JP4590516B2 - Tank drainage - Google Patents

Tank drainage Download PDFInfo

- Publication number

- JP4590516B2 JP4590516B2 JP2004307485A JP2004307485A JP4590516B2 JP 4590516 B2 JP4590516 B2 JP 4590516B2 JP 2004307485 A JP2004307485 A JP 2004307485A JP 2004307485 A JP2004307485 A JP 2004307485A JP 4590516 B2 JP4590516 B2 JP 4590516B2

- Authority

- JP

- Japan

- Prior art keywords

- drainage device

- drainage

- tank

- tank body

- fitted

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Sink And Installation For Waste Water (AREA)

Description

本発明は、洗面台や流し台などの、キャビネット部を備えた排水機器に用いられる槽体の排水器、特にトラップ機能を備えた槽体の排水器に関するものである。 The present invention relates to a drainage device for a tank body used for drainage equipment having a cabinet portion such as a wash basin or a sink, and more particularly to a drainage device for a tank body having a trap function.

従来より、洗面台や流し台など、槽体部分を備え、使用によって排水の生じる生活機器(以降、これらの機器を「排水機器」と呼ぶ)には、槽体内に生じた排水を床下の配管から下水側に排出するため、槽体の底面に排水器を接続する。これらの排水器には、単純にその内部に排水が通過するだけの排水器から、その内部に排水の溜まり部分を設け、この排水の溜まり部分によって下水側から臭気や害虫類が逆流しないように構成した排水トラップと呼ばれる排水器など、様々な種類があるが、いずれの構造を採用する場合でも、通常、排水器を槽体に接続する必要があった。 Conventionally, living equipment that has a tank part such as a wash basin and a sink and generates drainage when used (hereinafter referred to as “drainage equipment”), drainage generated in the tank from the piping under the floor. A drainer is connected to the bottom of the tank body to discharge to the sewage side. These drainers are provided with a drainage reservoir in the drainage system that simply allows the drainage to pass through the drainage so that odors and pests do not flow back from the sewage side. There are various types such as a drainage device called a drainage trap constructed, but it is usually necessary to connect the drainage device to the tank body in any of the structures.

図18に示したのは従来より良く知られた排水器の一例であって、その詳細を説明すると、有底円筒形状であって、上方に設けた開口からなる排水口、排水器本体の上端周縁に円周に沿って連続して設けた突出部分であるフランジ部、該フランジ部分の下方に円周に沿って設けた雄ねじ部、側面下端に設けた排出口、からなる排水器本体と、リング状であってその内面に雄ねじ部と螺合する雌ねじ部を備え、上面に取着孔の周縁を介してフランジ部材下面を押圧する当接面を備えたナット部材と、から構成される。 FIG. 18 shows an example of a well-known drainage device, and the details thereof will be described. The drainage port having a bottomed cylindrical shape and having an opening provided above, and the upper end of the drainage device main body are shown in detail. A drainage body comprising a flange portion which is a protruding portion provided continuously along the circumference at the periphery, a male screw portion provided along the circumference below the flange portion, and a discharge port provided at the lower end of the side surface; The nut member is provided with a female screw portion that is ring-shaped and screwed with the male screw portion on the inner surface thereof, and has an abutting surface that presses the lower surface of the flange member via the peripheral edge of the attachment hole.

上記の排水器を槽体に取着する場合、まずシンクなど槽体の底面に設けた取着孔に、排水器本体を、フランジ部下面が取着孔の周縁にパッキングなどを介して当接するように配置する。

次にナット部材の上面を取着孔の周縁に当接させてから、ナット部材を回転させて、排水器本体の雄ねじ部と、ナット部材の雌ねじ部を螺合させることで、フランジ部下面とナット部材上面とで、パッキングを介し取着孔の周縁を強く挟持して固定するため、排水器が槽体の取着孔に水密的に取着される。この後、排出口に下水側に連通する、S字トラップ管や蛇腹管などからなる排水配管を接続して、排水機器への配管が完了する。

When attaching the above drainage device to the tank body, first, the drainage device main body is brought into contact with the attachment hole provided on the bottom surface of the tank body such as a sink, and the lower surface of the flange portion is brought into contact with the peripheral edge of the attachment hole through packing or the like. Arrange as follows.

Next, the upper surface of the nut member is brought into contact with the peripheral edge of the mounting hole, and then the nut member is rotated, and the male screw portion of the drainage device main body and the female screw portion of the nut member are screwed together, Since the periphery of the attachment hole is strongly sandwiched and fixed with the upper surface of the nut member via the packing, the drainage is attached to the attachment hole of the tank body in a watertight manner. Thereafter, drainage pipes such as S-shaped trap pipes and bellows pipes communicating with the sewage side are connected to the discharge port, and piping to the drainage equipment is completed.

上記段落0004に記載したような、排水機器の槽体と排水器との接続は、ほとんどの場合、排水機器を製造する工場において接続作業が行われるが、排水器本体は大きくて重く、またこれを取着孔にはめ込むと視線が遮られて槽体の裏面の様子が槽体の表側からは視認できなくなる。このため、排水機本体とロックナット部材との螺合の作業を行う場合に、

1.接続時、雄ねじ部と雌ねじ部を噛み合うように調整する際、大きくて重い排水器本体の位置あわせが困難である

2.接続時、雄ねじ部と雌ねじ部を噛み合うように調整する際、槽体の表面側からはロックナット部材の状態が視認できないため、ねじが正しく噛み合っているかどうか直接確認できず、施工不良を生じる場合がある。裏面側から作業する場合はロックナット部材の状態が視認できるが、逆にフランジ部が槽体の定位置(槽体の取着孔周縁に設けられた、フランジ部を収納するための段押し部)に配置されているかどうか、確認できず正しいないため、ねじが正しく噛み合っているかどうか直接確認できず、施工不良を生じる場合がある

