US20240260745A1 - Table for food preparation and/or consumption - Google Patents

Table for food preparation and/or consumption Download PDFInfo

- Publication number

- US20240260745A1 US20240260745A1 US18/436,007 US202418436007A US2024260745A1 US 20240260745 A1 US20240260745 A1 US 20240260745A1 US 202418436007 A US202418436007 A US 202418436007A US 2024260745 A1 US2024260745 A1 US 2024260745A1

- Authority

- US

- United States

- Prior art keywords

- heat

- aperture

- cooking

- generally flat

- table top

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 235000013305 food Nutrition 0.000 title abstract description 30

- 238000002360 preparation method Methods 0.000 title description 5

- 238000010411 cooking Methods 0.000 claims abstract description 34

- 230000004888 barrier function Effects 0.000 claims abstract description 10

- 230000005855 radiation Effects 0.000 claims abstract description 6

- 239000000463 material Substances 0.000 claims description 20

- 239000010875 treated wood Substances 0.000 claims description 10

- 229910000831 Steel Inorganic materials 0.000 claims description 6

- 239000010959 steel Substances 0.000 claims description 6

- 230000002093 peripheral effect Effects 0.000 claims description 4

- 230000001105 regulatory effect Effects 0.000 abstract description 2

- 230000000087 stabilizing effect Effects 0.000 abstract description 2

- 239000007789 gas Substances 0.000 description 20

- ATUOYWHBWRKTHZ-UHFFFAOYSA-N Propane Chemical compound CCC ATUOYWHBWRKTHZ-UHFFFAOYSA-N 0.000 description 8

- 241000237502 Ostreidae Species 0.000 description 6

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 6

- 235000020636 oyster Nutrition 0.000 description 6

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 6

- 239000007788 liquid Substances 0.000 description 5

- 235000015170 shellfish Nutrition 0.000 description 5

- 238000010025 steaming Methods 0.000 description 5

- 238000000034 method Methods 0.000 description 4

- 239000001294 propane Substances 0.000 description 4

- 238000009835 boiling Methods 0.000 description 3

- 238000002485 combustion reaction Methods 0.000 description 3

- 235000021268 hot food Nutrition 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 239000003345 natural gas Substances 0.000 description 3

- 229910001018 Cast iron Inorganic materials 0.000 description 2

- 239000010425 asbestos Substances 0.000 description 2

- 239000003292 glue Substances 0.000 description 2

- 239000012212 insulator Substances 0.000 description 2

- 229910052895 riebeckite Inorganic materials 0.000 description 2

- 235000014102 seafood Nutrition 0.000 description 2

- 208000027418 Wounds and injury Diseases 0.000 description 1

- 235000021168 barbecue Nutrition 0.000 description 1

- 239000003610 charcoal Substances 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 230000007812 deficiency Effects 0.000 description 1

- 230000009977 dual effect Effects 0.000 description 1

- 230000009970 fire resistant effect Effects 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000010813 municipal solid waste Substances 0.000 description 1

- 238000004382 potting Methods 0.000 description 1

- 235000013580 sausages Nutrition 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

- 229920002994 synthetic fiber Polymers 0.000 description 1

- 235000013311 vegetables Nutrition 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47B—TABLES; DESKS; OFFICE FURNITURE; CABINETS; DRAWERS; GENERAL DETAILS OF FURNITURE

- A47B33/00—Kitchen or dish-washing tables

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47B—TABLES; DESKS; OFFICE FURNITURE; CABINETS; DRAWERS; GENERAL DETAILS OF FURNITURE

- A47B37/00—Tables adapted for other particular purposes

- A47B37/04—Tables specially adapted for use in the garden or otherwise in the open air, e.g. with means for holding umbrellas or umbrella-like sunshades

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24C—DOMESTIC STOVES OR RANGES ; DETAILS OF DOMESTIC STOVES OR RANGES, OF GENERAL APPLICATION

- F24C3/00—Stoves or ranges for gaseous fuels

- F24C3/08—Arrangement or mounting of burners

Definitions

- the present invention relates generally to tables, and, more particularly, to a table for streamlined food preparation and/or consumption comprising a heat-shielded cooking (e.g., gas burner) system.

- a heat-shielded cooking e.g., gas burner

- the food In the preparation and consumption of foods such as seafood (e.g., oysters or other shellfish), the food may be prepared (such as by steaming) on a remote cooking apparatus (e.g., a traditional pot and heating system) and then, when the food has been heated to a sufficient temperature, the food items may be transported to and dumped onto a serving table for consumption.

- a remote cooking apparatus e.g., a traditional pot and heating system

- This two-step standard practice for food preparation and consumption involving the transport of hot food items and/or boiling water from one area to another is not without risk to food preparers, servers, and consumers, especially when the food items are prepared by steaming in a relatively large pot that can have a substantial capacity (e.g., 15-20 gallons).

- the body of the barbeque which is located beneath the table top, is contained by a casing, which is externally surrounded by a thermal barrier, which conveniently is in the form of asbestos sheeting and which in turn is externally surrounded by a wooden housing, which forms part of the table and which supports the table top.

- the present invention can provide an effective all-in-one approach to preparing, serving, and consuming food (e.g., steaming of oysters or other shellfish, serving the prepared food items, and consuming them, and optionally disposing of any food remains, such as empty shells, into a trash receptacle, all at the same location).

- food e.g., steaming of oysters or other shellfish, serving the prepared food items, and consuming them, and optionally disposing of any food remains, such as empty shells, into a trash receptacle, all at the same location.

- An exemplary table may comprise a generally flat table top that can be stably positioned horizontally, or substantially horizontally, at a suitable height by a support system comprising at least two vertical, or substantially vertical, table top support members (e.g., two load-bearing members with stabilizing footing or plate at the floor or ground or a sufficient number of individual support legs depending on the size, shape, and weight of the table top).

- the support system may be in the form of a frame structure comprising the at least two vertical, or substantially vertical, table top support members and other members, such as (but not limited to) horizontal, or substantially horizontal, beam members.

- the table may be provided in the form of a communal table (e.g., a rectangular communal table).

- the generally flat table top may be provided with at least one aperture of any desired shape and size.

- the table may be configured such that at least one food container (e.g., pots or chafing pans) may be received and stably held above and proximate the at least one aperture through which heat may be supplied from underneath by a cooking system comprising at least one heat-adjustable, regulated heat source (e.g., a gas burner system), which is at least partially shielded by a heat shroud configured to provide a heat-insulating air barrier for reducing or preventing heat radiation to structural areas of the table.

- a food container e.g., pots or chafing pans

- a heat shroud configured to provide a heat-insulating air barrier for reducing or preventing heat radiation to structural areas of the table.

- the particular type of heat source is not particularly limited and can be based on any gas source (e.g., propane gas tank, natural gas supply, etc.).

- a table configured in this manner may reduce the risk of injury to food preparers, servers, and/or consumers by streamlining the standard two-step process for preparing and consuming food by combining the cooking and consumption areas into one location, thereby eliminating the need to transport and/or dump hot food items and/or boiling water onto a table's surface as in the prior art. Additionally, it may also be configured and used to maintain a desired temperature of the cooked food items, thereby reducing waste and preventing contamination.

- a table may comprise:

- a table according to another exemplary embodiment may comprise:

- the at least one adjustable gas burner heat source may be supported on a bracket.

- the generally flat table top, bracket, and/or the heat shroud may be attached to the support system or frame structure.

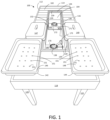

- FIG. 1 presents a side perspective view of a communal table in accordance with one embodiment of the present invention, along with cooking trays and other cooking accessories;

- FIG. 2 presents a side perspective view of a partially constructed table showing the fabrication of the generally flat table top

- FIG. 3 presents a side perspective view of an outer frame structure and an inner frame structure of a table in accordance with an embodiment of the invention

- FIG. 4 presents a perspective view of a heat shroud with brackets holding two gas burners about to be installed into an aperture of an unfinished table in accordance with an embodiment of the invention

- FIG. 5 presents a side perspective view of a two gas burner assembly installed in a recessed well of a table according to an embodiment of the invention

- FIG. 6 presents a partial front view of a table showing the gas control panel and a propane gas supply tank in accordance with an embodiment of the invention.

- FIG. 7 presents a perspective view of chafing dishes that are cantilevered or suspended on the heat shroud that has been installed in the aperture of a table in accordance with an embodiment of the invention

- FIG. 8 shows the creation of steam in the chafing pans with heat generated by a cooking system in accordance with an embodiment of the invention.

- FIG. 9 presents a perspective view of a perforated inner tray comprising perforations around an upper edge of the inner tray.

- the word “exemplary” or “illustrative” means “serving as an example, instance, or illustration.” Any implementation described herein as “exemplary” or “illustrative” is not necessarily to be construed as preferred or advantageous over other implementations. All of the implementations described below are exemplary implementations provided to enable persons skilled in the art to make or use the embodiments of the disclosure and are not intended to limit the scope of the disclosure, which is defined by the claims.

- an exemplary form of the present invention is directed toward a table 100 .

- the exemplary table 100 may be implemented and used as an all-in-one approach to cooking (e.g., steaming oysters/seafood) for gatherings.

- the table 100 in this embodiment is shown as a communal table comprising a generally flat table top 102 having a generally rectangular outer shape provided with an aperture 104 having a smaller generally rectangular shape.

- the generally flat table top 102 may be constructed from any suitable material, such as (but not limited to) concrete fibrous board material.

- the use of concrete fibrous board material when selected as the material of choice, may be advantageous because it is resistant to ignition and combustion.

- the generally flat table top 102 can comprise multiple concrete fibrous boards in the form of slats (e.g., 1′′ ⁇ 6′′ concrete fibrous boards cut to desired lengths) to form a generally flat table top 102 having the aperture 104 as shown in FIG. 1 (coated concrete fibrous boards) and FIG. 2 (uncoated concrete fibrous boards).

