JP5173728B2 - Shelf holder - Google Patents

Shelf holder Download PDFInfo

- Publication number

- JP5173728B2 JP5173728B2 JP2008263428A JP2008263428A JP5173728B2 JP 5173728 B2 JP5173728 B2 JP 5173728B2 JP 2008263428 A JP2008263428 A JP 2008263428A JP 2008263428 A JP2008263428 A JP 2008263428A JP 5173728 B2 JP5173728 B2 JP 5173728B2

- Authority

- JP

- Japan

- Prior art keywords

- hole

- screw

- mounting

- moving member

- shelf

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000000630 rising effect Effects 0.000 claims description 2

- 238000009434 installation Methods 0.000 claims 1

- 239000002023 wood Substances 0.000 description 6

- 238000010276 construction Methods 0.000 description 4

- 239000011521 glass Substances 0.000 description 4

- 229910001297 Zn alloy Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 239000011347 resin Substances 0.000 description 2

- 229920005989 resin Polymers 0.000 description 2

- 238000010079 rubber tapping Methods 0.000 description 2

- 101100460719 Mus musculus Noto gene Proteins 0.000 description 1

- 101100187345 Xenopus laevis noto gene Proteins 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

Images

Landscapes

- Connection Of Plates (AREA)

- Furniture Connections (AREA)

- Display Racks (AREA)

Description

この発明は、壁面等に棚板を取り付けて支持する棚受具に関するものである。 The present invention relates to a shelf holder for attaching and supporting a shelf plate on a wall surface or the like.

従来、下記特許文献1には、図8に示すように、壁面等の被取付面Wに取り付ける固定部材51と、この固定部材51に対して上下にスライドする移動部材52とから成り、固定部材51の上部の前方突出片53の下面と、移動部材52のブラケット部54の上面との間に棚板Sを挟み込んで支持するものが記載されている。

Conventionally, as shown in FIG. 8, the following

固定部材51は、中間部の取付用貫穴55を介して取付ねじ61を被取付面Wにねじ込むことにより、被取付面Wに固定され、棚板Sを固定部材51と移動部材52とで挟持するには、移動部材52の下部の締付用貫穴56を介して固定部材51の下部のねじ穴57に締付ねじ62をねじ込み、固定部材51に対して移動部材52を上昇させる。

The

ここで、取付用貫穴55は、取付ねじ61のねじ径に応じた丸穴とされている。締付用貫穴56とねじ穴57とは、それぞれの中心と移動部材52及び固定部材51の被取付面Wに対向する基準面までの距離とが一致している。また、締付ねじ62の先端は、棚板Sが固定部材51と移動部材52の間から抜け出すのを防止するため、棚板Sに食い込むようになっている。

Here, the mounting through

しかしながら、上記のような棚受具では、固定部材51を被取付面Wに固定すると、移動部材52も被取付面Wに強く当接するので、棚板Sの挟み込みに際し、移動部材52と被取付面Wとの摩擦により、締付ねじ62を回転させて、固定部材51に対し移動部材52をスライドさせることが難しくなるという問題がある。

However, in the shelf holder as described above, when the

その対策として、移動部材52が被取付面Wから離れた状態で上昇するように設定すると、施工後の状態においても、移動部材52と被取付面Wとの間に隙間が開いたままとなり、棚板Sの安定性や美観が損なわれるという問題が生じる。

As a countermeasure, if the moving

また、棚板Sがガラス製の場合、締付ねじ62の先端を棚板Sに食い込ませて棚板Sを抜け止めする方法は採用できないという問題がある。

Further, when the shelf board S is made of glass, there is a problem that a method of preventing the shelf board S from being pulled out by biting the tip of the

そのほか、複数個の棚受具で棚板Sを支持する場合、棚板Sを水平にするため、固定部材51の取付高さを微調整しようとしても、取付ねじ61のねじ込み位置を変えない限り不可能であるという問題がある。

In addition, when the shelf board S is supported by a plurality of shelf holders, even if an attempt is made to finely adjust the attachment height of the

また、この微調整を可能とするため、取付用貫穴55を上下方向に延びる通常の長穴とすると、取付ねじ61が取付用貫穴55の下方部分に位置して固定部材51が高い位置にある状態で、取付ねじ61を少し緩めたとき、固定部材51が取付ねじ61に対し取付用貫穴55の範囲で下端まで落下してしまい、作業がやりにくいという問題が生じる。

Further, in order to enable this fine adjustment, if the mounting through

そこで、この発明は、容易かつ確実に、美観に優れた施工状態で棚板を被取付面に取り付けられるようにすることを課題とする。 Then, this invention makes it a subject to make it possible to attach a shelf board to a to-be-attached surface easily and reliably in the construction state excellent in aesthetics.

上記課題を解決するため、この発明では、壁等の被取付面に取付用貫穴を介して取付ねじをねじ込むことにより固定される固定部材と、これに対して上下にスライドする移動部材とから成り、移動部材の締付用貫穴を介して固定部材のねじ穴に締付ねじをねじ込み、固定部材に対して移動部材を上昇させ、固定部材と移動部材との間に棚板を挟持する棚受具において、前記固定部材の被取付面に対向する基準面からねじ穴の中心までの距離よりも、移動部材の被取付面に対向する基準面から締付用貫穴の中心までの距離を大きく設定し、被取付面から移動部材が離れた状態で、締付ねじをねじ穴にねじ込むと、締付ねじの頭部のテーパ面と締付用貫穴の周囲に形成した皿モミ部のテーパ面とが相互に滑動し、移動部材が被取付面に引き寄せられて密着するようにしたのである。 In order to solve the above-described problems, the present invention includes a fixing member that is fixed by screwing a mounting screw into a mounting surface such as a wall through a mounting through hole, and a moving member that slides up and down relative to the fixing member. The fastening screw is screwed into the screw hole of the fixing member through the through hole for fastening of the moving member, the moving member is raised with respect to the fixing member, and the shelf board is sandwiched between the fixing member and the moving member. In the shelf holder, the distance from the reference surface facing the mounting surface of the moving member to the center of the through hole for fastening is larger than the distance from the reference surface facing the mounting surface of the fixing member to the center of the screw hole. When the tightening screw is screwed into the screw hole with the moving member away from the mounting surface, the countersunk part formed around the taper surface of the head of the tightening screw and the through hole for tightening The taper surfaces of the Than it was into close contact Te.

また、前記移動部材の上面に凹所を設け、棚板の下面から突出する突起物が凹所に係合し、又は、凹所の底部から立ち上がる突起物が棚板の係止穴に係合して、棚板が固定部材と移動部材の間から抜け出さないようにしたのである。 Also, a recess is provided on the upper surface of the moving member, and a protrusion protruding from the lower surface of the shelf engages with the recess, or a protrusion rising from the bottom of the recess engages with the locking hole of the shelf. Thus, the shelf plate is prevented from coming out between the fixed member and the moving member.

さらに、前記固定部材の取付用貫穴を、上下に長く上窄まりのテーパ状とし、取付ねじの緩み量に応じて、皿ねじである取付ねじの頭部のテーパ面と取付用貫穴の周囲に形成した皿モミ部のテーパ面との当接位置が変化し、取付ねじが取付用貫穴の下方部分に位置して固定部材が高い位置にある状態で、取付ねじを少し緩めても、固定部材が取付ねじに対し取付用貫穴の範囲で下端まで落下しないようにしたのである。 Furthermore, the mounting through hole of the fixing member is formed in a tapered shape that is long and vertically narrowed, and according to the amount of looseness of the mounting screw, the taper surface of the head of the mounting screw that is a countersunk screw and the mounting through hole Even if the mounting screw is slightly loosened in the state where the contact position with the tapered surface of the countersink formed around changes, the mounting screw is located in the lower part of the through hole for mounting and the fixing member is at a high position The fixing member is prevented from dropping to the lower end within the range of the mounting through hole with respect to the mounting screw.

この発明に係る棚受具では、固定部材のねじ穴と移動部材の締付用貫穴の中心のずれ及びテーパ面同士の滑動により、固定部材に締付ねじをねじ込むと、移動部材が被取付面に引き寄せられて密着するようにしたので、施工後の状態で、移動部材と被取付面との間に隙間が開くことを防止でき、正面や側面のほか、下方から見たときの美観に優れ、棚板に重い物を載せた場合における棚板の安定性も向上する。 In the shelf holder according to the present invention, when the fastening screw is screwed into the fixing member due to the shift of the center of the screw hole of the fixing member and the through hole for fastening of the moving member and the sliding of the tapered surfaces, the moving member is attached. Since it is drawn close to the surface and in close contact with it, it can be prevented from opening a gap between the moving member and the surface to be mounted after construction. It is excellent, and the stability of the shelf board when a heavy object is placed on the shelf board is also improved.

また、移動部材の上面に凹所を設けたものでは、棚板が木製である場合、棚板にねじ込んだ木ねじ等の突起物を移動部材の凹所に係合させ、棚板がガラス製である場合、棚板に形成した係止穴に凹所の底部から立ち上がるタッピングねじ等の突起物を係合させて、棚板の抜け出しを防止することができる。 In addition, in the case where the upper surface of the moving member is provided with a recess, when the shelf board is made of wood, a protrusion such as a wood screw screwed into the shelf board is engaged with the recess of the moving member, and the shelf board is made of glass. In some cases, a protrusion such as a tapping screw that rises from the bottom of the recess can be engaged with a locking hole formed in the shelf board to prevent the shelf board from slipping out.

さらに、固定部材の取付用貫穴を上窄まりのテーパ状としたものでは、取付ねじを少し緩めることにより、固定部材の取付高さを少しずつ下げて容易に調整することができ、棚板を簡単に水平に取り付けることができる。 In addition, in the case where the through hole for mounting the fixing member has a tapered shape, the mounting height of the fixing member can be easily lowered and gradually adjusted by loosening the mounting screw. Can be easily mounted horizontally.

以下、この発明の実施形態を添付図面に基づいて説明する。 Embodiments of the present invention will be described below with reference to the accompanying drawings.

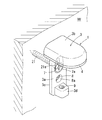

この棚受具は、図1に示すように、壁等の被取付面Wに棚板Sを取り付けて支持するものであり、被取付面Wに固定する固定部材1と、この固定部材1に対して上下にスライドする移動部材2とから構成される。

As shown in FIG. 1, the shelf holder is configured to attach and support a shelf board S to a mounting surface W such as a wall, a

図2及び図3に示すように、固定部材1は、亜鉛合金等の金属製の固定本体3と樹脂製のパッド4とから成り、移動部材2は、亜鉛合金等の金属製の移動本体5と樹脂製のパッド6とから成る。

As shown in FIGS. 2 and 3, the fixed

固定部材1のパッド4は、固定本体3の幹部3aの上部から前方に延びる前方突出片3bの下面に取り付けられ、移動部材2のパッド6は、ブラケット形状の移動本体5の上面に取り付けられている。

The

固定本体3の幹部3aの両側にはガイド部3cが設けられ、このガイド部3cが移動本体5の両側内面に形成された縦溝5aに上下方向にスライド自在に挿入されている。縦溝5aの幅は、ガイド部3cの幅よりも大きく、固定部材1と移動部材2とは前後方向に遊びをもって係合している。

幹部3aの中間部には、上下方向に長く、上窄まりのテーパ状となった取付用貫穴7が前後に貫通するように設けられ、その下方に菱形状の位置決め用貫穴8が前後に貫通するように設けられている。

In the middle part of the

取付用貫穴7の下方部分の径は、後述する取付ねじ21より大きく、上方部分の径は、取付ねじ21に対応した大きさとなっている。取付用貫穴7の周囲には皿モミ部7aが、位置決め用貫穴8の周囲には座ぐり部8aがそれぞれ形成されている。

The diameter of the lower part of the mounting through-

幹部3aの下部前面には、ねじ枠部3dが突設され、このねじ枠部3dに軸線が上下方向に向いたねじ穴9が設けられている。このねじ穴9には、後述する締付ねじ22がねじ込まれる。

A

移動本体5の下部には、丸穴の締付用貫穴10が上下に貫通するように設けられ、締付用貫穴10の径は、ねじ穴9の径よりも大きくなっている。締付用貫穴10の周囲には、移動本体5の底面側に皿モミ部10aが形成されている。

A round hole tightening through

パッド6には、上面に凹所11が設けられ、後部に固定本体3のねじ枠部3dが通過する切欠部が設けられている。パッド4には、凹所11の上方に位置する逃穴4aが設けられている。

The

このような棚受具を使用して被取付面Wに棚板Sを取り付けるには、まず、図4に示すように、取付用貫穴7を介し被取付面Wに取付ねじ21をねじ込んで、固定部材1を被取付面Wに固定する。取付ねじ21としては、頭部21aが皿状の木ねじを使用する。

In order to attach the shelf S to the attachment surface W using such a shelf holder, first, as shown in FIG. 4, the

このとき、取付ねじ21を取付用貫穴7の下方部分に位置させて、固定部材1を初期状態で高い位置に設定しておく。

At this time, the

これにより、固定部材1の取付高さを変更したいとき、取付ねじ21を少し緩めると、その緩み量に応じて、取付ねじ21の頭部21aのテーパ面と皿モミ部7aのテーパ面との当接位置が変化し、固定部材1が取付ねじ21に対し取付用貫穴7の範囲で下端まで落下せず、固定部材1の取付高さを少しずつ下げて容易に調整できる。

Thereby, when it is desired to change the mounting height of the

なお、被取付面Wに十字状の目印を予め記しておき、これを菱形状とした位置決め用貫穴8の二組の対角に合わせるようにしてもよい。

In addition, a cross-shaped mark may be recorded in advance on the mounting surface W, and this may be matched with two sets of diagonals of the positioning through-

また、固定部材1の取付高さを微調整した後、位置決め用貫穴8を介し木ねじを被取付面Wにねじ込んで、固定部材1を確実に固定するようにしてもよい。

Further, after finely adjusting the mounting height of the

そして、次に、図5に示すように、固定部材1に移動部材2を下側から嵌め、締付用貫穴10を介してねじ穴9に締付ねじ22をねじ込むことにより、固定部材1に対して移動部材2を上昇させ、固定部材1のパッド4と移動部材2のパッド6との間に棚板Sを挟み込む。締付ねじ22としては、頭部22aが皿状のボルトを使用する。

Then, as shown in FIG. 5, the moving

このとき、上述のように、締付用貫穴10の径は、ねじ穴9の径よりも大きく、固定部材1と移動部材2とは前後方向に遊びをもって係合していることから、締付ねじ22の頭部22aが締付用貫穴10の皿モミ部10aに進入するまでは、移動部材2を被取付面Wから離れた位置で、被取付面Wの抵抗を受けることなく上昇させることができる。

At this time, as described above, the diameter of the through

また、図6に示すように、固定部材1の被取付面Wに対向する基準面からねじ穴9の中心までの距離L1よりも、移動部材2の被取付面Wに対向する基準面から締付用貫穴10の中心までの距離L2が大きく設定されている。

Further, as shown in FIG. 6, the distance L 1 from the reference surface facing the mounting surface W of the fixing

このため、締付ねじ22をさらにねじ込むと、締付ねじ22の頭部22aのテーパ面と皿モミ部10aのテーパ面とが相互に滑動し、移動部材2が被取付面Wに引き寄せられて密着することとなり、施工後の状態において、移動部材2と被取付面Wとの間に隙間が開くことを防止できる。

For this reason, when the tightening

そのほか、棚板Sが木製である場合には、棚板Sの下面に頭部が突出するように木ねじ等の突起物23をねじ込んでおき、この突起物23を移動部材2の凹所11に係合させると、棚板Sが固定部材1と移動部材2の間から抜け出さないようにすることができる。

In addition, when the shelf board S is made of wood, a

このとき、突起物23の先端部が棚板Sの上面から飛び出しても、突出量がパッド4の厚さ以下であれば、突起物23の先端部の固定本体3への衝突を、逃穴4aにより回避することができる。

At this time, even if the tip of the

また、棚板Sがガラス製である場合には、図7に示すように、凹所11の底部に形成された下穴11aにタッピングねじ等の突起物24をねじ込んで立ち上がらせ、この突起物24を棚板Sに形成した係止穴25に係合させると、棚板Sが固定部材1と移動部材2の間から抜け出さないようにすることができる。

Further, when the shelf board S is made of glass, as shown in FIG. 7, a

1 固定部材

2 移動部材

3 固定本体

3a 幹部

3b 前方突出片

3c ガイド部

3d ねじ枠部

4 パッド

5 移動本体

5a 縦溝

6 パッド

7 取付用貫穴

7a 皿モミ部

8 位置決め用貫穴

8a 座ぐり部

9 ねじ穴

10 締付用貫穴

10a 皿モミ部

11 凹所

21 取付ねじ

21a 頭部

22 締付ねじ

22a 頭部

23,24 突起物

25 係止穴

W 被取付面

S 棚板

DESCRIPTION OF

Claims (3)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008263428A JP5173728B2 (en) | 2008-10-10 | 2008-10-10 | Shelf holder |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008263428A JP5173728B2 (en) | 2008-10-10 | 2008-10-10 | Shelf holder |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010088755A JP2010088755A (en) | 2010-04-22 |

| JP5173728B2 true JP5173728B2 (en) | 2013-04-03 |

Family

ID=42252075

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008263428A Active JP5173728B2 (en) | 2008-10-10 | 2008-10-10 | Shelf holder |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5173728B2 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102151019A (en) * | 2010-12-30 | 2011-08-17 | 汪正新 | Adjustable laminate support |

| ITPN20130018A1 (en) * | 2013-04-03 | 2014-10-04 | Livenza Ferramenta Srl | FIXING DEVICE FOR SHELVES OR SHELVES |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH01114832U (en) * | 1988-01-27 | 1989-08-02 | ||

| JP3016281U (en) * | 1995-03-28 | 1995-09-26 | 株式会社藤村 | Shelf mount |

| JP2002262952A (en) * | 2001-03-13 | 2002-09-17 | Lec Inc | Supporter for shelf board |

| JP4140966B2 (en) * | 2003-11-21 | 2008-08-27 | サンライズ金属工業株式会社 | Wall structure for installation such as shelf holder |

| JP2005177216A (en) * | 2003-12-22 | 2005-07-07 | Matsushita Electric Works Ltd | Shelf board mounting structure |

| JP2006102424A (en) * | 2004-10-01 | 2006-04-20 | Nakazawa Chuzo Hanbai Kk | Holding device for shelf board |

-

2008

- 2008-10-10 JP JP2008263428A patent/JP5173728B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2010088755A (en) | 2010-04-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8585165B2 (en) | Device for adjusting height of drawer | |

| JP6577486B2 (en) | Drawer guide for drawer | |

| KR20100102602A (en) | Table | |

| US20110037365A1 (en) | Undermount drawer slide | |

| JP5173728B2 (en) | Shelf holder | |

| JP2011208406A (en) | Mounting structure of front panel | |

| JP4740936B2 (en) | Telescopic stand | |

| US11399641B1 (en) | Device for hanging objects on a vertical surface and a method of using the same | |

| WO2017047577A1 (en) | Leg structure and article of furniture | |

| JP2009095422A (en) | Fixture of table leg, and table | |

| CN213197949U (en) | Hole puncher | |

| JPH1057170A (en) | Shelf board attaching device for bookshelf | |

| JP6580369B2 (en) | Handrail bar end mounting structure | |

| JP2019174592A (en) | Mounting structure of long component of piano | |

| JP3112402U (en) | Sliding equipment for sliding doors | |

| JP2018115672A (en) | Component holding tool, fastening structure and fixture | |

| JP2006280810A (en) | Display shelf apparatus | |

| KR101000586B1 (en) | A holder for supporter of a fishing rod | |

| JP5085507B2 (en) | Door hinge member | |

| JP3118499U (en) | Shelf support column | |

| KR200327581Y1 (en) | The Books for support of a added plate table. | |

| JP4238363B2 (en) | Shelf receiving device | |

| JP2013032627A (en) | Glass door hinge | |

| JP4878787B2 (en) | Display shelf bracket | |

| US1138708A (en) | Sight for firearms. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110929 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20121130 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20121211 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20121227 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5173728 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20160111 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |