US3175515A - Jet suction device - Google Patents

Jet suction device Download PDFInfo

- Publication number

- US3175515A US3175515A US267244A US26724463A US3175515A US 3175515 A US3175515 A US 3175515A US 267244 A US267244 A US 267244A US 26724463 A US26724463 A US 26724463A US 3175515 A US3175515 A US 3175515A

- Authority

- US

- United States

- Prior art keywords

- housing

- suction tube

- annular

- housing member

- inner face

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000011144 upstream manufacturing Methods 0.000 claims description 19

- 239000007788 liquid Substances 0.000 claims description 6

- 230000008093 supporting effect Effects 0.000 claims description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 6

- 239000007787 solid Substances 0.000 description 4

- 238000010276 construction Methods 0.000 description 3

- 239000012530 fluid Substances 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 239000004576 sand Substances 0.000 description 3

- 238000005065 mining Methods 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 229910000906 Bronze Inorganic materials 0.000 description 1

- 235000013175 Crataegus laevigata Nutrition 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 239000010974 bronze Substances 0.000 description 1

- KUNSUQLRTQLHQQ-UHFFFAOYSA-N copper tin Chemical compound [Cu].[Sn] KUNSUQLRTQLHQQ-UHFFFAOYSA-N 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000001939 inductive effect Effects 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 229920001084 poly(chloroprene) Polymers 0.000 description 1

- 239000011435 rock Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21C—MINING OR QUARRYING

- E21C50/00—Obtaining minerals from underwater, not otherwise provided for

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02F—DREDGING; SOIL-SHIFTING

- E02F3/00—Dredgers; Soil-shifting machines

- E02F3/04—Dredgers; Soil-shifting machines mechanically-driven

- E02F3/88—Dredgers; Soil-shifting machines mechanically-driven with arrangements acting by a sucking or forcing effect, e.g. suction dredgers

- E02F3/90—Component parts, e.g. arrangement or adaptation of pumps

- E02F3/902—Component parts, e.g. arrangement or adaptation of pumps for modifying the concentration of the dredged material, e.g. relief valves preventing the clogging of the suction pipe

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04F—PUMPING OF FLUID BY DIRECT CONTACT OF ANOTHER FLUID OR BY USING INERTIA OF FLUID TO BE PUMPED; SIPHONS

- F04F5/00—Jet pumps, i.e. devices in which flow is induced by pressure drop caused by velocity of another fluid flow

- F04F5/44—Component parts, details, or accessories not provided for in, or of interest apart from, groups F04F5/02 - F04F5/42

- F04F5/46—Arrangements of nozzles

Definitions

- This invention has to do generally with jet suction devices and particularly with such devices as are useful for moving a mixture of rocks, sand and gravel using water as the fluid medium, such as in stripping such materials from a stream bed in placer mining operations.

- An object of the invention is to provide a new and improved, jet or injection type suction device designed for use in moving solids such as sand and gravel entrained in a liquid medium such as water.

- Another object is to provide a highly eflicient device of the type indicated which produces a relatively high vacuum in the suction tube portion of the device capable of flowing a mixture of liquid and solids with a very high percentage of solids.

- a further object is to provide a novel construction in which the parts can be easily assembled or readily removed for replacement, and to provide a construction wherein the jet orifice can be adjusted in several different ways.

- Another object is to provide a durable, efi'icient and relatively light-weight device.

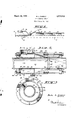

- FIG. 1 is a side elevational view, somewhat diagrammatic, of apparatus embodying the invention shown in a typical environment;

- FIG. 2 is a central longitudinal sectional View through a device embodying the invention.

- FIG. 3 is a cross-sectional view on line 33 of FIG. 2.

- the jet suction device designated 11, is designed particularly for raising sand and gravel from a stream bed in placer mining operations, although it may be used for other purposes.

- the device 11 is normally located relatively close to the surface of the water 12 of a stream and is provided with a suction hose 13 of desired length leading to the stream bed.

- a motor-driven pump unit 15 is shown on a float 16 and this supplies water under pressure to the unit 11 through a hose 18.

- the device 11 discharges the material picked up from the stream bed and the water into a flow control box 20 at the head of a sluice 21, the latter two elements being supported upon a series of floats 16.

- the unit 11 includes a housing consisting of two main housing members, namely an upstream housing member and a downstream housing member 26. These members are provided with flanges 27 and 28 respectively and the parts are secured together by bolts 30 passing through the flanges, a suitable gasket 31 being provided.

- the upstream housing member 25 is annular in shape and is provided with an outer wall 33 having an inlet opening or port 34.

- the member has an end wall 35 and an inner or re'entrant wall 36 which is cylindrical and which, together with the outer Wall 33, defines an annular chamber 37 which is open at its downstream end.

- the downstream housing member 26 comprises an upstream section 38 which is characterized by frusto-conical or conoidal inner surface 39 which diverges in the direction upstream to a diameter substantially equal to the inner diameter of the wall 33 of housing member 25.

- the member 26 has a downstream cylindrical section or end portion 40 having an internal diameter substan- 3,175,515 Patented Mar. 30, 1965 tially the same as the internal diameter of wall 36 of the other housing member.

- a suction tube 42 is mounted in the upstream housing member 25 and projects into the downstream housing member nearly to the small diameter end of the conoidal face 39.

- the suction tube is held in place by an annular ring 43 which is secured to the housing 25 by screws 44.

- the ring serves to compress a seal ring 45 of neoprene or other suitable material between it, tube 42 and housing member 25, the seal ring being partially received within a recess 46 defined by the suction tube and a flared section 47 of the inner wall 36 of the housing member.

- a discharge tube 50 is mounted in the end portion 40 of housing member 26 and is secured there by an annular ring 51, bolts 52 passing through the ring and threaded into the housing member, and by a seal ring 53 provided between ring 51, tube 50 and section 40 of housing member 26.

- the wall or section 40 is provided with an outwardly beveled end wall 54 to accommodate the ring. It is desirable to provide a recess 56 in the housing member 26 at the small diameter end of the conoidal section or face 39 to receive a wear-resistant ring 57.

- the latter has an annular groove 58 to receive the inner end of the discharge tube so that the latter is positioned outside a projection of the face 39 inside the tube.

- annular orifice 60 is formed furnishing an outlet for pressure fluid introduced through port 34 into chamber 37.

- the pressure fluid passing through the orifice tends to form a cone 61 within the discharge tube and forms in effect a perfect aqueous seal which moves out the discharge tube thereby inducing a relatively high vacuum in the suction tube 42.

- the size of orifice 60 can be adjusted by moving the suction tube 42 axially within the housing member 25 or by means of various sized gaskets placed between the flanges 27 and 28 of the two housing members. In actual practice I have found that as high as solids can be moved in a stream of water through the device. In operation, the device can be used as shown in FIG. 1 and previously described; however it is also etfective for other uses and can be used at any angle.

- the parts of the housing may be cast of any suitable metal, such as steel, bronze, aluminum or the like and it will be apparent that the device is easily assembled and disassembled, enabling easy replacement of parts.

- a jet suction device comprising an annular, openended housing having an intermediate section with a conoidal inner face, a suction tube mounted in said housing and extending therein from the upstream end of the housing beyond the large-diameter upstream end of said inner face through said intermediate section substantially to the small-diameter downstream end of said inner face, said housing having an annular inner wall extending for a substantial distance inwardly of the housing from the upstream end thereof and closely receiving and support ing said suction tube, said housing and suction tube together defining a high pressure liquid chamber, said housing having an inlet to said chamber, and a discharge tube mounted in said housing beyond and in axial alignment with said suction tube, said suction tube and said conoidal inner face of said intermediate section of said housing 3, I defining an annular orifice for escape of pressure liquid 'from said chamber into said discharge tube, said suction tube being adjustable axially in said housing to vary the size of said orifice.

- a jet'suction device comprising an annular upstream housing member having spaced inner and outer walls defining an annular chamber open at the downstream end of the member, an annular downstream housing member attached to the downstream end of said upstream housing member, said downstream housing member having a downstream end portion in axial alignment with the inner wall of said upstream housing member and having an upstream end portion provided with a conoidal face diverging in a direction upstream, a suction tube mounted in the inner Wall of said upstream housing member and extending into the upstream end portion of the downstream housing member, said suction tube together with said upstream end of said downstream housing member forming a continuation of said annular chamber and defining an annular orifice at the small-diameter end of References Qited by the Examiner V i V V UNITED STATES PATENTS 334,597 1/86 Marsh l03-267 894,758 7/08 Starre 103-264 1,806,287 5/31 Forrest 103-262 1,854,098 4/32 Black 103263 2,44

Landscapes

- Engineering & Computer Science (AREA)

- Mining & Mineral Resources (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Civil Engineering (AREA)

- Fluid Mechanics (AREA)

- Physics & Mathematics (AREA)

- Structural Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Geochemistry & Mineralogy (AREA)

- Geology (AREA)

- Jet Pumps And Other Pumps (AREA)

Description

March 30, 1965 B. L. CHEELY JET SUCTION DEVICE Filed March 22, 1963 I z l I 2 BURL L. CHEELY INVENTOR.

%M VQAM/ ATTORNEYS United States Patent ice 3,175,515 JET SUCTION DEVICE Burl L. Cheely, 3534 W. Rosecrans, Hawthorne, Calif. Filed Mar. 22, 1963, er. No. 267,244 2 Claims. (Cl. 103-262) This invention has to do generally with jet suction devices and particularly with such devices as are useful for moving a mixture of rocks, sand and gravel using water as the fluid medium, such as in stripping such materials from a stream bed in placer mining operations.

An object of the invention is to provide a new and improved, jet or injection type suction device designed for use in moving solids such as sand and gravel entrained in a liquid medium such as water.

Another object is to provide a highly eflicient device of the type indicated which produces a relatively high vacuum in the suction tube portion of the device capable of flowing a mixture of liquid and solids with a very high percentage of solids.

A further object is to provide a novel construction in which the parts can be easily assembled or readily removed for replacement, and to provide a construction wherein the jet orifice can be adjusted in several different ways.

Another object is to provide a durable, efi'icient and relatively light-weight device.

These and other objects will be apparent from the drawing and the following description.

Referring to the drawings:

FIG. 1 is a side elevational view, somewhat diagrammatic, of apparatus embodying the invention shown in a typical environment;

FIG. 2 is a central longitudinal sectional View through a device embodying the invention; and

FIG. 3 is a cross-sectional view on line 33 of FIG. 2.

More particularly describing the invention, as previously indicated, the jet suction device, designated 11, is designed particularly for raising sand and gravel from a stream bed in placer mining operations, although it may be used for other purposes. Thus, as shown in FIG. 1, the device 11 is normally located relatively close to the surface of the water 12 of a stream and is provided with a suction hose 13 of desired length leading to the stream bed. A motor-driven pump unit 15 is shown on a float 16 and this supplies water under pressure to the unit 11 through a hose 18. The device 11 discharges the material picked up from the stream bed and the water into a flow control box 20 at the head of a sluice 21, the latter two elements being supported upon a series of floats 16.

Referring more particularly to the details of construction as shown in FIGS. 2 and 3, the unit 11 includes a housing consisting of two main housing members, namely an upstream housing member and a downstream housing member 26. These members are provided with flanges 27 and 28 respectively and the parts are secured together by bolts 30 passing through the flanges, a suitable gasket 31 being provided.

