- the total thickness of the plurality of steel plates is not particularly limited, and can be, for example, 1.0 to 7.0 mm.

- the component steel composition and the metal structure of the plurality of spot-welded steel plates are not particularly limited.

- the steel plate coated with zinc plating on the surface where the steel plate and electrode are in contact or the overlapping surface of the steel plate or the steel plate coated with zinc plating and the steel plate overlapped via the zinc plating

- the steel plate coated with zinc plating and the steel plate overlapped via the zinc plating

- cracking of the welded portion is likely to occur. This is effective for such a steel plate.

- the steel plate may have at least part of a plate-like portion, and the plate-like portion may have a portion where the plate-like portions are stacked on each other, and the whole may not be a plate.

- the plurality of steel plates are not limited to those composed of separate steel plates, and may be a superposition of a single steel plate formed into a predetermined shape such as a tubular shape.

- test spot welding is preferably performed when at least one of the above (a) to (g) generated in actual production is satisfied.

- Test spot welding is performed under the conditions including the target plate assembly and the crack generation factors (a) to (g) that occur in actual production, under the welding conditions used in actual production.

- the electrode may be a dome radius type tip having a diameter of 6 to 8 mm, a pressing force of 2.5 to 8.0 kN, an energization time of 5 to 99 cycles, and an energization current of 4 to 15 kA.

- the energization current value it is desirable to adopt the current value before and after setting in actual production. This is because a crack at a welded portion may be missed in a test with a pinpoint current value.

- ⁇ Confirmation of cracks at the weld location> In a spot welded joint obtained by test spot welding, the presence or absence of cracks in the welded part is confirmed.

- the method for confirming the occurrence of cracks is not particularly limited, and visual observation, penetration inspection, observation of the cross section in the plate thickness direction including the melt-solidified part, and tensile testing of spot welded joints The determination can be made based on whether or not a predetermined tensile strength can be obtained. Alternatively, in addition to observation of the cross section in the plate thickness direction including the spot welded portion, an X-ray transmission test may be performed for confirmation.

- the crack just below the electrode at the contact point between the steel plate and the electrode occurs immediately below the electrode (near the center) at the contact point between the steel plate and the electrode, and the shoulder crack and the electrode outer crack occur near the outer periphery of the weld.

- the welding method of the present invention is characterized in that the plating of the steel plate to be welded is removed before spot welding.

- the removal range of the plating is preferably set to the following range depending on the position of the crack confirmed by the test spot welding.

- the range of plating to be removed is at least a steel plate in which the external cracks of a plurality of stacked steel plates have been confirmed, and the plating is coated on the welding electrode side, and the outer circumference is The range is within the circle that is the outer edge of the weld heat affected zone on the welding electrode side.

- Outer cracks include cracks directly under the electrodes, shoulder cracks, and electrode outer cracks. For example, if no plating was removed at the part where the electrode shaft core contacts because cracks directly under the electrode were not observed, repeated spot welding would result in molten plated metal or an alloy of plated metal and electrode copper Adheres to the surface of the removed steel plate through the electrode due to the occurrence of cracks, and cracks occur again. For this reason, even when only one of the cracks has occurred, it is necessary to remove the plating in all the regions in the circle whose outer periphery is the outer edge of the weld heat affected zone on the welding electrode side.

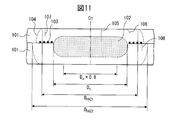

- FIG. 11 is a cross-sectional view in the plate thickness direction for explaining a range of plating to be removed when a crack on the contact surface side with the electrode of the steel plate and the overlap surface of the steel plate is confirmed in the two-layer plate set.

- the heat-affected zone outer edge formation scheduled position 104 is also indicated by a dotted line.

- the plating removal range for preventing external cracking is within a circle of diameter D HAZ1 with the outer periphery being the outer edge of the heat affected zone.

- the heat affected zone outer edge formation planned position of the steel plate is a position where the steel plate is heated to about 700 ° C. For this reason, the plated metal within this range melts during the welding process and has sufficient fluidity. For this reason, in order to prevent an external crack, even if it removes the plating of only the site

- a range for removing the plating for example, within a circle having a diameter of D HAZ1 ⁇ 1.5, it may be wider than the circle of diameter D HAZ1. However, it should be as narrow as possible because it reduces corrosion resistance.

- the outer edge position of the heat-affected zone has a different distance from the nugget center Cn in the thickness direction. This is because the side in contact with the steel plate electrode is cooled by the electrode, whereas the superposed surface does not have such a cooling action.

- the diameter D HAZ1 in the range in which plating is removed to prevent external cracking may be determined at the outer edge of the heat-affected zone near the electrode-side surface of the steel plate.

- the range of plating to be removed is the overlapping surface of the steel plates to be welded, and the outer periphery is the overlapping surface

- the diameter of the outer edge of the weld heat-affected zone is the range within the circle whose diameter is D HAZ2 .

- the range of the plating removal is the wider outer edge of the weld-affected zone formed on the overlapping surface of the plurality of steel plates with the outer periphery overlapped, and the center of the nugget formed on the overlapping surface of the steel plate with the inner periphery It is good also as a range in a ring which is a circle having a diameter that is 0.8 times the diameter of the nugget and sharing the center with the planned position. This is because plating in a circle having a diameter that is 0.8 times the nugget diameter does not substantially contribute to internal cracking.

- FIG. 11 is a cross-sectional view in the plate thickness direction for explaining the range of plating to be removed when a crack on the overlapping surface of the steel plates is confirmed in a two-layer plate set.

- the nugget formation scheduled portion 102, the corona bond formation planned portion 103, and the portion 108 where cracking is expected just outside the corona bond is indicated by dotted lines on the steel plates 101 to be welded.

- a portion 109 where the occurrence of a crack at the time of corona bond nugget is predicted, and a portion 110 where the occurrence of a crack within the nugget is predicted are indicated by dotted lines.

- the cracks directly outside the corona bond are melted at the location where the corona bond is to be formed, and the plated metal discharged by the electrode press and the molten plated metal inside the heat-affected zone outside the corona bond are directly outside the corona bond. Generated by applying tensile stress in the wet state.

- the internal crack is caused by the plated metal melted in the heat-affected zone and the molten plated metal that is melted at the overlapping surface of the steel plates and discharged in the direction away from the center of the nugget (outward direction) in the welding process. .

- the molten plated metal includes a liquefied plated metal after evaporation and vaporization.

