THERMOFORMABLE OPHTHALMIC LENS

BACKGROUND OF THE INVENTION

This invention relates to the preparation of ophthalmic devices through a molding process. More particularly, the invention relates to a thermoformable hydrogel polymer, and to ophthalmic lenses, in particular, contact lenses, made by the melt processing of that polymer.

The use of contact lenses as corrective ophthalmic devices, as well as for cosmetic purposes, is well known. Various materials have been utilized in making contact lenses, but these materials have been found less than ideal. To be effective as a material for a contact lens, the material must possess certain key properties: (a) sufficient oxygen permeability, (b) good wettability by tear fluid, (c) resistance to protein deposition, (d) dehydration resistance (for hydrogels), (e) sufficient durability for its intended use (e.g. disposable, extended wear, etc.), (f) optical clarity, (g) sufficient light transmission, (h) appropriate manufacturing costs, and (i) comfortable to wear.

Various materials possess some but not all of these properties. For example, contact lenses derived from hydrophobic materials often possess good durability and oxygen permeability, but are not comfortable to wear. Some hydrophobic materials used to make contact lens include methacrylate and acrylate monomers containing large bulky pendant groups containing substituted silicones, styrene monomers containing bulky substituents and the like. However, these lack wettability and comfort.

On the other hand, contact lenses derived from hydrophilic material permit wettability and oxygen permeability. Examples of hydrophilic monomers commonly used include hydroxyalkyl methacrylates, N-vinyl pyrrolidone and polyvinyl alcohol. But these materials lack such properties as durability and dehydration resistance.

Accordingly, there is a need for an ophthalmic lens material that has the benefits of both hydrophobic and hydrophilic materials without the attendant

disadvantages of those materials. Substantial research efforts have focused on developing such new materials. These new materials are in the form of crosslinked hydrogel polymers that have improved physical properties. A hydrogel polymer is generally considered to be a polymer having substantial hydrophilic character that is plasticized by the water it absorbs, and can be described as a soft, elastic, water- containing gel. Materials which contain both hydrophilic and hydrophobic components can form hydrogels. In some cases these materials can be considered amphiphilic, that is exhibiting either hydrophilic or hydrophobic characteristics, depending on the conditions. In addition to the desirability of good physical properties found in hydrogel polymers, it is likewise desirable to be able to efficiently manufacture the polymer and/or convert it into an ophthalmic lens.

Historically, contact lenses have been manufactured by one of the three processes: lathing, spin-casting, and cast molding. Lathing is not able to meet demands of cheap, high- volume, fast production. Efforts to reduce the inherent cost disadvantages of lathing have produced a process that is a hybrid of lathing and cast molding. For example, lenses may be prepared by casting one side of the lens and lathing the other side. This process is cheaper than lathing, but not as cheap as a complete cast molding process. Spin-casting, on the other hand, often results in lenses with optical quality and fitting problems because the back surface of the lens is determined by centrifugal force and not the requirements of an optimized lens mold design.

In contrast, cast molding requires the use of two complementary molds. These molds are often disposable, and the cost to replace the mold for each new lens is a significant part of the total cost of the final lens. Furthermore, lenses made by cast molding also suffer a large number of quality defects during in situ polymerization due to shrinkage. For example, shrinkage may cause surface voids and the non-adherence of the final product to the lens design. Others have attempted to eliminate shrinkage and thereby improve cast molding techniques. For example, U.S. Patent No. 5,039,459 to Kindt-Larsen et al. discloses a replaceable diluent in the monomer mixture polymerized in the casting cup.

However, the disposable casting cup with all of its costs and complications, as well as the complexities of removing the replaceable diluent, are still present. The advantage of the invention described below is that the need for the casting cup and replaceable diluent are eliminated. Accordingly, there is room for improvement in developing suitable processes to make lenses from new polymers with improved properties. Due to processing difficulties of crosslinked polymers, however, the complete polymerization is typically done in the final molding step in making contact lenses. A crossliked polymer is a polymer having linkages between the polymer chains, resulting in a network structure. But in that final molding/polymerization step, numerous quality control issues are present due to process variations. Accordingly, it would be desirable to use a process where the polymerization is performed before the final molding step.

In the contact lens industry, attempts have been made to use injection molding processes to make contact lenses from polymethylmethacrylate (PMMA).

PMMA lenses are hard and not oxygen permeable, i.e., they do not compare to the quality of hydrogel lenses. Thus, while injection molded processes, such as typically used in the plastics industry, are capable of high-speed, high-volume, consistent-quality mass production, there have not been good contact lens materials that possess the key properties outlined above that could take advantage of those plastics manufacturing processes.

Crosslinked hydrophilic polymers for use as hydrogels that may be first prepared in large batches, however, cannot generally be later melt processed in injection molding equipment. Once crosslinked, the polymer cannot be dissolved. Crosslinked polymer can be molded and/or recycled only under special circumstances. Partially, or lightly, crosslinked polymers can be somewhat molded to form a more highly crosslinked thermoset shape through the process of heat stabilization. Also, some crosslinks can be broken during processing under conditions of heat and shear stress. Because of the difficulties in processing crosslinked polymers, there is a need for a thermoformable or melt processable polymer that can be made in large batches of a consistent quality, and processed

using high speed, high volume injection molding equipment to make a soft contact lens with desirable physical qualities. The present invention addresses these needs, and also provides other advantages as will be evident from the following description.

SUMMARY OF THE INVENTION

In one embodiment, the present invention is directed to a melt processable hydrophilic polymer prepared by polymerizing monomers comprising between about 20 and 90% by weight of total monomer of at least one hydrophilic monomer, between about 5 and 80% by weight of total monomer of at least one copolymerizable hydrophobic monomer and no crosslinking agents. In the unhydrated state, the polymer is melt processable at a temperature between about 50°C and 300°C. In the hydrated state, the polymer is a hydrogel that includes a water content between about 35% and about 90% by weight of the total hydrated hydrogel. Preferably, the water content is between about 40% and about 80% by weight. The polymer is optically transparent after it has been formed into an ophthalmic lens and hydrated.

In a second embodiment, this invention includes an ophthalmic lens comprising the polymer in accordance with the first embodiment, and sufficient water absorbed by the polymer to become a hydrogel. In a third embodiment of the invention, a melt processable block copolymer without substantial chemical crosslinks is provided. The uncrosslinked copolymer includes blocks that are self-segregating into immiscible phases. The major volume component in the copolymer includes blocks of hydrophilic units, and the minor volume component includes blocks of hydrophobic units. At temperatures above at least about 80°C or higher, the blocks made from the hydrophobic monomer sufficiently disassociate to allow the polymer to be thermally processed and formed into the desired shape of the ophthalmic device. The uncrosslinked copolymer has sufficient amount of internal hydrophobic association within the hydrophobic domains to be dimensionally stable when

hydrated into a hydrogel polymer, and subject to temperatures up to at least about 60°C or higher.

In a fourth embodiment of the invention, a method is provided for making an ophthalmic lens comprising the steps of providing a polymer prepared by copolymerizing monomers comprising at least one hydrophilic monomer and at least one hydrophobic monomer without the formation of substantial amounts of chemical crosslinks, raising the temperature of the polymer above either the glass transition temperature or the melting temperature, introducing said polymer into an ophthalmic lens mold, forming the polymer into a lens, allowing said lens to solidify in the mold, removing the lens from the mold, and hydrating the lens in a saline solution to form a hydrogel lens having a water content of between about 35 and 90% by weight.

In a fifth embodiment of the invention, a method is provided for molding an ophthalmic lens comprising the steps of copolymerizing a hydrophilic monomer and a hydrophobic monomer in the presence of a monomer with a latent reactive functional group to form a melt processable polymer, then introducing the polymer into a mold, molding said polymer into a lens, reacting said latent functional group to form covalently bonded crosslinks in the polymer, and hydrating the lens to form a hydrogel material. In a sixth embodiment of the invention, a method is provided for molding an ophthalmic lens comprising the steps of providing a solid crosslinkable polymer that is substantially uncrosslinked, introducing the polymer into a lens mold, thermally processing the polymer to allow it to solidify in the lens mold, crosslinking the polymer while it is in the shape of the lens mold, and removing the lens from the mold and hydrating the lens to form a hydrogel with more than

35 weight percent water content of the hydrated lens.

In a seventh embodiment of this invention, a melt processable graft copolymer without substantial chemical crosslinks is provided. The uncrosslinked copolymer includes a backbone chain and grafted side chains that are self- segregating into immiscible phases, or domains. The major volume component in the copolymer is hydrophilic, and the minor volume component is hydrophobic.

