JP3181217U - Wire branch connector - Google Patents

Wire branch connector Download PDFInfo

- Publication number

- JP3181217U JP3181217U JP2012006861U JP2012006861U JP3181217U JP 3181217 U JP3181217 U JP 3181217U JP 2012006861 U JP2012006861 U JP 2012006861U JP 2012006861 U JP2012006861 U JP 2012006861U JP 3181217 U JP3181217 U JP 3181217U

- Authority

- JP

- Japan

- Prior art keywords

- wire

- branch

- molded product

- covered

- lid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000002184 metal Substances 0.000 claims abstract description 23

- 238000003780 insertion Methods 0.000 claims abstract description 20

- 230000037431 insertion Effects 0.000 claims abstract description 20

- 239000004020 conductor Substances 0.000 claims abstract description 9

- 238000010292 electrical insulation Methods 0.000 claims description 3

- 239000000463 material Substances 0.000 claims description 3

- 229920003002 synthetic resin Polymers 0.000 claims description 3

- 239000000057 synthetic resin Substances 0.000 claims description 3

- 230000005611 electricity Effects 0.000 description 3

- 230000000694 effects Effects 0.000 description 2

- 229910000906 Bronze Inorganic materials 0.000 description 1

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 239000010974 bronze Substances 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- KUNSUQLRTQLHQQ-UHFFFAOYSA-N copper tin Chemical compound [Cu].[Sn] KUNSUQLRTQLHQQ-UHFFFAOYSA-N 0.000 description 1

- 238000001746 injection moulding Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 229920005668 polycarbonate resin Polymers 0.000 description 1

- 239000004431 polycarbonate resin Substances 0.000 description 1

- -1 polypropylene Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

Images

Landscapes

- Connections By Means Of Piercing Elements, Nuts, Or Screws (AREA)

Abstract

【課題】被覆電線の任意の箇所から、必要に応じて、確実に分岐線を分岐させることができるようにした電線分岐コネクタを提供する。

【解決手段】成型品本体1と蓋体2とこれら両体1,2を繋ぐ連結体3とで構成されたハウジング部材と、良導体金属製の被覆電線接続部分と分岐電線接続部分とを備えた通電金具とからなる。成型品本体1に、上方開放形状の被覆電線載置用案内溝11と、その下方に形成された被覆電線圧入溝12と、該圧入溝12と直交する壁面13の分岐電線挿入用開口14の内奥部に分岐電線挿入用空洞15が形成され、押圧力によって被覆電線の被覆を破壊して内部導線と接するU字形切り込み通電部42を備えた導電片41と、分岐電線受入部に形成された接触片とを備えた通電金具を、U字形切り込み通電部42を上部に開放させ、接触片を空洞15内に内装させた構成とする。

【選択図】図1Provided is an electric wire branch connector which can reliably branch a branch line from an arbitrary portion of a covered electric wire as needed.

SOLUTION: A housing member composed of a molded product main body 1, a lid body 2 and a connecting body 3 that connects both bodies 1 and 2, a coated conductor connecting portion and a branch wire connecting portion made of a good conductor metal are provided. It consists of a current-carrying metal fitting. In the molded product main body 1, there are a covered wire placement guide groove 11 having an open top shape, a covered wire press-fitting groove 12 formed below, and a branch wire insertion opening 14 on the wall surface 13 orthogonal to the press-fit groove 12. A branch wire insertion cavity 15 is formed in the inner back, and is formed in the branch wire receiving portion and a conductive piece 41 having a U-shaped cut energizing portion 42 that contacts the internal conductor by breaking the sheath of the covered wire by pressing force. The current-carrying metal fitting provided with the contact piece is configured such that the U-shaped cut-out current-carrying portion 42 is opened upward and the contact piece is internally provided in the cavity 15.

[Selection] Figure 1

Description

本考案は、被覆電線から分岐電線を必要とする任意の箇所から分岐電線を分岐させることができるようにした電線分岐コネクタである。より詳しくは、分岐電線の先端部に予め連結させた端子を被覆電線の導電体と連通する部分と接触させて電気的に確実に分岐させることができるようにした電線分岐コネクタに関するものである。 The present invention is a wire branch connector that can branch a branch wire from an arbitrary place that requires a branch wire from a covered wire. More specifically, the present invention relates to a wire branch connector in which a terminal connected in advance to the tip of a branch wire is brought into contact with a portion communicating with a conductor of a covered wire so as to be surely branched electrically.