- the range of plating to be removed is D HAZ2 , which is the overlapped surface of the steel plates to be welded, and the outer circumference is the larger equivalent circle diameter of the outer edge of the weld heat affected zone of the overlapped surface. And a range within a circle centering on the center Cn of the nugget formation scheduled portion 102.

- the equivalent circle diameter of the outer edge of the weld heat affected zone is the diameter of a circle having the same area as the larger area at the outer edge of the heat affected zone on the overlapping surface of two superposed steel plates.

- ⁇ ⁇ ⁇ Plating must be removed for both of the plated steel plates. This is because, when the plated steel plates are superposed, even if only the plating of the cracked steel plate is removed, the molten plated metal is supplied from the mated steel plate. In this way, by removing plating in this range of plating, even if several cracking factors overlap and a strong tensile stress is generated on the overlapping surface of the steel plates, there is no molten plated metal. No cracking occurs.

- the range in which the plating is removed is a circle whose outer periphery is centered on the center Cn of the nugget formation planned portion 102 and has a diameter D HAZ2 or D HAZ3 , and the inner periphery is formed on the overlapping surface of the steel plates. It may be a range within an annulus that is a circle having a diameter 0.8 times the diameter of the nugget Dn formed on the overlapping surface with the center Cn of the nugget formation planned portion 102 as the center. This is because plating in a circle that is 0.8 times the diameter of the nugget does not substantially contribute to internal cracking.

- the removal range of the plating becomes wide, corrosion may occur from the removed place, and it is not preferable to remove the plating indiscriminately, but in order to prevent weld cracking, the plating exceeds the range specified in the present invention. It does not prevent removal.

- the plating to be removed can be all of the portion equal to or less than 2.0 times the equivalent circle diameter D HAZ2 or D HAZ3 , more preferably all of the portion equal to or less than 1.5 times.

- the equivalent circle diameters D HAZ2 and D HAZ3 of the heat affected zone outer edge formation planned location and the circle equivalent diameter Dn of the nugget formation planned location are determined by a coupon (test piece) prior to spot welding of a plurality of steel plates. This is the equivalent circle diameter observed when Even in actual spot welding, the welding length is not necessarily the same, but this error can be sufficiently covered within the plating removal range of the welding method of the present invention.

- the sealer and the adhesive are not particularly limited, and known ones used in the assembly of the vehicle body can be used. It is also effective to ensure corrosion resistance by mixing metal fine particles made of zinc or the like into a sealer or an adhesive.

- ⁇ Plating removal method As a plating removal method, at least one of mechanical removal and evaporation removal can be employed. As mechanical removal, it can grind with a rotating tool. At this time, if grinding is performed with a tool having a protrusion at a circle-equivalent center such as a planned contact point, the center of rotation is determined, and plating can be removed with high accuracy. By making the protrusion sufficiently small, the hole in which the protrusion is formed can be filled by welding.

- Evaporation removal is a method of evaporating and removing by irradiating the plating with a laser having a condensing shape such as a circle, a ring, or a rectangle exceeding the range that must be removed. According to this, it is possible to selectively remove low boiling point metals that cause embrittlement of liquid metals such as zinc and magnesium.

- ⁇ It is important that the laser irradiation is angled so that the reflected light does not return to the oscillator. From the viewpoint of environmental conservation, it is preferable to provide a device for sucking the evaporated metal. Further, ablation can be removed by a laser focused to several tens of ⁇ m. Further, the plating can be removed by evaporation by irradiating with plasma.

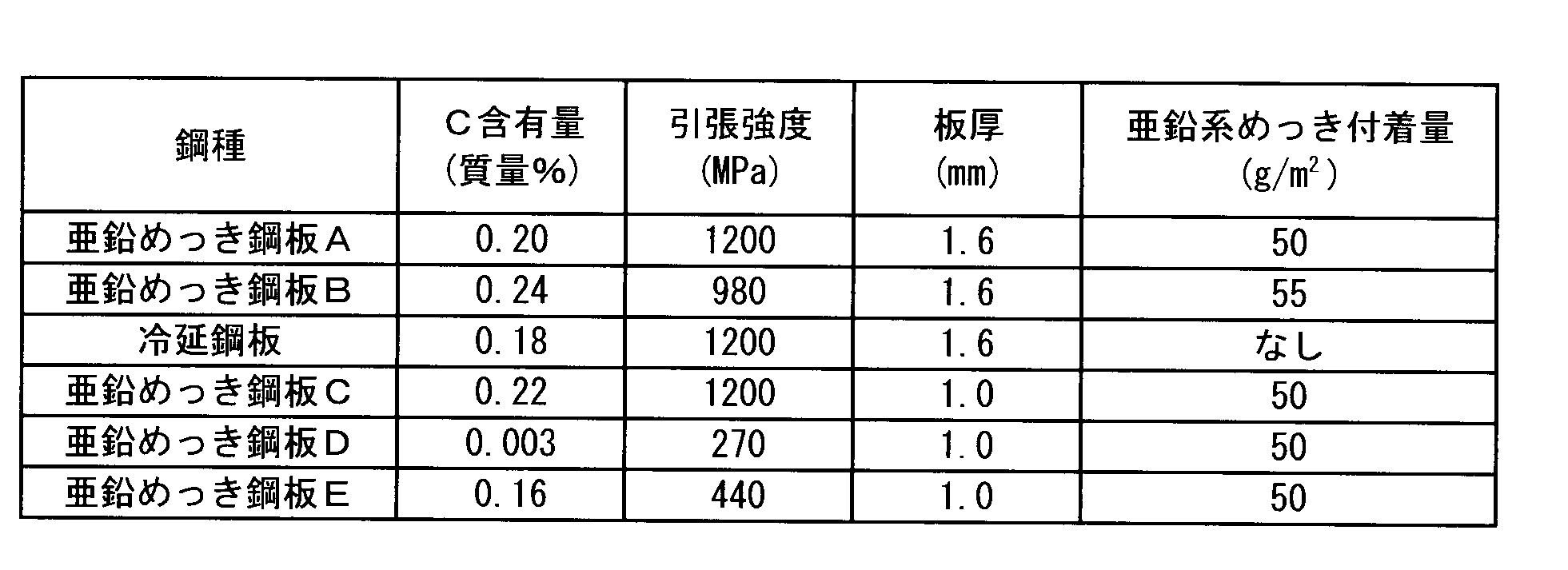

- Table 1 shows the steel plates used.

- the galvanized steel sheets A to E are alloyed hot dip galvanized steel sheets, and both surfaces thereof are coated with galvanizing.