At temperatures above at least about 80°C or higher, the domains containing the hydrophobic component sufficiently disassociate to allow the polymer to be thermally processed and formed into the desired shape of the ophthalmic device. The uncrosslinked copolymer has sufficient internal hydrophobic association within the hydrophobic domains to be dimensionally stable when hydrated into a hydrogel polymer, and subjected to temperatures up to at least about 60°C or higher.

In an eighth embodiment of this invention, a melt processable polymer is provided. The polymer includes at least one of a variety of repeating units. In the unhydrated state, the polymer is melt processable at a temperature between about

50°C and 300°C. In the hydrated state, the polymer is a hydrogel that includes a water content between about 35% and about 90% by weight of the total hydrated hydrogel. Preferably, the water content is between about 40% and about 80% by weight. The polymer is optically transparent after it has been formed into an ophthalmic lens and hydrated.

Various embodiments of this invention provide the advantage of a material that can be made into a contact lens that combines excellent key properties otherwise found in either hydrophilic materials or hydrophobic materials. Moreover, various embodiments of this invention provide a material that can be made into a contact lens taking advantage of high speed, high volume thermal molding equipment that uses reusable molds, and eliminates the need for single- use molds. Those advantages and other advantages of the invention will be more readily apparent from the detailed description of the preferred embodiments of the invention that follows.

DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

The present invention may take the form of several different embodiments. One embodiment of the present invention includes a melt processable hydrophilic polymer prepared by polymerizing monomers comprising between about 20 and 90%) by weight monomer of at least one hydrophilic monomer, and between about

5 and 80% by weight of at least one copolymerizable hydrophobic monomer. Preferably, the polymer comprises substantially no crosslinking agents.

In the unhydrated state, the hydrophilic polymer (i.e., xerogel) is melt processable or thermoformable at a temperature between about 50°C and about 300°C. Melt processing is a general method of processing polymers and includes, but is not limited to, such techniques as thermoforming, injection molding, compression molding, resin transfer molding, and extrusion. Melt processing can be carried out in more than one stage, such as extruding the polymer into an intermediate form followed by compression molding into the final shape. Preferably, the xerogel is melt processable at a temperature between about 80°C and 250°C. More preferably, the xerogel is melt processable at a temperature between about 115°C and about 200°C. At these temperatures, the polymer preferably has a viscosity of less than about 100,000 centipoises (cps), or more preferably between about l,000cps and 50,000cps. For some melt processing techniques, such as compression molding, however, the working melt viscosity may be greater than the preferred viscosity ranges stated above. The temperature at which the xerogel is melt processable is preferably greater than the glass transition temperature (Tg) or melt temperature (Tm) of the xerogel, but less than the temperature at which the xerogel degrades. The xerogel has a Tg preferably between about 30°C and 200°C, and a creep stability preferably of at least about

30 minutes at about 120°C. The preferred composition and parameters will depend on the manufacturing process conditions and required characteristics (e.g., oxygen permeability, optical clarity, and water content) of the lens.

In the hydrated state, the hydrophilic polymer forms a hydrogel that includes a water content between about 35% and about 90% by weight of the hydrated polymer (unless stated otherwise herein, water content is expressed by weight percent of the total weight of the hydrated lens), an oxygen permeability (Dk) between about 8 and about 50 barrers (Dk units), a tear strength greater than about 1 g/mm, a tensile modulus between about 20 and about 140 g/mm2. Preferably, the hydrogel polymer is mechanically stable and dimensionally stable after it has been formed into an ophthalmic lens, and is optically transparent with a

visible light transmission of at least 90%, more preferably at least 95%, most preferably at least 99%.

The terms "mechanically stable" and "mechanical stability" are used herein to mean that when the polymer is hydrated into a hydrogel, it maintains its coherent structural integrity and does not dissolve, or become so fragile that it cannot support its own hydrated weight. For example, the fragility or lack of mechanical stability may be demonstrated by the hydrogel tearing apart when attempting to pick up a lens size portion with tweezers. Of course, to be useful as an ophthalmic device, a hydrogel material must have certain mechanical stability to withstand the normal forces associated with handling the device.

The terms "dimensionally stable" and "dimensional stability" are used herein to mean that the change in linear dimension and/or curvature of the polymeric hydrogel material is relatively consistent in any direction (i.e., isotropic) when the material, after being shaped into a lens and hydrated, is subject to a one-time change in temperature. That is to say that the diameter of the lens does not change significantly more in one direction compared to another direction in the plane of the lens, and that the curved shape of the lens does not distort to a degree that it is no longer suitable for its intended use.

A second embodiment of this invention includes an ophthalmic lens that comprises the polymer in accordance with the first embodiment, which becomes a hydrogel material that incorporates between about 35% and 90% by weight water based on the total hydrated weight of the lens, is optically clear, and is dimensionally stable. Preferably, the ophthalmic lens hydrogel material has substantially no covalently bonded crosslinks, which, in other words, means that the crosslink density is sufficiently low so that the hydrogel, if it were dehydrated, would be melt processable at a temperature below where it begins to degrade.

In a third embodiment of the invention, a melt processable block copolymer without substantial chemical crosslinks is provided. The uncrosslinked copolymer includes blocks that are self-segregating into immiscible phases. The

major volume component in the copolymer includes blocks of hydrophilic units, and the minor volume component includes blocks of hydrophobic units. The term "unit" is defined as a moiety linked through at least two bonds to other units to form a polymer. Monomers are transformed into units of a polymer during the polymerization process, thus units are derived or formed from monomers.

At temperatures above at least about 80°C, the blocks of hydrophobic units sufficiently disassociate to allow the polymer to be thermally processed and formed into the desired shape of the ophthalmic device. The uncrosslinked copolymer has sufficient amount of internal hydrophobic association within the domains of hydrophobic units to be mechanically stable when hydrated into a hydrogel polymer, and dimensionally stable when the hydrogel is subject to temperatures up to at least about 60°C or higher.

The copolymer may optionally undergo subsequent treatment to chemically crosslink the polymer and enhance its dimensional stability after being formed into the shape of an ophthalmic device. Alternatively, to enhance dimensional stability, the uncrosslinked polymer may optionally incorporate long side chains pendant to the main polymer chain that can form entanglements or self- segregating immiscible phases. Typically, those long side chains have a weight average molecular weight between about 300 and about 100,000. Preferably, the long side chains have a weight average molecular weight between about 500 and about 50,000. More preferably, the long side chains have a weight average molecular weight between about 1,000 and 10,000. For example, long-chain polysiloxanes or poly(ethylene glycol) acrylates may be incoφorated into the polymer for this purpose. Further, the ophthalmic device of the present invention may take the form of a contact lens, a corneal implant, or an intraocular lens.

When the copolymer is an amorphous polymer without crystalline ordering of the polymer chains, the uncrosslinked copolymer preferably should have a glass transition temperature (Tg) high enough so that it is not soft or tacky at ambient temperatures when it may be handled, stored or transported. Also, the Tg should preferably be low enough so that it does not require a melt processing temperature

to be used near the thermal decomposition temperature, to avoid degradation of the polymer during processing. Accordingly, the Tg may be -40°C to 200°C. For practical purposes, it is desirable that the Tg be between about 30°C and about 200°C. Preferably, the Tg is between about 50°C and 150°C. More preferably, the Tg is between about 60°C and about 125°C. The Tg is the temperature below which the polymer is a rigid glass and above which the polymer is a more flexible material. For example, as the temperature of a polymer is increased through the glass transition region, the polymer may be transformed from a rubbery material to a gum and eventually into a liquid. The Tg is conveniently measured by differential scanning calorimetry (DSC) as the temperature at which there is a change in heat capacity of the polymer. Also, an amorphous polymer will not yield a sharp pattern when analyzed by X-ray diffraction techniques.

Likewise, when the copolymer is a crystalline polymer, the uncrosslinked copolymer should have a melting temperature (Tm) high enough so that it is not soft or tacky at ambient temperatures when it may be handled, stored or transported. Also, the Tm should be low enough so that it does not require a melt processing temperature to be used near the thermal decomposition temperature, to avoid degradation of the polymer during processing. Accordingly, for practical purposes, it is desirable for the polymer to have a Tm between about 100°C or the Tg (whichever is greater) and 250°C. More preferably, the Tm is at least about 5°C above steam sterilization temperature, which is typically about 120°C, but less than about 250°C. Still more preferably, for practical operation in a variety of thermal processing equipment, the Tm is desired to be about 20°C above steam sterilization temperature, that is, about 140°C, but less than about 200°C. The Tm is the temperature at which the crystalline domains in the polymer become disordered. The Tm is conveniently measured by DSC as the temperature at which there is an endothermic transition. Also, a crystalline polymer will yield a pattern of rings, spots, or arcs when analyzed by X-ray diffraction techniques.