- FIG. 1 shows the generally flat table top 102 as comprising multiple concrete fibrous boards, it should be understood that a monolithic or one-piece table top is also within the scope of the present invention, unless otherwise recited in the appended claims.

- the generally flat table top 102 comprising the cut concrete fibrous boards may be supported on a frame structure 140 that may comprise an outer frame structure 110 comprising pressure-treated wood beam materials 112 , 114 , 116 , and 118 , to which are attached pressure-treated wood support legs 120 , 122 , 124 , and 126 , and an inner frame structure 130 comprising milled steel beam members in tubular form (e.g., 2′′ ⁇ 2′′), which can also be ignition and combustion resistant.

- Various manufacturing techniques, such as water jet cutting technology, may be used. As shown in FIG.

- inner, upper portions of the pressure-treated wood beam materials 112 , 114 , 116 , and 118 and pressure-treated wood support legs 120 , 122 , 124 , and 126 may be partially recessed to facilitate the correct fit and suspension/support of the cut concrete fibrous boards that make up the generally flat table top 102 , as best viewed in FIG. 4 .

- the non-recessed upper portions of pressure-treated wood beam materials 112 , 114 , 116 , and 118 may form a lip 119 confining the outer periphery of the generally flat table top 102 .

- the individual cut concrete fibrous boards of the generally flat table top 102 may be fastened (e.g., fire and/or heat-resistant glue, nails, screws, etc.) to the frame structure 140 by any convenient technique.

- outer frame structure 110 shown in FIG. 3 is exemplified as comprising pressure-treated wood beams (e.g., 2′′ ⁇ 6′′ pressure treated lumber approximately 93′′ and 36′′ in length) 112 , 114 , 116 , and 118 attached to 36′′ pressure-treated wood legs 120 , 122 , 124 , and 126 , it should be understood that other suitable materials (e.g., fire and/or heat-resistant synthetic materials or steel) may also be used in lieu of, or in combination, with pressure-treated wood.

- the inner frame structure 130 may also be selected from alternative materials (e.g., synthetic polymeric materials or composite materials) that possess the desired strength and fire and/or heat resistance characteristics.

- the fire-resistant materials may not comprise asbestos.

- the dimensions and sizes of the members making up the frame structure 140 comprising outer frame structure 110 and inner frame structure 130 can be selected according to the desired table size and other table design variables.

- a heat shroud 150 comprising members 152 , 154 , 156 , and 158 , which may be made of a suitable noncombustible material such as metal (e.g., 16-gauge stainless steel), can be installed in the aperture 104 of the generally flat table top 102 to protect the structural materials of the table 100 from heat.

- the heat shroud 150 may be configured to form an air barrier (e.g., at least about 3 ⁇ 4′′), which can act as an insulator and protect the structural materials of the table 100 .

- burners producing the cooking heat may be mounted on 16 -gauge steel brackets attached to heat shielding or heat breaks in the form of a 16-gauge steel apron placed around the perimeter of the chafing dish recessed well.

- brackets 160 and 162 for holding two cast-iron gas burners 170 and 172 , respectively, are attached to the heat shroud 150 .

- members 132 , 134 , 136 , and 138 which may be made of the same material as the generally flat table top 102 or another suitable material, may be attached to the frame structure 140 (e.g., inner frame structure 130 ) by any suitable attachment mean (screws, bolts/nuts, heat resistant glue, etc.) in such a way as to create a lip 139 that may surround heat shroud 150 's upper portion.

- the heat shroud 150 may simply be installed at the aperture 104 in a substantially coplanar fashion with the generally flat table top 102 by allowing the former to rest on the latter, as illustrated in FIGS. 7 and 8 .

- the heat shroud 150 can be configured to cantilever and support/suspend the cooking trays (e.g., chafing dishes 142 and 144 ). This unique design may advantageously allow the easy removal of the sets of chafing dishes/pans for cleaning.

- the table 100 may employ at least one chafing dish, e.g., a double set of standard chafing dishes that can be or 4′′ depth chafing dishes 142 and 144 that can each measure 12′′ ⁇ 22′′, each with perforated inner trays 146 and 148 , respectively, and each covered with, e.g., 2′′ raised handled lid covers 147 and 149 , respectively.

- the perforated inner trays 146 and 148 may comprise perforations 151 in the bottom of the tray that allow liquid from cooking to flow into the chafing dishes 142 and 144 .

- the perforated inner trays 146 and 148 may comprise perforations 153 ( FIG.

- the perforations Under the chafing dishes 142 and 144 may be provided two banjo-style gas burners 170 and 172 (e.g., 200,000 BTU cast-iron propane burners), which are each mounted on their own brackets 160 and 162 , respectively, as illustrated in FIGS. 1 and 5 .

- the banjo-style gas burners 170 and 172 heat the chafing dishes 142 and 144 which can hold a liquid. The heat can convert the liquid into steam 192 ( FIG. 8 ).

- the steam 192 can enter the perforated inner trays 146 and 148 through the perforations.

- the steam 192 can cook food held in the perforated inner trays 146 and 148 .

- These brackets 160 and 162 are attached to the heat shroud 150 , which, as described previously, may be configured to provide protection to the structural members of the table 100 by creating a 3 ⁇ 4′′ air barrier, which acts as an insulator and thereby protects the structural members of the table.

- the heat shroud 150 can be configured to cantilever and support/suspend the cooking trays (e.g., chafing dishes 142 and 144 ).

- the BTU ratings of the gas burners may vary according to cooking needs and the design of the table 100 .

- FIGS. 1-10 As illustrated in FIGS.

- gas supplied from a propane tank 180 is fed to a dual valve assembly ( 184 , 186 ) in control panel 190 , which controls the flow of gas to either or both of the burners 170 and 172 through flexible tubing 182 (which may be fed through openings 161 and 163 in brackets 160 and 162 and splits into regulators 171 and 173 , respectively), whereby push-button battery-powered ignitors 175 and 177 (activated by push button 188 mounted through a wall fitting to the brackets as shown in FIG. 6 ) initiate combustion.

- each of the burners 170 and 172 may be adjusted as desired by manipulating valves 184 and 186 , respectively, which may be located in the front control panel 190 of the table 100 .

- manipulating valves 184 and 186 respectively, which may be located in the front control panel 190 of the table 100 .

- the heat supplied can rapidly boil any water in the chafing dish/pans, which may have, e.g., a depth of or 4′′.

- food such as oysters are placed in perforated pans 146 and/or 148 , which may have a depth of about 2′′, and are suspended above the water in the chafing dishes/pans 142 and/or 144 , the oysters are subjected to extreme steam temperatures, causing them to cook and open rapidly. It is possible to generate steam in about 5 minutes or less.

- the shape and size of the generally flat table top 102 can vary (e.g., rectangular, square, circular, oval, elliptical, oyster-shaped, etc.).

- the shape and size of the aperture 104 may also vary (e.g., rectangular, etc.).

- the provision of more than one aperture 104 may be possible.

- the present invention may provide various benefits such as, but not limited to:

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Cookers (AREA)

Abstract

A table, for either indoor or outdoor use, may comprise a generally flat table top that can be stably positioned horizontally, or substantially horizontally, at a suitable height by a support system comprising at least two vertical, or substantially vertical, table top support members (e.g., two load-bearing members with stabilizing footing or plate at the floor or ground or a sufficient number of individual support legs). The table may be configured such that at least one food container or cooking tray may be received and stably held above and proximate the at least one aperture through which heat may be supplied from underneath by a cooking system comprising at least one heat-adjustable, regulated heat source, which is at least partially shielded by a heat shroud configured to provide a heat-insulating air barrier for reducing or preventing heat radiation to structural areas of the table.

Description

- This application claims benefit of Ser. No. 63/483,753 filed Feb. 7, 2023, with the same title, which is incorporated by reference as if fully restated herein.

- The present invention relates generally to tables, and, more particularly, to a table for streamlined food preparation and/or consumption comprising a heat-shielded cooking (e.g., gas burner) system.

- In the preparation and consumption of foods such as seafood (e.g., oysters or other shellfish), the food may be prepared (such as by steaming) on a remote cooking apparatus (e.g., a traditional pot and heating system) and then, when the food has been heated to a sufficient temperature, the food items may be transported to and dumped onto a serving table for consumption. This two-step standard practice for food preparation and consumption involving the transport of hot food items and/or boiling water from one area to another is not without risk to food preparers, servers, and consumers, especially when the food items are prepared by steaming in a relatively large pot that can have a substantial capacity (e.g., 15-20 gallons).

- Tables with built-in cooking systems that would eliminate the need to transport hot food items and/or boiling water from one area to another have previously been proposed. For example, U.S. Pat. No. 4,840,128, issued to McFarlane et al. on Jun. 20, 1989, discloses an eating table comprising a table top having a centralized aperture into which a charcoal grill barbeque is inset. The reference teaches that eating stations are provided around the barbeque on the table top and a frame arrangement fitted to barbeque projects above the level of the table top to prevent splashing thereof during use of the barbeque. According to this reference, the body of the barbeque, which is located beneath the table top, is contained by a casing, which is externally surrounded by a thermal barrier, which conveniently is in the form of asbestos sheeting and which in turn is externally surrounded by a wooden housing, which forms part of the table and which supports the table top.

- There remains a need for a table cooking system that can be used for streamlined food preparation and consumption.

- The present invention, described below by way of non-limiting aspects, embodiments, or examples, can provide an effective all-in-one approach to preparing, serving, and consuming food (e.g., steaming of oysters or other shellfish, serving the prepared food items, and consuming them, and optionally disposing of any food remains, such as empty shells, into a trash receptacle, all at the same location).

- Tables according to various embodiments of the present invention may be suitable for both indoor and outdoor applications. An exemplary table may comprise a generally flat table top that can be stably positioned horizontally, or substantially horizontally, at a suitable height by a support system comprising at least two vertical, or substantially vertical, table top support members (e.g., two load-bearing members with stabilizing footing or plate at the floor or ground or a sufficient number of individual support legs depending on the size, shape, and weight of the table top). The support system may be in the form of a frame structure comprising the at least two vertical, or substantially vertical, table top support members and other members, such as (but not limited to) horizontal, or substantially horizontal, beam members. If desired, the table may be provided in the form of a communal table (e.g., a rectangular communal table). The generally flat table top may be provided with at least one aperture of any desired shape and size. The table may be configured such that at least one food container (e.g., pots or chafing pans) may be received and stably held above and proximate the at least one aperture through which heat may be supplied from underneath by a cooking system comprising at least one heat-adjustable, regulated heat source (e.g., a gas burner system), which is at least partially shielded by a heat shroud configured to provide a heat-insulating air barrier for reducing or preventing heat radiation to structural areas of the table. The particular type of heat source is not particularly limited and can be based on any gas source (e.g., propane gas tank, natural gas supply, etc.). A table configured in this manner may reduce the risk of injury to food preparers, servers, and/or consumers by streamlining the standard two-step process for preparing and consuming food by combining the cooking and consumption areas into one location, thereby eliminating the need to transport and/or dump hot food items and/or boiling water onto a table's surface as in the prior art. Additionally, it may also be configured and used to maintain a desired temperature of the cooked food items, thereby reducing waste and preventing contamination.

- In one aspect of the invention, a table according to an exemplary embodiment may comprise:

-

- (a) a generally flat table top comprising at least one aperture, wherein a peripheral portion of the table adjacent to the at least one aperture is configured to receive and stably hold at least one food container;

- (b) a support system comprising at least two vertical, or substantially vertical, support members for stably positioning the generally flat table top in a horizontal, or substantially horizontal, position at an elevated height; and

- (c) at least one cooking system comprising at least one adjustable gas burner heat source positioned underneath the at least one aperture for providing heat through the at least one aperture and to the at least one food container;

- wherein the adjustable gas burner heat source is at least partially shielded with a heat shroud configured to provide a heat-insulative air barrier for reducing or preventing heat radiation to structural areas of the table.

- In another aspect of the invention, a table according to another exemplary embodiment may comprise:

-

- (a) a generally flat table top comprising at least one aperture, wherein a peripheral portion of the table adjacent the at least one aperture is configured to receive and stably hold at least one food container;

- (b) a frame structure comprising (i) a plurality of vertical, or substantially vertical, support members for stably positioning the generally flat table top in a horizontal, or substantially horizontal, position at an elevated height and (ii) a plurality of horizontal, or substantially horizontal, beam members; and

- (c) at least one cooking system comprising at least one adjustable gas burner heat source positioned underneath the at least one aperture for providing heat through the at least one aperture and to the at least one food container;

- wherein the at least one adjustable gas burner heat source is at least partially shielded with a heat shroud configured to provide an insulative air barrier for reducing or preventing heat radiation to structural areas of the table.

- In a further aspect of the invention, the at least one adjustable gas burner heat source may be supported on a bracket.

- In a further aspect of the invention, the generally flat table top, bracket, and/or the heat shroud may be attached to the support system or frame structure.

- These exemplary embodiments, as well as other exemplary embodiments, are described in further detail below.

- The preferred embodiments of the invention will hereinafter be described in conjunction with the appended drawings provided to illustrate but not limit the invention, where like designations denote like elements, and in which:

-

FIG. 1 presents a side perspective view of a communal table in accordance with one embodiment of the present invention, along with cooking trays and other cooking accessories; -

FIG. 2 presents a side perspective view of a partially constructed table showing the fabrication of the generally flat table top; -

FIG. 3 presents a side perspective view of an outer frame structure and an inner frame structure of a table in accordance with an embodiment of the invention; -

FIG. 4 presents a perspective view of a heat shroud with brackets holding two gas burners about to be installed into an aperture of an unfinished table in accordance with an embodiment of the invention; -

FIG. 5 presents a side perspective view of a two gas burner assembly installed in a recessed well of a table according to an embodiment of the invention; -

FIG. 6 presents a partial front view of a table showing the gas control panel and a propane gas supply tank in accordance with an embodiment of the invention; and -

FIG. 7 presents a perspective view of chafing dishes that are cantilevered or suspended on the heat shroud that has been installed in the aperture of a table in accordance with an embodiment of the invention; -

FIG. 8 shows the creation of steam in the chafing pans with heat generated by a cooking system in accordance with an embodiment of the invention. -

FIG. 9 presents a perspective view of a perforated inner tray comprising perforations around an upper edge of the inner tray. - Like reference numerals refer to like parts throughout the several views of the drawings.

- The following detailed description is merely exemplary in nature and is not intended to limit the described embodiments or the application and uses of the described embodiments. As used herein, the word “exemplary” or “illustrative” means “serving as an example, instance, or illustration.” Any implementation described herein as “exemplary” or “illustrative” is not necessarily to be construed as preferred or advantageous over other implementations. All of the implementations described below are exemplary implementations provided to enable persons skilled in the art to make or use the embodiments of the disclosure and are not intended to limit the scope of the disclosure, which is defined by the claims.

- Some features may be described using relative terms, such as “upper,” “lower,” “left,” “rear,” “right,” “front,” “vertical,” or “horizontal.” Such positional relative terms are only for reference with respect to the appended Figures and are not meant to limit the disclosed embodiments.

- Furthermore, there is no intention to be bound by any expressed or implied theory presented in the preceding technical field, background, brief summary or the following detailed description. It is also to be understood that the specific devices and processes illustrated in the attached drawings, and described in the following specification, are simply exemplary embodiments of the inventive concepts defined in the appended claims. Hence, specific dimensions and other physical characteristics relating to the embodiments disclosed herein are not to be considered as limiting but merely exemplary, unless the claims expressly state otherwise.

- Furthermore, a person skilled in the art would understand from reading this disclosure that “a” and “an” each generally denotes “at least one,” but does not exclude a plurality unless the contextual use dictates otherwise. Also, the term “or” in a list of enumerated items denotes “at least one of the items” and, therefore, does not exclude a plurality of items of the list.

- Shown throughout the figures, an exemplary form of the present invention is directed toward a table 100.

- Referring to

FIG. 1 , the exemplary table 100 may be implemented and used as an all-in-one approach to cooking (e.g., steaming oysters/seafood) for gatherings. The table 100 in this embodiment is shown as a communal table comprising a generallyflat table top 102 having a generally rectangular outer shape provided with anaperture 104 having a smaller generally rectangular shape. The generallyflat table top 102 may be constructed from any suitable material, such as (but not limited to) concrete fibrous board material. The use of concrete fibrous board material, when selected as the material of choice, may be advantageous because it is resistant to ignition and combustion. In this embodiment, the generally flat table top 102 can comprise multiple concrete fibrous boards in the form of slats (e.g., 1″×6″ concrete fibrous boards cut to desired lengths) to form a generallyflat table top 102 having theaperture 104 as shown inFIG. 1 (coated concrete fibrous boards) andFIG. 2 (uncoated concrete fibrous boards). AlthoughFIG. 1 shows the generally flat table top 102 as comprising multiple concrete fibrous boards, it should be understood that a monolithic or one-piece table top is also within the scope of the present invention, unless otherwise recited in the appended claims. - Referring to

FIGS. 3 and 4 , the generallyflat table top 102 comprising the cut concrete fibrous boards may be supported on aframe structure 140 that may comprise anouter frame structure 110 comprising pressure-treatedwood beam materials wood support legs inner frame structure 130 comprising milled steel beam members in tubular form (e.g., 2″×2″), which can also be ignition and combustion resistant. Various manufacturing techniques, such as water jet cutting technology, may be used. As shown inFIG. 3 , inner, upper portions of the pressure-treatedwood beam materials wood support legs flat table top 102, as best viewed inFIG. 4 . In this way, the non-recessed upper portions of pressure-treatedwood beam materials lip 119 confining the outer periphery of the generallyflat table top 102. The individual cut concrete fibrous boards of the generallyflat table top 102 may be fastened (e.g., fire and/or heat-resistant glue, nails, screws, etc.) to theframe structure 140 by any convenient technique. - While the

outer frame structure 110 shown inFIG. 3 is exemplified as comprising pressure-treated wood beams (e.g., 2″×6″ pressure treated lumber approximately 93″ and 36″ in length) 112, 114, 116, and 118 attached to 36″ pressure-treatedwood legs inner frame structure 130 may also be selected from alternative materials (e.g., synthetic polymeric materials or composite materials) that possess the desired strength and fire and/or heat resistance characteristics. The fire-resistant materials may not comprise asbestos. Additionally, the dimensions and sizes of the members making up theframe structure 140 comprisingouter frame structure 110 andinner frame structure 130 can be selected according to the desired table size and other table design variables. - Referring again to

FIG. 4 , aheat shroud 150 comprisingmembers aperture 104 of the generally flat table top 102 to protect the structural materials of the table 100 from heat. Theheat shroud 150 may be configured to form an air barrier (e.g., at least about ¾″), which can act as an insulator and protect the structural materials of the table 100. Thus, for example, burners producing the cooking heat may be mounted on 16-gauge steel brackets attached to heat shielding or heat breaks in the form of a 16-gauge steel apron placed around the perimeter of the chafing dish recessed well. Specifically, in the illustrated embodiment,brackets iron gas burners heat shroud 150. Furthermore, in the embodiment shown inFIG. 1 ,members lip 139 that may surroundheat shroud 150's upper portion. Alternatively, theheat shroud 150 may simply be installed at theaperture 104 in a substantially coplanar fashion with the generallyflat table top 102 by allowing the former to rest on the latter, as illustrated inFIGS. 7 and 8 . In either option or other embodiments, theheat shroud 150 can be configured to cantilever and support/suspend the cooking trays (e.g., chafingdishes 142 and 144). This unique design may advantageously allow the easy removal of the sets of chafing dishes/pans for cleaning. - Referring to