- Test No. 1 is a comparative example in which spot welding was performed without removing the zinc plating in a state where the axis of the welding electrode was 3 ° from the vertical to the surface of the steel plate. Spot welding was performed from both sides with a dome radius type electrode having a tip diameter of 6 mm, sandwiching two steel plates, and pressing with a pressure of 4 kN, with an energization time of 18 cycles and an energization current of 9 kA. As a result, internal cracks directly outside the corona bond were confirmed.

- Test numbers 2 to 6 are examples in which the result of test number 1 was received and galvanization was removed and spot welding was performed.

- Test No. 7 uses an angled electrode whose axis is 5 ° from the vertical to the surface of the steel plate during welding, and without removing the galvanized plate with a gap of 0.5 mm on the overlapping surface It is the comparative example which carried out spot welding. In test number 7, an internal crack just outside the corona bond was confirmed.

- Test No. 8 is an example in which the result of Test No. 7 was received and galvanization was removed and spot welding was performed.

- Test No. 9 is a comparative example in which spot welding was performed without removing the galvanizing with a combination of steel plates having a large strength ratio. In the test number 9, an internal crack was confirmed during the nugget in the corona bond.

- Test numbers 10 to 12 are examples in which the result of test number 9 was received and galvanization was removed and spot welding was performed.

- Test No. 13 is a state in which the axial center of the opposing welding electrode is relatively shifted by 0.5 mm, and the position of the welding electrode pressing direction on the fixed side with respect to the steel plate is 0.2 mm. This is a comparative example in which spot welding is performed without removing the plating. In test number 13, internal cracks that developed from the corona bond into the nugget were confirmed.

- Test numbers 14 to 17 are examples in which the result of test number 9 was received and galvanization was removed and spot welding was performed.

- Test No. 18 is a comparative example in which spot welding was performed without removing the galvanization using a welding gun that bends so that the axis is 3 ° perpendicular to the surface of the steel sheet during welding. In test number 18, external cracks were confirmed directly under the electrode and at the shoulder.

- Test Nos. 19 to 20 are examples in which spot welding was performed after removing the galvanization based on the result of Test No. 18.

- Test No. 21 uses a welding gun that bends so that the axis is 3 ° from the vertical to the surface of the steel sheet during welding, and further has a welded spot having a gap of 0.5 mm or more on the overlapping surface, It is a comparative example in which spot welding was performed without removing the zinc plating. In test number 21, external cracks were confirmed on the outside of the electrode.

- the galvanization was heated by laser and plasma.

- the removal of galvanization using evaporation by laser was performed by irradiating the galvanizing with a laser focused to a diameter of 9.5 mm for 0.1 second at an output of 1 kW to remove the galvanizing in the removal range.

- Removal of galvanizing using laser ablation is performed by galvanizing 10 shots at the same point with a laser focused to a diameter of 40 ⁇ m at an average output of 9 W, a repetition rate of 50 kHz, and a pulse width (laser emission time) of 20 ns.

- the galvanizing was removed by scanning the entire area of the removal range.

- Removal using plasma was performed by discharging at a current of 200 A and a voltage of 20 V, and heating the zinc plating for 0.2 seconds. Since the plasma has a distribution of energy density, the target galvanized area was completely removed, and its periphery was also partially removed.

- the CCT test was conducted by repeating the treatment for 8 hours per cycle for 30 cycles based on the automotive material corrosion test method (JASOM 609-91).

- One cycle consists of a salt spray test (2 hours, 5% NaCl, 35 ° C.), drying (4 hours, 30% RH, 60 ° C.), wet test (2 hours, 95% RH, 50 ° C.).

- the evaluation was “ ⁇ ” when no change was observed around the spot weld between steel plates, “ ⁇ ” when white rust was observed, and “X” when red rust was generated.

- the crack was confirmed by cutting the test piece in the thickness direction so as to include the nugget and confirming the cross section.

- Test Nos. 2 to 3, 8, 10, 14 to 15, 19 to 20, and 22 to 23 show the occurrence of cracks in the weld as a result of removing the zinc plating in the range specified in the present invention and performing spot welding. The corrosion resistance was also good.

- an adhesive was applied to the place where the galvanizing was removed, and in Test No. 20, since a sealer was applied to the plating removal portion after welding, particularly good corrosion resistance was exhibited.

- the present invention has high industrial applicability.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Plasma & Fusion (AREA)

- Resistance Welding (AREA)

Abstract

Description

スポット溶接の前に、めっきを除去する工程を含み、

上記めっきを除去する工程において、めっきが除去される範囲を、少なくとも、外周が重ね合わされた複数の鋼板の溶接電極側に形成される溶接熱影響部外縁となる円内とすることを特徴とするスポット溶接方法。

スポット溶接の前に、めっきを除去する工程を含み、

めっきを除去する工程において、めっきが除去される範囲を、

外周が重ね合わされた複数の鋼板の重ね合わせ面に形成される溶接熱影響部外縁の広いほうとなる円内とすることを特徴とするスポット溶接方法。

スポット溶接の前に、めっきを除去する工程を含み、

めっきを除去する工程において、めっきが除去される範囲を、

外周が重ね合わされた複数の鋼板の重ね合わせ面に形成される溶接熱影響部外縁の広いほうであり、

内周が上記鋼板の重ね合わせ面に形成されるナゲットの中心となる予定の位置と中心を共有し、ナゲット直径の0.8倍である直径を有する円である円環内とすることを特徴とするスポット溶接方法。

のいずれか1以上を含む条件下で行われる場合にテストスポット溶接を行うことを特徴とする前記(3)又は(7)のスポット溶接方法。

図4は、軸心が鋼板の表面に対して3°以上となる角度を付けて溶接している状態を示す板厚方向の断面図である。図4に示す被溶接部材は、鋼板1aと鋼板1bからなる。鋼板1aは、立上がり部Wを有する、断面ハット形状の鋼板である。このような立上がり部Wの近傍において、鋼板1aと鋼板1bとをスポット溶接する場合、溶接箇所の周囲の空間が狭小となり、スポット溶接ガンの一部が立上がり部Wに干渉することがある。

図5は、角度付き電極を使用して溶接している状態を示す板厚方向の断面図である。図5に示す被溶接部材は、鋼板1aと鋼板1bからなる。鋼板1aは、立上がり部Wを有する、断面ハット形状の鋼板である。このような立上がり部Wの近傍において、鋼板1aと鋼板1bとをスポット溶接する場合、溶接箇所の周囲の空間が狭小となり、スポット溶接ガンのアーム等が立上がり部Wに干渉することがある。