等の問題が発生する。

As described in paragraph 0004 above, the drainage device tank and drainage are mostly connected at the factory where the drainage device is manufactured, but the drainage body is large and heavy. If it fits in the attachment hole, the line of sight is blocked, and the state of the back surface of the tank body cannot be seen from the front side of the tank body. For this reason, when performing the screwing operation of the drainage machine body and the lock nut member,

1. 1. When connecting, it is difficult to align the large and heavy drainage body when adjusting so that the male screw part and the female screw part are engaged with each other. When adjusting so that the male screw part and female screw part are meshed at the time of connection, the state of the lock nut member is not visible from the surface side of the tank body. There is. When working from the back side, the state of the lock nut member can be visually recognized, but conversely, the flange portion is a fixed position of the tank body (the stepped portion for housing the flange section provided at the periphery of the mounting hole of the tank body) ) Is not correct because it cannot be confirmed, and it is not possible to directly confirm whether the screw is correctly meshed.

また、稀に施工現場に排水機器が設置されてから、排水器が排水機器に施工される場合がある。これは、たとえば、排水器の排出口が排水器の下面にあり、排水器の排出口と床下配管とを接続する排水管を、硬質材の直管を用いる場合に、一旦排水器を排水機器から取り外さなければ排水管を配管できない等の理由による。この排水機器の取着孔と排水器との接続において、上記雄ねじ部と雌ねじ部の締め付け強さ(以下、「締め付けトルク」と呼ぶ)が弱いと漏水を生じてしまうなどの問題がある。工場などで接続を行う場合は、機材が充実しているため、高度な目盛り付きの治具を使って締め付けトルクを数値的に管理するトルク管理と呼ばれる作業を行っている。ところが、冶具を常備している工場と違い、施工現場ではこのような治具を用意することは手間がかかることであり、レンチ様の簡単な目盛りの無い冶具を用いて適当に締め付け、短時間槽体に水を溜めて漏水が無ければ問題なしとする場合が多く、このトルク管理が徹底されないため、品質の管理が怠られる傾向が強かった。

本発明は上記問題点を解決するために発明されたものであって、槽体の排水機において、排水器を容易に槽体に接続することができ、また施工現場で排水器を槽体に取着する場合でも確実にトルク管理を徹底できる槽体の排水器を提供するものである。

In rare cases, the drainage device is installed on the drainage device after the drainage device is installed at the construction site. For example, when the drain of the drain is on the lower surface of the drain and the drain pipe connecting the drain of the drain and the underfloor piping is a straight pipe made of hard material, the drain is temporarily drained. This is because the drain pipe cannot be piped unless it is removed from. In connection between the attachment hole of the drainage device and the drainage device, there is a problem that water leakage occurs if the tightening strength (hereinafter referred to as “tightening torque”) of the male screw portion and the female screw portion is weak. When connecting in factories, etc., because the equipment is extensive, a work called torque management is performed to numerically manage the tightening torque using a highly calibrated jig. However, unlike a factory that always has jigs, it is time-consuming to prepare such jigs at the construction site. In many cases, there was no problem if water was collected in the tank body and there was no water leakage. Since this torque management was not thorough, there was a strong tendency for quality management to be neglected.

The present invention was invented to solve the above problems, and in a drainage device for a tank body, the drainage device can be easily connected to the tank body, and the drainage device can be connected to the tank body at the construction site. It is intended to provide a tank drainer that can ensure thorough torque management even when it is attached.

本発明の請求項1に記載の槽体の排水器は、槽体の底面に備えられる排水器であって、該排水器の取着装置を、槽体の底面に設けられた取着孔に取り付けられる被嵌合部材(2)と、排水器本体(1)に設けた、該被嵌合部材(2)とワンタッチで嵌合する嵌合部と、から構成し、更に、排水器本体(1)の外周と、被嵌合部材(2)の内周とにそれぞれ凹溝を周設し、該排水器本体(1)と該被嵌合部材(2)の間隙に、係合用突子(5)とパッキンを周設して構成したことを特徴とする槽体の排水器である。

尚、ここで言う「ワンタッチ」とは、位置決めなどを厳密に行うことなく、部材、ボタンなどを特定の方向に押す、差し込むなどの単純な作業を1乃至数工程行うだけで、容易に作業を行うことができる方法を指し示す表現である。

The drainage device for a tank body according to

The term “one-touch” as used herein means that a simple operation such as pushing or inserting a member, button or the like in a specific direction is performed by one or several steps without strict positioning. An expression that points out how it can be done.

本発明の請求項2に記載の槽体の排水器は、上記段落0008に記載の槽体の排水器において、被嵌合部材を、上縁周縁にフランジ部(7)を突設させ、外周面に雄ねじ部(8)を形成させたフランジ部材(6)と、円環形状にして内周面に、上記雄ねじ部(8)と螺合する雌ねじ部(10)と凹溝とを周設し、上面に取着孔の周縁を介してフランジ部材(8)下面を押圧する当接面(11)を備えたナット部材(9)と、から構成したことを特徴とする槽体の排水器である。

The tank drainage device according to

本発明の請求項3に記載の槽体の排水器は、上記段落0008又は段落0009に記載の槽体の排水器において、排水器に、下水などからの異臭や害虫などの逆流を防止するトラップ部(12)を備えたことを特徴とする槽体の排水器である。

The drainage device for a tank according to

本発明の請求項4に記載の槽体の排水器は、上記段落0008乃至段落0010のいずれか1つに記載の槽体の排水器において、槽体と被嵌合部材(2)の取り付けを工場内で行い、その後施工現場にて、排水器本体(1)の嵌合部と被嵌合部材との嵌合を行うことを特徴とする槽体の排水器である。