従来から、電線ケーブルどうしを電気的に接続させて分岐線を得るようにした電線分岐コネクタは、コネクタに対して複数本の電線ケーブルを並列的に差し込む操作によって、差し込んだ複数本の電線ケーブルどうしを電気的に接続するようにしたものが多く提案されている(例えば、後記特許文献1参照)。

Conventionally, an electric wire branch connector in which electric wires are electrically connected to obtain a branch line is obtained by inserting multiple electric wires into the connector in parallel. There are many proposals in which these are electrically connected (see, for example,

他方、電線の先端部に通電用の端子金具を予め連結しておき、この端子金具を連結した複数本の電線ケーブルをコネクタのハウジングに差し込んで、ハウジング内の電導板を介して複数本の電線ケーブルどうしを電気的に接続するようにしたものも提案されていて既に周知である(例えば、後記特許文献2参照)。

On the other hand, a current-carrying terminal metal fitting is connected in advance to the tip of the electric wire, and a plurality of electric cables connected to the terminal metal fitting are inserted into the housing of the connector, and a plurality of electric wires are connected via the conductive plate in the housing. A cable in which cables are electrically connected has been proposed and already known (for example, see

これらの電線分岐コネクタには、2本の電線だけを接続するようにしたもののみならず3本の電線を接続するもの、4本接続用のもの、さらに多くの本数を接続するようにしたものも知られており、また、接続した電線の内の1本をアース線として使用することも適宜に行われている。そして、これらの電線分岐コネクタは、何れのものもコネクタの内部に挿入してある通電金具に、ケーブルどうしを直接に接触させるか、またはケーブルの先端に予め取り付けた端子金具を介して接触するようにしたものも知られている。 These wire branch connectors are not only those that connect only two wires, but also those that connect three wires, those that connect four wires, and those that connect more It is also known that one of the connected wires is used as a ground wire as appropriate. And these electric wire branching connectors are made so that the cables are brought into direct contact with the current-carrying metal fittings inserted into the connectors, or via the terminal metal fittings attached in advance to the ends of the cables. The ones made are also known.

前者の特許文献1に記載の電線分岐コネクタにあっては、電線径が直径1〜1.5mm程度の圧入強度を備えた比較的太い線径の電線を用いることが多い。後者の特許文献2に記載の電線分岐コネクタにあっては、電線自体が差し込み強度を備えているもののみならず、差し込み強度の小さい細径電線や多数細線の集束電線にも使用されている。

In the former electric wire branch connector described in

本考案は、被覆電線の任意の箇所から通常の被覆電線や、必要に応じて例えばアース線のような電線自体が差し込み強度に乏しい電線であっても、確実に分岐線を分岐させることができるようにした電線分岐コネクタの提供を目的としたものである。 The present invention can reliably branch a branch line from an arbitrary portion of a covered electric wire even if it is a normal covered electric wire or, if necessary, an electric wire itself having a low insertion strength such as a ground wire. An object of the present invention is to provide an electric wire branch connector.

この目的を達成するために講じた本考案の請求項1に記載の電線分岐コネクタは、電気絶縁性を備えた合成樹脂素材製の成形品であって、成型品本体1と蓋体2とこれらの両体1,2を繋ぐ連結体3とを備えたハウジング部材Aと、良導体金属製の加工品であって、被覆電線接続用部分と分岐電線通電用部分とを備えた通電金具4とからなり、前記成型品本体1が、上面に向かって開放された被覆電線載置用案内溝11と、該案内溝11の下方に形成された被覆電線圧入溝12と、該圧入溝12と直交する壁面13に形成された分岐電線挿入用開口14と、該開口14の内奥部で前記被覆電線圧入溝12の下方に形成された分岐電線挿入用空洞15と、前記被覆電線載置用案内溝11と平行する両側壁16,17に突出形成された蓋体掛止突起18,18とを備え、前記蓋体2が、成型品本体1における被覆電線載置用案内溝11に陥入する突条21と、該突条21と平行な両外側に上方へ向かって突出形成された成型品本体1との嵌合用突壁22,23と、該突壁22,23のそれぞれに形成された成型品本体1における前記蓋体掛止突起18,18と契合する開口部24,24とを備え、前記連結体3が、肉厚の薄い細帯状で、その両端が、前記成型品本体1における蓋体2に隣接する側の側壁16と、前記蓋体2における成型品本体1に隣接する側の突壁22とに連結され、前記通電金具4が、押圧力によって被覆電線の被覆を破壊して内部導線と接するU字形切り込み通電部42を備えた被覆電線接続用導電片41と、所定の間隔を隔てて形成された分岐電線通電用接触片43とを備え、該導電片41の通電部42が成型品本体1における前記被覆電線載置用案内溝11に面して配置され、前記接触片43が成型品本体1における前記分岐電線挿入用空洞15内において、分岐電線受入部44を前記分岐電線挿入用開口14と対向させて配置されている構成としたものである。