図6は、撓み易い溶接ガン(溶接ガンの先端に電極がついている)を使用して溶接している状態を示す板厚方向の断面図である。図6に示す溶接電極10a、10bは、その軸芯11a、11bが鋼板1a、1bの表面に対して、垂直となっておらず、先端面が鋼板1a、1bの表面に対して平行になっていない。溶接による加圧により溶接ガン(図示せず)が撓むと、溶接電極10a、10bの先端側が溶接電極を保持するホルダ(図示せず)から離れる方向に変位させられる。

図7は、対向する溶接電極の軸芯の相対的なズレを生じたまま溶接している状態を示す板厚方向の断面図である。図7に示すように、溶接電極10a、10bは、電極チップの取り付け不良により、それぞれの軸芯11a、11bに相対的なズレ12(以下「電極芯ズレ」という)を生じることがある。また、図6に示した撓みやすい溶接ガンで、上下の撓みが均一ではない場合、電極に角度が生じるとともに軸芯のズレが発生する。

図8は、重ね合わせ面に隙間を有する溶接箇所を溶接している状態を示す板厚方向の断面図である。図8に示すように、鋼板1a、1bの間に、他の部材13が挿入されている場合など、溶接箇所の重ね合わせ面の鋼板1a、1bの間に隙間14(以下「板隙」という)を生じることがある。

図9は、複数の鋼板に対する溶接電極の加圧方向の位置が不適切なまま溶接している状態を示す板厚方向の断面である。スポット溶接では、複数の鋼板に対する溶接電極の加圧方向の位置を適切にするために、固定側の溶接電極を鋼板に当接させてその位置をロボットに教示して溶接することや、加圧方向に自由に移動できるようにロボットとスポット溶接ガンの間にイコライズ機構を設けて溶接することが行われている。

図10は、真ん中に軟鋼板を、上下に高強度鋼板を設けて溶接している状態を示す板厚方向の断面である。スポット溶接では3枚重ねの溶接がしばしば行われる。しかし、溶接される鋼板の引張強度の差が大きいと、たとえば、図10の場合、スポット溶接工程において、強度の低い真ん中の軟鋼板が電極直下から押し出されて周囲で増肉される。この時、上下の高強度鋼板を上下に押しのけるようにして、高強度鋼板表面に、鋼板表面に平行な引き張り応力が発生する。

スポット溶接される複数の鋼板は、少なくとも一方の表面の溶接箇所にめっきが被覆された鋼板を1枚以上含む複数の鋼板であれば、特に限定されるものでない。たとえば、鋼板と電極が接触する側の面にめっきが被覆された鋼板同士の組合せや、鋼板と電極が接触する側の面にめっきが被覆された鋼板とめっきが被覆されていない鋼板の組合せ、鋼板と電極が接触する側の面及び鋼板の重ね合わせ面にめっきが被覆された鋼板同士の組合せなどが例示される。また、溶接継手の耐食性を考慮すれば、鋼板と電極が接触する側の面及び鋼板の重ね合わせ面にめっきが被覆されていることが好ましい。

次に、テストスポット溶接について説明する。テストスポット溶接は、実際の生産で発生する上記(a)~(g)の1以上を満たす場合に行うことが好ましい。

テストスポット溶接によって得られたスポット溶接継手において、溶接箇所の割れの発生の有無を確認する。この割れの発生の有無の確認方法は、特に限定されるものでなく、目視での観察や浸透探傷検査、溶融凝固部を含む板厚方向の断面の観察や、スポット溶接継手の引張試験を実施して所定の引張強度が得られるか否かで判定などして行うことができる。または、スポット溶接部を含む板厚方向の断面の観察に加えて、X線透過試験を行って確認してもよい。

本発明の溶接方法は、スポット溶接の前に、溶接される鋼板のめっきを除去することを特徴とする。めっきの除去範囲は、テストスポット溶接で確認された割れの位置によって、以下の範囲とするのがよい。

テストスポット溶接によって外割れを確認したときには、除去するめっきの範囲は、少なくとも、重ね合わされた複数の鋼板の外割れが確認された鋼板で、溶接電極側に被覆されためっきであって、外周が溶接電極側の溶接熱影響部外縁となる円内の範囲とする。これにより、割れの発生因子がいくつか重なって、鋼板の電極と接触する側の表面に強い応力が発生しても、溶融しためっき金属が存在しないので外割れの発生は無くなる。

テストスポット溶接によってナゲット内あるいはコロナボンドのナゲット際の割れあるいはコロナボンド直外の割れを確認したときには、除去するめっきの範囲は、溶接される鋼板の重ね合わせ面であって、外周が重ね合わせ面の溶接熱影響部外縁の広いほうとなる直径がDHAZ2である円内の範囲とする。この範囲のめっきを除去することにより、割れの発生因子がいくつか重なって、鋼板の重ね合わせ面に強い応力が発生しても、溶融しためっき金属が存在しないので内割れは発生しない。

特定の位置のめっきが除去された鋼板を含む複数の鋼板のスポット溶接では、鋼板と電極との接触箇所の割れや鋼板の重ね合わせ面の割れを確認したときは、テストスポット溶接の際と、ナゲット径が同じになるように電流値を調整する。それにより、本来目標としたスポット溶接継手の強度を確保することができる。

めっきを除去したことにより、鋼板と電極との溶接箇所や鋼板の重ね合わせ面の耐食性が十分でなくなることがある。そこで、鋼板と溶接電極との接触予定箇所のめっきを除去したときは、スポット溶接後に、めっきが除去された部分の一部又は全部に、シーラを塗布し、鋼板の重ね合わせ面のめっきを除去したときは、スポット溶接前に、めっきが除去された部分の一部又は全部に、シーラ又は接着剤を塗布することが好ましい。

めっきの除去方法としては、機械的除去、及び蒸発除去の少なくとも一方を採用することができる。機械的除去としては、回転するバイトによって研削することができる。この際、接触予定箇所などの円相当中心に突起のあるバイトによって研削すれば回転中心が定まり、精度よくめっきを除去することができる。突起を十分小さくすることにより、溶接によって、突起の形成した穴を埋めることができる。

