KR101003674B1 - Deposition and Coating Method of Nano Far Infrared Radiation - Google Patents

Deposition and Coating Method of Nano Far Infrared Radiation Download PDFInfo

- Publication number

- KR101003674B1 KR101003674B1 KR1020100025512A KR20100025512A KR101003674B1 KR 101003674 B1 KR101003674 B1 KR 101003674B1 KR 1020100025512 A KR1020100025512 A KR 1020100025512A KR 20100025512 A KR20100025512 A KR 20100025512A KR 101003674 B1 KR101003674 B1 KR 101003674B1

- Authority

- KR

- South Korea

- Prior art keywords

- weight

- deposition

- far

- clothing

- infrared radiation

- Prior art date

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M11/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising

- D06M11/83—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with metals; with metal-generating compounds, e.g. metal carbonyls; Reduction of metal compounds on textiles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82Y—SPECIFIC USES OR APPLICATIONS OF NANOSTRUCTURES; MEASUREMENT OR ANALYSIS OF NANOSTRUCTURES; MANUFACTURE OR TREATMENT OF NANOSTRUCTURES

- B82Y30/00—Nanotechnology for materials or surface science, e.g. nanocomposites

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82Y—SPECIFIC USES OR APPLICATIONS OF NANOSTRUCTURES; MEASUREMENT OR ANALYSIS OF NANOSTRUCTURES; MANUFACTURE OR TREATMENT OF NANOSTRUCTURES

- B82Y40/00—Manufacture or treatment of nanostructures

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F9/00—Artificial filaments or the like of other substances; Manufacture thereof; Apparatus specially adapted for the manufacture of carbon filaments

- D01F9/08—Artificial filaments or the like of other substances; Manufacture thereof; Apparatus specially adapted for the manufacture of carbon filaments of inorganic material

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Nanotechnology (AREA)

- Crystallography & Structural Chemistry (AREA)

- General Physics & Mathematics (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Textile Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Composite Materials (AREA)

- Materials Engineering (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Chemical Or Physical Treatment Of Fibers (AREA)

Abstract

Description

본 발명은 원적외선 방사물의 제조 및 침착, 코팅방법에 있어서, 다종의 세균, 곰팡이 균에 대하여 항균 및 살균효과를 가지는 항균성 원적외선 방사와 은나노 분산체에 의한 안전성이 우수한 항균성 의류침착 코팅용 방사체 조성물을 구성하여 섬유직물로 제조된 의류, 헬스 복 등에 침투시켜 침착 코팅하는 소재인 은나노 원적외선 방사물의 침착 코팅방법에 관한 것이다.The present invention provides an antimicrobial antimicrobial garment deposition coating composition excellent in antimicrobial far-infrared radiation and silver nano dispersion having antimicrobial and bactericidal effect against many kinds of bacteria and fungi in the method of manufacturing, depositing and coating far-infrared radiation. The present invention relates to a deposition coating method of silver nano far-infrared radiation, which is a material that penetrates and coats clothing, health clothing, and the like made of a textile fabric.

일반적으로 원적외선 방사체나 은 나노 코팅을 이용한 구성이 다수 출원되고 공고 되여 있다, 그중에서 10-0512599호 음이온 방출 및 원적외선 방사 무기질 세라믹 조성물은 실란 또는 그로부터 파생된 바인더 역할을 하는 결합제와 분말 산화규소, 물로 이루어진 규소 혼합물과 토르말린, 황토, 견운모 자수정, 생광석, 죽탄, 의왕석, 귀양석, 흑요석, 맥반석, 광명석 중 선택된 천연석 재질로 된 분말상의 기능성 충진제와 석영 몬조나이트 편마암류 및 유문암질 응희암과 같이 천연 광물질군으로부터 선택된 하나의 천연색 재질로 이루어진 분말형태의 기능성 충진제와 편마암류 유문암질 천연 광물질에서 선택한 원적외선 방사물질과 음이온 방출물로 구성되는 세라믹 분말과 안료분을 혼합 한 것을 적정 wt%로 구성함을 특징으로 구성한 3단계의 구성을 요지로 한 것이고,In general, a number of applications using the far-infrared emitter or silver nano-coating have been applied and published, among which 10-0512599 anion-releasing and far-infrared radiation-inorganic ceramic composition is composed of a binder, a powder silicon oxide, and water which acts as a silane or a binder derived therefrom. Powdered functional filler and quartz monzonite gneiss and rhyolite rock Like this, it is composed of proper wt% of a mixture of a functional filler in the form of one natural color selected from the group of natural minerals, a ceramic powder composed of an infrared emitter and an anion emitter selected from the gneiss and rhyolite natural minerals 3 levels of configuration One would Girona,

10-0339776호 항균제의 제조방법은 무기입자 또는 합성수지입자의 표면에 친수성 유기물질에 의하여 직접 부착된 N-장쇄 아실 아미노산에 항균작용을 가진 금속이 포함되고 N-장쇄 아실 아미노산 이온함유 수용액과 접촉시키는 과정과 접촉 공정 후 상기 입자를 항균작용을 가진 금속함유 수용액과 접촉시키는 구성을 요지로 한 것이다,A method for preparing an antimicrobial agent includes a metal having an antimicrobial action on an N-long chain acyl amino acid directly attached to a surface of an inorganic particle or a synthetic resin particle by a hydrophilic organic material, and contacting with an N-long chain acyl amino acid ion-containing aqueous solution. After the process and the contact process, the particles are contacted with a metal-containing aqueous solution having an antimicrobial effect.

또한 10-2003-0090880호는 원적외선 방사물의 처리방법은 규소, 알미늄, 산화철 마그네슘 칼륨, 나트륨, 황토 등을 적정의 함량으로 조성한 것이나, 고령토, 황토로서 조성한 촉매 액60%와 유연제 40%로 혼합한 것에 직물원단을 침적하여 촉매제와 유연제 혼합액이 원단에 침투 침착되게 하고 염료와 촉매액의 혼합한 액상을 염색공정을 거쳐서 열처리 및 건조하여 처리함을 특징으로 한 구성이었다,In addition, 10-2003-0090880 discloses a method for treating far-infrared radiation in which silicon, aluminum, magnesium iron oxide, potassium, sodium, ocher, etc. are formed in an appropriate amount, but mixed with 60% of a catalyst liquid composed of kaolin and loess, and a softener 40%. The fabric was dipped into one fabric so that the mixture of catalyst and softener was penetrated and deposited on the fabric, and the mixed liquid of dye and catalyst was treated by heat treatment and drying through a dyeing process.

그러나 상기한 구성은 규소, 알미늄, 산화철 마그네슘, 칼륨, 나트륨, 황토 등으로 조성한 촉매액 60% 유연제 40%로 혼합한 용액 상에 직물원단을 침적하여 침투 침착되게 하고, 염료와 촉매액을 혼합한 것에 염색케 하여 열처리 및 건조 처리케 함을 요지로 한 것으로서, 은의 입자의 은나노 첨가 방사물이 아니어서 무독성을 필요로 하는 원적외선 방사 물로서는 다소 부적당하다는 문제점이 있었다.However, the above-described structure is fabricated by depositing the fabric fabric on a solution mixed with 40% of a catalyst liquid 60% softener composed of silicon, aluminum, magnesium oxide, magnesium oxide, potassium, sodium, ocher, etc., and mixing dye and catalyst solution. The main purpose of this is to dye and heat treatment and dry treatment, there is a problem that it is somewhat unsuitable as far-infrared radiation that requires non-toxic because it is not a silver nano-addition of silver particles.

본 발명은 상기한 종래의 구성들과 달리 원적외선 방사물 자체를 제조하거나 조성하는 과정에서 나트륨, 철, 칼슘, 마그네슘 등으로 포함되어 구성되는 원 재료 등을 미세하게 분쇄하여 액상으로 구성하여야 하고, 여기에 나노실버가 함유된 용액과 혼합 반응시켜서 섬유 직물이나 의류 헬스 복 등에 침투시켜 침착 코팅 하였을 때 세척에 따른 씻겨 나가지 않아야 한다는 문제점을 해결해야 하고, 또 의류에 처리 후 착용하여 사용할 경우에 착용자의 인체 특히 피부의 질환에 대하여 항균, 음이온 발생, 땀 냄새 등의 탈취는 물론 인체의 생체리듬에 유용한 원적외선 방사(방출)효과를 얻을 수 있어야 한다는 문제점을 해결하여야 하는 것이다,The present invention, unlike the conventional configuration described above, in the process of manufacturing or composition of the far-infrared radiation itself, should be composed of finely pulverized raw materials, etc. consisting of sodium, iron, calcium, magnesium, etc. When the solution is mixed with a solution containing nano silver and penetrated into a textile fabric or clothing health suit, the solution should not be washed away when the coating is deposited. In particular, it is necessary to solve the problem that far-infrared radiation (emission) effect, which is useful for the biological rhythm of the human body, as well as deodorization such as antibacterial, anion generation, sweat odor, etc. to skin diseases, should be solved.

즉 은(銀) 특히 콜로이드 은(Colloidal銀)은 세균의 600종 이상을 부작용 없이 짧은 시간 내에 박멸하는 효과가 있다는 점에 착안한 것인데, 상기와 같은 효과의 인정은 국내외에 이미 상식화되어 알려져 있는바, (미국 FDA가 은을 첨가한 약품: 주로항생제 은 판매를 허용한 바 있다) 본원에서는 이점에서 착안 하였다,In other words, silver (colloidal silver), in particular colloidal silver (Colloidal 銀) has been focused on the effect of eradicating more than 600 kinds of bacteria in a short time without side effects, the recognition of the above effect is already commonplace at home and abroad is known. (The US FDA has allowed the sale of silver-based drugs: predominantly antibiotic silver.)

