JP6175011B2 - Pneumatic ribbon gun - Google Patents

Pneumatic ribbon gun Download PDFInfo

- Publication number

- JP6175011B2 JP6175011B2 JP2014029720A JP2014029720A JP6175011B2 JP 6175011 B2 JP6175011 B2 JP 6175011B2 JP 2014029720 A JP2014029720 A JP 2014029720A JP 2014029720 A JP2014029720 A JP 2014029720A JP 6175011 B2 JP6175011 B2 JP 6175011B2

- Authority

- JP

- Japan

- Prior art keywords

- cylinder

- main body

- rear end

- trigger

- guide portions

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000010304 firing Methods 0.000 claims description 22

- 230000006835 compression Effects 0.000 claims description 12

- 238000007906 compression Methods 0.000 claims description 12

- 238000002347 injection Methods 0.000 claims description 10

- 239000007924 injection Substances 0.000 claims description 10

- 230000033001 locomotion Effects 0.000 claims description 3

- 238000011084 recovery Methods 0.000 claims description 3

- 238000003780 insertion Methods 0.000 description 3

- 230000037431 insertion Effects 0.000 description 3

- 230000001105 regulatory effect Effects 0.000 description 2

- 238000000034 method Methods 0.000 description 1

- 238000009527 percussion Methods 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 230000003252 repetitive effect Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

Images

Landscapes

- Toys (AREA)

Description

本発明は、お祝いや娯楽の場面でリボンまたはカラーペーパーを噴射する、エアー式連発リボンガンに関する。 The present invention relates to a pneumatic continuous ribbon gun that jets ribbon or color paper in celebration or entertainment scenes.

お祝いや娯楽の場面で、にぎやかな雰囲気を盛り上げるために、リボンやカラーペーパーを充填したシリンダーを備えたリボンガンを利用してリボンやカラーペーパーを噴射することがある。

従来公知のリボンガンとしては、特許文献1、特許文献2及び特許文献3に記載のものが知られている。しかし、これら従来のリボンガンは1回の噴射が終わった後、シリンダーを再び充填し直さなければもう一度噴射させることができない。一部のリボンガンには1回の噴射が終わった後、手動でシリンダーを回転させると2回目の噴射を行うことができるものもあるが、操作過程が比較的煩わしく、使用者があまり好まない。

In order to create a lively atmosphere during celebrations and entertainment, ribbons and color papers are sometimes sprayed using a ribbon gun equipped with a cylinder filled with ribbons and color papers.

Conventionally known ribbon guns include those described in

本発明が解決しようとする課題は、連続発射ができるエアー式連発リボンガンを提供することにある。 The problem to be solved by the present invention is to provide an air-type continuous ribbon gun capable of continuous firing.

本発明のエアー式連発リボンガンは、本体、フロントカバー、シリンダー、トリガー、撃発ユニット、回転ユニットを含み、前記本体が中空の殼体であり、前記フロントカバーが前記本体前端部に開閉可能に設置され、前記フロントカバーに前記本体内部に連通された一つの射出口が貫通され、前記シリンダーが前記本体内部に回動可能に設置され、かつ前記フロントカバーの後方に相隣し、前記シリンダーに複数のチャンバが環状に分布して形成され、各前記チャンバ内部にリボンまたはカラーペーパーが充填され、各前記チャンバの前端開口が前記フロントカバーの後方に相隣し、いずれか一つの前記チャンバの前端開口が前記射出口の後方に位置し、各前記チャンバの後端部に、空気を各前記チャンバに進入させてリボンまたはカラーペーパーを押し出して前記射出口から外部に向かって噴射させる吸気口がそれぞれ開設され、前記撃発ユニットは、空気を各前記チャンバに進入させて前記シリンダーを撃発させるものであって、前記本体内部において、前記シリンダーの後方に相隣して設置され、前記回転ユニットは、前記シリンダーを回動させるものであって、前記本体内部に設置され、かつ前記シリンダーに連接され、前記トリガーが枢動可能に前記本体に枢着され、かつ前記トリガーが前記本体底部の外部に延伸され、前記トリガーの後端部に前記撃発ユニットを駆動する駆動部が形成され、前記トリガーの側面に前記回転ユニットを駆動する柱体が突出して設けられ、前記撃発ユニットが、管体、ピストン、圧縮ばね、アーム、リンクバー、歯止め部材を含み、前記管体が前記シリンダーの後端部に相隣し、前記管体の前端部に前記シリンダーに相対する空気出口が形成され、前記ピストンが前記管体内に軸着され、前記圧縮ばねは前記ピストンを前記シリンダーの方向に向けて付勢するものであって、前記ピストンの後端部に設置され、前記アームの前端部が前記ピストンの後端部に可動的に連結され、前記アームの後端部が前記リンクバーの前端部に枢着され、前記リンクバーの下端部と前記歯止め部材が枢着され、前記歯止め部材が前記本体に枢着され、前記歯止め部材の尖部が前記駆動部の末端の旋回区域に延伸され、かつ前記尖部が前記駆動部の上方空間に位置し、前記駆動部が前記歯止め部材を押し動かして前記リンクバーを一方向に前記本体後端部の方向に旋回させ、前記リンクバーと前記歯止め部材の間に設置されたねじりばねが前記歯止め部材の位置回復弾力を提供し、前記回転ユニットが、往復棒、引張ばね、回動部材、回転軸を含み、前記往復棒の一側に2つの突起柱が設けられ、前記本体の内側に規制溝が形成され、各前記突起柱が前記規制溝に延伸され、前記往復棒に一端が前記本体の上端に向き、他端が前記本体の下端に向いた細長い形状のガイド溝が穿設され、前記柱体が前記ガイド溝に回動可能に係合し、前記トリガーの回転に伴って前記柱体が前記往復棒を駆動して前記シリンダーの方向に向かって移動させ、前記往復棒の前端側面にプッシュ部が突出した状態に設けられ、前記往復棒が往復動に伴って前記プッシュ部により周方向に前記回動部材を動かして旋回させ、前記プッシュ部の前縁に第1斜面が形成され、前記プッシュ部の後端部に第2斜面が形成され、前記引張ばねの前端部が前記往復棒の後端部に連結されると共に、後端部が前記本体内側に連結されて前記往復棒を前記本体後端部の方向に付勢し、前記回動部材が前記シリンダー後端部に設置され、前記回動部材の前端部が前記回転軸に軸着され、前記回転軸が前記シリンダーに軸支され、前記回動部材が前記シリンダーを連動して旋回させ、前記回動部材の外周に突出した複数の第1ガイド部及び複数の第2ガイド部が設けられ、各前記第1ガイド部は前記回動部材の前記シリンダーから遠い一端に相隣し、各前記第2ガイド部は前記回動部材の前記シリンダーに近い一端に相隣し、前記回動部材外周の相隣する2つの第1ガイド部の間に第1凹陥部がそれぞれ形成され、前記回動部材外周の相隣する2つの第2ガイド部の間に第2凹陥部がそれぞれ形成され、各前記第1ガイド部が各前記第2凹陥部にそれぞれ相対し、各前記第2ガイド部が各前記第1凹陥部にそれぞれ相対するとともに、各前記第1ガイド部の一側に第1弧面が形成され、第1弧面が各前記第1ガイド部と相対する各前記第2凹陥部の末端に隣接し、各前記第2ガイド部の一側に第2弧面が形成され、第2弧面が各前記第2ガイド部と相対する各前記第1凹陥部の末端に隣接し、前記プッシュ部が第1弧面及び第2弧面にガイドされて各前記第1凹陥部及び各前記第2凹陥部の間で往復摺動し、前記回動部材を旋回させ、前記トリガーを1回操作するごとに、前記トリガーが前記撃発ユニット及び回転ユニットを駆動して、前記シリンダーの各チャンバ内のリボンまたはカラーペーパーを順に前記射出口から噴射させる。

The air-type continuous ribbon gun of the present invention includes a main body, a front cover, a cylinder, a trigger, a firing unit, and a rotating unit, the main body is a hollow casing, and the front cover is installed at the front end of the main body so as to be opened and closed. A single injection port communicated with the inside of the main body passes through the front cover, the cylinder is rotatably installed inside the main body, and is adjacent to the rear of the front cover, and a plurality of The chambers are formed in an annular distribution, each of the chambers is filled with a ribbon or colored paper, the front end openings of the chambers are adjacent to the rear of the front cover, and the front end openings of any one of the chambers are The ribbon or collar is located behind the injection port and allows air to enter each chamber at the rear end of each chamber. An air inlet that pushes out the oper and injects outward from the outlet is opened, and the firing unit fires the cylinder by causing air to enter each chamber, and inside the main body, The rotation unit is installed next to the rear of the cylinder, and the rotation unit is configured to rotate the cylinder, and is installed inside the main body and connected to the cylinder so that the trigger can pivot. A column that is pivotally attached to the main body, the trigger extends to the outside of the bottom of the main body, a driving unit that drives the firing unit is formed at the rear end of the trigger, and a column that drives the rotating unit on the side of the trigger body protrudes, wherein the percussion unit, the tube, the piston, the compression spring, arm, link bar, a pawl member, before A tube body is adjacent to the rear end portion of the cylinder, an air outlet is formed at the front end portion of the tube body so as to face the cylinder, the piston is axially mounted in the tube body, and the compression spring is attached to the piston. Urging toward the direction of the cylinder, installed at the rear end of the piston, the front end of the arm being movably connected to the rear end of the piston, and the rear end of the arm Is pivotally attached to the front end portion of the link bar, the lower end portion of the link bar and the pawl member are pivotally attached, the pawl member is pivotally attached to the main body, and the apex portion of the pawl member is the end of the drive portion And the cusp is located in the upper space of the drive unit, and the drive unit pushes the pawl member to rotate the link bar in one direction toward the rear end of the main body. , The link bar and the A torsion spring installed between the pawl members provides the position recovery elasticity of the pawl member, and the rotating unit includes a reciprocating bar, a tension spring, a rotating member, and a rotating shaft. Two protruding columns are provided, a regulating groove is formed inside the main body, each protruding column extends into the regulating groove, one end of the reciprocating bar faces the upper end of the main body, and the other end is the lower end of the main body. A long and slender guide groove is formed, the column body is rotatably engaged with the guide groove, and the column body drives the reciprocating rod as the trigger rotates, so that the cylinder Moved toward the direction, provided in a state in which the push portion protrudes from the front end side surface of the reciprocating rod, and the reciprocating rod is rotated by moving the rotating member in the circumferential direction by the push portion along with the reciprocating motion, A first slope is formed at the front edge of the push part. A second slope is formed at the rear end of the push portion, the front end of the tension spring is connected to the rear end of the reciprocating rod, and the rear end is connected to the inner side of the main body. The rod is urged in the direction of the rear end of the main body, the rotating member is installed at the rear end of the cylinder, the front end of the rotating member is attached to the rotating shaft, and the rotating shaft is attached to the cylinder. A plurality of first guide portions and a plurality of second guide portions projecting on the outer periphery of the rotation member are provided, the rotation member rotating the cylinder in conjunction with each other, and each of the first guides is provided. Each of the second guide portions is adjacent to one end of the rotating member near the cylinder and adjacent to the outer periphery of the rotating member. First recesses are formed between the first guide parts, respectively, Second concave portions are formed between two adjacent second guide portions on the outer periphery of the member, each of the first guide portions is opposed to each of the second concave portions, and each of the second guide portions is A first arc surface is formed on one side of each of the first guide portions and is opposed to each of the first recess portions, and each of the second recess portions is opposed to each of the first guide portions. A second arc surface is formed on one side of each of the second guide portions, adjacent to the end, and the second arc surface is adjacent to the end of each first recessed portion facing each of the second guide portions, The push portion is guided by the first arc surface and the second arc surface and reciprocally slides between each of the first concave portions and each of the second concave portions, turns the rotating member, and rotates the trigger once. Each time it is operated, the trigger drives the firing unit and the rotation unit, and each cylinder of the cylinder is driven. The ribbon or color paper in the bar is sequentially ejected from the ejection port.

この場合、前記歯止め部材の上縁に第1平面が形成され、前記リンクバーに前記第1平面上縁に当接される第2平面が形成され、前記歯止め部材が第1平面及び第2平面を介して一方向に前記リンクバーを動かして前記本体の後端部方向に旋回させてもよい。

In this case, the pawl first plane upper edge member is formed, the link bar second plane is brought into contact with the first plane on the edge is formed on said pawl member is a first plane and the second The link bar may be moved in one direction via a plane and swiveled toward the rear end of the main body.

本発明のエアー式連発リボンガンによれば、トリガーを引いて再び解放する動作を1回実行すると、トリガーが同時に撃発ユニット及び回転ユニットを動かしてシリンダーに空気を送り込み、リボンまたはカラーペーパーを噴射すると共に、シリンダーが回転するので、複数回連続してシリンダーよりリボンまたはカラーペーパーを噴射させることができる。また、連続してリボンまたはカラーペーパーを噴射させた後に、フロントカバーを開けてシリンダーを交換することができ、使用上便利である。 According to the pneumatic continuous ribbon gun of the present invention, when the trigger is pulled and released again once, the trigger simultaneously moves the firing unit and the rotation unit to feed air into the cylinder and injects ribbon or colored paper. Since the cylinder rotates, the ribbon or color paper can be ejected from the cylinder continuously several times. Further, after the ribbon or color paper is continuously sprayed, the front cover can be opened and the cylinder can be replaced, which is convenient for use.

以下、本発明の実施例を図面に基づいて詳細に説明する。

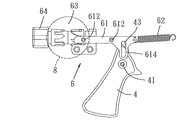

図1と図2に示すように、本実施例のエアー式連発リボンガンは、本体1、フロントカバー2、シリンダー3、トリガー4、撃発ユニット5、回転ユニット6を含む。

本体1は、右側殼体11、左側殼体12を閉じ合わせて構成される中空の殼体であり、フロントカバー2が本体1の前端部に開閉可能に設置され、フロントカバー2に本体1内部に連通された射出口21が貫通される。

シリンダー3は本体1内部に回動可能に設置され、かつフロントカバー2の後方に相隣し、シリンダー3が本体1前端部を通過して本体1に対して着脱される。

Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

As shown in FIGS. 1 and 2, the pneumatic continuous ribbon gun of this embodiment includes a

The

The

トリガー4は本体1に枢着され、かつトリガー4が本体1底部の外部に延伸される。また、トリガー4の側面に枢軸41が設置され、この枢軸41が右側殼体11及び左側殼体12に枢着される。これにより、使用者がトリガー4を引くと、トリガー4が枢軸41を中心として旋回する。

撃発ユニット5は本体1内部にシリンダー3の後方に相隣して設置され、シリンダー3を撃発させるために用いられる。

回転ユニット6は本体1内部にシリンダー3に連接して設置され、シリンダー3を回動させるために用いられる。

The

The

The rotation unit 6 is installed inside the

図3と図4に示すように、シリンダー3の後端部中央に軸方向に沿って非円形の嵌入孔31が設けられる。嵌入孔31は三角形、多辺形、または楕円形等その他円形ではない凹陥槽に変化させてもよく、図4に示すものに限定されない。

シリンダー3には複数のチャンバ32が形成され、各チャンバ32の内部にリボンまたはカラーペーパー(図示しない)が充填される。また、各チャンバ32はシリンダー3の中心軸を中心として環状に分布され、各チャンバ32の前端開口がフロントカバー2の後方に相隣し(図2参照)、各チャンバ32の後端部に、空気をチャンバ32の通路に進入させるための吸気口33がそれぞれ開設される。これにより空気で各チャンバ32内部のリボンまたはカラーペーパーを各チャンバ32の前端開口から押し出して射出口21から(図1参照)外部に向かって噴射させる。

As shown in FIGS. 3 and 4, a

A plurality of

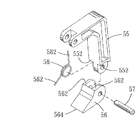

図2と図5に示すように、トリガー4の後端部には駆動部42が形成され、トリガー4は駆動部42により撃発ユニット5を駆動する。撃発ユニット5は、管体51、ピストン52、圧縮ばね53、アーム54、リンクバー55、歯止め部材56を含む。

管体51はシリンダー3の後端部に相隣し、管体51の前端部にシリンダー3の後端部に相対する空気出口512が形成される。

ピストン52は管体51内に軸着され、ピストン52の外縁に、ピストン52と管体51内壁間の気密性を高めるための少なくとも1つの密封リング522が設置される。

圧縮ばね53はピストン52の後端部に設置され、圧縮ばね53の前端部がピストン52の後端部に相隣する。圧縮ばね53の後端部は本体1の2つのストッパ部13に相隣し、圧縮ばね53がピストン52を弾性的に付勢してシリンダー3の方向に摺動させるために用いられる。

As shown in FIGS. 2 and 5, a

The

The

The

アーム54の前端部がピストン52の後端部に可動的に連結され、アーム54の後端部がリンクバー55の前端部に枢着される。図2、図5、図6に示すように、歯止め部材56は中軸57により本体1に枢着されて位置決めされ、リンクバー55の下端部と歯止め部材56が中軸57により枢着される。

歯止め部材56は上面に第1平面562が形成され、歯止め部材56の尖部564が駆動部42の末端の旋回区域に延伸され、かつ尖部564が駆動部42の上縁空間に位置する。それによりトリガー4が旋回されると、駆動部42が歯止め部材56を押し動かして中軸57を中心として旋回させる。リンクバー55には第1平面562の上縁に当接される第2平面552が形成され、旋回する歯止め部材56がリンクバー55を動かして、中軸57を中心として一方向に本体1の後端部方向に旋回させるように構成される。

リンクバー55と歯止め部材56間にはねじりばね58が設置され、ねじりばね58の2つのばね脚部582がリンクバー55と歯止め部材56にそれぞれ当接され、歯止め部材56とリンクバー55に対して旋回した後の位置回復弾力が提供される。

The front end portion of the

The

A

図2及び図7に示すように、トリガー4の側面には柱体43が突出して設けられる。柱体43は、回転ユニット6を駆動するために用いられ、かつ枢軸41と本体1上縁の間に位置する。

回転ユニット6は往復棒61、引張ばね62、回動部材63、回転軸64を含む。

往復棒61の一側に2つの突起柱612が設けられ、右側殼体11の内側に形成された規制溝112(図10参照)に各突起柱612が延伸される。往復棒61には、一端が本体1の上端に向き、他端が本体1の下端に向いた上下方向に細長い形状のガイド溝614が穿設され、柱体43がガイド溝614に回動可能に係合される。これにより、トリガー4を後方に向かって引き旋回させると、トリガー4が柱体43を介して往復棒61を駆動し、シリンダー3の方向に向かって移動させることができる。往復棒61は前端側面にプッシュ部616が突出した状態に設けられ(図9参照)、プッシュ部616の前縁に第1斜面6162が形成され、プッシュ部616の後端部に第2斜面6164が形成される。

As shown in FIGS. 2 and 7, a

The rotating unit 6 includes a reciprocating

Two protruding

引張ばね62は、前端部が往復棒61の後端部に連結され、後端部が本体1の後端部近くの内側に連結される。これにより往復棒61に牽引力を提供し、往復棒61を本体1後端部の方向に向かって付勢している。

回動部材63はシリンダー3の後端部に設置され、回動部材63の前端部が回転軸64に軸着される。回転軸64はシリンダー3の後端部の嵌入孔31に係合されて(図4参照)、回動部材63が回転軸64によりシリンダー3を連動して旋回させるように構成される。

The

The rotating

図8に示すように、回動部材63の外周面には突出した複数の第1ガイド部632と複数の第2ガイド部634が設けられる。第1ガイド部632及び第2ガイド部634の数量はシリンダー3のリボンまたはカラーペーパー充填に用いるチャンバ32の数量と同じとする。各第1ガイド部632は回動部材63のシリンダー3から遠い一端に相隣し、各第2ガイド部634は回動部材63のシリンダー3に近い一端に相隣する。

また、回動部材63外周の相隣する2つの第1ガイド部632の間に第1凹陥部633がそれぞれ形成され、回動部材63外周の相隣する2つの第2ガイド部634の間に第2凹陥部635がそれぞれ形成される。各第1ガイド部632が各第2凹陥部635にそれぞれ相対し、各第2ガイド部634が各第1凹陥部633にそれぞれ相対する。

各第1ガイド部632の一側に第1弧面6322が形成され、この第1弧面6322が各第1ガイド部632と相対する各第2凹陥部635の末端に隣接する。各第2ガイド部634の一側に第2弧面6342が形成され、第2弧面6342が各第2ガイド部634と相対する各第1凹陥部633の末端に隣接する。これにより、プッシュ部616をガイドして各第1凹陥部633及び各第2凹陥部635の間で往復摺動させ、往復棒61がプッシュ部616により相対的に周方向へ押され、回動部材63を旋回させるように構成される。

As shown in FIG. 8, a plurality of

In addition, a first recessed

A

使用者がトリガー4を後方に引くと、トリガー4が枢軸41を中心として図5及び図7の反時計回り方向に旋回し、駆動部42が尖部564に接触して、歯止め部材56が中軸57を中心として時計回り方向に旋回する。第2平面552が第1平面562の上縁に当接しているため、歯止め部材56が時計回り方向に旋回されると、リンクバー55が連動して中軸57を中心として本体1の後端部に向かって時計回り方向に同時に旋回され、さらにアーム54がピストン52を後方へと引っ張って移動させ、空気を吸引して管体51内部のピストン52と空気出口512の間の空間に進入させ、同時に、ピストン52が圧縮ばね53を圧縮する。

When the user pulls the

歯止め部材56の時計回り方向への旋回に伴い、尖部564が駆動部42の旋回区域を離れると、駆動部42と尖部564が相互に分離し、このとき、駆動部42の歯止め部材56に対する作用力が解除され、圧縮ばね53の復元力によりピストン52が前方向に移動し、管体51内の空気が空気出口512に向かって押され、管体51から流出して、シリンダー3後端部の空気出口512に相対する吸気口33から吸気口33に連通されたチャンバ32に進入する。これにより、チャンバ32内部のリボンまたはカラーペーパーがチャンバ32及び射出口21から押し出され、リボンガン前端部の外部へと噴射される。さらに、ピストン53の前方向への移動がアーム54、リンクバー55、歯止め部材56を連動して位置を回復させる。

As the

使用者がトリガー4を後方に向かって引くと、前述のように駆動部42により歯止め部材56を動かして、撃発ユニット5を作動させ、シリンダー3を撃発させると共に、トリガー4の反時計回りの旋回が同時に柱体43を動かして往復棒61を前方向へと移動させ、引張ばね62が引っ張られて変形する。使用者が撃発ユニット5でシリンダー3を撃発させた後、トリガー4に対する牽引作用力を解除すると、引張ばね62が弾力を提供して往復棒61を後方へ当初の位置まで移動させる。往復棒61が後方へ移動すると、トリガー4が枢軸41を中心として時計回り方向に旋回され、当初の位置に復帰する。

When the user pulls the

トリガー4が時計回り方向に旋回すると、駆動部42が尖部564の上縁に接触して歯止め部材56が中軸57を中心として反時計回り方向に旋回される。歯止め部材56はリンクバー55に中軸57により枢着されており、かつ歯止め部材56はリンクバー55を一方向のみに駆動して本体1の後端部方向に向かって旋回させることができるだけであるため、歯止め部材56が反時計回り方向に旋回されたとき、リンクバー55、アーム54、ピストン52を動かすことはできず、歯止め部材56はリンクバー55に対して旋回され、歯止め部材56がねじりばね58をひねる。尖部564が歯止め部材56の反時計回り方向の旋回に伴い、駆動部42の旋回区域を離れると、駆動部42と尖部564が相互に分離され、このとき、駆動部42の歯止め部材56に対する作用力が解除され、トリガー4が当初の位置を回復し、ねじりばね58が弾力を提供して歯止め部材56を時計回り方向に当初の位置まで旋回させる。

When the

使用者が前述のようにトリガー4を後方に引き、往復棒61を前方に向かって移動させると、プッシュ部616が第1凹陥部633から前方に向かって移動され、第1斜面6162が第1凹陥部633に相対する第2ガイド部634に接触したとき、第1斜面6162と第2ガイド部634一側の第2弧面6342相互間の相対した形状により、プッシュ部616が第2弧面6342によりガイドされて第2凹陥部635に進入し、プッシュ部616が第2弧面6342を周方向に押し、回動部材63を旋回させる。

回動部材63が回転軸64を介してシリンダー3を同時に旋回させ、シリンダー3後端部の吸気口33と管体51の空気出口512が相対し、空気がシリンダー3のチャンバ32に進入して、チャンバ32のリボンまたはカラーペーパーを前記射出口21から外部に向かって押し出し、噴射させることができる。

As described above, when the user pulls the

The rotating

使用者が撃発ユニット5でシリンダー3を撃発させた後、トリガー4に対する牽引作用力を解除し、往復棒61が後方に向かって移動されると、プッシュ部616が第2凹陥部635から後方に向かって移動し、第2斜面6164が第2凹陥部635に相対する別の第1ガイド部632に接触したとき、第2斜面6164と第1ガイド部632一側の第1弧面6322相互間の形状により、プッシュ部616が第1弧面6322にガイドされて別の第1凹陥部633に進入し、プッシュ部616が第1弧面6322を周方向に押し、再度回動部材63を旋回させる。回動部材63が回転軸64を介してシリンダー3を同時に旋回させ、空気出口512をシリンダー3後端部の2つの相隣する吸気口33の間の箇所に相対させる。

After the user has fired the

使用者がトリガー4を引いてトリガー4を解放する動作を1回実行すると、トリガー4が同時に撃発ユニット5及び回転ユニット6を動かすため、トリガー4を引いてから離す動作以外、使用者は別途操作を必要とすることなく、シリンダー3に空気を送り込みリボンまたはカラーペーパーを噴射すると共に、シリンダー3を回転させる動作が完了され、使用者はトリガー4を引いて離す操作を複数回繰り返し行うことで、シリンダー3の各チャンバ32内のリボンまたはカラーペーパーを順に外部に向かって噴射させることができる。各チャンバ32内のリボンまたはカラーペーパーをすべて外部に向かって噴射させた後、フロントカバー2を開いてシリンダー3を交換すればよい。使用者はシリンダー3から複数回リボンまたはカラーペーパーを噴射させた後、シリンダー3を交換することができるため、使用上便利である。

When the user pulls the

1 本体

11 右側殼体

112 規制溝

12 左側殼体

13 ストッパ部

2 フロントカバー

21 射出口

3 シリンダー

31 嵌入孔

32 チャンバ

33 吸気口

4 トリガー

41 枢軸

42 駆動部

43 柱体

5 撃発ユニット

51 管体

512 空気出口

52 ピストン

522 密封リング

53 圧縮ばね

54 アーム

55 リンクバー

552 第2平面

56 歯止め部材

562 第1平面

564 尖部

57 中軸

58 ねじりばね

582 ばね脚部

6 回転ユニット

61 往復棒

612 突起柱

614 ガイド溝

616 プッシュ部

6162 第1斜面

6164 第2斜面

62 引張ばね

63 回動部材

632 第1ガイド部

6322 第1弧面

633 第1凹陥部

634 第2ガイド部

6342 第2弧面

635 第2凹陥部

64 回転軸

DESCRIPTION OF

Claims (2)

前記本体が中空の殼体であり、

前記フロントカバーが前記本体前端部に開閉可能に設置され、前記フロントカバーに前記本体内部に連通された一つの射出口が貫通され、

前記シリンダーが前記本体内部に回動可能に設置され、かつ前記フロントカバーの後方に相隣し、前記シリンダーに複数のチャンバが環状に分布して形成され、各前記チャンバ内部にリボンまたはカラーペーパーが充填され、各前記チャンバの前端開口が前記フロントカバーの後方に相隣し、いずれか一つの前記チャンバの前端開口が前記射出口の後方に位置し、各前記チャンバの後端部に、空気を各前記チャンバに進入させてリボンまたはカラーペーパーを押し出して前記射出口から外部に向かって噴射させる吸気口がそれぞれ開設され、

前記撃発ユニットは、空気を各前記チャンバに進入させて前記シリンダーを撃発させるものであって、前記本体内部において、前記シリンダーの後方に相隣して設置され、

前記回転ユニットは、前記シリンダーを回動させるものであって、前記本体内部に設置され、かつ前記シリンダーに連接され、

前記トリガーが枢動可能に前記本体に枢着され、かつ前記トリガーが前記本体底部の外部に延伸され、前記トリガーの後端部に前記撃発ユニットを駆動する駆動部が形成され、前記トリガーの側面に前記回転ユニットを駆動する柱体が突出して設けられ、

前記撃発ユニットが、管体、ピストン、圧縮ばね、アーム、リンクバー、歯止め部材を含み、前記管体が前記シリンダーの後端部に相隣し、前記管体の前端部に前記シリンダーに相対する空気出口が形成され、前記ピストンが前記管体内に軸着され、前記圧縮ばねは前記ピストンを前記シリンダーの方向に向けて付勢するものであって、前記ピストンの後端部に設置され、前記アームの前端部が前記ピストンの後端部に可動的に連結され、前記アームの後端部が前記リンクバーの前端部に枢着され、前記リンクバーの下端部と前記歯止め部材が枢着され、前記歯止め部材が前記本体に枢着され、前記歯止め部材の尖部が前記駆動部の末端の旋回区域に延伸され、かつ前記尖部が前記駆動部の上方空間に位置し、前記駆動部が前記歯止め部材を押し動かして前記リンクバーを一方向に前記本体後端部の方向に旋回させ、前記リンクバーと前記歯止め部材の間に設置されたねじりばねが前記歯止め部材の位置回復弾力を提供し、前記回転ユニットが、往復棒、引張ばね、回動部材、回転軸を含み、前記往復棒の一側に2つの突起柱が設けられ、前記本体の内側に規制溝が形成され、各前記突起柱が前記規制溝に延伸され、前記往復棒に一端が前記本体の上端に向き、他端が前記本体の下端に向いた細長い形状のガイド溝が穿設され、前記柱体が前記ガイド溝に回動可能に係合し、前記トリガーの回転に伴って前記柱体が前記往復棒を駆動して前記シリンダーの方向に向かって移動させ、前記往復棒の前端側面にプッシュ部が突出した状態に設けられ、前記往復棒が往復動に伴って前記プッシュ部により周方向に前記回動部材を動かして旋回させ、前記プッシュ部の前縁に第1斜面が形成され、前記プッシュ部の後端部に第2斜面が形成され、前記引張ばねの前端部が前記往復棒の後端部に連結されると共に、後端部が前記本体内側に連結されて前記往復棒を前記本体後端部の方向に付勢し、前記回動部材が前記シリンダー後端部に設置され、前記回動部材の前端部が前記回転軸に軸着され、前記回転軸が前記シリンダーに軸支され、前記回動部材が前記シリンダーを連動して旋回させ、前記回動部材の外周に突出した複数の第1ガイド部及び複数の第2ガイド部が設けられ、各前記第1ガイド部は前記回動部材の前記シリンダーから遠い一端に相隣し、各前記第2ガイド部は前記回動部材の前記シリンダーに近い一端に相隣し、前記回動部材外周の相隣する2つの第1ガイド部の間に第1凹陥部がそれぞれ形成され、前記回動部材外周の相隣する2つの第2ガイド部の間に第2凹陥部がそれぞれ形成され、各前記第1ガイド部が各前記第2凹陥部にそれぞれ相対し、各前記第2ガイド部が各前記第1凹陥部にそれぞれ相対するとともに、各前記第1ガイド部の一側に第1弧面が形成され、第1弧面が各前記第1ガイド部と相対する各前記第2凹陥部の末端に隣接し、各前記第2ガイド部の一側に第2弧面が形成され、第2弧面が各前記第2ガイド部と相対する各前記第1凹陥部の末端に隣接し、前記プッシュ部が第1弧面及び第2弧面にガイドされて各前記第1凹陥部及び各前記第2凹陥部の間で往復摺動し、前記回動部材を旋回させ、

前記トリガーを1回操作するごとに、前記トリガーが前記撃発ユニット及び回転ユニットを駆動して、前記シリンダーの各チャンバ内のリボンまたはカラーペーパーを順に前記射出口から噴射させる、

ことを特徴とする、エアー式連発リボンガン。 Air type continuous ribbon gun, including main body, front cover, cylinder, trigger, firing unit, rotating unit,

The body is a hollow housing;

The front cover is installed to be openable and closable at the front end of the main body, and a single injection port communicating with the inside of the main body is passed through the front cover,

The cylinder is rotatably installed inside the main body, and is adjacent to the rear of the front cover, and a plurality of chambers are annularly distributed in the cylinder, and a ribbon or color paper is formed inside each chamber. The front end opening of each chamber is adjacent to the rear of the front cover, the front end opening of any one of the chambers is located behind the outlet, and air is supplied to the rear end of each chamber. Air inlets that are made to enter each of the chambers and extrude a ribbon or color paper and inject outward from the outlets are respectively opened,

The firing unit is for firing the cylinder by causing air to enter each chamber, and is installed next to the rear of the cylinder inside the main body,

The rotating unit rotates the cylinder, is installed inside the main body, and is connected to the cylinder.

The trigger is pivotally attached to the main body, the trigger is extended to the outside of the bottom of the main body, and a drive unit for driving the firing unit is formed at the rear end of the trigger, and the side surface of the trigger A column for driving the rotating unit is provided to protrude,

The firing unit includes a tube body, a piston, a compression spring, an arm, a link bar, and a pawl member, and the tube body is adjacent to a rear end portion of the cylinder and is opposed to the cylinder at a front end portion of the tube body. An air outlet is formed, the piston is pivotally mounted in the tube, and the compression spring biases the piston toward the cylinder, and is installed at a rear end of the piston. A front end portion of the arm is movably connected to a rear end portion of the piston, a rear end portion of the arm is pivotally attached to a front end portion of the link bar, and a lower end portion of the link bar and the pawl member are pivotally attached. The pawl member is pivotally attached to the main body, the apex of the pawl is extended to the swivel zone at the end of the drive unit, and the apex is located in the upper space of the drive unit, and the drive unit is The pawl member The link bar is pivoted in one direction toward the rear end of the main body, and a torsion spring installed between the link bar and the pawl member provides position recovery elasticity of the pawl member, and the rotation The unit includes a reciprocating rod, a tension spring, a rotating member, and a rotating shaft, two protruding columns are provided on one side of the reciprocating rod, a restriction groove is formed inside the main body, and each protruding column is An elongated guide groove is formed in the reciprocating rod so that one end faces the upper end of the main body and the other end faces the lower end of the main body, and the column body is rotatable in the guide groove. The column body is driven in the direction of the cylinder by driving the reciprocating bar as the trigger rotates, and is provided in a state in which a push portion protrudes from the front end side surface of the reciprocating bar. The reciprocating rod moves along with the reciprocating motion. The rotating member is moved in the circumferential direction by the shoe portion to be turned, a first inclined surface is formed at the front edge of the push portion, a second inclined surface is formed at the rear end portion of the push portion, and the front end of the tension spring A reciprocating rod is coupled to the rear end of the reciprocating rod, and a rear end is coupled to the inside of the main body to urge the reciprocating rod toward the rear end of the main body. It is installed at the end, the front end of the rotating member is pivotally attached to the rotating shaft, the rotating shaft is pivotally supported by the cylinder, the rotating member rotates the cylinder in conjunction with the rotating shaft, and the rotating A plurality of first guide portions and a plurality of second guide portions projecting from the outer periphery of the member are provided, and each of the first guide portions is adjacent to one end of the rotating member far from the cylinder, and each of the second guide portions. The part is adjacent to one end of the rotating member near the cylinder, A first recessed portion is formed between two adjacent first guide portions on the outer periphery of the rotating member, and a second recessed portion is formed between two adjacent second guide portions on the outer periphery of the rotating member. Each of the first guide portions is opposed to each of the second recessed portions, and each of the second guide portions is opposed to each of the first recessed portions, and one side of each of the first guide portions. A first arc surface is formed, the first arc surface is adjacent to the end of each of the second recessed portions facing each of the first guide portions, and a second arc surface is formed on one side of each of the second guide portions. The second arc surface is formed adjacent to the end of each first recessed portion facing each of the second guide portions, and the push portion is guided by the first arc surface and the second arc surface to each of the first arc surfaces. Reciprocatingly slide between the recessed portion and each of the second recessed portions, and swivel the rotating member,

Each time the trigger is operated once, the trigger drives the firing unit and the rotation unit, and the ribbon or color paper in each chamber of the cylinder is sequentially ejected from the ejection port.

This is an air-type continuous ribbon gun.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014029720A JP6175011B2 (en) | 2014-02-19 | 2014-02-19 | Pneumatic ribbon gun |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014029720A JP6175011B2 (en) | 2014-02-19 | 2014-02-19 | Pneumatic ribbon gun |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2015150390A JP2015150390A (en) | 2015-08-24 |

| JP6175011B2 true JP6175011B2 (en) | 2017-08-02 |

Family

ID=53893260

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014029720A Expired - Fee Related JP6175011B2 (en) | 2014-02-19 | 2014-02-19 | Pneumatic ribbon gun |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP6175011B2 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110193209B (en) * | 2019-06-27 | 2023-12-19 | 广州灵动创想文化科技有限公司 | Turntable type ejection toy |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5186156B1 (en) * | 1991-11-18 | 1997-03-11 | Richard A Clayton | Air operated toy gun |

| JP2604931Y2 (en) * | 1993-09-24 | 2000-06-12 | 株式会社カネコ | Magazine for machine gun crackers |

| US6120346A (en) * | 1999-08-09 | 2000-09-19 | Wang; Kun-Meng | Ribbon gun with replaceable decorated head and cartridge |

| JP4335239B2 (en) * | 2006-07-26 | 2009-09-30 | 株式会社スナミヤ | Cracker launcher |

| JP5401677B2 (en) * | 2008-11-25 | 2014-01-29 | 株式会社スナミヤ | Highly safe launcher that can be used repeatedly |

| JP2010269080A (en) * | 2009-05-25 | 2010-12-02 | Konmo O | Structure of ribbon gun |

| US8146579B2 (en) * | 2009-08-21 | 2012-04-03 | Hasbro, Inc. | Toy employing central shaft cocking mechanism for rapid fire projectile launching and method thereof |

| HK1138476A2 (en) * | 2009-12-23 | 2010-08-20 | Buzz Bee Toys H K Co | Toy air gun |

| JP2012177491A (en) * | 2011-02-25 | 2012-09-13 | Explore:Kk | Compressed air cracker device |

-

2014

- 2014-02-19 JP JP2014029720A patent/JP6175011B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2015150390A (en) | 2015-08-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9707573B1 (en) | Controller of water dispensing apparatus | |

| US2589977A (en) | Water gun | |

| JP3150387U (en) | Water gun toy | |

| US7032837B2 (en) | Toy water gun with variable spray patterns | |

| US6935531B1 (en) | Toy water gun | |

| US6279562B1 (en) | Toy gun with multiple discharge ports | |

| US20070181116A1 (en) | Air gun | |

| ITMI940554A1 (en) | HEAD FOR SHOWER | |

| US20060180134A1 (en) | Combination solid projectile and paintball gun, and solid projectile adapter for paintball gun | |

| US4630757A (en) | Toy gun | |

| JP2013127335A (en) | Water gun | |

| JP6175011B2 (en) | Pneumatic ribbon gun | |

| US4784293A (en) | Toy water gun | |

| US20140246516A1 (en) | Replaceable head part of probe of spray gun | |

| EP1939576B1 (en) | Air gun | |

| KR101497632B1 (en) | packaging easy while adjustable water spray century squirt | |

| JP2017106675A (en) | Toy gun | |

| US9086252B2 (en) | Automatic shooting ribbon dispenser | |

| JP2016161225A (en) | Toy gun | |

| US2706067A (en) | Toy pistols | |

| WO2015013614A1 (en) | Projectile launcher and method of operating the same | |

| US3040932A (en) | Toy liquid ejecting pistol | |

| JP5567537B2 (en) | Device for changing the number of bullets in a bullet feed mechanism | |

| EP2884219B1 (en) | Automatic shooting ribbon dispenser | |

| JP6395661B2 (en) | Liquid ejector |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20160531 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20160607 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160816 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20161129 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170119 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20170613 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20170707 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6175011 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |