KR20140021894A - Preparation of antioxidation chilli sauce - Google Patents

Preparation of antioxidation chilli sauce Download PDFInfo

- Publication number

- KR20140021894A KR20140021894A KR1020120088368A KR20120088368A KR20140021894A KR 20140021894 A KR20140021894 A KR 20140021894A KR 1020120088368 A KR1020120088368 A KR 1020120088368A KR 20120088368 A KR20120088368 A KR 20120088368A KR 20140021894 A KR20140021894 A KR 20140021894A

- Authority

- KR

- South Korea

- Prior art keywords

- oil

- red pepper

- garlic

- beef

- pepper

- Prior art date

Links

- 240000004160 Capsicum annuum Species 0.000 title claims abstract description 79

- 235000015067 sauces Nutrition 0.000 title claims abstract description 31

- 238000002360 preparation method Methods 0.000 title claims 2

- 230000003064 anti-oxidating effect Effects 0.000 title 1

- 235000008534 Capsicum annuum var annuum Nutrition 0.000 claims abstract description 78

- 235000007862 Capsicum baccatum Nutrition 0.000 claims abstract description 78

- 239000001728 capsicum frutescens Substances 0.000 claims abstract description 78

- 239000010647 garlic oil Substances 0.000 claims abstract description 45

- 235000015278 beef Nutrition 0.000 claims abstract description 36

- 240000002234 Allium sativum Species 0.000 claims abstract description 29

- 235000004611 garlic Nutrition 0.000 claims abstract description 29

- 239000003921 oil Substances 0.000 claims abstract description 26

- 235000019198 oils Nutrition 0.000 claims abstract description 26

- 235000015112 vegetable and seed oil Nutrition 0.000 claims abstract description 26

- 230000003078 antioxidant effect Effects 0.000 claims abstract description 23

- 235000008331 Pinus X rigitaeda Nutrition 0.000 claims abstract description 16

- 241000018646 Pinus brutia Species 0.000 claims abstract description 16

- 235000011613 Pinus brutia Nutrition 0.000 claims abstract description 16

- 235000014571 nuts Nutrition 0.000 claims abstract description 16

- 244000144725 Amygdalus communis Species 0.000 claims abstract description 15

- 244000000231 Sesamum indicum Species 0.000 claims abstract description 15

- 235000003434 Sesamum indicum Nutrition 0.000 claims abstract description 15

- 235000020224 almond Nutrition 0.000 claims abstract description 15

- 244000178231 Rosmarinus officinalis Species 0.000 claims abstract description 13

- 238000010438 heat treatment Methods 0.000 claims abstract description 12

- 238000000034 method Methods 0.000 claims abstract description 12

- 239000000843 powder Substances 0.000 claims abstract description 12

- 239000008169 grapeseed oil Substances 0.000 claims abstract description 11

- 238000004519 manufacturing process Methods 0.000 claims abstract description 11

- 150000003839 salts Chemical class 0.000 claims abstract description 8

- 235000002639 sodium chloride Nutrition 0.000 claims abstract description 8

- 235000002566 Capsicum Nutrition 0.000 claims description 29

- 239000006002 Pepper Substances 0.000 claims description 29

- 241000722363 Piper Species 0.000 claims description 29

- 235000016761 Piper aduncum Nutrition 0.000 claims description 29

- 235000017804 Piper guineense Nutrition 0.000 claims description 29

- 235000008184 Piper nigrum Nutrition 0.000 claims description 29

- 239000003963 antioxidant agent Substances 0.000 claims description 10

- 235000011437 Amygdalus communis Nutrition 0.000 claims description 9

- 235000002568 Capsicum frutescens Nutrition 0.000 claims description 7

- 238000001914 filtration Methods 0.000 claims description 7

- 239000000796 flavoring agent Substances 0.000 abstract description 9

- 235000019634 flavors Nutrition 0.000 abstract description 9

- 235000015097 nutrients Nutrition 0.000 abstract description 2

- 238000000605 extraction Methods 0.000 abstract 2

- 238000003860 storage Methods 0.000 description 21

- 235000013305 food Nutrition 0.000 description 10

- 235000006708 antioxidants Nutrition 0.000 description 7

- 240000008574 Capsicum frutescens Species 0.000 description 5

- 239000000203 mixture Substances 0.000 description 5

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 3

- 239000000654 additive Substances 0.000 description 3

- 230000003247 decreasing effect Effects 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 238000005259 measurement Methods 0.000 description 3

- 235000013372 meat Nutrition 0.000 description 3

- 235000016709 nutrition Nutrition 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- GVJHHUAWPYXKBD-UHFFFAOYSA-N (±)-α-Tocopherol Chemical compound OC1=C(C)C(C)=C2OC(CCCC(C)CCCC(C)CCCC(C)C)(C)CCC2=C1C GVJHHUAWPYXKBD-UHFFFAOYSA-N 0.000 description 2

- CIWBSHSKHKDKBQ-JLAZNSOCSA-N Ascorbic acid Chemical compound OC[C@H](O)[C@H]1OC(=O)C(O)=C1O CIWBSHSKHKDKBQ-JLAZNSOCSA-N 0.000 description 2

- 241000894006 Bacteria Species 0.000 description 2

- 239000002253 acid Substances 0.000 description 2

- FPIPGXGPPPQFEQ-OVSJKPMPSA-N all-trans-retinol Chemical compound OC\C=C(/C)\C=C\C=C(/C)\C=C\C1=C(C)CCCC1(C)C FPIPGXGPPPQFEQ-OVSJKPMPSA-N 0.000 description 2

- YKPUWZUDDOIDPM-SOFGYWHQSA-N capsaicin Chemical compound COC1=CC(CNC(=O)CCCC\C=C\C(C)C)=CC=C1O YKPUWZUDDOIDPM-SOFGYWHQSA-N 0.000 description 2

- HHEAADYXPMHMCT-UHFFFAOYSA-N dpph Chemical compound [O-][N+](=O)C1=CC([N+](=O)[O-])=CC([N+]([O-])=O)=C1[N]N(C=1C=CC=CC=1)C1=CC=CC=C1 HHEAADYXPMHMCT-UHFFFAOYSA-N 0.000 description 2

- 235000019197 fats Nutrition 0.000 description 2

- 230000006870 function Effects 0.000 description 2

- 235000002532 grape seed extract Nutrition 0.000 description 2

- JVTAAEKCZFNVCJ-UHFFFAOYSA-N lactic acid Chemical compound CC(O)C(O)=O JVTAAEKCZFNVCJ-UHFFFAOYSA-N 0.000 description 2

- KJFMBFZCATUALV-UHFFFAOYSA-N phenolphthalein Chemical compound C1=CC(O)=CC=C1C1(C=2C=CC(O)=CC=2)C2=CC=CC=C2C(=O)O1 KJFMBFZCATUALV-UHFFFAOYSA-N 0.000 description 2

- 239000001967 plate count agar Substances 0.000 description 2

- 238000011160 research Methods 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- 235000019640 taste Nutrition 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- OYHQOLUKZRVURQ-NTGFUMLPSA-N (9Z,12Z)-9,10,12,13-tetratritiooctadeca-9,12-dienoic acid Chemical compound C(CCCCCCC\C(=C(/C\C(=C(/CCCCC)\[3H])\[3H])\[3H])\[3H])(=O)O OYHQOLUKZRVURQ-NTGFUMLPSA-N 0.000 description 1

- ZZZCUOFIHGPKAK-UHFFFAOYSA-N D-erythro-ascorbic acid Natural products OCC1OC(=O)C(O)=C1O ZZZCUOFIHGPKAK-UHFFFAOYSA-N 0.000 description 1

- 206010061218 Inflammation Diseases 0.000 description 1

- 235000010676 Ocimum basilicum Nutrition 0.000 description 1

- 240000007926 Ocimum gratissimum Species 0.000 description 1

- 240000007594 Oryza sativa Species 0.000 description 1

- 235000007164 Oryza sativa Nutrition 0.000 description 1

- 230000002292 Radical scavenging effect Effects 0.000 description 1

- 241001165494 Rhodiola Species 0.000 description 1

- 208000005718 Stomach Neoplasms Diseases 0.000 description 1

- 229930003270 Vitamin B Natural products 0.000 description 1

- 229930003268 Vitamin C Natural products 0.000 description 1

- 229930003427 Vitamin E Natural products 0.000 description 1

- 240000006365 Vitis vinifera Species 0.000 description 1

- 235000014787 Vitis vinifera Nutrition 0.000 description 1

- 238000002835 absorbance Methods 0.000 description 1

- 238000009825 accumulation Methods 0.000 description 1

- 239000013543 active substance Substances 0.000 description 1

- 241001148470 aerobic bacillus Species 0.000 description 1

- 239000011717 all-trans-retinol Substances 0.000 description 1

- 235000019169 all-trans-retinol Nutrition 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- 239000003242 anti bacterial agent Substances 0.000 description 1

- 230000001093 anti-cancer Effects 0.000 description 1

- 229940088710 antibiotic agent Drugs 0.000 description 1

- 235000019463 artificial additive Nutrition 0.000 description 1

- 230000001580 bacterial effect Effects 0.000 description 1

- 210000004556 brain Anatomy 0.000 description 1

- 210000004958 brain cell Anatomy 0.000 description 1

- 229960002504 capsaicin Drugs 0.000 description 1

- 235000017663 capsaicin Nutrition 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 238000010411 cooking Methods 0.000 description 1

- 239000002537 cosmetic Substances 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 235000005911 diet Nutrition 0.000 description 1

- 230000037213 diet Effects 0.000 description 1

- 238000010790 dilution Methods 0.000 description 1

- 239000012895 dilution Substances 0.000 description 1

- 238000003113 dilution method Methods 0.000 description 1

- MGJZITXUQXWAKY-UHFFFAOYSA-N diphenyl-(2,4,6-trinitrophenyl)iminoazanium Chemical compound [O-][N+](=O)C1=CC([N+](=O)[O-])=CC([N+]([O-])=O)=C1N=[N+](C=1C=CC=CC=1)C1=CC=CC=C1 MGJZITXUQXWAKY-UHFFFAOYSA-N 0.000 description 1

- 239000012153 distilled water Substances 0.000 description 1

- 101150010415 eat-5 gene Proteins 0.000 description 1

- 235000004626 essential fatty acids Nutrition 0.000 description 1

- 230000003203 everyday effect Effects 0.000 description 1

- 239000000284 extract Substances 0.000 description 1

- 238000000855 fermentation Methods 0.000 description 1

- 230000004151 fermentation Effects 0.000 description 1

- 229930003935 flavonoid Natural products 0.000 description 1

- 235000017173 flavonoids Nutrition 0.000 description 1

- 150000002215 flavonoids Chemical class 0.000 description 1

- 235000011194 food seasoning agent Nutrition 0.000 description 1

- 238000009472 formulation Methods 0.000 description 1

- 239000003205 fragrance Substances 0.000 description 1

- 230000007760 free radical scavenging Effects 0.000 description 1

- WIGCFUFOHFEKBI-UHFFFAOYSA-N gamma-tocopherol Natural products CC(C)CCCC(C)CCCC(C)CCCC1CCC2C(C)C(O)C(C)C(C)C2O1 WIGCFUFOHFEKBI-UHFFFAOYSA-N 0.000 description 1

- 206010017758 gastric cancer Diseases 0.000 description 1

- 229940087603 grape seed extract Drugs 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 238000011059 hazard and critical control points analysis Methods 0.000 description 1

- 235000008216 herbs Nutrition 0.000 description 1

- 230000008676 import Effects 0.000 description 1

- 230000004054 inflammatory process Effects 0.000 description 1

- 235000021109 kimchi Nutrition 0.000 description 1

- 239000004310 lactic acid Substances 0.000 description 1

- 235000014655 lactic acid Nutrition 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 230000000813 microbial effect Effects 0.000 description 1

- 244000005700 microbiome Species 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000035764 nutrition Effects 0.000 description 1

- 235000008935 nutritious Nutrition 0.000 description 1

- 230000000050 nutritive effect Effects 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 150000008442 polyphenolic compounds Chemical class 0.000 description 1

- 235000013824 polyphenols Nutrition 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 108090000623 proteins and genes Proteins 0.000 description 1

- 102000004169 proteins and genes Human genes 0.000 description 1

- 235000009566 rice Nutrition 0.000 description 1

- 239000010668 rosemary oil Substances 0.000 description 1

- 235000015639 rosmarinus officinalis Nutrition 0.000 description 1

- 238000009331 sowing Methods 0.000 description 1

- 235000021259 spicy food Nutrition 0.000 description 1

- 235000019654 spicy taste Nutrition 0.000 description 1

- 230000006641 stabilisation Effects 0.000 description 1

- 238000011105 stabilization Methods 0.000 description 1

- 230000001954 sterilising effect Effects 0.000 description 1

- 235000013547 stew Nutrition 0.000 description 1

- 201000011549 stomach cancer Diseases 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

- 238000002560 therapeutic procedure Methods 0.000 description 1

- 238000004448 titration Methods 0.000 description 1

- 235000019156 vitamin B Nutrition 0.000 description 1

- 239000011720 vitamin B Substances 0.000 description 1

- 235000019154 vitamin C Nutrition 0.000 description 1

- 239000011718 vitamin C Substances 0.000 description 1

- 235000019165 vitamin E Nutrition 0.000 description 1

- 229940046009 vitamin E Drugs 0.000 description 1

- 239000011709 vitamin E Substances 0.000 description 1

- 239000001717 vitis vinifera seed extract Substances 0.000 description 1

- 230000004580 weight loss Effects 0.000 description 1

- 230000036642 wellbeing Effects 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23L—FOODS, FOODSTUFFS, OR NON-ALCOHOLIC BEVERAGES, NOT COVERED BY SUBCLASSES A21D OR A23B-A23J; THEIR PREPARATION OR TREATMENT, e.g. COOKING, MODIFICATION OF NUTRITIVE QUALITIES, PHYSICAL TREATMENT; PRESERVATION OF FOODS OR FOODSTUFFS, IN GENERAL

- A23L23/00—Soups; Sauces; Preparation or treatment thereof

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23L—FOODS, FOODSTUFFS, OR NON-ALCOHOLIC BEVERAGES, NOT COVERED BY SUBCLASSES A21D OR A23B-A23J; THEIR PREPARATION OR TREATMENT, e.g. COOKING, MODIFICATION OF NUTRITIVE QUALITIES, PHYSICAL TREATMENT; PRESERVATION OF FOODS OR FOODSTUFFS, IN GENERAL

- A23L27/00—Spices; Flavouring agents or condiments; Artificial sweetening agents; Table salts; Dietetic salt substitutes; Preparation or treatment thereof

- A23L27/10—Natural spices, flavouring agents or condiments; Extracts thereof

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23V—INDEXING SCHEME RELATING TO FOODS, FOODSTUFFS OR NON-ALCOHOLIC BEVERAGES AND LACTIC OR PROPIONIC ACID BACTERIA USED IN FOODSTUFFS OR FOOD PREPARATION

- A23V2002/00—Food compositions, function of food ingredients or processes for food or foodstuffs

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23V—INDEXING SCHEME RELATING TO FOODS, FOODSTUFFS OR NON-ALCOHOLIC BEVERAGES AND LACTIC OR PROPIONIC ACID BACTERIA USED IN FOODSTUFFS OR FOOD PREPARATION

- A23V2300/00—Processes

- A23V2300/24—Heat, thermal treatment

Landscapes

- Health & Medical Sciences (AREA)

- Nutrition Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Polymers & Plastics (AREA)

- Seeds, Soups, And Other Foods (AREA)

Abstract

Description

본 발명은 항산화성을 구비한 고추소스의 제조방법 및 이에 따른 고추소스에 관한 것으로, 마늘오일과 고추씨 기름에 의해 산화방지제를 첨가하지 않고도 산패되지 않고 저장기간이 증가된 항산화성을 구비한 고추소스 제조방법 및 이에 따른 고추소스에 관한 것이다.

The present invention relates to a method for producing a red pepper sauce having antioxidative properties and a pepper sauce according to the present invention, which comprises an antioxidant-resistant red pepper sauce which is not corroded without addition of an antioxidant by garlic oil and red pepper seed oil, And a pepper sauce accordingly.

최근 메가트렌드(Mega trend)인 웰빙 푸드의 선호도가 높아지면서 좋은 먹거리에 대한 소비자의 관심이 높아지고 있으며, 생활패턴의 서구화로 많은 음식에 소스를 곁들여 먹거나 소스를 이용한 음식 메뉴가 증가하면서 소스 소비량이 빠른 속도로 증가하고 있다. 또한 바쁜 현대인들 사이에서 요리시간을 단축할 수 있는 간편한 식품으로서 백화점이나 마트 등에서의 시판과 소비량이 급증하고 있다. 이러한 추세에 따라 국내외 양념소스 시장의 규모는 계속 커지고 있으며, 이에 따라 소비자들의 입맛에 맞는 다양한 종류의 소스 개발이 요구되는 실정이다.Recently, as the popularity of mega trend (well-being trend) has increased, consumers are increasingly interested in good food. With the westernization of lifestyle, many foods are served with sauces, Speed. In addition, as a convenient food that can shorten the cooking time among busy modern people, the market and consumption amount in department stores, marts and the like are rapidly increasing. According to this tendency, the size of the domestic and international sauce market continues to grow, and accordingly, it is required to develop various kinds of sauces to suit the taste of consumers.

이에 따라 다양한 음식에 맞는 여러 가지 소스의 개발이 요구되고 있으며, 소비자들은 천연 향미물질을 이용하여 관능적으로 우수하고 간편성과 기능성을 가진 소스 및 양념류를 선호하고, 특히 여러 가지 수입상품에 대한 안전도에 관심을 주면서 유해물질이 첨가되지 않은 친환경 음식에 대한 수요는 계속 높아지고 있다. Therefore, it is required to develop various sauces for various foods. Consumers prefer natural sauces, sauces and sauces which are excellent in sensuality, simplicity and functionality, and are especially interested in the safety of various imported products The demand for eco-friendly foods that do not contain harmful substances is continuously increasing.

즉, MSG(인공화학조미료) 등 일체의 인공첨가물을 넣지 않거나 HACCP(식품위해요소중점관리기준)에 적합한 식품의 개발을 통한 다양한 음식에 대한 요구가 나날이 늘어나고 있으며, 또한, 식품의 색깔, 풍미, 맛 등의 관능적 요소들은 점차 그 중요도가 증가되고 있다.

In other words, there is an increasing demand for diverse foods through the development of foods that do not contain any artificial additives such as MSG (artificial chemical seasoning) or HACCP (Critical Control Criteria for Food Hazard Factors), and also the color, flavor, The sensual elements such as taste are gradually increasing in importance.

일상생활에서 고춧가루와 마늘을 즐겨 섭취하는 우리나라 사람의 매운 음식에 대한 요구는 날로 늘어나고 있으며, 최근 일본에서는, 매운맛을 내는 조미료인 '라유'(辣油.고추기름)가 일본의 올해 '히트상품 30선(選)' 1위에 올라 눈길을 끌고 있다. In recent years, the demand for spicy food of Koreans who enjoy red pepper powder and garlic in everyday life has been increasing day by day. In Japan, "rayle" (hot oil. Pepper oil) (Election) 'in the first place.

이에 반하여, 우리나라의 고추 소비방법은 주로 김치나 고추장과 각종 찌개, 무침 류에 고춧가루 형태로 소비되고 있으나 최근 연구에서는 고추의 소비량을 늘리기 위한 방법으로 다양한 섭취방법을 유도할 필요성이 대두 되고 있다.

On the other hand, the consumption method of red pepper in Korea is mainly consumed in the form of red pepper powder in kimchi, kochujang, various stew, and non - stick, but in recent research, it is necessary to induce various methods of consumption as a method for increasing consumption of red pepper.

본 발명의 목적은 마늘오일 및 고추씨기름에 의해 처리하여, 저장성을 증가시키고, 영양을 농축시키며, 풍미를 향상시킨 항산화성을 구비한 고추소스 제조방법 을 제공하는 것이다.

It is an object of the present invention to provide a method of manufacturing a red pepper sauce having antioxidative properties by treating with garlic oil and red pepper seed oil to increase storage stability, enrich nutrition, and improve flavor.

본 발명은 포도씨유에 로즈마리 및 마늘을 넣고 가열하여 마늘오일을 형성하는 제1단계;The present invention relates to a method for producing garlic oil, comprising the steps of: adding rosemary and garlic to grape seed oil and heating to form garlic oil;

제1단계에 의해 가열되어 형성된 마늘오일에 고추씨를 넣고 추출 및 여과하여 고추씨기름을 형성하는 제2단계;A second step of adding pepper seed to the garlic oil formed by heating in the first step and extracting and filtering the pepper seed oil to form red pepper seed oil;

제2단계에 의해 형성된 고추씨기름에 고추가루를 넣고 추출하여 고추기름을 형성하는 제3단계;A third step of adding pepper powder to the red pepper seed oil formed by the second step and extracting it to form red pepper oil;

제3단계에 의해 형성된 고추기름에 고추장, 마늘, 소금, 소고기, 육포, 아몬드, 잣, 참깨를 첨가하여 고추비빔소스를 형성하는 제4단계;를 포함하되,And a fourth step of adding red pepper paste, garlic, salt, beef, beef jerky, almond, pine nut and sesame to the pepper oil formed by the third step to form a red pepper beef sauce,

상기 제4단계의 소고기, 육포, 아몬드, 잣 및, 참깨는 마늘오일에 의해 가공처리되도록 되어 있다.

The beef, jerky, almond, pine nut and sesame in the fourth step are processed by garlic oil.

본 발명은 한국인이 가장 선호하고, 우수한 지역 농산물인 고추를 기본으로 한 고품질 기능성 한국형 고추비빔소스를 개발하여 수입 대체품으로의 효과뿐만 아니라, 외식산업시장에서의 경쟁력 상승효과를 기대할 수 있다. The present invention can be expected not only to be an import substitute product but also to enhance the competitiveness in the food service industry by developing a high quality functional Korean red pepper bibim sauce based on the red pepper which is the most preferred and excellent local agricultural product of the Korean people.

본 발명은 지역의 우수한 농산물(영양고추)을 이용한 새로운 가공품을 개발, 생산함으로써 지역농민의 경제적 안정을 보조할 수 있다. The present invention can assist the economic stabilization of local farmers by developing and producing new processed products using excellent agricultural products (nutritious red pepper) in the region.

본 발명은 고추를 기본성분으로 하므로, 고추의 매운 맛 성분인 캡사이신에 의해 체내의 지방연소 및, 지방축적을 방지하고, 체중감량에 도움을 주어 다이어트에 효과가 있으며, 특히 젖산균의 발육을 도와 음식을 발효시키는데 도움을 주는 효과가 있다. Since the present invention uses pepper as a base component, capsaicin, which is a pungent flavor component of pepper, prevents fat burning and fat accumulation in the body and is effective for diet by helping weight loss. Especially, Which is effective for fermentation.

본 발명은 고추의 독특한 향미를 그대로 유지하면서 밥과 비벼서 충분한 영양가를 제공하면서 소비자의 기호도를 충족시킬 수 있다.The present invention can meet consumers' preferences while providing sufficient nutritional value by rubbing with rice while maintaining the unique flavor of pepper.

본 발명은 소고기, 참깨, 아몬드, 잣을 마늘오일에 의해 처리하고, 마늘오일에 의해 고추기름을 형성하도록 되어 있어, 고추소스의 색과 풍미를 최대한 유지함과 동시에 항산화성을 구비할 수 있다. In the present invention, the beef, sesame, almond and pine nut are treated with garlic oil, and the pepper oil is formed by the garlic oil, so that the color and flavor of the pepper sauce can be maintained to the maximum and the antioxidant property can be provided.

본 발명은 마늘오일에 의해 각종 첨가물을 가공처리 하도록 되어 있어, 소고기 및 육포 등의 육류가 첨가되어도 장기간 저장성을 확보할 수 있는 효과가 있다. In the present invention, various additives are processed by garlic oil, so that even if meat such as beef or beef jerky is added, it is possible to secure long-term storage stability.

본 발명은 마늘오일에 의해 고추씨기름을 형성하고, 고추씨기름에 의해 고추기름을 형성하도록 되어 있어, 항산화성을 향상시키고, 장기간 동안 산패되지 않으며, 저장기간을 증가시키는 효과가 있다.The present invention has the effect of forming red pepper seed oil by garlic oil and forming red pepper oil by red pepper seed oil, thereby improving antioxidative properties, preventing sowing for a long period of time, and increasing storage period.

본 발명은 마늘오일, 고추씨, 고추에 의해 고추기름을 형성하도록 되어 있어, 고추씨의 영양성분과 고추의 매운맛을 그대로 보유할 수 있는 등 많은 효과가 있다.

In the present invention, pepper oil is formed by garlic oil, red pepper seeds, and red pepper, so that it has many effects such that it can retain the nutritive components of red pepper seed and the hot spicy taste of red pepper.

도 1 은 본 발명에 따른 제조방법을 보인 예시도

도 2 는 본 발명의 실시예 3 에 따른 저장기간별 항산화성을 보인 예시도

도 3 은 본 발명의 실시예 5 에 따른 바질페스토의 저장기간에 따른 총균수 측정결과를 보인 예시도

도 4 는 본 발명에 따른 고추비빔소스를 보인 사진예시도1 is an illustration of a manufacturing method according to the present invention;

Fig. 2 is an example showing antioxidative activity according to the storage period according to Example 3 of the present invention

3 is a graph showing the results of measurement of total number of bacteria according to the storage period of basil pesto according to Example 5 of the present invention

FIG. 4 is a photograph showing an example of a pepper bimbe source according to the present invention

도 1 은 본 발명에 따른 제조방법을 보인 예시 도를, 도 4 는 본 발명에 따른 고추비빔소스를 보인 사진 예시도를 도시한 것으로, FIG. 1 is an exemplary view showing a manufacturing method according to the present invention, FIG. 4 is a photograph illustrating an example of a pepper bimbe source according to the present invention,

본 발명은 포도씨유에 로즈마리 및 마늘을 넣고 가열하여 마늘오일을 형성하는 제1단계;The present invention relates to a method for producing garlic oil, comprising the steps of: adding rosemary and garlic to grape seed oil and heating to form garlic oil;

제1단계에 의해 가열되어 형성된 마늘오일에 고추씨를 넣고 20∼30분동안 추출 및 여과하여 고추씨기름을 형성하는 제2단계;A second step of adding red pepper seeds to the garlic oil formed by heating in the first step and extracting and filtering for 20 to 30 minutes to form red pepper seed oil;

제2단계에 의해 형성된 고추씨기름에 고추가루를 넣고 추출 및 여과하여 고추기름을 형성하는 제3단계;A third step of adding pepper powder to the red pepper seed oil formed by the second step and extracting and filtering to form red pepper oil;

제3단계에 의해 형성된 고추기름에 고추장, 마늘, 소금, 소고기, 육포, 아몬드, 잣, 참깨를 첨가하여 고추비빔소스를 형성하는 제4단계;를 포함하되,And a fourth step of adding red pepper paste, garlic, salt, beef, beef jerky, almond, pine nut and sesame to the pepper oil formed by the third step to form a red pepper beef sauce,

상기 제4단계의 소고기, 육포, 아몬드, 잣 및, 참깨는 마늘오일에 의해 가공처리되도록 되어 있다.

The beef, jerky, almond, pine nut and sesame in the fourth step are processed by garlic oil.

상기 제1단계는 마늘오일을 형성하기 위한 단계로, 마늘 8∼15 중량%, 로즈마리 0.1∼5중량%, 포도씨유 80∼90 중량%를 178∼183℃에서 15∼25분간 가열하여 마늘오일을 추출한다. The first step is a step for forming garlic oil, which comprises heating 8-15 wt% of garlic, 0.1-5 wt% of rosemary and 80-90 wt% of grape seed oil at 178 ~ 183 캜 for 15~25 min to remove garlic oil .

상기 마늘오일의 추출을 위한 가열온도 및 가열시간은 마늘의 항산화성을 최대화하기 위한 것으로, 상기의 범위를 벗어날 경우, 마늘에 의한 항산화성이 저하되거나, 항산화성에 큰 변화가 없게 된다. The heating temperature and the heating time for extracting the garlic oil are intended to maximize the antioxidant activity of garlic. When the temperature is outside the above range, the antioxidative activity by garlic is lowered and the antioxidative activity is not greatly changed.

상기 포도씨유는 천연 항산화제인 비타민E와 필수지방산인 리놀레산이 풍부하고 발연점이 높아 산패 속도가 느리고 잘 타지 않는 특성으로 마늘의 천연 항산화제로서의 효능을 활용하기 위한 것으로, 마늘오일의 추출효율을 향상시키고, 산화방지기능을 부여하며, 각종 첨가물에 대한 품질 및 저장기간을 향상시키는 기능을 구비한다. The grape seed oil is rich in vitamin E, a natural antioxidant, and linoleic acid, an essential fatty acid, has a high fuming point, and is low in acidity and does not burn well. Therefore, the grape seed oil is used as a natural antioxidant for garlic, , An oxidation-preventing function, and a function of improving the quality and storage period of various additives.

상기 마늘은 마늘의 주성분은 '알리신'이라는 성분으로 마늘에 열을 가하거나 으깨면 '알린' 성분이 자기방어물질인 '알리신'으로 바뀐다. '알리신'은 냄새가 독한 만큼 살균력이 좋아, 항생제가 발견되기 전에는 거의 모든 종류의 염증 치료에도 쓰였다. 하루 5g 정도의 마늘을 매일 먹는 사람은 거의 먹지 않는 사람에 비해 위암 발생 위험률이 50%나 적었다. 현재 미국 암연구소에서도 가장 효과적인 항암식품으로 마늘을 꼽는다. 또한 열에 의해 수용성 비타민C, B는 감소할지 몰라도 항산화물질의 활성도와 폴리페놀, 플라보노이드 함량은 오히려 증가 한다.

Garlic is the main component of garlic, which is called 'Alicin'. When garlic is heated or crushed, 'Alin' is changed to 'Alicin', a self-defense substance. 'Alicin' is as good as sterilizing smell, so it was used to treat almost all types of inflammation before antibiotics were discovered. People who eat 5 grams of garlic per day have a 50 percent lower risk of developing stomach cancer than those who rarely eat it. Currently, the American Cancer Research Institute is the most effective anticancer food, garlic. In addition, soluble vitamin C and B may be decreased by heat, but the activity of antioxidants and polyphenol and flavonoid contents are rather increased.

상기 로즈마리는 많은 허브 중에서 마늘오일의 향을 우수하게 하고, 육포 및 소고기 등 육류첨가물에 대한 육질개선 및 풍미를 향상시키기 위한 것이다.The rosemary is intended to enhance the flavor of garlic oil among many herbs and to improve meat quality and flavor of meat additives such as beef jerky and beef.

상기 로즈마리는 아시아가 그 원산지이며 지중해 지방에서 많이 재배되고 향유를 추출하고 있다. 국제 학술지인 미용 피부과학지 'Journal of Cosmetic Dermatology'은 지난해 새로운 약용식물요법의 과학적 증명을 위해 10대 항산화 성분으로 로즈마리(Rosmarinus officinalis), 포도씨 추출물(Vitis vinifera) 등을 들어 항산화작용이 뛰어나고 살균소독작용이 있고 뇌세포를 활성화시켜 두뇌를 맑게 하고 기억력을 증진시키고 집중력을 높여주는 효능을 발휘한다.

The rosemary is the origin of Asia and is cultivated in the Mediterranean region and extracts the fragrance. The Journal of Cosmetic Dermatology, an international scientific journal, published last year's scientific evidence of the new medicinal herb therapy. It contains antioxidants such as rosemary (Rosmarinus officinalis) and grape seed extract (Vitis vinifera) It activates brain cells, cleanses the brain, improves memory and enhances concentration.

상기 제2단계는 마늘오일과 고추씨에 의해 고추씨기름을 형성하기 위한 것으로, 마늘, 로즈마리, 포도씨유를 178∼183℃, 바람직하게는 약 180℃에서 15∼25분간 바람직하게는 약 20분 동안 오븐에서 가열하여 추출된 마늘오일에 고추씨를 넣고 20∼40분, 바람직하게는 약 30∼40분 동안 추출 및 여과하여 고추씨기름을 형성한다. The second step is to form red pepper seed oil by garlic oil and red pepper seed, and the garlic, rosemary and grape seed oil is heated at 178 to 183 캜, preferably about 180 캜 for 15 to 25 minutes, , And the mixture is extracted and filtered to form red pepper seed oil for 20 to 40 minutes, preferably about 30 to 40 minutes.

상기 고추씨는 178∼183℃, 바람직하게는 약 180℃에서 8∼12분간 바람직하게는 약 10분 동안 오븐에서 가열하여 구운 후, 분쇄기에 의해 곱게 갈아 사용하며, 상기 고추씨는 마늘오일 100 중량부에 대하여, 15∼25중량부를 첨가한다. The hot pepper seeds are heated in an oven at 178 to 183 DEG C, preferably about 180 DEG C for 8 to 12 minutes, preferably about 10 minutes, and then finely ground by a grinder. The hot pepper seeds are added to 100 parts by weight of garlic oil 15 to 25 parts by weight are added.

즉, 본 발명은 구운 고추씨 분말에 제1단계에 의해 생성된 뜨거운 마늘오일을 부어 뜨거운 마늘오일에 의해 고추씨를 우려냄으로써, 고추씨 기름을 생성한다.

That is, the present invention poured hot roasted garlic oil produced by the first step into roasted hot pepper seed powder to cause red hot pepper seeds by hot garlic oil, thereby producing hot pepper seed oil.

이와 같이 제조된 고추씨 기름은 고추씨의 각종 성분이 마늘 오일 내에 추출되어 고추씨의 매운맛 성분이 함유되고, 항산화 효능과 생리활성 물질을 함유하게 된다.

The thus-produced red pepper seed oil contains various components of red pepper seed extracted into garlic oil, and contains a hot component of red pepper seed, and contains antioxidant activity and physiologically active substances.

상기 제3단계는 고추기름을 제조하는 단계로, 제2단계에 의해 제조된 고추씨기름 100중량부에 대하여, 고춧가루 30∼50중량부를 넣고 여과하여 고추기름을 형성한다.

The third step is a step of producing red pepper oil, wherein 30 to 50 parts by weight of red pepper powder is added to 100 parts by weight of the red pepper seed oil prepared by the second step and filtered to form red pepper oil.

상기 제4단계는 본 발명에 따른 고추비빔소스에 다양한 식감을 부여하고, 단백질 등의 각종 영양소를 공급하여 영양성을 강화하기 위한 것으로, 고추기름 35∼40중량%, 고추장 15∼20% 마늘 10∼15중량%, 소금 1∼4중량%, 소고기 4∼6중량%, 육포 8∼15중량%, 아몬드 5∼10중량%, 잣 5∼10중량%, 참깨 1∼3중량%를 첨가하여 고추비빔소스를 형성한다.

The fourth step is to enhance the nutritional value of the pepper beanbeam sauce according to the present invention by feeding various nutrients such as protein and the like, and it contains 35 to 40% by weight of chili oil, 15 to 20% of garlic, 15 to 15 wt% of salt, 1 to 4 wt% of salt, 4 to 6 wt% of beef, 8 to 15 wt% of beef jerky, 5 to 10 wt% of almond, 5 to 10 wt% of pine nut and 1 to 3 wt% Source.

이때, 상기 소고기 및 육포는 마늘오일을 이용하여 170∼205℃, 약 10∼25분동안, 바람직하게는 약 200℃에서 약 15분정도 구운 것을 갈아서 사용한다. At this time, the beef and jerky are grinded using garlic oil at 170 to 205 DEG C for about 10 to 25 minutes, preferably about 200 DEG C for about 15 minutes.

이와 같이 마늘오일에 의해 가공처리된 소고기 또는, 소고기와 육포는 포도씨유를 함유한 마늘오일의 조직내 침투를 통해, 식감 및 풍미감이 향상되고, 산화가 방지되어 저장성을 증대시키게 된다. As described above, the beef treated with garlic oil or the beef and jugo oil are improved in texture and flavor through the penetration of the garlic oil containing the grape seed oil into the tissues, and the oxidation is prevented, thereby increasing the storage stability.

또한, 상기 육포는 소고기만을 첨가할 경우, 발생되는 식감의 부족함을 보충하기 위하여 첨가되는 것으로, 소고기와 함께 마늘오일에 의해 가공처리하여 첨가하는 것이 바람직하고, 육포를 갈아서 그냥 첨가할 수도 있다. The jerky is added in order to compensate for the lack of texture when the beef is added only. It is preferably added by processing with garlic oil together with the beef, and the jerky may be added by grinding.

상기 참깨, 아몬드, 잣 및 마늘은 마늘오일을 이용하여 170∼205℃, 약 10∼25분, 바람직하게는 약 180℃에서 약 20분정도 구운 것을 사용한다. 이와 같이 마늘오일에 의해 가공된 참깨, 아몬드 및 잣은 항산화성을 구비하고, 색도가 안정되어 우수한 식감을 구비하게 된다.

The above sesame, almond, pine nut and garlic are baked in garlic oil at 170 to 205 DEG C for about 10 to 25 minutes, preferably about 180 DEG C for about 20 minutes. As described above, sesame, almond and pine processed by garlic oil have antioxidative properties, and the color is stable, so that a good texture is obtained.

또한, 본 발명은 백련초 가루, 건 사과 및 각종 견과류를 1∼5중량% 더 첨가할 수 있다.

In addition, the present invention may further comprise 1 to 5% by weight of Rhodiola powder, dried apple, and various nuts.

이하, 본 발명을 실시예에 의해 상세히 설명하면 다음과 같다.

Hereinafter, the present invention will be described in detail by way of examples.

실시예 1Example 1

아래 [표1]에 따른 배합에 의해 고추비빔소스를 제조하고, 이에 따른 성분분석을 실시하였으며, 그 결과는 [표2]에 나타내었다.

The red pepper beam sauce was prepared according to the formulation according to the following Table 1, and the composition analysis was performed according to the result. The results are shown in [Table 2].

[표1]Table 1

이때, 상기 본 발명에 따른 S1, S2 에 기재된 고추기름은 고추씨기름 100중량부에 대하여, 고추가루 40중량부를 넣고 여과하여 제조하였고, 상기 고추씨 기름은 가열된 마늘오일 100중량부를, 180℃ 오븐에서 10분간 구운 후 분쇄한 고추씨분말 20중량부에 넣어 약 40분동안 우려낸 후, 이를 여과기에 의해 여과시켜 제조하였으며, 상기 마늘오일은 포도씨유 85중량%에 마늘 14.5 중량%, 로즈마리 0.5중량%를 넣고, 오븐에서 180℃, 20분간 가열 추출하여 제조하였다.The pepper oil described in S1 and S2 according to the present invention was prepared by adding 40 parts by weight of red pepper powder to 100 parts by weight of red pepper seed oil and filtering the 100 parts by weight of the heated red pepper seed oil in a 180 ° C oven After 10 minutes of baking, the mixture was placed in 20 parts by weight of pulverized red pepper seed powder, followed by filtration for about 40 minutes. The garlic oil was prepared by adding 14.5% by weight of garlic and 0.5% by weight of rosemary to 85% , And heated in an oven at 180 캜 for 20 minutes.

또한, [표1]에 있어서, 본원발명의 대조군으로 사용된 S3와 S4는 현재 시판되고 있는 한국산 라유(고추기름)이고, S5는 시판되고 있는 일본산 라유(고추기름)이며, 이들의 구성성분은 전문 시험기관에 의뢰(영웅 생명과학원)한 결과이다.

In Table 1,

[표2][Table 2]

위의 [표2]에서와 같이, 본 발명에 따른 S1 및 S2의 단백질 함량이 대조군에 비해 매우 우수함을 알 수 있다.

As shown in the above [Table 2], it can be seen that the protein content of S1 and S2 according to the present invention is much better than that of the control group.

실시예 2Example 2

실시예 1 에 따른 S1 내지 S5 에 대하여, pH 와 산도를 측정하였으며, 그 결과를 [표3] 및 [표4]에 나타내었다. 저장기간에 따른 pH 와 산도를 측정은 저장 기간 동안 5℃의 저온 저장을 하였다.For S1 to S5 according to Example 1, pH and acidity were measured, and the results are shown in [Table 3] and [Table 4]. PH and acidity were measured at 5 ℃ during storage.

상기 pH 는 시료를 각각 5g씩 취하여 증류수 25㎖를 가하여 stirrer를 사용하여 균질화시키면서 pH meter(pH 210, Hanna, Italy)을 사용하여 측정하였다. 또한, 산도는 0.1% 페놀프탈레인(phenolphthalein)을 지시약으로 사용하여 희석액을 중화시키는데 소비된 0.1 N NaOH 용액의 ㎖를 lactic acid(%, w/w) 함량으로 환산하여 적정산도(%, w/w)로 표시하였다.

The pH was measured using a pH meter (pH 210, Hanna, Italy) while taking 5 g of each sample, adding 25 ml of distilled water, and homogenizing using a stirrer. The acidity was determined by titration (%, w / w) of lactic acid (%, w / w) content of 0.1 N NaOH solution consumed to neutralize the dilution with 0.1% phenolphthalein as indicator. Respectively.

[표3][Table 3]

[표3]에서와 같이, 초기 pH는 S2와 S5(대조군)가 6.52, 6.60으로 가장 높게 나타났으며 S1은 6.30을 나타냈다. 저장기간에 따라 모든 시료군의 pH(4.93∼6.02)는 초기 pH(5.17∼6.60)에 비해 낮아졌으며 저장기간에 따른 유의적인 차이를 나타냈다. S1은 저장 2주 이후 완만한 감소를 보였으며 S2 의 경우, 저장기간동안 pH 6.02∼6.52으로 안정적임을 알 수 있었다.

As shown in Table 3, the initial pH of S2 and S5 (control group) was the highest at 6.52 and 6.60 and S1 was 6.30. The pH (4.93 ~ 6.02) of all the samples was lower than that of the initial pH (5.17 ~ 6.60) according to storage period and showed significant difference according to storage period. S1 showed a gradual decrease after 2 weeks of storage and S2 was stable at pH 6.02 ~ 6.52 during storage.

[표4][Table 4]

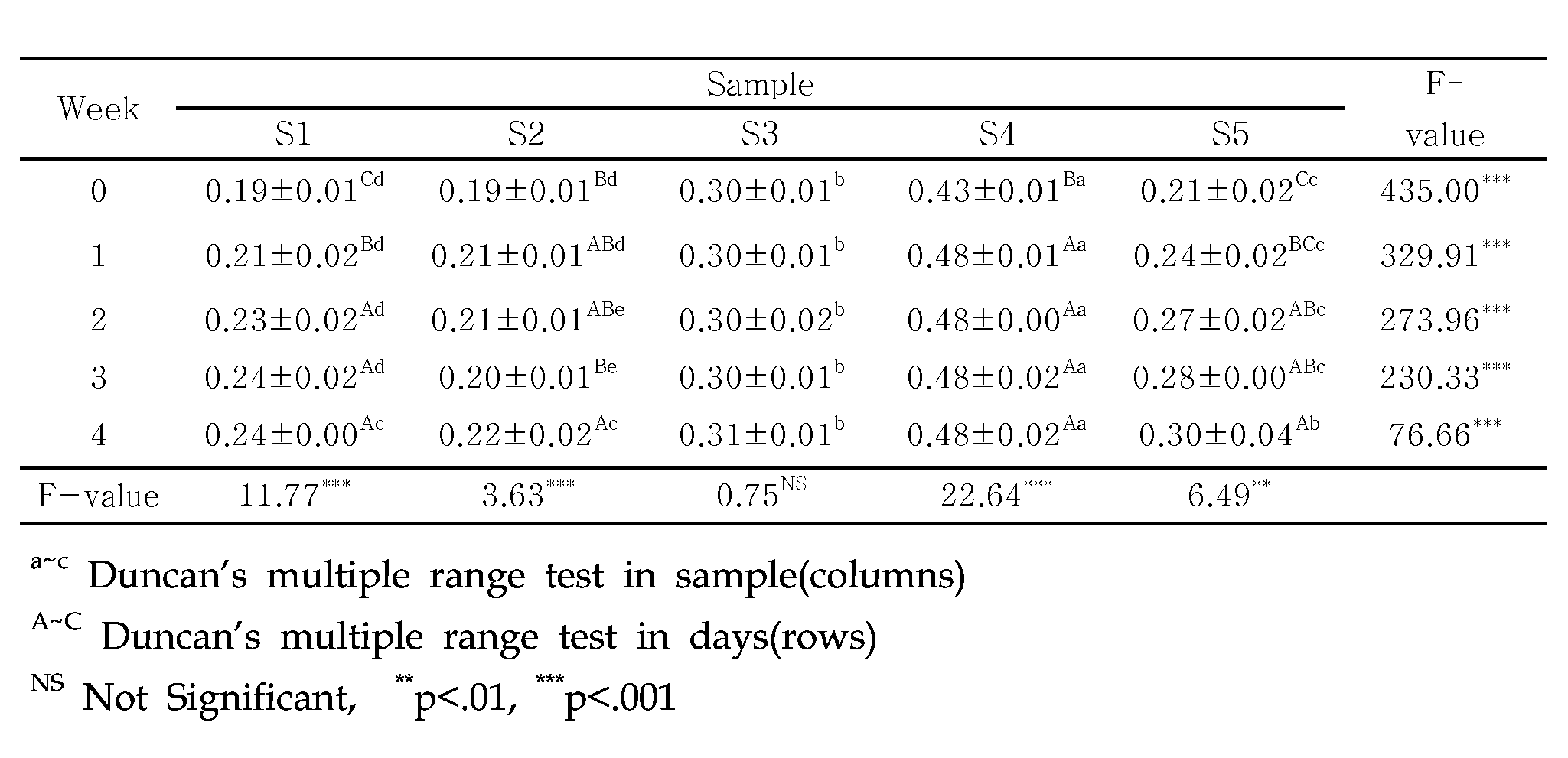

[표4]에서와 같이, 저장기간에 따른 산도는 pH의 변화와 반대의 양상을 나타냈으며, pH가 가장 낮은 S4가 가장 높은 산가를 나타냈다. S1은 0.19∼0.24, S2는 0.19∼0.22, S3은 0.30∼0.31, S4는 0.43∼0.48, S5는 0.21∼0.30으로, S1과 S2는 대조군에 비해 낮은 산가를 나타내고 있음을 알 수 있으며, 이를 통해 고추기름에 대한 고추비빔소스의 안정성을 알 수 있었다.

As shown in [Table 4], the acidity in the storage period was opposite to that in the pH change, and S4 with the lowest pH showed the highest acid value. S1 is 0.19 to 0.24, S2 is 0.19 to 0.22, S3 is 0.30 to 0.31, S4 is 0.43 to 0.48, S5 is 0.21 to 0.30, and S1 and S2 are lower in acid value than the control group. The stability of pepper bibum sauce to pepper oil was confirmed.

실시예 3Example 3

실시예 1 에 따른 S1 내지 S5 에 대하여, 전자 공여능을 측정하였으며, 그 결과를 [도2]에 나타내었다. 전자 공여능 측정(DPPH 라디칼 소거능)은 Blois의 방법에 의한 DPPH free radical 소거법을 변형하여 측정하였으며 DPPH 용액 2 ㎖를 가하여 섞은 뒤 30분간 정치한 후 517 ㎚에서 흡광도를 측정하였다.The electron donating ability was measured for S1 to S5 according to Example 1, and the results are shown in Fig. Measurement of electron donating ability (DPPH radical scavenging ability) was measured by modifying DPPH free radical scavenging method by Blois method. 2 ml of DPPH solution was added, and the mixture was allowed to stand for 30 minutes and absorbance was measured at 517 nm.

도 2 는 본 발명의 실시예 3 에 따른 저장기간별 항산화성을 도시한 것으로, 저장기간별 항산화성을 살펴본 결과 저장기간에 따라 모든 시료군에서 감소되는 경향을 나타냈으나 산화방지제를 첨가하지 않은 S1는 77.69∼87.09, S2는 73.27∼76.15, S3는 69.94∼76.15, S5는 30,48∼44.51, S4는 7.71∼12.77순으로 나타나 S1 및 S2가 강한 항산화성이 나타남을 알 수 있었다.

FIG. 2 shows the antioxidative activity according to the storage period according to Example 3 of the present invention. As a result of examining the antioxidative activity according to the storage period, it showed a tendency to decrease in all the samples according to the storage period, but S1 without the antioxidant S1 and S2 exhibited strong antioxidative activity, with S2 being 73.27 ~ 76.15, S3 being 69.94 ~ 76.15, S5 being 30, 48 ~ 44.51 and S4 being 7.71 ~ 12.77.

실시예 4Example 4

실시예 1 에 따른 S1 내지 S5 에 대하여, 저장기간별 색도를 측정하였으며, 그 결과를 [표5]에 나타내었다.For S1 to S5 according to Example 1, the chromaticity was measured for each storage period, and the results are shown in Table 5.

상기 색도는 색차계(CR-400, Hanseung E&I Co.,LTD., Japan)를 사용하여 명도(L*-value, (100)lightnessblack(0)), 적색도(a*-value, (+)rednessgreenness(-)), 황색도(b*-value, (+)yellownessblueness(-)) 값을 3회 반복 측정하여 그 평균값으로 나타내었으며 이때 사용된 표준 백판은 L값은 94.61, a값은 -0.02, b값은 2.77이었다. The chromaticity was measured using a color difference meter (CR-400, Hanseung E & I Co., Ltd., Japan) using a L * -value, (100) lightness black (0), a * rednessgreenness (-)), yellowness (b * -value, (+) yellownessblueness (-)) by the value measured three times showed that the mean value the standard white board is used L value of 94.61, a value -0.02 , and the b value was 2.77.

[표5][Table 5]

위의 [표5]에서와 같이, 저장 기간에 따른 시료의 색도를 살펴본 결과 명도 L 값은 S4가 가장 높게 나타났으며 S5가 가장 낮게 나타났다. 대부분의 시료들이 저장기간에 지남에 따라 명도가 유의적으로 낮아졌으며 적색도 a값은 S4가 20.56으로 높게 나타났으며, S1과 S2는 대조군인 S5와 비슷한 적색도 값을 나타냈다. 저장 기간에 따라 적색도는 약간 감소하는 경향을 나타냈으며 황색도 b값은 모든 시료군에서 감소하는 경향을 나타냈다. S4의 황색도가 다른 시료군에 비해 높게 나타났는데 이는 시료 첨가물 증 청국장 분말의 영향으로 사료된다.

As shown in [Table 5], when the chromaticity of the sample according to the storage period was examined, the L value was the highest in S4 and the S5 was the lowest. In most of the samples, the brightness decreased significantly with storage period. The redness value a was higher at S4 and 20.56, and S1 and S2 showed similar redness values as the control S5. The redness tended to decrease slightly with storage period and the b value of yellowness tended to decrease in all samples. The yellowness of S4 was higher than that of the other samples.

실시예 5Example 5

실시예 1 에 따른 S1 내지 S5 에 대하여, 저장기간별 미생물을 측정하였으며, 그 결과를 [도3]에 나타내었다.For S1 to S5 according to Example 1, microorganisms were measured for each storage period, and the results are shown in Fig.

미생물 측정은 시료 10 g을 90 ㎖ 멸균수와 함께 균질화한 후 그 균질액을 10배 희석법으로 희석하여 일반 호기성 세균은 PCA(Plate Count Agar. Difco, USA)배지에 1 ㎖ 도말하여 37℃에서 48시간 배양한 후 나타난 colony수를 계수하였다.For microbial determination, 10 g of the sample was homogenized with 90 ml of sterilized water, and the homogenate was diluted by a 10-fold dilution method. General aerobic bacteria were plated in PCA (Plate Count Agar. Difco, USA) The number of colonies after counting was counted.

도 3 은 본 발명의 실시예 5 에 따른 총균수 측정결과를 도시한 것으로, S1과 S3 이 1.1∼2.5×102으로 가장 낮은 균수를 보였으며, 저장 4주 경과 후에도 1.11∼2.25×104로 나타났으며 증가율이 감소되는 것을 확인할 수 있었다.

FIG. 3 shows the results of the measurement of the total number of bacteria according to Example 5 of the present invention. S1 and S3 showed the lowest bacterial counts of 1.1 to 2.5 × 10 2 , and they were 1.11 to 2.25 × 10 4 And the growth rate was decreased.

본 발명은 상술한 특정의 바람직한 실시예에 한정되지 아니하며, 청구범위에서 청구하는 본 발명의 요지를 벗어남이 없이 당해 발명이 속하는 기술분야에서 통상의 지식을 가진 자라면 누구든지 다양한 변형실시가 가능한 것은 물론이고, 그와 같은 변경은 청구범위 기재의 범위내에 있게 된다.It will be understood by those skilled in the art that various changes in form and details may be made therein without departing from the spirit and scope of the invention as defined in the appended claims and their equivalents. Of course, such modifications are within the scope of the claims.

Claims (5)

제1단계에 의해 가열되어 형성된 마늘오일에 고추씨를 넣고 추출 및 여과하여 고추씨기름을 형성하는 제2단계;

제2단계에 의해 형성된 고추씨기름에 고춧가루를 넣고 추출 및 여과하여 고추기름을 형성하는 제3단계;

제3단계에 의해 형성된 고추기름에 고추장, 마늘, 소금, 소고기, 육포, 아몬드, 잣, 참깨를 첨가하여 고추비빔소스를 형성하는 제4단계;를 포함하되,

상기 제4단계의 소고기, 육포, 아몬드, 잣 및, 참깨는 마늘오일에 의해 가공처리된 것을 특징으로 하는 항산화성을 구비한 고추소스 제조방법.

A first step of adding rosemary and garlic to grape seed oil and heating to form garlic oil;

A second step of adding pepper seed to the garlic oil formed by heating in the first step and extracting and filtering the pepper seed oil to form red pepper seed oil;

A third step of adding red pepper powder to the red pepper seed oil formed by the second step and extracting and filtering to form red pepper oil;

And a fourth step of adding red pepper paste, garlic, salt, beef, beef jerky, almond, pine nut and sesame to the pepper oil formed by the third step to form a red pepper beef sauce,

Beef, beef jerky, almonds, pine nuts, and sesame seeds of the fourth step is a pepper sauce manufacturing method with an antioxidant, characterized in that processed by garlic oil.

마늘오일은 마늘 8∼15 중량%, 로즈마리 0.1∼5중량%, 포도씨유 80∼90 중량%를 178∼183℃에서 15∼25분간 가열하여 추출하고,

고추씨기름은 상기 마늘오일 100중량부에 대하여, 고추씨 15∼25중량부를 넣고 20∼40분동안 추출 및 여과하되, 상기 고추씨는 178∼183℃ 오븐에서 8∼12분동안 가열하여 구운 후, 분쇄기에 의해 갈아 사용한 것을 특징으로 하는 항산화성을 구비한 고추기름 제조방법.

The method of claim 1,

Garlic oil is extracted by heating for 8 to 15 wt% of garlic, 0.1 to 5 wt% of rosemary, and 80 to 90 wt% of grape seed oil at 178 to 183 캜 for 15 to 25 minutes,

Pepper seed oil is added to 15 to 25 parts by weight of pepper seeds with respect to 100 parts by weight of the garlic oil, and extracted and filtered for 20 to 40 minutes. Red pepper oil production method with an antioxidant, characterized in that the ground using.

고추비빔소스는 고추기름 35∼40중량%, 고추장 15∼20% 마늘 10∼15중량%, 소금 1∼4중량%, 소고기 4∼6중량%, 육포 8∼15중량%, 아몬드 5∼10중량%, 잣 5∼10중량%, 참깨 1∼3중량%로 이루어진 것을 특징으로 하는 항산화성을 구비한 고추소스 제조 방법.

The method of claim 1,

The pepper bibim sauce contains 35 to 40% by weight of chili oil, 15 to 20% of garlic, 10 to 15% of garlic, 1 to 4% of salt, 4 to 6% of beef, 8 to 15% 5 to 10 wt% of pine nut, and 1 to 3 wt% of sesame seeds.

소고기, 육포, 참깨, 아몬드, 잣 및 마늘은 마늘오일을 이용하여 170∼205℃ 오븐에서 10∼25분동안 구운 후 갈은 것을 특징으로 하는 항산화성을 구비한 고추소스 제조방법.

The method of claim 3,

Beef, beef jerky, sesame seeds, almonds, pine nuts and garlic roasted with garlic oil for 10-25 minutes in an oven at 170-205 ℃ oven, characterized in that the pepper sauce preparation method characterized in that the antioxidant properties.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020120088368A KR101415279B1 (en) | 2012-08-13 | 2012-08-13 | preparation of antioxidation chilli sauce |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020120088368A KR101415279B1 (en) | 2012-08-13 | 2012-08-13 | preparation of antioxidation chilli sauce |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR20140021894A true KR20140021894A (en) | 2014-02-21 |

| KR101415279B1 KR101415279B1 (en) | 2014-08-06 |

Family

ID=50268113

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020120088368A KR101415279B1 (en) | 2012-08-13 | 2012-08-13 | preparation of antioxidation chilli sauce |

Country Status (1)

| Country | Link |

|---|---|

| KR (1) | KR101415279B1 (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101686622B1 (en) * | 2015-07-03 | 2016-12-14 | 대구가톨릭대학교산학협력단 | Method for producing hot pepper paste sauce adding grape branch and seed extract |

| CN107296860A (en) * | 2017-06-22 | 2017-10-27 | 利康行(北京)生物科技有限公司 | A kind of complex health care product of anti-oxidant nti-freckle |

| KR102636664B1 (en) * | 2023-02-07 | 2024-02-14 | (주)인맥에프엔씨 | Manufacturing method of sauce composition for dried fish with excellent palatability and preservation |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100332100B1 (en) * | 2000-02-01 | 2002-04-10 | 김숭희 | Hot pepper paste enriched with beef and honey |

| KR100522412B1 (en) * | 2002-12-30 | 2005-10-19 | 강창환 | A bibimbab mixed with fresh vegetables. |

| KR101256739B1 (en) * | 2011-01-06 | 2013-04-19 | 경상북도 영양군 | Mixed sauce and process thereof |

-

2012

- 2012-08-13 KR KR1020120088368A patent/KR101415279B1/en active IP Right Grant

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101686622B1 (en) * | 2015-07-03 | 2016-12-14 | 대구가톨릭대학교산학협력단 | Method for producing hot pepper paste sauce adding grape branch and seed extract |

| CN107296860A (en) * | 2017-06-22 | 2017-10-27 | 利康行(北京)生物科技有限公司 | A kind of complex health care product of anti-oxidant nti-freckle |

| KR102636664B1 (en) * | 2023-02-07 | 2024-02-14 | (주)인맥에프엔씨 | Manufacturing method of sauce composition for dried fish with excellent palatability and preservation |

Also Published As

| Publication number | Publication date |

|---|---|

| KR101415279B1 (en) | 2014-08-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Kabir et al. | Formulation of yogurt with banana peel extracts to enhance storability and bioactive properties | |

| El Anany | Nutritional composition, antinutritional factors, bioactive compounds and antioxidant activity of guava seeds (Psidium Myrtaceae) as affected by roasting processes | |

| RU2332882C1 (en) | Method of semi-finished products making on fish and vegetable basis for school food | |

| Boby et al. | Effect of long coriander leaf (Eryngium foetidum) extract as a natural antioxidant on chicken meatballs during at freezing temperature | |

| CN105995933A (en) | Natto chili sauce | |

| Šulcerová et al. | Effect of addition of pollen and propolis to feeding mixtures during the production of broiler chickens ROSS 308 to the colour of thigh and breast muscle and pH determination | |

| KR101415279B1 (en) | preparation of antioxidation chilli sauce | |

| KR101520629B1 (en) | Tomato sauce having increased lycopene content and manufacturing method | |

| KR101547896B1 (en) | Method for producing oat soybean paste with increased antioxidant activity and oat soybean paste produced by the same method | |

| KR20120049500A (en) | Feed additive, method for manufacturing the same and meat acquired by feeding a feed mixed with the same | |

| KR101105931B1 (en) | A manufacturing method of functional mul-kimchi using natural herbal materials | |

| Lee et al. | Effects of lemon balm on the oxidative stability and the quality properties of hamburger patties during refrigerated storage | |

| El Ghizzawi et al. | A focused insight into sumac: biological, chemical, health benefits and its applications in food industry | |

| KR20170086196A (en) | Rice bran composition and preparing method for fermented rice bran composition | |

| KR101558134B1 (en) | Soybean paste and method for preparing the same | |

| KR101793700B1 (en) | fish paste composition improved storage periods comprising natural complex extract | |

| KR101335658B1 (en) | Meat products containing extract and method for preparing the same | |

| KR20110123905A (en) | A composition of kimchi sauce using seaweeds | |

| CN112438329A (en) | Edible oil added with natural antioxidant and preparation method thereof | |

| Hayoglu et al. | Cream zahter: a functional food some chemical and sensory properties | |

| KR101167293B1 (en) | Noodle comprising enzymatic extracts of native plants and method of preparing the same | |

| KR101970046B1 (en) | A Novel Seed Juice of High Antioxidant Activity and Digestive Activity | |

| KR20080092186A (en) | Smoked ham containing of herbs extracts with preservative capacity and quality to be enhanced | |

| KR101686622B1 (en) | Method for producing hot pepper paste sauce adding grape branch and seed extract | |

| KR101808935B1 (en) | Head cheese comprising of turmeric and method for preparing thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| E902 | Notification of reason for refusal | ||

| E701 | Decision to grant or registration of patent right | ||

| GRNT | Written decision to grant | ||

| FPAY | Annual fee payment |

Payment date: 20170602 Year of fee payment: 4 |

|

| FPAY | Annual fee payment |

Payment date: 20180426 Year of fee payment: 5 |