본원에서의 원적외선 방사물의 조성에 있어서, 섬유직물에 침착할 수 있는 조성물 제조에 첨가 조성물로서 겸용 가능한 원적외선 방사물을 제조하고자 하는 방법에 그 목적이 있다.In the composition of the far-infrared radiant herein, the object is to produce a far-infrared radiant that can be used as an additive composition in the preparation of a composition that can be deposited on a textile fabric.

본 발명은 상기한 종래의 방법에서, 직물의 원사와 원단 및 의류에 원적외선 소재와 의류에 침투 침착하는 항균성 첨가조성물로 사용하도록 구성한 것으로서, 분말로 이루어지는 방사체와는 달리 액상이나 겔(gel)상의 시료로 구성하여 의류에 침투 침착이 우수한 원적외선 방사와 항균 및 살균효과를 갖도록 한 것으로서,The present invention is configured to use as an antimicrobial additive composition that penetrates and deposits far-infrared material and clothes in the yarn, fabric, and clothing of the fabric in the conventional method, unlike liquid emitters made of powder, liquid or gel samples It is composed of so that it has excellent far-infrared radiation, antibacterial and bactericidal effect on clothing,

마그네슘, 칼륨, 칼슘, 규소, 철, 나트륨 등의 성분을 함유한 알루미늄 실리케이트로서 상기와 같은 성분을 가진 알루미늄 실리케이트를 건조하여 사용할 수 있고 건조가 불필요한 것은 원료 그대로를 극 미세하게 분쇄하여 걸러 주는데 3,000∼ 3,500메쉬로 분쇄하며, 상기 알루미늄 실리케이트 는 진흙상의 원재료 물질 을 구성하고 있어서 건조, 분쇄, 가열과정을 거치는데 일라이트와 같이 100℃의 온도로 건조한 다음 35-40㎛ 입자로 분쇄하여 사용 하는 것이 바람직하다,Aluminum silicate containing components such as magnesium, potassium, calcium, silicon, iron and sodium, which can be used by drying the aluminum silicate having the above components. It is pulverized to 3,500 mesh, and the aluminum silicate is composed of mud-like raw material , which is dried, pulverized, and heated. Do,

은 나노의 제조는 두 가지로서 첫째는 전기분해 공정에 은판을 양 전극으로 구비하고 고전압을 인가하되, 미세전류로 제어하여 5nm이하의 은 나노 입자를 생산하여 사용하는 방법과, 둘째는 은 나노입자를 제조하기 위하여 AgNO3 와 PVP를 EG 와 혼합하여 교반한 후 100-140 ℃로 가열하고 평상 온도로 냉각하며, 증류수를 첨가 희석하여 여과장치에서 여과 세척하고, 농축액을 제조하는 방법이 있는데, 상기 두가지 방법 중 어느 것이나 본 발명에서 실시 가능한 것이며, 본원의 이하 설명에서는 균일성 분산의 안전성이 좋은 후자의 방법으로 설명 한다Silver nanoparticles are manufactured in two ways. First, a silver plate is provided as a positive electrode in an electrolysis process, and a high voltage is applied. However, silver nanoparticles of 5 nm or less are produced and controlled by microcurrent, and second, silver nanoparticles. AgNO 3 and PVP are mixed with EG and stirred to heat the mixture, and then heated to 100-140 ° C., cooled to normal temperature, distilled water is diluted, filtered and washed in a filtration apparatus, and a concentrate is prepared. Either of the two methods can be implemented in the present invention, the following description of the present application will be described by the latter method with good safety of uniform dispersion.

0.01-0.02중량%의 나노실버를 첨가하여 균일성 분산의 장기 안전성이 우수하고, 나노실버 의류로 이루어지는 것과 원적외선의 방출, 항균과 변색방지 되는 은 나노와 상기 광물질을 이용한 방사물의 조성방법으로서, 은나노와 알루미늄, 마그네슘, 칼륨, 칼슘, 규소, 철, 나트륨이 포함된 천연알루미늄 실리케이트와 일라이트를 상호 적정량을 조합하여 구성한 조성물을 유연제와 혼합하여 조성한 다음, 직물로 제조한 의류,헬스 복 등에 침투 또는 코팅시켜서 건강의류를 제조하여 방사물과 상기 조성한 방사물에서 은 나노의 효능을 함께 얻는 조성물을 침투 코팅제로 활용토록 하였다.As a method of composition of nano-silver clothing, which is composed of nano silver clothing, which emits far-infrared rays, antibacterial and anti-discoloration, and nano-silver, which is added with 0.01-0.02% by weight of nano silver, A composition composed of a combination of silver nano, aluminum, magnesium, potassium, calcium, silicon, iron, and sodium with an appropriate amount of natural aluminum silicate and illite is mixed with a softening agent, and then penetrated into clothing and health clothing made of fabric. Or by coating the health clothing to prepare a composition to obtain the efficacy of the silver nanoparticles in the radiant and the composition of the composition as a penetration coating agent.

여기서 원적외선의 방사는 항균은 물론 부패방지와 혈액순환촉진 알카리 체질화에 활발한 활동의 촉진 등을 가지며, 원적외선의 성질을 살펴보면, 빛의 에너지 가운데 약80%를 적외선이 차지하고 있고, 4㎛ 을 기준으로 하여 짧은 쪽을 근적외선, 먼 쪽을 원적외선이라 하는데 열의전도 방식에는 대류, 전도, 복사(輻射Radiation:방사放射)의 세가지 형태가 있으며 적외선은 세가지 중 복사(방사)로 열을 전달하는 방법으로 열효율이 대단히 좋다는 장점이 있는데, 방사는 공기 물 등에 간접적으로 열을 전파하는 대류나, 전도와 달리 대상물에 직접 열을 전달하는 방법으로 열 효율이 대단히 우수한 장점을 갖고 있다Here, the radiation of far-infrared radiation not only has antibacterial effect but also promotes active activities in preventing corruption and promoting blood circulation, and looking at the nature of far-infrared rays, about 80% of light energy occupies about infrared rays, based on 4㎛. The short side is called near-infrared and the far side is far-infrared. There are three types of heat conduction methods: convection, conduction, and radiation. Infrared rays transmit heat by radiation. Radiation is a convection that indirectly propagates heat, such as air and water, and unlike heat conduction, radiation has a very good thermal efficiency by directly transferring heat to an object.

이와 같이 된 본 발명은 직물원단에 침투 및 코팅되게 침착하여 사용하는데 나노실버를 첨가함으로 인하여 살균, 정균, 항균작용은 물론 침구류, 의류 등을 만들기 전 침투 코팅시켜 사용하게 되면 사용 및 착용 시에 원적외선의 다량 방출로 인하여 인체의 생리작용에 영향을 주는 생체리듬을 활성화시켜 건강에 유익하고, 은 나노를 첨가 혼합함으로서 각종 세균의 번식에 대한 멸균과 항균, 음이온 발생 등으로 본 발명에 의하여 처리된 의류 및 헬스 복 등을 착용하여 운동할 경우, 조기 피로를 방지하는데 보조 역할을 할 수 있고, 사용자의 건강을 증진 시키는 데에 효과가 있다The present invention as described above is used to penetrate and coat the fabric fabric is used for wearing and wearing the coating before making the sterilization, bacteriostatic, antibacterial action as well as bedding, clothing, etc. by adding nanosilver. It is beneficial to health by activating a biorhythm that affects the physiology of the human body due to the large amount of far-infrared radiation, and by adding and mixing silver nano, it is treated according to the present invention by sterilization, antibacterial and anion generation for various bacteria. When exercising with clothing and health clothing, it can play a role in preventing premature fatigue and is effective in improving the user's health.

도 1은 본 발명의 개략도1 is a schematic diagram of the present invention

원적외선의 방출로 인해 인체의 생체활동에 영향을 주는 물질인 철, 마그네슘, 나트륨, 칼륨, 칼슘 규소 등이 함유되어 있는 알루미늄 실리케이트 70중량%와 100℃에서 건조한 다음 35∼40㎛ 크기의 입자로 분쇄(3000∼3500메쉬)한 일라이트 30중량%의 비율로 혼합하는데 미세한 극 미분으로 여과하여 시료1(실시예 1공정기재)을 준비한다,70% by weight of aluminum silicate containing iron, magnesium, sodium, potassium and calcium silicon, which are substances that affect the human body's biological activities due to the emission of far infrared rays, dried at 100 ℃ and then crushed into particles of 35-40㎛ size Sample 1 (Example 1 process base material) was prepared by filtration with fine polar fine powder (3000-3500 mesh) at a ratio of 30% by weight of illite.

알루미늄 실리케이트는 채광하면 진흙의 반죽 상으로서 약 600∼800℃로 가열하는데 원광에 직접 화염이 닿지 않도록 간접 가열하여 냉각 후 불순물과 극 미세한 미분이 아닌 것은 선별 제거과정을 거쳐서 순수 알루미늄 실리케이트만을 얻고, 일라이트 역시 100℃ 의 온도로 간접가열 한 다음 냉각 후 건조한 다음 35∼40㎛ 입자로 분쇄하여 사용하며, 단지 일라이트는 600℃ 가열하지 않아도 사용에는 지장이 없다When the aluminum silicate is mined, it is heated to about 600 ~ 800 ℃ as the dough phase of the mud, but it is indirectly heated so that it does not directly touch the ore. After cooling, only the pure aluminum silicate is obtained through the screening removal process. The light is also indirectly heated to a temperature of 100 ℃, then cooled and dried before being crushed into 35-40㎛ particles.

삭제delete

삭제delete

삭제delete

삭제delete

삭제delete

상기한 시료1에 은 나노 입자를 미세입자로 가공한 은을 함유시켜서 원적외선의 방출효과를 가일층 증대하도록 하는데, 나노실버 0.01-0.02중량%를 조성한 시료2를 혼합하여 시료 3을 조성 한다In order to further increase the emission effect of far infrared rays by containing silver processed silver nanoparticles into fine particles in sample 1, sample 3 is prepared by mixing sample silver having 0.01-0.02% by weight of nanosilver.

시료 3으로 제조된 것을 원적외선 방사시험을 한 결과 아래 표와 같다The far infrared radiation test prepared from sample 3 is shown in the table below.

시험 1Test 1

1) 시험방법 : KFIA - FI-10051) Test Method: KFIA-FI-1005

2) 본시험은 37℃에서 시험하였으며, FT-IR Spectrometer를 이용한 BLACK - BODY대비 측정결과 임.2) This test was conducted at 37 ℃, and the result was measured by BLACK-BODY using FT-IR Spectrometer.

상기 시험에서 시료3을 다이어트 헬스복에 침착시켜서 시험한 결과임It is the result of depositing sample 3 in the diet health suit in the test.

다음은 음이온 (ION / CC) 발생시험표이다The following is an anion (ION / CC) generation test table

시험2(음이온방출시험)Test 2 (anion release test)

1) 시험방법 : KFIA - FI - 10421) Test Method: KFIA-FI-1042

2) 시험편 : 100× 150mm2) Test piece: 100 × 150mm

3) 하전입자 측정 장치를 이용하여 실내온도가 21℃, 습도 30%, 대기 중 음이온수 102ion/cc조건에서 시험하였으며, 측정 대상물에서 방출되는 음이온을 측정하여 단위 체적당 ION수로 표시한 결과임3) Tested under the condition of room temperature 21 ℃, humidity 30%, and anion water 102ion / cc using charged particle measuring device. It is the result of measuring the anion emitted from the object to be expressed as ION per volume.

시험 3(항균시험)Test 3 (antibacterial test)

(주) 배지상의 균수는 희석배수를 곱하여 산출한 것임(Note) The number of bacteria on the medium is calculated by multiplying the dilution factor.

1) 시험방법 : KS K0693-20011) Test Method: KS K0693-2001

2 ) 사용균수 : Staphy lococcus aureus ATCC 65382) Number of bacteria used: Staphy lococcus aureus ATCC 6538

Klebstells Pneumoniae ATCC 4352 Klebstells Pneumoniae ATCC 4352

3) 비이온성계면활성제 : 접종균에 0.05% 비이온계면 활성제 사용(Sonogen)3) Nonionic Surfactant: 0.05% nonionic surfactant is used for inoculating bacteria (Sonogen)

4) 표준포 : KSK 0905 염색견뢰도용 첨부백포(Cotton)4) Standard cloth: KSK 0905 Dyeing fastness

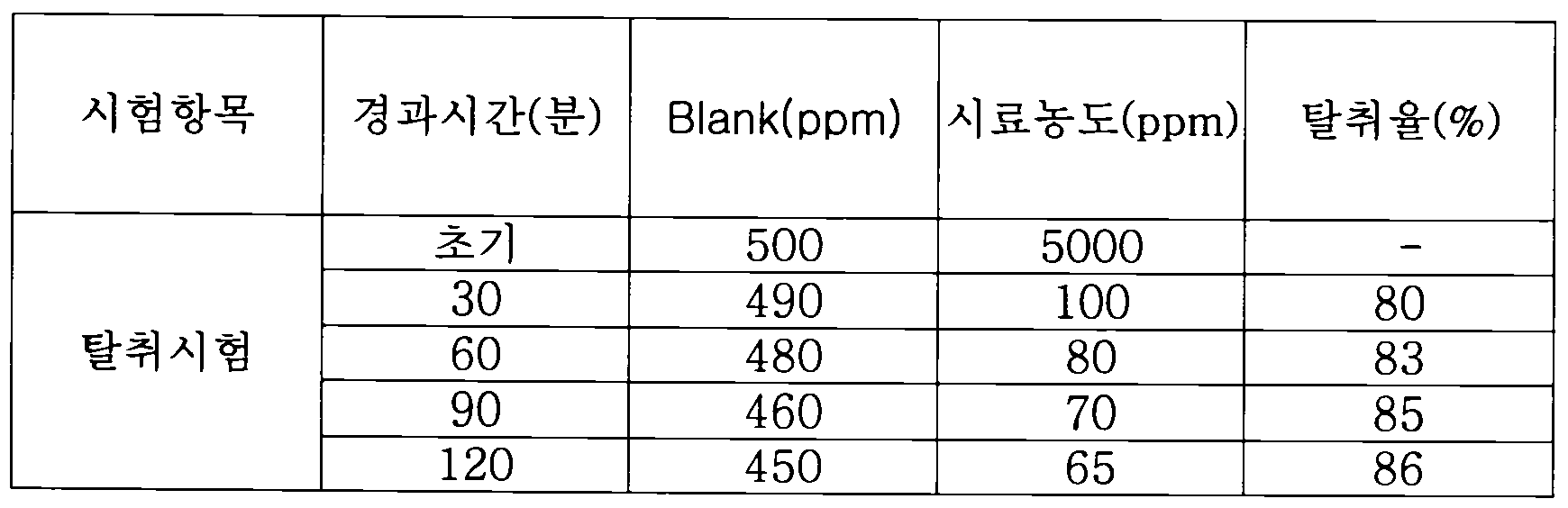

시험 4(탈취시험)Exam 4 (Deodorization Test)

(주) Blank : 시료를 넣지 않은 상태에서 측정한 것임(Note) Blank: Measured without sample

1) 시험방법 : KFIA - FI - 10041) Test Method: KFIA-FI-1004

2) 시험가스명 : 암모니아2) Test gas name: Ammonia

3) 가스농도측정 : 가스검지관3) Gas concentration measurement: gas detector

상기시험들은 한국원적외선 응용평가연구원에서 시험한 것임The above tests were conducted by Korea Far Infrared Applied Evaluation Institute

상기와 같이 조성된 시료의 방사물은 액상으로서 직조된 의류에 침투되어 흡수 착상이 잘되도록 하는데 예를 들어 상기 시험에서와 같은 헬스복을 원적외선의 방사물에 침적시켜서 임의 시간이 경과토록하면 헬스복의 표면은 물론 내부까지 흡수 침적되고 침착 착상이 된다, 여기서 상기 조성에 의한 방사물은 헬스복의 부드러움을 주기위하여 유연제를 시료70중량%에 대하여 30중량%의 비율로 하여 헬스 복을 침적시킨다, 침적하여 100∼120℃의 온도로 15∼20분의 시간이 경과하면 침적 착상이 완료되고 다시 상온에서 건조 하면 완성된다,The radiant of the sample prepared as described above penetrates into the woven clothing as a liquid phase, so that the absorption is well conceived. For example, if the health clothing as in the test is deposited on the far-infrared radiation, the surface of the health clothing is allowed to elapse for a certain time. Of course, it is absorbed and deposited onto the inside, whereby the constituents of the composition deposit the health clothing with the softener in a ratio of 30% by weight to 70% by weight of the sample to give the softness of the health clothing. When the time of 15 to 20 minutes elapses at a temperature of ˜120 ° C., immersion implantation is completed and dried again at room temperature, thereby completing.

침적 착상과정에서 열처리 온도는 헬스복에 따라서 조절할 필요가 있고, 열처리과정은 은 나노가 첨가된 본 발명에 의한 방사물이 의류에 침적 착상되어 착용 시 과도한 운동에 의한 땀에 젖거나 동절기의 기후변화, 반복 되풀이되는 세탁과정에서 의류의 질감이나 성질 등의 변형이 없게 하고 특히 침투 착상된 원적외선 방사물의 이탈을 저지하여 원적외선 및 음이온 방사로 항균, 멸균, 정전기 발생의 방지는 물론 원적외선 방사로 인한 유익한 기능성 의류를 얻게 된다,In the deposition process, the heat treatment temperature needs to be adjusted according to the health clothing, and the heat treatment process is carried out by the deposition of the silver nanoparticles added to the clothing by the deposition on the sweat caused by excessive exercise when worn or winter climate change, In the repeated washing process, there is no alteration of the texture or properties of clothing, and in particular, it prevents the detachment of the far-infrared radiation that is infiltrated and prevents the antibacterial, sterilization and static electricity generation by far-infrared and anion radiation, as well as the beneficial function of far-infrared radiation. You get clothing,

1 공정1 step

인체에 유익하면서 생체활동에 필수적 영향을 주는 철, 마그네슘, 나트륨, 칼슘, 칼륨, 규소 등을 함유하고 있는 알루미늄 실리케이트(알루미늄 실리케이트는 알루미나와 무수규산과의 화합물로서 통상 진흙형태의 바위속의 장석의 풍화에 의해 생기는 회, 백색 두 가지가 있다)를 600-800℃로 가열하여 건조한 다음 3000-3500메쉬로 분쇄하고, 안료, 도료 리놀륨 등에 사용되는 일라이트를 70:29.98∼29.99 중량%의 함량으로 혼합하는데 일라이트를 100℃로 건조한 다음 35-40㎛ 크기의 입자로 분쇄 하여 시료 1을 구성한다.Aluminum silicates containing iron, magnesium, sodium, calcium, potassium, and silicon, which are beneficial to the human body and have an essential effect on biological activity. (Aluminum silicate is a compound of alumina and silicic anhydride. It is usually weathered in feldspar in mud rock. Ash, white), which is heated to 600-800 ° C, dried, and then pulverized to 3000-3500 mesh, and the illite used for pigments, paint linoleum, etc. is mixed in an amount of 70: 29.98 to 29.99% by weight. Sample 1 is composed by drying the illite at 100 ° C. and then crushing it into particles having a size of 35-40 μm.

2 공정2 process

0.01∼0.02중량%의 은 나노를 첨가하기 위하여 은 나노 입자의 제조는 질산은 (AgNO3 ) 과 폴리비닐 피롤리돈(PVP)을 에틸렌글리콜(EG)과 혼합하여 교반 후 100-140℃로 가열하고 평상온도로 환원 시킨 다음 증류수를 첨가하고, 여과장치에서 세척하여 농축액을 조성하여 건조한 후, 시료2를 제조한다. 여기서,In order to add 0.01 to 0.02% by weight of silver nanoparticles, silver nanoparticles were prepared by mixing silver nitrate (AgNO 3 ) and polyvinyl pyrrolidone (PVP) with ethylene glycol (EG), followed by heating to 100-140 ° C. After reducing to normal temperature, distilled water was added, washed with a filtration device to form a concentrated liquid and dried, to prepare Sample 2. here,

※ PVP는 C6 H9 ON, 분자량 111.14의 비닐중합체 Pyrroliaone은 무색의 액체, 비중 1.04(25℃) 융점 13.5℃ 비점 214-215℃ 용도는 발열체(發熱體) 직물사상제(織物仕上濟) 분산제 등으로 사용됨.※ PVP is C 6 H 9 ON, vinyl polymer Pyrroliaone with molecular weight 111.14 is a colorless liquid, specific gravity 1.04 (25 ℃) melting point 13.5 ℃ boiling point 214-215 ℃ Use for heating element Textile dye dispersant Used as

※ EG : CH2 OHCH2 OH, 분자량 62.07 무색무취 비중 1.11336(20/20℃) 융점 -13℃ 비점 197.2℃, 인화점 111.1℃ 용도는 폴리에스텔 섬유원료, 부동액 용제, 글리세린의 대용, 내한 윤할제, 건조방지제, 계면활성제등※ EG: CH 2 OHCH 2 OH, Molecular Weight 62.07 Colorless, Odorless Specific Gravity 1.11336 (20/20 ℃) Melting Point -13 ℃ Boiling Point 197.2 ℃, Flash Point 111.1 ℃ Applications: Substitute polyester fiber, antifreeze solvent, glycerin, cold-resistant lubricant, Desiccant, surfactant, etc.

3 공정3 process

상기 공정에 의한 99.98∼99.99중량%의 시료1에 제 2공정에 의한 나노실버 0.01-0.02중량%를 첨가 혼합하여 본 발명에 의한 나노 원적외선 방사물을 제조한다.The nano far-infrared radiant according to the present invention is prepared by adding and mixing 0.01-0.02% by weight of the nanosilver according to the second step to 99.98 to 99.99% by weight of the sample 1 according to the above process.

상기 공정에 의하여 조성된 원적외선 방사물 70중량%에 유연제 30%를 첨가한 방사물 조성체에 의류 및 헬스복 등을 침적하여 100-120℃ 온도로 15-20분간 경과하면 상기한 본 발명에 의한 방사물이 의류에 침투 코팅되어져서 침착되어, 반복 되풀이하여 세탁하여도 탈취, 항균, 멸균 및 음이온 방출 효과가 그대로 유지되며 전술한 시험에 의한 효과를 얻을 수 있게 된다.The method according to the present invention described above is obtained when 15-20 minutes at 100-120 ° C. temperature is deposited by dipping clothing and a health clothing on the radiation composition to which the softening agent 30% is added to 70% by weight of the far-infrared radiation formed by the above process. Objects are infiltrated and coated with clothing, and the deodorizing, antibacterial, sterilizing and anion releasing effects are retained even after repeated washing, and the effect of the above test can be obtained.

Claims (1)

알루미늄 실리케이트를 600-800℃로 가열한 후 건조하여 3000-3500메쉬(45㎛) 로 분쇄하여 극 미세하게 한 70중량%에, 일라이트를 100℃ 에서 건조한 다음 35-40㎛ 크기의 입자로 분쇄한 29.98∼29.99중량%의 함량으로 혼합한 99.98∼99.99중량%의 시료에, 은나노 시료를 0.01-0.02중량% 혼합 조성하여 유연제를 첨가한 방사물에 의류를 침적하여 100-120℃ 온도로 15-20분간 가열하여 침착 코팅케 하는 나노 원적외선 방사물의 침착, 코팅방법In the deposition coating method of far-infrared radiation added with nano silver,

The aluminum silicate was heated to 600-800 ° C., dried and pulverized to 3000-3500 mesh (45 μm) to 70% by weight. The illite was dried at 100 ° C. and then pulverized to 35-40 μm particles. To 99.98 to 99.99% by weight of the sample, which was mixed at a content of 29.98 to 29.99% by weight, 0.01-0.02% by weight of the silver nano sample was mixed, and the clothes were immersed in the spinning material to which the softening agent was added. Deposition and coating method of nano-infrared radiation which is heated and deposited for 20 minutes

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020100025512A KR101003674B1 (en) | 2010-03-19 | 2010-03-19 | Deposition and Coating Method of Nano Far Infrared Radiation |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020100025512A KR101003674B1 (en) | 2010-03-19 | 2010-03-19 | Deposition and Coating Method of Nano Far Infrared Radiation |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR101003674B1 true KR101003674B1 (en) | 2010-12-24 |

Family

ID=43513307

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020100025512A KR101003674B1 (en) | 2010-03-19 | 2010-03-19 | Deposition and Coating Method of Nano Far Infrared Radiation |

Country Status (1)

| Country | Link |

|---|---|

| KR (1) | KR101003674B1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103639423A (en) * | 2013-12-27 | 2014-03-19 | 哈尔滨理工大学 | Nano-Ag-coated aluminum silicate nuclear shell particle, and preparation method and application thereof |

-

2010

- 2010-03-19 KR KR1020100025512A patent/KR101003674B1/en active IP Right Grant

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103639423A (en) * | 2013-12-27 | 2014-03-19 | 哈尔滨理工大学 | Nano-Ag-coated aluminum silicate nuclear shell particle, and preparation method and application thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111519341B (en) | Compound antiviral and antibacterial multifunctional PP, PE and PET non-woven fabric and preparation and application thereof | |

| Andra et al. | Emerging nanomaterials for antibacterial textile fabrication | |

| Thilagavathi et al. | Combined antimicrobial and aroma finishing treatment for cotton, using micro encapsulated geranium (Pelargonium graveolens L’Herit. Ex Ait.) leaves extract | |

| CN102704022B (en) | Health anion fiber | |

| CN107675292B (en) | A kind of nano-silver bamboo charcoal fiber and its Bactericidal underwear product | |

| CN106012510B (en) | Have anti-bacterial fibre, antibacterial textile of washability and preparation method thereof | |

| KR101003674B1 (en) | Deposition and Coating Method of Nano Far Infrared Radiation | |

| Ganesan et al. | Extraction of copper enriched seeds for healthcare textiles | |

| KR20060073796A (en) | Multi-functional nano-bio ceramic composition :l-bas and preparation thereof | |

| KR20030054074A (en) | Multi-Functional Fiber Containing Natural Magma-Stone Powder and A Manufacturing Process for the Same | |

| KR101869800B1 (en) | Manufacturing method for functional down clothes and functional down clothes manufactured by the same | |

| Sadeghi-Kiakhani et al. | Inorganic nanoparticles and natural dyes for production of antimicrobial and antioxidant wool fiber | |

| CN109837603A (en) | A kind of preparation method of sun-proof mosquito proof cool feeling fabric | |

| CN1451811A (en) | Preparing process and use of antibacterial nano silver fabric | |

| KR102184455B1 (en) | Method for depositing nano silver with excellent antibacterial power and objects to which the nano silver is deposited | |

| KR100299699B1 (en) | Aaaaa | |

| CN111021097A (en) | Preparation method of children's sports coat fabric | |

| KR100514976B1 (en) | Fiber article comprising natural pozzolan | |

| CN102691206B (en) | Tourmaline-containing cloth and production process thereof | |

| Chowdhury et al. | Nanomaterials for multifunctional textiles | |

| KR100755019B1 (en) | Antibiotic composition for fiber and cloth coated with the same | |

| KR101073179B1 (en) | The manufacturing method of the composition added natural minenals and The manufacturing method of the funtionnal yarn used that | |

| WO2016009095A1 (en) | Functional textile fabrics | |

| KR101076672B1 (en) | The manufacturing method of functional textile | |

| KR200392113Y1 (en) | Nanosilver particles impregnated anti-bacterial textile and anti-bacterial socks, anti-bacterial cushiony products or inner wear using thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| A302 | Request for accelerated examination | ||

| E902 | Notification of reason for refusal | ||

| E902 | Notification of reason for refusal | ||

| E701 | Decision to grant or registration of patent right | ||

| GRNT | Written decision to grant | ||

| FPAY | Annual fee payment |

Payment date: 20140303 Year of fee payment: 4 |

|

| FPAY | Annual fee payment |

Payment date: 20150212 Year of fee payment: 5 |

|

| FPAY | Annual fee payment |

Payment date: 20161227 Year of fee payment: 7 |

|

| FPAY | Annual fee payment |

Payment date: 20170926 Year of fee payment: 8 |

|

| FPAY | Annual fee payment |

Payment date: 20180918 Year of fee payment: 9 |

|

| FPAY | Annual fee payment |

Payment date: 20191216 Year of fee payment: 10 |