In addition, the copolymer may include a combination of amorphous hydrophilic domain, and a crystalline hydrophobic domain. As the temperature of a semicrystalline polymer is increased through the glass transition region, the

polymer may be transformed from a glassy state to an elastomeric state. Further increases in temperature may transform the material to a liquid at its Tm. For this copolymer, the Tg of the amorphous domain and the Tm of the crystalline domain may be independently optimized to attain beneficial advantages associated with the morphological and rheological attributes imparted on the copolymer by each domain. Both the Tg and the Tm should be measurable by DSC.

Optimizing the Tg and Tm has certain advantages. Decreasing the Tg and Tm is expected to allow the polymer to be melt processed at lower temperatures. This, in turn, will improve processability by extending the processable lifetime of the polymers, especially those containing heat-activated latent crosslinking functional groups. Also, lowering the Tg is expected to minimize any crosslinking and/or curing of the polymer before it reaches a lens mold. The Tg and Tm may be varied by adjusting the amount of hydrophobic units in the polymer. Also, greater amounts of units that contain flexible (long) side chains will lower the Tg of the polymer. The degree of crystallinity in a polymer can be lowered by incorporating unsymmetrical units or side chains into the structure. In extreme cases of this embodiment, Tg values well below room temperature could be achieved. Poly(alkyl acrylates) can exhibit Tg values of about -50°C, and polysiloxanes can exhibit values of about -120°C. Incorporation of large amounts of units derived from alkyl acrylates or siloxanes into the overall material could be expected to decrease the Tg values below the temperature ranges specified above.

Preferably, a melt processed hydrogel block copolymer in accordance with this embodiment of the invention would comprise the block copolymer of this embodiment and a water content greater than about 35 weight percent of the hydrated lens. More preferably, the water content is between 35 weight percent and 90 weight percent. Even more preferably, the water content is between 40 weight percent and 80 weight percent. Desirably, the hydrogel block copolymer is optically clear and has a refractive index between about 1.3 and 1.5, preferably about 1.4.

In a fourth embodiment of the invention, a method is provided for making an ophthalmic lens comprising the steps of providing a polymer prepared by copolymerizing monomers comprising at least one hydrophilic monomer and at least one hydrophobic monomer without forming substantial amounts of chemical crosslinks (i.e., less than about 0.25 percent by weight solids of crosslinking agents, preferably about zero percent), introducing said polymer into a lens mold, raising the temperature of the polymer above its glass transition temperature and/or melting temperature, forming a lens, allowing said lens to solidify in the mold, removing the lens from the mold, and hydrating the lens in an aqueous solution to form a hydrogel lens having a water content of between about 35 and

90% by weight of the hydrated lens.

The temperature of the polymer is raised either before or after it is introduced into the mold, or in both steps, depending on the type of processing equipment used. For example, for typical thermoplastic injection molding equipment, the temperature of the polymer would be raised before injecting it into the mold. On the other hand, for compression molding, or vacuum-assisted molding, the polymer being shaped in a thin film, likely need not be heated up until introduced into the mold. Depending on whether the polymer is amorphous or crystalline, the temperature is raised above the Tg or the Tm of the polymer, respectively. The desirable ranges for the Tg or the Tm are consistent with the desirable ranges described above for the third embodiment of the invention.

Optionally, a mold release agent may be used to prevent the polymer from adhering to the mold. A typical mold release agent is a food-grade silicon. One skilled in the art may select any suitable mold release agent that is commercially available and compatible for use with the polymer materials of this invention.

In a fifth embodiment of the invention, a method is provided for molding an ophthalmic lens comprising the steps of copolymerizing a hydrophilic monomer and a hydrophobic monomer in the presence of a monomer with a latent reactive functional group to form a melt processable polymer, then introducing the

polymer into a mold, shaping said polymer into a lens, reacting said latent functional group to form covalently bonded crosslinks in the polymer, and hydrating the lens into a clear hydrogel having a water content greater than about 35 weight percent. The latent reaction of the functional groups may be performed during or after the shaping, and before, during or after the hydrating step. To obtain sufficient latent crosslinking it is desirable to use up to about 40% by weight of monomer having latent reactive functional groups. Preferably between about 2% and about 25% by weight of total monomer is used. More preferably, between about 5% and about 20% by weight of such monomer is used.

The amount of latent reactive functional group-containing units used to obtain a certain level of crosslink density in this embodiment of the invention is believed to be appreciably more than the amount of crosslinking agent used to obtain a like amount of crosslink density in a typical crosslinking polymerization reaction of conventional hydrogel polymers. For example, about 0.5 weight percent of EGDMA is typically used during the polymerization of HEMA-based hydrogels to obtain suitable crosslink densities. Likely, the low amounts of EGDMA needed is believed to be attributable to the more efficient mobility of crosslinking agents in the polymerization mixture compared to the limited mobility of pendant latent functional groups already tied to a fixed position in the polymer chain, or the limited access to crosslinking sites by pendant latent functional groups on monomer compounded with the uncrosslinked polymer of an alternative embodiment of the invention.

Because of the perceived inefficiency in crosslinking by this invention, however, it is expected that one skilled in the art may be able to determine whether a crosslinked hydrogel has been crosslinked by use of conventional crosslinking agents during polymerization, or crosslinked by use of the methods of this invention. Simple analytical measurements should be able to provide a ratio of crosslink density per units of functional crosslinking groups. It is believed that for conventionally crosslinked hydrogels, this ratio would be relatively high, and for

hydrogels crosslinked in accordance with this invention, the ratio would be relatively low.

In a sixth embodiment of the invention, an ophthalmic lens is made by a process that includes the steps of providing a solid crosslinkable polymer that is substantially uncrosslinked, introducing the polymer into a lens mold, thermally processing (i.e., heating) the polymer to allow it to solidify in the lens mold, crosslinking the polymer while it is in the shape of the lens mold, and removing the lens from the mold. The crosslinking may be initiated or activated by the heat provided when thermally processing the polymer. Also, a curing agent could be used to crosslink the polymer. The curing agent may be compounded with the polymer before it is introduced into the mold, or the curing agent may be applied to the polymer after it has been shaped into the form of a lens. Preferably, a mold release agent is applied to the lens mold before introducing the polymer into the mold. The mold release agent should prevent the lens from adhering to the mold surface, thereby allowing its easy removal. After removal, the lens may be hydrated to form a hydrogel polymer with more than 35 weight percent water content of the hydrated lens.

In one variant of this sixth embodiment, the polymer is placed in a heated mold along with an agent capable of abstracting a part of the polymer to form a reactive species. For example, a suitable peroxide may be formulated with the polymer. The heat decomposes the peroxide, which abstracts a hydrogen from the polymeric material leaving a polymer radical that continues to cause other reactions and crosslinking. If the polymer contains alkenyl groups, the peroxy radicals might add to the alkenyl groups and form polymer radicals. The polymer radicals can combine or add to other alkenyl groups and form crosslinks. Similar effects should result from the use of azides or photosensitive compounds.

In a seventh embodiment of this invention, a melt processable graft copolymer without substantial chemical crosslinks is provided. The uncrosslinked copolymer includes a backbone chain and grafted side chains that are self-

segregating into immiscible phases, or domains. The major volume component in the copolymer is preferably hydrophilic, and the minor volume component is perferably hydrophobic. At temperatures above at least about 80°C or higher, the domains containing the hydrophobic component sufficiently disassociate to allow the polymer to be thermally processed and formed into the desired shape of the ophthalmic device. The uncrosslinked copolymer has sufficient internal hydrophobic association within the hydrophobic domains to be dimensionally stable when hydrated into a hydrogel polymer, and subjected to temperatures up to at least about 60°C or higher.

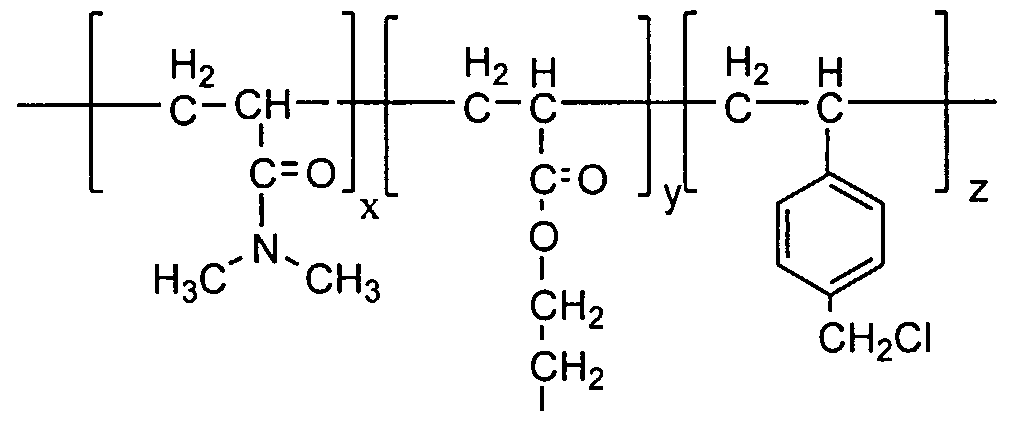

In an eighth embodiment of this invention, a melt processable polymer is provided. The polymer comprises units of formula I and formula II as illustrated below, wherein a unit is a moiety linked through at least two bonds to other units to form a polymer. The dissimilar units are not necessarily linked to each other as is suggested in the illustration. Also, more than one species according to each formula may be present in the polymer.

In formula I, R1 is H or CH3 and R2 is NR5R6 or OR7, wherein R5 is H, CH3, C1-C500 alkyloxy, C1-C500 alkenyloxy, CrC5oo alkylamino, or Cι-C50o alkenylamino; R6 is H, CH3, CH2CH3, Cι-C500 alkyloxy, -C500 alkenyloxy, Cr C500 alkylamino, or Cι-C50o alkenylamino; and R7 is H, CpCsoo alkyloxy, C1-C500 alkenyloxy, Cι-C50o alkylamino, or C1-C500 alkenylamino.

In formula II, R3 is H or CH3 and R4 is Cι-C500 alkyl, C6-C500 aryl, C(O)NR8R9 or C(O)OR10, wherein R8 is H, CH3, C,-C5o0 alkyl, or C6-C500 aryl; R9

is C3-C5o0 alkyl, C6-C50o aryl, polysiloxane, or a chain comprising units of formula II; and R10 is H, C C5o0 alkyl, -C500 fluoroalkoxy optionally containing a linking group of -(CH2CH2N(CH2CH3)SO2)-, or a chain comprising units of formula II. Alkyl is a hydrocarbon chain which may be straight, branched, or cyclic. Alkyloxy is an alkyl group having at least one oxygen (O) present as hydroxy group or ether linkage, for example -(CH2CH(OH)CH3) and -(CH2CH2OCH2CH3). Alkylamino is an alkyl group having at least one nitrogen (N) present as an amino or amido groups or linkages, for example -(CH2CH(NH2)CH3) and - (CH2CH2N(H)CH2CH3). Alkenyl is a hydrocarbon chain which may be straight, branched, or cyclic, containing at least one multiple carbon-carbon bond, but which is not aromatic. Alkenyloxy is an alkyl group having at least one oxygen (O) present as hydroxy group or ether linkage, for example - (CH2CH2OCH2CH=CHCH3). Alkenylamino is an alkyl group having at least one nitrogen (N) present as an amino or amido groups or linkages, for example - (CH2CH2N(H)CH2CH=CHCH3). Aryl is a hydrocarbon comprising at least one aromatic carbocyclic group, optionally containing alkyl or alkoxy substituents or linkages, optionally containing halogen substituents. Polysiloxane is comprised of at least one unit of -(Si(CH3)O)-, optionally containing alkyl or alkoxy linkages or end groups, for example -(CH2CH2CH2O(Si(CH3)2O)xC(CH3)3). Fluoroalkoxy is an alkyl group having at least one fluorine (F) present, for example -

(CH2CH2(CF2)7CF3).

In the unhydrated state, the polymer is melt processable at a temperature between about 50°C and 300°C. In the hydrated state, the polymer is a hydrogel that includes a water content between about 35% and about 90% by weight of the total hydrated hydrogel. Preferably, the water content is between about 40% and about 80% by weight. The polymer is optically transparent after it has been formed into an ophthalmic lens and hydrated.

To practice the various embodiments of this invention, one may prepare the polymer by polymerizing at least one hydrophilic monomer and at least one hydrophobic monomer that are copolymerizable. Such monomers are generally

copolymerizable by free-radical-initiated polymerization at the vinylic bond to create a single unbranched polymer backbone. Preferably, vinylic monomers having either hydrophilic or hydrophobic substituents are used. A polymer prepared completely from a hydrophilic monomer will exhibit hydrophilic characteristics, whereas a polymer prepared completely from a hydrophobic monomer will exhibit hydrophobic characteristics. Hydrophilicity is determined by measuring the contact angle formed between the polymer surface and a drop of water on the surface. The angle is measured with a goniometer. Preferably, a hydrophilic polymer has a contact angle of 0-90°, more preferably 0-45°. Preferably, a hydrophobic polymer has a contact angle of 91 - 180°, more preferably 135-180°.

Generally, for all the embodiments disclosed herein, the hydrophilic monomer may be selected from the group which includes, but is not limited to N,N-dimethyl acrylamide (DMA), 2-hydroxyl ethylmethacrylate (HEMA), 1,2- dihydroxy-ethyl methacrylate, 2-hydroxyl ethyl acrylate (2-HEA), 2-ethoxy ethyl methacrylate (EOEMA), N-vinylpyrrolidone (NVP), glycidyl methacrylate (GMA), glycidyl acrylate, glycerol monomethacrylate, glycerol monoacrylate, 2,3- dihydroxypropylmethacrylate (DHPMA), 2,3-dihydroxypropyl acrylate (DHPA), 3-hydroxypropylmethacrylate, 3-hydroxypropylacrylate, polyhydroxy sucryl alkyl acrylates, acrylamide, acrylic acid, methacrylic acid, 4-hydroxybutyl methacrylate,

4-hydroxybutyl acrylate, N-(2-hydroxypropyl) methacrylamide, N- methylmethacrylamide, poly(ethyleneglycol)monomethacrylate, poly(ethylene glycol)monomethyl ethermonomethacryl, N-vinyl-N-methyl acetamide, vinylmethyl sulfone, N-acryloylmorpholine, N-methyacryloylmorpholine, N- methacryloylpiperidine, N-alkyl acryloyl amide, acid functional monomers (and salts, thereof), and the like, and combinations thereof. More than one hydrophilic monomer may be incorporated into the polymerization mixture.

The preferred hydrophilic monomers are DMA, HEMA, and NVP. The more preferred hydrophilic monomers are: DMA, and HEMA. If too little hydrophilic monomer is used, then the resulting polymer may possess insufficient water content and stiffness, the lens may not be compatible

with eye tissue, and the oxygen permeability may drop. If too much hydrophilic monomer is used, then the resulting polymer may not form a distinct hydrogel. In the preferred embodiment, the hydrophilic monomer is used in the amount between about 20% and about 90% by weight of the total monomeric mixture, preferably in the amount between about 35% and about 80% by weight, and more preferably in the amount between about 45% and about 65% by weight. The exact amount depends on the selected monomeric mixture, processing conditions, desired lens characteristics, and molecular weights of the monomers. The precise amounts of hydrophilic monomers used may be optimized by one of ordinary skill in the art to obtain the desired polymer qualities without undue experimentation based on the teachings contained herein.

Generally, for all embodiments disclosed herein, the hydrophobic monomers are selected from a broad range of monomers that are copolymerizable with the desired hydrophilic monomer. For example, the hydrophilic monomers and hydrophobic monomers may both be vinylic monomers. Such monomers are generally copolymerizable by free-radical-initiated polymerization at the vinylic bond to create a single unbranched polymer backbone. Examples of suitable hydrophobic monomers for use in this invention include, but are not limited to, methylmethacrylate and other alkylated alkyl acrylates, styrene, alkyl substituted styrenes, such as t-butyl styrene, substituted acrylamides and methacrylamides such as: N-isopropylacrylamide (N-IPA), N-(t-butyl)acrylamide, N-(n- octyl)acrylamide, N-(n-octadecyl)acrylamide, N-benzylmethacrylamide, N- diphenylmethacrylamide, N,N-diphenylmethacrylamide and the like, and combinations thereof.

Preferably, the hydrophilic monomer is copolymerized with a hydrophobic fluorinated monomer. Such fluorinated monomers are preferred because of their relatively stronger hydrophobicity compared to non- fluorinated hydrophobic monomers. Preferred fluorinated monomers include 2-(N-ethylperfluorooctane- sulfonamido)ethylacrylate (FX-13), 2-(N-ethylperfluorooctane- sulfonamido)ethylmethacrylate (FX-14), hexafiuoro isopropyl acrylate,

lH,lH,2H,2H-heptadeca fluorodecylacrylate, pentafluoro styrene, trifluoromethyl styrene, fluorostyrene, pentafluoro acrylate, pentafluoro methacrylate, and the like. The preferred hydrophobic monomers are FX-13, FX-14 and 1H,1H,2H,2H- heptadeca fluorodecylacrylate. The most preferred hydrophobic monomers are FX-13 and FX-14.

Also, the polymer may be prepared by copolymerizing a hydrophilic monomer with both a fluorinated hydrophobic monomer and a non- fluorinated hydrophobic monomer. But, it is preferred that the fluorinated hydrophobic monomers are not fluorinated silicon-containing monomer or fluorinated polysiloxane monomer. Such monomers are often used for making materials for rigid gas permeable lenses that often require surface treatments to obtain wetting qualities that are compatible with the cornea. Therefore, such qualities are not favorably disposed on hydrogel materials.

Further, amphiphilic monomers may also be used to prepare the polymer. Such monomers have both hydrophilic and hydrophobic characteristics on different portions of the molecule, and are known in the art. Depending upon which characteristic dominates, these monomers may be considered to be either a hydrophilic monomer or hydrophobic monomer.

The total sum of hydrophobic monomers, or monomers with hydrophobic characteristics, are desirably used in such amounts as to obtain a sufficient degree of association between the resulting hydrophobic units in the polymer chains. The resulting "blocky copolymers" or "block copolymers" have mechanical stability and dimensional stability at storage and use temperatures, and preferably at steam sterilization temperatures. The terms "blocky copolymer" or "block copolymer," unless stated otherwise, are used herein to mean a copolymer with a degree of aggregation of the hydrophobic regions sufficient to form distinct phases apart from the hydrophilic regions to a much greater extent than expected to be found in polymers having a random statistical distribution, in a strict mathematical sense, of a like ratio of hydrophobic and hydrophilic units. Use temperatures are approximately the surface temperature of the human eye, or about 35°C. Storage temperatures may typically range from about 0°C to 50°C, and may be for a

relatively unlimited duration of months, or a few years, and may entail large temperature swings. Heat or steam sterilization temperature is about 120°C, and is for a relatively short duration of about 30 minutes.

Sufficient amounts of hydrophobic monomers are used to achieve transitory pseudo-crosslinking properties. In other words, the hydrophobic units derived from hydrophobic monomers, distributed throughout the polymer have the ability to cause the characteristically hydrophobic portions of the polymer to aggregate and, by internal hydrophobic association, to hold the material together in the absence of covalent bond crosslinks. This domain may be either amorphous or crystalline in structure. The need for this aggregation is lessened as more covalently bonded crosslinking is employed in the material. If too much hydrophobic monomer is used, then lens made from the hydrogel may not be compatible with eye tissue, or segregation, cloudiness, and leatherlike characteristics may occur. If too little hydrophobic monomer is used, then the lens made from the hydrogel may not have sufficient strength, or the polymer may dissolve and the hydrogel not form at all when the dry polymer is hydrated.

In the preferred embodiments of the invention, the hydrophobic monomer is used in the amount between about 5% and about 80% by weight of the starting monomeric mixture, preferably in the amount between about 15% and about 50% by weight, and more preferably between about 20 and 40% by weight. The exact amount depends on the selected monomeric mixture, processing conditions, desired lens characteristics, and molecular weights of the monomers used. The precise amounts of hydrophobic monomers used may be optimized by one of ordinary skill in the art to obtain the desired polymer qualities without undue experimentation based on the teachings contained herein.

By using larger amounts of the same hydrophobic monomer, the water content of the resulting hydrated polymers may be lowered. Alternatively, amounts of additional different hydrophobic monomers may be used, such as methyl methacrylate and N-isopropyl acrylamide, to control water uptake in the resulting swollen hydrogel polymer.

Also, as noted above, the Tm and Tg of the polymer may be lowered by incorporating greater amounts of hydrophobic units or units with flexible side chains or units with unsymmetrical structure into the polymer. It should also be possible to alter Tg and/or Tm by varying the structure of the hydrophilic units. The following list of monomers are examples of some, but not all, of the monomers that are useful to lower the Tg and/or Tm of the polymer upon conversion into units: methyl acrylate, ethyl acrylate, propyl acrylate, butyl acrylate, 2-methoxyethyl acrylate, 2-ethoxyethyl acrylate, 2-propoxyethyl acrylate, 2-butoxyethyl acrylate, pentyl acrylate, hexyl acrylate, hexadecyl acrylate, octadecyl acrylate, poly(ethylene glycol) methyl ether acrylate, poly(ethylene glycol) alkyl ether acrylates, poly(ethylene glycol) phenyl ether acrylates, poly(ethylene glycol) mono acrylate, poly(propylene glycol) methyl ether acrylate, poly(propylene glycol) alkyl ether acrylates, poly(propylene glycol), poly(propylene glycol) mono acrylate, and perfluoro alkyl ether acrylates. In addition, corresponding methacrylate versions of these acrylate monomers could also be used. However, acrylates are more desirable, because their resulting polymers are known to have lower Tg values than the polymers formed from their corresponding methacrylates.

The polymer may also be prepared using small amounts of one or more high refractive index monomers to obtain a material which, when hydrated, will have a desirable refractive index of about 1.4. The presence of the resulting high refractive index units in a polymer can increase the refractive index of that polymer relative to a similar polymer without high refractive index units. High refractive index monomers include pentabromophenyl methacrylate, pentachlorophenyl methacrylate, 2,4,6-tribromophenyl acrylate, 2-phenoxyethyl acrylate, 2-phenoxyethyl methacrylate, phenyl methacrylate, phenyl acrylate, benzyl methacrylate, benzyl acrylate, and the like. In the case when fluorinated hydrophobic monomers are used, these aromatic monomers may be necessary to offset a possible reduction in refractive index of the resulting polymer caused by the presence of the fluorinated hydrophobic units.

In addition, one or more units comprising UV absorbing functional groups may be incoφorated into the polymer. Such groups include, but are not limited to, 2-hydroxy benzophenone groups, benzotriazole groups, and combinations thereof. The presence of UV absorbing units in a polymer results in that polymer having UV transmittance lower than that of a polymer not containing UV absorbing units.

The polymerization technique is not critical to this invention. Solution, bulk or emulsion polymerization methods may be used. Living radical (or controlled radical) polymerization techniques can be used to control block sizes if desired. Chain transfer agents, other than the reaction solvent, may be used to control molecular weight. Most any free radical initiator may be used. Preferred initiators are Vazo®64 (also known as AIBN) or Vazo®52, which are commercially availble from E.I. du Pont de Nemours & Co., Wilmington, Delaware, USA. Alternatively, the polymer system may be designed to rely on other types of initiation and polymerization, such as for example, thermal initiation, photoinitiation, cationic or anionic polymerization.

As noted above, at least one embodiment of this invention includes a polymer with pendant functional groups capable of latent crosslinking. Indeed, the latent crosslinking of the polymer may be combined with most embodiments of this invention by a number of means. In general, covalently bonded crosslinking in a material that has been polymerized can be brought about by (1) vulcanization; (2) free radical reactions caused by ionizing radiations; (3) actinic radiation induced reactions involving photosensitive functional groups; or (4) chemical reactions involving labile functional groups. The particular means selected depends on the chemical system and polymerization methods used to make the polymer. No matter which crosslinking means is selected, the crosslinkable functionality must be latent, that is, it cannot be activated during the polymerization process, but must be initiated during or after thermoforming the polymer into the desired shape of the ophthalmic lens. Of course, the crosslinking means selected should not detrimentally alter the chemical or physical properties of the lens.

Photocrosslinking is one of the preferred means for latent crosslinking of the polymer after it has been melt processed into its desired shape. The photocrosslinkers, or photoinitiators, or photosensitive chromophores, may be incoφorated into the polymer in several ways. For example, vinylic monomers having photosensitive functional groups may be readily incoφorated into a mixture comprised of other vinylic monomers during the initial polymerization process. Alternatively, the photosensitive chromophores may be compounded or blended into a polymer for subsequent crosslinking. Benzophenones are one such class of photosensitive chromophores that may be useful for crosslinking the polymer. Some examples of polymerizable latent photo-crosslinkers are as follows: 4-(2-acryloxyethoxy)-2-hydroxybenzophenone; 1 ,3-bis(4-benzoy-3- hydroxyphenoxy)-2-propyl acrylate (cinnamyl methacrylate); and 2-cinnamoyloxyethyl acrylate. Other latent photo-crosslinkers that can be used in the present invention are described in J. Macromol. Sci-Chem., A28(9), pp. 925-947 (1991) and include: l-2-diphenyl-2-hydroxy-2-(4-vinylphenyl)ethan-

1 -one; 1 -methoxy- 1 ,2-diphenyl-2-(4-vinylphenyl)ethan-2-ol; 1 , 1 -dimethoxy- 1 ,2- diphenyl-2-(4-vinylphenyl)ethan- 1 -one; 1 ,2-diphenyl-2-hydroxy-2-(4- vinylphenyl)ethan- 1 -one; 1 , 1 -dimethoxy- 1 -phenyl-2-(4-vinylphenyl)ethan-2-ol; 1 - phenyl-2-hydroxy-2-(4-vinylphenyl)ethan- 1 -one; 2-Hydroxy-2-methyl- 1 -(4- vinylphenyl)propan- 1 -one; 2-Hydroxy-2-methyl- 1 -(4-vinylphenyl)butan- 1 -one; and 2-methyl-2-methoxy-l-(4-vinylphenyl)propan-l-one. After a melt processing step, the lens can be subjected to UV radiation that cures the polymer, i.e., causes the photosensitive functional groups to react and induce crosslinking of the polymer. This UV curing may be performed with the polymer in a dry or wet state, either before, during or after hydration of the lens.