The electric wire branch connector according to

また、請求項2に記載の電線分岐コネクタは、前記請求項1に記載の電線分岐コネクタに従属する構成であって、成型品本体1に形成された蓋体掛止突起18,18と、蓋体2に形成された開口部24,24とが、被覆電線載置用案内溝11の長手方向に沿って、それぞれ2箇所ずつ形成させてある構成としたものである。

Moreover, the electric wire branch connector according to

本考案に係る電線分岐コネクタは、このように、被覆電線に対して分岐線の必要な任意の箇所において、通常の被覆線やアース線のような電線を電気的に接続させて分岐線として使用することができるようにしたものであるから、被覆電線が既設の電線であっても、分岐電線を引き出しておく必要性のある任意の箇所で、必要な分岐電線を被覆電線から任意に分岐させることができるという顕著な効果を期待できるものである。 In this way, the wire branch connector according to the present invention is used as a branch line by electrically connecting a wire such as a normal covered wire or a ground wire at any place where a branch wire is required with respect to the covered wire. Therefore, even if the covered electric wire is an existing electric wire, the necessary branch electric wire is arbitrarily branched from the covered electric wire at any place where the branch electric wire needs to be pulled out. It can be expected to have a remarkable effect.

さらに、電線案内溝と直交する壁面に分岐電線挿入用開口を形成し、分岐電線挿入用空洞をその内奥部において電線圧入溝の下方に形成してあるので、分岐させる電線を被覆電線と平行な姿勢で取り出すことができるので、分岐線取り出し部をコンパクトに形成できるという実用上の利点も有している。 Furthermore, the branch wire insertion opening is formed in the wall surface orthogonal to the wire guide groove, and the branch wire insertion cavity is formed below the wire press-fitting groove in the inner back thereof, so that the wire to be branched is parallel to the covered wire. Since it can be taken out in a simple posture, it has a practical advantage that the branch line takeout portion can be formed compactly.

さらに、本考案の請求項2に記載の電線分岐コネクタは、成型品本体に形成した蓋体掛止突起と蓋体に形成した開口部とを、それぞれ2箇所ずつ形成させてあるので、成型品本体と蓋体とを確実に閉塞状態としておくことができるという利点を有している。

Furthermore, in the electric wire branch connector according to

以下において、本考案の主たる実施例について図面に例示した構造と共に説明する。

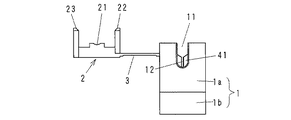

図1〜4は、本考案の電線分岐コネクタを示す斜視図であって、図1,2は通常状態、すなわち成型品本体と蓋体とを開放状態とした外観形状を示した斜視図であり、図3は組み立て状態を示した斜視図であり、図4は上部ハウジングの連結前の状態と通電金具を示した斜視図である。

In the following, a main embodiment of the present invention will be described together with the structure illustrated in the drawings.

1 to 4 are perspective views showing a wire branch connector of the present invention, and FIGS. 1 and 2 are perspective views showing an external shape in a normal state, that is, a molded product body and a lid body in an open state. 3 is a perspective view showing an assembled state, and FIG. 4 is a perspective view showing a state before connection of the upper housing and a current-carrying metal fitting.

