JP7031633B2 - Adhesive-imparting resin emulsion and water-based adhesive / adhesive composition - Google Patents

Adhesive-imparting resin emulsion and water-based adhesive / adhesive composition Download PDFInfo

- Publication number

- JP7031633B2 JP7031633B2 JP2019058285A JP2019058285A JP7031633B2 JP 7031633 B2 JP7031633 B2 JP 7031633B2 JP 2019058285 A JP2019058285 A JP 2019058285A JP 2019058285 A JP2019058285 A JP 2019058285A JP 7031633 B2 JP7031633 B2 JP 7031633B2

- Authority

- JP

- Japan

- Prior art keywords

- resin

- rosin

- adhesive

- group

- water

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J3/00—Processes of treating or compounding macromolecular substances

- C08J3/02—Making solutions, dispersions, lattices or gels by other methods than by solution, emulsion or suspension polymerisation techniques

- C08J3/03—Making solutions, dispersions, lattices or gels by other methods than by solution, emulsion or suspension polymerisation techniques in aqueous media

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J11/00—Features of adhesives not provided for in group C09J9/00, e.g. additives

- C09J11/08—Macromolecular additives

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J133/00—Adhesives based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Adhesives based on derivatives of such polymers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2333/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2357/00—Characterised by the use of unspecified polymers obtained by reactions only involving carbon-to-carbon unsaturated bonds

- C08J2357/02—Copolymers of mineral oil hydrocarbons

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2393/00—Characterised by the use of natural resins; Derivatives thereof

- C08J2393/04—Rosin

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Dispersion Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Adhesives Or Adhesive Processes (AREA)

- Compositions Of Macromolecular Compounds (AREA)

- Cosmetics (AREA)

Description

本発明は、粘着付与樹脂エマルジョン及び水系粘・接着剤組成物に関する。 The present invention relates to a tackifier resin emulsion and a water-based adhesive / adhesive composition.

テープやシート、ラベル等を製造する際に、基材である紙やプラスチックフィルム等に塗工する粘・接着剤組成物としては、従来、粘着力を付与するための粘着付与樹脂と( メタ)アクリル系重合体等のベースポリマーとを有機溶剤に溶解させた溶液型のものが一般的であったが、近年は環境、安全衛生、省資源等を考慮して、エマルジョン型の水系粘・接着剤組成物が主流になりつつある。 When manufacturing tapes, sheets, labels, etc., the adhesive / adhesive composition to be applied to paper, plastic film, etc., which is the base material, has conventionally been a tackifier resin for imparting adhesive strength (meth). A solution type in which a base polymer such as an acrylic polymer is dissolved in an organic solvent was generally used, but in recent years, an emulsion type water-based adhesive / adhesive has been taken into consideration for the environment, safety and health, resource saving, etc. Agent compositions are becoming mainstream.

水系粘・接着剤組成物としては、従来、前記ベースポリマーと粘着付与樹脂とを、別個に各種アニオン性乳化剤やノニオン性乳化剤の存在下でエマルジョン化し、混合したものが提案されている(特許文献1、2を参照)。しかしながら、前記乳化剤を使用して得られる粘着付与樹脂エマルジョンには凝集物が多く発生するものもあり、当該エマルジョンの乳化性は未だ十分なものではなかった。また、仮に乳化性の良い粘着付与樹脂エマルジョンが得られたとしても、当該エマルジョンを含む水系粘・接着剤は、前記乳化剤が水分と結びつき易いこともあって、水分や湿気の多い条件下での各種基材に対する接着力(以下、耐水接着力ともいう)が低くなることがあった。 As a water-based adhesive / adhesive composition, conventionally, the base polymer and the tackifier resin have been separately emulsified in the presence of various anionic emulsifiers and nonionic emulsifiers and mixed (Patent Documents). See 1 and 2). However, some of the tackifier resin emulsions obtained by using the emulsifier generate a large amount of agglomerates, and the emulsifying property of the emulsion is not yet sufficient. Further, even if an emulsifying adhesive resin emulsion having good emulsifying property is obtained, the water-based adhesive / adhesive containing the emulsion may be easily bound to water by the emulsifier, so that the emulsifier may easily bind to water under conditions of high water content and moisture. Adhesive strength to various substrates (hereinafter, also referred to as water resistant adhesive strength) may be low.

本発明は、乳化性に優れており、かつ、水系粘・接着剤組成物に高い耐水接着力を付与できる新規な粘着付与樹脂エマルジョンを提供することを課題とする。 An object of the present invention is to provide a novel tackifying resin emulsion which is excellent in emulsifying property and can impart high water-resistant adhesive force to a water-based viscous / adhesive composition.

本発明者は、鋭意検討を重ねた結果、特定の樹脂及び特定の多鎖多親水基型化合物を含有する粘着付与樹脂エマルジョンが前記課題を解決することを見出した。すなわち、本発明は以下の粘着付与樹脂エマルジョン及び水系粘・接着剤組成物に関する。 As a result of diligent studies, the present inventor has found that a tackifier resin emulsion containing a specific resin and a specific multi-chain multi-hydrophilic group compound solves the above-mentioned problems. That is, the present invention relates to the following tackifier resin emulsion and water-based viscous / adhesive composition.

1.ロジン系樹脂(a1)、石油樹脂(a2)及びテルペン系樹脂(a3)からなる群より選ばれる少なくとも1種の樹脂(A)、並びに疎水鎖及び親水基を分子内に少なくとも2個ずつ有する多鎖多親水基型化合物(B)を含む粘着付与樹脂エマルジョン。 1. 1. At least one resin (A) selected from the group consisting of a rosin-based resin (a1), a petroleum resin (a2) and a terpene-based resin (a3), and a poly having at least two hydrophobic chains and hydrophilic groups in the molecule. A tackifier resin emulsion containing the chain polyhydrophilic group compound (B).

2.(A)成分の軟化点が70~180℃である、前記項1の粘着付与樹脂エマルジョン。 2. 2. Item (A) The tackifier resin emulsion according to Item 1, wherein the softening point of the component is 70 to 180 ° C.

3.(a1)成分が、ロジンエステル類及び/又はロジンフェノール樹脂である、前記項1又は2の粘着付与樹脂エマルジョン。 3. 3. Item (a1) The tackifier resin emulsion according to Item 1 or 2, wherein the component is a rosin ester and / or a rosin phenol resin.

4.(B)成分が、疎水鎖及び親水基を分子内に少なくとも1個ずつ有する化合物(b)がスペーサーを介して2分子結合している化合物である、前記項1~3のいずれかの粘着付与樹脂エマルジョン。 4. The tackifier according to any one of Items 1 to 3 above, wherein the component (B) is a compound having at least one hydrophobic chain and at least one hydrophilic group in the molecule, and (b) is a compound in which two molecules are bonded via a spacer. Resin emulsion.

5.前記項1~4のいずれかの粘着付与樹脂エマルジョンとベースポリマーとを含む、水系粘・接着剤組成物。 5. A water-based adhesive / adhesive composition comprising the tackifier resin emulsion according to any one of Items 1 to 4 and a base polymer.

6.前記ベースポリマーがアクリル系重合体エマルジョンである、前記項5の水系粘・接着剤組成物 6. Item 5. The water-based adhesive / adhesive composition according to Item 5, wherein the base polymer is an acrylic polymer emulsion.

本発明の粘着付与樹脂エマルジョンは、従来の乳化剤を使用する場合に比べて、凝集物の発生等が抑制されており、乳化性に優れている。また、当該粘着付与樹脂エマルジョンを含む水系粘・接着剤組成物は、高い耐水接着力を有しており、耐水性が要求される用途での粘・接着剤として好適である。さらに、当該粘着付与樹脂エマルジョンを含む水系粘・接着剤組成物は、水分や湿気の多い条件下における粘・接着剤皮膜の耐白化性(以下、耐水白化性ともいう。)が良好であるため、水分や湿気の多い環境下で透明性や意匠性が要求される用途での粘・接着剤、例えば、化粧品容器やシャンプー容器に用いられる透明ラベルの粘・接着剤として好適である。 The tackifier resin emulsion of the present invention is excellent in emulsifying property because the generation of agglomerates is suppressed as compared with the case of using a conventional emulsifier. Further, the water-based adhesive / adhesive composition containing the tackifier resin emulsion has high water-resistant adhesive strength, and is suitable as a adhesive / adhesive in applications requiring water resistance. Further, the water-based adhesive / adhesive composition containing the tackifier resin emulsion has good whitening resistance (hereinafter, also referred to as water whitening resistance) of the adhesive / adhesive film under conditions of high moisture and humidity. It is suitable as a sticky / adhesive for applications where transparency and design are required in an environment with a lot of moisture and humidity, for example, a sticky / adhesive for a transparent label used for a cosmetic container or a shampoo container.

本発明の粘着付与樹脂エマルジョン(以下、粘着付与樹脂エマルジョンともいう)は、ロジン系樹脂(a1)(以下、(a1)成分という)、石油樹脂(a2)(以下、(a2)成分という)及びテルペン系樹脂(a3)(以下、(a3)成分という)からなる群より選ばれる少なくとも1種の樹脂(A)(以下、(A)成分という)、並びに疎水鎖及び親水基を分子内に少なくとも2個ずつ有する多鎖多親水基型化合物(B)(以下、(B)成分という)を含むものである。 The tackifier resin emulsion of the present invention (hereinafter, also referred to as a tackifier resin emulsion) includes a rosin-based resin (a1) (hereinafter referred to as (a1) component), a petroleum resin (a2) (hereinafter referred to as (a2) component), and a petroleum resin (a2) component. At least one resin (A) (hereinafter referred to as (A) component) selected from the group consisting of a terpene resin (a3) (hereinafter referred to as (a3) component), and at least a hydrophobic chain and a hydrophilic group are contained in the molecule. It contains a multi-chain multi-hydrophilic group compound (B) having two each (hereinafter referred to as a component (B)).

(A)成分は、(a1)成分、(a2)成分及び(a3)成分からなる群より選ばれる少なくとも1種の樹脂である。 The component (A) is at least one resin selected from the group consisting of the component (a1), the component (a2) and the component (a3).

(a1)成分としては、特に限定されず、各種公知のものを使用できる。例えば、馬尾松、スラッシュ松、メルクシ松、思茅松、テーダ松及び大王松等に由来する天然ロジン(ガムロジン、トール油ロジン、ウッドロジン)、天然ロジンを減圧留去法、水蒸気蒸留法、抽出法、再結晶法等で精製して得られる精製ロジン(以下、天然ロジンと精製ロジンを纏めて原料ロジンともいう)、原料ロジンを水素化反応させて得られる水素化ロジン、原料ロジンを不均化反応させて得られる不均化ロジン、重合ロジン、アクリル化ロジン、マレイン化ロジン、フマル化ロジン等のα,β―不飽和カルボン酸変性ロジン、又はこれらのエステル化物(以下、ロジンエステル類とする)、ロジンフェノール樹脂などが挙げられる。これらは単独でも2種以上を組み合わせても良い。その中でも、耐水接着力、耐水白化性及び粘着性能に優れる点から、ロジンエステル類及び/又はロジンフェノール樹脂が好ましい。 The component (a1) is not particularly limited, and various known components can be used. For example, natural rosin (gum rosin, tall oil rosin, wood rosin) derived from Mao pine, slush pine, Merck pine, Shikaya pine, Theda pine, Daio pine, etc., natural rosin under reduced pressure distillation method, steam distillation method, extraction method, etc. Purified rosin obtained by purification by recrystallization method (hereinafter, natural rosin and purified rosin are collectively referred to as raw material rosin), hydride obtained by hydrogenating raw material rosin, and disproportionate reaction of raw material rosin. Α, β-unsaturated carboxylic acid-modified rosins such as disproportionated rosin, polymerized rosin, acrylicized rosin, maleated rosin, and fumarized rosin, or esterified products thereof (hereinafter referred to as rosin esters). , Rosin phenol resin and the like. These may be used alone or in combination of two or more. Among them, rosin esters and / or rosin phenol resins are preferable because they are excellent in water-resistant adhesive strength, water-whitening resistance, and adhesive performance.

(a2)成分としては、特に限定されず、各種公知のものを使用できる。例えば、ペンテン、ペンタジエン、イソプレン等のナフサのC5留分から得られるC5系石油樹脂;インデン、メチルインデン、ビニルトルエン、スチレン、α-メチルスチレン、β-メチルスチレン等のナフサのC9留分から得られるC9系石油樹脂;前記C5留分、C9留分から得られるC5-C9共重合系石油樹脂;スチレン等を主成分として重合して得られるピュアモノマー樹脂;シクロペンタジエン、ジシクロペンタジエンから得られるDCPD系石油樹脂;これらの石油樹脂の水素化物等が挙げられる。これらは単独でも2種以上を組み合わせても良い。これらの中でも、耐水接着力、耐水白化性及び粘着性能に優れる点から、C9系石油樹脂が好ましい。 The component (a2) is not particularly limited, and various known components can be used. For example, C5 based petroleum resin obtained from C5 distillate of naphtha such as penten, pentadiene and isoprene; C9 obtained from C9 distillate of naphtha such as inden, methyl inden, vinyl toluene, styrene, α-methyl styrene and β-methyl styrene. Based petroleum resin; C5-C9 copolymerized petroleum resin obtained from the C5 distillate and C9 distillate; pure monomer resin obtained by polymerizing styrene or the like as a main component; DCPD based petroleum obtained from cyclopentadiene and dicyclopentadiene. Resin; Examples thereof include hydrides of these petroleum resins. These may be used alone or in combination of two or more. Among these, C9-based petroleum resin is preferable because it is excellent in water-resistant adhesive strength, water-whitening resistance, and adhesive performance.

(a3)成分としては、特に限定されず、公知のテルペン類とフェノール類とを共重合させた樹脂、ポリテルペン樹脂等が挙げられる。なお、(a3)成分は水素化されたものであってもよい。これらの中でも、耐水接着力、耐水白化性及び粘着性能に優れる点から、テルペンフェノール樹脂が好ましい。 The component (a3) is not particularly limited, and examples thereof include a resin obtained by copolymerizing known terpenes and phenols, a polyterpene resin, and the like. The component (a3) may be hydrogenated. Among these, the terpene phenol resin is preferable because it is excellent in water-resistant adhesive strength, water-whitening resistance, and adhesive performance.

以下、(a1)成分に関して、ロジンエステル類、ロジンフェノール樹脂について説明する。本明細書において、ロジンエステル類は、ロジンエステル、重合ロジンエステル、不飽和カルボン酸変性ロジンエステルを意味する。ロジンエステル類は、耐水接着力、耐水白化性及び粘着性能に優れる点から、重合ロジンエステルがより好ましい。 Hereinafter, the rosin esters and the rosin phenol resin will be described with respect to the component (a1). As used herein, the rosin esters mean rosin esters, polymerized rosin esters, and unsaturated carboxylic acid-modified rosin esters. As the rosin esters, polymerized rosin esters are more preferable because they are excellent in water-resistant adhesive strength, water-whitening resistance and adhesive performance.

ロジンエステルは、前記の原料ロジン、水素化ロジン、不均化ロジンにアルコール類を反応させて得られる。 The rosin ester is obtained by reacting the raw material rosin, hydrogenated rosin, and disproportionated rosin with alcohols.

前記ロジンと、アルコール類との反応条件としては、該ロジン及びアルコール類を溶媒の存在下又は不存在下に、必要によりエステル化触媒を加え、250~280℃程度で、1~8時間程度で行えば良い。 As the reaction conditions between the rosin and the alcohols, an esterification catalyst was added to the rosin and the alcohols in the presence or absence of a solvent, if necessary, at about 250 to 280 ° C. for about 1 to 8 hours. Just go.

前記アルコール類としては、特に限定されず、例えば、メタノール、エタノール、プロパノール、ステアリルアルコール等の1価のアルコール類、エチレングリコール、ジエチレングリコール、トリエチレングリコール、プロピレングリコール、ネオペンチルグリコール、ダイマージオール等の2価のアルコール類、グリセリン、トリメチロールエタン、トリメチロールプロパンなどの3価のアルコール類、ペンタエリスリトール、ジグリセリンなどの4価のアルコール類、ジペンタエリスリトールなどの6価のアルコール類等が挙げられる。これらの中でも、2つ以上の水酸基を有する多価アルコール類が好ましく、特にペンタエリスリトールが好ましい。 The alcohols are not particularly limited, and for example, monohydric alcohols such as methanol, ethanol, propanol and stearyl alcohol, ethylene glycol, diethylene glycol, triethylene glycol, propylene glycol, neopentyl glycol, dimerdiol and the like 2 Examples thereof include valent alcohols, trihydric alcohols such as glycerin, trimethylolethane and trimethylolpropane, tetrahydric alcohols such as pentaerythritol and diglycerin, and hexahydric alcohols such as dipentaerythritol. Among these, polyhydric alcohols having two or more hydroxyl groups are preferable, and pentaerythritol is particularly preferable.

重合ロジンエステルは、重合ロジンにアルコール類を反応させて得られる。重合ロジンとは、二量化された樹脂酸を含むロジン誘導体である。 The polymerized rosin ester is obtained by reacting the polymerized rosin with alcohols. The polymerized rosin is a rosin derivative containing a dimerized resin acid.

重合ロジンを製造する方法としては、公知の方法を採用することができる。具体的には、例えば、前記原料ロジンを、硫酸、フッ化水素、塩化アルミニウム、四塩化チタン等の触媒を含むトルエン、キシレン等の溶媒中、温度40~160℃程度で、1~5時間程度反応させる方法等が挙げられる。 As a method for producing the polymerized rosin, a known method can be adopted. Specifically, for example, the raw material rosin is placed in a solvent such as toluene or xylene containing a catalyst such as sulfuric acid, hydrogen fluoride, aluminum chloride or titanium tetrachloride at a temperature of about 40 to 160 ° C. for about 1 to 5 hours. Examples thereof include a method of reacting.

重合ロジンの具体例としては、前記原料ロジンにガムロジンを使用したガム系重合ロジン(例えば、商品名「重合ロジンB-140」、新洲(武平)林化有限公司製)、トール油ロジンを使用したトール油系重合ロジン(例えば、商品名「シルバタック140」、アリゾナケミカル社製)、ウッドロジンを使用したウッド系重合ロジン(例えば、商品名「ダイマレックス」、ASHLAND社製)等が挙げられる。 Specific examples of the polymerized rosin include gum-based polymerized rosin using gum rosin as the raw material rosin (for example, trade name "polymerized rosin B-140", manufactured by Shinshu (Takehira) Forestry Co., Ltd.) and tall oil rosin. Examples thereof include tall oil-based polymerized rosin (for example, trade name “Silva Tack 140”, manufactured by Arizona Chemical Co., Ltd.), wood-based polymerized rosin using wood rosin (for example, trade name “Dymalex”, manufactured by ASHLAND) and the like.

また、重合ロジンとしては、重合ロジンに、水素化、不均化、アクリル化、マレイン化、フマル化等の各種処理を施したものを使用しても良い。また各種処理も単独であっても2種以上を組み合わせても良い。重合ロジンは、アクリル化、マレイン化、又はフマル化を施したものであるのが好ましい。 Further, as the polymerized rosin, those obtained by subjecting the polymerized rosin to various treatments such as hydrogenation, disproportionation, acrylicization, maleinization, and fumarization may be used. Further, various treatments may be performed alone or in combination of two or more. The polymerized rosin is preferably acrylicated, maleated, or fumarized.

前記重合ロジンとアルコール類との反応条件としては、重合ロジン及びアルコール類を溶媒の存在下又は不存在下に、必要によりエステル化触媒を加え、250~280℃程度で、1~8時間程度で行えば良い。 As the reaction conditions between the polymerized rosin and the alcohols, an esterification catalyst was added to the polymerized rosin and the alcohols in the presence or absence of a solvent, if necessary, at about 250 to 280 ° C. for about 1 to 8 hours. Just go.

重合ロジンをエステル化する際に用いるアルコール類は前記同様である。 The alcohols used for esterifying the polymerized rosin are the same as described above.

なお、重合反応とエステル化反応の順番は、前記に限定されず、エステル化反応の後に、重合反応を行ってもよい。 The order of the polymerization reaction and the esterification reaction is not limited to the above, and the polymerization reaction may be carried out after the esterification reaction.

重合ロジンエステルの物性としては特に限定されない。耐水接着力や粘着性能に優れる点から、重合ロジンエステルの物性は、軟化点が150~180℃程度であるのが好ましい。なお、本発明において、軟化点は、環球法(JISK5902)により測定した値である。 The physical characteristics of the polymerized rosin ester are not particularly limited. From the viewpoint of excellent water resistance and adhesive performance, the physical properties of the polymerized rosin ester preferably have a softening point of about 150 to 180 ° C. In the present invention, the softening point is a value measured by the ring-and-ball method (JISK5902).

不飽和カルボン酸変性ロジンエステルは、前記原料ロジンをα,β-不飽和カルボン酸で付加反応させた変性ロジン(α,β-不飽和カルボン酸変性ロジン)に、更にアルコール類を反応させてエステル化させたものである。 The unsaturated carboxylic acid-modified rosin ester is an ester obtained by further reacting alcohols with a modified rosin (α, β-unsaturated carboxylic acid-modified rosin) obtained by addition-reacting the raw material rosin with α, β-unsaturated carboxylic acid. It is an esterification.

α,β-不飽和ジカルボン酸としては、特に限定されず、各種公知のものを使用できる。具体的には、例えば、アクリル酸、メタクリル酸、マレイン酸、フマル酸、イタコン酸、シトラコン酸、ムコン酸、無水マレイン酸、無水イタコン酸、無水シトラコン酸、無水ムコン酸等が挙げられる。これらの中でも、アクリル酸、マレイン酸、無水マレイン酸、フマル酸が好ましい。α,β-不飽和ジカルボン酸の使用量は、乳化性の点から、通常は、前記原料ロジン100重量部に対して1~20重量部程度、好ましくは1~3重量部程度である。 The α, β-unsaturated dicarboxylic acid is not particularly limited, and various known ones can be used. Specific examples thereof include acrylic acid, methacrylic acid, maleic acid, fumaric acid, itaconic acid, citraconic acid, muconic acid, maleic anhydride, itaconic anhydride, citraconic anhydride, and muconic anhydride. Among these, acrylic acid, maleic acid, maleic anhydride, and fumaric acid are preferable. From the viewpoint of emulsifying property, the amount of α, β-unsaturated dicarboxylic acid used is usually about 1 to 20 parts by weight, preferably about 1 to 3 parts by weight, based on 100 parts by weight of the raw material rosin.

α,β-不飽和カルボン酸変性ロジンの製造方法としては、特に限定されないが、例えば、加熱下で溶融させた前記原料ロジンに、α,β-不飽和カルボン酸を加えて、温度180~240℃程度で、1~9時間程度で反応させることが挙げられる。また、前記反応は、密閉した反応系内に窒素等の不活性ガスを吹き込みながら行っても良い。さらに反応では、例えば、塩化亜鉛、塩化鉄、塩化スズ等のルイス酸や、パラトルエンスルホン酸、メタンスルホン酸等のブレンステッド酸等の公知の触媒を使用してもよい。これらの触媒の使用量は、前記原料ロジンに対して通常0.01~10重量%程度である。 The method for producing the α, β-unsaturated carboxylic acid-modified rosin is not particularly limited, but for example, α, β-unsaturated carboxylic acid is added to the raw material rosin melted under heating, and the temperature is 180 to 240. The reaction may be carried out at about ° C. for about 1 to 9 hours. Further, the reaction may be carried out while blowing an inert gas such as nitrogen into the closed reaction system. Further, in the reaction, known catalysts such as Lewis acid such as zinc chloride, iron chloride and tin chloride, and blended acid such as p-toluenesulfonic acid and methanesulfonic acid may be used. The amount of these catalysts used is usually about 0.01 to 10% by weight with respect to the raw material rosin.

得られたα,β-不飽和カルボン酸変性ロジンには、前記原料ロジン由来の樹脂酸が含まれても良い。 The obtained α, β-unsaturated carboxylic acid-modified rosin may contain a resin acid derived from the raw material rosin.

前記α,β-不飽和カルボン酸変性ロジンと、アルコール類との反応条件としては、特に限定されないが、例えば、加熱下で溶融させたα,β-不飽和カルボン酸変性ロジンに、アルコールを加えて、温度250~280℃程度で、15~20時間程度で反応させることが挙げられる。また、前記反応は、密閉した反応系内に窒素等の不活性ガスを吹き込みながら行っても良く、前述の触媒を使用してもよい。 The reaction conditions between the α, β-unsaturated carboxylic acid-modified rosin and the alcohols are not particularly limited, but for example, alcohol is added to the α, β-unsaturated carboxylic acid-modified rosin melted under heating. The reaction may be carried out at a temperature of about 250 to 280 ° C. for about 15 to 20 hours. Further, the reaction may be carried out while blowing an inert gas such as nitrogen into the closed reaction system, or the above-mentioned catalyst may be used.

α,β-不飽和カルボン酸変性ロジンをエステル化する際に用いるアルコール類は前記同様である。 The alcohols used for esterifying the α, β-unsaturated carboxylic acid-modified rosin are the same as described above.

ロジンフェノール樹脂は、前記原料ロジンにフェノール類を反応させて得られる。 The rosin phenol resin is obtained by reacting the raw material rosin with phenols.

フェノール類としては、特に限定されず、各種公知のものを使用できる。具体的には、クレゾール、ブチルフェノール、オクチルフェノール、ノニルフェノール等のアルキルフェノール類、フェノール、ビスフェノール類、ナフトール類等が挙げられる。これらは1種を単独で用いても2種以上を混合して用いてもよい。フェノール類の使用量は、乳化性の点から、通常、前記原料ロジン1モルに対して0.8~1.5モル程度のフェノール類を反応させればよい。 The phenols are not particularly limited, and various known phenols can be used. Specific examples thereof include alkylphenols such as cresol, butylphenol, octylphenol and nonylphenol, phenols, bisphenols and naphthols. These may be used alone or in combination of two or more. As for the amount of phenol used, from the viewpoint of emulsifying property, usually, about 0.8 to 1.5 mol of phenol may be reacted with 1 mol of the raw material rosin.

ロジンフェノール樹脂の製造方法としては、特に限定されないが、例えば、前記原料ロジン及びフェノール類を必要に応じて酸触媒の存在下、加熱して反応させることが挙げられる。反応温度としては、通常、180~350℃で6~18時間程度反応させればよい。なお、当該反応に用いることができる酸触媒としては、特に限定されないが、例えば、硫酸、塩化水素、三フッ化ホウ素等の無機酸触媒やパラトルエンスルホン酸、メタンスルホン酸等の有機酸触媒を挙げることができる。酸触媒を使用する場合には、前記原料ロジン100重量部に対し、0.01~1.0重量部程度用いればよい。また、ロジンフェノール樹脂は、前記反応で得られた樹脂に、更にアルコール類を反応させてエステル化したものであっても良い。その際に用いるアルコール類は前記同様である。 The method for producing the rosin phenol resin is not particularly limited, and examples thereof include heating and reacting the raw material rosin and phenols in the presence of an acid catalyst, if necessary. As the reaction temperature, usually, the reaction may be carried out at 180 to 350 ° C. for about 6 to 18 hours. The acid catalyst that can be used in the reaction is not particularly limited, but for example, an inorganic acid catalyst such as sulfuric acid, hydrogen chloride, or boron trifluoride, or an organic acid catalyst such as paratoluenesulfonic acid or methanesulfonic acid can be used. Can be mentioned. When an acid catalyst is used, it may be used in an amount of about 0.01 to 1.0 part by weight with respect to 100 parts by weight of the raw material rosin. Further, the rosin phenol resin may be one obtained by further reacting the resin obtained in the above reaction with alcohols to esterify it. The alcohols used at that time are the same as described above.

(A)成分の軟化点としては、特に限定されないが、耐水接着力や粘着性能に優れる点から、好ましくは70~180℃程度である。なお、本発明において、軟化点は、環球法(JISK5902)により測定した値である。 The softening point of the component (A) is not particularly limited, but is preferably about 70 to 180 ° C. from the viewpoint of excellent water resistance and adhesive performance. In the present invention, the softening point is a value measured by the ring-and-ball method (JISK5902).

(B)成分は、疎水鎖及び親水基を分子内に少なくとも2個ずつ有する多鎖多親水基型化合物である。その構造は、疎水鎖及び親水基を分子内に少なくとも1個ずつ有する化合物(b)(以下、(b)成分ともいう)が、スペーサーを介して少なくとも2分子結合している構造である。(B)成分は、単独でも2種以上を組み合わせてもよい。 The component (B) is a multi-chain multi-hydrophilic group compound having at least two hydrophobic chains and two hydrophilic groups in the molecule. The structure is such that at least two molecules of the compound (b) (hereinafter, also referred to as the component (b)) having at least one hydrophobic chain and one hydrophilic group in the molecule are bonded via a spacer. The component (B) may be used alone or in combination of two or more.

(B)成分は、粘着付与樹脂エマルジョンにおいて、前記(A)成分を水中で乳化させるために用いる。従来の粘着付与樹脂エマルジョンは、公知のアニオン性乳化剤やノニオン性乳化剤を用いて乳化させて得られるが、乳化性及び耐水接着力が共に優れるものを得るのが困難な場合があった。本発明の粘着付与樹脂エマルジョンは、複数の疎水鎖及び親水基を含有する(B)成分を用いることで、乳化性及び耐水接着力が共に優れることが明らかになった。また、(B)成分を含む当該粘着付与樹脂エマルジョンは、耐水白化性が良好であることも明らかになった。 The component (B) is used to emulsify the component (A) in water in a tackifier resin emulsion. The conventional tackifier resin emulsion is obtained by emulsifying with a known anionic emulsifier or nonionic emulsifier, but it may be difficult to obtain one having both excellent emulsifying property and water-resistant adhesive force. It has been clarified that the tackifier resin emulsion of the present invention is excellent in both emulsifying property and water resistance by using the component (B) containing a plurality of hydrophobic chains and hydrophilic groups. It was also clarified that the tackifier resin emulsion containing the component (B) has good water whitening resistance.

(B)成分は、前記構造のものであれば特に限定されないが、入手し易く乳化性に優れる点から、(b)成分がスペーサーを介して2分子結合している化合物であるのが好ましく、b-s-b(式中、bは(b)成分を表し、sは後述するスペーサーを表す。2つのbは互いに同一又は異なっていても良い)で表される化合物であるのが好ましい。また、(b)成分は、同様の点から、分子内に疎水鎖を1個及び親水基を1個有する化合物(以下、1鎖1親水基型化合物ともいう)又は分子内に疎水鎖を1個及び親水基を2個有する化合物(以下、1鎖2親水基型化合物ともいう)であるのが好ましい。1鎖1親水基型化合物又は1鎖2親水基型化合物としては、例えば、各種公知の1鎖1親水基型界面活性剤(乳化剤)又は1鎖2親水基型界面活性剤(乳化剤)等が挙げられる。 The component (B) is not particularly limited as long as it has the above-mentioned structure, but it is preferably a compound in which two molecules of the component (b) are bonded via a spacer from the viewpoint of easy availability and excellent emulsifying property. It is preferably a compound represented by bs-b (in the formula, b represents the component (b), s represents the spacer described later, and the two bs may be the same or different from each other). Further, from the same point of view, the component (b) has a compound having one hydrophobic chain and one hydrophilic group in the molecule (hereinafter, also referred to as a 1-chain 1-hydrophilic group compound) or 1 hydrophobic chain in the molecule. It is preferably a compound having two hydrophilic groups (hereinafter, also referred to as a 1-chain 2-hydrophilic group compound). Examples of the 1-chain 1-hydrophilic group-type compound or the 1-chain 2-hydrophilic group-type compound include various known 1-chain 1-hydrophilic group-type surfactants (emulsifiers) and 1-chain 2-hydrophilic group-type surfactants (emulsifiers). Can be mentioned.

(B)成分に含まれる前記疎水鎖は、それぞれ独立に、炭素数2~20個の飽和又は不飽和の直鎖、分枝鎖、環状鎖を有する疎水鎖であるのが好ましい。該疎水鎖の具体例としては、例えば、エチル、n-プロピル、n-ブチル、n-ペンチル、n-ヘキシル、n-ヘプチル、n-オクチル、n-ノニル、n-デシル、n-ウンデシル、n-ドデシル、n-トリデシル、n-テトラデシル、n-ペンタデシル、n-ヘキサデシル、n-ヘプタデシル、n-オクタデシル、n-ノナデシル、n-エイコシル、フェニル、直鎖又は分枝鎖アルキル基で置換されたフェニル、芳香族ビニル化合物オリゴマー残基で置換されたフェニル等の各残基とこれらの分枝鎖異性体、並びにこれらに対応した、1カ所、2カ所または3カ所に不飽和部分を有する不飽和残基等が挙げられる。その中でも、乳化性に優れる点から、該疎水鎖は、炭素数10~16個の飽和又は不飽和の直鎖、炭素数10~16個の飽和又は不飽和の分枝鎖、炭素数10~16個の飽和又は不飽和の環状鎖、炭素数10~16個の飽和又は不飽和の直鎖アルキル基で置換されたフェニル、炭素数10~16個の飽和又は不飽和の分枝鎖アルキル基で置換されたフェニル、芳香族ビニル化合物オリゴマー残基で置換されたフェニルであるのがより好ましく、n-ドデシル基、n-トリデシル基、ドデシルフェニル、ヘキサデシルフェニル、トリスチレン化フェニルが特に好ましい。 The hydrophobic chain contained in the component (B) is preferably a hydrophobic chain having a saturated or unsaturated linear chain, a branched chain, or a cyclic chain having 2 to 20 carbon atoms independently. Specific examples of the hydrophobic chain include, for example, ethyl, n-propyl, n-butyl, n-pentyl, n-hexyl, n-heptyl, n-octyl, n-nonyl, n-decyl, n-undecyl, n. -Dodecyl, n-tridecyl, n-tetradecyl, n-pentadecyl, n-hexadecyl, n-heptadecyl, n-octadecyl, n-nonadecyl, n-eicosyl, phenyl, linear or branched phenyl substituted with an alkyl group. , Each residue such as phenyl substituted with an aromatic vinyl compound oligomer residue and their branched isomers, and the corresponding unsaturated residue having unsaturated moieties at one, two or three locations. Group etc. can be mentioned. Among them, from the viewpoint of excellent emulsifying property, the hydrophobic chain is a saturated or unsaturated linear chain having 10 to 16 carbon atoms, a saturated or unsaturated branched chain having 10 to 16 carbon atoms, and 10 to 16 carbon atoms. 16 saturated or unsaturated cyclic chains, phenyl substituted with 10-16 saturated or unsaturated linear alkyl groups, 10-16 saturated or unsaturated branched alkyl groups Phenyl substituted with, phenyl substituted with an aromatic vinyl compound oligomer residue is more preferable, and n-dodecyl group, n-tridecyl group, dodecylphenyl, hexadecylphenyl, and tristyrene phenyl are particularly preferable.

(B)成分に含まれる前記親水基は、それぞれ独立に、カルボキシル基、スルホン酸基、硫酸残基、リン酸基若しくはそれらの塩、又はポリオキシエチレン基、ポリオキシプロピレン基等のポリオキシアルキレン基であることが好ましい。塩として用いる場合には、例えばアルカリ金属塩、アルカリ土類金属塩、アンモニウム塩、有機アミン塩、塩基性アミノ酸塩等が挙げられ、具体的には、ナトリウム、カリウム、リチウム等のアルカリ金属、カルシウム、マグネシウム等のアルカリ土類金属、アルミニウム、亜鉛等の金属、アンモニア、モノエタノールアミン、ジエタノールアミン、トリエタノールアミン、トリイソプロパノールアミン等の有機アミン、アルギニン、リシン等の塩基性アミノ酸等から任意に選ばれる1種または2種以上との塩である。その中でも、乳化性、耐水接着力及び耐水白化性に優れる点から、該親水基はカルボキシル基又はその塩、スルホン酸基又はその塩、リン酸基又はその塩、ポリオキシエチレン基であるのがより好ましい。 The hydrophilic groups contained in the component (B) are independently carboxyl groups, sulfonic acid groups, sulfuric acid residues, phosphate groups or salts thereof, or polyoxyalkylenes such as polyoxyethylene groups and polyoxypropylene groups. It is preferably a group. When used as a salt, examples thereof include alkali metal salts, alkaline earth metal salts, ammonium salts, organic amine salts, basic amino acid salts and the like, and specific examples thereof include alkali metals such as sodium, potassium and lithium, and calcium. , Alkaline earth metals such as magnesium, metals such as aluminum and zinc, organic amines such as ammonia, monoethanolamine, diethanolamine, triethanolamine and triisopropanolamine, and basic amino acids such as arginine and lysine. It is a salt with one or more kinds. Among them, the hydrophilic group is a carboxyl group or a salt thereof, a sulfonic acid group or a salt thereof, a phosphoric acid group or a salt thereof, or a polyoxyethylene group because of its excellent emulsifying property, water adhesion resistance and water whitening resistance. More preferred.

(B)成分に含まれる前記スペーサーは、(b)成分を共有結合によって連結させる二価の連結基であれば特に限定されない。連結基としては、例えば、単結合、炭素数1~20の飽和又は不飽和の直鎖、分枝鎖、環状鎖のアルキレン基やアルケニレン基、エーテル基、チオエーテル基、イミノ基、カルボニル基、リン酸残基、又は各種公知のアミノ酸残基、ヒドロキシカルボン酸残基、ジカルボン酸残基、ポリカルボン酸残基、ジアミン残基、ポリアミン残基、ジイソシアネート残基、ポリイソシアネート残基、ジオール残基、ポリオール残基等が挙げられる。 The spacer contained in the component (B) is not particularly limited as long as it is a divalent linking group that links the component (b) by a covalent bond. Examples of the linking group include a single bond, a saturated or unsaturated linear or branched chain having 1 to 20 carbon atoms, a branched chain, a cyclic chain alkylene group, an alkenylene group, an ether group, a thioether group, an imino group, a carbonyl group, and phosphorus. Acid residues, or various known amino acid residues, hydroxycarboxylic acid residues, dicarboxylic acid residues, polycarboxylic acid residues, diamine residues, polyamine residues, diisocyanate residues, polyisocyanate residues, diol residues, Examples include polyol residues.

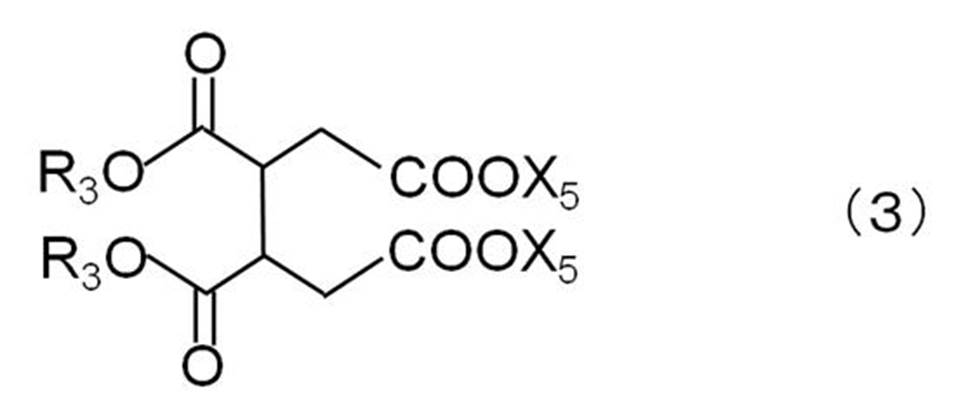

(B)成分は、前記構造のものであれば特に限定されず、具体的には、例えば、下記一般式(1)~(4)で表される化合物が挙げられる。 The component (B) is not particularly limited as long as it has the above-mentioned structure, and specific examples thereof include compounds represented by the following general formulas (1) to (4).

(B)成分は、乳化性に優れる点から、一般式(1)~(4)で表される化合物が好ましい。一般式(1)で表される化合物の中でも、式中のR1がドデシル基又はヘキサデシル基である、ドデシルジフェニルエーテルジスルホン酸若しくはヘキサデシルジフェニルエーテルジスルホン酸(ドデシルフェニルスルホン酸又はヘキサデシルフェニルスルホン酸とフェニルスルホン酸が(b)成分、エーテル基がスペーサーに該当)又はそのナトリウム塩、アンモニウム塩が好ましい。一般式(2)で表される化合物の中でも、式中のR2がトリデシル又はトリスチレン化フェニル基、jが3、6又は10である、ポリオキシエチレントリデシルエーテルリン酸若しくはポリオキシエチレン(トリスチレン化フェニル)エーテルリン酸(ポリオキシエチレントリデシルエーテル又はポリオキシエチレン(トリスチレン化フェニル)エーテルが(b)成分、リン酸残基がスペーサーに該当)又はそのナトリウム塩、アンモニウム塩がより好ましく、市販品としてはRhodafac RS-410、Rhodafac RS-610、Rhodafac RS-710(以上、ソルベイ日華(株)製)がより好ましい。一般式(4)で表される化合物の中でも、ジラウロイルグルタミン酸リシン(N-ラウロイル-L-グルタミン酸が(b)成分、リシン残基がスペーサーに該当)又はそのナトリウム塩がより好ましく、市販品としてはペリセア(登録商標)L-30(旭化成ファインケム(株)製)がより好ましい。 The component (B) is preferably a compound represented by the general formulas (1) to (4) from the viewpoint of excellent emulsifying property. Among the compounds represented by the general formula (1), dodecyldiphenyl ether disulfonic acid or hexadecyldiphenyl ether disulfonic acid (dodecylphenylsulfonic acid or hexadecylphenylsulfonic acid and phenyl) in which R 1 in the formula is a dodecyl group or a hexadecyl group. Sulfonic acid corresponds to the component (b) and the ether group corresponds to the spacer), or a sodium salt or an ammonium salt thereof is preferable. Among the compounds represented by the general formula (2), polyoxyethylene tridecyl ether phosphoric acid or polyoxyethylene (R 2 in the formula is tridecyl or a tristyrene phenyl group and j is 3, 6 or 10). Tristyrene phenyl) ether phosphoric acid (polyoxyethylene tridecyl ether or polyoxyethylene (tristyrene phenyl) ether corresponds to component (b), phosphoric acid residue corresponds to spacer) or its sodium salt and ammonium salt. Preferably, as commercially available products, Rhodafac RS-410, Rhodafac RS-610, and Rhodafac RS-710 (all manufactured by Solvay Nikka Co., Ltd.) are more preferable. Among the compounds represented by the general formula (4), lysine dilauroyl glutamate (N-lauroyl-L-glutamic acid corresponds to component (b), lysine residue corresponds to spacer) or a sodium salt thereof is more preferable, and as a commercially available product. Is more preferably Pericea (registered trademark) L-30 (manufactured by Asahi Kasei Finechem Co., Ltd.).

(B)成分の使用量は特に限定されないが、乳化性、耐水接着力及び耐水白化性に優れる点から、固形分換算で、(A)成分100重量部に対して、0.75~2重量部程度が好ましく、1~1.5重量部程度がより好ましい。(B)成分の使用量を0.75重量部以上とすることにより、前記粘着付与樹脂エマルジョンは乳化性が優れたものとなり、また、2重量部以下とすることにより、当該エマルジョンを含む水系粘・接着剤は耐水接着力が優れたものとなる。また、(B)成分は、従来のアニオン性乳化剤やノニオン性乳化剤に比べて少ない使用量でも、乳化性に優れる粘着付与樹脂エマルジョンが得られる特徴を有する。 The amount of the component (B) used is not particularly limited, but from the viewpoint of being excellent in emulsifying property, water-resistant adhesive force and water-whitening resistance, 0.75 to 2 weight by weight with respect to 100 parts by weight of the component (A) in terms of solid content. About 1 to 1.5 parts by weight is preferable, and about 1 to 1.5 parts by weight is more preferable. When the amount of the component (B) used is 0.75 parts by weight or more, the tackifying resin emulsion has excellent emulsifying property, and when the amount is 2 parts by weight or less, the water-based viscosity containing the emulsion is used. -The adhesive has excellent water resistance and adhesive strength. Further, the component (B) has a feature that a tackifier resin emulsion having excellent emulsifying property can be obtained even if the amount used is smaller than that of the conventional anionic emulsifier or nonionic emulsifier.

本発明の粘着付与樹脂エマルジョンは、当該エマルジョンの乳化性を向上させることを目的に、必要に応じて乳化剤(C)(以下(C)成分ともいう)を含めてもよい。なお、(C)成分は、(B)成分とは異なるものである。 The tackifier resin emulsion of the present invention may contain an emulsifier (C) (hereinafter, also referred to as a component (C)), if necessary, for the purpose of improving the emulsifying property of the emulsion. The component (C) is different from the component (B).

(C)成分は、特に限定されず各種公知の乳化剤を使用できる。具体的には、モノマーを重合させて得られる高分子量乳化剤、低分子量アニオン性乳化剤、低分子量ノニオン性乳化剤等が挙げられる。これらは単独でも2種以上を組み合わせてもよい。これらの中でも、乳化性に優れる点から、低分子量アニオン乳化剤が好ましい。 The component (C) is not particularly limited, and various known emulsifiers can be used. Specific examples thereof include a high molecular weight emulsifier obtained by polymerizing a monomer, a low molecular weight anionic emulsifier, and a low molecular weight nonionic emulsifier. These may be used alone or in combination of two or more. Among these, a low molecular weight anionic emulsifier is preferable because it is excellent in emulsifying property.

前記高分子量乳化剤の製造に用いられるモノマーとしては、例えば、(メタ)アクリル酸メチル、(メタ)アクリル酸エチル等の(メタ)アクリル酸エステル系モノマー類、;(メタ)アクリル酸、クロトン酸等のモノカルボン酸系ビニルモノマー類、;マレイン酸、無水マレイン酸等のジカルボン酸系ビニルモノマー類、;ビニルスルホン酸、スチレンスルホン酸、等のスルホン酸系ビニルモノマー類;及びこれら各種有機酸のアルカリ金属塩、アルカリ土類金属塩、アンモニウム塩、有機塩基類の塩、;(メタ)アクリルアミド、N-メチロール(メタ)アクリルアミド等の(メタ)アクリルアミド系モノマー類;(メタ)アクリロニトリル等のニトリル系モノマー類;酢酸ビニル等のビニルエステル系モノマー類;(メタ)アクリル酸2-ヒドロキシエチル、(メタ)アクリル酸2-ヒドロキシプロピル等のヒドロキシ基含有(メタ)アクリル酸エステル系モノマー類;メチルビニルエーテル、グリシジル(メタ)アクリレート、ウレタンアクリレート、炭素数6~22のα-オレフィン、ビニルピロリドン等のその他のモノマー類などが挙げられる。これらは単独でも2種以上組み合わせても良い。 Examples of the monomer used for producing the high molecular weight emulsifier include (meth) acrylic acid ester-based monomers such as methyl (meth) acrylic acid and ethyl (meth) acrylic acid; (meth) acrylic acid, crotonic acid and the like. Monocarboxylic acid-based vinyl monomers; Dicarboxylic acid-based vinyl monomers such as maleic acid and maleic anhydride; and sulfonic acid-based vinyl monomers such as vinyl sulfonic acid and styrene sulfonic acid; and alkalis of these various organic acids. Metal salts, alkaline earth metal salts, ammonium salts, organic base salts; (meth) acrylamide-based monomers such as (meth) acrylamide and N-methylol (meth) acrylamide; nitrile-based monomers such as (meth) acrylonitrile Classes; Vinyl ester-based monomers such as vinyl acetate; Hydroxy group-containing (meth) acrylic acid ester-based monomers such as (meth) 2-hydroxyethyl acrylate, (meth) 2-hydroxypropyl acrylate; Methylvinyl ether, glycidyl Examples thereof include (meth) acrylate, urethane acrylate, α-olefin having 6 to 22 carbon atoms, and other monomers such as vinylpyrrolidone. These may be used alone or in combination of two or more.

重合方法としては、溶液重合、懸濁重合、後述する高分子量乳化剤以外の反応性乳化剤、高分子量乳化剤以外の非反応性乳化剤などを用いた乳化重合などが挙げられる。 Examples of the polymerization method include solution polymerization, suspension polymerization, emulsion polymerization using a reactive emulsifier other than the high molecular weight emulsifier described later, and a non-reactive emulsifier other than the high molecular weight emulsifier.

かくして得られた前記高分子量乳化剤の重量平均分子量は特に限定されないが、通常1,000~500,000程度とすることが、得られる粘着付与樹脂エマルジョンの粘着特性の点で好ましい。ここでいう重量平均分子量は、ゲルパーメーションクロマトグラフィー(GPC)法によるポリスチレン換算値である。 The weight average molecular weight of the high molecular weight emulsifier thus obtained is not particularly limited, but is usually preferably about 1,000 to 500,000 in terms of the adhesive properties of the obtained tackifier resin emulsion. The weight average molecular weight referred to here is a polystyrene-equivalent value obtained by a gel permeation chromatography (GPC) method.

前記高分子量乳化剤以外の反応性乳化剤としては、例えば、スルホン酸基、カルボキシル基などの親水基と、アルキル基、フェニル基などの疎水基を有するものであって、分子中に炭素-炭素二重結合を有するものをいう。 The reactive emulsifier other than the high molecular weight emulsifier has, for example, a hydrophilic group such as a sulfonic acid group or a carboxyl group and a hydrophobic group such as an alkyl group or a phenyl group, and has a carbon-carbon double bond in the molecule. Those having a bond.

前記低分子量アニオン性乳化剤としては、例えばジアルキルスルホコハク酸エステル塩、アルカンスルホン酸塩、α-オレフィンスルホン酸塩、ポリオキシエチレンアルキルエーテルスルホコハク酸エステル塩、ポリオキシエチレンスチリルフェニルエーテルスルホコハク酸エステル塩、ナフタレンスルホン酸ホルマリン縮合物、ポリオキシエチレンアルキルエーテル硫酸エステル塩、ポリオキシエチレンジアルキルエーテル硫酸エステル塩、ポリオキシエチレントリアルキルエーテル硫酸エステル塩、ポリオキシエチレンアルキルフェニルエーテル硫酸エステル塩等が挙げられる。 Examples of the low molecular weight anionic emulsifier include dialkyl sulfosuccinic acid ester salt, alkane sulfonate, α-olefin sulfonate, polyoxyethylene alkyl ether sulfosuccinic acid ester salt, polyoxyethylene styrylphenyl ether sulfosuccinic acid ester salt, and naphthalene. Examples thereof include formalin sulfonic acid condensate, polyoxyethylene alkyl ether sulfate ester salt, polyoxyethylene dialkyl ether sulfate ester salt, polyoxyethylene trialkyl ether sulfate ester salt, polyoxyethylene alkyl phenyl ether sulfate ester salt and the like.

前記低分子量ノニオン性乳化剤としては、例えばポリオキシエチレンアルキルエーテル、ポリオキシエチレンスチリルフェニルエーテル、ポリオキシエチレンソルビタン脂肪酸エステル等が挙げられる。 Examples of the low molecular weight nonionic emulsifier include polyoxyethylene alkyl ether, polyoxyethylene styrylphenyl ether, and polyoxyethylene sorbitan fatty acid ester.

前記高分子量乳化剤以外の乳化剤は単独でも2種以上を適宜選択して使用しても良い。 As the emulsifier other than the high molecular weight emulsifier, one or two or more kinds may be appropriately selected and used.

(C)成分の使用量は、乳化性及び耐水接着力に優れる点から、固形分換算で、(A)成分100重量部に対して、1~10重量部程度が好ましく、2~8重量部程度がより好ましい。 The amount of the component (C) used is preferably about 1 to 10 parts by weight with respect to 100 parts by weight of the component (A) in terms of solid content, from the viewpoint of excellent emulsifying property and water resistance, and 2 to 8 parts by weight. The degree is more preferable.

本発明の粘着付与樹脂エマルジョンは、所望の特性を損なわない限り、必要に応じて消泡剤、増粘剤、充填剤、酸化防止剤、耐水化剤、造膜助剤、アンモニア水や重曹等のpH 調整剤等を含めてもよい。 The tackifier resin emulsion of the present invention may be used as a defoaming agent, a thickener, a filler, an antioxidant, a water resistant agent, a film forming aid, ammonia water, baking soda, etc., as required, as long as the desired properties are not impaired. May include a pH adjuster and the like.

本発明の粘着付与樹脂エマルジョンは、(B)成分及び必要に応じて(C)成分(以下、これらをまとめて「乳化剤」という)の存在下、(A)成分を乳化させてなるものであり、粘着付与樹脂として用いることができる。 The tackifier resin emulsion of the present invention is obtained by emulsifying the component (A) in the presence of the component (B) and, if necessary, the component (C) (hereinafter collectively referred to as "emulsifier"). , Can be used as a tackifier resin.

前記乳化方法としては、特に限定されず、高圧乳化法、転相乳化法等の公知の乳化法を採用することができる。 The emulsification method is not particularly limited, and known emulsification methods such as a high-pressure emulsification method and a phase inversion emulsification method can be adopted.

前記高圧乳化法は、(A)成分を液体状態とした上で、乳化剤と水を予備混合して、高圧乳化機を用いて微細乳化した後、必要に応じて溶剤を除去する方法である。(A)成分を液体状態とする方法は、加熱のみでも、溶剤に溶解してから加熱しても、可塑剤等の非揮発性物質を混合して加熱してもよいが、加熱のみで行うことが好ましい。なお、溶剤としては、トルエン、キシレン、メチルシクロヘキサン、酢酸エチル等の(A)成分を溶解できる有機溶剤が挙げられる。 The high-pressure emulsification method is a method in which the component (A) is put into a liquid state, an emulsifier and water are premixed, finely emulsified using a high-pressure emulsifier, and then the solvent is removed if necessary. The method of making the component (A) into a liquid state may be heated only by heating, dissolved in a solvent and then heated, or mixed with a non-volatile substance such as a plasticizer and heated, but it is performed only by heating. Is preferable. Examples of the solvent include organic solvents capable of dissolving the component (A) such as toluene, xylene, methylcyclohexane, and ethyl acetate.

前記転相乳化法は、(A)成分を加熱溶融した後、撹拌しながら乳化剤・水を加え、まずW/Oエマルジョンを形成させ、次いで、水の添加や温度変化等によりO/Wエマルジョンに転相させる方法である。 In the phase inversion emulsification method, after the component (A) is heated and melted, an emulsifier and water are added while stirring to form a W / O emulsion first, and then an O / W emulsion is formed by adding water or changing the temperature. This is a method of inverting the phase.

このようにして得られた粘着付与樹脂エマルジョンの濃度は特に限定されないが、通常は固形分が20~70重量%程度となるように適宜に調整して用いる。また、得られた粘着付与樹脂エマルジョンの体積平均粒子径は、通常0.1~2μm程度であり、大部分は1μm以下の粒子として均一に分散しているが、0.7μm以下とすることが、貯蔵安定性の点から好ましい。また、(A)成分は白色ないし乳白色の外観を呈し、粘度は通常10~1,000mPa・s程度(温度25℃、濃度50重量%)である。また、pHは通常2~10程度であるが、必要に応じて、塩酸、硫酸、リン酸等の無機酸;モノメチルアミン、モノエタノールアミン、ジエタノールアミン、ジイソプロパノールアミン等のアルカノールアミン;エチルアミン、n-ブチルアミン、トリエチルアミン等の脂肪族アミン;水酸化カリウム、水酸化ナトリウム等のアルカリ金属水酸化物;水酸化カルシウム等のアルカリ土類金属水酸化物等を適宜添加して、pHを調整しても良い。 The concentration of the tackifier resin emulsion thus obtained is not particularly limited, but is usually adjusted appropriately so that the solid content is about 20 to 70% by weight. The volume average particle size of the obtained tackifier resin emulsion is usually about 0.1 to 2 μm, and most of the particles are uniformly dispersed as particles of 1 μm or less, but may be 0.7 μm or less. , Preferred from the viewpoint of storage stability. The component (A) has a white to milky white appearance, and the viscosity is usually about 10 to 1,000 mPa · s (temperature 25 ° C., concentration 50% by weight). The pH is usually about 2 to 10, but if necessary, inorganic acids such as hydrochloric acid, sulfuric acid, and phosphoric acid; alkanolamines such as monomethylamine, monoethanolamine, diethanolamine, and diisopropanolamine; ethylamine, n-. An aliphatic amine such as butylamine or triethylamine; an alkali metal hydroxide such as potassium hydroxide or sodium hydroxide; an alkaline earth metal hydroxide such as calcium hydroxide may be appropriately added to adjust the pH. ..

本発明の水系粘・接着剤組成物は、本発明の粘着付与樹脂エマルジョン及びベースポリマーを含むものである。また、本発明の水系粘・接着剤組成物は、水系粘・接着剤として使用することができる。 The water-based adhesive / adhesive composition of the present invention contains the tackifier resin emulsion and the base polymer of the present invention. Further, the water-based viscous / adhesive composition of the present invention can be used as a water-based viscous / adhesive.

前記ベースポリマーとして、アクリル系重合体エマルジョン、ゴム系ラテックス及び合成樹脂系エマルジョン等が挙げられ、またそれぞれを併用することもでき、さらに必要に応じて架橋剤、消泡剤、増粘剤、充填剤、酸化防止剤、耐水化剤、造膜助剤、アンモニア水や重曹等のpH 調整剤等を使用することもできる。また、公知の粘着付与樹脂エマルジョンをさらに使用しても良い。これら水系粘・接着剤組成物の濃度は、通常は固形分が40~70重量%程度であり、好ましくは55~70重量%である。ベースポリマーは、少なくとも1種以上用いればよい。 Examples of the base polymer include acrylic polymer emulsions, rubber latexes, synthetic resin emulsions and the like, and each of them can be used in combination, and if necessary, a cross-linking agent, a defoaming agent, a thickener and a filling agent can be used. Agents, antioxidants, water resistant agents, film-forming aids, pH regulators such as ammonia water and baking soda can also be used. Further, a known tackifier resin emulsion may be further used. The concentration of these water-based viscous / adhesive compositions is usually about 40 to 70% by weight, preferably 55 to 70% by weight, in terms of solid content. At least one base polymer may be used.

前記アクリル系重合体エマルジョンとしては、一般に各種のアクリル系粘・接着剤に用いられているものを使用でき、(メタ)アクリル酸エステル等のモノマーの一括仕込み重合法、モノマー逐次添加重合法、乳化モノマー逐次添加重合法、シード重合法等の公知の乳化重合法により容易に製造することができる。 As the acrylic polymer emulsion, those generally used for various acrylic adhesives / adhesives can be used, and a batch charging polymerization method of monomers such as (meth) acrylic acid ester, a monomer sequential addition polymerization method, and emulsification can be used. It can be easily produced by a known emulsion polymerization method such as a monomer sequential addition polymerization method and a seed polymerization method.

前記(メタ)アクリル酸エステルとしては、たとえば、(メタ)アクリル酸メチル、(メタ)アクリル酸エチル、(メタ)アクリル酸ブチル、(メタ)アクリル酸2-エチルヘキシル、(メタ)アクリル酸グリシジル、(メタ)アクリル酸2-ヒドロキシエチル等をあげることができ、これらを単独で又は二種以上を混合して用いる。また、得られるエマルジョンに貯蔵安定性を付与するため前記(メタ)アクリル酸エステルの一部に代えて(メタ)アクリル酸を使用してもよい。さらに所望により(メタ)アクリル酸エステル重合体の接着特性を損なわない程度において、たとえば、酢酸ビニル、スチレン等の共重合可能なモノマーを併用できる。なお、アクリル系重合体エマルジョンに用いられる乳化剤にはアニオン系乳化剤、部分ケン化ポリビニルアルコール等を使用でき、その使用量は固形分換算で、(メタ)アクリル酸エステル重合体100重量部に対して0.1~5重量部程度、好ましくは0.5~3重量部程度である。 Examples of the (meth) acrylic acid ester include methyl (meth) acrylate, ethyl (meth) acrylate, butyl (meth) acrylate, 2-ethylhexyl (meth) acrylate, and glycidyl (meth) acrylate. Meta) 2-hydroxyethyl acrylate and the like can be mentioned, and these may be used alone or in combination of two or more. Further, in order to impart storage stability to the obtained emulsion, (meth) acrylic acid may be used instead of a part of the (meth) acrylic acid ester. Further, if desired, a copolymerizable monomer such as vinyl acetate or styrene can be used in combination to the extent that the adhesive properties of the (meth) acrylic acid ester polymer are not impaired. As the emulsifier used in the acrylic polymer emulsion, an anionic emulsifier, partially saponified polyvinyl alcohol, or the like can be used, and the amount used is based on 100 parts by weight of the (meth) acrylic acid ester polymer in terms of solid content. It is about 0.1 to 5 parts by weight, preferably about 0.5 to 3 parts by weight.

前記アクリル系重合体エマルジョンと粘着付与樹脂エマルジョンの含有比率は、特に限定されないが、粘着付与樹脂エマルジョンによる改質の効果が十分に発現でき、かつ、過剰使用による耐熱保持力、タック等の低下を引き起こさない適当な使用範囲としては、固形分換算で、アクリル系重合体エマルジョン100重量部に対して、粘着付与樹脂エマルジョンを通常2~40重量部程度とするのがよい。 The content ratio of the acrylic polymer emulsion and the tackifier resin emulsion is not particularly limited, but the effect of modification by the tackifier resin emulsion can be sufficiently exhibited, and the heat retention and tackiness can be reduced due to excessive use. As an appropriate range of use that does not cause the problem, it is preferable that the pressure-sensitive resin emulsion is usually about 2 to 40 parts by weight with respect to 100 parts by weight of the acrylic polymer emulsion in terms of solid content.

前記ゴム系ラテックスとしては、水系粘・接着剤組成物に用いられる各種公知のものを使用できる。例えば天然ゴムラテックス、スチレン-ブタジエン共重合体ラテックス、クロロプレンラテックス等が挙げられる。 As the rubber-based latex, various known ones used in the water-based viscous / adhesive composition can be used. For example, natural rubber latex, styrene-butadiene copolymer latex, chloroprene latex and the like can be mentioned.

前記ゴム系ラテックスと粘着付与樹脂エマルジョンの含有比率は、特に限定されないが、粘着付与樹脂エマルジョンによる改質の効果が十分に発現でき、かつ、過剰使用による接着力、タック等の低下を引き起こさない適当な使用範囲としては、固形分換算で、ゴム系ラテックス100重量部に対して、粘着付与樹脂エマルジョンを通常10~150重量部程度とするのがよい。 The content ratio of the rubber-based latex and the tack-imparting resin emulsion is not particularly limited, but it is appropriate that the effect of modification by the tack-imparting resin emulsion can be sufficiently exhibited and the adhesive strength, tack, etc. are not deteriorated due to excessive use. As a range of use, it is preferable that the pressure-sensitive resin emulsion is usually about 10 to 150 parts by weight with respect to 100 parts by weight of the rubber-based latex in terms of solid content.

前記合成樹脂系エマルジョンとしては、水系粘・接着剤組成物に用いられる各種公知のものを使用でき、例えば酢酸ビニル系エマルジョン、エチレン-酢酸ビニル共重合体エマルジョン、ウレタン系エマルジョン等の合成樹脂エマルジョンが挙げられる。 As the synthetic resin emulsion, various known emulsions used for water-based viscous / adhesive compositions can be used, and for example, synthetic resin emulsions such as vinyl acetate emulsion, ethylene-vinyl acetate copolymer emulsion, and urethane emulsion can be used. Can be mentioned.

前記合成樹脂系エマルジョンと粘着付与樹脂エマルジョンの含有比率は、特に限定されないが、粘着付与樹脂エマルジョンの改質の効果が十分に発現でき、かつ、過剰使用による接着力、タック等の低下を引き起こさない適当な使用範囲としては、固形分換算で、合成樹脂系エマルジョン100重量部に対して、粘着付与樹脂エマルジョンを通常2~40重量部程度とするのがよい。 The content ratio of the synthetic resin-based emulsion and the tack-imparting resin emulsion is not particularly limited, but the effect of modifying the tack-imparting resin emulsion can be sufficiently exhibited, and the adhesive strength, tack, etc. do not decrease due to excessive use. As an appropriate range of use, it is preferable that the pressure-sensitive resin emulsion is usually about 2 to 40 parts by weight with respect to 100 parts by weight of the synthetic resin emulsion in terms of solid content.

本発明の水系粘・接着剤組成物は、前記粘着付与樹脂エマルジョンと前記ベースポリマーとを混合させることで得られる。混合方法としては、特に限定されず各種公知の方法を用いることができ、例えば、粘着付与樹脂エマルジョンをエマルジョン化して混合してもよいし、粘着付与樹脂エマルジョンをベースポリマーに添加し、高せん断回転ミキサーを使用混合してもよい。 The water-based adhesive / adhesive composition of the present invention can be obtained by mixing the tackifier resin emulsion and the base polymer. The mixing method is not particularly limited, and various known methods can be used. For example, the tackifier resin emulsion may be emulsified and mixed, or the tackifier resin emulsion may be added to the base polymer and subjected to high shear rotation. You may mix using a mixer.

本発明の水系粘・接着剤組成物は、前記粘着付与樹脂エマルジョンを含むため、高い耐水接着力を有しており、耐水性が要求される用途での水系粘・接着剤として好適である。本発明の水系粘・接着剤組成物は、例えば、建材用粘・接着剤、自動車内装部材用粘・接着剤、フィルムラベル用粘・接着剤等に好適である。また、本発明の水系粘・接着剤組成物は、耐水白化性が良好であるため、水分や湿気の多い環境下で透明性や意匠性が要求される用途での粘・接着剤、例えば、化粧品容器やシャンプー容器に用いられる透明ラベルの粘・接着剤として好適である。 Since the water-based adhesive / adhesive composition of the present invention contains the tackifier resin emulsion, it has high water-resistant adhesive strength and is suitable as a water-based adhesive / adhesive in applications requiring water resistance. The water-based adhesive / adhesive composition of the present invention is suitable for, for example, adhesives / adhesives for building materials, adhesives / adhesives for automobile interior members, adhesives / adhesives for film labels, and the like. Further, since the water-based adhesive / adhesive composition of the present invention has good water whitening resistance, the adhesive / adhesive in applications where transparency and designability are required in an environment with high moisture and humidity, for example, It is suitable as a sticky / adhesive for transparent labels used in cosmetic containers and shampoo containers.

以下、実施例及び比較例を挙げて本発明をさらに詳細に説明するが、本発明はこれらに限定されるものではない。実施例中の「部」及び「%」は特に断りがない限り、重量基準である。 Hereinafter, the present invention will be described in more detail with reference to Examples and Comparative Examples, but the present invention is not limited thereto. Unless otherwise specified, "parts" and "%" in the examples are based on weight.

[ベースポリマーの製造]

製造例1

撹拌装置、温度計、還流冷却管、滴下ロート及び窒素導入管を備えた反応容器に、窒素ガス気流下、水43.4部及びポリオキシエチレンアルキルエーテル硫酸エステルアンモニウム塩(アニオン性乳化剤:商品名「ハイテノールLA-16」,第一工業製薬(株)製)0.92部からなる水溶液を仕込み、70℃に昇温した。次いで、アクリル酸ブチル90部、アクリル酸2-エチルヘキシル7部及びアクリル酸3部からなる混合物と、過硫酸カリウム(重合開始剤)0.24部、重曹(pH調整剤)0.11部及び水8.83部からなる開始剤水溶液の1/10量を反応容器に添加し、窒素ガス気流下にて70℃、30分間予備重合反応を行った。次いで、前記混合物と前記開始剤水溶液の残りの9/10量を2時間にわたり反応容器に添加して乳化重合を行い、その後70℃で1時間保持して重合反応を完結させた。こうして得られたアクリル系重合体エマルジョンを室温まで冷却した後100メッシュ金網を用いてろ過し、固形分濃度47.8%のアクリル系重合体エマルジョンを得た。

[Manufacturing of base polymer]

Production Example 1

In a reaction vessel equipped with a stirrer, thermometer, reflux condenser, dropping funnel and nitrogen introduction tube, 43.4 parts of water and polyoxyethylene alkyl ether sulfate ammonium salt (anionic emulsifier: trade name) under a nitrogen gas stream. An aqueous solution consisting of 0.92 parts of "HITENOL LA-16" (manufactured by Dai-ichi Kogyo Seiyaku Co., Ltd.) was charged and the temperature was raised to 70 ° C. Next, 90 parts of butyl acrylate, 7 parts of 2-ethylhexyl acrylate and 3 parts of acrylic acid, 0.24 parts of potassium persulfate (polymerization initiator), 0.11 part of baking soda (pH adjuster) and water. A 1/10 amount of an initiator aqueous solution consisting of 8.83 parts was added to the reaction vessel, and a prepolymerization reaction was carried out at 70 ° C. for 30 minutes under a nitrogen gas stream. Then, the remaining 9/10 of the mixture and the aqueous initiator solution were added to the reaction vessel for 2 hours to carry out emulsion polymerization, and then held at 70 ° C. for 1 hour to complete the polymerization reaction. The acrylic polymer emulsion thus obtained was cooled to room temperature and then filtered using a 100-mesh wire mesh to obtain an acrylic polymer emulsion having a solid content concentration of 47.8%.

[重合ロジンエステルの製造]

製造例2

撹拌装置、コンデンサー、温度計および窒素導入管・水蒸気導入管を備えた反応容器に、重合ロジン100部(酸価145mgKOH/g、軟化点140℃)、ペンタエリスリトール14部を仕込んだ後、窒素ガス気流下に250℃で2時間反応させた後、さらに280℃まで昇温し同温度で12時間反応させ、エステル化を完了させた。その後、減圧下に水分等を除去し、軟化点160℃の重合ロジンエステルを得た。

[Manufacturing of polymerized rosin ester]

Manufacturing example 2

After charging 100 parts of polymerized rosin (acid value 145 mgKOH / g, softening point 140 ° C.) and 14 parts of pentaerythritol into a reaction vessel equipped with a stirrer, condenser, thermometer and nitrogen introduction tube / steam introduction tube, nitrogen gas After reacting in an air stream at 250 ° C. for 2 hours, the temperature was further raised to 280 ° C. and the reaction was carried out at the same temperature for 12 hours to complete esterification. Then, water and the like were removed under reduced pressure to obtain a polymerized rosin ester having a softening point of 160 ° C.

[ロジンフェノール樹脂の製造]

製造例3

製造例2と同様の反応容器に、ガムロジン100.0部、フェノール100.0部仕込んだ後、100℃まで昇温し96%硫酸を2.1部仕込み窒素ガス気流下に3時間反応させた。次いで消石灰を3.0部加えた後、10kPa減圧下で280℃まで昇温し、同温度で4時間反応させた。その後、水分等を除去し、軟化点150℃のロジンフェノール樹脂を得た。

[Manufacturing of rosin phenol resin]

Production example 3

After charging 100.0 parts of gum rosin and 100.0 parts of phenol in the same reaction vessel as in Production Example 2, the temperature was raised to 100 ° C., 2.1 parts of 96% sulfuric acid was charged, and the mixture was reacted under a nitrogen gas stream for 3 hours. .. Then, after adding 3.0 parts of slaked lime, the temperature was raised to 280 ° C. under a reduced pressure of 10 kPa, and the reaction was carried out at the same temperature for 4 hours. Then, water and the like were removed to obtain a rosin phenol resin having a softening point of 150 ° C.

[粘着付与樹脂エマルジョンの製造]

実施例1

製造例2の重合ロジンエステル100部をメチルシクロヘキサン70部に80℃にて3時間かけて溶解させた後、ジラウロイルグルタミン酸リシンナトリウム(商品名「ペリセア(登録商標)L-30」 旭化成ファインケム(株)製)(以下、(B)-1成分とする)0.75部(固形分換算)および水120部を添加し、1時間撹拌した。次いで、高圧乳化機(マントンガウリン社製)により30MPaの圧力で高圧乳化して乳化物を得た。次いで、70℃、2.93×10-2MPaの条件下に6時間減圧蒸留を行い、固形分濃度50%の粘着付与樹脂エマルジョンを得た。

[Manufacturing of adhesive resin emulsion]

Example 1

After dissolving 100 parts of the polymerized rosin ester of Production Example 2 in 70 parts of methylcyclohexane at 80 ° C. for 3 hours, sodium dilauroyl glutamate lysine (trade name "Pericea (registered trademark) L-30" Asahi Kasei Finechem Co., Ltd. ) (Hereinafter referred to as (B) -1 component) 0.75 parts (in terms of solid content) and 120 parts of water were added, and the mixture was stirred for 1 hour. Then, a high-pressure emulsifier (manufactured by Menton Gaulin Co., Ltd.) was used to perform high-pressure emulsification at a pressure of 30 MPa to obtain an emulsion. Then, distillation was carried out under reduced pressure for 6 hours under the conditions of 70 ° C. and 2.93 × 10 −2 MPa to obtain a tackifier resin emulsion having a solid content concentration of 50%.

実施例2~5

実施例1において、(B)-1成分の使用量を表1で示される部数に変えた以外は、同様に行い、粘着付与樹脂エマルジョン(いずれも固形分濃度50%)を得た。

Examples 2-5

In Example 1, the same procedure was carried out except that the amount of component (B) -1 used was changed to the number of copies shown in Table 1, to obtain a tackifier resin emulsion (both having a solid content concentration of 50%).

実施例6

実施例1において、(B)-1成分をドデシルジフェニルエーテルジスルホン酸ナトリウム(商品名「DowFax8390」 Dow Chemical社製)(以下、(B)-2成分とする)に代えて、その使用量を表1で示される部数に変えた以外は、同様に行い、粘着付与樹脂エマルジョン(いずれも固形分濃度50%)を得た。

Example 6

In Example 1, the amount of (B) -1 component used is shown in place of sodium dodecyldiphenyl ether disulfonate (trade name "DowFax 8390" manufactured by Dow Chemical Co., Ltd.) (hereinafter referred to as (B) -2 component). The same procedure was carried out except that the number of copies was changed to that shown in 1, to obtain a tackifier resin emulsion (both having a solid content concentration of 50%).

実施例7

実施例1において、重合ロジンエステルを製造例3のロジンフェノール樹脂に代えて、その使用量を表1で示される部数に変えた以外は、同様に行い、粘着付与樹脂エマルジョン(いずれも固形分濃度50%)を得た。

Example 7

In Example 1, the polymerized rosin ester was replaced with the rosin phenol resin of Production Example 3, and the same procedure was carried out except that the amount used was changed to the number of copies shown in Table 1. 50%) was obtained.

実施例8

実施例1において、重合ロジンエステルをC9系石油樹脂(商品名「ネオポリマー140」 JXTGエネルギー(株)製 軟化点140℃)に代えて、その使用量を表1で示される部数に変えた以外は、同様に行い、粘着付与樹脂エマルジョン(いずれも固形分濃度50%)を得た。

Example 8

In Example 1, the polymerized rosin ester was replaced with a C9-based petroleum resin (trade name “Neopolymer 140”, softening point 140 ° C. manufactured by JXTG Energy Co., Ltd.), and the amount used was changed to the number of copies shown in Table 1. In the same manner, a tackifier resin emulsion (both having a solid content concentration of 50%) was obtained.

実施例9

実施例1において、重合ロジンエステルを、重合ロジンエステル及びC9系石油樹脂(商品名「ネオポリマー140」 JXTGエネルギー(株)製)の併用に代えて、その使用量を表1で示される部数に変えた以外は、同様に行い、粘着付与樹脂エマルジョン(いずれも固形分濃度50%)を得た。なお、重合ロジンエステル70部とC9系石油樹脂30部を併用した場合の軟化点は155℃あった。

Example 9

In Example 1, the polymerized rosin ester was replaced with the polymerized rosin ester and a C9-based petroleum resin (trade name "Neopolymer 140" manufactured by JXTG Energy Co., Ltd.), and the amount used was changed to the number of copies shown in Table 1. Except for the change, the same procedure was carried out to obtain a tackifier resin emulsion (both having a solid content concentration of 50%). When 70 parts of the polymerized rosin ester and 30 parts of the C9 petroleum resin were used in combination, the softening point was 155 ° C.

実施例10

実施例1において、重合ロジンエステルをテルペンフェノール(商品名「Dertophene T115」 DRT社製 軟化点125℃)に代えて、その使用量を表1で示される部数に変えた以外は、同様に行い、粘着付与樹脂エマルジョン(いずれも固形分濃度50%)を得た。

Example 10

In Example 1, the polymerized rosin ester was replaced with terpenephenol (trade name “Dertophene T115”, softening point 125 ° C. manufactured by DRT), and the amount used was changed to the number of copies shown in Table 1, but the same procedure was carried out. A tackifying resin emulsion (both having a solid content concentration of 50%) was obtained.

実施例11

実施例1において、(B)-1成分をポリオキシエチレントリデシルエーテルリン酸ナトリウム(商品名「Rhodafac RS-610」 ソルベイ日華(株)製)(以下、(B)-3成分とする)に代えて、その使用量を表1で示される部数に変えた以外は、同様に行い、粘着付与樹脂エマルジョン(いずれも固形分濃度50%)を得た。

Example 11

In Example 1, the component (B) -1 is sodium polyoxyethylene tridecyl ether phosphate (trade name "Rhodafac RS-610" manufactured by Solvay Nikka Co., Ltd.) (hereinafter referred to as the component (B) -3). Instead, the same procedure was carried out except that the amount used was changed to the number of copies shown in Table 1, to obtain a tackifier resin emulsion (both having a solid content concentration of 50%).

比較例1~2

実施例1において、(B)-1成分をポリオキシエチレンアルキル(炭素数12~14)スルホコハク酸二ナトリウム(以下、(B)’-1成分とする)に代えて、その使用量を表1で示される部数に変えた以外は、同様に行い、粘着付与樹脂エマルジョン(いずれも固形分濃度50%)を得た。

Comparative Examples 1-2

In Example 1, the component (B) -1 was replaced with polyoxyethylene alkyl (12 to 14 carbon atoms) disodium sulfosuccinate (hereinafter referred to as the component (B) ′ -1), and the amount used was shown in Table 1. The same procedure was carried out except that the number of copies was changed to that indicated by (1), to obtain a tackifier resin emulsion (both having a solid content concentration of 50%).

比較例3

実施例1において、(B)-1成分をラウロイルグルタミン酸ナトリウム(以下、(B)’-2成分とする)に代えて、その使用量を表1で示される部数に変えた以外は、同様に行い、粘着付与樹脂エマルジョン(いずれも固形分濃度50%)を得た。

Comparative Example 3

Similarly, in Example 1, the component (B) -1 was replaced with sodium lauroyl glutamate (hereinafter referred to as the component (B)'-2) and the amount used was changed to the number of copies shown in Table 1. This was carried out to obtain a tackifier resin emulsion (both having a solid content concentration of 50%).

(乳化性の評価)

各実施例および比較例の粘着付与樹脂エマルジョンの体積平均粒子径を、レーザー回折式粒度測定装置((株)島津製作所製、商品名「SALD-7500nano」)を用い、屈折率1.70-0.20i、吸光度0.06の条件下で測定した。得られた体積平均粒子径に関して、以下の基準にて評価した。結果を表1に示す。体積平均粒子径が小さいほど、粘着付与樹脂エマルジョンの乳化性や貯蔵安定性は良好である。

○:体積平均粒子径0.7μm未満

△:体積平均粒子径0.7μm以上1.0μm未満

×:体積平均粒子径1.0μm以上あるいは乳化できない

(Evaluation of emulsifying property)

The volume average particle size of the tackifier resin emulsion of each example and comparative example was measured with a laser diffraction type particle size measuring device (manufactured by Shimadzu Corporation, trade name "SALD-7500no") and a refractive index of 1.70-0. Measured under the conditions of .20i and absorbance 0.06. The obtained volume average particle size was evaluated according to the following criteria. The results are shown in Table 1. The smaller the volume average particle size, the better the emulsifying property and storage stability of the tackifying resin emulsion.

◯: Volume average particle diameter less than 0.7 μm Δ: Volume average particle diameter 0.7 μm or more and less than 1.0 μm ×: Volume average particle diameter 1.0 μm or more or cannot be emulsified

また、各実施例および比較例の粘着付与樹脂エマルジョンを150メッシュの金網でろ過し、得られた残渣の樹脂(A)に対する重量%を秤量した。当該残渣の重量%に関して、以下の基準にて評価した。結果を表1に示す。残渣の重量%が小さいほど、粘着付与樹脂エマルジョンにおいて凝集物の発生が抑制されており、その乳化性は良好である。

○:0.1重量%未満

△:0.1重量%以上1.0重量%未満

×:1.0重量%以上あるいは乳化できない

Further, the tackifier resin emulsions of each Example and Comparative Example were filtered through a wire mesh of 150 mesh, and the weight% of the obtained residue with respect to the resin (A) was weighed. The weight% of the residue was evaluated according to the following criteria. The results are shown in Table 1. The smaller the weight% of the residue is, the more the generation of agglomerates is suppressed in the tackifier resin emulsion, and the emulsifying property is good.

◯: Less than 0.1% by weight Δ: 0.1% by weight or more and less than 1.0% by weight ×: 1.0% by weight or more or cannot be emulsified

[水系粘・接着剤組成物の製造]

製造例1にて合成したアクリル系重合体エマルジョン80部(固形分換算)と実施例1の粘着付与樹脂エマルジョン20部(固形分換算)とを混合し、水系粘・接着剤組成物を得た。実施例2~5および比較例1~2の各粘着付与樹脂エマルジョンについても、同様にして水系粘・接着剤組成物を製造した。

[Manufacturing of water-based viscous / adhesive composition]

80 parts (solid content equivalent) of the acrylic polymer emulsion synthesized in Production Example 1 and 20 parts (solid content equivalent) of the tackifier resin emulsion of Example 1 were mixed to obtain an aqueous viscous / adhesive composition. .. For each of the tackifier resin emulsions of Examples 2 to 5 and Comparative Examples 1 and 2, water-based adhesive / adhesive compositions were produced in the same manner.

[試料テープの作成]

サイコロ型アプリケーター(太佑機材(株)製)を用いて、前記水系粘・接着剤組成物をポリエステルフィルム(商品名「S-100」、三菱ケミカル(株)製 厚み:38μm)に厚みが50μm程度となるように塗布し、次いで105℃の循風乾燥機で5分間乾燥させて試料テープを作成した。

[Preparation of sample tape]

Using a dice type applicator (manufactured by Taiyu Equipment Co., Ltd.), the water-based viscous / adhesive composition is applied to a polyester film (trade name "S-100", manufactured by Mitsubishi Chemical Corporation, thickness: 38 μm) with a thickness of about 50 μm. Then, it was dried in a circulation dryer at 105 ° C. for 5 minutes to prepare a sample tape.

(耐水接着力の評価)

前記試料テープを幅25mmに切り、被着体(ステンレス板(SS))に2kgのローラーを2往復させて貼り合わせ、1日静置した。次いで、高温高湿機(60℃、90%RH)にて試料テープを貼り合わせた被着体を7日間静置した後、高温高湿機から当該被着体を取り出し、直ちに180度剥離テストを、引張速度300mm/分、測定温度23℃の条件で行い、接着力(N/25mm)を測定した。結果を表1に示す。

(Evaluation of water resistance adhesive strength)

The sample tape was cut to a width of 25 mm, and a 2 kg roller was reciprocated twice on an adherend (stainless steel plate (SS)) to be bonded and allowed to stand for one day. Next, the adherend to which the sample tape was attached was allowed to stand for 7 days in a high-temperature and high-humidity machine (60 ° C., 90% RH), and then the adherend was taken out from the high-temperature and high-humidity machine and immediately subjected to a 180-degree peeling test. Was carried out under the conditions of a tensile speed of 300 mm / min and a measurement temperature of 23 ° C., and the adhesive force (N / 25 mm) was measured. The results are shown in Table 1.

(耐水白化性の評価)

前記試料テープを適当な大きさに切り、20℃水中に24時間浸漬した後、試料テープの白化度合いをヘーズメーター(HM-150、村上色彩技術研究所製)を使用してヘーズ値を測定し、水浸漬前後でのヘーズ値の差を算出した。結果を表1に示す。試料テープにおけるヘーズ値の差が小さいほど、粘・接着剤皮膜において水分や湿気の多い環境下での白化が抑制されており、その耐水白化性は良好である。

○:ヘーズ値の差が10%未満

△:ヘーズ値の差が10%以上20%未満

×:ヘーズ値の差が20%以上

(Evaluation of water whitening resistance)

The sample tape is cut into an appropriate size, immersed in water at 20 ° C. for 24 hours, and then the degree of whitening of the sample tape is measured using a haze meter (HM-150, manufactured by Murakami Color Technology Laboratory). , The difference in haze value before and after immersion in water was calculated. The results are shown in Table 1. The smaller the difference in the haze value of the sample tape, the more the whitening of the adhesive / adhesive film is suppressed in an environment with high moisture and humidity, and the water whitening resistance is good.

◯: Difference in haze value is less than 10% Δ: Difference in haze value is 10% or more and less than 20% ×: Difference in haze value is 20% or more

※表1の各成分の使用量は固形分換算の値であり、注釈は、以下の通りである。

1)乳化ができず粘着付与樹脂エマルジョンが得られなかったので、耐水接着力及び耐水白化性が評価出来なかった。

* The amount of each component used in Table 1 is the value in terms of solid content, and the notes are as follows.

1) Since emulsification was not possible and a tackifying resin emulsion could not be obtained, the water-resistant adhesive strength and water-whitening resistance could not be evaluated.

Claims (7)

前記多鎖多親水基型化合物(B)が、下記一般式(3)~(4)で表される化合物である、粘着付与樹脂エマルジョン。

A tackifier resin emulsion in which the multi-chain multi-hydrophilic group compound (B) is a compound represented by the following general formulas (3) to (4) .

前記樹脂(A)の軟化点が70~180℃であり、The softening point of the resin (A) is 70 to 180 ° C.

前記ロジン系樹脂(a1)がロジンエステル類及び/又はロジンフェノール樹脂であり、The rosin-based resin (a1) is a rosin ester and / or a rosin phenol resin.

前記多鎖多親水基型化合物(B)が、下記一般式(2)で表される化合物である、The multi-chain, multi-hydrophilic group compound (B) is a compound represented by the following general formula (2).

粘着付与樹脂エマルジョン。Adhesive-imparting resin emulsion.

前記樹脂(A)の軟化点が70~180℃であり、The softening point of the resin (A) is 70 to 180 ° C.

前記ロジン系樹脂(a1)がロジンエステル類及び/又はロジンフェノール樹脂であり、The rosin-based resin (a1) is a rosin ester and / or a rosin phenol resin.

前記多鎖多親水基型化合物(B)が、下記一般式(1)で表される化合物であり、The multi-chain, multi-hydrophilic group compound (B) is a compound represented by the following general formula (1).

前記多鎖多親水基型化合物(B)の使用量が、固形分換算で、(A)成分100重量部に対して、0.75重量部以上2.0重量部未満である、The amount of the multi-chain, multi-hydrophilic group compound (B) used is 0.75 parts by weight or more and less than 2.0 parts by weight with respect to 100 parts by weight of the component (A) in terms of solid content.

粘着付与樹脂エマルジョン。Adhesive-imparting resin emulsion.

The water-based adhesive / adhesive composition according to claim 6 , wherein the base polymer is an acrylic polymer emulsion.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018063074 | 2018-03-28 | ||

| JP2018063074 | 2018-03-28 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2019172994A JP2019172994A (en) | 2019-10-10 |

| JP7031633B2 true JP7031633B2 (en) | 2022-03-08 |

Family

ID=68113118

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2019058285A Active JP7031633B2 (en) | 2018-03-28 | 2019-03-26 | Adhesive-imparting resin emulsion and water-based adhesive / adhesive composition |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP7031633B2 (en) |

| CN (1) | CN110317350B (en) |

| TW (1) | TWI787490B (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111690263B (en) * | 2019-03-14 | 2023-02-21 | 荒川化学工业株式会社 | Tackifier resin emulsion, water-based adhesive and/or cohesive agent composition, and adhesive and/or cohesive sheet |

| US20220411597A1 (en) * | 2019-11-27 | 2022-12-29 | Arakawa Chemical Industries, Ltd. | Composition for fiber-reinforced resin, fiber-reinforced resin, molded article, method for using composition for fiber-reinforced resin, method for reinforcing fiber-reinforced resin, and method for producing fiber-reinforced resin |

| KR102713612B1 (en) * | 2021-12-30 | 2024-10-07 | 동화특수산업 주식회사 | Manufacturing method of coating material for wood |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2004532303A (en) | 2001-03-23 | 2004-10-21 | インペリアル・ケミカル・インダストリーズ・ピーエルシー | Resin composition containing phosphorus-containing surfactant for pressure-sensitive adhesive |

| JP2007056131A (en) | 2005-08-24 | 2007-03-08 | Arakawa Chem Ind Co Ltd | Tackifying resin emulsion, its manufacturing method and aqueous pressure-sensitive adhesive composition |

| US20070249759A1 (en) | 2006-04-21 | 2007-10-25 | Peter James Miller | Tackifier dispersions with improved humid age performance |

| JP2012180508A (en) | 2011-02-07 | 2012-09-20 | Arakawa Chem Ind Co Ltd | Adhesion imparting resin emulsion, emulsion-type adhesive composition, and adhesive composition for film label |

| JP2017145364A (en) | 2016-02-19 | 2017-08-24 | 旭化成ワッカーシリコーン株式会社 | Method for producing silicone particle dispersion emulsion |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5948030B2 (en) * | 1976-07-23 | 1984-11-22 | 荒川林産化学工業株式会社 | Aqueous emulsion of rosin material |

| JP3953796B2 (en) * | 2001-12-04 | 2007-08-08 | 日東電工株式会社 | Tackifying resin emulsion, method for producing the same, and water-based pressure-sensitive adhesive composition |

| US7531595B2 (en) * | 2006-03-08 | 2009-05-12 | 3M Innovative Properties Company | Pressure-sensitive adhesive containing silica nanoparticles |

| TW200846429A (en) * | 2007-03-22 | 2008-12-01 | Arakawa Chem Ind | Polymelyzed rosin, polymerized rosin ester, these hydride, manufacturing process thereof, soldering flux, solder paste, tackifier resin, tackifier resin emulsion, and adhesive composition of matter |

| JP5937570B2 (en) * | 2011-03-30 | 2016-06-22 | リンテック株式会社 | Emulsion type adhesive composition and releasable adhesive sheet |

| JP2017533289A (en) * | 2014-09-04 | 2017-11-09 | スリーエム イノベイティブ プロパティズ カンパニー | Nanocrystalline cellulose-containing pressure-sensitive adhesive |

| JP6525397B2 (en) * | 2015-09-28 | 2019-06-05 | 荒川化学工業株式会社 | Rosin-based emulsion sizing agent and paper obtained using the sizing agent |

-

2019

- 2019-03-26 JP JP2019058285A patent/JP7031633B2/en active Active

- 2019-03-27 CN CN201910240410.6A patent/CN110317350B/en active Active

- 2019-03-28 TW TW108110943A patent/TWI787490B/en active

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2004532303A (en) | 2001-03-23 | 2004-10-21 | インペリアル・ケミカル・インダストリーズ・ピーエルシー | Resin composition containing phosphorus-containing surfactant for pressure-sensitive adhesive |

| US20050075425A1 (en) | 2001-03-23 | 2005-04-07 | Imperial Chemical Industries Plc | Resin composition comprising a phosphorous containing surfactant for pressure sensitive adhesives |

| JP2007056131A (en) | 2005-08-24 | 2007-03-08 | Arakawa Chem Ind Co Ltd | Tackifying resin emulsion, its manufacturing method and aqueous pressure-sensitive adhesive composition |

| US20070249759A1 (en) | 2006-04-21 | 2007-10-25 | Peter James Miller | Tackifier dispersions with improved humid age performance |

| JP2012180508A (en) | 2011-02-07 | 2012-09-20 | Arakawa Chem Ind Co Ltd | Adhesion imparting resin emulsion, emulsion-type adhesive composition, and adhesive composition for film label |

| JP2017145364A (en) | 2016-02-19 | 2017-08-24 | 旭化成ワッカーシリコーン株式会社 | Method for producing silicone particle dispersion emulsion |

| US20190055362A1 (en) | 2016-02-19 | 2019-02-21 | Wacker Chemie Ag | Manufacturing method of silicone rubber particle-dispersed emulsion |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110317350B (en) | 2023-11-21 |

| TW201942252A (en) | 2019-11-01 |

| JP2019172994A (en) | 2019-10-10 |

| TWI787490B (en) | 2022-12-21 |

| CN110317350A (en) | 2019-10-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP7031633B2 (en) | Adhesive-imparting resin emulsion and water-based adhesive / adhesive composition | |

| JP5915707B2 (en) | Tackifying resin emulsion and acrylic emulsion type adhesive / adhesive composition | |

| US20100092774A1 (en) | Pressure sensitive adhesive for paper labels | |

| CN114539954B (en) | Screen-printable acrylic pressure-sensitive adhesive, preparation method and application | |

| TWI771600B (en) | Tackifier resin emulsion, water-based adhesive/adhesive composition and adhesive sheet/adhesive sheet | |

| US20160186023A1 (en) | Additive for caustic removable hot melt adhesives and formulations containing the same | |

| JP6880883B2 (en) | Adhesive-imparting resin emulsion and water-based adhesive / adhesive composition | |

| JP6907932B2 (en) | Adhesive-imparting resin emulsion for water-based adhesives and adhesives and water-based adhesives / adhesive compositions | |

| JP7180628B2 (en) | Tackifying resin emulsion, water-based adhesive/adhesive composition, and adhesive/adhesive sheet | |

| EP2697304A2 (en) | Additive for caustic removable hot melt adhesives and formulations containing the same | |

| JP5614706B2 (en) | Tackifying resin emulsion, method for producing the same, and water-based adhesive / adhesive composition | |

| WO2017065072A1 (en) | Tackifier | |

| JP2022085858A (en) | Photocurable adhesive composition and adhesive film | |

| JP6361289B2 (en) | Adhesive and adhesive sheet | |

| JP6930103B2 (en) | Adhesive-imparting resin emulsion, water-based adhesive / adhesive composition | |

| JP2012180508A (en) | Adhesion imparting resin emulsion, emulsion-type adhesive composition, and adhesive composition for film label | |

| JPS63256672A (en) | Water-base self-adhesive composition | |