As an alternative to incoφorating photoinitiators into the polymer during the polymerization step, it is proposed that melt processable polymers be compounded just prior to or during the melt processing step with the photoinitiators such as those listed below. These photoinitiators could induce crosslinking after molding is complete. It is possible to photocrosslink either non- hydrated polymer or the corresponding hydrated polymer. The photoinitiators

listed below may be used in this invention and are commercially available from Ciba Specialty Chemicals Additives Division, Tarrytown, New York, USA. The commercial designation is in parentheses following the chemical name of each compound: 1-hydroxycyclohexyl phenyl ketone (Irgacure® 184); 2,2-dimethoxy- 2-phenylacetophenone (Irgacure® 651); 2-hydroxy-2-methyl- 1 -phenyl propanl- one (Darocur® 1173); 1-hydroxycyclohexyl phenyl ketone (Irgacure® 500); 2- methyl- 1 -[4-(methylthio)phenyl-2-moφholino]propan- 1 -one (Irgacure® 907); 2,4,6-trimethyl benzoyl diphenyl phosphineoxide (Darocur® 4265); 4-(2- hydroxyethoxy)phenyl-(2-hydroxy propyl)ketone (Irgacure® 2959); 2-benzyl-2- N,N-dimethylamino- 1 -(4-moφholinophenyl) 1 -butanone (η 5-2,4-cyclopentadien- l-yl)[(l, 2, 3,4,5,6-η)-(l -methyl ethyl)benzen]iron(+) hexafluorophosphate(l) (Irgacure® 369); 25% bis(2,6-dimethoxybenzoyl)-2,4,4-trimethylpentyl phosphine oxide plus 75% 2-hydroxy-2-methyl-l-phenyl-propan-l-one (Irgacure® 261); and bis((η5-2,4-cyclopentadien-l-yl)bis[2,6-difluoro-3-(lH-pyrrol-l- yl)phenyl]titanium (Irgacure® 784 DC).

Also, it is believed that the photoinitiators may be incoφorated into the polymer of the present invention after it has been shaped into the form of an ophthalmic lens during the hydration step of the process. The hydration solution may contain water soluble photoinitiators that would be incoφorated into the polymer as it uptakes water and swells into a hydrogel. For example, it might be possible to induce crosslinking by soaking the polymers in hydrogen peroxide solution. Crosslinking reactions could be promoted by UV light or heat. Alternatively, a reducing agent such as a ferrous salt (e.g., Iron(II) acetate, Iron(II) chloride, Iron(II) bromide) could be added to peroxide-containing hydration solution.

Another preferred means for latent crosslinking of the polymer is the secondary reaction of labile functional groups. For example, vinylic monomers having secondary reactive functional groups may be readily incoφorated into a mixture comprised of other vinylic monomers during the polymerization process. Peroxy, isocyanato, epoxy, hydroxyl, anhydride and more particularly N-

hydroxymethyl functional groups are capable of latent crosslinking activated by the heat used during the thermoforming step.

As noted above, epoxy containing units may be incoφorated into the polymer to provide latent crosslinking functionality. Epoxy-containing monomers may be polymerized by free radical polymerization, and so may be copolymerized when making the polymers of this invention. These monomers that contain epoxy functionality include, but are not limited to: glycidyl methacrylate, glycidyl methacrylate plus glycerol monomethacrylate*, glycidyl acrylate, glycerol monovinylbenzyl ether, glycerol monovinylether, glycidyl acrylate plus glycerol monoacrylate*, glycidyl vinylbenzyl ether, glycidyl vinyl ether, allylglycidyl ether, l,2-epoxy-3-butene, l,2-epoxy-4-pentene, and l,2-epoxy-5-hexene, etc. (* denotes that glycerol monomethacrylate or glycerol monoacrylate should promote crosslinking reactions of epoxy groups). Most epoxy (or glycidyl) monomers might contain diol impurities. The diol impurities (if present) are expected to promote/enhance crosslinking reactions.

Further, as noted above, functionalized acrylamides and methacrylamides, such as monomers listed below, are capable of providing for latent crosslinking, and may be incoφorated into the polymerization mixture of the present invention. These monomers include, but are not limited to: acrylamide, N- (hydroxymethyl)acrylamide, N-(hydroxymethyl)methacrylamide, N-(iso- butoxymethyl)acrylamide, N-(iso-butoxymethyl)methacrylamide, N-(2- hydroxypopyl)methacrylamide, and N-(2-hydroxypropyl)acrylamide.

Also, as noted above, polymerizable isocyanates are useful for providing units with latent crosslinking groups. These isocyanate monomers include, for example, at least 2-isocyanatamethacrylate, and α,α-dimethyl-3- isopropenylbenzyl isocyanate.

Likewise, as noted above anhydrides are useful for latent crosslinking. Anhydride-containing monomers include, for example, at least 4- methacryloxyethyl trimellitic anhydride, and itaconic anhydride.

Moreover, monomers, such as those listed below, could be used to introduce units functionalized with hydroxy groups into polymers. Crosslinking of hydroxy-containing groups within the polymer can be activated by treating the polymers with diisocyanates (one could also use tri-, tetra-, etc., isocyanates), diepoxides (or tri-, tetra, etc., epoxides) or anhydrides (or dianhydrides). The hydroxy group-containing monomers that may be used include, for example, at least 2-hydroxyethyl methacrylate, 2-hydroxyethyl acrylate, 3-hydroxypropyl methacrylate, 3-hydroxypropyl acrylate, 4-hydroxybutyl methacrylate, 4- hydroxybutyl acrylate, and the like, glycerol monomethacrylate, glycerol monoacrylate, vinyl benzyl alcohol, various isomers thereof, glycerol methacrylate, and other functionally similar generalized structures.

In addition, the polymer may be compounded with materials such as diols, triols or diamines to enhance the crosslinking of those functional groups. The curing agents for polymers containing pendant hydroxy groups include, for example, at least 1,6-hexamethylenediisocyanate, toluenediisocyanate, methylenediphenyl diisocyanate, 4,4"-methylenebis(N,N-diglycidylaniline), N,N-diglycidylaniline, N,N-diglycidylaniline, diglycidyl 1,2- cyclohexanedicarboxylate, diglycolic anhydride, ethylene glycol diglycidyl ether, 3 ,4-epoxycyclohexylmethy 1 3 ,4-epoxycyclohexanecarboxylate, glycerol triglycidyl ether, succinic anhydride, phthalic anhydride, and pyromellitic anhydride. The possible curing agents for epoxy- and isocyanate-containing polymers include, for example, at least ethylene glycol, glycerol, 1 ,2-propanediol, 1,3-propanediol, 1 ,4-butanediol, 1,2-butanediol, 1 ,3 -butanediol, pentane diols (and various isomers thereof), hexane diols (and various isomers thereof), 1 ,4- diaminobutane, 1,3-diaminobutane, butylamine (and various isomers thereof), bisphenol-A, ethanol amine, 3-amino-l-propanol, l-amino-2-propanol, 3-amino-l- butanol, 4,4"-methylenedianiline, water, and sodium hydroxide. Also, those curing agents may be used to treat the lens made after the thermoforming process step. In addition, the crosslinking may be carried out by reactive processing of the polymer with a number of reagents. For example, benzyl alcohol groups could

be incoφorated into the polymer by using vinyl benzyl alcohol in the polymerization step. This hydroxyl group may be reacted with diisocyanates, diepoxides, dianhydrides, or anhydrides, for example, during an injection molding process. If needed, additional heat or UV radiation may be applied to initiate the reaction to carry out the crosslinking.

Another similar example of reactive latent crosslinking would involve an alkenyl (i.e., olefinically unsaturated) pendant functional group on the polymer. Pendant alkenyl functionality can be incoφorated into copolymers by copolymerizations involving monomers such as dicyclopentenyl methacrylate, dicyclopentenyloxyethyl methacrylate, dicyclopentenyl acrylate and dicyclopentenyloxyethyl acrylate. The double bond in the dicyclopentenyl group does not participate in polymerization, but can be post-reacted (e.g., by oxidative crosslinking).

For latent crosslinking of an alkenyl-containing polymer during a molding or shaping process, the polymer is first compounded with a peroxide to induce crosslinking of the polymer. Several types of peroxy compounds could be used to promote crosslinking. Some examples are given below.

• Acyl peroxides such as diacetyl peroxide and dibenzoyl peroxide

• Alkyl peroxides such as dicumylperoxide and di- tertiarybutylperoxide

• Hydroperoxides such as t-butyl hydroperoxide and cumyl hydroperoxide

• Peresters such as t-butyl perbenzoate, t-butyl peracetate and Lupersol® 256 (2,5-dimethyl-2,5-di-(2-ethylhexanoyl peroxyhexane)) commercially available from Elf-Atochem North

America, Inc., Philadelphia, PA, USA

• Diperoxycarbonates such as OO-t-butyl O-isopropyl monoperoxycarbonate

• Di-Peroxyketals such as Ethyl-3,3-di(t-butylperoxy)butyrate and 2,2-di-(t-butylperoxy)butane

Some of these above-listed peroxy compounds are described in Polymer Engineering and Science, July, 1979, Vol. 19, No. 9, pp. 597-606.

Similarly, rather than activating the latent crosslinking reaction with heat, the crosslinking reaction may be activated by moisture, acid or base catalysis, or combinations thereof. To allow for moisture-activated crosslinking, incoφorating one or more of the following into the polymer is desirable: alkoxysilane, silanol, acetoxysilane, silanes, or halosilane groups. Alkoxysilane, acetoxysilane, silanes, or halosilane form silanols upon exposure to moisture. The silanols react with each other to form siloxane bonds. Therefore, polymer chains containing pendant silanol groups (or precursors) can combine to form crosslinks through the formation of siloxane linkages. Accordingly, polymers prepared by copolymerizing such siloxane-functionalized monomers may be melt processed before the crosslinks are formed. Being moisture activated, the crosslinks would form during hydration of the polymer.

Crosslinking reactions involving organosilicon functional groups could also occur by non-hydrolytic processes. Halosilanes can form siloxane bonds by being exposed to alkoxy silane, metal oxides (e.g., calcium calcium oxide, magnesium oxide, zinc oxide, copper oxide, etc.) and alcohol + carboxylic acid. Alkoxysilanes can combine with each other to form siloxane bonds. Crosslinking and curing of silicones is well known (see W. Noll, Chemistry and Technology of Silicones, Academic Press, Inc., London). In addition, alkoxysilanes also form siloxane bonds when exposed to silanols, acetoxysilanes, carboxylic acids, and acids such as HCl. Hydrolytic and non-hydrolytic reactions in which siloxane bonds are formed could be used to introduce crosslinks into melt processed contact lens materials. If moisture or other crosslinking initiators were mixed with polymers containing silanol (or silanol precursors), then crosslinking reactions could be initiated and gellation might occur in the lens mold under appropriate processing conditions. Alternatively, placing the melt-processed lens in hydrating solution could induce gellation. Catalysts could be added to the hydration solution if needed.

Possible organosilicon monomers for introducing moisture-activated crosslinks into a polymer by way of copolymerization with other monomers are given below. The monomers contain carbon-carbon double bonds that participate

in initial polymerization reactions and silicon-containing groups that can be converted siloxane bonds. Examples of these monomers include, but are not limited to: methacryloxy ethyltrimethoxysilane, methacryloxyethylmethyldimethoxysilane, methacryloxyethyldimethyl- methoxysilane, methacryloxyethyltriethoxysilane, methacryloxyethylmethyl- diethoxysilane, methacryloxyethyldimethylethoxysilane, methacryloxyethyltrichlorosilane, methacryloxypropyltrimethoxysilane, methacryloxy propylmethyldimethoxysilane, methacryloxy propyldimethylmethoxysilane, methacryloxy propyltriethoxysilane, methacryloxy propylmethyldiethoxysilane, methacryloxy propyldimethylethoxysilane, methacryloxy propyltrichlorosilane, styrylethyltrimethoxysilane, and 3- (N-styrlmethyl-2-aminoethylamino)propyltrimethoxysilane hydrochloride.

To carry out the latent crosslinking of the polymer, a specific thermoforming process may be selected to facilitate that crosslinking. For example, if only heat is needed to activate the crosslinking, thermal compression molding of the uncrosslinked polymer film may be the most efficient processing technique. On the other hand, if it is necessary to compound the uncrosslinked polymer with a curing agent, then a thermoplastic injection molding process may be suitable. Likewise, the uncrosslinked polymer could be dissolved in an organic solvent and mixed with the curing agent in a typical reaction injection molding

(RIM) process.

A polymer for this application, whether undergoing latent crosslinking or not, should preferably possess, in addition to the usual properties of contact lenses, transparency, oxygen transmissibility, mechanical and geometric integrity, structural and dimensional stability during sterilization conditions, biocompatibility, softness (comfort), nontoxicity, etc. Also, for use in injection molding equipment, the polymer may require special properties, such as low viscosity at elevated processing temperatures, thermal stability of the material at high temperature without degradation, and short cycle time implying little or no chemical reactions during processing.

Without being bound by any theory of operation, it is believed that suitable polymer systems in accordance with at least one embodiment of this invention will aggregate in a certain way at room temperature. By heating the polymer up to elevated processing temperatures, those aggregates will melt out to provide a flowable and processable thermoplastic material. When the polymer cools to room temperature, the domains will reaggregate, and will maintain those aggegrations when the lens formed of that polymer is hydrated to a swollen gel state. Those aggregates may be crystalline domains with high melting temperature, Tm, amoφhous domains with high glass transition temperature, Tg, highly hydrophobic domains, or domains with high degree of ionic interactions or chain entanglements. These domains remain structurally stable at low temperatures because of the cohesive forces between the segments of the polymers in those domains. For example, high Tg blocks are known to have high transition temperatures, resulting in strong cohesive force at temperatures below Tg. This may impart enough structural integrity to a hydrogel to withstand osmotic forces tending to pull the polymers apart.

Likewise, hydrophobic blocks may form due to the immiscibility of long sequences of hydrophobic units in a copolymer with a majority of hydrophilic units. Fluorinated units, in particular, are more immiscible with the hydrophilic domain than are their corresponding hydrocarbon analogs, thereby enhancing the cohesive forces, or hydrophobic association, within the hydrophobic blocks. Thus, dimensional stability of the hydrated hydrogel may be enhanced with lesser amounts of fluorinated hydrophobic units as compared to their hydrocarbon counteφarts incoφorated into the polymer. It is believed that certain preferred embodiments of the present invention take advantage of the transitory, virtual, physical, thermally-reversible, non- covalently bonded pseudo-crosslinks in the aggregate elements. These aggregates hold the polymer together at low temperature, and under hydrated conditions, yet can be melted out at elevated temperatures to permit thermoforming. In contrast, prior art polymers for contact lenses typically relied upon the formation of

covalently bonded crosslinks during polymerization that are permanent and do not allow the polymers to be thermoformed into molded shapes.

In addition, it is believed that this invention may take the form of several alternate embodiments. In one alternate embodiment, a block copolymer is employed in which the blocks are self segregating into immiscible phases. The volume fraction of the major component consists of blocks of known hydrophilic material: e.g. poly(2-hydroxy ethyl methacrylate), polyethylene oxide, polyacrylamide, polystyrene-maleic acid copolymer, and Zwitterionic phosphate containing units as described in U.S. Patent No. 5,658,561 to Nakabayashi et al. Such materials may be polar, cationic, anionic, or Zwitterionic and have only their hydrophilic nature in common. The minor component consists of hard hydrophobic blocks having high glass transition temperature (Tg) or high melting temperature (Tm) relative to the sterilization or use temperature, but low Tg or Tm compared to the degradation temperature. Such high temperature hard blocks are exemplified by various types of nylons, perfluoroalkyl chains, perfluoroalkyl ether chains, polyacrylonitrile units, poly(ethyleneterephthalate) units, polyvinylcarbazole units, suitable polymeric liquid crystalline blocks of all chemistries, etc.

The types of linkage between the hard and soft blocks is not critical to the invention. However, the domain size of the hard blocks must be small enough so as not to provoke significant light scattering, and thereby obtain optical quality light transmission. The block copolymer can be of any moφhology enabling this to occur, i.e. di-block, tri-block or multi-block, all of which are known. Importantly, optical clarity must be attained in any case. Therefore, it is believed that the domain size of the hydrophobic blocks should be smaller than the wavelength of visible light, that is on the order of 100 nm or smaller. Alternatively, if the hydrophilic and hydrophobic blocks exhibit substantially similar refractive indices, the domain size of the hydrophobic blocks may be larger than 100 nm, yet optical clarity can be maintained. When processing these polymers in injection molding equipment, one would expect the polymer to have the following properties. At high temperatures,

the polymer flows as expected according to the rheological behavior experienced by block copolymers. The blocks melt out at elevated temperatures to provide a thermoformable material. Preferably, there is no chemical reaction taking place during lens formation. Cycle time is short due to the thin walled nature of the ophthalmic lens and the fast cure time of the material. After molding and during solidification, the heterogeneous structure forms and is stable at use and sterilization temperatures. The structure is also stable under the osmotic stresses generated in hydrating the hydrophilic portion of the system. The hydration and solidification process must produce reproducible mechanical and optical outcomes. Crosslinking must be controlled so as to not change the flow characteristics of the material significantly. Once the lens is formed, any crosslinking should have reproducible effects on the lens and optics.

A second alternate form of the present invention relies on the fact that moφhologies of block copolymers are known to form discrete patterns as they are constrained by thermodynamics and chain statistics and entropy. One of the well- recognized patterns is a closed packed (possibly hexagonal, but not necessarily so) arrangement of cylinders embedded in a matrix phase. The cylinders will probably be the minority component, that is, less than about 30 percent. At about 70 percent, phase inversion will occur. The moφhology of the intermediate concentrations remains to be seen. The ability of rods to be aligned by external fields is well known. Extensional flow fields are particularly effective. The orientation of a rod moφhology in the X- Y plane along a principal director axis would in general provide a highly anisotropic and birefringent film. Rod size must be sufficiently small such as to avoid light scattering, that is, not to degrade visible light transmission. A lens such as described would represent an innovative bifocal for simultaneous vision.

A third alternate form of the present invention achieves short processing cycle time through the use of polyurethane chemistry in which, for example, isocyanates react with hydrophilic macromonomers in a steel mold cavity to directly form a lens. Such chemistry is known to be rapid and the cycle time will be further reduced by the use of the macromonomers. Urethane linkages are

known to be good transmitters of oxygen so a reduced water content may be applicable. Previous workers in the area of polyurethane lenses lamented the lack of mechanical strength, but this is now not perceived as an issue in the era of disposable lenses. The process described above can utilize the RIM (Reaction Injection Molding) technique in which liquid reactive components are injected into a mold for reaction to form the final part. Efficient manufacturing processes may take advantage of multiple RIM molds placed on a rotating table, i.e. "Lazy Susan" device.

The above embodiments of the present invention are suited to take advantage of high-speed, high-volume, screw extrusion thermoplastic injection molding equipment, thermal stamping, vacuum-assisted thermal molding, as well as RIM injection molding equipment. The direct molding or injection molding of a lens requires some attention to the placement of the gates and possible discomfort to the lens-wearer due to the vestige in the final lens. There are a number of advanced approaches which can be developed to obviate this effect.

Hot runner molding is well known to process technologists. Additional effects which can be called upon to minimize gate effects are rotating or vibrating the mold halves with respect to each other while the lens body is in the fluid state. The application of an ultrasonic beam to the gate area is an extension of the above mentioned concept. RIM technology may be employed so as to reduce or eliminate the vestiges of a gate.

In addition, other molding processes may be used to take advantage of the thermoformable or melt-processable polymers made in accordance with this invention. Such processes include resin transfer molding, compression molding, extrusion, vacuum assisted plug thermoforming, and stamped thermoforming.

Those processes may be adapted by those skilled in the art to manufacture ophthalmic lenses.

The methods of this invention also include a method for making a hydrogel contact lens comprising forming a polymeric material into a thin film, introducing the film between heated mold halves, closing the mold halves onto the film for a sufficient period of time, with a sufficient force, and with a sufficient amount of

heat for the film to form into the shape of a contact lens precursor, opening the mold halves, removing the lens precursor from the mold halves, and hydrating the lens precursor to form a hydrogel contact lens.

Another embodiment of the invention includes a method for making a hydrogel contact lens comprising applying heat to melt a polymeric material; injecting the melted polymer into a cavity of a lens mold; allowing the melted polymer to solidify in the lens mold for a sufficient period to retain the shape of the lens mold; opening the lens mold; removing the lens from the mold halves; and hydrating the lens precursor to form a hydrogel contact lens. Also, the lens precursor can be hydrated before removing from the mold halves.

Another embodiment of the invention includes a method for making a hydrogel contact lens comprising dissolving a polymeric material in an organic solvent; mixing said polymeric material with a curing agent; dispensing said mixture of polymer and agent into the cavity of a lens mold; allowing the mixture to remain in the cavity for a crosslinking reaction to occur such that the reacted mixture solidifies in the shape of the lens mold; opening the lens mold; removing the lens from the mold halves; and hydrating the lens to form a hydrogel contact lens. Also, the lens can be hydrated before removing from the mold halves.

The above processes have the advantage of using re-useable lens molds. Thus, the present cost disadvantage of single-use plastic lens molds is eliminated.

These re-useable molds may be comprised of metal or a transparent durable material such as quartz. The transparent molds would be advantageous for processes requiring UV curing of the polymer in the mold.

The methods for making ophthalmic lenses of the present invention may be modified by those skilled in the art to allow for the incoφoration of additives into or onto the lenses. These additives may include colorants and handling tints, printed indicia, wetting agents and surface treatments, pharmaceutical or other active ingredients. Also, the additive may be a plasticizer that makes processing of the polymer easier. The plasticizer may be reactive, such as glycerol, or non- reactive, such as phthalate esters. Examples of possible phthalate esters are di(2-

ethylhexyl)phthalate and diethylphthalate. Depending on the nature of the additive, it may be added during the initial polymerization, added during the melt processing, added before, during or after the hydration of the polymer, added by dissolving with the polymer, or compounded or blended with dry ground polymer particles.

Accordingly, one of the advantages of this invention may be found in the adaptability of manufacturing methods to the particular designed characteristics of the polymer and processing constraints of the ingredients of the finished ophthalmic lens. Thus, one of a variety of melt processing methods may be selected depending on the constraints, such as a temperature limit, established by a particular additive desired to be incoφorated into the lens.

One skilled in the art may appreciate that this invention may have broader application than for use in making ophthalmic devices. For example, hydrogel polymers made in accordance with this invention, or the methods of this invention, may be useful for making thin film wound dressings, subcutaneous drug delivery devices, or coatings for catheters (via coextrusion).

The following examples illustrate just a few embodiments in accordance with this invention, and are not intended to limit the invention. Unless otherwise expressly stated, amounts are by weight, percentages are by weight percentage, and temperatures are by degrees Celsius.

Examples

Several new polymers have been synthesized, and characterized. These evaluations are summarized in Table 1. The polymers have been prepared from N,N-dimethylacrylamide and one or more of the following: a perfluoroacrylate known as FX-13, a perfluoromethacrylate known as FX-14, N-isopropyl- acrylamide (N-IPA) and methylmethacrylate (MMA). It has been possible to melt-press clear films from polymers made from these monomers. These films were clear and formed hydrogels with water contents ranging from about 55 to about 90 weight percent by total weight of the hydrated lens. The oxygen

permeability, i.e., Dk values for these materials ranged from about 45 to 31 barrers.

The dehydration behaviors of the new polymers for Examples 1 through 4 were tested. The dehydration behavior of these materials is similar to that of netrafilcon contact lenses manufactured and sold by Wesley-Jessen Coφ.,

Des Plaines, Illinois, USA under the trademark Gentle Touch™.

Characteristics of some of the moldable materials are given in Table 1. Although none of the hydrogel polymers in Table 1 were dimensionally stable at the high temperatures seen during autoclave sterilization (e.g., 120°C), alternative sterilization techniques are available, such as irradiation, that do not subject the lenses to high temperatures. Moreover, sterilization steps may not be necessary if contact lenses made from these polymers are thermoformed under sterile conditions, and thereafter, while being maintained in a sterile environment, placed in sterile packaging.

Experimental Materials and Methods

2-(N-ethylperfluorooctanesulfonamido) ethyl acrylate (FX-13) was supplied by 3M Coφoration of St. Paul, Minnesota, USA. when noted herein as being purified, the FX-13 was recrystallized twice from methanol before use. The following materials were used as received from Aldrich Chemical: N,N-dim ethyl acrylamide, N-isopropyl acrylamide, 2,2'-azobisisobutyronitrile (AIBN), 1,4- diaminobutane and 1 ,4-dioxane.

For examples 1 through 4, the following general polymerization procedure was used. A round bottom flask was charged with the noted proportional amounts of monomers, and the noted solvent, either toluene or dioxane. After the monomers dissolved, the flask was charged with a polymerization initiator, AIBN, and solvent. The flask was lowered into a 60°C oil bath. The reaction mixture was stirred for about 24 hours under nitrogen. Most of the solvent was removed from the reaction mixture by rotary evaporation. The viscous solution was poured into stirred diethyl ether, and the polymer precipitated. The precipitated polymer

was separated from the diethyl ether and dried in a vacuum oven (65-70°C, pressure was less than or equal toabout 0.1 mm of Hg) for at least 24 hours.