2 ナゲット

3 電極直下部割れ

4 熱影響部

5 肩部割れ

6 電極外側割れ

7 コロナボンド直外の割れ

8 コロナボンドのナゲット際の割れ

9 ナゲット内の割れ

10a、10b 電極

11a、11b 軸芯

12 電極芯ズレ

13 部材

14 板隙

15 クリアランス

101 鋼板

102 ナゲット形成予定箇所

103 コロナボンド形成予定位置

104 熱影響部外縁形成予定位置

105 電極直下部割れ発生予定箇所

106 電極肩部割れ発生予定箇所

107 電極外側割れ発生予定箇所

108 コロナボンド直外割れ発生予定箇所

109 コロナボンドのナゲット際割れ発生予定箇所

110 ナゲット内割れ発生予定箇所

Cn ナゲット形成予定箇所の中心

Dc コロナボンド形成予定箇所の円相当直径

Dn ナゲット形成予定箇所の円相当直径

DHAZ1 外割れを回避するためにめっきを除去する範囲の直径

DHAZ2 2枚重ね板組で内割れを回避するためにめっきを除去する範囲の直径

DHAZ3 3枚重ね板組で内割れを回避するためにめっきを除去する範囲の直径

W 立上がり部

Claims (11)

- 少なくとも一方の表面の溶接箇所にめっきが被覆された鋼板を1枚以上含む重ね合わされた複数の鋼板を対向する溶接電極で挟み込みスポット溶接する方法であって、

スポット溶接の前に、めっきを除去する工程を含み、

上記めっきを除去する工程において、めっきが除去される範囲を、少なくとも、外周が重ね合わされた複数の鋼板の溶接電極側に形成される溶接熱影響部外縁となる円内とすることを特徴とするスポット溶接方法。 - スポット溶接後に、めっきが除去された部分の一部又は全部に、シーラを塗布することを特徴とする請求項1に記載のスポット溶接方法。

- めっきを除去する前にテストスポット溶接を行い、溶接箇所の割れの発生の有無を確認し、重ね合わされた複数の鋼板の溶接電極側の割れを確認したときに、割れの確認された鋼板表面のめっきを除去することを特徴とする請求項1又は2に記載のスポット溶接方法。

- 少なくとも一方の表面の溶接箇所にめっきが被覆された鋼板を1枚以上含む重ね合わされた複数の鋼板を対向する溶接電極で挟み込みスポット溶接する方法であって、

スポット溶接の前に、めっきを除去する工程を含み、

めっきを除去する工程において、めっきが除去される範囲を、

外周が重ね合わされた複数の鋼板の重ね合わせ面に形成される溶接熱影響部外縁の広いほうとなる円内とすることを特徴とするスポット溶接方法。 - 少なくとも一方の表面の溶接箇所にめっきが被覆された鋼板を1枚以上含む重ね合わされた複数の鋼板を対向する溶接電極で挟み込みスポット溶接する方法であって、

スポット溶接の前に、めっきを除去する工程を含み、

めっきを除去する工程において、めっきが除去される範囲を、

外周が重ね合わされた複数の鋼板の重ね合わせ面に形成される溶接熱影響部外縁の広いほうであり、内周が上記鋼板の重ね合わせ面に形成されるナゲットの中心となる予定の位置と中心を共有し、ナゲットの直径の0.8倍である直径を有する円である円環内とすることを特徴とするスポット溶接方法。 - スポット溶接前に、めっきが除去された部分の一部又は全部に、シーラ又は接着剤を塗布することを特徴とする請求項4又は5に記載のスポット溶接方法。

- めっきを除去する前にテストスポット溶接を行い、溶接箇所の割れの発生の有無を確認し、重ね合わされた複数の鋼板の割れを確認したときに、割れの確認された鋼板の割れの発生した表面と重ね合わされた鋼板の重ね合わされた面にあるめっきを除去することを特徴とする請求項4~6のいずれか1項に記載のスポット溶接方法。

- 前記スポット溶接が、

(a)溶接電極の軸心が鋼板の表面に対して垂直から3°以上となる角度を付けて溶接する場合、

(b)溶接電極の軸芯が鋼板の表面に対して垂直から5°以上となっている角度付き電極を使用して溶接する場合、

(c)溶接中に電極の軸芯が鋼板の表面に対して垂直から3°以上に撓む溶接ガンを使用して溶接する場合、

(d)対向する溶接電極の軸芯の相対的なズレが0.5mm以上生じた状態で溶接する場合、

(e)重ね合わせ面の隙間が0.5mm以上有する溶接箇所を溶接する場合、

(f)鋼板に対する固定側の溶接電極の加圧方向の位置が0.2mm以上のクリアランスを有するまま溶接する場合、及び

(g)強度比が2.5倍を超える鋼板を含む板組を溶接する場合

のいずれか1以上を含む条件下で行われる場合にテストスポット溶接を行うことを特徴とする請求項3又は7に記載のスポット溶接方法。 - 前記テストスポット溶接において、割れの発生が確認されなかった鋼板のめっきも除去することを特徴とする請求項3、7、又は8に記載のスポット溶接方法。

- めっきの除去を、機械的除去、及び蒸発除去の少なくとも一方で行うことを特徴とする請求項1~9のいずれか1項に記載のスポット溶接方法。

- 前記めっきが亜鉛系めっきであることを特徴とする請求項1~10のいずれか1項に記載のスポット溶接方法。

Priority Applications (10)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CA2980692A CA2980692C (en) | 2015-03-30 | 2016-03-30 | Method of spot welding |

| JP2016562041A JP6108049B2 (ja) | 2015-03-30 | 2016-03-30 | めっき鋼板のスポット溶接方法 |

| CN201680020469.9A CN107530820B (zh) | 2015-03-30 | 2016-03-30 | 镀层钢板的点焊方法 |

| MYPI2017703520A MY186160A (en) | 2015-03-30 | 2016-03-30 | Method of spot welding |

| US15/563,489 US10350701B2 (en) | 2015-03-30 | 2016-03-30 | Method of spot welding |

| KR1020177026773A KR101901085B1 (ko) | 2015-03-30 | 2016-03-30 | 도금 강판의 스폿 용접 방법 |

| RU2017135023A RU2685928C2 (ru) | 2015-03-30 | 2016-03-30 | Способ точечной сварки |

| MX2017012458A MX366087B (es) | 2015-03-30 | 2016-03-30 | Metodo para soldar mediante soldadura por puntos lamina de acero enchapada. |

| BR112017020590A BR112017020590A2 (pt) | 2015-03-30 | 2016-03-30 | método de soldagem por pontos de chapa de aço chapeada |

| EP16773050.6A EP3278917B1 (en) | 2015-03-30 | 2016-03-30 | Method for spot welding of plated steel sheet |