The tank drainage device according to

本発明の排水機器の配管構造によれば、以下の効果を奏する。

請求項1に記載の槽体の排水器によれば、槽体と排水器の取着を、槽体に取り付けられた被嵌合部材と、それにワンタッチで接続される排水器の嵌合部とで行うようにしたため、施工作業を容易化することができると共に、トルク管理の作業と、排水器の接続作業を別の行程で行うようにすることができる。

これは、請求項4に記載の槽体の排水器のように、槽体と被嵌合部材の取り付けを工場等の設備が整った作業場で行い、その後接続作業を(工場等に比べ)比較的設備が充実していない施工現場で行う場合に特に効果的に機能する。

請求項2に記載の槽体の排水器によれば、排水器と被嵌合部材とが嵌合した後でも、被嵌合部材を分解することで、排水器を槽体より脱着することができる。

請求項3に記載の槽体の排水器によれば、排水器にトラップ機能を付加することができる。

According to the piping structure of the drainage device of the present invention, the following effects are obtained.

According to the drainage device of the tank body according to

This is the same as the drainage device of the tank body according to

According to the drainage device of the tank body according to

According to the tank drainage device of the third aspect , a trap function can be added to the drainage device.

槽体の底面に備えられる排水器であって、該排水器の構造を、槽体の底面に設けられた開口に取り付けられる被嵌合部材(2)と、排水器に設けた、該被嵌合部材(2)とワンタッチで嵌合する嵌合部と、から構成する。この場合において、槽体と被嵌合部材(2)の取り付けを工場内で行い、その後施工現場にて、排水器の嵌合部と被嵌合部材(2)との嵌合を行うようにすれば、トルク管理が確実に行うことができるようになり好適である。

また、上記記載の槽体の排水器における、嵌合部と被嵌合部材(2)とのワンタッチの接続構造の一例として、排水器の外周と、被嵌合部材(2)の内周とにそれぞれ嵌合用凹溝(3)と被嵌合凹溝(4)を周設し、該排水器と該被嵌合部材(2)の間隙に、係合用突子(5)とパッキンを周設する構成が挙げられる。更に被嵌合部材(2)の構成の具体例として、上縁周縁にフランジ部(7)を突設させ、外周面に雄ねじ部(8)を形成させたフランジ部材(6)と、円環形状にして内周面に、上記雄ねじ部(8)と螺合する雌ねじ部(10)と、被嵌合凹溝(4)とを周設したナット部材(9)と、から成る構成が挙げられる。

また、上記記載の槽体の排水器において、排水器に、トラップ部(12)を備えると、下水などからの異臭や害虫などの逆流を防止することができ好適である。

A drainage device provided on a bottom surface of a tank body, wherein the drainage structure is fitted to a fitting member (2) attached to an opening provided on the bottom surface of the tank body, and the fitment provided on the drainage device. It comprises a mating member (2) and a fitting part that fits with one touch. In this case, the tank body and the fitted member (2) are attached in the factory, and then the fitting portion of the drainage device and the fitted member (2) are fitted at the construction site. This is preferable because torque management can be performed reliably.

Moreover, as an example of the one-touch connection structure with a fitting part and a to-be-fitted member (2) in the drainage device of the said tank body, the outer periphery of a drainage device, the inner periphery of a to-be-fitted member (2), Are respectively provided with a fitting groove (3) and a fitting groove (4), and an engagement protrusion (5) and a packing are provided in the gap between the drainage device and the fitting member (2). The structure to set is mentioned. Further, as a specific example of the configuration of the fitted member (2), a flange member (6) in which a flange portion (7) is provided on the periphery of the upper edge and a male screw portion (8) is formed on the outer peripheral surface; A configuration comprising a female screw part (10) screwed into the male screw part (8) and a nut member (9) provided with a fitting recessed groove (4) on the inner peripheral surface in a shape is given. It is done.

Moreover, in the drainage device of the tank body described above, it is preferable that the drainage device is provided with a trap portion (12), which can prevent backflow of odors and pests from sewage.

以下に、本発明の実施例について図面を参照しつつ説明する。

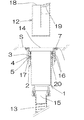

本発明の第一実施例は、図1乃至図5に示した、排水器本体(1)及び被嵌合部材(2)から構成されてなる。

排水器本体(1)は、有底略円筒形状にして上方に排水口(14)としての開口を、また底面に排出口(15)を備えてなり、また、上縁外周側にはフランジ部(7)を備え、更に、排水器本体(1)のフランジ部(7)の下側であって、排水器本体(1)の外周面に、嵌合部として、周縁に沿って連続した嵌合用凹溝(3)を設けてなる。

更に排水器本体(1)の排水口(14)には、トラップ機能を有するトラップ部(12)が、所謂嵌め殺しと呼ばれる方法によって排水器本体(1)内部に水密的且つ抜脱不能に嵌合するように構成されてなる。

トラップ部(12)は、図6及び図7に示したように、円筒形状にして軸方向視Y字型に略均等に3分割され、流入口(18)から第一の流路の下端側と連通し、第二の流路に入って排水が上昇し、その上端側と連通し、第三の流路に入って下水方向へ排水される。また該トラップ部(12)は排水口(14)側に第二の流路と第三の流路の天面を形成するパッキンが取り付けられている。

被嵌合部材(2)は、図2乃至図5に示したように、以下に記載したフランジ部材(6)と、ナット部材(9)と、から構成される。

フランジ部材(6)は円筒形状であって、上方に排水器本体(1)の上端周縁に円周に沿って連続して設けた突出部分であるフランジ部(7)と、該フランジ部(7)の下方に円周に沿って設けた雄ねじ部(8)と、フランジ部材(6)の内周面であって、排水器本体(1)の嵌合用凹溝(3)に対応する位置に設けた、周面に沿って連続して設けた被嵌合凹溝(4)と、平面視略C字形状、断面視逆略V字形状であって、被嵌合凹溝(4)に収納され、内周側ほど下向方向に傾斜する係合用突子(5)と、から成る。

ナット部材(9)は、円筒形状であって、雄ねじ部(8)と螺合する雌ねじ部(10)と、雌ねじ部(10)の上方に設けた当接面(11)と、から成る。

Embodiments of the present invention will be described below with reference to the drawings.

The first embodiment of the present invention comprises the drainage device main body (1) and the fitted member (2) shown in FIGS.

The drainage device body (1) has a substantially cylindrical shape with a bottom and is provided with an opening as a drainage port (14) on the upper side and a discharge port (15) on the bottom surface, and a flange portion on the outer peripheral side of the upper edge. (7), and further on the lower side of the flange portion (7) of the drainage device main body (1), and as a fitting portion, a continuous fit along the periphery on the outer peripheral surface of the drainage device body (1) A joint groove (3) is provided.

Further, a trap part (12) having a trap function is fitted into the drainage body (1) in a watertight and non-removable manner in a drainage body (1) by a so-called fitting killing method. Configured to match.

As shown in FIGS. 6 and 7, the trap portion (12) has a cylindrical shape and is substantially equally divided into three Y-shapes when viewed in the axial direction. The trap portion (12) extends from the inlet (18) to the lower end side of the first flow path. , Enters the second flow path, and the drainage rises, communicates with the upper end side thereof, enters the third flow path, and drains in the sewage direction. The trap portion (12) is provided with a packing for forming the top surfaces of the second flow path and the third flow path on the drain outlet (14) side.

As shown in FIGS. 2 to 5, the member to be fitted (2) includes a flange member (6) described below and a nut member (9).

The flange member (6) has a cylindrical shape, and a flange portion (7), which is a protruding portion continuously provided along the circumference at the upper end periphery of the drainage body (1), and the flange portion (7 ) At the position corresponding to the fitting groove (3) of the drainage body (1) on the inner peripheral surface of the male screw portion (8) provided along the circumference and the flange member (6). The provided recessed groove (4) provided continuously along the peripheral surface, the substantially concave C-shape in plan view, and the inverted substantially V-shaped in sectional view, wherein the recessed groove (4) is The engaging protrusion (5) is housed and is inclined downward in the inner peripheral side.

The nut member (9) has a cylindrical shape, and includes a female screw portion (10) screwed with the male screw portion (8), and a contact surface (11) provided above the female screw portion (10).

上記のように構成された本発明の第一実施例の排水器は、以下のように構成された、排水機器である流し台に取着される。流し台は、底面に排水口(14)を備えたシンク(S)と、該シンク(S)の下方に配置された引き出し部を有するキャビネット部、および該キャビネット部の下方に設けられた、袴部と呼ばれる床面上に設置された高さ10センチ前後の立ち上がりの部分からなる。また該袴部とキャビネット部の間に、配管用の開口部を備えた、キャビネット部の底板となる化粧板が設けられている。 The drainage device of the first embodiment of the present invention configured as described above is attached to a sink that is configured as follows and is a drainage device. The sink includes a sink (S) having a drain outlet (14) on the bottom surface, a cabinet portion having a drawer portion disposed below the sink (S), and a flange portion provided below the cabinet portion. It consists of a rising part about 10 cm high installed on the floor. In addition, a decorative plate serving as a bottom plate of the cabinet portion, which is provided with an opening for piping, is provided between the flange portion and the cabinet portion.

上記の各部材より構成される本発明の第一実施例の排水器は、以下のようにして排水機器である流し台のシンク(S)等の槽体等に設けられた取着孔に取着される。

まず流し台の製作工場において、槽体の底面に設けた取着孔に、フランジ部材(6)を、フランジ部(7)下面が取着孔の周縁にパッキングを介して当接するように配置する。

次にナット部材(9)の雄ねじ部(8)に、フランジ部材(6)の雌ねじ部(10)を螺合させ、図3に示したようにフランジ部(7)と当接面(11)との間で取着孔の周縁を挟着させて取着孔に保持させる。このときの作業は工場内で行うため、作業にはトルク管理を行うことができる治具を容易に使用することができ、被嵌合部材(2)の取着孔への取り付けに際し、トルク管理を徹底することが容易になる。

The drainage device according to the first embodiment of the present invention composed of the above-described members is attached to a mounting hole provided in a tank body such as a sink (S) of a sink as a drainage device as follows. Is done.

First, in the manufacturing factory of the sink, the flange member (6) is disposed in the attachment hole provided on the bottom surface of the tank body so that the lower surface of the flange portion (7) abuts the periphery of the attachment hole via the packing.

Next, the female screw portion (10) of the flange member (6) is screwed into the male screw portion (8) of the nut member (9), and the flange portion (7) and the contact surface (11) as shown in FIG. The peripheral edge of the attachment hole is sandwiched between and attached to the attachment hole. Since the work at this time is performed in the factory, a jig capable of performing torque management can be easily used for the work, and torque management is performed when the fitting member (2) is attached to the attachment hole. It becomes easy to thoroughly.

次に、上記のようにして被嵌合部材(2)を槽体の取着孔に取着した流し台を工場より出荷し、施工現場に搬入する。

流し台を施工現場に設置した後、硬質にして適切な長さに切断/調節された、直線状の排水管(13)を床下配管より直立させ、さらに排水器本体(1)を、排出口(15)が排水管(13)の上端に接続するようにしつつ、被嵌合部材(2)のフランジ部材(6)の開口に差込むと、平面視C字形状の係合用突子(5)がまず縮径し、さらに降下させると排水器本体(1)の嵌合用凹溝(3)の位置で拡径して係合用突子(5)を嵌合させ、図4に示した状態となって、排水機器の槽体への排水器の取着が完了する。

更に排水器本体(1)の排水口(14)に、トラップ部(12)を、水密的且つ抜脱不能に嵌合固定することで、排水器にトラップ機能を付加して、図5に示したように槽体の排水器の取着が完了する。

なお、この嵌合の際、上方向には嵌合用凹溝(3)及び被嵌合凹溝(4)内での係合用突子(5)の拡径によって、また下方向には硬質の排水管(13)が支えとなって、排水器が槽体から抜脱不能となる。

Next, the sink with the fitted member (2) attached to the attachment hole of the tank body as described above is shipped from the factory and is carried into the construction site.

After installing the sink on the construction site, straighten the drainage pipe (13), which is hard and cut / adjusted to an appropriate length, upright from the underfloor pipe, and the drainage body (1) is connected to the outlet ( 15) is connected to the upper end of the drain pipe (13), and is inserted into the opening of the flange member (6) of the fitted member (2). When the diameter is first reduced and further lowered, the diameter is increased at the position of the fitting groove (3) of the drainage body (1) to engage the engaging protrusion (5), and the state shown in FIG. Thus, the attachment of the drainage device to the tank body of the drainage device is completed.

Furthermore, a trap function is added to the drainage device by fitting and fixing the trap portion (12) to the drainage port (14) of the drainage device body (1) in a watertight and non-removable manner, as shown in FIG. As shown, the installation of the tank drain is completed.

At the time of this fitting, the upward direction is due to the expansion of the engaging protrusion (5) in the fitting groove (3) and the fitting groove (4), and the downward direction is hard. The drain pipe (13) serves as a support, and the drain cannot be removed from the tank body.

上記のように施工された槽体の排水器において槽体内に排水が生じると、排水は排水器本体(1)の排水口(14)からトラップ部(12)の流入口(18)から第一の流路を降下し、下端側で連通している第二の流路に流入して上昇し、その上端側(14)で連通している第三の流路に流入して再度降下したのち排水管(13)内に流入し、最終的には床下配管から下水方向へ排水される。 In the drainage device of the tank body constructed as described above, when drainage is generated in the tank body, the drainage is first from the drainage port (14) of the drainage body (1) to the inlet (18) of the trap part (12). The flow path is lowered, flows into the second flow path communicating at the lower end side, rises, flows into the third flow path communicated at the upper end side (14), and descends again. It flows into the drain pipe (13) and finally drains from the underfloor pipe in the sewer direction.

また、上記実施例の排水配管において、排水管(13)などに管詰まりが発生した場合、キャップ体(19)をトラップ本体部から着脱し、清掃口を開口して、清掃口から第一の流路を介しカンツール法のコイル線や、高圧洗浄法の高圧洗浄管などの清掃部材を挿通させることで、管詰まりの原因物質に到達することができ、容易に管詰まりを解消することができる。 Further, in the drain pipe of the above embodiment, when the drain pipe (13) or the like is clogged, the cap body (19) is detached from the trap body, the cleaning port is opened, and the first through the cleaning port. By inserting a cleaning member such as a coil wire of the Kantool method or a high-pressure washing tube of the high-pressure washing method through the flow path, it is possible to reach the substance causing the tube clogging, and the tube clogging can be easily eliminated. it can.

次に、本発明の第二実施例について図面を参照しつつ説明する。

本発明の第二実施例は、図8乃至図12に示した、排水器本体(1)及び被嵌合部材(2)から構成されてなる。

排水器本体(1)は、有底略円筒形状にして上方に排水口(14)としての開口を、また底面に排出口(15)を備えてなり、また、上縁外周側にはフランジ部(7)を備え、更に、排水器本体(1)のフランジ部(7)の下側であって、排水器本体(1)の外周面に、嵌合部として、周縁に沿って連続した嵌合用凹溝(3)を設けてなる。

更に排水器本体(1)の排水口(14)には、トラップ機能を有するトラップ部(12)が、所謂嵌め殺しと呼ばれる方法によって排水器本体(1)内部と水密的且つ抜脱不能に嵌合するように構成されてなる。また、排水器本体(1)の外周形状は、上方ほど拡径する略円錐形状に形成されてなる。

トラップ部(12)は、上記段落0015に記載された第一実施例の同部材と同様に構成されてなる。

被嵌合部材(2)は、図9に示したように、以下に記載したフランジ部材(6)と、ナット部材(9)と、から構成される。

フランジ部材(6)は円筒形状であって、上方に排水器本体(1)の上端周縁に円周に沿って連続して設けた突出部分であるフランジ部(7)と、該フランジ部(7)の下方に一部に切欠部を設けつつ円周に沿って設けた下向き矢印形状からなる嵌合爪(17)と、嵌合爪(17)の下端に、内周方向に突出して設けた抜け止め防止部(20)と、フランジ部材(6)の内周面であって、排水器本体(1)の嵌合用凹溝(3)に対応する位置に設けた、周面に沿って連続して設けた被嵌合凹溝(4)と、平面視略C字形状、断面視逆

略V字形状であって、被嵌合凹溝(4)に収納され、内周側ほど下向方向に傾斜する係合用突子(5)と、から成る。

ナット部材(9)は、円筒形状であって、上方に当接面(11)を設けて成る。

Next, a second embodiment of the present invention will be described with reference to the drawings.

The second embodiment of the present invention comprises the drainage device main body (1) and the fitted member (2) shown in FIGS.

The drainage device body (1) has a substantially cylindrical shape with a bottom and is provided with an opening as a drainage port (14) on the upper side and a discharge port (15) on the bottom surface, and a flange portion on the outer peripheral side of the upper edge. (7), and further on the lower side of the flange portion (7) of the drainage device main body (1), and as a fitting portion, a continuous fit along the periphery on the outer peripheral surface of the drainage device body (1) A joint groove (3) is provided.

Furthermore, a trap part (12) having a trap function is fitted into the drainage outlet (14) of the drainage body (1) in a watertight and non-removable manner with the inside of the drainage body (1) by a so-called fitting killing method. Configured to match. Moreover, the outer peripheral shape of the drainage device main body (1) is formed in a substantially conical shape whose diameter increases toward the top.

The trap portion (12) is configured in the same manner as the member of the first embodiment described in paragraph 0015 above.

As shown in FIG. 9, the fitted member (2) includes a flange member (6) described below and a nut member (9).

The flange member (6) has a cylindrical shape, and a flange portion (7), which is a protruding portion continuously provided along the circumference at the upper end periphery of the drainage body (1), and the flange portion (7 ) And a fitting claw (17) having a downward arrow shape provided along the circumference while providing a cutout part in a part below, and provided at the lower end of the fitting claw (17) so as to protrude in the inner circumferential direction. Continuously along the circumferential surface provided at the position corresponding to the fitting groove (3) of the drainage body (1) on the inner circumferential surface of the retaining member (20) and the flange member (6). The groove (4) to be fitted is substantially C-shaped in plan view, and is substantially V-shaped in reverse in section, and is housed in the groove (4) to be fitted, and downwards toward the inner peripheral side. And an engaging protrusion (5) inclined in the direction.

The nut member (9) has a cylindrical shape and is provided with a contact surface (11) on the upper side.

上記のように構成された本発明の第二実施例の排水器は、上記段落0016に記載された第一実施例の流し台と同様の流し台に取着される。 The drainage device of the second embodiment of the present invention configured as described above is attached to a sink similar to the sink of the first embodiment described in paragraph 0016 above.

上記の各部材より構成される本発明の第二実施例の排水器は、以下のようにして排水機器である流し台のシンク(S)等の槽体等に設けられた取着孔に取着される。

まず流し台の製作工場において、槽体の底面に設けた取着孔に、フランジ部材(6)を、フランジ部(7)下面が取着孔の周縁にパッキングを介して当接するように配置する。

次にナット部材(9)を、フランジ部材(6)の嵌合爪(17)に挿通させると、嵌合爪(17)の切欠部で嵌合爪(17)が宿径して挿通が可能となり、ナット部材(9)の下端を乗り越えた箇所で再び拡径して、図10に示したようにナット部材(9)とフランジ部材(6)が仮止め状態となって取着孔に取着される。

The drainage device of the second embodiment of the present invention composed of the above members is attached to a mounting hole provided in a tank body such as a sink (S) of a sink as a drainage device as follows. Is done.

First, in the manufacturing factory of the sink, the flange member (6) is disposed in the attachment hole provided on the bottom surface of the tank body so that the lower surface of the flange portion (7) abuts the periphery of the attachment hole via the packing.

Next, when the nut member (9) is inserted into the fitting claw (17) of the flange member (6), the fitting claw (17) has a diameter at the notch portion of the fitting claw (17) and can be inserted. As shown in FIG. 10, the nut member (9) and the flange member (6) are temporarily fixed as shown in FIG. Worn.

次に、上記のようにして被嵌合部材(2)を槽体の取着孔に取着した流し台を工場より出荷し、施工現場に搬入する。

さらに排水器本体(1)を、被嵌合部材(2)のフランジ部材(6)の開口に差込むと、平面視C字形状の係合用突子(5)がまず縮径し、さらに降下させると排水器本体(1)の嵌合用凹溝(3)の位置で拡径して係合用突子(5)を嵌合させ、且つ排水器本体(1)の外周面がフランジ部材(6)の抜け止め防止部(20)に当接して降下を抑制される。更に図11に示したように、排水器の排出口(15)と、床下配管との間を、可撓性を有したホース管などを利用して接続する。

更に排水器本体(1)の排水口(14)に、トラップ部(12)を、Oリング(16)及び係合爪(17)によって係合固定することで、排水器にトラップ機能を付加して、図12に示したように槽体の排水器の取着が完了する。

なお、この嵌合の際、上方向には嵌合用凹溝(3)及び被嵌合凹溝(4)内での係合用突子(5)の拡径によって、また下方向には排水器本体(1)の外周面がフランジ部材(6)の抜け止め防止部(20)に当接して、排水器が槽体から抜脱不能となる。

Next, the sink with the fitted member (2) attached to the attachment hole of the tank body as described above is shipped from the factory and is carried into the construction site.

Further, when the drainage device main body (1) is inserted into the opening of the flange member (6) of the fitted member (2), the engagement protrusion (5) having a C-shape in plan view is first reduced in diameter and further lowered. Then, the diameter of the drainage body (1) is expanded at the position of the fitting groove (3) to engage the engaging protrusion (5), and the drainage body (1) has an outer peripheral surface with a flange member (6). ) Is prevented from descending by abutting against the retaining portion (20). Furthermore, as shown in FIG. 11, the outlet (15) of the drainer and the underfloor pipe are connected using a flexible hose pipe or the like.

Further, the trap part (12) is engaged and fixed to the drain port (14) of the drainage body (1) by the O-ring (16) and the engagement claw (17), thereby adding a trap function to the drainage device. Thus, as shown in FIG. 12, the attachment of the drainage device for the tank body is completed.