The upstream housing member 25 is annular in shape and is provided with an outer wall 33 having an inlet opening or port 34. The member has an end wall 35 and an inner or re'entrant wall 36 which is cylindrical and which, together with the outer Wall 33, defines an annular chamber 37 which is open at its downstream end.

The downstream housing member 26 comprises an upstream section 38 which is characterized by frusto-conical or conoidal inner surface 39 which diverges in the direction upstream to a diameter substantially equal to the inner diameter of the wall 33 of housing member 25. The member 26 has a downstream cylindrical section or end portion 40 having an internal diameter substan- 3,175,515 Patented Mar. 30, 1965 tially the same as the internal diameter of wall 36 of the other housing member.

A suction tube 42 is mounted in the upstream housing member 25 and projects into the downstream housing member nearly to the small diameter end of the conoidal face 39. The suction tube is held in place by an annular ring 43 which is secured to the housing 25 by screws 44. The ring serves to compress a seal ring 45 of neoprene or other suitable material between it, tube 42 and housing member 25, the seal ring being partially received within a recess 46 defined by the suction tube and a flared section 47 of the inner wall 36 of the housing member.

A discharge tube 50 is mounted in the end portion 40 of housing member 26 and is secured there by an annular ring 51, bolts 52 passing through the ring and threaded into the housing member, and by a seal ring 53 provided between ring 51, tube 50 and section 40 of housing member 26. The wall or section 40 is provided with an outwardly beveled end wall 54 to accommodate the ring. It is desirable to provide a recess 56 in the housing member 26 at the small diameter end of the conoidal section or face 39 to receive a wear-resistant ring 57. The latter has an annular groove 58 to receive the inner end of the discharge tube so that the latter is positioned outside a projection of the face 39 inside the tube.

It will be apparent that with the suction tube 42 adjusted so that its inner end 42' is spaced from the surface or face 39, an annular orifice 60 is formed furnishing an outlet for pressure fluid introduced through port 34 into chamber 37. The pressure fluid passing through the orifice tends to form a cone 61 within the discharge tube and forms in effect a perfect aqueous seal which moves out the discharge tube thereby inducing a relatively high vacuum in the suction tube 42. The size of orifice 60 can be adjusted by moving the suction tube 42 axially within the housing member 25 or by means of various sized gaskets placed between the flanges 27 and 28 of the two housing members. In actual practice I have found that as high as solids can be moved in a stream of water through the device. In operation, the device can be used as shown in FIG. 1 and previously described; however it is also etfective for other uses and can be used at any angle.

The parts of the housing may be cast of any suitable metal, such as steel, bronze, aluminum or the like and it will be apparent that the device is easily assembled and disassembled, enabling easy replacement of parts.

Although I have shown and described preferred forms of my invention, I contemplate that various changes and modifications can be made therein without departing from the invention, the scope of which is indicated by the following claims.

I claim:

1. A jet suction device comprising an annular, openended housing having an intermediate section with a conoidal inner face, a suction tube mounted in said housing and extending therein from the upstream end of the housing beyond the large-diameter upstream end of said inner face through said intermediate section substantially to the small-diameter downstream end of said inner face, said housing having an annular inner wall extending for a substantial distance inwardly of the housing from the upstream end thereof and closely receiving and support ing said suction tube, said housing and suction tube together defining a high pressure liquid chamber, said housing having an inlet to said chamber, and a discharge tube mounted in said housing beyond and in axial alignment with said suction tube, said suction tube and said conoidal inner face of said intermediate section of said housing 3, I defining an annular orifice for escape of pressure liquid 'from said chamber into said discharge tube, said suction tube being adjustable axially in said housing to vary the size of said orifice.

2. A jet'suction device, comprising an annular upstream housing member having spaced inner and outer walls defining an annular chamber open at the downstream end of the member, an annular downstream housing member attached to the downstream end of said upstream housing member, said downstream housing member having a downstream end portion in axial alignment with the inner wall of said upstream housing member and having an upstream end portion provided with a conoidal face diverging in a direction upstream, a suction tube mounted in the inner Wall of said upstream housing member and extending into the upstream end portion of the downstream housing member, said suction tube together with said upstream end of said downstream housing member forming a continuation of said annular chamber and defining an annular orifice at the small-diameter end of References Qited by the Examiner V i V V UNITED STATES PATENTS 334,597 1/86 Marsh l03-267 894,758 7/08 Starre 103-264 1,806,287 5/31 Forrest 103-262 1,854,098 4/32 Black 103263 2,444,615 7/48 Reinhardt -103-267 LAURENCE v. EFNER, Primary Examiner. WARREN E. COLEMAN, Examiner.

Claims (1)

1. A JET SUCTION DEVICE COMPRISING AN ANNULAR, OPENENDED HOUSING HAVING AN INTERMEDIATE SECTION WITH A CONOIDAL INNER FACE, A SUCTION TUBE MOUNTED IN SAID HOUSING AND EXTENDING THEREIN FROM THE UPSTREAM END OF THE HOUSING BEYOND THE LARGE-DIAMETER UPSTREAM END OF SAID INNER FACE THROUGH SAID INTERMEDIATE SECTION SUBSTANTIALLY TO THE SMALL-DIAMETER DOWNSTREAM END OF SAID INNER FACE, SAID HOUSING HAVING AN ANNULAR INNER WALL EXTENDING FOR A SUBSTANTIAL DISTANCE INWARDLY INNER WALL EXTENDING FOR UPSTREAM END THEREOF AND CLOSELY RECEIVING AND SUPPORTING SAID SUCTION TUBE, SAID HOUSING AND SUCTION TUBE TOGETHER DEFINING A HIGH PRESSURE LIQUID CHAMBER, SAID HOUSING HAVING AN INLET TO SAID CHAMBER, AND A DISCHARGE TUBE MOUNTED IN SAID HOUSING BEYOND AND IN AXIAL ALIGNMENT WITH SAID SUCTION TUBE, SUCTION TUBE AND SAID CONOIDAL INNER FACE OF SAID INTERMEDIATE SECTION OF SAID HOUSING DEFINING AN ANNULAR ORIFICE FOR ESCAPE OF PRESSURE LIQUID FROM SAID CHAMBER INTO SAID DISCHARGE TUBE, SAID SUCTION TUBE BEING ADJUSTABLE AXIALLY IN SAID HOUSING TO VARY THE SIZE OF SAID ORIFICE.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US267244A US3175515A (en) | 1963-03-22 | 1963-03-22 | Jet suction device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US267244A US3175515A (en) | 1963-03-22 | 1963-03-22 | Jet suction device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US3175515A true US3175515A (en) | 1965-03-30 |

Family

ID=23017940

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US267244A Expired - Lifetime US3175515A (en) | 1963-03-22 | 1963-03-22 | Jet suction device |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US3175515A (en) |

Cited By (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3276821A (en) * | 1964-02-28 | 1966-10-04 | Howard C Edwards | Materials handling draft eductor |

| US3353497A (en) * | 1967-02-03 | 1967-11-21 | George K Williams | Pump apparatus |

| US3368849A (en) * | 1966-06-17 | 1968-02-13 | Burl L. Cheely | Jet suction device |

| US3376077A (en) * | 1966-07-18 | 1968-04-02 | American Mach & Foundry | Pneumatic conveyor |

| US3446157A (en) * | 1967-07-27 | 1969-05-27 | Schafer Davis Eng Co Inc | Means for aspirating liquid and solid materials |

| US3474953A (en) * | 1969-03-05 | 1969-10-28 | Air Vac Eng Co Inc | Vacuum creating device |

| US3720482A (en) * | 1970-05-14 | 1973-03-13 | Piab Ab | Device for generating an air system by means of an ejector |

| JPS5299409A (en) * | 1976-02-16 | 1977-08-20 | Takuo Mochizuki | Jet spraying pumps |

| JPS52112380A (en) * | 1976-03-18 | 1977-09-20 | Oki Kougiyou Kk | Taking on and off means for cylinndrical instruments |

| US4186772A (en) * | 1977-05-31 | 1980-02-05 | Handleman Avrom Ringle | Eductor-mixer system |

| US4310288A (en) * | 1979-03-23 | 1982-01-12 | Kobe, Inc. | Method and apparatus for improving erosion resistance of the mixing chamber of a jet pump |

| US4400138A (en) * | 1981-10-19 | 1983-08-23 | Baer William F | Multiple jet eductor |

| US4558990A (en) * | 1980-05-12 | 1985-12-17 | Marco Seattle, Inc. | Composite pumping system |

| US4756671A (en) * | 1983-02-28 | 1988-07-12 | Marco Seattle, Inc. | Low damage hydraulic fish pumping system |

| US4850291A (en) * | 1985-03-14 | 1989-07-25 | Mac Engineering Co., Ltd. | Movable type of device for fertilizing the soil by piercing a nozzle into the same |

| US5083710A (en) * | 1988-09-06 | 1992-01-28 | Oxy-Dry Corporation | Powder sprayer with automatic powder supply system |

| US5088860A (en) * | 1991-03-08 | 1992-02-18 | Poly-Vac Co. | Process and apparatus for selectively gathering lightweight low density objects |

| US5213271A (en) * | 1991-08-09 | 1993-05-25 | Oxy-Dry Corporation | Powder sprayer with pneumatic powder supply system |

| US5232314A (en) * | 1991-08-20 | 1993-08-03 | Central Pharmaceuticals, Inc. | Particle conveying apparatus |

| US5746583A (en) * | 1995-01-20 | 1998-05-05 | Spear; Scott | Vacuum boost device |

| US6402068B1 (en) | 1998-08-06 | 2002-06-11 | Avrom R. Handleman | Eductor mixer system |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US334597A (en) * | 1886-01-19 | Steam-jet pump | ||

| US894758A (en) * | 1907-09-23 | 1908-07-28 | Charlle F Starre | Inspirator. |

| US1806287A (en) * | 1929-03-13 | 1931-05-19 | Universal Lifting Appliance Co | Ejector |

| US1854098A (en) * | 1929-06-14 | 1932-04-12 | Commercial Patents Dev Company | Ejector |

| US2444615A (en) * | 1946-11-21 | 1948-07-06 | Derbyshire Machine & Tool Comp | Eductor |

-

1963

- 1963-03-22 US US267244A patent/US3175515A/en not_active Expired - Lifetime

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US334597A (en) * | 1886-01-19 | Steam-jet pump | ||

| US894758A (en) * | 1907-09-23 | 1908-07-28 | Charlle F Starre | Inspirator. |

| US1806287A (en) * | 1929-03-13 | 1931-05-19 | Universal Lifting Appliance Co | Ejector |

| US1854098A (en) * | 1929-06-14 | 1932-04-12 | Commercial Patents Dev Company | Ejector |

| US2444615A (en) * | 1946-11-21 | 1948-07-06 | Derbyshire Machine & Tool Comp | Eductor |

Cited By (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3276821A (en) * | 1964-02-28 | 1966-10-04 | Howard C Edwards | Materials handling draft eductor |

| US3368849A (en) * | 1966-06-17 | 1968-02-13 | Burl L. Cheely | Jet suction device |

| US3376077A (en) * | 1966-07-18 | 1968-04-02 | American Mach & Foundry | Pneumatic conveyor |

| US3353497A (en) * | 1967-02-03 | 1967-11-21 | George K Williams | Pump apparatus |

| US3446157A (en) * | 1967-07-27 | 1969-05-27 | Schafer Davis Eng Co Inc | Means for aspirating liquid and solid materials |

| US3474953A (en) * | 1969-03-05 | 1969-10-28 | Air Vac Eng Co Inc | Vacuum creating device |

| US3720482A (en) * | 1970-05-14 | 1973-03-13 | Piab Ab | Device for generating an air system by means of an ejector |

| JPS5299409A (en) * | 1976-02-16 | 1977-08-20 | Takuo Mochizuki | Jet spraying pumps |

| JPS60718B2 (en) * | 1976-03-18 | 1985-01-09 | 沖興業株式会社 | Cylindrical instrument attachment/detachment device |

| JPS52112380A (en) * | 1976-03-18 | 1977-09-20 | Oki Kougiyou Kk | Taking on and off means for cylinndrical instruments |

| US4186772A (en) * | 1977-05-31 | 1980-02-05 | Handleman Avrom Ringle | Eductor-mixer system |

| US4310288A (en) * | 1979-03-23 | 1982-01-12 | Kobe, Inc. | Method and apparatus for improving erosion resistance of the mixing chamber of a jet pump |

| US4558990A (en) * | 1980-05-12 | 1985-12-17 | Marco Seattle, Inc. | Composite pumping system |

| US4400138A (en) * | 1981-10-19 | 1983-08-23 | Baer William F | Multiple jet eductor |

| US4756671A (en) * | 1983-02-28 | 1988-07-12 | Marco Seattle, Inc. | Low damage hydraulic fish pumping system |

| US4850291A (en) * | 1985-03-14 | 1989-07-25 | Mac Engineering Co., Ltd. | Movable type of device for fertilizing the soil by piercing a nozzle into the same |

| US5083710A (en) * | 1988-09-06 | 1992-01-28 | Oxy-Dry Corporation | Powder sprayer with automatic powder supply system |

| US5088860A (en) * | 1991-03-08 | 1992-02-18 | Poly-Vac Co. | Process and apparatus for selectively gathering lightweight low density objects |

| US5213271A (en) * | 1991-08-09 | 1993-05-25 | Oxy-Dry Corporation | Powder sprayer with pneumatic powder supply system |

| US5232314A (en) * | 1991-08-20 | 1993-08-03 | Central Pharmaceuticals, Inc. | Particle conveying apparatus |

| US5746583A (en) * | 1995-01-20 | 1998-05-05 | Spear; Scott | Vacuum boost device |

| US6402068B1 (en) | 1998-08-06 | 2002-06-11 | Avrom R. Handleman | Eductor mixer system |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3175515A (en) | Jet suction device | |

| US2801133A (en) | Angle nozzle | |

| US5335459A (en) | Nozzle for abrasive cleaning or cutting | |

| US3330217A (en) | Pump | |

| US2125740A (en) | Hydraulic excavating device or booster | |

| US3212217A (en) | Cleaning device | |

| US3664768A (en) | Fluid transformer | |

| US3334657A (en) | Adjustable fluid mixing devices | |

| US4810170A (en) | Jet pump | |

| US3074351A (en) | Pumps | |

| US3871583A (en) | Cement spray gun with remote air injection | |

| US6402068B1 (en) | Eductor mixer system | |

| US3256642A (en) | Underwater sandblasting gun | |

| US2100185A (en) | Apparatus for the movement of viscous materials | |

| ES344846A1 (en) | Apparatus for conveying sand or the like | |

| US2963979A (en) | Porcelain lined centrifugal pumps | |

| US20100157722A1 (en) | Means and method for mixing a particulate material and a liquid | |

| US3994631A (en) | Pump and pump manifold assembly with adjustable ball valve | |

| GB1500746A (en) | Jet nozzle | |

| US3446157A (en) | Means for aspirating liquid and solid materials | |

| US536415A (en) | Vacuum-pump | |

| US3218982A (en) | Pump | |

| GB1236205A (en) | Improvements in or relating to abrading | |

| RU2293223C2 (en) | Air-operated jet pump with ring controlled nozzle | |

| US3304007A (en) | Flow regulating turbulence arrestor for centrifugal pumps |