US20030019083A1 - Clip for mounting a vehicle sunvisor - Google Patents

Clip for mounting a vehicle sunvisor Download PDFInfo

- Publication number

- US20030019083A1 US20030019083A1 US10/076,196 US7619602A US2003019083A1 US 20030019083 A1 US20030019083 A1 US 20030019083A1 US 7619602 A US7619602 A US 7619602A US 2003019083 A1 US2003019083 A1 US 2003019083A1

- Authority

- US

- United States

- Prior art keywords

- clip

- projection

- flat bottom

- width

- length

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

- 238000003780 insertion Methods 0.000 claims abstract description 4

- 230000037431 insertion Effects 0.000 claims abstract description 4

- 229910000831 Steel Inorganic materials 0.000 abstract description 4

- 239000010959 steel Substances 0.000 abstract description 4

- 239000000463 material Substances 0.000 description 2

- 230000037237 body shape Effects 0.000 description 1

- 230000037396 body weight Effects 0.000 description 1

- 238000005034 decoration Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000003351 stiffener Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16B—DEVICES FOR FASTENING OR SECURING CONSTRUCTIONAL ELEMENTS OR MACHINE PARTS TOGETHER, e.g. NAILS, BOLTS, CIRCLIPS, CLAMPS, CLIPS OR WEDGES; JOINTS OR JOINTING

- F16B5/00—Joining sheets or plates, e.g. panels, to one another or to strips or bars parallel to them

- F16B5/06—Joining sheets or plates, e.g. panels, to one another or to strips or bars parallel to them by means of clamps or clips

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60J—WINDOWS, WINDSCREENS, NON-FIXED ROOFS, DOORS, OR SIMILAR DEVICES FOR VEHICLES; REMOVABLE EXTERNAL PROTECTIVE COVERINGS SPECIALLY ADAPTED FOR VEHICLES

- B60J3/00—Antiglare equipment associated with windows or windscreens; Sun visors for vehicles

- B60J3/02—Antiglare equipment associated with windows or windscreens; Sun visors for vehicles adjustable in position

- B60J3/0204—Sun visors

- B60J3/0213—Sun visors characterised by the mounting means

- B60J3/0217—Brackets for mounting the sun visor support arm to the vehicle

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T24/00—Buckles, buttons, clasps, etc.

- Y10T24/30—Trim molding fastener

- Y10T24/309—Plastic type

Definitions

- the present invention relates to a clip for mounting a vehicle sunvisor, and more particularly, to a clip for mounting a vehicle sunvisor made of plastic which can reduce contact noise generated in the conventional steel clip and reduce the clip weight.

- the body of a vehicle comprises panels which outline the external body shape, stiffeners, which reinforce the strength of the panels and trims, which are used as materials for interior decorations. More specifically, there are roof panels and roof side panels located on the upper portion of a vehicle body. The roof panel is where headlining and roof trim are mounted. The mountings of headlining and roof trim onto the roof panel have been carried out using clips.

- the conventional clips used in mounting vehicle sunvisors were either bolt fixing clips 100 or fixing clips with wings 200 , which are easily released due to weak assembly force thus lowering the reliance and quality of the product. Further, conventional clips have been less than advantageous in that they were made of steel thus making unwanted noise by contacting with roof trim.

- the present invention provides a clip for mounting a vehicle sunvisor, wherein roof trim with sloping multiple steps is in close contact with the bottom part of the clip.

- Elastic wings on the clip extend downwardly at an angle on both sides. The wings are inserted into clip assembly holes in the trim, which are prepared for the insertion of the projection of the clip and fixed thereafter.

- the bottom part of the clip is fixed by bolting through bolt holes, thus preventing dislocation or horizontal movement.

- the present invention is made of plastic and thus can prevent contact noise usually produced in conventional clips made of steel. Also, the lightness in weight of the clip of the present invention made of plastic can help to reduce the body weight of a vehicle to comply with the current global trend of manufacturing automobiles.

- FIG. 1 is a perspective view of a clip for mounting a vehicle sunvisor according to the present invention

- FIG. 2 is a perspective view of an alternative clip for mounting a vehicle sunvisor according to an alternative embodiment of the present invention

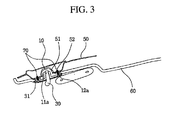

- FIG. 3 is a schematic cross-sectional view of the mounted state of the clip shown in FIG. 1;

- FIG. 4 is a schematic cross-sectional view of the mounted state of the alternative clip shown in FIG. 2;

- FIGS. 5 and 6 are perspective views of conventional clips for mounting a vehicle sunvisor.

- a first clip 10 for mounting a vehicle sunvisor comprises a cubic projection 11 , and a rectangular bottom 12 perpendicular to the above cubic projection 11 .

- Elastic wings 13 laterally extend from the cubic projection 11 on two sides, and clip bolt holes 12 a are formed on the rectangular bottom 12 .

- the elastic wings 13 extend laterally at an angle on both left and right faces toward the rectangular bottom 12 , and a flange 13 a is produced at the end of the projection 11 so that the edge of clip assembly hole 51 of the roof trim 50 can be received in the stepped portion of the flange 13 a and fixed thereon.

- An alternative clip 20 for mounting a vehicle sunvisor has a scaled-down shape of the first clip 10 and comprises a cubic projection 21 , a rectangular bottom 22 perpendicular to the cubic projection 21 , and elastic wings 23 that laterally extend from the cubic projection 21 on both sides.

- a flange 23 a is formed at each end of the projection 21 so that the edge of a hole for clip assembly 51 of roof trim 50 (FIG. 4) can be fitted into a stepped part of the flange 23 a .

- a clip bolt hole 22 a is formed on the center of the rectangular bottom 22 .

- the bolt 70 which is used to fix the retractor 40 , is bolted down through the bolt hole 22 a.

- both of the above-mentioned clips 10 and 20 for mounting a vehicle sunvisor are characterized by being made of plastic material to avoid the generation of contact noise.

- multiply stepped roof trim 50 is made to be in close contact with the bottom 12 of the first clip 10 for fixing sunvisor pivot arm 30 for the purpose of fixing the roof trim 50 to headlining 60 .

- Elastic wings 13 are inserted into the clip assembly hole 51 , wherein the projection 11 of the first clip 10 is inserted. Then, the elastic wings 13 are bent toward the projection 11 of the first clip 10 and a stepped part of the flange 13 a formed on elastic wings 13 is fitted into the clip assembly hole 51 and fixed thereon, which then leads to an elastic diversion of the elastic wings 13 thereby fixing the first clip 10 to the roof trim 50 .

- sunvisor pivot arm 30 is closely contacted to the bottom surface of the roof trim 50 , and then pivot arm hole 31 , clip bolt hole 12 a , trim bolt hole 52 are aligned in this order and the bolt 70 is bolted down through them.

- the second clip 20 for fixing sunvisor retractor 40 is fixed to headlining 60 by using the same mounting method as in the first clip 10 , and the retractor bolt hole 41 formed on sunvisor retractor 40 and the clip bolt hole 22 a formed on the center of the second clip 20 are aligned and assembled by bolting down using the bolt 70 .

- Clips 10 and 20 for mounting vehicle sunvisors elastically fixed into the roof trim 50 as well as fixed to the headlining 60 , can secure the mounting of vehicle sunvisors thus contributing to the quality increase of an automobile mounted with these clips. Consequently, the clips for mounting vehicle sunvisors of the present invention are advantageous as compared to those of conventional ones in that they can reduce contact noise, are much lighter in weight and the resulting assembly strengthened over the conventional clip, thus increasing the quality and reliance of an automobile mounted with the clips according to the present invention.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Connection Of Plates (AREA)

- Vehicle Interior And Exterior Ornaments, Soundproofing, And Insulation (AREA)

Abstract

Disclosed are clips for mounting a vehicle sunvisor made of plastic wherein multiply stepped sloping roof trim is made to be in close contact with the bottom part of the clips so that sunvisors can be securely fixed onto the headlining; sloping elastic wings, which are extended laterally from the projection of the clip on both sides, are inserted into clip assembly holes prepared for the insertion of the projection of the clip, and fixed thereon; the bottom part is fixed by bolting down bolts through the clip bolt holes thus preventing the dislocation or horizontal movement; which can prevent contact noise and also reduce its weight to become much lighter as compared to the conventional clips made of steel.

Description

- The present invention relates to a clip for mounting a vehicle sunvisor, and more particularly, to a clip for mounting a vehicle sunvisor made of plastic which can reduce contact noise generated in the conventional steel clip and reduce the clip weight.

- In general, the body of a vehicle comprises panels which outline the external body shape, stiffeners, which reinforce the strength of the panels and trims, which are used as materials for interior decorations. More specifically, there are roof panels and roof side panels located on the upper portion of a vehicle body. The roof panel is where headlining and roof trim are mounted. The mountings of headlining and roof trim onto the roof panel have been carried out using clips.