Applications Claiming Priority (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015069553 | 2015-03-30 | ||

| JP2015-069553 | 2015-03-30 | ||

| JP2016-022066 | 2016-02-08 | ||

| JP2016022066 | 2016-02-08 | ||

| JP2016048893 | 2016-03-11 | ||

| JP2016-048893 | 2016-03-11 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2016159169A1 true WO2016159169A1 (ja) | 2016-10-06 |

Family

ID=57006878

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2016/060541 WO2016159169A1 (ja) | 2015-03-30 | 2016-03-30 | めっき鋼板のスポット溶接方法 |

Country Status (12)

| Country | Link |

|---|---|

| US (1) | US10350701B2 (ja) |

| EP (1) | EP3278917B1 (ja) |

| JP (1) | JP6108049B2 (ja) |

| KR (1) | KR101901085B1 (ja) |

| CN (1) | CN107530820B (ja) |

| BR (1) | BR112017020590A2 (ja) |

| CA (1) | CA2980692C (ja) |

| MX (1) | MX366087B (ja) |

| MY (1) | MY186160A (ja) |

| RU (1) | RU2685928C2 (ja) |

| TW (1) | TWI628022B (ja) |

| WO (1) | WO2016159169A1 (ja) |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2018117459A1 (ko) * | 2016-12-22 | 2018-06-28 | 주식회사 포스코 | 고강도 아연도금 강판의 점 용접 방법 |

| JP2020012752A (ja) * | 2018-07-19 | 2020-01-23 | 株式会社神戸製鋼所 | スポット溶接部の検査方法 |

| JP2020179413A (ja) * | 2019-04-25 | 2020-11-05 | Jfeスチール株式会社 | スポット溶接部材 |

| JP2021501260A (ja) * | 2016-12-21 | 2021-01-14 | アルセロールミタル | 被覆鋼板の製造方法、スポット溶接された2枚の金属板及びその使用 |

| JP2022015124A (ja) * | 2020-07-08 | 2022-01-21 | フタバ産業株式会社 | 抵抗スポット溶接方法及び抵抗スポット溶接装置 |

| WO2023080076A1 (ja) | 2021-11-02 | 2023-05-11 | Jfeスチール株式会社 | 抵抗スポット溶接部材およびその抵抗スポット溶接方法 |

| WO2023233705A1 (ja) | 2022-06-03 | 2023-12-07 | Jfeスチール株式会社 | 溶接継手、溶接部材およびその製造方法、ならびに、抵抗スポット溶接方法 |

| WO2023233704A1 (ja) | 2022-06-03 | 2023-12-07 | Jfeスチール株式会社 | 溶接継手、溶接部材およびその製造方法、ならびに、抵抗スポット溶接方法 |

| KR20240134244A (ko) | 2022-06-03 | 2024-09-06 | 제이에프이 스틸 가부시키가이샤 | 용접 이음매, 용접 부재 및 그 제조 방법, 그리고 저항 스폿 용접 방법 |

| KR20240138521A (ko) | 2022-06-03 | 2024-09-20 | 제이에프이 스틸 가부시키가이샤 | 용접 이음매, 용접 부재 및 그 제조 방법, 그리고 저항 스폿 용접 방법 |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR102058305B1 (ko) * | 2015-12-16 | 2019-12-20 | 제이에프이 스틸 가부시키가이샤 | 저항 스폿 용접 방법 및 용접 부재의 제조 방법 |

| EP3413030A4 (en) * | 2016-02-05 | 2019-10-16 | Nippon Steel Corporation | METHOD AND DEVICE FOR BREAK PREDICTION, PROGRAM, AND RECORDING MEDIUM |

| CN108311787A (zh) * | 2018-01-18 | 2018-07-24 | 上海业识科技有限公司 | 基于连续激光、准连续激光的不锈钢面板表面焊接工艺 |

| US20190314915A1 (en) * | 2018-04-13 | 2019-10-17 | GM Global Technology Operations LLC | Resistance Spot Welding Workpiece Stack-Ups Having Steel Workpieces With Surface Coatings |

| US20200114459A1 (en) * | 2018-10-15 | 2020-04-16 | GM Global Technology Operations LLC | Quality welding of similar and dissimilar metal welds with space between workpieces |

| US11065711B2 (en) * | 2018-11-02 | 2021-07-20 | GM Global Technology Operations LLC | High aspect ratio weld face design for dissimilar metal welding |

| WO2020096271A1 (en) * | 2018-11-08 | 2020-05-14 | Renault-Samsung Motors Co., Ltd. | Combination structure of metal sheets for automobile by using trip steel and method for manufacturing the same |

| JP2020082104A (ja) * | 2018-11-19 | 2020-06-04 | 株式会社神戸製鋼所 | 接合構造体及び接合構造体の製造方法 |

| US12037665B2 (en) | 2018-12-21 | 2024-07-16 | Jfe Steel Corporation | Spot welded member |

| US11548091B2 (en) * | 2019-10-10 | 2023-01-10 | GM Global Technology Operations LLC | Pretreatment of weld flanges to mitigate liquid metal embrittlement cracking in resistance welding of galvanized steels |

| WO2021172080A1 (ja) * | 2020-02-25 | 2021-09-02 | 株式会社神戸製鋼所 | 抵抗スポット溶接方法 |

| JP7152439B2 (ja) * | 2020-03-30 | 2022-10-12 | フタバ産業株式会社 | 接合部材の製造方法 |

| JP7132300B2 (ja) * | 2020-09-18 | 2022-09-06 | フタバ産業株式会社 | 抵抗スポット溶接方法及び抵抗スポット溶接装置 |

| CN113275724A (zh) * | 2021-05-28 | 2021-08-20 | 天津津荣天宇精密机械股份有限公司 | 一种镀锌板电阻点焊方法及焊接装置 |

| WO2023107907A1 (en) * | 2021-12-06 | 2023-06-15 | Arconic Technologies Llc | Methods for resistance spot welding, resistance spot welding systems and apparatus, and parts formed using resistance spot welding |

| CN115213579B (zh) * | 2022-06-22 | 2024-08-13 | 首钢集团有限公司 | 一种镀层钢板焊点表面凸点的控制方法及装置 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS55139190A (en) * | 1979-04-13 | 1980-10-30 | Mazda Motor Corp | Seam welding equipment of mild metal plated steel plate |

| JPS6343775A (ja) * | 1986-08-07 | 1988-02-24 | Toyota Motor Corp | メツキ鋼板のスポツト溶接方法 |

| JP2004188495A (ja) * | 2002-11-27 | 2004-07-08 | Daihen Corp | 抵抗溶接制御方法 |

Family Cites Families (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1814801A1 (de) * | 1966-09-21 | 1970-09-17 | Becker Dr Otto Alfred | Verfahren zum Widerstandsschweissen und -Loeten von beschichteten Blechen und Maschinen dazu |

| NL7101684A (ja) | 1970-03-10 | 1971-09-14 | ||

| JPS5536051A (en) * | 1978-09-05 | 1980-03-13 | Kobe Steel Ltd | Resistance welding method of surface treated material |

| US5047608A (en) * | 1989-02-23 | 1991-09-10 | Nippon Steel Corporation | Method and apparatus for resistance welding wherein the electrode axis is included with respect to the electrode forcing axis |

| JP2881273B2 (ja) | 1992-03-31 | 1999-04-12 | 日新製鋼株式会社 | 表面処理鋼管の製造方法 |

| RU2066264C1 (ru) * | 1992-12-14 | 1996-09-10 | Волжское объединение по производству легковых автомобилей "АвтоВАЗ" | Способ контактной точечной сварки оцинкованных стальных листов |

| JP2638413B2 (ja) * | 1993-01-11 | 1997-08-06 | 菊池プレス工業株式会社 | 抵抗溶接方法 |

| GB2274257A (en) | 1993-01-19 | 1994-07-20 | British Aerospace | Method of preparing and welding zinc coated steel |

| JPH10143212A (ja) | 1996-11-08 | 1998-05-29 | Nissan Motor Co Ltd | 溶接電極の面直検出方法 |

| JP2000271758A (ja) * | 1999-03-26 | 2000-10-03 | Kyushu Fukugo Zairyo Kenkyusho:Kk | チタン板と鋼板のシーム溶接方法 |

| JP2003089881A (ja) | 2001-09-17 | 2003-03-28 | Sumitomo Metal Ind Ltd | 無機潤滑皮膜を有する亜鉛系めっき鋼板とその製造方法 |

| RU2243071C2 (ru) * | 2002-07-01 | 2004-12-27 | Открытое акционерное общество "АВТОВАЗ" | Способ контактной точечной сварки оцинкованных стальных листов |

| JP4854920B2 (ja) * | 2003-08-29 | 2012-01-18 | 豊田鉄工株式会社 | スポット溶接方法およびスポット溶接された鋼板部材 |

| JP2005088029A (ja) | 2003-09-16 | 2005-04-07 | Nissan Motor Co Ltd | 亜鉛めっき鋼板のスポット溶接方法および装置 |

| JP2006265671A (ja) | 2005-03-25 | 2006-10-05 | Nisshin Steel Co Ltd | 加工性及び耐溶融金属脆化割れ性に優れた合金化溶融亜鉛めっき高張力鋼板 |

| JP4791992B2 (ja) | 2007-03-20 | 2011-10-12 | 日新製鋼株式会社 | スポット溶接用合金化溶融亜鉛めっき鋼板の製造方法 |

| KR101277778B1 (ko) * | 2008-12-03 | 2013-06-24 | 신닛테츠스미킨 카부시키카이샤 | 도장 금속재 및 그 제조 방법 |

| CN101961814A (zh) * | 2009-07-24 | 2011-02-02 | 宝山钢铁股份有限公司 | 一种热镀铝锌钢板的点焊方法 |

| EP2460613A4 (en) * | 2009-07-31 | 2015-11-04 | Neturen Co Ltd | WELDED CONSTRUCTION ELEMENT AND WELDING METHOD |

| JP5531743B2 (ja) | 2010-04-12 | 2014-06-25 | 新日鐵住金株式会社 | レーザろう付け方法 |

| CN101985189A (zh) * | 2010-10-26 | 2011-03-16 | 聂健 | 汽车金属燃油箱的表盘双脉冲凸点焊工艺方法 |

| JP2013063460A (ja) | 2011-09-20 | 2013-04-11 | Nippon Steel & Sumikin Welding Co Ltd | 亜鉛系めっき鋼板の重ね継手アークスポット溶接方法 |

| KR101737712B1 (ko) * | 2012-08-10 | 2017-05-18 | 신닛테츠스미킨 카부시키카이샤 | 겹침 용접 부재, 자동차용 부품, 겹침부의 용접 방법 및 겹침 용접 부재의 제조 방법 |

| CN105189014B (zh) | 2013-03-08 | 2017-06-30 | 杰富意钢铁株式会社 | 电阻点焊方法 |

| JP6001478B2 (ja) * | 2013-03-19 | 2016-10-05 | 株式会社神戸製鋼所 | スポット溶接継手 |

| WO2014171495A1 (ja) * | 2013-04-17 | 2014-10-23 | 新日鐵住金株式会社 | スポット溶接方法 |

| KR101325871B1 (ko) * | 2013-05-13 | 2013-11-05 | 현대하이스코 주식회사 | 핫 스탬핑 부품 용접성 개선방법 |

| CN203265868U (zh) * | 2013-05-27 | 2013-11-06 | 武汉钢铁(集团)公司 | 一种能清理涂镀层钢板表层的点焊机 |

| WO2015106455A1 (en) * | 2014-01-20 | 2015-07-23 | GM Global Technology Operations LLC | Welding method and system |

| CN104084686B (zh) * | 2014-06-12 | 2017-01-18 | 上海翼锐汽车科技有限公司 | 一种用于抑制铝合金电阻点焊裂纹产生的电极 |

-

2016

- 2016-03-30 WO PCT/JP2016/060541 patent/WO2016159169A1/ja active Application Filing

- 2016-03-30 EP EP16773050.6A patent/EP3278917B1/en active Active

- 2016-03-30 US US15/563,489 patent/US10350701B2/en active Active

- 2016-03-30 RU RU2017135023A patent/RU2685928C2/ru not_active IP Right Cessation

- 2016-03-30 BR BR112017020590A patent/BR112017020590A2/pt active Search and Examination