該実施例に示したコネクタは、電気絶縁性を備えた合成樹脂素材を用いて射出成形したものであって、例えばポリプロピレン樹脂を用いて上部本体1aを形成し、例えばポリカーボネイト樹脂を用いて下部本体1bを形成し、これらの2部材1a,1bを図1,2に示したように上下に連結して一体として成型品本体1を構成させてある。また、良導体金属素材を成型加工した加工品であって、後述する被覆電線接続用導電片41と分岐電線接続用接触片43とを備えた通電金具4を形成し、この金具4を図4のように、被覆電線接続用導電片41を上にして下部本体1bの所定箇所に取り付け、その上部に上部本体1aを載置させて一体的に連結させてある構成としたものである。

The connector shown in the embodiment is formed by injection molding using a synthetic resin material having electrical insulation. For example, the upper body 1a is formed using polypropylene resin, and the lower body is formed using, for example, polycarbonate resin. 1b is formed, and these two

本実施例に示したハウジング部材Aは、このようにして通電金具4を固定させた成型品本体1と、この上面を覆う蓋体2と、これらの両部材1,2を、可撓性を保持するように薄肉に形成した後述する連結体3によって連結してある構造としたものである。

The housing member A shown in the present embodiment has a flexible molded

而して、成型品本体1には、図1,2に示したように、上面に向かって開放された被覆電線載置用の案内溝11と、該案内溝11の下方に連ねて形成されている被覆電線圧入溝12とを形成してある。また、該圧入溝12と直交する一方の、図1〜3において手前側の壁面13には分岐電線挿入用の開口14を形成してあり、この開口14に連なる内奥部で、前記圧入溝12の下方部分に分岐電線挿入用の空洞15を形成してある。他方、前記案内溝11と平行する両側壁16,17の外面部分には、長手方向に沿った2箇所に外側に向かって突出する蓋体掛止突起18,18を突出形成してある。この構造については、後述する図5乃至図8にも具体的に図示してある。

Thus, as shown in FIGS. 1 and 2, the

前記蓋体2は、閉蓋姿勢において成型品本体1における前記被覆電線載置用案内溝11と対向する箇所に、被覆電線を上方から押圧しながら案内溝11上に陥入する突条21を形成してあり、該突条21と平行な両外側に成型品本体1との嵌合用突壁22,23を上方に向かって突出形成してある。また、これらの突壁22,23のそれぞれには成型品本体1における前記蓋体掛止突起18,18と契合する開口部24,24を形成してあり、図3のように、閉蓋時にこれらが契合して閉蓋姿勢を維持するようにしてある。この構造については、殊に図6,7においてその側面形状を示してある。

The

前記連結体3は、肉厚の薄い細帯状に形成して、湾曲自在で柔軟性を維持するものとしてあり、その両端部の一方を成型品本体1における蓋体2と隣接する側の側壁16に連結し、他方を蓋体2における成型品本体1と隣接する側の突壁22に連結してある。この連結構造についても、図5乃至図7において具体的に図示してある。

The

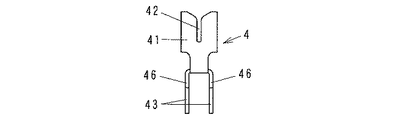

前記通電金具4は、導電性に優れたりん青銅の板金製で、図10乃至12に示したように、外部からの押圧力によって被覆電線の被覆を破壊して内部の導電線と接するU字形の切り込み通電部42を上向きに形成した2枚の被覆電線接続用導電片41,41を所定の間隔を隔てて上向けに立ち上げ、これらの導電片41,41と直交する両部分46,46を底板45から下向きに折り曲げた後、その下方部分を導電片41と直交する方向にL字形に突出させて所定の間隔を隔てた平行板形に形成させて分岐電線通電用接触片43を形成してある。より具体的には、アース線のような分岐用細線の先端部に予め連結した端子金具をこの接触片43と接触させて分岐線を取り出すようにしたものである。

The current-carrying

この通電金具4における被覆電線接続用導電片41の通電部42は、図4,9,10に示したように、成型品本体1における被覆電線載置用案内溝11において上面に向けて配置させてあり、分岐電線通電用接触片43は、成型品本体1における分岐電線挿入用空洞15の内部に配置させ、平面視においてコの字形または平行線形に形成された接触片43の間に分岐電線受入部44が分岐電線挿入用開口14に向かうようにして配置してある。なお、この分岐電線挿入用開口14の開口入り口端には、図9に示したように、当該開口14から内部に挿入した分岐用電線の、具体的には電線端に連結した端子の抜け落ちを阻止するための段部14aを開口下辺に上向きに突出させて形成してある。

