US3894561A - Four-way reversing valve with differential area operator - Google Patents

Four-way reversing valve with differential area operator Download PDFInfo

- Publication number

- US3894561A US3894561A US45098474A US3894561A US 3894561 A US3894561 A US 3894561A US 45098474 A US45098474 A US 45098474A US 3894561 A US3894561 A US 3894561A

- Authority

- US

- United States

- Prior art keywords

- chamber

- valve

- pressure

- piston

- pistons

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K11/00—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves

- F16K11/02—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit

- F16K11/06—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit comprising only sliding valves, i.e. sliding closure elements

- F16K11/065—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit comprising only sliding valves, i.e. sliding closure elements with linearly sliding closure members

- F16K11/0655—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit comprising only sliding valves, i.e. sliding closure elements with linearly sliding closure members with flat slides

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K31/00—Actuating devices; Operating means; Releasing devices

- F16K31/12—Actuating devices; Operating means; Releasing devices actuated by fluid

- F16K31/36—Actuating devices; Operating means; Releasing devices actuated by fluid in which fluid from the circuit is constantly supplied to the fluid motor

- F16K31/363—Actuating devices; Operating means; Releasing devices actuated by fluid in which fluid from the circuit is constantly supplied to the fluid motor the fluid acting on a piston

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B41/00—Fluid-circulation arrangements

- F25B41/20—Disposition of valves, e.g. of on-off valves or flow control valves

- F25B41/26—Disposition of valves, e.g. of on-off valves or flow control valves of fluid flow reversing valves

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/8593—Systems

- Y10T137/86493—Multi-way valve unit

- Y10T137/86718—Dividing into parallel flow paths with recombining

- Y10T137/86726—Valve with bypass connections

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/8593—Systems

- Y10T137/86493—Multi-way valve unit

- Y10T137/86839—Four port reversing valves

Definitions

- the four-way reversing valve is utilized in refrigerating [2!] App! 0384 systems for heat pump applications to interchange the heating and cooling effects of the evaporator and conl52] US. Cl. 137/6252); l37/625.43; 251/3l denser.

- the three-way pilot valve controls application [5 1] Int. Cl. H F16k 31/363 of high or low system pressure to the end of the cham- [58] Field of Search ]37/625,29 599,1, 62543; ber adjacent the large piston.

- the two pistons result in movement of the slide valve to the left (both modifications) when high pressure is [56] R fe Cit d applied and to the right when low pressure is applied.

- the object of this invention is to provide a four-way valve which is reliable in operation. competitive in cost. has tolerance to system dirt. and can be manufactured easily with reduced tolerance requirements.

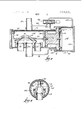

- FIG. 4 is a section on line 44 of FIG. 3 (but can be considered a similar section in FIG. I).

- compressor It delivers hot refrigerant through conduit 12 to the slide valve chamber 14 in the reversing valve body 16. With the slide valve 18 in the position shown, the hot gas is delivered to outlet 20 and conduit 22 leading to the condenser 24.

- Flow from the condenser 24 may be regulated by any suitable valve 26 to the evaporator 28 and flow from the evaporator goes through conduit 30 to port 32 below the slide valve 18 with the slide valve directing the flow to outlet 34 for return to the compressor 10 through conduit 36. Under these conditions the condenser 24 is hot and the evaporator 28 is cold.

- the functions of the evaporator and condenser are reversed with the result that the formerly cold evaporator becomes hot and thus is suitable for heating the space rather than cooling the space.

- the reversing valve I6 has a central chamber 14 in which the slide valve 18 is mounted.

- the operation of the slide valve is controlled by the two pistons 38, which are of unequal size and interconnected for movement as a unit.

- Pressure in chamber 42 between the piston 40 and the cylinder head is supplied through conduit 44 from either the high pressure or low pressure in accordance with the position of the three-way valve 46.

- high pressure is supplied from conduit 12 through conduit 48, the three way valve 46, and conduit 44.

- high pressure acts on both sides of piston 40 in the position shown in FIG. 1 with no net force tending to move piston 40.

- three-way valve 46 When three-way valve 46 is actuated, low pressure is supplied to chamber 42 from conduit 36 through conduit 52, the three-way valve 46 and conduit 44. This results in a net force across piston 40 urging it to the right.

- the left end of the valve body 16 is provided with a reduced diameter cylinder 54 with chamber 56 between piston 38 and cylinder head 58.

- the pressure in chamber 56 is always at low pressure conditions, being connected to conduit 36 through conduit 60.

- the two pistons are interconnected by the rod 62 which has an oblate portion 64 straddling slide valve 18 and connecting the rod to the valve so the piston motion will be transferred to the valve.

- An oblate spring 66 underlies rod portion 64 with the spring being in the general shape of an M as seen in FIG. I.

- the ends of the spring bear against the ledges 68 at either end of the slide valve and the two humps of the spring bear against the underside of the rod 64 so the slide valve 18 is held against the flat surface 70 through which the ports 32, 34 and 20 are bored.

- the size of the cavity 72 in the slide valve and the projection of ledges 68 are important to achieve proper timing of the valve to prevent the system pressure being equalized during movement of the valve. Should that occur, the actuating forces on the piston assembly would be neutralized and the valve would hang up.

- the net effect is a pressure derived force actuating interconnected pistons and the slide valve I8 to the right so that flow to the condenser 24 and evaporator 28 is reversed resulting in a reversal of function so the evaporator 28, which was cold. now becomes hot and can be used for heating a space rather than cooling the space.

- Both piston heads are provided with bosses or pads 37, 41 (small and large pistons, respectively) which engage the cylinder heads to act as stops limiting movement of the piston assembly.

- FIG. 3 The modification of FIG. 3 is not as desirable as that of FIG. I because it is more expensive to manufacture, but it illustrates the fact that there are variations possible in the construction.

- the small diameter piston I38 and the large diameter piston 140 are interconnected by spindle with the chamber 94 at low system pressure supplied by conduit 96.

- the larger diameter cylinder 92 is mounted on the right end of the main body 16 with ring 93 interconnecting the two. Flange 91 of the spindle 90 engages the ring 93 as illustrated in FIG. 3 to limit the movement of the piston assembly to the left.

- Low pressure is provided to chamber 94 through conduit 96 at all times and can be communicated to chamber 142 between piston I40 and cylinder head 102 if the position of the three-way valve 46 is reversed from that illustrated.

- high side pressure is communicated through conduit I48, the three-way valve 46, and conduit 144 to chamber 142. This, then, has a high side pressure acting in chamber 142 as well as in slide valve chamber 114.

- the low pressure in chamber 94 is of no effect and, therefore, the net force acting on the piston assembly is to the left to the position shown.

- the piston assembly is connected to the slide valve friction material pad 100 which prevents deflection of the rod under the force of spring 166 which acts between rod 162 and the slide valve 18 in the same manner as in FIG. 1.

- the pressure differential required to initiate movement is about l psi which is readily attainable in an operating refrigerant system.

- the force which must be overcome is the static friction load.

- a reversing valve comprising,

- a body including a valve chamber, a high pressure inlet to the chamber, a low pressure outlet from the chamber, and a pair of ports adjacent the outlet,

- a slide valve in the chamber movable between two positions in which it serves to connect either of said ports to said outlet while the other port communicates with the chamber

- said body including a large diameter cylinder and a small diameter cylinder

- valve chamber is between the pistons.

- a valve according to claim 1 in which both pistons are located at one end of the valve chamber and the space between the pistons is at low pressure.

- a body including a valve chamber

- a slide valve in the chamber movable between two positions in which either of the two ports comm unicates with said outlet while the other port communicates with the chamber to direct high pressure flowto the associated coil

- said body including two cylinders of unequal size

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Thermal Sciences (AREA)

- Multiple-Way Valves (AREA)

- Air Conditioning Control Device (AREA)

- Fluid-Driven Valves (AREA)

Abstract

Description

Claims (4)

Priority Applications (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US05450984 US3894561A (en) | 1974-03-14 | 1974-03-14 | Four-way reversing valve with differential area operator |

| FR7507710A FR2264234A1 (en) | 1974-03-14 | 1975-03-12 | |

| IT2124675A IT1034264B (en) | 1974-03-14 | 1975-03-13 | INVERSION VALVE IN PARTICULAR FOR COMPRESSOR OF FRIEGERANT SYSTEMS |

| JP3102675A JPS50127232A (en) | 1974-03-14 | 1975-03-14 | |

| DE19752511370 DE2511370A1 (en) | 1974-03-14 | 1975-03-14 | REVERSING SLIDER |

| ES435623A ES435623A1 (en) | 1974-03-14 | 1975-03-14 | Four-way reversing valve with differential area operator |

| US05/703,840 USRE30076E (en) | 1974-03-14 | 1976-07-09 | Four-way reversing valve with differential area operator |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US05450984 US3894561A (en) | 1974-03-14 | 1974-03-14 | Four-way reversing valve with differential area operator |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US05/703,840 Reissue USRE30076E (en) | 1974-03-14 | 1976-07-09 | Four-way reversing valve with differential area operator |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US3894561A true US3894561A (en) | 1975-07-15 |

Family

ID=23790325

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US05450984 Expired - Lifetime US3894561A (en) | 1974-03-14 | 1974-03-14 | Four-way reversing valve with differential area operator |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US3894561A (en) |

| JP (1) | JPS50127232A (en) |

| DE (1) | DE2511370A1 (en) |

| ES (1) | ES435623A1 (en) |

| FR (1) | FR2264234A1 (en) |

| IT (1) | IT1034264B (en) |

Cited By (36)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4144905A (en) * | 1977-08-19 | 1979-03-20 | Robertshaw Controls Company | Reversing valve construction and method of making the same |

| US4212324A (en) * | 1978-11-15 | 1980-07-15 | Robershaw Controls Company | Reversing valve construction and method of making the same |

| US4248058A (en) * | 1979-04-04 | 1981-02-03 | Robertshaw Controls Company | Differential piston type reversing valve construction, system utilizing the same and method of making |

| US4255939A (en) * | 1979-05-21 | 1981-03-17 | Emerson Electric Co. | Four way reversing valve |

| US4406306A (en) * | 1982-03-19 | 1983-09-27 | Eaton Corporation | Heat pump switchover valve |

| US4492252A (en) * | 1981-03-18 | 1985-01-08 | Kabushiki Kaisha Saginomiya Seisakusho | Reversible valve for reversible refrigeration cycle |

| EP0173138A2 (en) * | 1984-08-23 | 1986-03-05 | Ranco Incorporated | Refrigerant reversing valve |

| US4976286A (en) * | 1989-12-14 | 1990-12-11 | Automatic Switch Company | Four-way slide valve |

| ES2079279A2 (en) * | 1992-09-09 | 1996-01-01 | Hitachi Ltd | Air conditioner |

| US6063169A (en) * | 1996-05-10 | 2000-05-16 | Litton Systems, Inc. | Control means for molecular sieve on-board oxygen generator |

| US6158466A (en) * | 1999-01-14 | 2000-12-12 | Parker-Hannifin Corporation | Four-way flow reversing valve for reversible refrigeration cycles |

| EP1092928A1 (en) * | 1998-07-02 | 2001-04-18 | Kabushiki Kaisha Saginomiya Seisakusho | Flow path selector valve and method of selecting and driving the valve, compressor with flow path selector valve, and refrigerating cycle control device |

| US6409807B1 (en) | 2000-05-23 | 2002-06-25 | Litton Systems, Inc. | Linear gas valve cycle control, shut-off-valve and self test |

| EP1371889A3 (en) * | 2002-06-13 | 2004-02-11 | TGK Co., Ltd. | Three-way switching valve |

| US6698452B2 (en) | 2000-01-19 | 2004-03-02 | Emerson Electric Co. | Cycle reversing valve for use in heat pumps |

| CN100342139C (en) * | 2003-09-30 | 2007-10-10 | 三星电子株式会社 | Variable capacity rotary compressor |

| CN100346074C (en) * | 2003-09-30 | 2007-10-31 | 三星电子株式会社 | Variable capacity rotary compressor |

| CN100395453C (en) * | 2003-09-19 | 2008-06-18 | 三星电子株式会社 | Variable capacity rotary compressor |

| CN101319734B (en) * | 2007-06-04 | 2010-09-22 | 浙江三花制冷集团有限公司 | Piston link lever of four-way reversing valve |

| US20100307607A1 (en) * | 2009-06-04 | 2010-12-09 | James Glenn Ary | Reversing valve |

| US20110088427A1 (en) * | 2008-06-12 | 2011-04-21 | Yutaka Ishii | Control Valve and Air Conditioner Equipped with the Valve |

| CN101666386B (en) * | 2009-09-18 | 2012-01-18 | 清华大学 | Self-operated type three-way valve |

| CN102954243A (en) * | 2011-08-29 | 2013-03-06 | 浙江三花制冷集团有限公司 | Large four-way reversing valve and slide block component thereof |

| CN104634010A (en) * | 2014-12-31 | 2015-05-20 | 浙江陆特能源科技股份有限公司 | Construction technology for refrigerating and heating switching pipelines and switching system for refrigerating and heating switching pipelines |

| CN106032846A (en) * | 2015-03-17 | 2016-10-19 | 浙江盾安禾田金属有限公司 | Self-operated three-way valve and air-conditioning system thereof |

| CN106763894A (en) * | 2015-11-24 | 2017-05-31 | 株式会社鹭宫制作所 | Switching valve and freeze cycle |

| CN107237900A (en) * | 2016-03-29 | 2017-10-10 | 珠海华宇金属有限公司 | A kind of flat spring and four-way reversing valve |

| CN108253669A (en) * | 2016-12-29 | 2018-07-06 | 杭州三花研究院有限公司 | Mostly logical reversing arrangement and air-conditioning system |

| US20180299173A1 (en) * | 2015-05-14 | 2018-10-18 | Jhejiang Sanhua Climate And Appliance Controls Group., Ltd. | Reversing valve and cooling system having same |

| CN111120690A (en) * | 2018-10-31 | 2020-05-08 | 广东美芝精密制造有限公司 | Four-way valve |

| CN111911661A (en) * | 2019-05-07 | 2020-11-10 | 株式会社不二工机 | Flow path switching valve |

| US10907748B2 (en) * | 2016-03-30 | 2021-02-02 | Ckd Corporation | Flow path switching valve and manufacturing method therefor |

| US11268628B2 (en) | 2017-12-25 | 2022-03-08 | Ckd Corporation | Electromagnetic actuator |

| WO2022161457A1 (en) * | 2021-02-01 | 2022-08-04 | 浙江三花智能控制股份有限公司 | Electromagnetic switching valve |

| US20230228334A1 (en) * | 2020-09-25 | 2023-07-20 | Zhejiang Dunan Artificial Environment Co., Ltd. | Guide frame for four-way reversing valve |

| US20230358323A1 (en) * | 2020-08-20 | 2023-11-09 | Zhejiang Dunan Artificial Environment Co., Ltd. | Valve Core Assembly and Reversing Valve with Valve Core Assembly |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5749017Y2 (en) * | 1979-10-16 | 1982-10-27 | ||

| JPH0447493Y2 (en) * | 1984-12-26 | 1992-11-10 | ||

| JP6215802B2 (en) * | 2014-09-10 | 2017-10-18 | 株式会社鷺宮製作所 | Slide valve and refrigeration cycle |

| JP2017155887A (en) * | 2016-03-03 | 2017-09-07 | 株式会社鷺宮製作所 | Slide type selector valve and refrigeration cycle system |

| JP2017150670A (en) * | 2017-04-28 | 2017-08-31 | 株式会社鷺宮製作所 | Slide valve and refrigeration cycle |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2920653A (en) * | 1954-07-16 | 1960-01-12 | Charles J Wolff | Valve apparatus |

| US3448959A (en) * | 1966-08-29 | 1969-06-10 | Robertshaw Controls Co | Valve construction having rolling diaphragm actuator means therefor |

-

1974

- 1974-03-14 US US05450984 patent/US3894561A/en not_active Expired - Lifetime

-

1975

- 1975-03-12 FR FR7507710A patent/FR2264234A1/fr not_active Withdrawn

- 1975-03-13 IT IT2124675A patent/IT1034264B/en active

- 1975-03-14 ES ES435623A patent/ES435623A1/en not_active Expired

- 1975-03-14 DE DE19752511370 patent/DE2511370A1/en active Pending

- 1975-03-14 JP JP3102675A patent/JPS50127232A/ja active Pending

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2920653A (en) * | 1954-07-16 | 1960-01-12 | Charles J Wolff | Valve apparatus |

| US3448959A (en) * | 1966-08-29 | 1969-06-10 | Robertshaw Controls Co | Valve construction having rolling diaphragm actuator means therefor |

Cited By (51)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4144905A (en) * | 1977-08-19 | 1979-03-20 | Robertshaw Controls Company | Reversing valve construction and method of making the same |

| US4212324A (en) * | 1978-11-15 | 1980-07-15 | Robershaw Controls Company | Reversing valve construction and method of making the same |

| US4248058A (en) * | 1979-04-04 | 1981-02-03 | Robertshaw Controls Company | Differential piston type reversing valve construction, system utilizing the same and method of making |

| US4255939A (en) * | 1979-05-21 | 1981-03-17 | Emerson Electric Co. | Four way reversing valve |

| US4492252A (en) * | 1981-03-18 | 1985-01-08 | Kabushiki Kaisha Saginomiya Seisakusho | Reversible valve for reversible refrigeration cycle |

| US4406306A (en) * | 1982-03-19 | 1983-09-27 | Eaton Corporation | Heat pump switchover valve |

| EP0173138A2 (en) * | 1984-08-23 | 1986-03-05 | Ranco Incorporated | Refrigerant reversing valve |

| EP0173138A3 (en) * | 1984-08-23 | 1987-08-05 | Ranco Incorporated | Refrigerant reversing valve |

| US4976286A (en) * | 1989-12-14 | 1990-12-11 | Automatic Switch Company | Four-way slide valve |

| FR2656061A1 (en) * | 1989-12-14 | 1991-06-21 | Automatic Switch Co | VALVE WITH DRAWER AND FOUR WAYS. |

| BE1004131A5 (en) * | 1989-12-14 | 1992-09-29 | Automatic Switch Co | Valve and drawer four-lane. |

| ES2079279A2 (en) * | 1992-09-09 | 1996-01-01 | Hitachi Ltd | Air conditioner |

| US6063169A (en) * | 1996-05-10 | 2000-05-16 | Litton Systems, Inc. | Control means for molecular sieve on-board oxygen generator |

| EP1092928A1 (en) * | 1998-07-02 | 2001-04-18 | Kabushiki Kaisha Saginomiya Seisakusho | Flow path selector valve and method of selecting and driving the valve, compressor with flow path selector valve, and refrigerating cycle control device |

| EP1092928A4 (en) * | 1998-07-02 | 2005-01-05 | Saginomiyaseisakusho Kk | Flow path selector valve and method of selecting and driving the valve, compressor with flow path selector valve, and refrigerating cycle control device |

| US6158466A (en) * | 1999-01-14 | 2000-12-12 | Parker-Hannifin Corporation | Four-way flow reversing valve for reversible refrigeration cycles |

| US6698452B2 (en) | 2000-01-19 | 2004-03-02 | Emerson Electric Co. | Cycle reversing valve for use in heat pumps |

| US6409807B1 (en) | 2000-05-23 | 2002-06-25 | Litton Systems, Inc. | Linear gas valve cycle control, shut-off-valve and self test |

| EP1371889A3 (en) * | 2002-06-13 | 2004-02-11 | TGK Co., Ltd. | Three-way switching valve |

| US6883545B2 (en) | 2002-06-13 | 2005-04-26 | Tgk Co., Ltd. | Three-way switching valve |

| CN100395453C (en) * | 2003-09-19 | 2008-06-18 | 三星电子株式会社 | Variable capacity rotary compressor |

| CN100342139C (en) * | 2003-09-30 | 2007-10-10 | 三星电子株式会社 | Variable capacity rotary compressor |

| CN100346074C (en) * | 2003-09-30 | 2007-10-31 | 三星电子株式会社 | Variable capacity rotary compressor |

| CN101319734B (en) * | 2007-06-04 | 2010-09-22 | 浙江三花制冷集团有限公司 | Piston link lever of four-way reversing valve |

| US20110088427A1 (en) * | 2008-06-12 | 2011-04-21 | Yutaka Ishii | Control Valve and Air Conditioner Equipped with the Valve |

| US8505580B2 (en) | 2009-06-04 | 2013-08-13 | Parker-Hannifin Corporation | Reversing valve |

| US20100307607A1 (en) * | 2009-06-04 | 2010-12-09 | James Glenn Ary | Reversing valve |

| CN101666386B (en) * | 2009-09-18 | 2012-01-18 | 清华大学 | Self-operated type three-way valve |

| CN102954243A (en) * | 2011-08-29 | 2013-03-06 | 浙江三花制冷集团有限公司 | Large four-way reversing valve and slide block component thereof |

| CN104634010A (en) * | 2014-12-31 | 2015-05-20 | 浙江陆特能源科技股份有限公司 | Construction technology for refrigerating and heating switching pipelines and switching system for refrigerating and heating switching pipelines |

| CN104634010B (en) * | 2014-12-31 | 2018-02-16 | 浙江陆特能源科技股份有限公司 | Cooling and warming switches the construction technology and its switching system of pipeline |

| CN106032846A (en) * | 2015-03-17 | 2016-10-19 | 浙江盾安禾田金属有限公司 | Self-operated three-way valve and air-conditioning system thereof |

| CN106032846B (en) * | 2015-03-17 | 2019-12-24 | 浙江盾安禾田金属有限公司 | Self-operated three-way valve and air conditioning system thereof |

| US20180299173A1 (en) * | 2015-05-14 | 2018-10-18 | Jhejiang Sanhua Climate And Appliance Controls Group., Ltd. | Reversing valve and cooling system having same |

| US10619897B2 (en) * | 2015-05-14 | 2020-04-14 | Zhejiang Sanhua Climate And Appliance Controls Group., Ltd | Reversing valve and cooling system having same |

| CN106763894A (en) * | 2015-11-24 | 2017-05-31 | 株式会社鹭宫制作所 | Switching valve and freeze cycle |

| CN106763894B (en) * | 2015-11-24 | 2019-09-13 | 株式会社鹭宫制作所 | Switching valve and refrigerating circulation system |

| CN107237900A (en) * | 2016-03-29 | 2017-10-10 | 珠海华宇金属有限公司 | A kind of flat spring and four-way reversing valve |

| US11566723B2 (en) | 2016-03-30 | 2023-01-31 | Ckd Corporation | Flow path switching valve and manufacturing method therefor |

| US10907748B2 (en) * | 2016-03-30 | 2021-02-02 | Ckd Corporation | Flow path switching valve and manufacturing method therefor |

| CN108253669A (en) * | 2016-12-29 | 2018-07-06 | 杭州三花研究院有限公司 | Mostly logical reversing arrangement and air-conditioning system |

| CN108253669B (en) * | 2016-12-29 | 2021-10-19 | 杭州三花研究院有限公司 | Multi-way reversing device and air conditioning system |

| US11268628B2 (en) | 2017-12-25 | 2022-03-08 | Ckd Corporation | Electromagnetic actuator |

| CN111120690A (en) * | 2018-10-31 | 2020-05-08 | 广东美芝精密制造有限公司 | Four-way valve |

| CN111120690B (en) * | 2018-10-31 | 2021-10-22 | 广东美芝精密制造有限公司 | Four-way valve |

| CN111911661A (en) * | 2019-05-07 | 2020-11-10 | 株式会社不二工机 | Flow path switching valve |

| CN111911661B (en) * | 2019-05-07 | 2024-04-16 | 株式会社不二工机 | Flow path switching valve |

| US20230358323A1 (en) * | 2020-08-20 | 2023-11-09 | Zhejiang Dunan Artificial Environment Co., Ltd. | Valve Core Assembly and Reversing Valve with Valve Core Assembly |

| US20230228334A1 (en) * | 2020-09-25 | 2023-07-20 | Zhejiang Dunan Artificial Environment Co., Ltd. | Guide frame for four-way reversing valve |

| US12104708B2 (en) * | 2020-09-25 | 2024-10-01 | Zhejiang Dunan Artificial Environment Co., Ltd. | Guide frame for four-way reversing valve |

| WO2022161457A1 (en) * | 2021-02-01 | 2022-08-04 | 浙江三花智能控制股份有限公司 | Electromagnetic switching valve |

Also Published As

| Publication number | Publication date |

|---|---|

| FR2264234A1 (en) | 1975-10-10 |

| ES435623A1 (en) | 1976-12-16 |

| JPS50127232A (en) | 1975-10-07 |

| IT1034264B (en) | 1979-09-10 |

| DE2511370A1 (en) | 1975-09-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3894561A (en) | Four-way reversing valve with differential area operator | |

| US2983286A (en) | Reversing valve | |

| JP6530991B2 (en) | Direct acting solenoid valve and four-way switching valve equipped with the same as a pilot valve | |

| JP6556000B2 (en) | Direct acting solenoid valve and four-way switching valve equipped with it as a pilot valve | |

| AU623069B2 (en) | Four-way slide valve | |

| US3369790A (en) | Fluid system and method and parts therefor or the like | |

| US2714394A (en) | Four-way change-over valve | |

| US2708561A (en) | Four-way valve | |

| US4027700A (en) | Reversing valve construction | |

| US4055056A (en) | Reversible refrigerant system and four-way reversing valve therefor or the like | |

| USRE30076E (en) | Four-way reversing valve with differential area operator | |

| US4178768A (en) | Internally piloted reversing valve for heat pump | |

| US2723537A (en) | Reversing valve for refrigeration system | |

| US3293880A (en) | Reversing valve for refrigeration systems and air conditioning systems | |

| US4221237A (en) | Refrigeration heat pump changeover valve assembly | |

| US2768509A (en) | Control valve for reversible refrigerating system | |

| JPH0316513B2 (en) | ||

| US2768506A (en) | Combined unloading and reversing valve for reversible refrigerating system | |

| JPH0718494B2 (en) | Four-way valve for refrigeration cycle | |

| US5944299A (en) | Rotation switching mechanism in rotary type switching valve | |

| JP2694032B2 (en) | Air conditioner for both heating and cooling | |

| US3045700A (en) | Piston slide valve | |

| US3972347A (en) | Reversible refrigerant system and four-way reversing valve therefor or the like | |

| US3527255A (en) | Reversing valve | |

| JPS6367472A (en) | Four-way valve for refrigerating cycle |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| AS | Assignment |

Owner name: CONTROLS COMPANY OF AMERICA, 9655 W. SORENG AVENUE Free format text: ASSIGNMENT OF ASSIGNORS INTEREST.;ASSIGNOR:SINGER COMPANY, THE;REEL/FRAME:004505/0515 Effective date: 19860110 |

|

| AS | Assignment |

Owner name: EATON CORPORATION, EATON CENTER, 1111 SUPERIOR AVE Free format text: ASSIGNMENT OF ASSIGNORS INTEREST.;ASSIGNOR:CONTROLS COMPANY OF AMERICA;REEL/FRAME:004614/0433 Effective date: 19861002 |

|

| STCF | Information on status: patent grant |

Free format text: PATENTED FILE - (OLD CASE ADDED FOR FILE TRACKING PURPOSES) |