US2390743A - Permanent magnet holding device - Google Patents

Permanent magnet holding device Download PDFInfo

- Publication number

- US2390743A US2390743A US485740A US48574043A US2390743A US 2390743 A US2390743 A US 2390743A US 485740 A US485740 A US 485740A US 48574043 A US48574043 A US 48574043A US 2390743 A US2390743 A US 2390743A

- Authority

- US

- United States

- Prior art keywords

- magnet

- pole pieces

- plate

- pole

- contact

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23Q—DETAILS, COMPONENTS, OR ACCESSORIES FOR MACHINE TOOLS, e.g. ARRANGEMENTS FOR COPYING OR CONTROLLING; MACHINE TOOLS IN GENERAL CHARACTERISED BY THE CONSTRUCTION OF PARTICULAR DETAILS OR COMPONENTS; COMBINATIONS OR ASSOCIATIONS OF METAL-WORKING MACHINES, NOT DIRECTED TO A PARTICULAR RESULT

- B23Q3/00—Devices holding, supporting, or positioning work or tools, of a kind normally removable from the machine

- B23Q3/15—Devices for holding work using magnetic or electric force acting directly on the work

- B23Q3/154—Stationary devices

- B23Q3/1546—Stationary devices using permanent magnets

Definitions

- This invention relates to permanent magnet holding devices, such as magnetic chucks used to hold work in position for a tooling operation.

- Various magnet chucks have been proposed heretofore in which a plurality of permanent magnets-have been so mounted for movement relative to the pole pieces of a work plate that the pole pieces may be energized for holding a work piece in position, or alternatively a part of the magnetic flux may be shunted out of the work.

- the volume occupied by the non-magnetic separators between a set of parallel, narrow bar magnets may be 10% or more of the available space.

- a massive permanent magnet so arranged as to extend longitudinally beneath the work plate pole pieces and to fill the available portion of the chuck casing and thus give the maximum holding power per unit area of the work plate.

- a massive magnet will de velop more iiux or field strength than can a set of narrow bar magnets, and the magnetic circuit may be made short and adequate.

- a. massive magnet with a smooth under face will slide easily on the casing bottom plate, whereas narrow bar magnets offer greater ,frictional resistance opposing the movement, and they tend to wear the base plate rapidly.

- the massive magnet can be slidably mounted with the minimum oi air gap interposed in the circuit.

- a construction of this type should provide an adequate and short magnetic circuit of low reluctance and a satisfactory flux distribution for the normal operation of the chuck; and it should be capable of shunting sumcient flux from the work to insure an easy release of the same, but without wasting valuable space, either laterally or vertically.

- Increasing the height of the magnet, as well as its cross sectional area, increases the holding power, and particularly because the magnet of larger volume can be provided with or absorb a greater concentration of flux.

- an e1- ficient permanent magnet holding device such as a chuck, in which one or more massive magnets are so arranged relative to the pole pieces of the work plate that a work piece may be held securely in place or the pole pieces may be connected with both magnet poles to shunt a substantial portion of the magnetic flux from the work for releasing the same.

- a permanent magnet may be made of Alnico, an alloy of iron, aluminum, nickel and cobalt; but this metal has a low permeability as compared with a soft carbon steel. Hence, if a plurality of Alnico magnets are mounted in a reverse to provide an eillcient and satisfactory return path for the flux and to secure the maximum magnetomotive force for a given volume 01 available space within the casing.

- a further object of the invention is to provide a construction in which a massive permanent magnet unit is so arranged relative to two sets of evenly spaced and equal width pole pieces on the work plate that the unit may energize each pole piece with a satisfactory flux distribution, or alternatively the opposite poles of the unit may contact with individual pole pieces and form a shunt circuit that removes flux from the work.

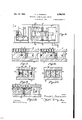

- Fig. 1 is a top plan view, with the work plate partly broken away, of a permanent magnet chuck having a massive permanent magnet arranged between two members to form a ma net unit which is movable to and from work holding and flux shunting positions;

- Fig. 2 is a, vertical section, partly broken away, showing the parts in an on or work holding position;

- Fig. 3 is a similar view with the parts in an off or shunting position

- Fig. 4 is a section taken on the line 4- of Fig. 1;

- Fig. 5 is another section taken on the line 5-5 of Fig. 1;

- Fig. 6 is a view corresponding with Fig. 1 01'

- Fig. 12 is a vertical section of the chuck of Fig.

- a chuck or other holding device may comprise a massive. permanent magnet and associated parts arranged to form a magnet unit having its north and south poles at the top which terminate in two sets of spaced polar faces.

- One set is shaped and arranged-to contact magnetically with alternate pole pieces of a work plate and the other set contacts with the remaining pole pieces, when work is to be held, in place.

- the polar faces are movable to alternative positions where both a north and a south pole contact with a single pole piece, so that the interconnected polar faces and pole pieces serve to shunt the flux from the work.

- Figs. 1 to 5 represents a largemagnetlc chuck wherein two or more permanent magnets II and ii are employed in place of a single m net because of the limitations imposed on the manufacture of large Alnico bodies.

- each magnet may be made of two or more parts in butting contact.

- the Alnico blocks l and H are shaped substantially as long and narrow paralleleplpedons with poles at their long top and bottom surfaces. The blocks are located with their top faces extending beneath all of the pole pieces of the work plate.

- the top pole herein termed the north pole of the magnet, terminates in spaced ribs l2 whose top polar faces contact with alternate pole pieces of the work plate and energize the same.

- the magnet has a smooth or plane faced bottom which rests on an iron or steel plate I.

- One or more nonenergizing plates [5 of soft steel or other suitable magnetic material of high permeability have plane bottom faces which rest on and make full magnetic contact with the bottom plate. These plates have spaced ribs [6 providing top polar faces which are arranged to contact with the The massive magnet, or each of the magnets II. and H, has its upper pole terminating in the spaced polar faces formed by the tops of the ribs I2. Each of these faces has substantially the same area as that of the under side of the adjacent pole piece insert IS. The polar faces are so located and shaped as to make a full contact with the north pole pieces of the work plate when-the chuck is on," as shown in Fig. 2. The Babbitt metal spacing between the north and south pole pieces I!

- each polar face I may interconnect the adjacent pole pieces when moved to the of! position, as shown in Fig, 3.

- the ribs l2 are separated by spaces corresponding with the widths of the cross ribs l1 and the adjacent Babbitt metal inserts so that they may be fully isolated from the south pole ribs II.

- the Alnico metal may be provided with the spaced ribs i2 by casting it in a mold of proper shape. or, if desired, the magnet may be initially formed with a fiat or suitably shaped face, and

- the spaced ribs may be made ofsteel or other Y metal of high permeability formed separately or on a single body welded or otherwise secured to integral part thereof.

- the width of the soft steel plate or plates l5 may be narrow as compared with that of the magnet.

- major portion of the volume of the casing may other set of pole pieces ll of the work plate and thus form with a work piece thereon a complete circuit with the magnet duringoperative use of the chuck.

- the chuck casing comprises the ends 20, sides 2

- the end and side walls of this casing may be made of aluminum, brass or other non-magnetic material or, if desired, they may be made of iron so as to form a secondary path for the leakage flux. In either case the chuck casing does not form a primary part of the magnetic circuit, since the lines of force will take the shortest path from the magnet to the steel plate l5 and thus will not permeate the casing to any material extent.