As shown in FIGS. 4, 9, and 10, the energizing

而して、該実施例に示した成型品本体1は、前記のように、上部本体1aと下部本体1bとの二体に分けて成形し、図4のように、下部本体1bに通電金具4を装着して、その上方に上部本体1aを配置し、これらの2部材1a,1bを上下に連結して一体としたものとして示してある。また、これら上下2部材1a,1bの連結手段は、図1〜3及び図8,9に示したように、上部本体1aの側壁16,17下半部の外面に外側に向かって突出する契合突起19を形成し、下部本体1bの対向側壁には前記契合突起19と契合する縦長の契合溝20を形成して、これらの契合突起19と契合溝20とを契合させることによって上部本体1aと下部本体1bとを連結してある構造としたものである。

Thus, the molded product

以上の実施例に示した電線分岐コネクタにおいて分岐させる電線は、通常の被覆電線に限られるものではなく、例えばアース線のような細い電線であってもよいことは言うまでもない。 It goes without saying that the electric wires to be branched in the electric wire branch connector shown in the above embodiments are not limited to ordinary coated electric wires, and may be thin electric wires such as ground wires.

以上に本考案の代表例と思われる実施例について説明したが、本考案の電線分岐コネクタは、上記の実施例に示した構造のみに限定されるものではなく、その他本考案にいう前記の構成要件を備え、かつ本考案にいう目的を達成し、本考案にいう効果を有する範囲内において適宜改変して実施することができるものである。 Although the embodiment considered to be a representative example of the present invention has been described above, the wire branch connector of the present invention is not limited to the structure shown in the above embodiment, and the other configurations described in the present invention. The present invention can be implemented with appropriate modifications within a range that has the requirements and achieves the object of the present invention and has the effects of the present invention.

本考案は、既設の被覆電線における任意の箇所において、分岐線を電気的に接続し、分岐させて取り出すことができるので、これを市場に提供すれば、当業者間において大いに重宝されて使用されるものと思われる。 The present invention can be connected to a branch line at any point in an existing covered electric wire, and can be taken out by branching. Therefore, if this is provided to the market, it will be very useful for those skilled in the art. It seems to be.

A ハウジング部材

1 成型品本体

11 被覆電線載置用案内溝

12 被覆電線圧入溝

13 壁面

14 分岐電線挿入用開口

15 分岐電線挿入用空洞

16 側壁

17 側壁

18 蓋体掛止突起

2 蓋体

21 突条

22 突壁

23 突壁

3 連結体

4 通電金具

41 被覆電線接続用導電片

42 通電部

43 分岐電線通電用接触片

44 分岐電線受入部

A

Claims (2)

良導体金属製の加工品であって、被覆電線接続用部分と分岐電線通電用部分とを備えた通電金具(4)とからなり、

前記成型品本体(1)が、上面に向かって開放された被覆電線載置用案内溝(11)と、該案内溝(11)の下方に形成された被覆電線圧入溝(12)と、該圧入溝(12)と直交する壁面(13)に形成された分岐電線挿入用開口(14)と、該開口(14)の内奥部で前記被覆電線圧入溝(12)の下方に形成された分岐電線挿入用空洞(15)と、前記被覆電線載置用案内溝(11)と平行する両側壁(16,17)に突出形成された蓋体掛止突起(18,18)とを備え、

前記蓋体(2)が、成型品本体(1)における被覆電線載置用案内溝(11)に陥入する突条(21)と、該突条(21)と平行な両外側に上方へ向かって突出形成された成型品本体(1)との嵌合用突壁(22,23)と、該突壁(22,23)のそれぞれに形成された成型品本体(1)における前記蓋体掛止突起(18,18)と契合する開口部(24,24)とを備え、

前記連結体(3)が、肉厚の薄い細帯状で、その両端が、前記成型品本体(1)における蓋体(2)に隣接する側の側壁(16)と、前記蓋体(2)における成型品本体(1)に隣接する側の突壁(22)とに連結され、

前記通電金具(4)が、押圧力によって被覆電線の被覆を破壊して内部導線と接するU字形切り込み通電部(42)を備えた被覆電線接続用導電片(41)と、所定の間隔を隔てて形成された分岐電線通電用接触片(43)とを備え、該導電片(41)の通電部(42)が成型品本体(1)における前記被覆電線載置用案内溝(11)に面して配置され、前記接触片(43)が成型品本体(1)における前記分岐電線挿入用空洞(15)内において、分岐電線受入部(44)を前記分岐電線挿入用開口(14)と対向させて配置されている構造