- 2016-03-30 KR KR1020177026773A patent/KR101901085B1/ko active IP Right Grant

- 2016-03-30 MX MX2017012458A patent/MX366087B/es active IP Right Grant

- 2016-03-30 MY MYPI2017703520A patent/MY186160A/en unknown

- 2016-03-30 JP JP2016562041A patent/JP6108049B2/ja active Active

- 2016-03-30 CN CN201680020469.9A patent/CN107530820B/zh active Active

- 2016-03-30 TW TW105110065A patent/TWI628022B/zh not_active IP Right Cessation

- 2016-03-30 CA CA2980692A patent/CA2980692C/en not_active Expired - Fee Related

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS55139190A (en) * | 1979-04-13 | 1980-10-30 | Mazda Motor Corp | Seam welding equipment of mild metal plated steel plate |

| JPS6343775A (ja) * | 1986-08-07 | 1988-02-24 | Toyota Motor Corp | メツキ鋼板のスポツト溶接方法 |

| JP2004188495A (ja) * | 2002-11-27 | 2004-07-08 | Daihen Corp | 抵抗溶接制御方法 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP3278917A4 * |

Cited By (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2021501260A (ja) * | 2016-12-21 | 2021-01-14 | アルセロールミタル | 被覆鋼板の製造方法、スポット溶接された2枚の金属板及びその使用 |

| WO2018117459A1 (ko) * | 2016-12-22 | 2018-06-28 | 주식회사 포스코 | 고강도 아연도금 강판의 점 용접 방법 |

| JP7144225B2 (ja) | 2018-07-19 | 2022-09-29 | 株式会社神戸製鋼所 | スポット溶接部の検査方法 |

| JP2020012752A (ja) * | 2018-07-19 | 2020-01-23 | 株式会社神戸製鋼所 | スポット溶接部の検査方法 |

| JP2020179413A (ja) * | 2019-04-25 | 2020-11-05 | Jfeスチール株式会社 | スポット溶接部材 |

| JP7059979B2 (ja) | 2019-04-25 | 2022-04-26 | Jfeスチール株式会社 | スポット溶接部材 |

| JP2022015124A (ja) * | 2020-07-08 | 2022-01-21 | フタバ産業株式会社 | 抵抗スポット溶接方法及び抵抗スポット溶接装置 |

| JP7208193B2 (ja) | 2020-07-08 | 2023-01-18 | フタバ産業株式会社 | 抵抗スポット溶接方法及び抵抗スポット溶接装置 |

| WO2023080076A1 (ja) | 2021-11-02 | 2023-05-11 | Jfeスチール株式会社 | 抵抗スポット溶接部材およびその抵抗スポット溶接方法 |

| KR20240056833A (ko) | 2021-11-02 | 2024-04-30 | 제이에프이 스틸 가부시키가이샤 | 저항 스폿 용접 부재 및 그 저항 스폿 용접 방법 |

| WO2023233705A1 (ja) | 2022-06-03 | 2023-12-07 | Jfeスチール株式会社 | 溶接継手、溶接部材およびその製造方法、ならびに、抵抗スポット溶接方法 |

| WO2023233704A1 (ja) | 2022-06-03 | 2023-12-07 | Jfeスチール株式会社 | 溶接継手、溶接部材およびその製造方法、ならびに、抵抗スポット溶接方法 |

| KR20240134244A (ko) | 2022-06-03 | 2024-09-06 | 제이에프이 스틸 가부시키가이샤 | 용접 이음매, 용접 부재 및 그 제조 방법, 그리고 저항 스폿 용접 방법 |

| KR20240138521A (ko) | 2022-06-03 | 2024-09-20 | 제이에프이 스틸 가부시키가이샤 | 용접 이음매, 용접 부재 및 그 제조 방법, 그리고 저항 스폿 용접 방법 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3278917A4 (en) | 2018-12-05 |

| JP6108049B2 (ja) | 2017-04-05 |

| EP3278917A1 (en) | 2018-02-07 |

| MY186160A (en) | 2021-06-30 |

| US10350701B2 (en) | 2019-07-16 |

| CA2980692A1 (en) | 2016-10-06 |

| US20180079026A1 (en) | 2018-03-22 |

| JPWO2016159169A1 (ja) | 2017-04-27 |

| RU2017135023A3 (ja) | 2019-04-05 |

| CN107530820B (zh) | 2019-04-19 |

| KR20170113689A (ko) | 2017-10-12 |

| RU2017135023A (ru) | 2019-04-05 |

| RU2685928C2 (ru) | 2019-04-23 |

| BR112017020590A2 (pt) | 2018-07-03 |

| KR101901085B1 (ko) | 2018-09-20 |

| TW201641201A (zh) | 2016-12-01 |

| CN107530820A (zh) | 2018-01-02 |

| MX366087B (es) | 2019-06-27 |

| TWI628022B (zh) | 2018-07-01 |

| CA2980692C (en) | 2018-04-24 |

| MX2017012458A (es) | 2018-01-30 |

| EP3278917B1 (en) | 2020-12-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6108049B2 (ja) | めっき鋼板のスポット溶接方法 | |

| US11198195B2 (en) | Welded blank assembly and method | |

| US10668570B2 (en) | Method and device for preparing aluminum-coated steel sheets intended for being welded and then hardened under a press; corresponding welded blank | |

| CN106488824B (zh) | 用于接合两个坯件的方法 | |

| JP6108018B2 (ja) | スポット溶接方法 | |

| JP6108017B2 (ja) | スポット溶接方法 | |

| JP6384603B2 (ja) | スポット溶接方法 | |

| JP2018039019A (ja) | スポット溶接方法 | |

| WO2017038981A1 (ja) | スポット溶接方法 | |

| KR102061471B1 (ko) | 레이저 브레이징 방법 및 겹치기 이음 부재의 제조방법 | |

| US20240123539A1 (en) | Resistance spot welded joint and method for manufacturing resistance spot welded joint | |

| WO2021130602A1 (en) | Pre-coated steel sheet comprising an additional coating for increasing the mechanical strength of the weld metal zone of a welded steel part prepared from said pre-coated sheet |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| ENP | Entry into the national phase |

Ref document number: 2016562041 Country of ref document: JP Kind code of ref document: A |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 16773050 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2980692 Country of ref document: CA Ref document number: 20177026773 Country of ref document: KR Kind code of ref document: A |

|

| WWE | Wipo information: entry into national phase |

Ref document number: MX/A/2017/012458 Country of ref document: MX |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 15563489 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| REEP | Request for entry into the european phase |

Ref document number: 2016773050 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2017135023 Country of ref document: RU |

|

| REG | Reference to national code |

Ref country code: BR Ref legal event code: B01A Ref document number: 112017020590 Country of ref document: BR |

|

| ENP | Entry into the national phase |

Ref document number: 112017020590 Country of ref document: BR Kind code of ref document: A2 Effective date: 20170926 |