- the work supporting plate 22 may be suitably constructed. As illustrated, it comprises an iron plate having rectangular openings cut therein separated by the cross ribs l1.

- the cross ribswith the surrounding framework of the plate form one pole of the energized circuit, herein designated the south pole.

- the north pole pieces Q iii are formed of strips of soft steel of substantially the samewidth as the ribs H. These are suitably secured within the rectangular openings in the late, as by means of spot brazing, after which the remainder of the space is filled with Babbitt metal 23 or other non-magnetic material.

- the brazing metal is preferably copper or brass.

- the under sides ofthe south pole ribs l1 and the north pole piece inserts I3 are exposed and lie in substantially the same horizontal plane so as to make sliding contact with the magnet unit.

- the bottom surfaces of the Babbitt metal between the ribs IT and the north pole pieces i3 lie preferably in that same plane.

- the construction shown in Figs. 1 to 5 has the massive permanent magnet substantially surrounded on its sides and ends by a soft steelconductor frame, made preferably of a low carbon, high permeability steel.

- This frame forms a return path for the flux.

- the frame comprises two soft steel plates i5 arranged parallel with and closely adjacent to the long sides of the massive permanent magnet in the center. plates or cross' pieces 25 are suitably secured to the side plates 15, as by means of screws, to form a rigid hollow rectangular unit. Rivets, bolts or screws 21 pass'through the side steel plate l5 and through suitable holes provided in the magnet.

- the Alnico metal is difiicult to machine, it is preferred to cast it with cored holes in which is molded non-magnetic material, such as Babbitt or brass 28, and the latter is then drilled and reamed to fit the brass "rivets 21.

- a suitable strip 29 of brass or other non-magnetic material separates the two magnets I0 and H, Y

- the magnet unit is adapted to be moved longi tudinally of the chuck casing by any suitable mechanism, such as the manually operated device shown in the drawings.

- the right hand end End plate 25 is provided with a centrally located opening within which is inserted a shouldered bushing 34 having a flange located between the magnet and the plate 25.

- the bushing 34 has a central threaded opening within which is secured a screw 35 projecting laterally from a narrow plate 36. The latter'is held by the screw against the outer surface of the end wall 25 and is thus rigidly secured in position.

- This part 36 has a vertically elongated slot 31 adjacent to its outer end which carries a pin 38 projecting laterally from the enlarged end 39 of a shaft 40 suitably mounted in bearings in the casing wall.

- This shaft is adapted to be turned by means of a handle 42 suitably secured thereto and projecting at the outside of the casing.

- the pin 38 is eccentric relative to the shaft 40 to such an extent that movement of the handle will serve to slide the magnet unit lengthwise of the chuck casing to and from the positions of Figs. 2 and 3.

- the end plate-25, at the left hand side of Fig. 1, likewise has a central hole therein within which is secured a shouldered bushing 44 that is centrally screw threaded and carries a screw 45. By turning the screw inwardly relative to the plate 25, the inner magnet may be moved endwise into a tight clamping engagement with the plate 25 atthe opposite end of the unit before the parts 7 are secured together.

- each of the ribs l2 of the magnet lies directly beneath a north pole insert I301 the work plate; but these ribs l2 are staggered zlative to the ribs of the two steel plates In.

- the ribs i6 thus contact fully with the cross ribs H, or south pole pieces, of the work plate when the ribs 12 contact with the north pole pieces l3. Since the lower plane faces of the magnet blocks I0 and il and the steel plates l5, as well as the end plates 25, rest on and in full contact with the soft steel bottom plate M, the south poles of the magnets are transferred to the upper polar faces of the ribs IS on the two side plates IS.

- the end plates 25 make a full contact with the under surface of the work .plate and thus aid materially in carrying the flux.

- the ribs l2 of the magnets connect the work plate pole pieces across the non-magnetic gaps of the Babbitt inserts 23.

- the ribs it connect the pole pieces adjacent the peripheral portion of the work plate.

- the flux passes directly from the magnet north polar faces through the work plate pole cause the later tends to take the shortest available path through the steel frame which lies as close as possible to the magnet.

- the steel frame has a high permeability and maybe net system has a greater holding power than would be the case if one used separate spaced magnets of the same width as the pole pieces of the work plate.

- the work plate 50 may be made as above described to provide the cross ribs 5] and the polar inserts 52 separated by non-magnetic Babbitt metal.

- the bottom plate 53 of the casing may be made of a low carbon high permeability steel.

- the side and end walls 54 and 55 are made of brass, aluminum or other suitable non-magnetic material.

- the movable magnet unit comprises two permanent magnets 58 made preferably of Alnico metal which are located on opposite sides of a non-energizing steel body 59 forming the return path for the flux. Since the permeability of the soft steel central body may be as much as four times that of the Alnico metal, this body may be only a quarter as wide as the combined width of the two magnets.

- the two magnets 58 are provided with spaced polar ribs 60 which are DO- sitioned so as to contact with the frame of the work plate 50 and its cross ribs 5

- the central steel body 59 has spaced polar ribs 52 thereon which operatively contact with the pole inserts 52 of the work plate.

- and 52 have their under faces exposed and lying in the same plane as above-described, so that the top polar faces of the ribs 60 and 62 will make sliding contact therewith.

- the under faces of the magnets and steel body 59 lie in the same plane and make a full magnetic contact with the iron or soft steel bottom plate 53 of the casing.

- the magnets 58 and steel body 59 are secured together as a rigid magnet unit by means of bolts 64. End plates 65 are connected between the magnets and thus make a hollow magnet body surrounding the steel body. Brass strips 66 separate the magnets from the central steel body; and the outer non-ma netic walls 54 may be shaped as shown particularly in Fig. 9 so as to provide surfaces contacting with the outer side faces of the magnets which form a runway for the magnet unit. The upper portions of these side :walls may be cut away so as to reduce friction.

- the magnet unit may be moved by a crank and eccentric as above described.

- throw of the eccentric pin 38 is such that movemade of minimum width, this leaves a large space size of the Alnico generator of magnetomotive' force. It will also be noted that the lines of force at the north pole of the generating magnet are concentrated in the spaced ribs, hence the magment of the handle 42 through a suitable arc,

- the pole pieces of the work plate may be made of any required width, and the polar faces of the magnet unit are shaped to correspond therewith. Since the polar faces of the magnet unit extend'to the full extent of the pole piece inserts of the work plate, and the north and south polar faces of the unit are arranged diagonally close'together, the flux will maintain a short path through a. work piece and thus give a highholdlng power.

- the movable unit consisting of both magnet and steel conductor is shifted so that both sets of polar ribs of the unit touch adjacent pole pieces of 1 the work plate and thus divert r shunt the flux 60 and 52 having polar faces that are movablev relative to the pole pieces contacting therewith, as shown in Figs. 1 to inclusive, it is also within the scope of my invention to locate the polar face members within a movable body arranged to make the required contacts with the pole pieces while the permanent magnet is held stationary.

- the magnetic unit of the chuck shown in Figs. 6 to 10 inclusive may be so constructed that the magnets are stationary and the spaced polar face members are mounted in a. separate slidable plate.