At the time of this fitting, the upper direction is due to the diameter of the engaging protrusion (5) in the fitting concave groove (3) and the fitting concave groove (4), and the drainage is downward. The outer peripheral surface of the main body (1) comes into contact with the retaining portion (20) of the flange member (6) so that the drainage device cannot be removed from the tank body.

上記のように施工された槽体の排水器の使用法は、上記段落0019、0020に記載された第一実施例の排水器と同様である。 The method of using the tank drainage constructed as described above is the same as the drainage of the first embodiment described in paragraphs 0019 and 0020 above.

本発明の実施例は上記のようであるが、本発明は上記実施例に限定されること無く、必要に応じて要旨を変更しない範囲で自在に変更することができる。例えば、上記実施例ではトラップ部(12)を施工する排水機器を流し台としているが、洗面台など排水機器であれば、どのような排水機器にも配管構造を適用することができる。 The embodiments of the present invention are as described above. However, the present invention is not limited to the above-described embodiments, and can be freely changed without changing the gist as necessary. For example, although the drainage device for constructing the trap portion (12) is a sink in the above embodiment, the piping structure can be applied to any drainage device as long as it is a drainage device such as a wash basin.

また、上記実施例では、排水器本体(1)とトラップ部(12)との接続は、上方から下方にはめ込む構造を採用してなるが本発明は上記実施例に限定されることなく、図13乃至図15に示したように、排水器本体(1)とトラップ部(12)との接続を下方から上方にはめ込む構造を採用してももちろん構わない。 Moreover, in the said Example, although the connection of a drainage body (1) and a trap part (12) employ | adopts the structure inserted below from upper direction, this invention is not limited to the said Example, FIG. Of course, as shown in FIGS. 13 to 15, a structure in which the connection between the drainage device main body (1) and the trap portion (12) is inserted from below to above may be adopted.

また、上記実施例ではトラップ部(12)を円筒の軸方向視Y字型に略均等に3分割した構造としているが、図16に示したように、円筒の断面が略S字形状となっている、トラップの構造を持つものでもよい。また、トラップ部(12)の外形形状も排水管(13)の形状に応じて、排水管(13)の内面に水密に嵌合し、且つ着脱可能であれば円筒でなくてもよい。また、図17に示したように、ワン型トラップと呼ばれる、トラップ内の、下水に通じる排水口(14)にトラップ内の排水を仕切るようにワン部を逆向きにかぶせることで、排水が一度封水部に入り、逆オワン型形状のトラップ部を排水が上昇し下水されるトラップ構造としてもよい。 Moreover, in the said Example, although the trap part (12) is made into the structure divided into three substantially equally in the cylindrical axial view Y shape, as shown in FIG. 16, the cross section of a cylinder becomes a substantially S shape. It may have a trap structure. Further, the external shape of the trap part (12) may not be a cylinder as long as it fits watertightly on the inner surface of the drain pipe (13) and is detachable according to the shape of the drain pipe (13). In addition, as shown in FIG. 17, the drainage is once covered by placing the one part in a reverse direction so as to partition the drainage in the trap to the drainage port (14) in the trap that leads to the sewage, which is called a one-type trap. It is good also as a trap structure in which drainage goes up and drains the trap part of a reverse Owan type shape entering a sealed water part.

また、上記実施例では、排水配管を槽体の排水口(14)から直下方向に向けて配置し、床下配管に接続させているが、これに対して、排水器本体(1)又は排水管(13)を屈曲させ、排水管(13)を下方奥向きに傾斜させた後、キャビネットの背面壁部に沿って真下方向に屈曲させて床下配管に接続するように構成してもかまわない。 Moreover, in the said Example, although drainage piping is arrange | positioned toward the direct downward direction from the drain outlet (14) of a tank body, and is connected to underfloor piping, on the other hand, a drainage device main body (1) or drainage pipe (13) may be bent, and the drain pipe (13) may be inclined downward and then bent downward along the back wall portion of the cabinet and connected to the underfloor pipe.

1 排水器本体 2 被嵌合部材

3 嵌合用凹溝 4 被嵌合凹溝

5 係合用突子 6 フランジ部材

7 フランジ部 8 雄ねじ部

9 ナット部材 10 雌ねじ部

11 当接面 12 トラップ部

13 排水管 14 排水口

15 排出口 16 Oリング

17 嵌合爪 18 流入口

19 キャップ体 20 抜け止め防止リブ

S シンク

DESCRIPTION OF

Claims (4)

槽体の底面に設けられた取着孔に取り付けられる被嵌合部材(2)と、

排水器本体(1)に設けた、該被嵌合部材(2)とワンタッチで嵌合する嵌合部と、から構成し、

更に、排水器本体(1)の外周と、被嵌合部材(2)の内周とにそれぞれ凹溝を周設し、

該排水器本体(1)と該被嵌合部材(2)の間隙に、係合用突子(5)とパッキンを周設して構成したことを特徴とする槽体の排水器。 A drainage device provided on the bottom surface of the tank body, the attachment device for the drainage device,

A fitted member (2) attached to an attachment hole provided in the bottom surface of the tank body;

The drainage device main body (1) is provided with the fitting member (2) and the fitting portion fitted with one touch ,

Furthermore, a groove is provided around the outer periphery of the drainage device main body (1) and the inner periphery of the fitted member (2), respectively.

A drainage device for a tank body comprising an engaging protrusion (5) and a packing provided in a gap between the drainage body (1) and the fitted member (2).