- However, the conventional clips used in mounting vehicle sunvisors, as shown in FIGS. 5 and 6, were either

bolt fixing clips 100 or fixing clips withwings 200, which are easily released due to weak assembly force thus lowering the reliance and quality of the product. Further, conventional clips have been less than advantageous in that they were made of steel thus making unwanted noise by contacting with roof trim. - The present invention provides a clip for mounting a vehicle sunvisor, wherein roof trim with sloping multiple steps is in close contact with the bottom part of the clip. Elastic wings on the clip extend downwardly at an angle on both sides. The wings are inserted into clip assembly holes in the trim, which are prepared for the insertion of the projection of the clip and fixed thereafter. The bottom part of the clip is fixed by bolting through bolt holes, thus preventing dislocation or horizontal movement. Further, the present invention is made of plastic and thus can prevent contact noise usually produced in conventional clips made of steel. Also, the lightness in weight of the clip of the present invention made of plastic can help to reduce the body weight of a vehicle to comply with the current global trend of manufacturing automobiles.

- FIG. 1 is a perspective view of a clip for mounting a vehicle sunvisor according to the present invention;

- FIG. 2 is a perspective view of an alternative clip for mounting a vehicle sunvisor according to an alternative embodiment of the present invention;

- FIG. 3 is a schematic cross-sectional view of the mounted state of the clip shown in FIG. 1;

- FIG. 4 is a schematic cross-sectional view of the mounted state of the alternative clip shown in FIG. 2; and

- FIGS. 5 and 6 are perspective views of conventional clips for mounting a vehicle sunvisor.

- The present invention is further described with reference to the drawings as set forth hereunder.

- As shown in FIG. 1, a

first clip 10 for mounting a vehicle sunvisor comprises acubic projection 11, and arectangular bottom 12 perpendicular to the abovecubic projection 11.Elastic wings 13 laterally extend from thecubic projection 11 on two sides, andclip bolt holes 12 a are formed on therectangular bottom 12. There is aspace 11 a provided inside theprojection 11 so that thesunvisor pivot arm 30 can be inserted. Theelastic wings 13 extend laterally at an angle on both left and right faces toward therectangular bottom 12, and aflange 13 a is produced at the end of theprojection 11 so that the edge ofclip assembly hole 51 of theroof trim 50 can be received in the stepped portion of theflange 13 a and fixed thereon. - An

alternative clip 20 for mounting a vehicle sunvisor, as shown in FIG. 2, has a scaled-down shape of thefirst clip 10 and comprises acubic projection 21, arectangular bottom 22 perpendicular to thecubic projection 21, andelastic wings 23 that laterally extend from thecubic projection 21 on both sides. Aflange 23 a is formed at each end of theprojection 21 so that the edge of a hole forclip assembly 51 of roof trim 50 (FIG. 4) can be fitted into a stepped part of theflange 23 a. Aclip bolt hole 22 a is formed on the center of therectangular bottom 22. Thebolt 70, which is used to fix theretractor 40, is bolted down through thebolt hole 22 a. - More specifically, both of the above-mentioned

clips - The basic principle of the operation of the clip for mounting a vehicle sunvisor of the present invention is described below.

- As shown in FIG. 3, multiply stepped

roof trim 50 is made to be in close contact with thebottom 12 of thefirst clip 10 for fixingsunvisor pivot arm 30 for the purpose of fixing theroof trim 50 to headlining 60.Elastic wings 13 are inserted into theclip assembly hole 51, wherein theprojection 11 of thefirst clip 10 is inserted. Then, theelastic wings 13 are bent toward theprojection 11 of thefirst clip 10 and a stepped part of theflange 13 a formed onelastic wings 13 is fitted into theclip assembly hole 51 and fixed thereon, which then leads to an elastic diversion of theelastic wings 13 thereby fixing thefirst clip 10 to theroof trim 50. Meanwhile,sunvisor pivot arm 30 is closely contacted to the bottom surface of theroof trim 50, and thenpivot arm hole 31,clip bolt hole 12 a,trim bolt hole 52 are aligned in this order and thebolt 70 is bolted down through them. - As shown in FIG. 4, the

second clip 20 forfixing sunvisor retractor 40 is fixed to headlining 60 by using the same mounting method as in thefirst clip 10, and theretractor bolt hole 41 formed onsunvisor retractor 40 and theclip bolt hole 22 a formed on the center of thesecond clip 20 are aligned and assembled by bolting down using thebolt 70. -

Clips roof trim 50 as well as fixed to the headlining 60, can secure the mounting of vehicle sunvisors thus contributing to the quality increase of an automobile mounted with these clips. Consequently, the clips for mounting vehicle sunvisors of the present invention are advantageous as compared to those of conventional ones in that they can reduce contact noise, are much lighter in weight and the resulting assembly strengthened over the conventional clip, thus increasing the quality and reliance of an automobile mounted with the clips according to the present invention.

Claims (10)

1. A clip for mounting a vehicle sunvisor, comprising:

a cubic projection wherein internal space is provided for the insertion of a pivot arm;

a rectangular flat bottom which is formed in parallel to a lower part of said projection;

elastic wings extending laterally on both sides of the projection at an angle toward said rectangular flat bottom wherein a flange is formed at each end of said wings so that an edge of a hole for a clip assembly of a roof trim can be fitted into said flange; and

a hole for a clip bolt formed on the outer surface of said rectangular flat bottom.

2. A clip for mounting a vehicle sunvisor comprising:

a cubic projection wherein a hole for clip bolt is provided for insertion of a bolt which is assembled into a retractor;

a rectangular flat bottom which is formed in parallel to a lower part of said projection; and

elastic wings extending at an angle toward said rectangular flat bottom from said projection wherein a flange is formed at each end of said wing so that an edge of a hole for a clip assembly of a roof trim can be fitted into said flange.

3. The clip according to claim 1 , wherein said clip is made of plastic to reduce noise produced by contact between said clip and the roof trim.

4. The clip according to claim 2 , wherein said clip is made of plastic to prevent noise produced by contact between said clip and the roof trim.

5. The clip according to claim 1 , wherein said flat bottom has a width and a length with the length being of a greater dimension than the width and said elastic wings extend along said length.

6. The clip according to claim 2 , wherein said flat bottom has a width and a length with the length being of a greater dimension than the width and said elastic wings extend along said width.

7. A clip for mounting a vehicle sunvisor, comprising:

a flat bottom portion;

a projection extending from said bottom portion, said projection defining a hollow interior;

elastic wings extending from the projection at an angle towards the flat bottom portion; and

notched flanges formed on an end of the elastic wings opposite the projection.

8. The clip according to claim 7 , wherein:

said projection is generally cubic in shape; and

said wings are formed in pairs on two opposite sides of the projection.

9. The clip according to claim 8 , wherein:

said flat bottom portion has a width and a length with the length being of a greater dimension than the width and said elastic wings extend along said length; and

said flat bottom portion defines at least one bolt hole therethrough.

10. The clip according to claim 8 , wherein said flat bottom has a width and a length with the length being of a greater dimension than the width and said elastic wings extend along said width.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/371,418 US20060173395A1 (en) | 2002-02-12 | 2006-03-09 | Set for blood processing |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020010044384A KR20030009768A (en) | 2001-07-24 | 2001-07-24 | Clip for mounting sun-visor for automobile |

| KR2001-44384 | 2001-07-24 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US11/371,418 Continuation US20060173395A1 (en) | 2002-02-12 | 2006-03-09 | Set for blood processing |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US20030019083A1 true US20030019083A1 (en) | 2003-01-30 |

Family

ID=19712461

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US10/076,196 Abandoned US20030019083A1 (en) | 2001-07-24 | 2002-02-12 | Clip for mounting a vehicle sunvisor |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US20030019083A1 (en) |

| KR (1) | KR20030009768A (en) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20060082187A1 (en) * | 2004-10-19 | 2006-04-20 | Arvinmeritor Technology, Llc | Snap pin for door module positioning |

| DE202005011955U1 (en) * | 2005-07-29 | 2006-12-07 | Hellermann Tyton Gmbh | Snap clip for attaching e.g. support structure to another structure, has guiding surfaces formed at central body, where body is formed without undercut in dimension with reference to axis that extends between stop end and insertion end |

| US20070068717A1 (en) * | 2005-09-27 | 2007-03-29 | Austin James B | Hidden fastening system for motor vehicle instrument panels |

| KR101055043B1 (en) * | 2005-05-11 | 2011-08-05 | 현대자동차주식회사 | Headlining clip |

| US20140342208A1 (en) * | 2013-05-20 | 2014-11-20 | Nintendo Co., Ltd. | Battery accommodation structure and battery accommodation method |

| USD773589S1 (en) * | 2015-12-30 | 2016-12-06 | Raptor Products, Inc | Interlocking stand-off |

| CN108248348A (en) * | 2018-03-06 | 2018-07-06 | 重庆华博汽车饰件有限公司 | Automotive sunshade panel rotational structure |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100928282B1 (en) * | 2007-10-30 | 2009-11-24 | 엔브이에이치코리아(주) | Automotive module clips |

| KR101939943B1 (en) * | 2018-04-11 | 2019-04-11 | 주식회사 신성화학 | Method for manufacturing a fastener for fixing car body panels |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH01113609A (en) * | 1987-10-27 | 1989-05-02 | Marine Instr Co Ltd | Recording method of echo sounder for mine sweeping |

| JPH0357144A (en) * | 1989-07-26 | 1991-03-12 | Mitsubishi Electric Corp | Color picture tube |

| JPH0743467Y2 (en) * | 1989-08-30 | 1995-10-09 | 本田技研工業株式会社 | Holders such as plates |

| DE4307434A1 (en) * | 1993-03-09 | 1994-09-15 | United Carr Gmbh Trw | Holding element made of plastic |

| JP3401849B2 (en) * | 1993-07-29 | 2003-04-28 | 日産自動車株式会社 | Mounting structure |

| KR200233068Y1 (en) * | 2001-02-28 | 2001-09-26 | 한일이화주식회사 | The clip for fixing the sunvisor |

-

2001

- 2001-07-24 KR KR1020010044384A patent/KR20030009768A/en not_active Application Discontinuation

-

2002

- 2002-02-12 US US10/076,196 patent/US20030019083A1/en not_active Abandoned

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20060082187A1 (en) * | 2004-10-19 | 2006-04-20 | Arvinmeritor Technology, Llc | Snap pin for door module positioning |

| KR101055043B1 (en) * | 2005-05-11 | 2011-08-05 | 현대자동차주식회사 | Headlining clip |

| DE202005011955U1 (en) * | 2005-07-29 | 2006-12-07 | Hellermann Tyton Gmbh | Snap clip for attaching e.g. support structure to another structure, has guiding surfaces formed at central body, where body is formed without undercut in dimension with reference to axis that extends between stop end and insertion end |

| US20070068717A1 (en) * | 2005-09-27 | 2007-03-29 | Austin James B | Hidden fastening system for motor vehicle instrument panels |

| US20140342208A1 (en) * | 2013-05-20 | 2014-11-20 | Nintendo Co., Ltd. | Battery accommodation structure and battery accommodation method |

| USD773589S1 (en) * | 2015-12-30 | 2016-12-06 | Raptor Products, Inc | Interlocking stand-off |

| CN108248348A (en) * | 2018-03-06 | 2018-07-06 | 重庆华博汽车饰件有限公司 | Automotive sunshade panel rotational structure |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20030009768A (en) | 2003-02-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US20150321622A1 (en) | Fastener Clip Over a Carrier | |

| US20030019083A1 (en) | Clip for mounting a vehicle sunvisor | |

| US20050258665A1 (en) | Trim panel module | |

| KR20060012003A (en) | Vehicular rear cargo module | |

| KR200272341Y1 (en) | Sticking structure of car roof box | |

| US5489135A (en) | Anti-squeak spacer and stop for automotive fixed glass | |

| KR100333287B1 (en) | weatherstrip mounting structure for supporting fixed glass of automobile door | |

| JPH0569856A (en) | Roof structure for automobile | |

| JPH0541084Y2 (en) | ||

| KR100239661B1 (en) | Clip structure for clamping glass and trim | |

| KR200377569Y1 (en) | Vehicle door | |

| KR100197266B1 (en) | Assembling structure of the bumper for a vehicle | |

| JPH05105007A (en) | Pillar section mounting structure of molded ceiling | |

| JPH021164Y2 (en) | ||

| CN118618212A (en) | Joint structure of plaque and panel beating in connection | |

| KR200224281Y1 (en) | weatherstrip mounting sturcture for a vehicle | |

| KR0137480Y1 (en) | Cover molding of automotive window chassis | |

| KR100207214B1 (en) | High convertible trim mounting structure | |

| KR100188781B1 (en) | Structure for installing roof antenna of a car | |

| KR200192382Y1 (en) | Structure reinforcing the qualter inner upper center pillar trim of vehicle | |

| JPH06293280A (en) | Mounting structure for fender panel | |

| KR0138547Y1 (en) | Automobile rear glass molding mounting structure | |

| JPH0222349Y2 (en) | ||

| KR200150865Y1 (en) | Bumper mounting structure of bumpre | |

| KR0124509B1 (en) | Radiator cross lower member assembly |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| AS | Assignment |

Owner name: HYUNDAI MOTOR COMPANY, KOREA, REPUBLIC OF Free format text: ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNOR:WON, SUNG-JAI;REEL/FRAME:012620/0521 Effective date: 20011202 |

|

| STCB | Information on status: application discontinuation |

Free format text: ABANDONED -- FAILURE TO RESPOND TO AN OFFICE ACTION |