- the work plate 10 may comprise a soft steel frame having a set of spaced cross ribs 1

- a set of soft steel pole pieces 12 are secured in the openings and isolated from the ribs by Babbitt metal 13.

- the base plate 14 of the casing may be made of soft steel,

- . and the sides 15 may be formed of brass, aluminum or other non-magnetic material.

- Two ma nets 15 of Alnico or other suitable permanent magnet material are mounted in fixed positions on the bottom of the casing. Between the magnets is a steel body 18 separated therefrom by copper or brass separator strips 19. Both the magnets and the steel body are shaped as parallelepipedons having smooth top and bottom surfaces. The magnets and the steel body.

- the parts rest on and in full magnetic contact with the steel bottom plate H, and the parts are so arranged as to form a double U-shaped magnetin which the two outside bodies 16 are the generators of magnetomotive force and the inner non-energizing steel body 18 serves merely to form a return path for the flux and to transfer the south poles of the magnets to the .top surface of this steel body.

- the parts are preferably of such, dimensions that the steel body is'not fully saturated with the generated flux, so that the full power of the magnets is utilized.

- the spaced polar face members of the magnets and the steel body are formed in a separate slide Plate which is made of a suitable non-mag etic material, such as brass or aluminum

- This slide asooass slidably with the under exposed faces of the north and south polev pieces H and 12 of the work plate.

- the slide plate 80 has two soft steel strips 83 and" at its two ends which remain in contact with the two magnets and at the same time 7 are always in contact with thework platerim in so that the latter has the north P larity of the tops of the magnet.

- the central steel body 18 may be secured to the steel bottom of the chuck casing by screws 81 suitably located therein.

- the magnets may be likewise secured in place by screws 88 which are surrounded by Babbitt metal or lead 88.

- the magnets may be cast with cored openings and these may be filled with lead which is thereafter drilled out to form the bolt holes.

- the slide plate may be moved by the same type of manually operated device as above described with reference to the construction of Fig. 1.

- the slide plate has a, downwardly depending arm 82 provided with a. vertical slot 93 within which rides the eccentric pin 84 of the throw crank. It will be appreciated that the construction of Figs. 1 to 5 may be similarly modified to employ a slide plate in place of the polar ribs of the two central magnets and the two outer steel bodies I5.

- the slide plate 80 has each of its soft steel inserts 8

- the steel inserts 82 located over and contacting always with the steel body 18 will contact on their top surfaces with the south pole inserts H of the work plate.

- the plates or bodies i5, 59 and 18 forming the south pole of the magnet units above described are not energizing magnets 01', enerators of magnetomotive force and they are incapable of retaining residual magnetism to any material extent when not in circuit with a permanent magnet; hence the expressions non-magnet" and non-energizing" are to be interpreted accordingly as applying to such parts.

- the magnet unit may be considered as a substantially U- shaped magnet, whether provided with two or more poles.

- the permanent magnet portion oi the unit need not necessarily contact directly plate slides on the top of the magnet unit. It

- the inserts have fiat top and bottom faces adapted to make a sliding contact with the top faces of the magnets and the steel body II, and they have such a thickness as to contact with a set of pole pieces, since it may be suitably Figs. 1 to 5 of the drawings, the permanent magnet unit comprises a central element having one pole at its top mounted between two outside nonenergizing elements having the opposite polarity at their tops; or as shown in Figs. 6 to 10, the energizing unit comprises two outside magnets separated by a non-energizing body of magnetic material.

- the energizing unit extends longitudinally beneath all of the pole pieces of the work plate, and each pole of the magnet unit, made up of both the energizing and the nonenergizing elements, terminates in spaced polar face members which are so located in a staggered arrangement that the north polar faces thereof contact operatively, when the chuck is on, with one set of pole pieces of the work plate and the south polar faces contact only with the remaining pole pieces.

- Each of the pole pieces of the work plate extends crosswise of the work plate and preferably through the full distance subtended by the polar faces of the two outside bodies.

- the staggered arrangement of polar faces and the length and position of the cross ribs and pole piece inserts of the work plate are such that each magnet polar face may contact solely with one pole iece or it may be moved to contact with two adjacent pole pieces.

- the elements of the magnet unit may be formed of long massive magnets in a reverse polarity arrangement. That is, the soft steel members l of Fig. 1', 59 of Fig. 6 and 18 of Fig. 11 may be made of permanently magnetized material.

- the two outside bodies of Fig. 1 may be magnets with like poles at their tops providing a polarity opposite to that of the central magnet.

- the magnetic circuit is established permanently at the bottom of the magnet unit, such as by the steel bottom plates on which the magnets rest or slide.

- a magnetic holding device comprising a casing, a work plate thereon having two sets of alternately arranged, spaced pole pieces provided with lower contact surfaces, a permanent magnet unit having its north and south poles at the top thereof, a movable slide of non-magnetic material having magnetic inserts provided with plane top and bottom faces, one set of inserts contacting magnetically with the north pole of the magnet unit and alternate pole pieces of the work plate and the other set of inserts contacting magnetically with the south pole of the unit and the remaining pole pieces when the slide is in an operative work holding position, said slide plate being movable to an alternative position in which north and south pole inserts contact with a single pole piece of the work plate and thus provide a shunt path, and means for moving said slide plate to locate the metal inserts in either of said operative and shunting positions.

- a magnetic holding device comprising a work plate having two sets of alternately arranged

- a magnetic holding device comprising a work plate having two sets of alternately ar ranged, spaced pole pieces of substantially equal width separated by narrower non-magnetic gaps and providing lower contact surfaces, a magnet 'unit comprising a permanent magnet connected magnetically to a non-energizing magnetic metal body on each side thereof and having its north and south poles close to and extendin lengthwise beneath said pole pieces, each of said poles of the magnet unit terminating in a set of spaced ribs forming polar faces which operatively contact with alternate contact surfaces of the pole pieces, said magnet unit being alternatively movable to a position in which north andmagnetically and form a magnet unit having its north .and south poles'close to and extending lengthwise beneath said pole pieces, each of said poles of the magnet unit terminating in a set spaced pole pieces provided with lower contact surfaces, 9.

- a magnetic holding device comprising a work plate having two sets of alternately arranged, spaced pole pieces provided with lower contact surfaces, a single massive permanent magnet forming one arm of a magnet unit having an upper pole, a non-energizing magnetic metal body of high permeability which is always connected magnetically to'the lower pole of the magnet and is arranged to form a second arm of the unit, the magnet arm and the second arm each extending lengthwise beneath the two sets of work plate pole pieces, a plurality of spaced the work plate -pole pieces and the polar face members of the second arm, contacting operatively with the remaining pole pieces, said polar face members being movable relative to the work plate to positions where they contact simultaneously with the surfaces of adjacent pole pieces of the work plate and thus form a shunt path for the flux, and means for moving the polar I face members to and from the operative and flux shunting positions.