FIGS. 1, 7, and 8 , the table 100 may employ at least one chafing dish, e.g., a double set of standard chafing dishes that can be or 4″depth chafing dishes inner trays inner trays perforations 151 in the bottom of the tray that allow liquid from cooking to flow into the chafingdishes inner trays FIG. 9 ) around an upper edge of the perforatedinner trays dishes dishes style gas burners 170 and 172 (e.g., 200,000 BTU cast-iron propane burners), which are each mounted on theirown brackets FIGS. 1 and 5 . The banjo-style gas burners dishes FIG. 8 ). Thesteam 192 can enter the perforatedinner trays steam 192 can cook food held in the perforatedinner trays brackets heat shroud 150, which, as described previously, may be configured to provide protection to the structural members of the table 100 by creating a ¾″ air barrier, which acts as an insulator and thereby protects the structural members of the table. Additionally, as described above, theheat shroud 150 can be configured to cantilever and support/suspend the cooking trays (e.g., chafingdishes 142 and 144). - Referring to

FIG. 5 , it should be understood from this disclosure that the BTU ratings of the gas burners may vary according to cooking needs and the design of the table 100. For example, it is possible to configure the table 100 and theburners FIG. 8 . As illustrated inFIGS. 5 and 6 , gas supplied from apropane tank 180 is fed to a dual valve assembly (184, 186) incontrol panel 190, which controls the flow of gas to either or both of theburners openings brackets regulators ignitors 175 and 177 (activated bypush button 188 mounted through a wall fitting to the brackets as shown inFIG. 6 ) initiate combustion. The amount of gas fed into, and correspondingly the heat generated by, each of theburners valves 184 and 186, respectively, which may be located in thefront control panel 190 of the table 100. Unless otherwise recited in the appended claims, it is within the scope of the present invention to implement the use of a natural gas supply, in a manner similar to natural gas barbecue grills. - As can be understood from

FIG. 8 , the heat supplied can rapidly boil any water in the chafing dish/pans, which may have, e.g., a depth of or 4″. When food such as oysters are placed inperforated pans 146 and/or 148, which may have a depth of about 2″, and are suspended above the water in the chafing dishes/pans 142 and/or 144, the oysters are subjected to extreme steam temperatures, causing them to cook and open rapidly. It is possible to generate steam in about 5 minutes or less. - It should also be understood that the shape and size of the generally flat table top 102 can vary (e.g., rectangular, square, circular, oval, elliptical, oyster-shaped, etc.). Likewise, the shape and size of the

aperture 104 may also vary (e.g., rectangular, etc.). Depending on the table size, it may be possible to have anopening 104 designed for one, two, three, or more burners. Furthermore, depending on the size of the table 100, the provision of more than oneaperture 104 may be possible. - The present invention may provide various benefits such as, but not limited to:

-

- Safety: Often, shellfish roasts or parties may be crowded, and the danger of carrying a large steaming, hot basket, dish, pan, or pot is eliminated. Tables according to the present invention address the deficiencies inherent in prior art tables and methods in terms of safety, efficiency, and utility in cooking and serving foods (e.g., shellfish) at both small and large gatherings.

- Simplification and Streamlining: Tables according to the present invention simplify the cooking and consumption areas to one location, thereby keeping both in one location and simplifying all aspects including cleanup.

- Versatility: Several types of foods including, e.g., shellfish, vegetables, and sausages, can be prepared simultaneously in a safe and efficient manner.

- Keeping Food Warm: Food served on traditional tables (e.g., oyster tables) will cool quickly, making the food unappetizing, whereas tables according to the present invention can keep the food warm until it is consumed.

- Since many modifications, variations, and changes in detail can be made to the described embodiments and aspects of the invention, it is intended that all matters in the foregoing description and shown in the accompanying drawings be interpreted as illustrative and not in a limiting sense. Thus, the scope of coverage of the invention should be determined by the appended claims and their legal equivalents.

Claims (14)

1. A table comprising:

(a) a generally flat table top comprising at least one aperture, wherein a peripheral portion of the table adjacent to the at least one aperture is configured to receive and stably hold at least one cooking tray;

(b) a support system comprising at least two vertical, or substantially vertical, support members for stably positioning the generally flat table top in a horizontal, or substantially horizontal, position at an elevated height; and

(c) at least one cooking system comprising at least one adjustable gas burner heat source positioned underneath the at least one aperture for providing heat through the at least one aperture and to the at least one cooking tray;

wherein the adjustable gas burner heat source is at least partially shielded with a heat shroud configured to provide a heat-insulative air barrier for reducing or preventing heat radiation to structural areas of the table.

2. The table of claim 1 , wherein the cooking tray is a chafing dishes comprising a perforated inner tray.

3. The table of claim 1 , wherein the heat shroud is made from a noncombustible material.

4. A table comprising:

(a) a generally flat table top comprising at least one aperture, wherein a peripheral portion of the table adjacent the at least one aperture is configured to receive and stably hold at least one cooking tray;

(b) a frame structure comprising (i) a plurality of vertical, or substantially vertical, support members for stably positioning the generally flat table top in a horizontal, or substantially horizontal, position at an elevated height and (ii) a plurality of horizontal, or substantially horizontal, beam members, wherein the beam members are made from a noncombustible material; and

(c) at least one cooking system comprising at least one adjustable gas burner heat source positioned underneath the at least one aperture for providing heat through the at least one aperture and to the at least one cooking tray, wherein the at least one adjustable gas burner heat source is at least partially shielded with a heat shroud configured to provide an insulative air barrier for reducing or preventing heat radiation to structural areas of the table.

5. A table according to claim 4 , wherein the frame structure comprises an outer frame structure comprising pressure-treated wood beam members and pressure-treated wood support legs and an inner frame structure comprising milled steel beam members.

6. A table according to claim 4 , wherein the generally flat table top is comprised of concrete fibrous board material.

7. A table according to claim 4 , wherein the heat shroud defines heat shielding or heat breaks in the form of a 16-gauge steel apron placed around the perimeter of a recessed well in the aperture of the generally flat table top, the recessed well being configured to receive the cooking tray, pot, pan, or dish.

8. A table according to claim 7 , wherein brackets are attached to the heat shroud for holding the at least one adjustable gas burner heat source.

9. A table according to claim 7 , wherein the recessed well is configured to receive at least one chafing pan.

10. A table according to claim 9 , wherein the chafing pan rests on or is cantilevered or suspended by the heat shroud.

11. A table according to claim 7 , wherein the heat shroud is configured to provide an insulative air barrier of at least about ¾″.

12. A table according to claim 7 , wherein the cooking system is capable of providing up to about 200,000 BTUs.

13. The table of claim 4 , wherein the cooking tray is a chafing dishes comprising a perforated inner tray.

14. The table of claim 4 , wherein the heat shroud is made from a noncombustible material.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US18/436,007 US20240260745A1 (en) | 2023-02-07 | 2024-02-07 | Table for food preparation and/or consumption |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US202363483753P | 2023-02-07 | 2023-02-07 | |

| US18/436,007 US20240260745A1 (en) | 2023-02-07 | 2024-02-07 | Table for food preparation and/or consumption |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US20240260745A1 true US20240260745A1 (en) | 2024-08-08 |

Family

ID=92120544

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US18/436,007 Pending US20240260745A1 (en) | 2023-02-07 | 2024-02-07 | Table for food preparation and/or consumption |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US20240260745A1 (en) |

-

2024

- 2024-02-07 US US18/436,007 patent/US20240260745A1/en active Pending

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US12127709B2 (en) | Modular barbecue system and kits therefore | |

| US10426291B2 (en) | Food cooker | |

| US9474414B2 (en) | Interactive heating and cooking apparatus and disposable tray system therefore | |

| US3745303A (en) | Grill-heater for restaurant table | |

| US20140311356A1 (en) | Multi-Configurable Outdoor Cooking Grill | |

| US5121676A (en) | Barbecue grill and cooker | |

| JPH04261621A (en) | Outdoor cooking device with base stand | |

| WO1985000962A1 (en) | Portable cooking and barbecuing device | |

| US4840128A (en) | Eating table with inset barbecue | |

| US10610052B2 (en) | Grill | |

| US20240260745A1 (en) | Table for food preparation and/or consumption | |

| US20030126994A1 (en) | Apparatus for deep fat frying | |

| US9822982B2 (en) | Modular portable cooking system | |

| US20020014163A1 (en) | Flare-up suppressing cooking grill device | |

| KR200425826Y1 (en) | roasting plates used as cooking brazier | |

| KR200492598Y1 (en) | Cooking fire plate | |

| US20080135039A1 (en) | Cooker | |

| CN212678917U (en) | Multifunctional pot | |

| US20240374081A1 (en) | Cooking apparatus | |

| JP3226386U (en) | Fish grill | |

| JP2006087854A (en) | Barbecue range with drawer having oven function | |

| WO2020095096A1 (en) | Barbeque arrangement | |

| KR200214938Y1 (en) | Heating vessel using far-infrared radiating ceramics | |

| AU2015202246B2 (en) | Interactive heating and cooking apparatus and disposable tray system therefore | |

| JPH06284980A (en) | Cooking method using pumice stone and cooking using the method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STPP | Information on status: patent application and granting procedure in general |

Free format text: DOCKETED NEW CASE - READY FOR EXAMINATION |