JP7209309B2 - Degassing, heating, and high-pressure processing methods for food - Google Patents

Degassing, heating, and high-pressure processing methods for food Download PDFInfo

- Publication number

- JP7209309B2 JP7209309B2 JP2021111234A JP2021111234A JP7209309B2 JP 7209309 B2 JP7209309 B2 JP 7209309B2 JP 2021111234 A JP2021111234 A JP 2021111234A JP 2021111234 A JP2021111234 A JP 2021111234A JP 7209309 B2 JP7209309 B2 JP 7209309B2

- Authority

- JP

- Japan

- Prior art keywords

- treatment

- sample

- heating

- pressure

- pickled

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A40/00—Adaptation technologies in agriculture, forestry, livestock or agroalimentary production

- Y02A40/90—Adaptation technologies in agriculture, forestry, livestock or agroalimentary production in food processing or handling, e.g. food conservation

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P60/00—Technologies relating to agriculture, livestock or agroalimentary industries

- Y02P60/80—Food processing, e.g. use of renewable energies or variable speed drives in handling, conveying or stacking

- Y02P60/85—Food storage or conservation, e.g. cooling or drying

Landscapes

- General Preparation And Processing Of Foods (AREA)

- Preparation Of Fruits And Vegetables (AREA)

- Beans For Foods Or Fodder (AREA)

- Meat, Egg Or Seafood Products (AREA)

- Storage Of Fruits Or Vegetables (AREA)

- Alcoholic Beverages (AREA)

- Food Preservation Except Freezing, Refrigeration, And Drying (AREA)

Description

本発明は食品に対する脱気・加熱・高圧処理方法に関する。 The present invention relates to a method for degassing, heating, and high-pressure treatment of food.

特許文献1には、調味料の製造方法として、タンパク質分解酵素を含むか添加された鰯や生牡蠣などの食材を40℃~60℃の温度域で50MPa~100MPaの圧力下で保持することで、微生物の増殖を抑制しながら酵素の作用を促進して調味料の熟成期間を短縮する方法が開示されている。

In

特許文献2には、かぶら寿しなどの魚肉加工製品の製造方法として、ブリなどの魚肉材料に100MPa以下の比較的低い圧力を掛けることで、魚肉材料の組織を破壊し、塩漬などの調味に要する期間を短縮する技術が開示されている。

In

非特許文献1には、30kg/cm2の圧力で密閉される含浸装置を用いた山菜への機能性糖類(5%トレハロースと5%サイクロデキストリン)の注入方法について記載されている。

Non-Patent

非特許文献2、3には、木材に硬化剤を注入する際に利用されていた含浸法を食品の浅漬けに応用することで、野菜(ナス、キュウリなど)の浅漬けを短時間で製造する内容が記載されている。

In

高圧処理によって、短時間のうちに食品の内部まで調味液や酵素を含浸させることができ、また、微生物の増殖を抑制しながら酵素の作用を促進するため、呈味成分の増加や液化処理などが期待できる。

しかしながら、高圧処理を従来の食品の製法に併用する場合は当該従来方法の条件との兼ね合いがあり、また同一の製法であっても個々の食品ごとに含有成分が異なるため、同一の高圧処理の条件で同等の効果が期待できるものではなく、高圧処理を適用する製法及び個々の食品ごとに最適な処理条件が存在する。

High-pressure treatment makes it possible to impregnate the interior of food with liquid seasonings and enzymes in a short period of time. can be expected.

However, when high-pressure treatment is used in combination with conventional food manufacturing methods, there is a balance with the conditions of the conventional method, and even if the same manufacturing method is used, the ingredients contained in each individual food are different. Equivalent effects cannot be expected under different conditions, and there are optimal treatment conditions for each food product and manufacturing method that applies high-pressure treatment.

リンゴ、ウメ、アンズなどの「果実のシロップ漬」にあっては、食感を維持しながら殺菌効果を高めて保存期間を長くしたいという要望がある。 In the case of "fruits pickled in syrup" such as apples, plums and apricots, there is a demand to increase the sterilization effect while maintaining the texture and to extend the storage period.

上記課題を解決すべく、本発明に係る食品の製造に適用する脱気・加熱・高圧処理方法は、前記食品は、和梨またはぶどうのシロップ漬けであり、前記和梨またはぶどうをシロップとともにポリエチレン袋などの容器内に入れて脱気して前記容器内に和梨またはぶどうとシロップのみを保持し、このポリエチレン袋などの容器内に和梨またはぶどうを入れた状態で、80MPa以上300MPa以下、且つ40℃以上70℃以下で15分~60分処理する。 In order to solve the above problems, the degassing, heating, and high-pressure treatment method applied to the production of food according to the present invention is that the food is Japanese pears or grapes pickled in syrup, and the Japanese pears or grapes are Put it in a container such as a bag and deaerate, hold only Japanese pears or grapes and syrup in the container, and put the Japanese pears or grapes in a container such as a polyethylene bag at 80 MPa or more and 300 MPa or less, Then, it is treated at 40° C. or higher and 70° C. or lower for 15 to 60 minutes.

本発明に係る脱気・加熱・高圧処理方法によれば、遊離アミノ酸、糖などの旨味(呈味成分)成分を短時間のうちに増加させることができ、特に野菜の奈良漬を本発明方法で製造した場合には、従来1年から1年半かかっていた製造期間を数日に短縮することができる。 According to the degassing/heating/high-pressure treatment method according to the present invention, umami (taste component) components such as free amino acids and sugars can be increased in a short period of time. , the manufacturing period, which used to take one to one and a half years, can be shortened to several days.

また、リンゴ、ウメ、アンズなどの果実のシロップ漬の製造に本発明方法を適用した場合には、殺菌効果を高め保存期間を長くすることができる。 Moreover, when the method of the present invention is applied to the production of syrup-pickled fruits such as apples, plums and apricots, the sterilization effect can be enhanced and the storage period can be extended.

また、畜肉の漬物を本発明方法で製造した場合には、上記の他に肉の食感(柔らかさ)が向上し、豆腐の漬物を本発明方法で製造した場合には、舌でつぶせる程度の硬さでクリームチーズのような食感が得られ且つ遊離アミノ酸を増加させることができ、キノコ加工品を本発明方法で製造した場合には、今まで乾物製法でしかできなかったグアニル酸の増加を水煮においても可能とした。 In addition, when pickled livestock meat is produced by the method of the present invention, the texture (softness) of the meat is improved in addition to the above, and when pickled tofu is produced by the method of the present invention, it can be crushed with the tongue. It is possible to obtain a cream cheese-like texture with a hardness of 1, and to increase free amino acids. The increase was made possible even in boiling water.

更に、魚介類の粕漬けおよびソフトスモーク製品を本発明方法で製造した場合には、高圧加温処理の効果だけでなく、酒粕に含まれるアルコールや薫煙による殺菌効果との相乗効果によって菌の増殖などが抑制される。 Furthermore, when seafood lees pickles and soft smoked products are produced by the method of the present invention, not only the effect of the high pressure heating treatment but also the synergistic effect of the sterilization effect of the alcohol and smoke contained in the sake lees causes the growth of bacteria. etc. is suppressed.

以下に本発明を実施するための最良の形態を、「野菜の奈良漬」、「野菜の浅漬」、「野菜の生醤油漬」、「果実のシロップ漬」、「畜肉の漬物」、「豆腐の漬物」、「キノコの加工品」、これらの追加実験および魚介類の粕漬けとソフトスモークの製造に分けて説明する。 The best mode for carrying out the present invention is described below as ``narazuke of vegetables'', ``lightly pickled vegetables'', ``raw soy sauce pickled vegetables'', ``fruits pickled in syrup'', ``pickled meat'', and ``tofu. pickles,” “processed mushroom products,” additional experiments on these, and production of pickled fish and shellfish in sake lees and soft smoke.

野菜の奈良漬

1.実験方法

1-1 試料の調整

野菜として、ナス、ダイコン及びウリを用意し、天日乾燥や脱気処理によって植物組織内部の空気を抜き、粕床の成分の浸透が促進されるようにし、特に表面がツルツルのナスについては、剣山で多数の穴をあけるか、沸騰水中で一度煮て冷やす(ブランチング処理)ことで粕床の成分の浸透を速めた。

Narazuke of

1-2 加工処理

ナスについては、粕床を塗りポリエチレン袋に入れた後に脱気し、このポリエチレン袋に入れた状態で、100MPa、70℃、60時間の条件で加熱・高圧処理を施した。

ダイコンについては、粕床を塗りポリエチレン袋に入れた後に脱気し、このポリエチレン袋に入れた状態で、100MPa、70℃、18時間の条件で加熱・高圧処理を施した。

ウリについては、加熱処理で短期に製造した粕床を用いた。この粕を塗りポリエチレン袋に入れた後に脱気し、次いでポリエチレン袋に入れた状態で、100MPa、50℃、60時間の条件で加熱・高圧処理を施した。

1-2 Processing The eggplants were coated with a lees bed and placed in a polyethylene bag, degassed, and then placed in the polyethylene bag and subjected to heat and high pressure treatment under conditions of 100 MPa, 70° C., and 60 hours.

The radish was coated with a lees bed and placed in a polyethylene bag, then degassed. While placed in the polyethylene bag, it was subjected to heating and high pressure treatment under the conditions of 100 MPa, 70° C., and 18 hours.

For cucumbers, we used the lees bed that was produced in a short period of time by heat treatment. After applying this dregs and placing it in a polyethylene bag, it was degassed, and then, while it was placed in a polyethylene bag, it was subjected to heat and high pressure treatment under the conditions of 100 MPa, 50° C., and 60 hours.

粕床を短期間で製造するには、10%の砂糖と5%の食塩を添加し、70℃以上の高温で数時間~数日間処理し、メイラード反応を促進させた。通常の粕床の調製には長期間を要するが、本実施例の方法によれば奈良漬粕床独特の風味を有する促成粕床を数時間~数日で作ることができる。

上記の促成粕床を使用した場合には、GC-MSで分析すると、特有な成分(図1の枠で囲った成分)が検出されるので、従来品との判別が容易である。

In order to produce the lees bed in a short period of time, 10% sugar and 5% salt were added and treated at a high temperature of 70° C. or higher for several hours to several days to accelerate the Maillard reaction. It takes a long time to prepare ordinary lees bed, but according to the method of this embodiment, a forced lees bed having a unique flavor of Narazuke lees bed can be produced in several hours to several days.

When the forged lees bed is used, GC-MS analysis detects specific components (the components enclosed in the frame in FIG. 1), making it easy to distinguish from the conventional product.

また以下の(表1)は粕を加熱・高圧処理した際のバチルス胞子の殺菌効果を示すもの

であり、この表から100MPa、65℃以上、60時間の条件でバチルス胞子を検出しなくなることが分かる。

In addition, the following (Table 1) shows the sterilization effect of Bacillus spores when the dregs are heated and high pressure treated, and from this table, Bacillus spores can no longer be detected under the conditions of 100 MPa, 65 ° C. or higher, and 60 hours. I understand.

2. 試験結果・考察

図2は従来の製法と本発明の加熱・高圧処理方法を比較した図であり、本発明方法では、塩、ミリン入りの吟醸粕を用いて1工程で塩漬する方法と、塩、ミリン入りの酒粕で塩漬した後、吟醸粕に漬け込む2工程で行った。何れの場合も伝統的手法の製造期間(1年から1年半)を大幅に短縮できた。

2. Test results and discussion Fig. 2 is a diagram comparing the conventional method and the heat and high pressure treatment method of the present invention. In the method of the present invention, ginjo lees containing salt and mirin are salted in one step. After pickling in sake lees containing salt and mirin, it was pickled in ginjo lees. In both cases, the production period (one year to one and a half years) of the traditional method could be greatly shortened.

図3は上記の加熱・高圧処理で製造したナス、ダイコン及びウリの写真であり、何れの奈良漬も味、香り、食感が従来の伝統的手法で製造した奈良漬と遜色がなかった。 Fig. 3 is a photograph of the eggplant, radish and gourd produced by the above heat and high pressure treatment, and all narazuke were comparable in taste, aroma and texture to narazuke produced by conventional traditional methods.

以下の(表2)は加熱・高圧処理で製造したナスの奈良漬の一般生菌数及び酵母数の測定結果を示し、この表から本発明方法によって製造した奈良漬は実質的に無菌であることが分かる。 The following (Table 2) shows the measurement results of the number of viable bacteria and the number of yeasts in Narazuke of eggplant produced by heat and high pressure treatment. From this table, Narazuke produced by the method of the present invention is substantially sterile. I understand.

図4は加熱・高圧処理の殺菌原理を説明した図であり、常温では芽胞菌の一部しか発芽しないが、加熱では全ての芽胞菌が発芽する。そして、一旦発芽した細菌は途中で止まることがなく且つ発芽した菌は50℃以上の加熱処理で死滅する。

従来の常温常圧処理では最終的に高温で殺菌しなければならなかったが、加熱・高圧処理の場合は、高温処理が不要のため、殺菌処理に伴う食品の品質劣化を防止することができる。

FIG. 4 is a diagram illustrating the principle of sterilization by heating and high-pressure treatment. At room temperature, only a portion of spore-forming bacteria germinate, but with heating, all spore-forming bacteria germinate. Once germinated bacteria do not stop on the way, and the germinated bacteria are killed by heat treatment at 50° C. or higher.

Conventional normal temperature and pressure treatment requires final sterilization at high temperature, but in the case of heat and high pressure treatment, high temperature treatment is not required, so it is possible to prevent food quality deterioration that accompanies sterilization. .

3.100MPa以上の処理での効果

前記段落(0025)以降に記載した野菜の奈良漬けの製法を高圧処理条件の圧力条件のみ100~300MPa範囲で変えて検討したところ、表3に示す結果となり、本発明が100~300MPaの圧力範囲でも有効であることを確認した。

3. Effect of treatment at 100 MPa or more When the vegetable narazuke manufacturing method described in paragraph (0025) and after was examined by changing only the pressure condition of the high pressure treatment condition in the range of 100 to 300 MPa, the results shown in Table 3 were obtained. It was confirmed that the invention is also effective in the pressure range of 100-300 MPa.

咀嚼困難者用野菜の浅漬

1.実験方法

1-1 試料の調整

野菜として、ニンジン、ナス及びダイコンを用意し、厚さ約1cmにカットした。

Lightly Pickled Vegetables for People with Difficulties in

1-2 加工処理

上記のカットした野菜を調味液(市販の浅漬けの素)およびペクチナーゼとともにポリエチレン袋に入れた後に脱気引きし、このポリエチレン袋に入れた状態で、100MPa、50℃、15分の条件で加熱・高圧処理を施した。

この後、各野菜に0.1MPa、3~15時間の常圧加熱理を施した。具体的にはニンジンについては15時間、ナスについては3時間、ダイコンについては3時間及び5時間の二種類の処理を施した。

更にその後、沸騰水中で5分間加熱処理することで、酵素を失活させた。

1-2 Processing Treatment The above cut vegetables were placed in a polyethylene bag together with a seasoning liquid (commercially available lightly pickled base) and pectinase, degassed, and placed in the polyethylene bag. Heating and high-pressure treatment were performed under conditions of minutes.

After that, each vegetable was subjected to normal pressure heating at 0.1 MPa for 3 to 15 hours. Specifically, carrots were treated for 15 hours, eggplants for 3 hours, and radishes for 3 hours and 5 hours.

After that, the enzyme was deactivated by heating in boiling water for 5 minutes.

2. 試験結果・考察

図5は上記の本発明方法に係る加熱・高圧処理によって製造した野菜の浅漬の写真である。

図5に示した野菜は、表4に示す通り、いずれも咀嚼困難者でも喫食可能な口溶する程に極めて柔らかく、しかも殺菌効果も確認でき長期保存が可能であった。

2. Test Results and Discussion FIG. 5 is a photograph of lightly pickled vegetables produced by the heat and high pressure treatment according to the method of the present invention.

As shown in Table 4, all of the vegetables shown in FIG. 5 were extremely soft enough to melt in the mouth so that even those with difficulty chewing could eat them.

3.100MPa以上の処理での効果

前記段落(0037)以降に記載した野菜の浅漬けの製法を高圧処理条件の圧力条件のみ100~300MPa範囲で変えて検討したところ、表4に示す結果となり、本発明が100~300MPaの圧力範囲でも有効であることを確認した。

3. Effect of treatment at 100 MPa or more When the method for producing lightly pickled vegetables described in paragraph (0037) and after was examined by changing only the pressure condition of the high pressure treatment condition in the range of 100 to 300 MPa, the results shown in Table 4 were obtained. It was confirmed that the present invention is effective even in the pressure range of 100-300 MPa.

野菜の生醤油漬

1.実験方法

1-1 試料の調整

野菜として、ニンジン、ダイコン、キュウリ、ナス、ゴボウ、ナガイモ及びレンコンを用意し、厚さ0.5~1cmにカットした。

1-2 加工処理

図6に示すように、厚さ0.5~1cmにカットした上記野菜を日干する。この工程により水分が除去され、調味液(生醤油オリ)が浸透しやすくなる。

次いで、上記のカットした野菜を調味液(生醤油オリ)とともにポリエチレン袋に入れた後に脱気引きし、このポリエチレン袋に入れた状態で、100MPa、50℃、20分の条件で脱気・加熱・高圧処理を施した。

図7は、0.5cm厚に切った天日干しダイコンと1cm厚に切った天日干しダイコンの脱気・加熱・高圧処理の条件を変化させた場合の、処理直後と翌日の、色調及び塩分を測定した結果を示すグラフである。このグラフから、本発明方法によって、調味液(生醤油オリ)がダイコンに容易に浸透することが分かる。

また図8は、前記ダイコンを含む各種野菜について脱気・加熱・高圧処理により調味液(生醤油オリ)を浸透させた結果を示すグラフである。このグラフから、本発明方法はダイコン以外にも有効であることが分かる。

Vegetables Pickled in

1-2 Processing As shown in FIG. 6, the above vegetables cut into 0.5-1 cm thickness are dried in the sun. This process removes moisture, making it easier for the seasoning liquid (raw soy sauce) to permeate.

Next, the above-mentioned cut vegetables were placed in a polyethylene bag together with a seasoning liquid (raw soy sauce), degassed, and degassed and heated under the conditions of 100 MPa, 50° C., and 20 minutes while being placed in the polyethylene bag.・High pressure treatment is applied.

Figure 7 shows the color tone and salt content of the sun-dried radish cut into 0.5 cm thickness and the sun-dried radish cut into 1 cm thickness, immediately after the treatment and the next day, when the conditions of degassing, heating, and high pressure treatment are changed. It is a graph which shows the measured result. From this graph, it can be seen that the method of the present invention allows the seasoning liquid (raw soy sauce) to easily permeate the radish.

FIG. 8 is a graph showing the results of infiltration of seasoning liquid (raw soy sauce) into various vegetables including the radish by degassing, heating, and high-pressure treatment. From this graph, it can be seen that the method of the present invention is effective for other than radish.

2. 試験結果・考察

図6、図7及び図8に示すように、野菜に調味液の色調および塩分が均一に浸透し、製造期間も従来の2週間程度から20分まで大幅に短縮できた。しかも、表5に示すように殺菌効果も確認でき、長期保存が可能であった。

2. Test results and discussion As shown in Figures 6, 7 and 8, the color tone and salt content of the seasoning liquid permeated the vegetables uniformly, and the production period was greatly shortened from about two weeks to 20 minutes. . Moreover, as shown in Table 5, a bactericidal effect was confirmed, and long-term storage was possible.

3.ダイコンの形状別による比較例

上記とは別に調味液の浸透に関し、特にダイコンについて検討した。

材料としては石川農研産のフクホマレを3cm圧の輪切りにし、これを外観写真用と、塩分・色差測定用に分け、調味液としては直源醤油(株)製の濃口醤油を用い、濃度は20%、40%、60%、80%、100%とし、加熱・高圧処理としては、100MPa、30℃または50℃、24時間とした。

3. Comparative Examples by Different Shapes of Radish In addition to the above, the permeation of the seasoning liquid was investigated, especially the radish.

As a material, Fukuhomare produced by Ishikawa Agricultural Research Institute was cut into round slices with a thickness of 3 cm. 20%, 40%, 60%, 80% and 100%, and the heat/high pressure treatment was 100 MPa, 30° C. or 50° C. for 24 hours.

図9はダイコンへの醤油浸透効果を示す写真であり、図10はダイコンへの醤油浸透効果を比較したグラフであり、この写真及びグラフから処理温度が30℃から50℃に高くなり、且つ調味液の濃度を濃くすることで、内外の浸透効果が均一化されることが分かる。しかし、塩濃度が高いために漬け物食品としては適さない。 FIG. 9 is a photograph showing the effect of soy sauce permeation into radish, and FIG. 10 is a graph comparing the effect of soy sauce permeation into radish. It can be seen that increasing the concentration of the liquid equalizes the permeation effect inside and outside. However, it is not suitable as a pickled food due to its high salt concentration.

また図11はダイコンに切れ目を入れた場合の効果を示す写真とグラフであり、この図11から切れ目を入れることで、外側と内側の彩度の差が小さくなり、浸透性が向上することが分かる。しかし、この方法でも十分に内部まで調味液が浸透しなかった。 FIG. 11 is a photograph and a graph showing the effect of making cuts in the radish. By making cuts in FIG. I understand. However, even with this method, the liquid seasoning did not sufficiently permeate into the interior.

4.100MPa以上の処理での効果

前記段落(0038)以降に記載した野菜の生醤油漬けの製法を高圧処理条件の圧力条件のみ100~300MPa範囲で変えて検討したところ、表5に示す結果となり、本発明が100~300MPaの圧力範囲でも有効であることを確認した。

4. Effect of treatment at 100 MPa or more When the method for pickling vegetables in raw soy sauce described in paragraph (0038) and after was examined by changing only the pressure condition of the high pressure treatment condition in the range of 100 to 300 MPa, the results are shown in Table 5. , confirmed that the present invention is effective even in the pressure range of 100 to 300 MPa.

果実のシロップ漬

1.実験方法

1-1 試料の調整

果実としてリンゴ(シナノゴールドなど)、アンズ(信山丸など)、ウメ(石川1号など)を用意した。

Syrup Pickling of

1-2 加工処理

リンゴ、アンズ、ウメのそれぞれをシロップとともにポリエチレン袋に入れた後に脱気し、このポリエチレン袋に入れた状態で、100MPa、65℃~75℃、30分~60分の条件で加熱・高圧処理を施した。

1-2 Processing Apples, apricots, and plums were each placed in a polyethylene bag together with syrup, deaerated, and placed in the polyethylene bag under the conditions of 100 MPa, 65°C to 75°C, and 30 minutes to 60 minutes. It was subjected to heat and high pressure treatment.

2. 試験結果・考察

2-1 自滅的発芽殺菌効果

リンゴシロップ漬素材に107~108CFU/gのBacillus subtilis芽胞を接種し、各処理後に自滅的発芽殺菌効果を検討した。結果を図12に示す。

この図12から、脱気・加熱・高圧処理した場合は常温常圧または加熱常圧処理に比べ殺菌効果が高く、具体的には2log(CFU/g)程度の殺菌効果があることが分かる。特にシロップの濃度は薄いほど殺菌効果が高くなることを示している。

2. Test results and discussion 2-1 Self-defeating

From FIG. 12, it can be seen that the degassing/heating/high pressure treatment has a higher sterilizing effect than the normal temperature/normal pressure treatment or the heating/normal pressure treatment, and specifically has a sterilizing effect of about 2 log (CFU/g). In particular, the lower the syrup concentration, the higher the bactericidal effect.

図13はシロップの代替品として高甘味度甘味料であるスクラロース水溶液を用い、これに酸味料(フィチン酸)を添加した場合の自発的発芽誘導殺菌効果の結果を示すグラフであり、このグラフから、酸味料を添加した低濃度の甘味料を用い、脱気・加熱・高圧処理することで大幅に殺菌効果が高まることが分かる。 FIG. 13 is a graph showing the results of the spontaneous germination-inducing bactericidal effect when an aqueous solution of sucralose, which is a high-intensity sweetener, is used as a substitute for syrup, and an acidulant (phytic acid) is added thereto. , It can be seen that the sterilization effect is greatly enhanced by using a low-concentration sweetener with an added acidulant and degassing, heating, and high-pressure treatment.

2-2.リンゴに対する脱気・加熱・高圧処理

リンゴの種類は、つがる、秋映、シナノスイート、シナノゴールド及びふじの5種類を用

意した。

上記の5種類に対し、100MPa、65℃、30分間の脱気・加熱・高圧処理を施し、果汁とシロップの糖度及び酸度を比較した。結果を図14に示す。

図14から糖度については加熱・高圧処理の温度が高いほど果汁とシロップの糖度が近くなり、酸度については品種によって影響されることが分かる。

2-2. Degassing, Heating, and High-Pressure Treatment of Apples Five types of apples were prepared: Tsugaru, Shuuei, Shinanosweet, Shinanogold, and Fuji.

The above five types were subjected to degassing, heating and high pressure treatment at 100 MPa, 65° C. for 30 minutes, and the sugar content and acidity of fruit juice and syrup were compared. The results are shown in FIG.

From FIG. 14, it can be seen that the higher the temperature of the heating/high-pressure treatment, the closer the sugar content of the fruit juice and the syrup, and that the acidity is affected by the variety.

表6はリンゴの脱気・加熱・高圧処理の製造温度と保存期間を変化させた場合の菌の検出結果を示すグラフであり、表7は表6の保存期間が0ヶ月の場合、表8は保存期間が4ヶ月の場合を示す。これらの表から常温での保存は3ヶ月、好ましくは2ヶ月が安全と考えられる。 Table 6 is a graph showing the results of bacteria detection when the production temperature and storage period of apple degassing, heating, and high pressure treatment are changed. indicates that the storage period is 4 months. From these tables, storage at room temperature for 3 months, preferably 2 months, is considered safe.

また、図15は表6の4ヶ月(製造温度65℃、保存温度25℃)の場合の「果実」側での菌の状態を示す写真、図16は表6の4ヶ月(製造温度65℃、保存温度25℃)の場合の「シロップ」側での菌の状態を示す写真、図17は表6の4ヶ月(製造温度70℃、保存温度25℃)の場合の「シロップ」側での菌の状態を示す写真である。

In addition, FIG. 15 is a photograph showing the state of bacteria on the “fruit” side in the case of 4 months in Table 6 (manufacturing temperature 65 ° C.,

2-3.硬度向上(保持)

ふじとシナノゴールドに対し、硬度を向上させるため乳酸カルシウムを添加したところ、良好な結果が得られた。

2-3. Hardness improvement (retention)

Calcium lactate was added to Fuji and Shinano Gold to improve hardness, and good results were obtained.

2-4.保存性

表9は本発明方法の加熱・高圧処理を施したリンゴを5℃と常温(25℃)で保存した場合の、微生物の検出結果を示す表である。

2-4. Preservability Table 9 is a table showing the detection results of microorganisms when apples subjected to heat and high pressure treatment according to the method of the present invention were preserved at 5°C and room temperature (25°C).

この表9から、5℃で保存した場合は6ヶ月近く微生物が繁殖しないことが分かる。また常温で保存しても3ヶ月間は確保される。また、表9からは5℃で保存したリンゴは6ヶ月後も殆ど外観が変化しないことが分かる。 From Table 9, it can be seen that microorganisms do not propagate for nearly 6 months when stored at 5°C. In addition, even if it is stored at room temperature, it is ensured for 3 months. Moreover, it can be seen from Table 9 that the apples stored at 5°C show almost no change in appearance even after 6 months.

2-5.アンズに対する脱気・加熱・高圧処理

アンズと40%シロップを脱気包装後、100MPa、65~75℃、30~60分の脱気・加熱・高圧処理を行った。その結果、図18に示すように生の食感や、生の風味を持ったシロップ漬が得られた。

冷凍したアンズとホワイトリカーを合わせて、100MPa、65℃、30~120分の脱気・加熱・高圧処理を行った。その結果、図19に示すように高い有機酸抽出効果により、アンズ風味のリキュールが得られた。

表10はアンズ(品種:平和)のシロップ漬の殺菌効果を示すものである。この表から、本発明方法の脱気・加熱・高圧処理法はオートクレーブ処理と同程度の殺菌効果があることが分かる。

2-5. Degassing/heating/high-pressure treatment for apricots After degassing and packaging apricots and 40% syrup, they were subjected to degassing/heating/high pressure treatment at 100 MPa at 65-75°C for 30-60 minutes. As a result, as shown in FIG. 18, syrup pickles with raw texture and raw flavor were obtained.

The frozen apricots and white liquor were combined and subjected to degassing, heating, and high-pressure treatment at 100 MPa, 65° C., and 30 to 120 minutes. As a result, as shown in FIG. 19, an apricot-flavored liqueur was obtained due to the high organic acid extraction effect.

Table 10 shows the bactericidal effect of apricots (cultivar: Heiwa) pickled in syrup. From this table, it can be seen that the degassing/heating/high-pressure treatment method of the present invention has a sterilization effect equivalent to that of the autoclave treatment.

表11はアンズシロップ漬の保存期間0カ月の場合の菌数のデータであり、表12は保存試験の結果を表す表である。 Table 11 shows data on the number of bacteria in apricot syrup soaked for 0 months, and Table 12 shows the results of the storage test.

アンズ及びウメの脱気・加熱・高圧処理したシロップ漬に対しシアン化合物の分析を行った。結果は図20に示すように、果肉中のシアン化合物は未加工原料に比べてほとんど増加していなかった。

また、図21はアンズシロップ漬の写真である。

Degassed, heated, and high-pressure-treated apricots and plums pickled in syrup were analyzed for cyanide. As a result, as shown in FIG. 20, cyanide in the pulp was hardly increased compared to the unprocessed raw material.

Moreover, FIG. 21 is a photograph of pickled apricots in syrup.

2-6.ウメのシロップ漬

図22はウメのシロップ漬の一例を示す図であり、この実施例にあっては、急速冷凍した青ウメまたは黄熟ウメを材量とし、この冷凍ウメの芯の部分を刳り抜く穴あけ処理を行い、次いでブランチング水晒しし、この後、加熱・高圧処理を行う。加熱・高圧処理の条件は、100MPa、65℃、30分とする。この後、常圧、50℃、40時間静置し果実とシロップの味を均一にした。

2-6. Plum pickled in syrup Fig. 22 is a diagram showing an example of plum pickled in syrup. The part is hollowed out, followed by blanching water exposure, followed by heating and high pressure treatment. The conditions for the heating/high pressure treatment are 100 MPa, 65° C., and 30 minutes. After that, it was allowed to stand at normal pressure at 50° C. for 40 hours to make the flavors of the fruit and syrup uniform.

表13は加熱・高圧処理を行なわない生ウメの保存試験の結果を示す表であり、表14は加熱・高圧処理を行なったシロップ漬けのウメの保存試験の結果(0ヶ月)を示す表であり、表15は加熱・高圧処理を行なったシロップ漬けのウメの保存試験の結果(1ヶ月)を示す表であり、表16は加熱・高圧処理を行なったシロップ漬けのウメの保存試験の結果(2ヶ月)を示す表であり、表17は加熱・高圧処理を行なったシロップ漬けのウメの保存試験の結果(3ヶ月)を示す表であり、表18は加熱・高圧処理を行なったシロップ漬けのウメの保存試験の結果(4ヶ月)を示す表である。 Table 13 is a table showing the results of a storage test of raw plums not subjected to heat and high pressure treatment, and Table 14 is a table showing the results of a storage test (0 months) of plums soaked in syrup that were subjected to heat and high pressure treatment. Table 15 is a table showing the results (one month) of storage tests of plums soaked in syrup that were subjected to heat and high pressure treatment, and Table 16 is the results of storage tests of plums soaked in syrup that were subjected to heat and high pressure treatment. (2 months), Table 17 is a table showing the results of a storage test (3 months) of plums soaked in syrup subjected to heat and high pressure treatment, and Table 18 is a table showing syrup subjected to heat and high pressure treatment. It is a table|surface which shows the result (4 months) of the preservation|save test of the pickled plum.

また図23は、5℃で4ヶ月保存したウメシロップ漬けの写真、図24は25℃で4ヶ月保存したウメシロップ漬けの写真である。 FIG. 23 is a photograph of plum syrup-preserved at 5° C. for 4 months, and FIG. 24 is a photograph of plum syrup-preserved at 25° C. for 4 months.

図25は穴あけ加工したウメと穴あけ加工しないウメのシロップ漬け後の形状を比較した写真であり、穴あけ処理することで、見栄えの良いシロップ漬が得られる。 FIG. 25 is a photograph showing a comparison of the shapes of plums that have been punched and those that have not been punched after being pickled in syrup.

2-5.和ナシのシロップ漬

加熱・高圧処理の条件は、100MPa、65℃、30分とする。この後、常圧、50℃、40時間静置し果実とシロップの味を均一にした。

図26は上記の製造方法を適用して製造した和ナシのシロップ漬の写真である。さらに、表19で示す通り、本発明で行った和ナシのシロップ漬は、殺菌効果が向上した。

2-5. The conditions for heating and high-pressure treatment of Japanese pears in syrup are 100 MPa, 65° C., and 30 minutes. After that, it was allowed to stand at normal pressure at 50° C. for 40 hours to make the flavors of the fruit and syrup uniform.

FIG. 26 is a photograph of Japanese pears pickled in syrup produced by applying the above production method. Furthermore, as shown in Table 19, the sterilization effect of Japanese pears soaked in syrup according to the present invention was improved.

3.100MPa以上の処理での効果

前記段落(0049)以降に記載した果実のシロップ漬製法を高圧処理条件の圧力条件のみ100~300MPa範囲で変えて検討したところ、表19に示す結果となり、本発明が100~300MPaの圧力範囲でも有効であることを確認した。

3. Effect of treatment at 100 MPa or more When the fruit syrup production method described in paragraph (0049) and after was examined by changing only the pressure condition of the high pressure treatment condition in the range of 100 to 300 MPa, the results shown in Table 19 were obtained. It was confirmed that the invention is also effective in the pressure range of 100-300 MPa.

ウメ酒

上記ではウメをシロップ漬けすることを説明したが、本発明はウメ酒を製造する場合にも応用できる。

即ち、従来はウメ、砂糖、酒の3種の材料を混合して、常温常圧で72時間(3日間)処理し、その後3ヶ月程度熟成させていたが、本発明方法によれば、図27に示すように

、ウメと砂糖をパックに入れ、脱気・加熱・高圧処理(100MPa、50℃、72時間)することでエキスが抽出され、これを酒と混合することでウメ酒ができる。

ウメと砂糖の割合、処理条件は、例えばウメ(果肉)100gに対し砂糖を100~300g、圧力は100MPa以上、加熱温度は35~65℃、高圧処理時間は24~72時間とするのが好ましい。

結果は、図28-1、図28-2、図28-3図28-4、図29、図30に示すように、従来法(72時間)では、ウメのエキス(酸、ポリフェノール)は十分に抽出されていないが、本発明法(72時間)ではかなり抽出できている。同じく、熟成の目安であるショ糖の分解は、従来法ではほとんど起きていないが、中高圧法ではかなり進んでいる。更に色(b*値、褐色の指標)は、従来法より中高圧法の方が濃い。本発明法は1ヶ月熟成させると、従来法で3ヶ月以上熟成させたものと、ほぼ同等の色の濃さになることが分かる。

このように本発明方法により梅酒の熟成が早く進む理由は、ウメからエキス(酸、ポリフェノール)や熟成を促進させる酵素(糖分解酵素(インベルターゼ))が迅速に抽出され、加熱・高圧圧処理下では、糖の分解が早く進行するためである。

Plum wine While the above has described pickling plums in syrup, the present invention can also be applied to the production of plum wine.

That is, conventionally, three ingredients of plum, sugar, and sake are mixed, treated at normal temperature and pressure for 72 hours (3 days), and then aged for about 3 months. As shown in Figure 27, ume and sugar are put in a pack, deaerated, heated, and subjected to high pressure treatment (100 MPa, 50°C, 72 hours) to extract an extract, which is mixed with sake to make umeshu. .

The ratio of ume and sugar and the treatment conditions are, for example, 100 to 300 g of sugar per 100 g of ume (fruit pulp), pressure of 100 MPa or more, heating temperature of 35 to 65° C., and high pressure treatment time of 24 to 72 hours. .

As a result, as shown in Figures 28-1, 28-2, 28-3, 28-4, 29, and 30, the conventional method (72 hours) was sufficient for plum extract (acid, polyphenol). However, it can be extracted considerably by the method of the present invention (72 hours). Similarly, decomposition of sucrose, which is a measure of maturation, hardly occurs in the conventional method, but it progresses considerably in the medium-high pressure method. Furthermore, the color (b* value, index of brown color) is darker in the medium-high pressure method than in the conventional method. It can be seen that when the method of the present invention is aged for 1 month, the color depth is almost the same as that of the conventional method aged for 3 months or longer.

The reason why the ripening of umeshu proceeds quickly by the method of the present invention is that extracts (acids, polyphenols) and enzymes that promote ripening (sugar-degrading enzymes (invertase)) are rapidly extracted from ume plums, and are processed under heat and high pressure. This is because the decomposition of sugar proceeds quickly.

3.100MPa以上の処理での効果

前記段落(0083)以降に記載したウメ酒の製法を高圧処理条件の圧力条件のみ100~300MPa範囲で変えて検討したところ、表20に示す結果となり、本発明が100~300MPaの圧力範囲でも有効であることを確認した。

3. Effect of treatment at 100 MPa or more When the method for producing plum wine described in paragraph (0083) and after was examined by changing only the pressure condition of the high-pressure treatment condition in the range of 100 to 300 MPa, the results shown in Table 20 were obtained. is effective even in the pressure range of 100 to 300 MPa.

畜肉の漬物

1.豚肉の漬物

1-1 実験方法

1-1-a 試料の調整

加工処理に先立ち、約1cm厚にスライスした豚ロース肉の両面に、下記表21に示す調味液を肉の2/3重量塗り、ポリエチレン製の袋に入れ、脱気包装機を用いて、脱気度99%の脱気包装を行った。

pickled meat

1. Pork pickles 1-1 Experimental method 1-1-a Preparation of samples Prior to processing, the seasoning liquid shown in Table 21 below is applied to both sides of the pork loin sliced to a thickness of about 1 cm, and 2/3 weight of the meat is applied. It was placed in a polyethylene bag and deaerated and packaged with a deaeration degree of 99% using a deaeration packaging machine.

ここでは、豚肉の厚さを1cm、調味液の量を畜肉の2/3重量としたが、本発明はこの豚肉の厚さ、調味液の量に限定されるものではなく、脱気包装の真空度も、袋内の空気が十分に取り除かれるのであれば、任意の真空度でよい。 Here, the thickness of the pork is 1 cm and the amount of the seasoning liquid is 2/3 of the weight of the meat, but the present invention is not limited to the thickness of the pork and the amount of the seasoning liquid. Any degree of vacuum may be used as long as the air in the bag is sufficiently removed.

1-1-b 加工処理

脱気包装した試料に対して、下記表22に示す加工処理を行った。従来法では、調味液に味噌液を用いて、冷蔵庫内(常圧、4℃)にて72時間保管した。例1~3では、調味液に味噌液を用いて、100MPaの加熱・高圧処理を、それぞれ35、45、55℃の処理温度で、16時間行った。

例4では、調味液に100℃で10分間加熱して酵素類を失活させた加熱味噌液を用いて、100MPa の加熱・高圧処理を、45℃の処理温度で、16時間行った。

例5では、調味液に味噌液を用いて、100MPa の加熱・高圧処理を、45℃の処理温度で、1時間行った。

例6では、調味液に酒粕液を用いて、100MPa の加熱・高圧処理を、45℃の処理温度で、16時間行った。

例7では、調味液に塩麹を用いて、100MPa の加熱・高圧処理を、45℃の処理温度で、16時間行った。加熱・高圧処理は、(株)東洋高圧製「まるごとエキスTFS-20」を用いて行った。

1-1-b Processing The deaerated packaged sample was processed as shown in Table 22 below. In the conventional method, miso liquid was used as the seasoning liquid and stored in a refrigerator (normal pressure, 4° C.) for 72 hours. In Examples 1 to 3, miso liquid was used as the seasoning liquid, and heat/high pressure treatment at 100 MPa was performed at treatment temperatures of 35, 45, and 55° C. for 16 hours.

In Example 4, the seasoning liquid was heated at 100°C for 10 minutes to inactivate the enzymes, and a heated miso paste was used.

In Example 5, miso liquid was used as the seasoning liquid, and heat treatment at 100 MPa and high pressure was performed at a treatment temperature of 45° C. for 1 hour.

In Example 6, sake lees liquid was used as the seasoning liquid, and heat treatment at 100 MPa and high pressure was performed at a treatment temperature of 45° C. for 16 hours.

In Example 7, salt koji was used as the seasoning liquid, and heat treatment at 100 MPa and high pressure was performed at a treatment temperature of 45° C. for 16 hours. The heating and high pressure treatment was performed using "Marugoto Extract TFS-20" manufactured by Toyo Koatsu Co., Ltd.

1-1-C 呈味成分の測定

従来法および例1~3の加工処理を行った試料を用いて、呈味成分として遊離アミノ酸濃度およびグルコース濃度を測定した。

具体的には、各処理後の肉をホモジナイズした後、試料5gに8%トリクロロ酢酸水溶液を5ml加えて激しく振盪し、ろ過して清澄化した液を50mlに定容した。定容した液に含まれる主要なアミノ酸20種の合計濃度を測定し、元の試料に含まれる遊離アミノ酸濃度に換算した。アミノ酸は日立高速アミノ酸分析計L-8900を用いて測定した。また、定容した液のグルコース濃度を、和光純薬工業(株)製グルコースCIIテストを用いて測定し、元の試料に含まれるグルコース濃度に換算した。1処理あたり3反復ずつ行い、平均値と標準偏差を求めた。

1-1-C Measurement of Taste Components Samples processed by the conventional method and Examples 1 to 3 were used to measure free amino acid concentration and glucose concentration as taste components.

Specifically, after homogenizing the meat after each treatment, 5 ml of an 8% trichloroacetic acid aqueous solution was added to 5 g of the sample, vigorously shaken, filtered, and the clarified liquid was brought to a constant volume of 50 ml. The total concentration of 20 major amino acids contained in the constant-volume liquid was measured and converted to the concentration of free amino acids contained in the original sample. Amino acids were measured using a Hitachi high-speed amino acid analyzer L-8900. Further, the glucose concentration of the constant-volume liquid was measured using a glucose CII test manufactured by Wako Pure Chemical Industries, Ltd., and converted to the glucose concentration contained in the original sample. Three replicates were performed per treatment, and the mean and standard deviation were determined.

1-1-d 食感分析

従来法および例1~7の加工処理を行った試料を用いて、食感の目安として「硬さ」と「噛み切りやすさ」を測定した。

具体的には、各処理を行った肉から調味液を取り除き、肉表面の水分をペーパータオルでふき取った後、試料を新しいプラスチック袋に入れて脱気包装(真空度99%)した。

包装した試料を70℃で1時間湯煎した後、流水で30分間冷却し、カミソリを用いて肉をおおよそ1cm角に切断した。切断した試料を、レオメーター(株)サン科学製CR-500DX)を用いて、カミソリの刃の付いていない側で、筋線維に対して垂直方向に9mm圧縮し、5mm圧縮したときの応力を「硬さ」の指標に、切断したときの応力(せん断応力)を「噛み切りやすさ」の指標にした。

1試料あたり1cm角切片を12個測定し、最大値と最小値を除いた10個の平均値をその試料の測定値とした。以上の操作を1処理あたり3反復ずつ行い、平均値と標準偏差を求めた。

1-1-d Texture Analysis Using the samples processed by the conventional method and Examples 1 to 7, "hardness" and "easy to bite off" were measured as indicators of texture.

Specifically, after removing the seasoning liquid from each processed meat and wiping off moisture on the surface of the meat with a paper towel, the sample was placed in a new plastic bag and degassed and packaged (vacuum degree 99%).

After the packaged sample was boiled in hot water at 70° C. for 1 hour, it was cooled with running water for 30 minutes, and the meat was cut into approximately 1 cm squares using a razor. Using Rheometer CR-500DX manufactured by Sun Science Co., Ltd., the cut sample was compressed by 9 mm in the direction perpendicular to the muscle fiber on the side without a razor blade, and the stress when compressed by 5 mm was measured. As an index of "hardness", the stress (shear stress) at the time of cutting was used as an index of "easy to bite off".

Twelve pieces of 1 cm square were measured for each sample, and the average value of 10 pieces excluding the maximum and minimum values was used as the measured value of the sample. The above operation was repeated 3 times per treatment, and the average value and standard deviation were obtained.

1-2. 試験結果・考察

1-2-a 遊離アミノ酸濃度

図31に、従来法および例1~3の加工処理を行った試料の遊離アミノ酸濃度を示す。

従来法および例1~3では、処理前の生肉よりも遊離アミノ酸濃度が上昇しており、例1~3は、従来法よりも処理時間が大幅に短いにも関わらず、遊離アミノ酸濃度が従来法よりも高かった。

また、例1~3の中では、処理温度の最も高い例3が最も遊離アミノ酸濃度が高かった。従って、加熱・高圧処理を利用した例1~3では、従来法よりも短時間で旨味成分を増やすことができ、処理温度は55℃が最も旨味成分が増加すると考えられる。

1-2. Test Results/Discussion 1-2-a Free Amino Acid Concentration FIG.

In the conventional method and Examples 1 to 3, the free amino acid concentration is higher than that of the raw meat before treatment. higher than the law.

Among Examples 1 to 3, Example 3, which was treated at the highest temperature, had the highest concentration of free amino acids. Therefore, in Examples 1 to 3 using heat and high pressure treatment, the umami component can be increased in a shorter time than the conventional method, and the treatment temperature of 55° C. is considered to increase the umami component the most.

1-2-b グルコース濃度

図32に、従来法および例1~3の加工処理を行った試料のグルコース濃度を示す。

従来法および例1~3では、処理前の生肉よりもグルコース濃度が上昇しており、例1~3は、従来法よりも処理時間が大幅に短いにも関わらず、グルコース濃度が従来法とおおよそ同じ程度になっていた。また、例1~3の中では、処理温度の最も高い例3が最もグルコース濃度が高かった。従って、加熱・高圧処理を利用した例1~3では、従来法よりも短時間で調味液中のグルコース濃度を上昇させることができると考えられる。

1-2-b Glucose Concentration FIG. 32 shows the glucose concentrations of the samples processed by the conventional method and Examples 1-3.

In the conventional method and Examples 1 to 3, the glucose concentration is higher than the raw meat before treatment, and in Examples 1 to 3, the glucose concentration is higher than the conventional method, although the treatment time is significantly shorter than the conventional method. It was about the same. Further, among Examples 1 to 3, Example 3 with the highest treatment temperature had the highest glucose concentration. Therefore, in Examples 1 to 3 using heat and high pressure treatment, it is considered that the glucose concentration in the seasoning liquid can be increased in a shorter time than the conventional method.

1-2-c 処理温度による加熱後の硬さの変化

図33に、従来法および例1~4の加工処理を行った試料の、加熱後の硬さを示す。

従来法は無処理とほぼ同じ硬さであったが、例1~3は無処理よりも柔らかくなっていた。また、例1~3の中では、例2、例3が最も柔らかくなり、無処理のおおよそ半分の硬さになった。さらに、加熱して味噌の酵素を失活させた例4は、例2と同じ加工処理を行ったにもかかわらず、無処理とほぼ同じ硬さであった。したがって、例1~3において加熱後の肉が柔らかくなったのは、調味液に含まれる酵素と加工処理(加熱・高圧処理)の相乗効果によるものと考えられる。

1-2-c Change in Hardness after Heating Depending on Treatment Temperature FIG. 33 shows the hardness after heating of the samples processed by the conventional method and Examples 1-4.

The hardness of the conventional method was almost the same as that of no treatment, but Examples 1 to 3 were softer than those of no treatment. Further, among Examples 1 to 3, Examples 2 and 3 were the softest, and the hardness was about half that of the non-treated ones. Furthermore, in Example 4, in which the miso enzyme was deactivated by heating, although the same processing treatment as in Example 2 was performed, the hardness was almost the same as that of no treatment. Therefore, the fact that the meat became tender after heating in Examples 1 to 3 is considered to be due to the synergistic effect of the enzymes contained in the seasoning liquid and the processing treatment (heating and high pressure treatment).

1-2-d 処理温度による加熱後の噛み切りやすさの変化

図34に、従来法および例1~4の加工処理を行った試料の、加熱後の噛み切りやすさを示す。

従来法および例2、例3は、無処理よりも噛み切りやすくなっており、例2、例3は、従来法よりも処理時間が大幅に短いにも関わらず、従来法よりも噛み切りやすくなっていた。一方、例1は無処理とほぼ同じであったことから、加熱・高圧処理を利用して加熱後の肉を噛み切りやすくするには、35℃より高い温度で処理する必要があると考えられる。また、例4は無処理と噛み切りやすさに有意な差がなかったことから、加熱後の肉を噛み切りやすくするには、調味液に含まれる酵素が必要であると考えられる。

1-2-d Changes in easiness of biting off after heating depending on treatment temperature Fig. 34 shows the easiness of biting off after heating of the samples processed by the conventional method and examples 1 to 4.

The conventional method and examples 2 and 3 are easier to bite off than no treatment, and examples 2 and 3 are easier to bite off than the conventional method despite the treatment time being significantly shorter than the conventional method. was becoming On the other hand, since Example 1 was almost the same as no treatment, it is considered necessary to treat at a temperature higher than 35 ° C in order to make it easier to bite off the meat after heating using heat and high pressure treatment. . In addition, since there was no significant difference between the untreated meat and the ease of biting off in Example 4, it is considered that an enzyme contained in the seasoning liquid is necessary to make the meat after heating easy to bite through.

1-2-e 処理時間の違いによる加熱後の噛み切りやすさの変化

図35に、従来法、例2、例5の加工処理を行った試料の加熱後の噛み切りやすさを示す。

100 MPa、45℃の加熱・高圧処理を1時間行った例5は、従来法よりは劣るもの

の、無処理よりも噛み切りやすくなっていた。従って、加熱後の肉を噛み切りやすくするには、100 MPa、45℃という処理条件の場合、加熱・高圧処理を1時間以上行えば良いと考えられる。

1-2-e Changes in ease of biting off after heating due to differences in treatment time FIG.

Example 5, which was subjected to heating and high pressure treatment at 100 MPa and 45° C. for 1 hour, was inferior to the conventional method, but was easier to bite off than no treatment. Therefore, in the case of the treatment conditions of 100 MPa and 45.degree.

1-2-f 調味液の違いによる加熱後の噛み切りやすさの変化

図36に、例2、例6、例7の加工処理を行った試料の、加熱後の噛み切りやすさを示す。

調味液に酒粕液を用いた例6、塩麹を用いた例7ともに、調味液に味噌液を用いた例2とほぼ同じ程度の噛み切りやすさになっていた。従って、本発明は味噌漬に限定されるものではなく、酒粕漬や塩麹漬など、酵素を含む調味液に畜肉を漬ける食品全般に利用できる技術と考えられる。

1-2-f Changes in ease of chewing after heating due to differences in seasoning liquid FIG.

Both Example 6 using sake lees liquid as the seasoning liquid and Example 7 using shio-koji (salted rice malt) were almost as easy to bite off as Example 2 using miso liquid as the seasoning liquid. Therefore, the present invention is not limited to pickling in miso, but is considered to be a technology that can be applied to general foods such as pickling in sake lees and pickling in shio-koji, in which livestock meat is pickled in a seasoning solution containing enzymes.

1-2-g 殺菌効果

表24で示す通り、本発明で行った豚肉の味噌漬は、殺菌効果が向上した。

1-2-g Bactericidal effect As shown in Table 24, the miso-pickled pork performed in the present invention had an improved bactericidal effect.

2.牛肉の漬物

2-1 実験方法

2-1-a 試料の調整

加工処理に先立ち、約1cm厚にスライスしたホルスタインの外モモ肉の両面に、味噌調味液(味噌78%、砂糖11%、みりん11%)を肉の2/3重量塗り、ポリエチレン製の袋に入れ、脱気包装機を用いて、脱気度99%の脱気包装を行った。

2. Beef pickles 2-1 Experimental method 2-1-a Preparation of samples Prior to processing, a miso seasoning liquid (78% miso, 11% sugar, 11% mirin %) was applied to 2/3 of the weight of the meat, placed in a polyethylene bag, and degassed and packaged with a degassing degree of 99% using a degassing packaging machine.

ここでは、牛肉の厚さを1cm、調味液の量を畜肉の2/3重量としたが、本発明はこの牛肉の厚さ、調味液の量に限定されるものではなく、脱気包装の真空度も、袋内の空気が十分に取り除かれるのであれば、任意の真空度でよい。 Here, the thickness of the beef is 1 cm and the amount of the seasoning liquid is 2/3 of the weight of the livestock meat, but the present invention is not limited to the thickness of the beef and the amount of the seasoning liquid. Any degree of vacuum may be used as long as the air in the bag is sufficiently removed.

2-1-b 加工処理

脱気包装した試料に対して、下記表23に示す加工処理を行った。従来法では、調味液に味噌液を用いて、冷蔵庫内(常圧、4℃)にて72時間保管した。例1~3では、100MPaの加熱・高圧処理を、全ての例で処理温度を45℃にし、処理時間をそれぞれ4、8、16時間で行った。

加熱・高圧処理は、(株)東洋高圧製「まるごとエキスTFS-20」を用いて行った。

2-1-b Processing Treatment The processing shown in Table 23 below was performed on the vacuum-packaged sample. In the conventional method, miso liquid was used as the seasoning liquid and stored in a refrigerator (normal pressure, 4° C.) for 72 hours. In Examples 1 to 3, heat treatment at 100 MPa and high pressure were performed at a treatment temperature of 45° C. for 4, 8 and 16 hours, respectively.

The heating and high pressure treatment was performed using "Marugoto Extract TFS-20" manufactured by Toyo Koatsu Co., Ltd.

2-1-c 呈味成分の測定

従来法および例1~3の加工処理を行った試料を用いて、呈味成分として遊離アミノ酸濃度およびグルコース濃度を測定した。

具体的には、各処理後の肉をホモジナイズした後、試料5gに8%トリクロロ酢酸水溶液を5ml加えて激しく振盪し、ろ過して清澄化した液を50mlに定容した。タンパク質分解物(遊離アミノ酸およびペプチド)の指標として、トリクロロ酢酸抽出液中の窒素量をケルダール法で測定した。また、定容した液のグルコース濃度を、和光純薬工業(株)製グルコースCIIテストを用いて測定し、元の試料に含まれるグルコース濃度に換算した。1処理あたり3反復ずつ行い、平均値と標準偏差を求めた。

2-1-c Measurement of Taste Components Samples processed by the conventional method and Examples 1 to 3 were used to measure free amino acid concentration and glucose concentration as taste components.

Specifically, after homogenizing the meat after each treatment, 5 ml of an 8% trichloroacetic acid aqueous solution was added to 5 g of the sample, vigorously shaken, filtered, and the clarified liquid was brought to a constant volume of 50 ml. As an indicator of protein degradation products (free amino acids and peptides), the nitrogen content in the trichloroacetic acid extract was measured by the Kjeldahl method. Further, the glucose concentration of the constant-volume liquid was measured using a glucose CII test manufactured by Wako Pure Chemical Industries, Ltd., and converted to the glucose concentration contained in the original sample. Three replicates were performed per treatment, and the mean and standard deviation were determined.

2-1-d 食感分析

従来法および例1~3の加工処理を行った試料を用いて、食感の目安として「硬さ」と「噛み切りやすさ」を測定した。

具体的には、各処理を行った肉から調味液を取り除き、肉表面の水分をペーパータオルでふき取った後、試料を新しいプラスチック袋に入れて脱気包装(真空度99%)した。

包装した試料を70℃で1時間湯煎した後、流水で30分間冷却し、カミソリを用いて肉をおおよそ1cm角に切断した。切断した試料を、レオメーター(株)サン科学製CR-500DX)を用いて、カミソリの刃の付いていない側で、筋線維に対して垂直方向に9mm圧縮し、5mm圧縮したときの応力を「硬さ」の指標に、切断したときの応力(せん断応力)を「噛み切りやすさ」の指標にした。

1試料あたり1cm角切片を12個測定し、最大値と最小値を除いた10個の平均値をその試料の測定値とした。以上の操作を1処理あたり3反復ずつ行い、平均値と標準偏差を求めた。

2-1-d Texture Analysis Using the samples processed by the conventional method and Examples 1 to 3, "hardness" and "easy to bite off" were measured as indicators of texture.

Specifically, after removing the seasoning liquid from each processed meat and wiping off moisture on the surface of the meat with a paper towel, the sample was placed in a new plastic bag and degassed and packaged (vacuum degree 99%).

After the packaged sample was boiled in hot water at 70° C. for 1 hour, it was cooled with running water for 30 minutes, and the meat was cut into approximately 1 cm squares using a razor. Using Rheometer CR-500DX manufactured by Sun Science Co., Ltd., the cut sample was compressed by 9 mm in the direction perpendicular to the muscle fiber on the side without a razor blade, and the stress when compressed by 5 mm was measured. As an index of "hardness", the stress (shear stress) at the time of cutting was used as an index of "easy to bite off".

Twelve pieces of 1 cm square were measured for each sample, and the average value of 10 pieces excluding the maximum and minimum values was used as the measured value of the sample. The above operation was repeated 3 times per treatment, and the average value and standard deviation were obtained.

2-2. 試験結果・考察

2-2-a 酸可溶性窒素(遊離アミノ酸およびペプチド)濃度

図37に、従来法および例1~3の加工処理を行った試料の酸可溶性窒素濃度を示す。

従来法および例1~3では、処理前の生肉よりも酸可溶性窒素濃度が上昇しており、例1~3は、従来法よりも処理時間が大幅に短いにも関わらず、酸可溶性窒素濃度が従来法よりも高かった。

また、例1~3の中では、処理時間の最も長い例3が最も酸可溶性窒素濃度が高かった。従って、加熱・高圧処理を利用した例1~3では、従来法よりも短時間で旨味成分を増やすことができ、処理時間は16時間が最も旨味成分が増加すると考えられる。

2-2. Test Results/Discussion 2-2-a Acid-Soluble Nitrogen (Free Amino Acids and Peptides) Concentration FIG.

In the conventional method and Examples 1 to 3, the acid-soluble nitrogen concentration is higher than the raw meat before treatment, and in Examples 1 to 3, the acid-soluble nitrogen concentration is was higher than the conventional method.

Further, among Examples 1 to 3, Example 3 with the longest treatment time had the highest acid-soluble nitrogen concentration. Therefore, in Examples 1 to 3 using heat and high pressure treatment, the umami component can be increased in a shorter time than the conventional method, and the treatment time of 16 hours is considered to increase the umami component the most.

2-2-b グルコース濃度

図38に、従来法および例1~3の加工処理を行った試料のグルコース濃度を示す。

従来法および例2~3では、処理前の生肉よりもグルコース濃度が上昇しており、例2~3は、従来法よりも処理時間が大幅に短いにも関わらず、グルコース濃度が従来法とおおよそ同じ程度になっていた。また、例1~3の中では、処理温度の最も高い例3の処理時間16時間が最もグルコース濃度が高かった。従って、加熱・高圧処理を利用した例2~3では、従来法よりも短時間で調味液中のグルコース濃度を上昇させることができると考えられる。

2-2-b Glucose Concentration FIG. 38 shows the glucose concentrations of the samples processed by the conventional method and Examples 1-3.

In the conventional method and Examples 2 and 3, the glucose concentration is higher than the raw meat before treatment, and in Examples 2 and 3, despite the treatment time being significantly shorter than the conventional method, the glucose concentration is higher than the conventional method. It was about the same. Further, among Examples 1 to 3, the glucose concentration was the highest in Example 3, which had the highest treatment temperature and had a treatment time of 16 hours. Therefore, in Examples 2 and 3 using heat and high pressure treatment, it is considered that the glucose concentration in the seasoning liquid can be increased in a shorter time than the conventional method.

2-2-c 処理温度による加熱後の硬さの変化

図39に、従来法および例1~3の加工処理を行った試料の、加熱後の硬さを示す。

従来法は無処理とほぼ同じ硬さであったが、例1~3は無処理よりも柔らかくなっていた。また、例1~3の中では、例3が最も柔らかくなり、無処理のおおよそ2/3の硬さになった。

従って、加熱後の肉を噛み切りやすくするには、100 MPa、45℃という処理条件の場合、加熱・高圧処理を16時間行えば良いと考えられる。

2-2-c Change in Hardness after Heating Depending on Treatment Temperature FIG. 39 shows the hardness after heating of the samples processed by the conventional method and Examples 1-3.

The hardness of the conventional method was almost the same as that of no treatment, but Examples 1 to 3 were softer than those of no treatment. In addition, among Examples 1 to 3, Example 3 was the softest and had a hardness of about 2/3 of the untreated.

Therefore, in the case of the treatment conditions of 100 MPa and 45° C., it is thought that heating and high pressure treatment should be performed for 16 hours in order to make the meat easier to bite off after heating.

2-2-d 殺菌効果

表24で示す通り、本発明で行った牛肉の味噌漬は、殺菌効果が向上した。

2-2-d Bactericidal effect As shown in Table 24, the beef miso marinated according to the present invention had an improved bactericidal effect.

3.100MPa以上の処理での効果

前記段落(0086)以降に記載した畜肉の漬物の製法を高圧処理条件の圧力条件のみ100~300MPa範囲で変えて検討したところ、表24に示す結果となり、本発明が100~300MPaの圧力範囲でも有効であることを確認した。

3. Effect of treatment at 100 MPa or more When the method for producing pickled livestock meat described in paragraph (0086) and after was examined by changing only the pressure condition of the high-pressure treatment condition in the range of 100 to 300 MPa, the results shown in Table 24 were obtained. It was confirmed that the invention is also effective in the pressure range of 100-300 MPa.

豆腐の漬物

1. 実験方法

1-1 試料の調整

加工処理に先立ち、石川県特産の堅豆腐を1cmまたは5cmの厚さにスライスし、ガーゼで包んだ後、堅豆腐の全面に、下記表25に示す調味液を堅豆腐の1/2重量塗り、ポリエチレン製の袋に入れ、脱気包装機を用いて、真空度99%の脱気包装を行った。

ここでは、堅豆腐の厚さを1cmまたは5cmに、調味液の量を堅豆腐の1/2重量としたが、本発明はこの堅豆腐の厚さ、調味液の量に限定されるものではなく、脱気包装の真空度も、袋内の空気が十分に取り除かれるのであれば、任意の真空度でよい。

Tofu pickles 1. Experimental method 1-1 Sample preparation Prior to processing, Ishikawa prefecture's specialty hard tofu was sliced into 1 cm or 5 cm thick slices and wrapped in gauze. The seasoning liquid shown in 1 was applied to 1/2 weight of hard tofu, placed in a polyethylene bag, and degassed and packaged at a vacuum degree of 99% using a degassing packaging machine.

Here, the thickness of the hard tofu is 1 cm or 5 cm, and the amount of the seasoning liquid is 1/2 the weight of the hard tofu, but the present invention is not limited to the thickness of the hard tofu and the amount of the seasoning liquid. Also, the degree of vacuum of the degassed packaging may be any degree of vacuum as long as the air inside the bag is sufficiently removed.

1-2 加工処理

脱気包装した試料に対して、下記表26に示す加工処理を行った。従来法では、堅豆腐を5cm厚にスライスし、調味液に酒粕液を用いて、冷蔵庫内(常圧、4℃)にて9ヶ月間保管した。

1-2 Processing The processing shown in Table 26 below was performed on the deaerated and packaged sample. In the conventional method, hard tofu was sliced into 5 cm thick slices and stored in a refrigerator (normal pressure, 4° C.) for 9 months using sake lees liquid as a seasoning liquid.

例1では、堅豆腐を1cm厚にスライスし、調味液に酒粕液を用いて、100MPa、45℃の加熱・高圧処理を90時間行った。

例2では、堅豆腐を5cm厚にスライスし、調味液に酒粕液を用いて、前処理として冷蔵庫内(常圧、4℃)にて1週間保管した後、100MPa、45℃の加熱・高圧処理を16時間行った。

In Example 1, hard tofu was sliced into 1 cm thick slices, and a sake lees liquid was used as the seasoning liquid, and the slices were subjected to heating and high pressure treatment at 100 MPa and 45° C. for 90 hours.

In Example 2, hard tofu was sliced into 5 cm thick slices, and sake lees liquid was used as the seasoning liquid. After pretreatment, the slices were stored in a refrigerator (normal pressure, 4°C) for 1 week, and then heated at 100 MPa and 45°C under high pressure. Treatment was carried out for 16 hours.

前処理は、堅豆腐の表面と内部の成分のバラつきを抑えるための工程であり、加熱・高圧処理の前に冷蔵保管することにより、あらかじめ豆腐の内部に調味液の成分・酵素を染み込ませるために行う。ここでは、脱気包装した試料を用いて前処理を行ったが、樽やトレイなどを用いて大量の豆腐を一度に調味液に漬けこみ、冷蔵保管した後、豆腐を取り出し、個別に脱気包装してから加熱・高圧処理を行っても良い。 Pretreatment is a process to suppress variations in the surface and internal components of hard tofu, and by storing it in cold storage before heating and high pressure treatment, the ingredients and enzymes of the seasoning liquid are soaked into the inside of the tofu in advance. go to Here, pretreatment was performed using degassed packaged samples, but a large amount of tofu was soaked in the seasoning liquid at once using a barrel or tray, stored in a refrigerator, and then taken out and degassed individually. Heating and high-pressure treatment may be performed after packaging.

例3では、調味液の染込みを良くするために堅豆腐を1cm厚にスライスし、調味液に酒粕液を用いて、100MPa、45℃の加熱・高圧処理を16時間行った。

例4では、堅豆腐を1cm厚にスライスし、調味液に味噌液を用いて、100MPa、45℃の加熱・高圧処理を16時間行った。

例5では、堅豆腐を1cm厚にスライスし、調味液に塩麹液を用いて、100MPa、45℃の加熱・高圧処理を16時間行った。加熱・高圧処理は、(株)東洋高圧製「まるごとエキスTFS-20」を用いて行った。

In Example 3, hard tofu was sliced into 1 cm thick slices in order to improve the penetration of the seasoning liquid, and the slices were subjected to heating and high pressure treatment at 100 MPa and 45° C. for 16 hours using sake lees liquid as the seasoning liquid.

In Example 4, hard tofu was sliced into 1 cm thick slices, and a miso paste liquid was used as the seasoning liquid, followed by heating and high pressure treatment at 100 MPa and 45° C. for 16 hours.

In Example 5, hard tofu was sliced into a thickness of 1 cm and subjected to heating and high pressure treatment at 100 MPa and 45° C. for 16 hours using salt koji liquid as the seasoning liquid. The heating and high pressure treatment was performed using "Marugoto Extract TFS-20" manufactured by Toyo Koatsu Co., Ltd.

1-3 呈味成分の測定

従来法および例1~3の加工処理を行った試料を用いて、呈味成分として遊離アミノ酸濃度を測定した。具体的には、各処理後の試料からガーゼごと調味液を取り除き、豆腐の表層1cmを切り取ったものを「表層」、残った部分を「内部」として別々にサンプリングした。

例3~5は全体を表層としてサンプリングした。サンプリングした表層と内部を別々にホモジナイズした後、試料5gに8%トリクロロ酢酸水溶液を5ml加えて激しく振盪し、ろ過して清澄化した液を50mlに定容した。定容した液に含まれる主要なアミノ酸20種の合計濃度を測定し、元の試料に含まれる遊離アミノ酸濃度に換算した。アミノ酸は日立高速アミノ酸分析計L-8900を用いて測定した。従来法は1反復のみ、例1~3は3反復ずつ行い、平均値と標準偏差を求めた。

1-3 Measurement of Taste Component Samples processed by the conventional method and Examples 1 to 3 were used to measure free amino acid concentration as a taste component. Specifically, the seasoning liquid was removed together with the gauze from the sample after each treatment, and 1 cm of the surface layer of the tofu was cut off and sampled separately as the “surface layer” and the remaining portion as the “inside”.

Examples 3-5 were sampled entirely as the surface layer. After separately homogenizing the sampled surface layer and the inside, 5 ml of an 8% trichloroacetic acid aqueous solution was added to 5 g of the sample, vigorously shaken, filtered, and the clarified liquid was brought to a constant volume of 50 ml. The total concentration of 20 major amino acids contained in the constant-volume liquid was measured and converted to the concentration of free amino acids contained in the original sample. Amino acids were measured using a Hitachi high-speed amino acid analyzer L-8900. Only one repetition was performed for the conventional method, and three repetitions were performed for each of Examples 1 to 3, and average values and standard deviations were determined.

1-4 食感分析

従来法および例1~5の加工処理を行った試料を用いて、試料表面の硬さを測定し、食感の目安とした。

具体的には、各処理後の試料からガーゼごと調味液を取り除き、試料の表層1cmを切り取った。切り取った試料をさらに1cm角に切断し、レオメーター((株)サン科学製CR-500DX)を用いて、直径10mmの円柱プランジャーで、堅豆腐の表層から内部に向か

う方向に9mm圧縮し、最大応力を硬さの指標にした。1試料あたり1cm角切片を10個測定し、平均値をその試料の測定値とした。以上の操作を従来法は1反復のみ、例1~5は3反復ずつ行い、平均値と標準偏差を求めた。

1-4 Food Texture Analysis Using the samples processed by the conventional method and Examples 1 to 5, the hardness of the sample surface was measured and used as a measure of the food texture.

Specifically, the seasoning liquid was removed together with the gauze from the sample after each treatment, and 1 cm of the surface layer of the sample was cut off. The cut sample is further cut into 1 cm squares, and using a rheometer (CR-500DX manufactured by Sun Science Co., Ltd.), a cylindrical plunger with a diameter of 10 mm is used to compress the hard tofu by 9 mm in the direction from the surface to the inside, The maximum stress was used as an index of hardness. Ten pieces of 1 cm square were measured per sample, and the average value was taken as the measured value of the sample. The above operation was repeated once in the conventional method and three times in each of Examples 1 to 5, and the average value and standard deviation were obtained.

2 試験結果・考察

2-1 遊離アミノ酸濃度

図40に、従来法および例1~3の加工処理を行った試料の遊離アミノ酸濃度を示す。

従来法では、1週間冷蔵保管したものは表層が約1000mg/100g、内部が約900mg/100g、1カ月間冷蔵保管したものは表層が約1600mg/100g、内部が約1400mg/100g、9カ月間冷蔵保管したものは表層、内部ともに約3000mg/100gになり、冷蔵保管する期間が長くなるほど遊離アミノ酸濃度が上昇した。

2 Test Results and Discussion 2-1 Free Amino Acid Concentration FIG.

In the conventional method, after refrigerating for 1 week, the surface layer is about 1000 mg/100 g, and the inside is about 900 mg/100 g. After refrigeration, the concentration of free amino acids increased with the length of the refrigeration storage period.

これに対して、例1は、表層が約2500mg/100g、内部が約1600mg/100gになり、90時間という短い処理時間でありながら、1カ月間冷蔵保管したものよりも表層、内部ともに遊離アミノ酸濃度が高くなった。

例2は表層が約1500mg/100g、内部が約1000mg/100gとなり、表層は1カ月間冷蔵保管したものと、内部は1週間冷蔵保管したものとほぼ同じになった。

例3は約1500mg/100gとなり、16時間という短い処理時間でありながら、1カ月間冷蔵保管したものとほぼ同じになった。

以上の結果から、加熱・高圧処理を用いることにより、数日間(16~90時間)の加工処理で、従来法で1カ月以上かけて製造したものと同等の遊離アミノ酸濃度にすることができると考えられる。

On the other hand, in Example 1, the surface layer is about 2500 mg/100 g and the inside is about 1600 mg/100 g, and although the treatment time is as short as 90 hours, both the surface layer and the inside have more free amino acids than those stored in a refrigerator for one month. increased concentration.

In Example 2, the surface layer was about 1500 mg/100 g and the inside was about 1000 mg/100 g, and the surface layer was almost the same as the one after refrigerating for one month and the inside after one week.

Example 3 was about 1500 mg/100 g, which was almost the same as the one month refrigerated storage despite the short treatment time of 16 hours.

From the above results, by using heat and high pressure treatment, it is possible to achieve a free amino acid concentration equivalent to that of products manufactured by conventional methods over a month in a few days (16 to 90 hours) of processing. Conceivable.

2-2 処理方法による硬さの違い

図41に、従来法および例1~3の加工処理を行った試料の硬さを示す。

従来法では、1週間冷蔵保管したものは処理前よりもやや硬くなっていた。これは、調味液の浸透圧により堅豆腐の水分が抜け、組織が締まったからと考えられた。

1ヶ月冷蔵保管したものは、処理前よりもやや柔らかくなっていたが、官能評価ではほとんど区別することができない程度の差であった。

9カ月冷蔵保管したものは、処理前よりも非常に柔らかく、舌でつぶせる程度の硬さ(1×104N/m2以下)になっており、食べるとクリームチーズのような食感になっていた。

2-2 Difference in Hardness Depending on Treatment Method FIG. 41 shows the hardness of the samples treated by the conventional method and Examples 1 to 3.

In the conventional method, the product after refrigerating for one week was slightly harder than before treatment. It is considered that this is because the osmotic pressure of the seasoning liquid removes water from the hard tofu and tightens the structure.

The one after refrigerating for one month was slightly softer than before the treatment, but the difference was such that it could hardly be distinguished by sensory evaluation.

After refrigerating for 9 months, it was much softer than before treatment, and had a hardness that could be crushed with the tongue (1×10 4 N/m 2 or less), and when eaten, had a cream cheese-like texture. was

これに対して、例1は、90時間という短い処理時間でありながら、従来法で9カ月間冷蔵保管したものと同じく、舌でつぶせる程度の硬さになっており、食べるとクリームチーズのような食感になっていた。

例2、例3は、例1よりはやや硬いが、歯ぐきでつぶせる程度の硬さ(5×104N/m2以下)になっており、食べると、処理前と比較して明らかに柔らかく、チーズのような食感になっていた。

On the other hand, in Example 1, although the treatment time was as short as 90 hours, it was as hard as the product stored in the refrigerator for 9 months by the conventional method, and it was so hard that it could be crushed with the tongue, and it tasted like cream cheese. It had a nice texture.

Examples 2 and 3 are slightly harder than Example 1, but are hard enough to be crushed with gums (5×10 4 N/m 2 or less), and when eaten, are clearly softer than before treatment. , It had a cheese-like texture.

2-3 調味液の検証

図42に、例3~5の加工処理を行った試料の硬さを示す。

調味液に味噌液を用いた例4、塩麹を用いた例5ともに、調味液に酒粕液を用いた例3とほぼ同じ程度の硬さになっていた。

従って、本発明は酒粕漬に限定されるものではなく、味噌漬や塩麹漬など、酵素を含む調味液に豆腐を漬ける食品全般に利用できる技術と考えられる。

2-3 Verification of seasoning liquid Fig. 42 shows the hardness of samples processed in Examples 3-5.

Both Example 4 using miso liquid as the seasoning liquid and Example 5 using shio-koji had approximately the same hardness as Example 3 using sake lees liquid as the seasoning liquid.

Therefore, the present invention is not limited to pickling in sake lees, but is considered to be a technique that can be applied to general foods such as miso pickling and shio-koji pickling, in which tofu is pickled in a seasoning solution containing enzymes.

2-4 殺菌効果

表27で示す通り、本発明で行った豆腐の漬物は、殺菌効果が向上した。

2-4 Sterilization effect As shown in Table 27, the pickled tofu prepared in the present invention has an improved sterilization effect.

3.100MPa以上の処理での効果

前記段落(0112)以降に記載した豆腐の漬物の製法を高圧処理条件の圧力条件のみ100~300MPa範囲で変えて検討したところ、表27に示す結果となり、本発明が100~300MPaの圧力範囲でも有効であることを確認した。

3. Effect of treatment at 100 MPa or more When the method for producing pickled tofu described in paragraph (0112) and after was examined by changing only the pressure condition of the high-pressure treatment condition in the range of 100 to 300 MPa, the results shown in Table 27 were obtained. It was confirmed that the invention is also effective in the pressure range of 100-300 MPa.

キノコ加工品

1. 実験方法

1-1 試料の調整

加工処理に先立ち、軸を取り除いた生シイタケと、生シイタケの30%重量の調味液(醤油とバターを1:2の割合で混ぜ合わせたもの)をポリエチレン製の袋に入れ、脱気包装機を用いて、真空度99%の脱気包装を行った。

ここでは、シイタケは傘部分をまるごと使用し、調味液の量はシイタケの30%としたが、本発明はこのシイタケの形状、調味液の量に限定されるものではなく、脱気包装の真空度も、袋内の空気が十分に取り除かれるのであれば、任意の真空度でよい。

Here, the whole shiitake mushroom cap portion is used, and the amount of the seasoning liquid is 30% of the shiitake mushroom, but the present invention is not limited to the shape of the shiitake mushroom and the amount of the seasoning liquid. Any degree of vacuum may be used as long as the air inside the bag is sufficiently removed.

1-2 加工処理

脱気包装した試料に対して、下記表28に示す加工処理を行った。

従来法1では、ボイル殺菌として、0.1MPa、98℃で10分間の加熱処理を行った。

従来法2では、レトルト殺菌として、0.2MPa、121℃で20分間の加熱処理を行った。

従来法3では、加熱殺菌として、0.1MPa、70℃で30分間の加熱処理を行った。

本特許を利用した実施例では、加熱・高圧殺菌として、100MPa、70℃で30分間の加熱処理を行った。加熱・高圧処理は、(株)東洋高圧製「まるごとエキスTFS-20」を用いて行った。

1-2 Processing The processing shown in Table 28 below was performed on the degassed and packaged samples.

In

In

In

In the examples using this patent, heat treatment was performed at 100 MPa and 70° C. for 30 minutes as heat/high pressure sterilization. The heating and high pressure treatment was performed using "Marugoto Extract TFS-20" manufactured by Toyo Koatsu Co., Ltd.

1-3 グアニル酸の測定

従来法1~3および実施例の加工処理を行った試料を用いて、キノコの旨味成分であるグアニル酸の濃度を測定した。具体的には次のような方法で行った。

各処理後の試料から調味液を拭き取り、試料と同重量の蒸留水を加えてホモジナイズした後、遠心分離(3000rpm、10分間)を行い、上清を回収した。上清を孔径0.45μmのフィルタでろ過し、高速液体クロマトグラフィーで分析した。高速液体クロマトグラフィーは下記表29の条件で行った。標品には和光純薬工業(株)製のグアニル酸(グアノシン1リン酸)を使用した。

1-3 Measurement of Guanylic Acid Using the samples processed by

After wiping off the seasoning liquid from the sample after each treatment, distilled water of the same weight as the sample was added and homogenized, followed by centrifugation (3000 rpm, 10 minutes) to recover the supernatant. The supernatant was filtered through a filter with a pore size of 0.45 μm and analyzed by high performance liquid chromatography. High performance liquid chromatography was performed under the conditions shown in Table 29 below. Guanylic acid (guanosine monophosphate) manufactured by Wako Pure Chemical Industries, Ltd. was used as a standard.

1-4 塩分分析

従来法1~3および実施例の加工処理を行った試料を用いて、呈味成分として塩分を測定した。具体的には上記グアニル酸測定用の上清に含まれるナトリウム量を、原子吸光法により測定し、元の試料に含まれる塩化ナトリウム濃度に換算した。

1-4 Salt Content Analysis Salt content was measured as a taste component using the samples processed by

1.5 食感分析

従来法1~3および実施例の加工処理を行った試料を用いて、傘部分の硬さを春日ら(日本調理学会誌34、pp348-355、2000年)の方法を用いて測定した。すなわち、レオメーター((株)サン科学製CR-500DX)を用いて、直径1mmの円柱プランジャーで、傘部分の軸から5mm離れた箇所を、ヒダのある方向から圧縮し、貫入したときの応力を求めた。1試料あたり4か所測定し、平均値をその試料の測定値とした。1処理あたり5反復ずつ行い、平均値と標準偏差を求めた。

1.5 Texture analysis Using the samples processed by

2 試験結果・考察

2-1 グアニル酸の生成機構

グアニル酸はキノコに含まれる代表的な旨味物質である。図43にグアニル酸の生成および分解の模式図を示す。

グアニル酸は、細胞の核に含まれる核酸(RNA)が酵素(リボヌクレアーゼ)により分解されることで生成される。そのため、キノコの細胞が損傷を受けると、細胞核に存在する核酸が、細胞質中に存在するリボヌクレアーゼにより分解されやすくなるため、グアニル酸が生成されやすくなる。

干シイタケは、乾燥により細胞が損傷を受けているため、旨味成分のグアニル酸が生シイタケよりも増えやすく、古くからダシの材料として利用されている。グアニル酸はホスファターゼにより分解されると無味のグアノシンに変化する。グアニル酸を生成するリボヌクレアーゼは65~70℃で活性が高く、グアニル酸を分解するホスファターゼは40~60℃で活性が高い。さらにホスファターゼは65℃以上で失活するため、シイタケは65~70℃で加熱すると旨味が最も増加しやすいことが知られている。

2 Test results and discussion 2-1 Guanylic acid generation mechanism Guanylic acid is a typical umami substance contained in mushrooms. FIG. 43 shows a schematic diagram of the production and decomposition of guanylic acid.

Guanylic acid is produced by degrading nucleic acid (RNA) contained in the nucleus of cells with an enzyme (ribonuclease). Therefore, when mushroom cells are damaged, nucleic acid present in the cell nucleus is easily degraded by ribonuclease present in the cytoplasm, and guanylate is readily produced.

Since the cells of dried shiitake mushrooms are damaged by drying, the umami component guanylic acid is more likely to increase than fresh shiitake mushrooms, and has been used as an ingredient for dashi since ancient times. Guanylic acid is converted to tasteless guanosine when degraded by phosphatases. A ribonuclease that produces guanylate has high activity at 65-70°C, and a phosphatase that degrades guanylate has high activity at 40-60°C. Furthermore, since phosphatase is inactivated at 65°C or higher, it is known that shiitake mushrooms are most likely to develop their umami when heated at 65-70°C.

2-2 グアニル酸濃度

図44に、従来法1~3および実施例の加工処理を行った試料のグアニル酸濃度を示す

。

処理前の生シイタケにはグアニル酸はほとんど含まれていないが、加熱することによりグアニル酸濃度は上昇した。実施例は、従来法1および従来法2の3倍以上、従来法3の約1.5倍にグアニル酸濃度が上昇した。

以上の結果から、本発明方法を利用することにより、シイタケに含まれるグアニル酸を通常の加熱殺菌方法よりも増加させることができると考えられる。グアニル酸が増加した理由としては、加熱・高圧処理によりリボヌクレアーゼの活性が向上した可能性と、加熱・高圧処理により核膜が損傷した可能性が考えられる。

2-2 Guanylic Acid Concentration FIG. 44 shows the guanylic acid concentrations of the samples processed by

Raw shiitake mushrooms before treatment contained almost no guanylic acid, but the guanylic acid concentration increased by heating. In the example, the concentration of guanylic acid increased more than three times that of

From the above results, it is considered that the guanylic acid contained in shiitake mushrooms can be increased by using the method of the present invention as compared with the usual heat sterilization method. The reason for the increase in guanylic acid is thought to be the possibility that the ribonuclease activity was enhanced by the heat/high pressure treatment, and the possibility that the nuclear membrane was damaged by the heat/high pressure treatment.

2-3 塩分

図45に従来法1~3および実施例の加工処理を行った試料の塩分を示す。

塩分は加熱方法ではなく、加熱時間に依存して高くなった。また、シイタケは組織内の空隙が多いため、脱気包装した際に、気液置換により調味液が染込んだと考えられる。

2-3 Salinity Fig. 45 shows the salinity of the samples processed by

The salinity increased depending on the heating time but not on the heating method. In addition, since shiitake mushrooms have many voids in the tissue, it is thought that the seasoning liquid permeated due to air-liquid replacement when degassed and packaged.

2-4 食感

図46に従来法1~3および実施例の加工処理を行った試料の破断能力を示す。

この図から、食感に関しては有意な差異は認められなかった。

2-4 Texture Fig. 46 shows the breaking ability of the samples processed according to

From this figure, no significant difference in texture was observed.

2-5 殺菌効果

表30で示す通り、本発明で行ったキノコ加工品は、殺菌効果が向上した。

2-5 Bactericidal Effect As shown in Table 30, the mushroom processed product of the present invention has improved bactericidal effect.

3.100MPa以上の処理での効果

前記段落(0129)以降に記載したキノコ加工品の製法を高圧処理条件の圧力条件のみ100~300MPa範囲で変えて検討したところ、表30に示す結果となり、本発明が100~300MPaの圧力範囲でも有効であることを確認した。

3. Effect of treatment at 100 MPa or more When the manufacturing method of the processed mushroom product described in paragraph (0129) and after was examined by changing only the pressure condition of the high pressure treatment condition in the range of 100 to 300 MPa, the results shown in Table 30 were obtained. It was confirmed that the invention is also effective in the pressure range of 100-300 MPa.

追加実験(野菜)

(1)大根の粕漬け

・処理条件

圧力:1000気圧(100MPa)

温度:40~70℃

時間:1~5時間

・製造内容

野菜:大根(青首)

漬床:調味粕(酒粕70%、塩10%、砂糖20%)

製法:皮を剥ぎ、幅1cmの半月状にした大根に同重量の漬床を塗り、袋に入れ真空包装した。

・評価方法

塩分:各試料を粉砕してろ過し、ろ液を測定試料として塩分濃度計(東亜電波社製)に

より測定した。測定結果は図47に示すように、高圧加温処理することで、成分が浸透し、塩分濃度が高くなる。処理温度や処理時間による塩分濃度の違いは若干比例する傾向がある。

噛み切り易さ:各試料を高さ1cm、幅2cm角立方体に調製し、5mmφ円柱プランジャーで6mmまで進入した時の応力をレオメータにより測定した。測定結果は図48に示すように、高圧加温処理した大根の粕漬けは、処理温度および処理時間に比例して噛み切りやすさが良くなる。さらに、その噛み切りやすさは既製品の噛み切りやすさに近い。

色調:各処理条件の試料の色調について色彩色差計(日本電色社製)を用いて反射法によりL*,a*,b*を測定した。測定結果は図49に示すように、高圧加温処理することで、酒粕の色が大根に染み込む。処理温度および処理時間におおよそ比例して染み込むと考えられる。また、図50(a)は高圧加温処理前の色調を示し、(b)は高圧加温処理前の色調を示す。

微生物衛生検査法:各試料を生理食塩水にて懸濁の後に段階希釈し、各希釈試料を標準寒天培地 (栄研、一般生菌数用) および 0.01 (w/v) %クロラムフェニコール含有ポテトデキストロース寒天培地 (栄研、真菌用) に塗抹した (標準寒天の場合は混釈法を使用した)。30~37 ℃にて培養を3日間行った後に形成された微生物集落数を計数し、試料1gあたりの一般生菌および真菌の生菌数を算出した。基準値は、食品衛生法規格基準を参考に一般生菌数は 300 cfu /g 以下、真菌数は 1000 cfu /g 以下とした。また、不検出は、一般生菌および真菌共に、50 cfu /g 以下とした。

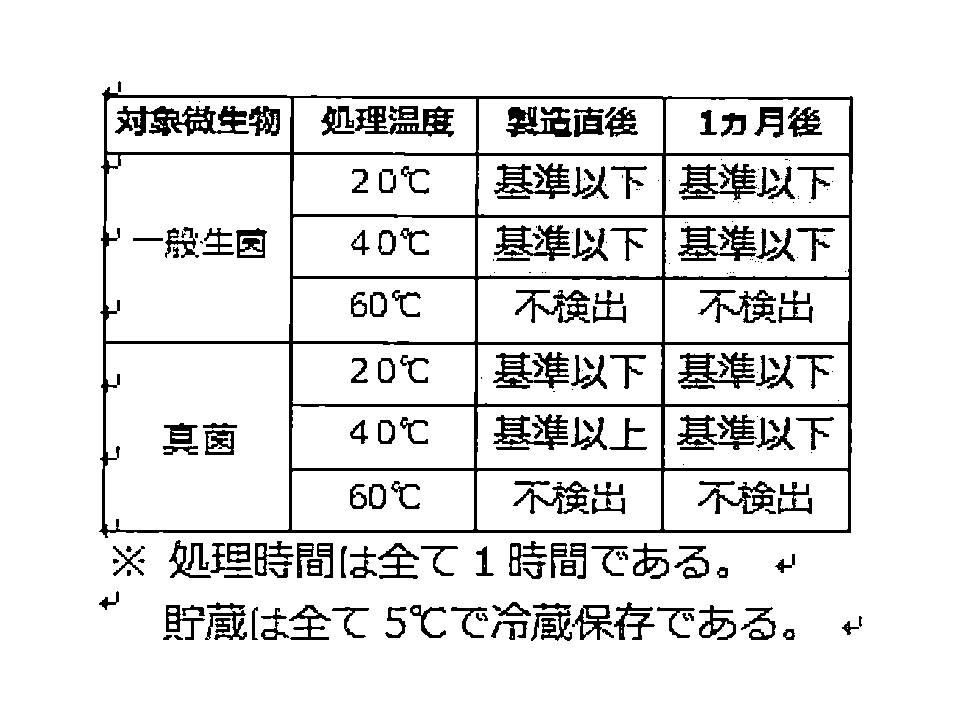

(表31A)は処理温度別(処理時間は全て3時間)の微生物衛生検査の結果を示し、(表31B)は処理時間別(処理温度は全て70℃)の微生物衛生検査の結果を示す。

Additional experiment (vegetables)

(1) Pickled radish in sake lees / processing conditions Pressure: 1000 atmospheres (100 MPa)

Temperature: 40-70°C

Time: 1 to 5 hours Production details Vegetables: Daikon radish (blue neck)

Pickles: seasoning lees (

Production method: Peeled daikon radish was cut into a half-moon shape with a width of 1 cm.

- Evaluation method Salinity: each sample was pulverized and filtered, and the filtrate was used as a measurement sample and measured with a salinity meter (manufactured by Toa Denpa Co., Ltd.). As shown in FIG. 47, the high-pressure heating treatment permeates the components and increases the salt concentration. Differences in salt concentration due to treatment temperature and treatment time tend to be slightly proportional.

Ease of biting off: each sample was prepared into a square cube of 1 cm high and 2 cm wide, and the stress when it was penetrated to 6 mm by a 5 mmφ cylindrical plunger was measured with a rheometer. As for the measurement results, as shown in FIG. 48, the daikon lees-pickled daikon radish that has been subjected to high-pressure heating improves the easiness of biting off in proportion to the treatment temperature and treatment time. Furthermore, its ease of biting off is close to that of ready-made products.

Color tone: L*, a*, and b* were measured by the reflection method using a color difference meter (manufactured by Nippon Denshoku Co., Ltd.) for the color tone of the sample under each processing condition. As shown in FIG. 49, the color of the sake lees permeates into the radish by high-pressure heating. It is believed that the penetration is roughly proportional to the treatment temperature and treatment time. Also, FIG. 50(a) shows the color tone before the high pressure heating treatment, and FIG. 50(b) shows the color tone before the high pressure heating treatment.

Microbial hygiene test method: Suspend each sample in physiological saline, serially dilute, and add each diluted sample to standard agar medium (Eiken, for general viable cell count) and 0.01 (w/v) % chloramphenicol. Potato dextrose agar medium (Eiken, for fungi) was smeared (in the case of standard agar, the pour method was used). After culturing at 30 to 37° C. for 3 days, the number of microbial colonies formed was counted, and the number of viable general bacteria and fungi per 1 g of sample was calculated. With reference to the standards of the Food Sanitation Act, the standard values were 300 cfu/g or less for the general viable count and 1000 cfu/g or less for the fungal count. Non-detection was defined as 50 cfu/g or less for both general viable bacteria and fungi.

(Table 31A) shows the results of microbial hygiene inspection by treatment temperature (all treatment times are 3 hours), and (Table 31B) shows the results of microbial hygiene inspection by treatment time (all treatment temperatures are 70°C).

尚、表において、基準以上とは、一般生菌は10万/g以上、真菌は1000/g以上、基準以下とは、一般生菌は10万/g以下、真菌は1000/g以下、不検出とは、検出限界、50/g以下を指す。

表に示すように、処理温度別および処理時間別ともに生菌数は衛生基準値を下回っている。これは高圧加温処理の効果だけでなく、大根に染み込んだ酒粕に含まれるアルコールによる殺菌効果との相乗効果によって菌の増殖などが抑制されたためと考えられる。

In the table, above the standard means 100,000/g or more for general viable bacteria, 1000/g or more for fungi, and below the standard means 100,000/g or less for general viable bacteria, 1000/g or less for fungi, and no Detection refers to the limit of detection, 50/g or less.

As shown in the table, the number of viable bacteria is below the sanitary standard value for both treatment temperature and treatment time. This is thought to be due not only to the effects of high-pressure heating, but also to the synergistic effect of the sterilizing effect of the alcohol contained in the sake lees soaked into the daikon radish, which inhibited the growth of bacteria.

(2)中島菜の粕漬け

・処理条件

圧力:1000気圧(100MPa)

温度:40~70℃

時間:15~45分

・製造内容

野菜:中島菜

漬床:調味粕(酒粕50%、清酒20%、塩10%、砂糖20%)

製法:中島菜の茎と葉の割合を1:1とし、総重量と同重量の漬床と共に袋に入れ真空包装した。

・評価方法

塩分:各試料を粉砕してろ過し、ろ液を測定試料として塩分濃度計(東亜電波社製)により測定した。測定結果は図51に示すように、高圧加温処理することで、成分が浸透し、塩分濃度が高くなる。処理温度は60℃まで温度の上昇に比例して塩分濃度が高くなるが、70℃では低くなる

硬さ:各試料を長さ1.5cm~2cmに切った茎に調整し、2mmφ針状プランジャーで切った茎を横にし、中心部を貫くように10mmまで進入した時の応力をレオメータにより測定した。測定結果は図52に示すように、高圧加温処理した中島菜の粕漬けの茎の硬さは未処理よりも柔らかくなり、既製品の中島菜漬に近い食感になる。

色調:各処理条件の試料の色調について色彩色差計(日本電色社製)を用いて反射法によりL*,a*,b*を測定した。測定結果は図53に示すように、処理温度および処理時間に比例して葉の緑色はかなりくすむ。また、図54(a)は高圧加温処理前の色調を示し、(b)は高圧加温処理前の色調を示す。

微生物衛生検査法:各試料を生理食塩水にて懸濁の後に段階希釈し、各希釈試料を標準寒天培地 (栄研、一般生菌数用) および 0.01 (w/v) %クロラムフェニコール含有ポテトデキストロース寒天培地 (栄研、真菌用) に塗抹した (標準寒天の場合は混釈法を使用した)。30~37 ℃にて培養を3日間行った後に形成された微生物集落数を計数し、試料1gあたりの一般生菌および真菌の生菌数を算出した。基準値は、食品衛生法規格基準を参考に一般生菌数は 300 cfu /g 以下、真菌数は 1000 cfu /g 以下とした。また、不検出は、一般生菌および真菌共に、50 cfu /g 以下とした。

(表32A)は処理温度別(処理時間は全て30分)の微生物衛生検査の結果を示し、(表32B)は処理時間別(処理温度は全て50℃)の微生物衛生検査の結果を示す。

(2) Nakashima greens pickled in sake lees / processing conditions Pressure: 1000 atmospheres (100 MPa)

Temperature: 40-70°C

Time: 15-45 minutes Production details Vegetables: Nakashima greens Pickled bed: seasoning lees (

Production method: The ratio of stems and leaves of Nakashima greens was set to 1:1, and the mixture was placed in a bag together with pickles of the same weight as the total weight and vacuum-packaged.

- Evaluation method Salinity: each sample was pulverized and filtered, and the filtrate was used as a measurement sample and measured with a salinity meter (manufactured by Toa Denpa Co., Ltd.). As shown in FIG. 51, the high-pressure heating treatment permeates the components and increases the salt concentration. The treatment temperature increases up to 60°C in proportion to the increase in salinity, but it decreases at 70°C. The stem cut with a jar was placed on its side, and the stress when it penetrated to 10 mm through the center was measured with a rheometer. As shown in FIG. 52, the measurement results show that the stalks of Nakashimana pickled in sake lees that have been subjected to high-pressure heating are softer than those that have not been treated, and have a texture similar to that of ready-made Nakashimanazuke.

Color tone: L*, a*, and b* were measured by the reflection method using a color difference meter (manufactured by Nippon Denshoku Co., Ltd.) for the color tone of the sample under each processing condition. As for the measurement results, as shown in FIG. 53, the green color of the leaves becomes considerably dull in proportion to the treatment temperature and treatment time. Further, FIG. 54(a) shows the color tone before the high pressure heating treatment, and (b) shows the color tone before the high pressure heating treatment.