- a magnetic holding. device comprising a work plate having two sets of alternately arranged pole pieces provided with lower contact surfaces, asingle, massive, elongated permanent magnet forming one arm of a magnet unit having an upper pole, a non-energizing magnetic metal plate of high permeability which is always connected magnetically to the lower pole of the magnet and is arranged at one side of the magnet to form a second arm of the unit and provide an upper pole, the magnet arm-extending lengthwise beneath the two sets of spaced pole pieces and having a set of spaced ribs at its top terminating in spaced polar faces of a single polarity which contact in an operative position with said surfaces of alternate pole pieces, the metal plate extending lengthwise beneath the work plate pole pieces and having a set of spaced ribs at its top which are offset relative to the magnet ribs and contact operatively with the remaining pole pieces, said magnet unit beingmovable relative to the work plate to a position where the ribs of both arms of the magnet unit.

- a magnetic holding device comprising a work plate having two sets of alternately arranged, spaced pole pieces of substantially equal widths separated by narrower non-magnetic gaps and providing lower contact surfaces, a rigid magnet unit comprising a frame having side plates and a magnetic member secured within and isolated atits sides from said plates, one of the parts of the unit being a single massive permanent magnet and the other being a non-energizing magnetic metal body of high permeability, each of the side plates of said frame and said member extending lengthwise beneath the two'sets of pole pieces and each-having a set of spaced ribs, one set of ribs operatively contacting with alternate contact surfaces of the pole pieces and the other ing pole pieces, each rib beingarranged to contact solely with one pole piece when in an operative position or alternatively to contact with two adjacent pole pieces and form a shunt

- a magnetic holding device comprising a casing, a work plate'thereon having two sets of alternately arranged, spaced pole pieces provided with lower contact faces lying in a single plane, a magnetic bottom plate, a single massive per.- manent magnet slidably mounted on the bottom plate and extending longitudinally of the casing beneath said sets of pole pieces, a non-energizing magnetic metal body ofhigh permeability slidable on said bottom plate and arranged parallel with and close to the magnet and extending beneath the pole pieces, said magnet and body facesarranged substantially in the same plane,

- each polar-face being shaped and spaced to contact solely with one pole pieceto hold a work piece or, alternatively, to contact with two adjacent pole pieces and shunt flux from the work, and means for slidably moving said magnet unit.

- a magnetic holding device comprising a work plate having -two sets of alternately arranged, spaced pole pieces provided with lower contact a magnet unit therebeneath including a central body having one polarity at its top operatively arranged between and permanently connected magnetically to two outside plate shaped bodies having the opposite polarity. at their tops, each of said bodies extending lengthwise beneath all of the pole pieces, a set of polar face members magnetically connected to the top of each body and spaced by wider non-magnetic gaps, the members being movable relative to the work plate pole pieces and arranged to contact their under surfaces when in an operative position, the polar face members of the outside bodies being ar-.

- each pair being opposite a gap between two polar face members of the intermediate body, each pole piece being long enough to contact simultaneously with the opposed polar faces of the two outer bodies, said pole pieces, polar faces and associated non-magnetic gaps being of such widths that a pole piece may contact solely with a single polar face or alternatively may contact with polar faces of both polarities for establishing a shunt circuit independent of a work piece on the plate, and means for moving the polar face members to and from set contacting simultaneously with the remain-.

- each of the polar faces of one pole of the magnet unit being operatively arranged opposite a magnetic gap between the polar faces of the other pole and providing a staggered arrangement such that the polar faces at one magnet pole slidably contact only with alternate pole pieces of the work plate and the polar faces of the other pole contact with the remaining pole pieces of the work plate when work is to be held on the plate, each pole piece of the work plate having a length sub tending the series of polar faces of both magnet poles, said magnet unit being movable to a position where each pole piece contacts with polar faces of opposite polarity and forms a shunt circuit independent of a work piece on said plate and means for slidably moving the magnet unit relative to the work plate polepieces to and and shunting positions.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Jigs For Machine Tools (AREA)

Description

Dec. 11, 1945. F. L. SIMMONS PERMANENT MAGNET HOLDING DEVICE Filed May 5, 1943 2 Sheets-Sheet 2 m m Mm w .m

S I 3. 2w

wiiness Her-bar Cove Patented Dec. 11, 1945 UNITED STATES PATENT orncs 2,390,143 PERMANENT MAGNET HOLDING nnvloa Frank L. Simmons, Woonsocket, R. 1.

Application May 5, 1943, Serial No. 435,740

7 10 Claims. (01. 175-367) This invention relates to permanent magnet holding devices, such as magnetic chucks used to hold work in position for a tooling operation.

Various magnet chucks have been proposed heretofore in which a plurality of permanent magnets-have been so mounted for movement relative to the pole pieces of a work plate that the pole pieces may be energized for holding a work piece in position, or alternatively a part of the magnetic flux may be shunted out of the work. There is only a limited amount of space available in a chuck casing and much of this space has not been occupied by the energizing magnets. For example, the volume occupied by the non-magnetic separators between a set of parallel, narrow bar magnets may be 10% or more of the available space.

it is desirable to employ a massive permanent magnet so arranged as to extend longitudinally beneath the work plate pole pieces and to fill the available portion of the chuck casing and thus give the maximum holding power per unit area of the work plate. A massive magnet will de velop more iiux or field strength than can a set of narrow bar magnets, and the magnetic circuit may be made short and adequate. Also, a. massive magnet with a smooth under face will slide easily on the casing bottom plate, whereas narrow bar magnets offer greater ,frictional resistance opposing the movement, and they tend to wear the base plate rapidly. The massive magnet can be slidably mounted with the minimum oi air gap interposed in the circuit.

A construction of this type should provide an adequate and short magnetic circuit of low reluctance and a satisfactory flux distribution for the normal operation of the chuck; and it should be capable of shunting sumcient flux from the work to insure an easy release of the same, but without wasting valuable space, either laterally or vertically. Increasing the height of the magnet, as well as its cross sectional area, increases the holding power, and particularly because the magnet of larger volume can be provided with or absorb a greater concentration of flux.

It is a primary object of this invention to overcome these disadvantages and to provide an e1- ficient permanent magnet holding device, such as a chuck, in which one or more massive magnets are so arranged relative to the pole pieces of the work plate that a work piece may be held securely in place or the pole pieces may be connected with both magnet poles to shunt a substantial portion of the magnetic flux from the work for releasing the same.

A permanent magnet may be made of Alnico, an alloy of iron, aluminum, nickel and cobalt; but this metal has a low permeability as compared with a soft carbon steel. Hence, if a plurality of Alnico magnets are mounted in a reverse to provide an eillcient and satisfactory return path for the flux and to secure the maximum magnetomotive force for a given volume 01 available space within the casing.

A further object of the invention is to provide a construction in which a massive permanent magnet unit is so arranged relative to two sets of evenly spaced and equal width pole pieces on the work plate that the unit may energize each pole piece with a satisfactory flux distribution, or alternatively the opposite poles of the unit may contact with individual pole pieces and form a shunt circuit that removes flux from the work. Other objects will be apparent in the following disclosure.

Referring to the drawings, which illustrate various embodiments of my invention:

Fig. 1 is a top plan view, with the work plate partly broken away, of a permanent magnet chuck having a massive permanent magnet arranged between two members to form a ma net unit which is movable to and from work holding and flux shunting positions;

Fig. 2 is a, vertical section, partly broken away, showing the parts in an on or work holding position; I

Fig. 3 is a similar view with the parts in an off or shunting position;

Fig. 4 is a section taken on the line 4- of Fig. 1;

Fig. 5 is another section taken on the line 5-5 of Fig. 1;

.Fig. 6 is a view corresponding with Fig. 1 01' Fig. 12 is a vertical section of the chuck of Fig.

with the slide located in a flux shunting position.

In accordance with one aspect of my invention, a chuck or other holding device may comprise a massive. permanent magnet and associated parts arranged to form a magnet unit having its north and south poles at the top which terminate in two sets of spaced polar faces. One set is shaped and arranged-to contact magnetically with alternate pole pieces of a work plate and the other set contacts with the remaining pole pieces, when work is to be held, in place. The polar faces are movable to alternative positions where both a north and a south pole contact with a single pole piece, so that the interconnected polar faces and pole pieces serve to shunt the flux from the work.

The form shown in Figs. 1 to 5 represents a largemagnetlc chuck wherein two or more permanent magnets II and ii are employed in place of a single m net because of the limitations imposed on the manufacture of large Alnico bodies.

They, however, act the same as a single magnet and will be considered as such. If the chuck is to be very large in size, each magnet may be made of two or more parts in butting contact. The Alnico blocks l and H are shaped substantially as long and narrow paralleleplpedons with poles at their long top and bottom surfaces. The blocks are located with their top faces extending beneath all of the pole pieces of the work plate. The top pole, herein termed the north pole of the magnet, terminates in spaced ribs l2 whose top polar faces contact with alternate pole pieces of the work plate and energize the same. The magnet has a smooth or plane faced bottom which rests on an iron or steel plate I. One or more nonenergizing plates [5 of soft steel or other suitable magnetic material of high permeability have plane bottom faces which rest on and make full magnetic contact with the bottom plate. These plates have spaced ribs [6 providing top polar faces which are arranged to contact with the The massive magnet, or each of the magnets II. and H, has its upper pole terminating in the spaced polar faces formed by the tops of the ribs I2. Each of these faces has substantially the same area as that of the under side of the adjacent pole piece insert IS. The polar faces are so located and shaped as to make a full contact with the north pole pieces of the work plate when-the chuck is on," as shown in Fig. 2. The Babbitt metal spacing between the north and south pole pieces I! and I1 is such that each polar face I: may interconnect the adjacent pole pieces when moved to the of!" position, as shown in Fig, 3. The ribs l2 are separated by spaces corresponding with the widths of the cross ribs l1 and the adjacent Babbitt metal inserts so that they may be fully isolated from the south pole ribs II.

The Alnico metal may be provided with the spaced ribs i2 by casting it in a mold of proper shape. or, if desired, the magnet may be initially formed with a fiat or suitably shaped face, and

the spaced ribs may be made ofsteel or other Y metal of high permeability formed separately or on a single body welded or otherwise secured to integral part thereof.

Since the permeability of soft steel is high as compared with that of Alnico metal, the width of the soft steel plate or plates l5 may be narrow as compared with that of the magnet. Hence, the

. major portion of the volume of the casing may other set of pole pieces ll of the work plate and thus form with a work piece thereon a complete circuit with the magnet duringoperative use of the chuck.

The chuck casing comprises the ends 20, sides 2| and the bottom plate l4. These in association with the work supporting plate22 form a complete enclosure for the magnet unit. The end and side walls of this casing may be made of aluminum, brass or other non-magnetic material or, if desired, they may be made of iron so as to form a secondary path for the leakage flux. In either case the chuck casing does not form a primary part of the magnetic circuit, since the lines of force will take the shortest path from the magnet to the steel plate l5 and thus will not permeate the casing to any material extent.

The work supporting plate 22 may be suitably constructed. As illustrated, it comprises an iron plate having rectangular openings cut therein separated by the cross ribs l1. The cross ribswith the surrounding framework of the plate form one pole of the energized circuit, herein designated the south pole. The north pole pieces Q iii are formed of strips of soft steel of substantially the samewidth as the ribs H. These are suitably secured within the rectangular openings in the late, as by means of spot brazing, after which the remainder of the space is filled with Babbitt metal 23 or other non-magnetic material. The brazing metal is preferably copper or brass. The under sides ofthe south pole ribs l1 and the north pole piece inserts I3 are exposed and lie in substantially the same horizontal plane so as to make sliding contact with the magnet unit. The bottom surfaces of the Babbitt metal between the ribs IT and the north pole pieces i3 lie preferably in that same plane.

be occupied by the magnet; and thus a larger magnet may be used for generating the flux than would be the case if the return path were made through another magnet of the same low permeability. Although the horizontal cross sectional areas of the steel and Alnico parts may be proportioned inversely to their permeabilities, I preferably make the steel parts somewhat larger than this theoretical value. v

The construction shown in Figs. 1 to 5 has the massive permanent magnet substantially surrounded on its sides and ends by a soft steelconductor frame, made preferably of a low carbon, high permeability steel. This frame forms a return path for the flux. The frame comprises two soft steel plates i5 arranged parallel with and closely adjacent to the long sides of the massive permanent magnet in the center. plates or cross' pieces 25 are suitably secured to the side plates 15, as by means of screws, to form a rigid hollow rectangular unit. Rivets, bolts or screws 21 pass'through the side steel plate l5 and through suitable holes provided in the magnet. Since the Alnico metal is difiicult to machine, it is preferred to cast it with cored holes in which is molded non-magnetic material, such as Babbitt or brass 28, and the latter is then drilled and reamed to fit the brass "rivets 21. A suitable strip 29 of brass or other non-magnetic material separates the two magnets I0 and H, Y

form a slideway which guides the magnet unit in its movement.

The magnet unit is adapted to be moved longi tudinally of the chuck casing by any suitable mechanism, such as the manually operated device shown in the drawings. The right hand end End plate 25 is provided with a centrally located opening within which is inserted a shouldered bushing 34 having a flange located between the magnet and the plate 25. The bushing 34 has a central threaded opening within which is secured a screw 35 projecting laterally from a narrow plate 36. The latter'is held by the screw against the outer surface of the end wall 25 and is thus rigidly secured in position. This part 36 has a vertically elongated slot 31 adjacent to its outer end which carries a pin 38 projecting laterally from the enlarged end 39 of a shaft 40 suitably mounted in bearings in the casing wall. This shaft is adapted to be turned by means of a handle 42 suitably secured thereto and projecting at the outside of the casing. The pin 38 is eccentric relative to the shaft 40 to such an extent that movement of the handle will serve to slide the magnet unit lengthwise of the chuck casing to and from the positions of Figs. 2 and 3. The end plate-25, at the left hand side of Fig. 1, likewise has a central hole therein within which is secured a shouldered bushing 44 that is centrally screw threaded and carries a screw 45. By turning the screw inwardly relative to the plate 25, the inner magnet may be moved endwise into a tight clamping engagement with the plate 25 atthe opposite end of the unit before the parts 7 are secured together.

As shown particularly in Fig. 1, each of the ribs l2 of the magnet lies directly beneath a north pole insert I301 the work plate; but these ribs l2 are staggered zlative to the ribs of the two steel plates In. The ribs i6 thus contact fully with the cross ribs H, or south pole pieces, of the work plate when the ribs 12 contact with the north pole pieces l3. Since the lower plane faces of the magnet blocks I0 and il and the steel plates l5, as well as the end plates 25, rest on and in full contact with the soft steel bottom plate M, the south poles of the magnets are transferred to the upper polar faces of the ribs IS on the two side plates IS. The end plates 25 make a full contact with the under surface of the work .plate and thus aid materially in carrying the flux. When moved to the off positicn by the handle 42, the ribs l2 of the magnets connect the work plate pole pieces across the non-magnetic gaps of the Babbitt inserts 23. Likewise. the ribs it connect the pole pieces adjacent the peripheral portion of the work plate. Hence, the flux passes directly from the magnet north polar faces through the work plate pole cause the later tends to take the shortest available path through the steel frame which lies as close as possible to the magnet. Also, since the steel frame has a high permeability and maybe net system has a greater holding power than would be the case if one used separate spaced magnets of the same width as the pole pieces of the work plate.

It will now be appreciated that the relative positions of the energizing magnet and the nonenergizing soft steel conducting plates may be reversed, as shown in Figs. 6 to 10 inclusive of the drawings. In this construction, the work plate 50 may be made as above described to provide the cross ribs 5] and the polar inserts 52 separated by non-magnetic Babbitt metal. The bottom plate 53 of the casing may be made of a low carbon high permeability steel. The side and end walls 54 and 55 are made of brass, aluminum or other suitable non-magnetic material.

The movable magnet unit comprises two permanent magnets 58 made preferably of Alnico metal which are located on opposite sides of a non-energizing steel body 59 forming the return path for the flux. Since the permeability of the soft steel central body may be as much as four times that of the Alnico metal, this body may be only a quarter as wide as the combined width of the two magnets. The two magnets 58 are provided with spaced polar ribs 60 which are DO- sitioned so as to contact with the frame of the work plate 50 and its cross ribs 5|. Likewise, the central steel body 59 has spaced polar ribs 52 thereon which operatively contact with the pole inserts 52 of the work plate. The pole pieces 5| and 52 have their under faces exposed and lying in the same plane as above-described, so that the top polar faces of the ribs 60 and 62 will make sliding contact therewith. The under faces of the magnets and steel body 59 lie in the same plane and make a full magnetic contact with the iron or soft steel bottom plate 53 of the casing.

The magnets 58 and steel body 59 are secured together as a rigid magnet unit by means of bolts 64. End plates 65 are connected between the magnets and thus make a hollow magnet body surrounding the steel body. Brass strips 66 separate the magnets from the central steel body; and the outer non-ma netic walls 54 may be shaped as shown particularly in Fig. 9 so as to provide surfaces contacting with the outer side faces of the magnets which form a runway for the magnet unit. The upper portions of these side :walls may be cut away so as to reduce friction.

The magnet unit may be moved by a crank and eccentric as above described.

The operation of each chuck is the same. The

throw of the eccentric pin 38 is such that movemade of minimum width, this leaves a large space size of the Alnico generator of magnetomotive' force. It will also be noted that the lines of force at the north pole of the generating magnet are concentrated in the spaced ribs, hence the magment of the handle 42 through a suitable arc,

such as serves to move the magnet units from the positions of Figs. 2 and '7 to those of Figs. 3 and 8. When the magnet unit is in the position of either Fig. 2 or Fig. 7, the north polar faces of the magnet make a full contact with their associated pole pieces of the work plate,

and the south polar ribs of the steel plates l5 or central steel body 59 provide a south pole in direct contact with the south pole pieces of the work plate. This provides the shortest possible path for the lines of force and the maximum field. The pole pieces of the work plate may be made of any required width, and the polar faces of the magnet unit are shaped to correspond therewith. Since the polar faces of the magnet unit extend'to the full extent of the pole piece inserts of the work plate, and the north and south polar faces of the unit are arranged diagonally close'together, the flux will maintain a short path through a. work piece and thus give a highholdlng power.

When the work is to be released, the movable unit consisting of both magnet and steel conductor is shifted so that both sets of polar ribs of the unit touch adjacent pole pieces of 1 the work plate and thus divert r shunt the flux 60 and 52 having polar faces that are movablev relative to the pole pieces contacting therewith, as shown in Figs. 1 to inclusive, it is also within the scope of my invention to locate the polar face members within a movable body arranged to make the required contacts with the pole pieces while the permanent magnet is held stationary. For example, the magnetic unit of the chuck shown in Figs. 6 to 10 inclusive may be so constructed that the magnets are stationary and the spaced polar face members are mounted in a. separate slidable plate. A chuck of this type is shown in Figs. 11 and 12 of the drawings. The work plate 10 may comprise a soft steel frame having a set of spaced cross ribs 1| separated by rectangular openings. A set of soft steel pole pieces 12 are secured in the openings and isolated from the ribs by Babbitt metal 13. The base plate 14 of the casing may be made of soft steel,

. and the sides 15 may be formed of brass, aluminum or other non-magnetic material. Two ma nets 15 of Alnico or other suitable permanent magnet material are mounted in fixed positions on the bottom of the casing. Between the magnets is a steel body 18 separated therefrom by copper or brass separator strips 19. Both the magnets and the steel body are shaped as parallelepipedons having smooth top and bottom surfaces. The magnets and the steel body. rest on and in full magnetic contact with the steel bottom plate H, and the parts are so arranged as to form a double U-shaped magnetin which the two outside bodies 16 are the generators of magnetomotive force and the inner non-energizing steel body 18 serves merely to form a return path for the flux and to transfer the south poles of the magnets to the .top surface of this steel body. The parts are preferably of such, dimensions that the steel body is'not fully saturated with the generated flux, so that the full power of the magnets is utilized.

The spaced polar face members of the magnets and the steel body are formed in a separate slide Plate which is made of a suitable non-mag etic material, such as brass or aluminum This slide asooass slidably with the under exposed faces of the north and south polev pieces H and 12 of the work plate. The slide plate 80 has two soft steel strips 83 and" at its two ends which remain in contact with the two magnets and at the same time 7 are always in contact with thework platerim in so that the latter has the north P larity of the tops of the magnet.

The central steel body 18 may be secured to the steel bottom of the chuck casing by screws 81 suitably located therein. The magnets may be likewise secured in place by screws 88 which are surrounded by Babbitt metal or lead 88. The magnets may be cast with cored openings and these may be filled with lead which is thereafter drilled out to form the bolt holes. v

The slide plate may be moved by the same type of manually operated device as above described with reference to the construction of Fig. 1. The slide plate has a, downwardly depending arm 82 provided with a. vertical slot 93 within which rides the eccentric pin 84 of the throw crank. It will be appreciated that the construction of Figs. 1 to 5 may be similarly modified to employ a slide plate in place of the polar ribs of the two central magnets and the two outer steel bodies I5.

The slide plate 80 has each of its soft steel inserts 8| arranged to contact solely with one of the pole piece ribs ll of the work plate or alternatively to be movable to c ntact with two adjacent pole pieces 1| and I2 or the "off" position of the chuck. When the slide. is in on position and the steel inserts 8| contact solely with the entire set of cross ribs 1|, then the steel inserts 82 located over and contacting always with the steel body 18 will contact on their top surfaces with the south pole inserts H of the work plate.

Thus a return circuit is eifected through a work piece carried on the work plate. When the flux is to be shunted out of the work piece, then the slide plate 80 is moved to the position of Fig. 12 in which both the inserts 8| and 82 contact with adjacent pole pieces Ii and 12 of the work plate and thus form a short return path for the flux.

The plates or bodies i5, 59 and 18 forming the south pole of the magnet units above describedare not energizing magnets 01', enerators of magnetomotive force and they are incapable of retaining residual magnetism to any material extent when not in circuit with a permanent magnet; hence the expressions non-magnet" and non-energizing" are to be interpreted accordingly as applying to such parts. Also, the magnet unit may be considered as a substantially U- shaped magnet, whether provided with two or more poles. The permanent magnet portion oi the unit need not necessarily contact directly plate slides on the top of the magnet unit. It

has a series of rectangular openings therethrough shaped and spaced as shown in Fig. 11, and these openings are filled with soft steel inserts 8| and 82 which are located and shaped substantially the same as the spaced polar ribs of the construction of Fig. 6. These inserts, as well as the other non-energizing magnetic metal parts of this and the other constructions, may be formed of a low carbon soft steel or Swedish or wrought iron or other suitable metal of high permeability. The inserts BI and 82 are suitably held in place, as by casting the brass plate around the steel inserts. The inserts have fiat top and bottom faces adapted to make a sliding contact with the top faces of the magnets and the steel body II, and they have such a thickness as to contact with a set of pole pieces, since it may be suitably Figs. 1 to 5 of the drawings, the permanent magnet unit comprises a central element having one pole at its top mounted between two outside nonenergizing elements having the opposite polarity at their tops; or as shown in Figs. 6 to 10, the energizing unit comprises two outside magnets separated by a non-energizing body of magnetic material. The energizing unit extends longitudinally beneath all of the pole pieces of the work plate, and each pole of the magnet unit, made up of both the energizing and the nonenergizing elements, terminates in spaced polar face members which are so located in a staggered arrangement that the north polar faces thereof contact operatively, when the chuck is on, with one set of pole pieces of the work plate and the south polar faces contact only with the remaining pole pieces. The polar faces of the magnet'poles 'are'each located opposite a wider non-magnetic 'gap or recess between two polar faces of the adjacent magnet pole of opposite polarity. Each of the pole pieces of the work plate extends crosswise of the work plate and preferably through the full distance subtended by the polar faces of the two outside bodies. Hence, the staggered arrangement of polar faces and the length and position of the cross ribs and pole piece inserts of the work plate are such that each magnet polar face may contact solely with one pole iece or it may be moved to contact with two adjacent pole pieces.

Although I prefer to employ a non-magnet or non-energizing body of high permeability as a part of the magnet unit, as above described, it will be appreciated that the elements of the magnet unit may be formed of long massive magnets in a reverse polarity arrangement. That is, the soft steel members l of Fig. 1', 59 of Fig. 6 and 18 of Fig. 11 may be made of permanently magnetized material. For example, the two outside bodies of Fig. 1 may be magnets with like poles at their tops providing a polarity opposite to that of the central magnet. In all of these constructions, the magnetic circuit is established permanently at the bottom of the magnet unit, such as by the steel bottom plates on which the magnets rest or slide. Various other modifications may be made in these constructions within the of spaced ribs forming polar faces which operatively contact with alternate contact surfaces of the pole pieces, said magnet unit being alternatively movable to a position in which north and south polar faces of the magnet unit contact simultaneously with each pole piece of the work plate and thus shunt the flux out of the work piece on said plate, and means for moving the magnet unit to and from its operative and flux shunting positions.

3. A magnetic holding device comprising a casing, a work plate thereon having two sets of alternately arranged, spaced pole pieces provided with lower contact surfaces, a permanent magnet unit having its north and south poles at the top thereof, a movable slide of non-magnetic material having magnetic inserts provided with plane top and bottom faces, one set of inserts contacting magnetically with the north pole of the magnet unit and alternate pole pieces of the work plate and the other set of inserts contacting magnetically with the south pole of the unit and the remaining pole pieces when the slide is in an operative work holding position, said slide plate being movable to an alternative position in which north and south pole inserts contact with a single pole piece of the work plate and thus provide a shunt path, and means for moving said slide plate to locate the metal inserts in either of said operative and shunting positions.

4. A magnetic holding device comprising a work plate having two sets of alternately arranged,

scope- 'of my invention; hence the above description is to be interpreted as explaining the principles of the invention and my preferred embodiments and not as limitations on the appended claims.

I claim:

1. A magnetic holding device comprising a work plate having two sets of alternately ar ranged, spaced pole pieces of substantially equal width separated by narrower non-magnetic gaps and providing lower contact surfaces, a magnet 'unit comprising a permanent magnet connected magnetically to a non-energizing magnetic metal body on each side thereof and having its north and south poles close to and extendin lengthwise beneath said pole pieces, each of said poles of the magnet unit terminating in a set of spaced ribs forming polar faces which operatively contact with alternate contact surfaces of the pole pieces, said magnet unit being alternatively movable to a position in which north andmagnetically and form a magnet unit having its north .and south poles'close to and extending lengthwise beneath said pole pieces, each of said poles of the magnet unit terminating in a set spaced pole pieces provided with lower contact surfaces, 9. single massive permanent magnet forming one arm of a U shaped magnet unit, a non-energizing magnetic metal body of high permeability which is connected magnetically to the lower pole of said magnet and is arranged to form a second arm of the unit, each arm extending lengthwise beneath the two sets of work plate pole pieces, a plurality of spaced polar face members which are always connected magnetically to each of the two arms and provide a set of spaced terminal polar faces for each arm, the polar faces of the terminal members of one am contacting with the lower surfaces of alternate pole pieces of the work plate when in an operative position and the polar faces of the terminal members of the other arm contacting simultaneously with the remaining pole pieces, said members being movable relative to the work plate to positions where they contact simultaneously with the surfaces of adjacent pole pieces and thus form a shunt path for the flux, and means for moving the members to and from the operative and flux shunting positions while they remain magnetically connected to the magnet and said metal body.

5. A magnetic holding device comprising a work plate having two sets of alternately arranged, spaced pole pieces provided with lower contact surfaces, a single massive permanent magnet forming one arm of a magnet unit having an upper pole, a non-energizing magnetic metal body of high permeability which is always connected magnetically to'the lower pole of the magnet and is arranged to form a second arm of the unit, the magnet arm and the second arm each extending lengthwise beneath the two sets of work plate pole pieces, a plurality of spaced the work plate -pole pieces and the polar face members of the second arm, contacting operatively with the remaining pole pieces, said polar face members being movable relative to the work plate to positions where they contact simultaneously with the surfaces of adjacent pole pieces of the work plate and thus form a shunt path for the flux, and means for moving the polar I face members to and from the operative and flux shunting positions.

6. A magnetic holding. device comprising a work plate having two sets of alternately arranged pole pieces provided with lower contact surfaces, asingle, massive, elongated permanent magnet forming one arm of a magnet unit having an upper pole, a non-energizing magnetic metal plate of high permeability which is always connected magnetically to the lower pole of the magnet and is arranged at one side of the magnet to form a second arm of the unit and provide an upper pole, the magnet arm-extending lengthwise beneath the two sets of spaced pole pieces and having a set of spaced ribs at its top terminating in spaced polar faces of a single polarity which contact in an operative position with said surfaces of alternate pole pieces, the metal plate extending lengthwise beneath the work plate pole pieces and having a set of spaced ribs at its top which are offset relative to the magnet ribs and contact operatively with the remaining pole pieces, said magnet unit beingmovable relative to the work plate to a position where the ribs of both arms of the magnet unit. contact individually and simultaneously with the adjacent work plate pole pieces and thus form a shunt path for the flux, and mechanism for moving the magnet unit to and from its operative and shunting positions. 7. A magnetic holding device comprising a work plate having two sets of alternately arranged, spaced pole pieces of substantially equal widths separated by narrower non-magnetic gaps and providing lower contact surfaces, a rigid magnet unit comprising a frame having side plates and a magnetic member secured within and isolated atits sides from said plates, one of the parts of the unit being a single massive permanent magnet and the other being a non-energizing magnetic metal body of high permeability, each of the side plates of said frame and said member extending lengthwise beneath the two'sets of pole pieces and each-having a set of spaced ribs, one set of ribs operatively contacting with alternate contact surfaces of the pole pieces and the other ing pole pieces, each rib beingarranged to contact solely with one pole piece when in an operative position or alternatively to contact with two adjacent pole pieces and form a shunt path for the flux, and means for moving the unit to and from the operative and shunting positions.

8. A magnetic holding device comprising a casing, a work plate'thereon having two sets of alternately arranged, spaced pole pieces provided with lower contact faces lying in a single plane, a magnetic bottom plate, a single massive per.- manent magnet slidably mounted on the bottom plate and extending longitudinally of the casing beneath said sets of pole pieces, a non-energizing magnetic metal body ofhigh permeability slidable on said bottom plate and arranged parallel with and close to the magnet and extending beneath the pole pieces, said magnet and body facesarranged substantially in the same plane,

forming a U shaped magnetic unit having its poles at the top, and each having a set of ribs form-- ing spaced polar faces, one set of ribs slidably contacting with alternate contact faces of the pole pieces and the other set contacting with the remaining pole pieces when in an operative position, each polar-face being shaped and spaced to contact solely with one pole pieceto hold a work piece or, alternatively, to contact with two adjacent pole pieces and shunt flux from the work, and means for slidably moving said magnet unit.

9. A magnetic holding device comprising a work plate having -two sets of alternately arranged, spaced pole pieces provided with lower contact a magnet unit therebeneath including a central body having one polarity at its top operatively arranged between and permanently connected magnetically to two outside plate shaped bodies having the opposite polarity. at their tops, each of said bodies extending lengthwise beneath all of the pole pieces, a set of polar face members magnetically connected to the top of each body and spaced by wider non-magnetic gaps, the members being movable relative to the work plate pole pieces and arranged to contact their under surfaces when in an operative position, the polar face members of the outside bodies being ar-.

ranged as aligned pairs, each pair being opposite a gap between two polar face members of the intermediate body, each pole piece being long enough to contact simultaneously with the opposed polar faces of the two outer bodies, said pole pieces, polar faces and associated non-magnetic gaps being of such widths that a pole piece may contact solely with a single polar face or alternatively may contact with polar faces of both polarities for establishing a shunt circuit independent of a work piece on the plate, and means for moving the polar face members to and from set contacting simultaneously with the remain-.'

neath all of the pole pieces, a set of spaced members integral'with the top of each body and forming the terminal polar faces thereof, said members being separated by wider non-magnetic gaps, each of the polar faces of one pole of the magnet unit being operatively arranged opposite a magnetic gap between the polar faces of the other pole and providing a staggered arrangement such that the polar faces at one magnet pole slidably contact only with alternate pole pieces of the work plate and the polar faces of the other pole contact with the remaining pole pieces of the work plate when work is to be held on the plate, each pole piece of the work plate having a length sub tending the series of polar faces of both magnet poles, said magnet unit being movable to a position where each pole piece contacts with polar faces of opposite polarity and forms a shunt circuit independent of a work piece on said plate and means for slidably moving the magnet unit relative to the work plate polepieces to and and shunting positions. L. SIMMONS.

from their operative

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US485740A US2390743A (en) | 1943-05-05 | 1943-05-05 | Permanent magnet holding device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US485740A US2390743A (en) | 1943-05-05 | 1943-05-05 | Permanent magnet holding device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US2390743A true US2390743A (en) | 1945-12-11 |

Family

ID=23929276

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US485740A Expired - Lifetime US2390743A (en) | 1943-05-05 | 1943-05-05 | Permanent magnet holding device |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US2390743A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2700744A (en) * | 1951-05-24 | 1955-01-25 | Frank L Simmons | Permanent magnet chuck |

| DE936785C (en) * | 1951-01-21 | 1955-12-22 | Wilhelm Binder K G Maschinen U | Permanent magnetic clamping device |

| US8393111B1 (en) * | 2008-12-11 | 2013-03-12 | Jeffrey A. Johnson | Easy attach fishing rod holder |

-

1943

- 1943-05-05 US US485740A patent/US2390743A/en not_active Expired - Lifetime

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE936785C (en) * | 1951-01-21 | 1955-12-22 | Wilhelm Binder K G Maschinen U | Permanent magnetic clamping device |

| US2700744A (en) * | 1951-05-24 | 1955-01-25 | Frank L Simmons | Permanent magnet chuck |

| US8393111B1 (en) * | 2008-12-11 | 2013-03-12 | Jeffrey A. Johnson | Easy attach fishing rod holder |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1301135A (en) | Fixture for use with magnetic chucks. | |

| US4468648A (en) | Switchable permanent magnetic chuck | |

| WO2009069146A1 (en) | An electro permanent magnetic apparatus with dual working face | |

| US2286238A (en) | Magnetic chuck | |

| US2390743A (en) | Permanent magnet holding device | |

| US2333230A (en) | Magnetic chuck | |

| US2193675A (en) | Dynamo-electric machine | |

| ES8201348A1 (en) | Magnetic block of the permanent magnets type comprising an on-off control mechanism. | |

| US2268011A (en) | Permanent magnetic chuck | |

| US2947921A (en) | Fine grid permanent magnetic chuck | |

| US2160405A (en) | Magnetic work holder | |

| US3503024A (en) | Chuck of permanent magnets | |

| US2700744A (en) | Permanent magnet chuck | |

| US2138864A (en) | Electromagnetic device and circuits for operating the same | |

| US3179858A (en) | Controllable permanent magnetic chuck | |

| US2319270A (en) | Permanent magnet chuck | |

| GB551329A (en) | Improvements in permanent magnetic chuck | |

| US1816888A (en) | Magnetic chuck and circuits therefor | |

| GB1041288A (en) | Electro-magnetic chucks | |

| JPS5882754U (en) | Electromagnetic device for electromagnetic switch | |

| US2359293A (en) | Permanent magnetic chuck | |

| DE655812C (en) | Electrical contactor | |

| US1267480A (en) | Electric welding apparatus. | |

| US2275904A (en) | Magnet structure | |

| US2404710A (en) | Permanent magnet structure |