US20070287780A1 - Curable Composition - Google Patents

Curable Composition Download PDFInfo

- Publication number

- US20070287780A1 US20070287780A1 US11/579,635 US57963505A US2007287780A1 US 20070287780 A1 US20070287780 A1 US 20070287780A1 US 57963505 A US57963505 A US 57963505A US 2007287780 A1 US2007287780 A1 US 2007287780A1

- Authority

- US

- United States

- Prior art keywords

- group

- component

- carbon atoms

- curable composition

- substituted

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

- ZXNGFKPTYFOOCA-FGSKAQBVSA-M C.CC1=CC(C)=O[Ti](C)O1 Chemical compound C.CC1=CC(C)=O[Ti](C)O1 ZXNGFKPTYFOOCA-FGSKAQBVSA-M 0.000 description 6

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G65/00—Macromolecular compounds obtained by reactions forming an ether link in the main chain of the macromolecule

- C08G65/02—Macromolecular compounds obtained by reactions forming an ether link in the main chain of the macromolecule from cyclic ethers by opening of the heterocyclic ring

- C08G65/32—Polymers modified by chemical after-treatment

- C08G65/329—Polymers modified by chemical after-treatment with organic compounds

- C08G65/336—Polymers modified by chemical after-treatment with organic compounds containing silicon

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K3/00—Use of inorganic substances as compounding ingredients

- C08K3/01—Use of inorganic substances as compounding ingredients characterized by their specific function

- C08K3/014—Stabilisers against oxidation, heat, light or ozone

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/0091—Complexes with metal-heteroatom-bonds

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/54—Silicon-containing compounds

- C08K5/544—Silicon-containing compounds containing nitrogen

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D171/00—Coating compositions based on polyethers obtained by reactions forming an ether link in the main chain; Coating compositions based on derivatives of such polymers

- C09D171/02—Polyalkylene oxides

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J171/00—Adhesives based on polyethers obtained by reactions forming an ether link in the main chain; Adhesives based on derivatives of such polymers

- C09J171/02—Polyalkylene oxides

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K3/00—Materials not provided for elsewhere

- C09K3/10—Materials in mouldable or extrudable form for sealing or packing joints or covers

Definitions

- the present invention relates to a curable composition

- a curable composition comprising an organic polymer containing a silicon-containing group (hereinafter referred to as a “reactive silicon group”) which has hydroxyl group or a hydrolyzable group bonded to the silicon atom and which is capable of crosslinking by forming siloxane bonds.

- an organic polymer having at least one reactive silicon group in the molecule undergoes crosslinking by formation of siloxane bonds accompanying a hydrolysis reaction of the reactive silicon group with moisture or the like even at room temperature, and a rubber-like cured article can be obtained.

- polymers having a reactive silicon group organic polymers in which the main chain skeleton is a polyoxyalkylene polymer or a (meth)acrylate polymer are disclosed in (Patent Document 1), (Patent Document 2) and the like. Those polymers have already been industrially produced, and are widely used in applications to sealants, adhesives, coatings and the like.

- Curable compositions comprising the above described organic polymers having a reactive silicon group are cured by using silanol condensation catalysts, and usually organotin catalysts having a carbon-tin bond such as dibutyltin bis(acetylacetonate) are widely used.

- organotin catalysts having a carbon-tin bond such as dibutyltin bis(acetylacetonate)

- toxicity of organotin catalysts is pointed out, and development of non-organotin catalysts are demanded.

- Patent Document 4 As described in (Patent Document 4), (Patent Document 5), (Patent Document 6), (Patent Document 7) and the like, as a result of various investigations made, improvement methods such as modification of a silicone-terminated structure, use of a chelate type titanium compound, and the like have been found, and at the present time, dealcoholization type silicone compositions using titanium catalysts are widely used in a variety of applications. Additionally, in (Patent Document 8), a technique for improving curability by using a chelate type methyl titanium is disclosed.

- Patent Document 1 JP-52-73998A

- Patent Document 2 JP-59-74149A

- Patent Document 3 JP-39-27643B (U.S. Pat. No. 3,175,993)

- Patent Document 4 U.S. Pat. No. 3,334,067

- Patent Document 5 JP-56-14701B

- Patent Document 6 JP-55-43119A

- Patent Document 7 JP-2-133490A

- Patent Document 8 JP-2001-302934A

- Patent Document 9 JP-58-17154A

- Patent Document 10 JP-11-209538A

- Patent Document 11 JP-5-311063A

- Patent Document 12 JP-2001-302929A

- Patent Document 13 JP-2001-302930A

- Patent Document 14 JP-2001-302931A

- Patent Document 15 JP-2001-302934A

- Patent Document 16 JP-2001-348528A

- Patent Document 17 JP-2002-249672A

- Patent Document 18 JP-2003-165916A

- Patent Document 19 JP-62-35421B

- a one-component type curable composition which comprises a reactive silicon group-containing organic polymer as a main component, is prepared using a titanium catalyst as a non-tin curing catalyst and contains an amino silane as an adhesion-imparting agent, and have found that mechanical properties of a cured article obtained from the composition having been stored for a given period of time are remarkably lowered as compared with a cured article obtained from the composition before storing.

- a curable composition having practical curability and good adhesion and minimizing lowering of mechanical properties of a cured article after storing can be obtained by use of a silane compound having a nitrogen-substituted group as an adhesion-imparting agent and a chelate type methyl titanate (b1) and/or a chelate type ethyl titanate (b2) as a curing catalyst for the polymer although the catalyst concerned is a non-tin curing catalyst.

- the present invention relates to a one-component type curable composition characterized by comprising, as components,

- the polyoxyalkylene polymer (al) is preferably a polyoxypropylene polymer.

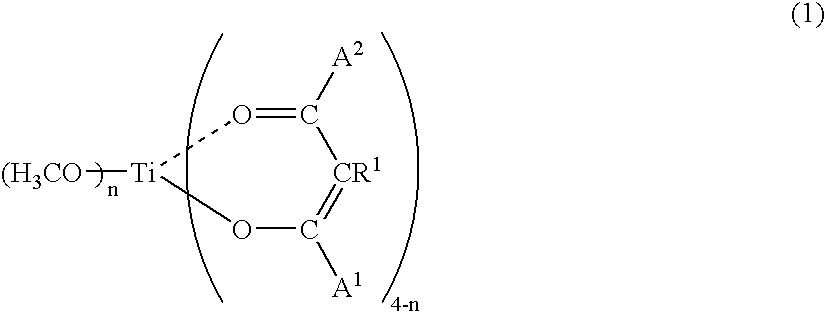

- the chelate type methyl titanate (b1) represented by the general formula (1) is preferable.

- the silicon-containing group contained in the component (A) and the hydrolyzable silicon group contained in the component (C) are groups represented by the following general formula (5) and the general formula (6), respectively: —SiR 5 3-a (OR 6 ) a (5) . . . silicon-containing group of the component (A) —SiR 7 3-b (OR 8 ) b (6) . . .

- each of R 5 and R 7 is independently a substituted or unsubstituted hydrocarbon group having 1 to 20 carbon atoms or a triorganosiloxy group represented by (R) 3 SiO— where each of R's is independently a substituted or unsubstituted hydrocarbon group having 1 to 20 carbon atoms, R 6 is an alkyl group having 1 to 4 carbon atoms, R 8 is an alkyl group having 1 to 4 carbon atoms, a is 1, 2 or 3, b is 1, 2 or 3, and R 6 is an alkyl group having the number of carbon atoms equal to or more than the number of carbon atoms of R 8 .

- the hydrolyzable silicon group contained in the component (C) is preferably a methoxysilyl group represented by the general formula (7): —SiR 7 3-b (OCH 3 ) b (7) wherein each of R 7 s is independently a substituted or unsubstituted hydrocarbon group having 1 to 20 carbon atoms or a triorganosiloxy group represented by (R′) 3 SiO— where each of R's is independently a substituted or unsubstituted hydrocarbon group having 1 to 20 carbon atoms, b is 1, 2 or 3.

- curable composition of the present invention are sealants or adhesives comprising any of the above described one-component type curable compositions.

- the curable composition of the present invention is excellent in curability and adhesion by use of a non-tin curing catalyst, and lowering of mechanical properties of a cured article obtained after storing is minimized.

- the polyoxyalkylene polymer (a1) having a reactive silicon group and/or the (meth)acrylate polymer (a2) having a reactive silicon group are used as the component (A).

- organic polymer By using the polyoxyalkylene polymer and/or the (meth)acrylate polymer as a main chain skeleton of the polymer of the component (A), a satisfactory adhesion can be achieved.

- a curable composition is prepared using a titanium catalyst as the component (B) of the present invention, there is a tendency that deep-part curability of the obtained composition is lowered depending on an added amount thereof.

- a polyoxyalkylene polymer and a (meth)acrylate polymer as used for the component (A) of the present invention are preferable because they are high in moisture permeability and excellent in deep-part curability in the case of a one-component type composition.

- the glass transition temperature of the organic polymer of the component (A) is preferably not more than 20° C., more preferably not more than 0° C., particularly preferably not more than ⁇ 20° C. If the glass transition temperature is higher than 20° C., in some cases, a viscosity increases and workability is lowered in wintertime or at a cold district or flexibility and elongation of the cured article are degraded.

- the above described glass transition temperature denotes values measured by DSC.

- the reactive silicon group contained in the polyoxyalkylene polymer (a1) having a reactive silicon group and the (meth)acrylate polymer (a2) having a reactive silicon group is a group which has a hydroxyl group or a hydrolyzable group bonded to a silicon atom, and is capable of cross-linking through a reaction accelerated by a curing catalyst.

- Examples of the reactive silicon groups include groups represented by the general formula (8): —(SiR 9 2-c X c O) m —SiR 10 3-d X d (8) wherein each of R 9 and R 10 is independently a substituted or unsubstituted hydrocarbon group having 1 to 20 carbon atoms or a triorganosiloxy group represented by (R′) 3 SiO—, where R′ is independently a substituted or unsubstituted hydrocarbon group having 1 to 20 carbon atoms, each of Xs is independently hydroxyl group or a hydrolyzable group, c is 0, 1 or 2, d is 0, 1, 2 or 3, c and d are not 0 at the same time, m is 0 or an integer of 1 to 19.

- the hydrolyzable group may be a hydrolyzable group well known in the art. More specifically, examples of the hydrolyzable group include, for instance, hydrogen atom, a halogen atom, an alkoxy group, an acyloxy group, a ketoximate group, an amino group, an amide group, an acid amide group, an aminooxy group, a mercapto group, an alkenyloxy group and the like.

- an alkoxy group hydrogen atom, an alkoxy group, an acyloxy group, a ketoximate group, an amino group, an amide group, an aminooxy group, a mercapto group and an alkenyloxy group are preferable and an alkoxy group is particularly preferable from the viewpoint that an alkoxy group is moderately hydrolyzable and easily handled.

- One to three hydrolyzable groups and hydroxyl groups can bond to one silicon atom, and (a+ ⁇ c) is preferably within a range from 1 to 5.

- two or more hydrolyzable groups and hydroxyl groups are bonded in the reactive silicon group, they may be the same or different.

- the number of silicon atoms forming the reactive silicon group is one or more, and is preferably not more than 20 in the case of the silicon atoms connected by siloxane bonds.

- R 9 and R 10 in the above described general formulae (8) and (9) include alkyl groups such as a methyl group and an ethyl group, cycloalkyl groups such as a cyclohexyl group, aryl groups such as a phenyl group, aralkyl groups such as a benzyl group, a triorganosiloxy group represented by (R′) 3 SiO— where R′ is a methyl group, a phenyl group or the like and the like group.

- R′ is a methyl group, a phenyl group or the like and the like group.

- a methyl group is particularly preferable.

- the reactive silicon group include a trimethoxysilyl group, a triethoxysilyl group, a triisopropoxysilyl group, a dimethoxymethylsilyl group, a diethoxymethylsilyl group and a diisopropoxymethylsilyl group.

- a trimethoxysilyl group, a triethoxysilyl group and a dimethoxymethylsilyl group are more preferable and a trimethoxysilyl group is particularly preferable because these groups are high in activity and satisfactory curability can be obtained.

- a dimethoxymethylsilyl group is particularly preferable.

- a triethoxysilyl group is particularly preferable because the alcohol produced by the hydrolysis reaction of the reactive silicon group is ethanol and hence a triethoxysilyl group has a high safety. Additionally, a trimethoxysilyl group and a triethoxysilyl group are preferable because lowering of physical properties of a cured article after storing is relatively small.

- the introduction of the reactive silicon group can be carried out by methods well known in the art. More specifically, examples of such methods include the followings.

- an organic polymer having in the molecule functional groups such as hydroxy groups an organic compound having both an active group exhibiting reactivity to the functional groups and an unsaturated group is reacted, to yield an unsaturated group-containing organic polymer.

- an unsaturated group-containing organic polymer is obtained by copolymerization of an epoxy compound having an unsaturated group with an organic polymer having in the molecule functional groups such as hydroxy groups. Then, a reactive silicon group-containing hydrosilane is reacted with the reaction product to be hydrosilylated.

- the method described in (a) or the method described in (c) in which a hydroxy group-terminated polymer is reacted with an isocyanate group- and reactive silicon group-containing compound is preferable because the method provides a high conversion rate at a relatively short reaction time. Additionally, the method described in (a) is particularly preferable because the reactive silicon group-containing organic polymer obtained by the method described in (a) is lower in viscosity and more satisfactory in workability than an organic polymer obtained by the method described in (c), and an organic polymer obtained by the method described in (b) is strong in odor due to mercaptosilane.

- hydrosilane compound used in the method described in (a) examples include halogenated silanes such as trichlorosilane, methyldichlorosilane, dimethylchlorosilane and phenyldichlorosilane; alkoxysilanes such as trimethoxysilane, triethoxysilane, methyldiethoxysilane, methyldimethoxysilane and phenyldimethoxysilane; acyloxysilanes such as methyldiacetoxysilane and phenyldiacetoxysilane; ketoximate silanes such as bis(dimethylketoximate)methylsilane and bis(cyclohexylketoximate)methylsilane and the like.

- halogenated silanes such as trichlorosilane, methyldichlorosilane, dimethylchlorosilane and phenyldichlorosilane

- the hydrosilane compound used in the method described in (a) is not limited to these compounds.

- halogenated silanes and alkoxysilanes are preferable and in particular, alkoxysilanes are most preferable because the obtained curable compositions are moderately hydrolyzable and easily handled.

- alkoxysilanes methyldimethoxysilane is particularly preferable because it is easily available and curability, storage stability, elongation property and tensile strength of the curable composition containing the obtained organic polymer are high.

- Examples of the synthesis method described in (b) include a method in which a mercapto group- and reactive silicon group-containing compound is introduced into the sites on the unsaturated bonds of an organic polymer by means of a radical addition reaction in the presence of a radical initiator and/or a radical generating source; however, the synthesis method concerned is not limited to these methods.

- Examples of the above described mercapto group- and reactive silicon group-containing compound include ⁇ -mercaptopropyltrimethoxysilane, ⁇ -mercaptopropylmethyldimethoxysilane, ⁇ -mercaptopropyltriethoxysilane, ⁇ -mercaptopropylmethyldiethoxysilane, mercaptomethyltrimethoxysilane, mercaptomethyltriethoxysilane and the like; however, the mercapto group- and reactive silicon group-containing compound is not limited to these compounds.

- Examples of the method, of the methods described in (c), in which a hydroxy-terminated polymer is reacted with an isocyanate group- and reactive silicon group-containing compound include a method disclosed in Japanese Patent Laid-Open No. 3-47825; however, the method concerned is not limited to these methods.

- Examples of the above described isocyanate group- and reactive silicon group-containing compound include ⁇ -isocyanatopropyltrimethoxysilane, ⁇ -isocyanatopropylmethyldimethoxysilane, ⁇ -isocyanatopropyltriethoxysilane, ⁇ -isocyanatopropylmethyldiethoxysilane, isocyanatomethyltrimethoxysilane, isocyanatomethyltriethoxysilane, isocyanatomethyldimethoxymethylsilane, isocyanatomethyldiethoxymethylsilane and the like; however, the compound concerned is not limited to these compounds.

- disproportionation reaction proceeds. If disproportionation reaction proceeds, a very dangerous compound like dimethoxysilane is generated. However in the cases of ⁇ -mercaptopropyltrimethoxysilane and ⁇ -isocyanatepropyltrimethoxysilane, such a disproportionation reaction does not proceed. Accordingly, when using, as a silicon-containing group, a group such as a trimethoxysilyl group in which three hydrolyzable groups are bonded to one silicon atom, it is preferable to employ the synthesis method of (b) or (c).

- the reactive silicon group-containing organic polymer may be a straight chain or may have branches, and the number average molecular weight thereof, measured by GPC relative to polystyrene standard, is preferably of the order of 500 to 100,000, more preferably 1,000 to 50,000, particularly preferably 3,000 to 30,000.

- the number average molecular weight is less than 500, it tends to be disadvantageous from the viewpoint of an elongation property of the cured article, while when the number average molecular weight exceeds 100,000, it tends to be disadvantageous from the viewpoint of workability because the viscosity becomes high.

- the number of reactive silicon groups contained in the organic polymer is, on average in one polymer molecule, at least one, and preferably 1.1 to 5.

- the reactive silicon group may be located at the terminal of the main chain or at the terminal of the side chain, or at the both in the organic polymer molecule chain.

- the reactive silicon group when located only at the terminal of the main chain, the effective network content in the organic polymer component contained in the finally formed cured article becomes large, so that it becomes easier to obtain a rubber-like cured article having a high strength, a high elongation property and a low elastic modulus.

- the polyoxyalkylene polymer (a1) is essentially a polymer having the repeating units represented by the general formula (10): —R 11 —O— (10) wherein R 11 is a linear or branched alkylene group having 1 to 14 carbon atoms.

- R 11 is preferably a linear or branched alkylene group having 1 to 14 carbon atoms, and more preferably 2 to 4 carbon atoms.

- repeating units represented by the general formula (10) include: —CH 2 O—, —CH 2 CH 2 O—, —CH 2 CH(CH 3 )O—, —CH 2 CH(C 2 H 5 )O—, —CH 2 C(CH 3 ) 2 O—, —CH 2 CH 2 CH 2 CH 2 O—, and the like.

- the main chain skeleton of the polyoxyalkylene polymer may be formed of either only one type of repeating unit or two or more types of repeating units.

- the main chain skeleton is formed of a polymer containing as the main component a propyleneoxide polymer because a polymer having such a main chain skeleton is amorphous and relatively low in viscosity.

- Examples of the synthesis method of the polyoxyalkylene polymer include a polymerization method in the presence of an alkaline catalyst such as KOH; a polymerization method in the presence of a transition metal compound-porphyrin complex catalyst prepared by reacting an organoaluminum compound with porphyrin, disclosed in Japanese Patent Laid-Open No. 61-215623; polymerization methods in the presence of composite metal cyanide complex catalysts, disclosed in Japanese Patent Examined Publication Nos. 46-27250 and 59-15336, and U.S. Pat. Nos.

- Examples of the preparation method of the reactive silicon group-containing polyoxyalkylene polymer (a1) of the present invention include the methods disclosed in Japanese Patent Examined Publication Nos. 45-36319 and 46-12154, Japanese Patent Laid-Open Nos. 50-156599, 54-6096, 55-13767, 55-13468 and 57-164123, Japanese Patent Examined Publication No. 3-2450, and U.S. Pat. Nos.

- the above described reactive silicon group-containing polyoxyalkylene polymers (a1) may be used either each alone or in combinations of two or more thereof.

- the (meth)acrylate monomers constituting the main chains of the above described (meth)acrylate polymers (a2) and various types can be used.

- the monomers concerned include (meth)acrylic acid monomers such as (meth)acrylic acid, methyl (meth)acrylate, ethyl (meth)acrylate, n-propyl (meth)acrylate, isopropyl (meth)acrylate, n-butyl (meth)acrylate, isobutyl (meth)acrylate, tert-butyl (meth)acrylate, n-pentyl (meth)acrylate, n-hexyl (meth)acrylate, cyclohexyl (meth)acrylate, n-heptyl (meth)acrylate, n-octyl (meth)acrylate, 2-ethylhexyl (meth)acrylate, nonyl (meth)

- (meth)acrylate monomers can be copolymerized with the following vinyl monomers.

- the vinyl monomers concerned include styrene monomers such as styrene, vinyltoluene, ⁇ -methylstyrene, chlorostyrene, styrenesulfonic acid and the salts thereof; fluorine-containing vinyl monomers such as perfluoroethylene, perfluoropropylene and fluorinated vinylidene; silicon-containing vinyl monomers such as vinyltrimethoxysilane and vinyltriethoxysilane; maleic anhydride, maleic acid, and monoalkyl esters and dialkyl esters of maleic acid; fumaric acid, and monoalkyl esters and dialkyl esters of fumaric acid; maleimide monomers such as maleimide, methylmaleimide, ethylmaleimide, propylmaleimide, butylmaleimide, hexyl

- These monomers may be used each alone or two or more of these monomers may be copolymerized.

- polymers formed of styrene monomers and (meth)acrylic acid monomers are preferable. More preferable are the (meth)acryl polymers formed of acrylate monomers and methacrylate monomers, and particularly preferable are the acryl polymers formed of acrylate monomers.

- the butyl acrylate monomers are further preferable because compositions concerned each are required to have physical properties including a low viscosity, and the cured articles each are required to have physical properties including a low modulus, a high elongation property, a weather resistance and a heat resistance.

- copolymers made of ethyl acrylate as the main material are further preferable.

- the copolymers made of ethyl acrylate as the main material are excellent in oil resistance, but slightly tend to be poor in low-temperature property (low-temperature resistance); for the purpose of improving the low-temperature property thereof, a part of ethyl acrylates can be replaced with butyl acrylate.

- the ratio of butyl acrylate is set preferably to not more than 40%, and more preferably to not more than 30%.

- 2-methoxyethyl acrylate and 2-ethoxyethyl acrylate which have side chain alkyl groups containing oxygen atoms introduced for the purpose of improving the low-temperature property and the like without degrading the oil resistance; in this connection, it is to be noted that the introduction of alkoxy groups having an ether bond in the side chains tends to degrade the heat resistance, so that the ratio of such an acrylate is preferably not more than 40% when heat resistance is required. It is possible to obtain appropriate polymers by varying the ratio in consideration of required physical properties such as oil resistance, heat resistance and low-temperature property according to the various applications and the required objectives.

- Examples of the polymers excellent in the balance between the physical properties including the oil resistance, heat resistance, low-temperature property and the like include a copolymer of ethyl acrylate/butyl acrylate/2-methoxyethyl acrylate (40 to 50/20 to 30/30 to 20 in a ratio by weight), this copolymer imposing no constraint on the polymers concerned.

- these preferable monomers can be copolymerized with other monomers, and moreover, block copolymerized with other monomers. In such cases, it is preferable that the preferable monomers are contained in an amount of not less than 40% in a ratio by weight.

- (meth)acrylic acid means acrylic acid and/or methacrylic acid.

- the living radical polymerization methods “the living radical polymerization methods” in which (meth)acrylate monomers are polymerized by use of an organic halogenated compound or a halogenated sulfonyl compound as an initiator and a transition metal complex as a catalyst has, in addition to the features of the above described “living radical polymerization methods,” features such that the obtained polymer has halogen atoms at the terminals relatively favorable for the functional group conversion reaction and freedom for designing the initiator and the catalyst is wide, so that the atom transfer radical polymerization method is further preferable as a method for preparing (meth)acrylate polymers having particular functional groups.

- the atom transfer radical polymerization method include the method reported by Matyjaszewski et al. in Journal of the American Chemical Society (J. Am. Chem. Soc.), Vol. 117, p. 5614 (1995).

- a reactive silicon group-containing (meth)acrylate polymer for example, Japanese Patent Examined Publication Nos. 3-14068 and 4-55444, and Japanese Patent Laid-Open No. 6-211922 and the like disclose preparation methods according to the free radical polymerization methods by using chain transfer agents. Additionally, Japanese Patent Laid-Open No. 9-272714 and the like disclose a preparation method according to the atom transfer radical polymerization method. However, the preparation method concerned is not limited to these methods.

- the above described reactive silicon group-containing (meth)acrylate polymers (a2) may be used either each alone or in combinations of two or more thereof.

- the preparation methods of the organic polymers formed by blending the reactive silicon group-containing polyoxyalkylene polymers (a1) with the reactive silicon group-containing (meth)acrylate polymers (a2) are proposed in Japanese Patent Laid-Open Nos. 59-122541, 63-112642, 6-172631, 11-116763 and the like. However, the preparation method concerned is not limited to these methods.

- a reactive silicon group-containing polyoxyalkylene polymer is blended with a copolymer formed of two (meth)acrylate monomer units: one (meth)acrylate monomer unit has the reactive silicon groups and alkyl groups having 1 to 8 carbon atoms, and the molecular chain is substantially represented by the following general formula (11): —CH 2 —C(R 12 )(COOR 13 )— (11) wherein R 12 represents hydrogen atom or a methyl group, and R 13 represents an alkyl group having 1 to 8 carbon atoms; and the other (meth)acrylate monomer unit has alkyl groups having 10 or more carbon atoms and is represented by the following general formula (12): —CH 2 —C(R 12 )(COOR 14 )— (12) wherein R 12 is the same as defined above, and R

- examples of R 13 include alkyl groups having 1 to 8 carbon atoms, preferably 1 to 4 carbon atoms and further preferably 1 to 2 carbon atoms such as a methyl group, an ethyl group, a propyl group, a n-butyl group, a t-butyl group and a 2-ethylhexyl group. It is also to be noted that the alkyl group of R 13 may represent either one type or admixtures of two or more types.

- examples of R 14 include long chain alkyl groups having 10 or more carbon atoms, usually 10 to 30 carbon atoms, and preferably 10 to 20 carbon atoms such as a lauryl group, a tridecyl group, a cetyl group, a stearyl group and a behenyl group. It is also to be noted that the alkyl group of R 14 may represent, similarly to R 13 , either one type or admixtures of two or more types.

- the molecular chains of the above described (meth)acrylate copolymers are substantially formed of the monomer units represented by formulas (11) and (12): “substantially” as referred to here means that in the copolymer concerned, the sum content of the monomer unit of formula (11) and the monomer unit of formula (12) exceeds 50 wt %.

- the sum content of the monomer units of formulas (11) and (12) is preferably not less than 70 wt %.

- the abundance ratio by weight of the monomer unit of formula (11) to the monomer unit of formula (12) is preferably 95:5 to 40:60, and further preferably 90:10 to 60:40.

- Examples of the monomer units other than the monomer units of formulas (11) and (12) which may be contained in the above described copolymer include acrylic acids such as acrylic acid and methacrylic acid; monomers containing amide groups such as acrylamide, methacrylamide, N-methylolacrylamide and N-methylolmethacrylamide, monomers containing epoxy groups such as glycidylacrylate and glycidylmethacrylate, and monomers containing amino groups such as diethylaminoethyl acrylate, diethylaminoethyl methacrylate and aminoethyl vinyl ether; and monomer units derived from acrylonitrile, styrene, ⁇ -methylstyrene, alkyl vinyl ethers, vinyl chloride, vinyl acetate, vinyl propionate and ethylene.

- acrylic acids such as acrylic acid and methacrylic acid

- monomers containing amide groups such as acrylamide, methacrylamide, N-methylolacrylamide and

- the main chain skeleton of the organic polymer of the present invention may include other components such as binding urethane components as far as such inclusion does not largely impair the effect of the invention.

- binding urethane components include groups (hereinafter referred to as amide segments) formed by a reaction of an isocyanate group with an active hydrogen group.

- amide segments are groups represented by the general formula (13): —NR 15 —C( ⁇ O)— (13) wherein R 15 represents hydrogen atom or a substituted or unsubstituted organic group.

- Examples of the above described amide segments include a urethane group formed by a reaction of an isocyanate group with hydroxyl group; a urea group formed by a reaction of an isocyanate group with an amino group; a thiourethane group formed by a reaction of an isocyanate group with a mercapto group; and the like. Additionally, in the present invention, groups formed by further reaction of an active hydrogen in the urethane group, urea group or thiourethane group with an isocyanate group are included in the groups of the general formula (13).

- Example of an industrially easy method of preparing an organic polymer having both of an amide segment and a reactive silicon group is a method in which after or at the same time of reacting an organic polymer having an active hydrogen-containing group at the terminal with an excessive amount of polyisocyanate compound to yield a polymer having isocyanate groups at the terminals of polyurethane main chains, a part or the whole of isocyanate groups are reacted with a W group of the silicon compound represented by the general formula (14): W—R 16 —SiR 10 3-e X e (14) wherein R 10 , X and e are the same as defined above; R 16 is a divalent organic group, more preferably a substituted or unsubstituted divalent hydrocarbon group having 1 to 20 carbon atoms; W is an active hydrogen-containing group selected from hydroxyl group, a carboxyl group, a mercapto group and an amino group (unsubstituted or mono-substituted).

- Polyether polyols prepared by any of preparation methods can be used, and preferred are polyether polyols having at least 0.7 hydroxyl group per a molecular terminal on average of the whole molecules.

- examples thereof are oxyalkylene polymers prepared by using conventional alkali metal catalysts, oxyalkylene polymers prepared by reacting an initiator such as a polyhydroxy compound having at least two hydroxyl groups with alkylene oxide in the presence of a composite metal cyanide complex and cesium, and the like.

- the method using a composite metal cyanide complex is preferable because oxyalkylene polymers having a lower degree of unsaturation, a narrow Mw/Mn, a lower viscosity and high acid resistance and weather resistance can be obtained.

- Examples of the above described polyacryl polyols include polyols having an alkyl (meth)acrylate (co)polymer skeleton and containing hydroxy groups in the molecule.

- the living radical polymerization method is preferable because this method can lead to narrow molecular weight distributions and low viscosities, and the atom transfer radical polymerization method is further preferable.

- examples thereof include UH-2000 produced by Toagosei Co., Ltd., and the like.

- polyisocyanate compound examples include aromatic polyisocyanates such as toluene (tolylene) diisocyanate, diphenylmethane diisocyanate and xylylene diisocyanate; and aliphatic polyisocyanates such as isophorone diisocyanate and hexamethylene diisocyanate.

- aromatic polyisocyanates such as toluene (tolylene) diisocyanate, diphenylmethane diisocyanate and xylylene diisocyanate

- aliphatic polyisocyanates such as isophorone diisocyanate and hexamethylene diisocyanate.

- examples thereof include silanes having amino group such as ⁇ -aminopropyltrimethoxysilane, N-( ⁇ -aminoethyl)- ⁇ -aminopropyltrimethoxysilane, ⁇ -(N-phenyl)aminopropyltrimethoxysilane, N-ethylaminoisobutyltrimethoxysilane, N-cyclohexylaminomethyltriethoxysilane, N-cyclohexylaminomethyldiethoxymethylsilane and N-phenylaminomethyltrimethoxysilane; silanes having hydroxy group such as ⁇ -hydroxypropyltrimethoxysilane; silanes having mercapto group such as ⁇ -mercaptopropyltrimethoxysilane; and the like.

- the reactive silicon group-containing isocyanate compound of the general formula (15) examples thereof include ⁇ -trimethoxysilylpropylisocyanate, ⁇ -triethoxysilylpropylisocyanate, ⁇ -methyldimethoxysilylpropylisocyanate, ⁇ -methyldiethoxysilylpropylisocyanate, trimethoxysilylmethylisocyanate, diethoxymethylsilylmethylisocyanate, dimethoxymethylsilylmethylisocyanate, diethoxymethylsilylmethylisocyanate and the like.

- a compound obtained by reacting the silicon compound of the general formula (14) with an excessive amount of the above described polyisocyanate compound can be used as the reactive silicon group-containing isocyanate compound of the general formula (15).

- the viscosity of the organic polymer becomes high and forms a composition poor in workability as the case may be.

- curability of the composition of the present invention tends to be enhanced by the amide segments contained in the main chain skeleton of the organic polymer.

- the organic polymer having amide segments in its main skeleton is used as the component (A)

- the composition prepared in a combination of the polymer with the component (B) is preferable because the composition has a quicker curability by use of a non-organotin catalyst.

- the average number of amide segments per molecule is preferably from 1 to 10, more preferably from 1.5 to 7, particularly preferably from 2 to 5.

- the number of amide segments is less than 1, in some cases, curability becomes insufficient, and when the number of amide segments is more than 10, the viscosity of the organic polymer becomes high and forms a composition poor in workability.

- the chelate type methyl titanate (b1) represented by the general formula (1): wherein each of (4-n) R 1 s is independently hydrogen atom or a substituted or unsubstituted hydrocarbon group having 1 to 20 carbon atoms, each of (4-n) A 1 s and (4-n) A 2 s is independently —R 2 or —OR 2 where R 2 is a substituted or unsubstituted hydrocarbon group having 1 to 20 carbon atoms, n is 1, 2 or 3, and/or the chelate type ethyl titanate (b2) represented by the general formula (2): wherein R 1 , A 1 , A 2 and n are the same as defined above, are used as the component (B).

- components (B) function as a curing catalyst for the organic polymer of the component (A).

- Organotin compounds such as dibutyltin dilaurate and dibutyltin bis(acetylacetonate) which have a fear of having an influence on environment have been so far used as a curing catalyst for the reactive silicon group-containing organic polymer of the component (A), but by using the titanium catalysts of the component (B) of the present invention, a load on environment is small and a curable composition having practical curing properties can be obtained. Further as compared with the case of using other curing catalysts such as organotin catalysts, adhesion to articles to be hardly adhered such as acrylic resins can be enhanced.

- Tetraalkoxy titanium, halogenated titanium, titanium chelate and the like are known as a titanium catalyst, and particularly when titanium chelate is used, there is a tendency that quick curability can be obtained.

- a one-component type curable composition is prepared using a silane compound having a nitrogen-substituted group like the component (C) as an adhesion-imparting agent and a commonly used titanium diisopropoxidebis(ethylacetoacetate) as a titanium catalyst, there is a tendency that mechanical properties such as a modulus and a strength of a cured article obtained from the stored composition are significantly lowered as compared with mechanical properties before storing.

- the reactive silicon group of the component (A) is a dimethoxymethylsilyl group

- a part or the whole of methoxy groups on silicon are converted to isopropoxy groups, and the reactive silicon group becomes a group having a lower reactivity.

- a titanium chelate in which an alkoxy-substituted group is limited to a methoxy group or an ethoxy group is used as a titanium catalyst like the component (B) of the present invention, lowering of mechanical properties of a cured article after storing can be inhibited. Namely, even if during the storing, an alkoxy group on the reactive silicon group of the component (A) and a methoxy group or an ethoxy group in the component (B) are exchanged with each other by the same mechanism as above, the converted reactive silicon group of the component (A) is a relatively active methoxy group or ethoxy group, and therefore it can be considered that a crosslinking reaction proceeds sufficiently.

- Examples of the chelate type methyl titanate (b1) include titanium dimethoxidebis(acetylacetonate), titanium dimethoxidebis(3-methylacetylacetonate), titanium dimethoxidebis(methylacetoacetate), titanium dimethoxidebis(ethylacetoacetate), titanium dimethoxidebis(ethyl-2-methylacetoacetate), titanium dimethoxidebis(ethyl-2-ethylacetoacetate), titanium dimethoxidebis(t-butylacetoacetate), titanium dimethoxidebis(allylacetoacetate), titanium dimethoxidebis(methyl-3-oxo-4,4-dimethylhexanoate), titanium dimethoxidebis(ethyl-3-oxo-4,4,4-trifluorobutanoate), titanium dimethoxidebis(2,2,6,6-tetramethyl-3,5-heptanedionate), titanium trimethoxide(acetylacetonate

- titanium dimethoxidebis(ethylacetoacetate), titanium dimethoxidebis(ethyl-2-methylacetoacetate) and titanium dimethoxidebis(acetylacetonate) are preferable from the viewpoint of catalytic activity, and titanium dimethoxidebis(ethylacetoacetate) and titanium dimethoxidebis(ethyl-2-methylacetoacetate) are especially preferable.

- examples of the chelate type ethyl titanate (b2) include titanium diethoxidebis(acetylacetonate), titanium diethoxidebis(3-methylacetylacetonate), titanium diethoxidebis(methylacetoacetate), titanium diethoxidebis(ethylacetoacetate), titanium diethoxidebis(ethyl-2-methylacetoacetate), titanium diethoxidebis(ethyl-2-ethylacetoacetate), titanium diethoxidebis(t-butylacetoacetate), titanium diethoxidebis(allylacetoacetate), titanium diethoxidebis(methyl-3-oxo-4,4-dimethylhexanoate), titanium diethoxidebis(ethyl-3-oxo-4,4,4-trifluorobutanoate), titanium diethoxidebis(2,2,6,6-tetramethyl-3,5-heptanedionate), titanium triethoxide(acetylacetonate), titanium triethoxide(

- titanium diethoxidebis(ethylacetoacetate), titanium diethoxidebis(ethyl-2-methylacetoacetate) and titanium diethoxidebis(acetylacetonate) are preferable from the viewpoint of catalytic activity, and titanium dimethoxidebis(ethylacetoacetate) and titanium dimethoxidebis(ethyl-2-methylacetoacetate) are especially preferable.

- the chelate type methyl titanate (b1) as the component (B) from the point that the effect of the present invention, i.e. an effect of inhibiting lowering of physical properties after storing is higher. Additionally, it is preferable to use the chelate type methyl titanate (b1) from the point that higher curability can be obtained. On the other hand, use of the chelate type ethyl titanate (b2) is preferable because a by-product derived from the titanate is ethanol which has less effect on environment.

- the reactive silicon group of the component (A) is an ethoxysilyl group such as a triethoxysilyl group

- Preferred examples of the chelating agents capable of forming chelate ligands of the above described component (B) include ⁇ -diketones such as acetylacetone, 3-methylacetylacetone and 2,2,4,4-tetramethyl-3,5-heptanedion; ⁇ -ketoesters such as methyl acetoacetate, ethyl acetoacetate, t-butyl acetoacetate, allyl acetoacetate, (2-methacryloxyethyl)acetoacetate, methyl 3-oxo-4,4-dimethylhexanoate, ethyl 3-oxo-4,4,4-trifluorobutanoate, 3-methylacetylacetone, ethyl 2-methylacetoacetate and ethyl 2-ethylacetoacetate; ⁇ -diesters such as dimethyl malonate and diethyl malonate; cyclic dicarbonyl compounds such as 2-acetylbutyrol

- ⁇ -Diketones and ⁇ -ketoesters are more preferred from the viewpoint of curability and storage stability, and ⁇ -ketoesters are particularly preferred.

- acetylacetone, methyl acetoacetate, ethyl acetoacetate and ethyl 2-methylacetoacetate are more preferred from the viewpoint of curability and storage stability and because those compounds are easily available, and ethyl acetoacetate and ethyl 2-methylacetoacetate are particularly preferable.

- those chelate ligands may be the same or different.

- the component (B) may be used either each alone or in combinations of two or more thereof.

- the used amount of the component (B) is preferably from 0.1 to 20 parts by weight, and more preferably from 0.5 to 15 parts by weight, especially preferably from 1 to 10 parts by weight with respect to 100 parts by weight of the component (A).

- the blended amount of the component (B) is less than the above described ranges, sometimes the practical curing rate cannot be obtained, and the curing reaction hardly proceeds to a sufficient extent.

- the blended amount of the component (B) exceeds the above described ranges, sometimes the work life becomes too short, and the workability is degraded.

- a titanium catalyst other than the component (B) can be used to an extent not to degrade the effect of the present invention.

- titanium chelates such as titanium diisopropoxidebis(ethylacetoacetate), titanium diisopropoxidebis(methylacetoacetate), titanium diisopropoxidebis(t-butylacetoacetate), titanium diisopropoxidebis(methyl-3-oxo-4,4-dimethylhexanoate), titanium diisopropoxidebis(ethyl-3-oxo-4,4,4-trifluoropentanoate), titanium diisopropoxidebis(acetylacetonate), titanium diisopropoxidebis(2,2,6,6-tetramethyl-3,5-heptanedionate), titanium di-n-butoxidebis(ethylacetoacetate), titanium di-t-butoxidebis(ethylacetoacetate), titanium di-2-ethylhexoxidebis(ethylacetoa)

- the component (C) of the present invention is a kind of so-called silane coupling agent, and acts as an adhesion-imparting agent.

- a marked effect of improving adhesion is exhibited under a non-primer condition or under a condition of treating with a primer when the composition is used on various articles to be adhered, namely, inorganic substrates such as glass, aluminum, stainless steel, zinc, copper and mortar and organic substrates such as polyvinyl chloride, acryl, polyester, polyethylene, polypropylene and polycarbonate.

- inorganic substrates such as glass, aluminum, stainless steel, zinc, copper and mortar

- organic substrates such as polyvinyl chloride, acryl, polyester, polyethylene, polypropylene and polycarbonate.

- hydrolyzable silicon groups of the component (C) are the groups represented by the general formula (8) in which X is a hydrolyzable group. Specifically there are groups exemplified supra as a hydrolyzable group, and a methoxy group and an ethoxy group are preferable from the viewpoint of a hydrolyzing rate.

- the number of hydrolyzable groups is preferably not less than 2, particularly not less than 3.

- the reactive silicon group contained in the component (A) is described as “a silicon-containing group being crosslinkable by forming siloxane bonds”, and the reactive silicon group contained in the component (C) is described as “a hydrolyzable silicon group”, and the both are substantially the same kind of reactive silicon groups.

- Representative examples of those reactive silicon groups are reactive silicon groups represented by the following general formulae (5) and (6), respectively. Those groups have an alkoxy group having 1 to 4 carbon atoms as a hydrolyzable group.

- R 6 is an alkyl group having the number of carbon atoms more than the number of carbon atoms of R 8 , from the viewpoint of curability. This is because when R 6 is an alkyl group having the number of carbon atoms less than that of R 8 , it is presumed that in some cases, inherent curability of the component (A) is lowered.

- the hydrolyzable silicon group of the component (C) is preferably a methoxysilyl group represented by the general formula (7): —SiR 7 3-b (OCH 3 ) b (7) wherein each of R 7 s is independently a substituted or unsubstituted hydrocarbon group having 1 to 20 carbon atoms or a triorganosiloxy group represented by (R′) 3 SiO— where each of R's is independently a substituted or unsubstituted hydrocarbon group having 1 to 20 carbon atoms, b is 1, 2 or 3.

- the methoxysilyl group are a methoxydimethylsilyl group, a methoxydiphenylsilyl group, a methoxybistrimethylsiloxysilyl group, a dimethoxymethylsilyl group, an ethyldimethoxysilyl group, a dimethoxyphenylsilyl group, a dimethoxytrimethylsiloxysilyl group, a trimethoxysilyl group and the like.

- the methoxysilyl group is not limited to them. From the viewpoint of curability of the obtained curable composition, a dimethoxymethylsilyl group and a trimethoxysilyl group are preferable and a trimethoxysilyl group is particularly preferable.

- the component (C) has the nitrogen-substituted group of the above described general formula (3) or (4), a higher adhesion can be obtained. Since an effect of imparting adhesion is higher, the substituent represented by the general formula (3) is preferable, and an amino group is particularly preferable.

- component (C) include amino group-containing silanes such as ⁇ -aminopropyltrimethoxysilane, ⁇ -aminopropylmethyldimethoxysilane, ⁇ -aminopropyltriethoxysilane, ⁇ -aminopropylmethyldiethoxysilane, ⁇ -aminopropyltriisopropoxysilane, ⁇ -(methylamino)propyltrimethoxysilane, ⁇ -(2-aminoethyl)aminopropyltrimethoxysilane, ⁇ -(2-aminoethyl)aminopropylmethyldimethoxysilane, ⁇ -(2-aminoethyl)aminopropyltriethoxysilane, ⁇ -(2-aminoethyl)aminopropylmethyldiethoxysilane, ⁇ -(2-aminoethyl)aminopropyltriis

- component (C) amino-modified silylpolymer, silylated aminopolymer, unsaturated aminosilane complex, phenylamino-long chain alkylsilane and aminosilylated silicone.

- the reactive silicon group of the component (A) is a methoxysilyl group represented by the general formula (5), it is essential to use the component (C) having a methoxysilyl group among those described above.

- the above described component (C) may be used alone or in a mixture of two or more kinds thereof.

- the used amount of the component (C) is preferably of the order of 0.1 to 20 parts by weight, and more preferably of the order of 0.5 to 10 parts by weight, especially preferably of the order of 2 to 7 parts by weight with respect to 100 parts by weight of the component (A).

- the blended amount of the component (C) is less than the above described ranges, sometimes sufficient adhesion cannot be obtained.

- the blended amount of the component (C) exceeds the above described ranges, sometimes the practical curing rate cannot be obtained, and the curing reaction hardly proceeds to a sufficient extent.

- a silane coupling agent other than the component (C) can be used to an extent not to degrade the effect of the present invention.

- these silane coupling agents are di-substituted amino group-containing silanes such as ⁇ -(dimethylamino)propyltrimethoxysilane; mercapto group-containing silanes such as ⁇ -mercaptopropyltrimethoxysilane, ⁇ -mercaptopropyltriethoxysilane, ⁇ -mercaptopropylmethyldimethoxysilane, ⁇ -mercaptopropylmethyldiethoxysilane, mercaptomethyltrimethoxysilane and mercaptomethyltriethoxysilane; epoxy group-containing silanes such as ⁇ -glycidoxypropyltrimethoxysilane, ⁇ -glycidoxypropyltriethoxysilane, ⁇ -glycidoxypropylmethyldimethoxysilane,

- adhesion-imparting agent for example, epoxy resins, phenolic resins, sulfur, alkyl titanates, aromatic polyisocyanates and the like can be used as an adhesion-imparting agent.

- the adhesion-imparting agent is not limited particularly to them.

- the above described adhesion-imparting agents may be used alone or in a mixture of two or more thereof.

- the component (B) is used, and other curing catalysts can be simultaneously used to an extent not to degrade the effect of the present invention.

- the curing catalyst include metal salts of carboxylic acids such as tin 2-ethylhexanoate, tin versatate and bismuth 2-ethylhexanoate; tetravalent organotin compounds such as dibutyltin dilaurate, dibutyltin maleate, dibutyltin phthalate, dibutyltin dioctanoate, dibutyltin bis(2-ethylhexanoate), dibutyltin bis(methylmaleate), dibutyltin bis(ethylmaleate), dibutyltin bis(butylmaleate), dibutyltin bis(octylmaleate), dibutyltin bis(tridecylmaleate), dibutyltin bis(benzyl

- a filler can be added to the composition of the present invention.

- the fillers include reinforcing fillers such as fumed silica, precipitated silica, crystalline silica, fused silica, dolomite, anhydrous silicic acid, hydrous silicic acid and carbon black; fillers such as ground calcium carbonate, precipitated calcium carbonate, magnesium carbonate, diatomite, sintered clay, clay, talc, titanium oxide, bentonite, organic bentonite, ferric oxide, aluminum fine powder, flint powder, zinc oxide, active zinc white, shirasu balloon, glass microballoon, organic microballoons of phenolic resin and vinylidene chloride resin, and resin powders such as PVC powder and PMMA powder; and fibrous fillers such as asbestos, glass fiber and glass filament.

- the used amount thereof is 1 to 250 parts by weight, and preferably 10 to 200 parts by weight with respect to 100 parts by weight of the polymer of the component (A).

- a highly transparent composition when preparing a highly transparent composition, as described in Japanese Patent Laid-Open No. 11-302527, it is possible to use, as a filler, a polymer powder prepared by using a polymer such as methyl methacrylate as a starting material or a non-crystalline silica. Also as described in Japanese Patent Laid-Open No. 2000-38560, a highly transparent composition can be obtained by using, as a filler, a hydrophobic silica which is a fine powder of silicon dioxide having hydrophobic groups bonded to the surface thereof.

- the surface of a fine powder of silicon dioxide has generally silanol groups (—SiOH), but can be formed into a hydrophobic silica by reacting those silanol groups with halides of organosilicon or alcohols to produce —SiO— hydrophobic group.

- the hydrophobic silica is obtained by reacting silanol groups being present in the surface of the fine powder of silicon dioxide with dimethylsiloxane, hexamethyldisilazane, dimethyldichlorosilane, trimethoxyoctylsilane, trimethylsilane or the like.

- a fine powder of silicon dioxide in which the surface thereof is formed by silanol groups (—SiOH) is called a hydrophilic fine powder of silica.

- a filler mainly selected from fumed silica, precipitated silica, crystalline silica, fused silica, dolomite, anhydrous silicic acid, hydrous silicic acid, carbon black, surface treated fine calcium carbonate, sintered clay, clay and active zinc white; a desirable effect is obtained when such a filler is used within a range from 1 to 200 parts by weight with respect to 100 parts by weight of the reactive silicone group-containing organic polymer (A).

- a desirable effect is obtained by use of a filler mainly selected from titanium oxide, calcium carbonate such as ground calcium carbonate and magnesium carbonate, talc, ferric oxide, zinc oxide and shirasu balloon within a range from 5 to 200 parts by weight with respect to 100 parts by weight of the reactive silicone group-containing organic polymer (A).

- the calcium carbonate exhibits, with increasing specific surface area value thereof, an increasing improvement effect of the tensile strength at break, elongation at break and adhesion of the cured article.

- these fillers may be used either each alone or in admixtures of two or more thereof.

- surface treated fine calcium carbonate in combination with calcium carbonate larger in particle size such as ground calcium carbonate.

- the particle size of surface treated fine calcium carbonate is preferably not more than 0.5 ⁇ m, and the surface treatment is preferably carried out by treating with a fatty acid or a fatty acid salt.

- the calcium carbonate larger in particle size is preferably not less than 1 ⁇ m in particle size, and can be used without being subjected to surface treatment.

- organic balloons and inorganic balloons are preferably added.

- Such fillers can be subjected to surface treatment, and may be used each alone or can be used in admixtures of two or more thereof.

- the particle sizes of these balloons are preferably not more than 0.1 mm.

- the particle sizes are preferably 5 to 300 ⁇ m.

- the composition of present invention is suitably used for joints of housing exterior wall such as sizing boards, in particular, ceramic sizing boards, for an adhesive for exterior wall tiles, for an adhesive for exterior wall tiles remaining in the joints and for the like purposes; in this connection, it is desirable that the design of the exterior wall and the design of the sealant are in harmony with each other.

- posh exterior walls have come to be used by virtue of sputter coating and mixing colored aggregates.

- the composition of the present invention When the composition of the present invention is blended with a scale-like or granulated material having a diameter of not less than 0.1 mm, preferably of the order of 0.1 to 5.0 mm, the cured article comes to be in harmony with such posh exterior walls, and is excellent in chemical resistance, so that the composition concerned comes to be an excellent composition in the sense that the exterior appearance of the cured article remains unchanged over a long period of time.

- Use of a granulated material provides a dispersed sand-like or sandstone-like surface with a rough texture, while use of a scale-like material provides an irregular surface based on the scale-like shape of the material.

- the diameter is not less than 0.1 mm, preferably of the order of 0.1 to 5.0 mm, and there is used a material having an appropriate size in conformity with the material quality and pattern of exterior wall. Materials having a diameter of the order of 0.2 mm to 5.0 mm and materials having a diameter of the order of 0.5 mm to 5.0 mm can also be used.

- the thickness is set to be as thin as the order of 1/10 to 1 ⁇ 5 the diameter (the order of 0.01 to 1.00 mm).

- the scale-like or granulated material is transported to the construction site as a sealant on condition that the material is beforehand mixed in the main component of the sealant, or is mixed in the main component of the sealant at the construction site when the sealant is used.

- the scale-like or granulated material is blended in a content of the order of 1 to 200 parts by weight with respect to 100 parts by weight of a composition such as a sealant composition and an adhesive composition.

- the blended amount is appropriately selected depending on the size of the scale-like or granulated material, and the material quality and pattern of exterior wall.

- the scale-like or granulated material natural products such as silica sand and mica, synthetic rubbers, synthetic resins and inorganic substances such as alumina are used.

- the material is colored in an appropriate color so as to match the material quality and pattern of exterior wall to heighten the design quality when filled in the joints.

- a balloon preferably the mean particle size thereof is not less than 0.1 mm

- the surface is formed to have a dispersed sand-like or sandstone-like surface with a rough texture, and a reduction of weight can be achieved.

- the preferable diameter, blended amount and materials for the balloon are described in Japanese Patent Laid-Open No. 10-251618 as follows.

- the balloon is a sphere-shaped material with a hollow interior.

- the material for such a balloon include inorganic materials such as glass, shirasu and silica; and organic materials such as phenolic resin, urea resin, polystyrene and SaranTM; however, the material concerned is not limited to these examples; an inorganic material and an organic material can be compounded, or can be laminated to form multiple layers.

- An inorganic balloon, an organic balloon, a balloon made of a compounded inorganic-organic material or the like can be used. Additionally, as a balloon to be used, either a type of balloon or an admixture of multiple types of balloons can be used.

- a balloon with the processed surface thereof or with the coated surface thereof can be used, and additionally, a balloon with the surface thereof subjected to treatment with various surface treatment agents can also be used. More specifically, examples are an organic balloon coated with calcium carbonate, talc, titanium oxide and the like, and an inorganic balloon subjected to surface treatment with a silane coupling agent.

- the particle size of the balloon is preferably not less than 0.1 mm.

- a balloon of a particle size of the order of 0.2 mm to 5.0 mm or a balloon of a particle size of the order of 0.5 mm to 5.0 mm can also be used.

- Use of a balloon of a particle size of less than 0.1 mm sometimes only increases the viscosity of the composition, and yields no rough texture, even when the used amount of the balloon is large.

- the blended amount of the balloon can be easily determined in conformity with the desired degree of the dispersed sand-like or sandstone-like rough texture.

- a balloon of not less than 0.1 mm in particle size is blended in a ratio of 5 to 25 vol % in terms of the volume concentration in the composition.

- the volume concentration of the balloon is less than 5 vol %, no rough texture can be obtained, while when the volume concentration of the balloon exceeds 25 vol %, the viscosity of the sealant and that of the adhesive tend to become high to degrade the workability, and the modulus of the cured article becomes high, so that the basic performance of the sealant and that of the adhesive tend to be impaired.

- the preferable volume concentration to balance with the basic performance of the sealant is 8 to 22 vol %.

- thermally expandable fine hollow particles disclosed in Japanese Patent Laid-Open No. 2004-51701 or 2004-66749 can be used.

- the thermally expandable fine hollow particles are plastic spherical particulates produced by surrounding a low boiling point compound such as a hydrocarbon having 1 to 5 carbon atoms with a high molecular weight shell material (vinylidene chloride copolymer, acrylonitrile copolymer or vinylidene chloride-acrylonitrile copolymer).

- a low boiling point compound such as a hydrocarbon having 1 to 5 carbon atoms

- a high molecular weight shell material vinylidene chloride-acrylonitrile copolymer

- the cured article can make irregularities on the surface to improve the design quality.

- the preferable diameter, blended amount and materials of the cured article particle material derived from a sealant is described in Japanese Patent Laid-Open No. 2001-115142 as follows.

- the diameter is preferably of the order of 0.1 mm to 1 mm, and further preferably of the order of 0.2 to 0.5 mm.

- the blended amount is preferably 5 to 100 wt %, and further preferably 20 to 50 wt % in the curable composition.

- the materials include urethane resin, silicone, modified silicone and polysulfide rubber. No constraint is imposed on the materials as long as the materials can be used as sealants; however, modified silicone sealants are preferable.

- an adhesion-imparting agent To the composition of the present invention can be added an adhesion-imparting agent. No particular constraint is imposed on the adhesion-imparting resins, and usual adhesion-imparting resins can be used irrespective of solid form or liquid form at ordinary temperature.

- adhesion-imparting resins include styrene block copolymers, hydrogenated products thereof, phenolic resins, modified phenolic resins (for example, cashew oil-modified phenolic resins, tall oil-modified phenolic resins and the like), terpene phenolic resins, xylene-phenol resins, cyclopentadiene-phenol resins, cumarone-indene resins, rosin resins, rosin ester resins, hydrogenated rosin ester resins, xylene resins, low molecular weight polystyrene resins, styrene copolymer resins, petroleum resins (for example, C5 hydrocarbon resin, C9 hydrocarbon resin, C5C9 hydrocarbon copolymer resin and the like), hydrogenated petroleum resins, terpene resins, DCPD resin-petroleum resin and the like.

- phenolic resins modified phenolic resins (for example, cashew oil-modified

- styrene block copolymers and hydrogenated products thereof include styrene-butadiene-styrene block copolymer (SBS), styrene-isoprene-styrene block copolymer (SIS), styrene-ethylenebutylene-styrene block copolymer (SEBS), styrene-ethylenepropylene-styrene block copolymer (SEPS), styrene-isobutylene-styrene block copolymer (SIBS) and the like.

- SBS styrene-butadiene-styrene block copolymer

- SIS styrene-isoprene-styrene block copolymer

- SEBS styrene-ethylenebutylene-styrene block copolymer

- SEPS styrene-ethylenepropylene-styrene block

- the adhesion-imparting resins are used within a range from 5 to 1,000 parts by weight, preferably from 10 to 100 parts by weight with respect to 100 parts by weight of the organic polymer (A).

- a solvent or a diluent To the composition of the present invention can be added a solvent or a diluent. No particular constraint is imposed on the solvent or the diluent, and aliphatic hydrocarbon, aromatic hydrocarbon, alicyclic hydrocarbon, halogenated hydrocarbon, alcohol, ester, ketone, ether and the like can be used.

- the boiling point of the solvent is preferably not less than 150° C., more preferably not less than 200° C., particularly preferably not less than 250° C. from the viewpoint of a problem with contamination to the air when the composition is used indoor.

- solvents or diluents may be used either each alone or in combinations of two or more thereof.

- a plasticizer can be added to the composition of the present invention. Addition of a plasticizer makes it possible to adjust the viscosity and slump property of the curable composition and the mechanical properties such as tensile strength and elongation of the cured article obtained by curing the composition.

- plasticizer examples include phthalates such as dibutyl phthalate, diheptyl phthalate, bis(2-ethylhexyl)phthalate, diisodecy phthalate, diundecyl phthalate and butyl benzyl phthalate; non-aromatic dibasic acid esters such as dioctyl adipate, dioctyl sebacate, dibutyl sebacate and diisodecyl succinate; aliphatic esters such as butyl oleate and methyl acetyl recinolate; phosphates such as tricresyl phosphate and tributyl phosphate; trimellitates; chlorinated paraffins; hydrocarbon oils such as alkyldiphenyls and partially hydrogenated terphenyls; process oils; epoxy plasticizers such as epoxidized soybean oil and benzyl epoxystearate.

- phthalates such as dibutyl phthalate,

- a polymer plasticizer can be used.

- a polymer plasticizer When a polymer plasticizer is used, there can be obtained effects of hardly causing curing retardation and improving drying property (also referred to as coating property) in the case of coating of an alkyd coating material on the cured article as compared with the case of using a low molecular weight plasticizer containing no polymer component in the molecule.

- polymer plasticizer examples include vinyl polymers obtained by polymerizing vinyl monomers by means of various methods; polyalkylene glycol esters such as diethylene glycol dibenzoate, triethylene glycol dibenzoate and pentaerythritol ester; polyester plasticizers obtained from dibasic acids such as sebacic acid, adipic acid, azelaic acid and phthalic acid and dihydric alcohols such as ethylene glycol, diethylene glycol, triethylene glycol, propylene glycol and dipropylene glycol; polyethers including polyether polyols each having a molecular weight of not less than 500, additionally not less than 1,000 such as polyethylene glycol, polyprolpylene glycol and polytetramethylene glycol, and the derivatives of these polyether polyols in which the hydroxy groups in these polyether polyols are substituted with acyl groups such as acetoxy groups, alkoxy groups such as methoxy groups, ethoxy groups, butoxy groups and allyl

- polymer plasticizers which are compatible with the polymer of component (A) are preferable.

- polyethers and vinyl polymers are preferable.

- polyethers when polyethers are used as plasticizers, the surface curability, deep-part curability and adhesion are improved, and no curing retardation after storage occurs, and hence polyethers are preferable; of polyethers, polypropylene glycol is more preferable.

- polymer plasticizers polyether polyols such as polyethylene glycol and polypropylene glycol in which hydroxyl groups thereof are converted to alkoxy groups or the like because storage stability is increased. Additionally, from the viewpoint of the compatibility, weather resistance and heat resistance, vinyl polymers are preferable.

- acryl polymers and/or methacryl polymers are preferable, and acryl polymers such as polyalkylacrylate are further preferable.

- the living radical polymerization method is preferable because this method can lead to narrow molecular weight distributions and low viscosities, and the atom transfer radical polymerization method is further preferable.

- the number average molecular weight of the polymer plasticizer is preferably 500 to 15,000, more preferably 800 to 10,000, further preferably 1,000 to 8,000, particularly preferably 1,000 to 5,000, and most preferably 1,000 to 3,000.

- the molecular weight is too low, the plasticizer is removed with time due to heat and by rainfall, and hence it is made impossible to maintain the initial physical properties over a long period of time, contamination is caused due to cohesion of dusts, and the coating property with an alkyd coating material cannot be improved.

- the molecular weight is too high, the viscosity becomes high and the workability is degraded. No particular constraint is imposed on the molecular weight distribution of the polymer plasticizer.

- the molecular weight distribution is narrow; the molecular weight distribution is preferably less than 1.80, more preferably not more than 1.70, further preferably not more than 1.60, yet further preferably not more than 1.50, particularly preferably not more than 1.40 and most preferably not more than 1.30.

- the number average molecular weight of a polyether polymer is measured with the terminal group analysis method, and that of other polymers is measured with the GPC method. Additionally, the molecular weight distribution (Mw/Mn) is measured with the GPC method (relative to polystyrene standard).

- the polymer plasticizer either may have no reactive silicon group or may have a reactive silicon group.

- the polymer plasticizer acts as a reactive plasticizer, and can prevent the migration of the plasticizer from the cured article.

- the average number of reactive silicon groups per molecule is not more than 1, and preferably not more than 0.8.

- the reactive silicon group-containing plasticizer in particular, a reactive silicon group-containing oxyalkylene polymer is used, it is necessary that the number average molecular weight thereof is lower than that of the organic polymer (A).

- the plasticizers may be used either each alone or in combinations of two or more thereof. Additionally, a low molecular weight plasticizer and a polymer plasticizer may be used in combination. It is to be noted that these plasticizers can also be blended when the polymer is produced.

- the used amount of the plasticizer is 5 to 150 parts by weight, preferably 10 to 120 parts by weight, and further preferably 20 to 100 parts by weight, with respect to 100 parts by weight of the polymer of the component (A).

- the used amount is less than 5 parts by weight, the effect as the plasticizer is not exhibited, while when the used amount exceeds 150 parts by weight, the mechanical strength of the cured article is insufficient.

- a physical properties-regulating agent for adjusting tensile properties of a produced cured article may be added.

- the physical properties-regulating agent include tetraalkoxysilanes (tetraalkylsilicates) such as tetramethoxysilane, tetraethoxysilane, ethoxytrimethoxysilane, dimethoxydiethoxysilane, methoxytriethoxysilane, tetra-n-propoxysilane, tetra-1-propoxysilane, tetra-n-butoxysilane, tetra-1-butoxysilane and tetra-t-butoxysilane; trialkoxysilanes such as methyltrimethoxysilane, methyltriethoxysilane, methyltriisopropoxysilane, methyltriphenoxysilane, ethy

- the above described physical properties-regulating agent when the composition of the present invention is cured, a hardness can be increased or reversely can be decreased and an elongation at break can be increased.

- the above described physical properties-regulating agent may be used alone or in a mixture of two or more kinds thereof. Additionally, by adding partially hydrolyzed condensates of tetraalkoxysilanes and alkoxysilanes, there can be obtained effects of enhancing water resistant adhesion of the curable composition and enhancing recovery properties of the obtained cured article.

- Partially hydrolyzed condensates of organosilicate compounds are commercially available.

- Examples of such condensates include Methyl silicate 51 and Ethyl silicate 40 (both are products of Colcoat Co., Ltd.).

- the used amount of the physical properties-regulating agent is preferably 0.1 to 20 parts by weight, and more preferably 0.5 to 10 parts by weight with respect to 100 parts by weight of the reactive silicon group-containing organic polymer (A).

- a compound to hydrolytically produce a compound having a monovalent silanol group in the molecule thereof This compound has an effect of decreasing the modulus of the cured article without degrading the stickiness of the surface of the cured article.

- a compound to produce trimethylsilanol is preferable.

- Examples of the compound to hydrolytically produce a compound having a monovalent silanol group in the molecule thereof include a compound described in Japanese Patent Laid-Open No. 5-117521.

- examples of such a compound include a compound which is a derivative of an alkyl alcohol such as hexanol, octanol or decanol, and produces a silicon compound to hydrolytically produce R 3 SiOH such as trimethylsilanol, and a compound described in Japanese Patent Laid-Open No. 11-241029 which is a derivative of a polyhydric alcohol having three or more hydroxy groups such as trimethylolpropane, glycerin, pentaerythritol or sorbitol, and produces a silicon compound to hydrolytically produce R 3 SiOH such as trimethylsilanol.

- the compound to hydrolytically produce a compound having a monovalent silanol group in the molecule thereof is used within a range from 0.1 to 20 parts by weight, and preferably from 0.5 to 10 parts by weight, with respect to 100 parts by weight of the reactive silicon group-containing organic polymer (A).

- a thixotropy providing agent may be added for the purpose of preventing sagging and improving workability.

- the antisagging agent include polyamide waxes; hydrogenated castor oil derivatives; and metal soaps such as calcium stearate, aluminum stearate and barium stearate.

- a rubber powder having a particle size of 10 to 500 ⁇ m as described in Japanese Patent Laid-Open No. 11-349916, and an organic fiber as described in Japanese Patent Laid-Open No. 2003-155389 are used, a composition having high thixotropy and satisfactory workability can be obtained.

- thixotropy providing agents may be used either each alone or in combinations of two or more thereof.

- the thixotropy providing agents each are used within a range from 0.1 to 20 parts by weight with respect to 100 parts by weight of the reactive silicon group-containing organic polymer (A).

- a compound containing an epoxy group in one molecule can be used.

- Use of an epoxy group-containing compound can increase the recovery properties of the cured article.

- the epoxy group-containing compound include compounds such as epoxidized unsaturated oils and fats, epoxidized unsaturated fatty acid esters, alicyclic epoxy compounds and epichlorohydrin derivatives, and admixtures of these compounds. More specific examples include epoxidized soybean oil, epoxidized flaxseed oil, bis(2-ethylhexyl)-4,5-epoxycyclohexane-1,2-dicarboxylate (E-PS), epoxyoctyl stearate and epoxybutyl stearate. Of these, E-PS is particularly preferable. It is recommended that these epoxy group-containing compounds each are used within a range from 0.5 to 50 parts by weight with respect to 100 parts by weight of the reactive silicon group-containing organic polymer (A).

- a photocuring substance can be used for the composition of the present invention.

- Use of a photocuring substance forms a coating film of the photocuring substance on the surface of the cured article to improve the stickiness and the weather resistance of the cured article.

- a photocuring substance means a substance which undergoes a chemical change, caused by action of light, of the molecular structure thereof in a fairly short time to result in changes of the physical properties such as curability.

- organic monomers, oligomers, resins and compositions containing these substances are organic monomers, oligomers, resins and compositions containing these substances, and any commercially available substances concerned can optionally be adopted.

- As representative photocuring substances unsaturated acryl compounds, polyvinyl cinnamates, azidized resins and the like can be used.

- the unsaturated acryl compounds are monomers, oligomers and admixtures of the monomers and the oligomers, the monomers and oligomers each having one or a few acryl or methacryl unsaturated groups; examples of the unsaturated acryl compounds include monomers such as propylene (or butylene, or ethylene)glycol di(meth)acrylate and neopentylglycol di(meth)acrylate, and oligoesters of not more than 10,000 in molecular weight related to these monomers.