とした電線分岐コネクタ。 A molded product made of a synthetic resin material with electrical insulation, comprising a molded product main body (1), a lid (2), and a connecting body (3) connecting these two bodies (1, 2). A housing member (A);

It is a processed product made of a good conductor metal, and consists of a current-carrying metal fitting (4) provided with a part for connecting a covered electric wire and a part for conducting a branched electric wire,

The molded product body (1) has a covered wire placement guide groove (11) opened toward the upper surface, a covered wire press-fitting groove (12) formed below the guide groove (11), The branch wire insertion opening (14) formed in the wall surface (13) orthogonal to the press-fitting groove (12), and formed below the covered wire press-fitting groove (12) at the inner back of the opening (14) A branch wire insertion cavity (15), and a lid hooking projection (18, 18) formed on both side walls (16, 17) parallel to the covered wire mounting guide groove (11),

The lid (2) has a ridge (21) that intrudes into the guide groove (11) for placing the covered electric wire in the molded product body (1), and upwards on both outer sides parallel to the ridge (21). Projection walls (22, 23) for fitting with the molded product body (1) formed so as to project toward the molded product body (1), and the lids of the molded product body (1) formed on the projection walls (22, 23). It has an opening (24, 24) that engages with a stop projection (18, 18),

The connecting body (3) is in the form of a thin thin strip, and both ends of the side wall (16) adjacent to the lid body (2) in the molded product body (1), and the lid body (2) Connected to the protruding wall (22) on the side adjacent to the molded product body (1) in

The current-carrying metal fitting (4) is spaced apart from a coated wire connecting conductive piece (41) provided with a U-shaped incision current-carrying portion (42) that breaks the sheath of the coated wire by pressing force and contacts the internal conductor. A branch wire energizing contact piece (43) formed in the manner described above, and the conducting portion (42) of the conductive piece (41) faces the guide groove (11) for placing the covered wire in the molded product body (1). The contact piece (43) is located in the branch wire insertion cavity (15) in the molded product body (1), and the branch wire receiving portion (44) is opposed to the branch wire insertion opening (14). Electric wire branch connector with a structure that is arranged.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012006861U JP3181217U (en) | 2012-11-12 | 2012-11-12 | Wire branch connector |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012006861U JP3181217U (en) | 2012-11-12 | 2012-11-12 | Wire branch connector |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP3181217U true JP3181217U (en) | 2013-01-31 |

Family

ID=50425461

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012006861U Expired - Lifetime JP3181217U (en) | 2012-11-12 | 2012-11-12 | Wire branch connector |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3181217U (en) |

-

2012

- 2012-11-12 JP JP2012006861U patent/JP3181217U/en not_active Expired - Lifetime

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR101352706B1 (en) | Connection member and harness connector | |

| KR101775381B1 (en) | Contacts means for attaching an end of a schielded cable | |

| US8753141B2 (en) | Adapter for connecting a harness to magnet wires | |

| US9893454B2 (en) | Connector, method of manufacturing connector, and wire harness | |

| US7950968B2 (en) | Electrical connector having detachable cover | |

| KR20120105383A (en) | Wire-to-wire connector | |

| KR200417442Y1 (en) | Joint connector | |

| US8992244B2 (en) | Terminal fitting | |

| CN109768419B (en) | Connector with a locking member | |

| US9627815B2 (en) | Receptacle connector for cable | |

| AU2007349106B2 (en) | Electric connector with a dust cover | |

| US8944836B2 (en) | Wire line connector | |

| US7931493B2 (en) | Cable assembly with a firm connection between a plurality of wires and a connector | |

| WO2012004170A1 (en) | An arrangement, in particular a plug and a method for production | |

| EP3648259B1 (en) | Electrical connector with latches and terminal position assurance projections provided on hinged cover | |

| JP3181217U (en) | Wire branch connector | |

| JP2014229376A (en) | Shield connector | |

| CN105390881B (en) | Socket connector and pin connector | |

| CN109219907B (en) | Electrical contact with autorotation feature | |

| JP5156288B2 (en) | Unit cable for indoor wiring | |

| JP2016110882A (en) | Wire relay plug and connector | |

| CN107732516B (en) | Cable assembly with improved cable retention | |

| KR101758673B1 (en) | Connector assembly | |

| JP5364687B2 (en) | Wire relay connector | |

| JP2010061840A (en) | Low-profile connector for cable connection |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 3181217 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| EXPY | Cancellation because of completion of term |