被嵌合部材を、

上縁周縁にフランジ部(7)を突設させ、外周面に雄ねじ部(8)を形成させたフランジ部材(6)と、

円環形状にして内周面に、上記雄ねじ部(8)と螺合する雌ねじ部(10)と凹溝とを周設し、上面に取着孔の周縁を介してフランジ部材(8)下面を押圧する当接面(11)を備えたナット部材(9)と、から構成したことを特徴とする槽体の排水器。 In the tank drainage device according to claim 1 ,

The mating member

A flange member (6) having a flange portion (7) projecting from the peripheral edge of the upper edge and a male screw portion (8) formed on the outer peripheral surface;

An annular shape is provided on the inner peripheral surface with a female screw portion (10) screwed into the male screw portion (8) and a concave groove, and the lower surface of the flange member (8) via the periphery of the attachment hole. And a nut member (9) provided with a contact surface (11) for pressing the tank.

排水器に、下水などからの異臭や害虫などの逆流を防止するトラップ部(12)を備えたことを特徴とする槽体の排水器。 In the tank drainage device according to any one of claims 1 and 2 ,

A drainage device for a tank body, characterized in that the drainage device is provided with a trap portion (12) for preventing backflow of odors and pests from sewage.

槽体と被嵌合部材(2)の取り付けを工場内で行い、

その後施工現場にて、排水器本体(1)の嵌合部と被嵌合部材との嵌合を行うことを特徴とする槽体の排水器。 In the tank drainage device according to any one of claims 1 to 3 ,

Attach the tank and mating member (2) in the factory,

Then, in the construction site, the drainage device of the tank body, wherein the fitting portion of the drainage device main body (1) and the fitted member are fitted.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004307485A JP4590516B2 (en) | 2004-10-21 | 2004-10-21 | Tank drainage |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004307485A JP4590516B2 (en) | 2004-10-21 | 2004-10-21 | Tank drainage |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006118224A JP2006118224A (en) | 2006-05-11 |

| JP4590516B2 true JP4590516B2 (en) | 2010-12-01 |

Family

ID=36536353

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004307485A Expired - Fee Related JP4590516B2 (en) | 2004-10-21 | 2004-10-21 | Tank drainage |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4590516B2 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101371894B1 (en) | 2013-04-01 | 2014-03-10 | 서광복 | Drainpipe for washbasin |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5352767B2 (en) * | 2009-07-29 | 2013-11-27 | 丸一株式会社 | Joint member |

| JP5779759B2 (en) * | 2010-03-01 | 2015-09-16 | 丸一株式会社 | Drain trap |

| JP6446630B2 (en) * | 2013-09-30 | 2019-01-09 | 丸一株式会社 | Drainage port and drainage member mounting structure |

| JP6454854B2 (en) * | 2015-02-10 | 2019-01-23 | 丸一株式会社 | Drainage mounting structure |

| JP6785400B2 (en) * | 2016-07-26 | 2020-11-18 | 丸一株式会社 | Drainer mounting structure |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0354864U (en) * | 1989-09-27 | 1991-05-27 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5329159U (en) * | 1976-08-19 | 1978-03-13 | ||

| JPS57193759U (en) * | 1981-05-29 | 1982-12-08 | ||

| JPH03218716A (en) * | 1990-01-22 | 1991-09-26 | Natl House Ind Co Ltd | Draining port structure of bathtub |

| JPH11303173A (en) * | 1998-04-17 | 1999-11-02 | Maruichi Kk | Device for attaching draining apparatus |

-

2004

- 2004-10-21 JP JP2004307485A patent/JP4590516B2/en not_active Expired - Fee Related

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0354864U (en) * | 1989-09-27 | 1991-05-27 |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101371894B1 (en) | 2013-04-01 | 2014-03-10 | 서광복 | Drainpipe for washbasin |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2006118224A (en) | 2006-05-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8028357B2 (en) | Method and associated apparatus for assembling and testing a plumbing system | |

| US8321970B2 (en) | Method and associated apparatus for assembling and testing a plumbing system | |

| US20150152627A1 (en) | Method and Associated Apparatus for Assembling and Testing a Plumbing System | |

| JP4590516B2 (en) | Tank drainage | |

| JP6031646B2 (en) | Connection structure between tank and drainage | |

| KR200409569Y1 (en) | A licker to assemble a faucet on the top | |

| JP4916839B2 (en) | Waste water drainage unit | |

| KR101186776B1 (en) | The washstand drainage device which possessed a globe fixed a conduit pipe | |

| JP4916674B2 (en) | Piping fixture | |

| JP4981638B2 (en) | Bathtub water receiving structure | |

| JP2008025216A (en) | Drainage trap pipe arrangement | |

| KR200375988Y1 (en) | A Trap Drain Connection Pipe | |

| JP4713910B2 (en) | Piping fixture | |

| JP6233912B2 (en) | Lid member mounting structure and lid member used therefor | |

| KR200457550Y1 (en) | Overflow unit of sink | |

| JP2023079010A (en) | Drainage device | |

| JP2018155084A (en) | Drain piping for washing machine | |

| CA2887181C (en) | Method and associated apparatus for assembling and testing a plumbing system | |

| KR20190105865A (en) | Pipe connecting device of a drain trap for a washhand stand | |

| JPS6235728Y2 (en) | ||

| JP2007023688A (en) | Drain trap | |

| JP6785400B2 (en) | Drainer mounting structure | |

| JP2010043497A (en) | Drainage unit | |

| KR101177490B1 (en) | Piping connection structure of multiple trap | |

| KR20130005461U (en) | Washstand Auto Pop-up drainpipe |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20071015 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20071025 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080317 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100222 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100330 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100519 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100727 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100809 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130924 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4590516 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130924 Year of fee payment: 3 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130924 Year of fee payment: 3 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |