JP2010086378A - Photoelectric smoke detector - Google Patents

Photoelectric smoke detector Download PDFInfo

- Publication number

- JP2010086378A JP2010086378A JP2008256064A JP2008256064A JP2010086378A JP 2010086378 A JP2010086378 A JP 2010086378A JP 2008256064 A JP2008256064 A JP 2008256064A JP 2008256064 A JP2008256064 A JP 2008256064A JP 2010086378 A JP2010086378 A JP 2010086378A

- Authority

- JP

- Japan

- Prior art keywords

- smoke

- light

- fire

- emitting element

- smoke detector

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Investigating Or Analysing Materials By Optical Means (AREA)

- Fire-Detection Mechanisms (AREA)

Abstract

Description

本発明は光電式煙感知器に関し、特に検煙部に流入した湯気による誤報を防止することができる光電式煙感知器に関する。 The present invention relates to a photoelectric smoke detector, and more particularly, to a photoelectric smoke detector that can prevent erroneous reporting due to steam flowing into a smoke detector.

従来の光電式煙感知器としては、例えば「検煙部本体5の下面には検煙部カバー11が脱着自在に取り付けられる。検煙部カバー11の周壁12の内側には複数のラビリンス部材13が形成され、ラビリンス部材13は外部からの煙を流入しやすくするとともに、外部からの光を遮断するように形成されている。また、検煙部カバー11の周壁12の外側には防虫網14が一体的に設けられ、虫が侵入して散乱光が発生するのを防止するようにしている。また、検煙部カバー11の周壁12には複数の煙流入口15が形成されている。検煙部本体5の下面には、ホルダ16,17、遮光部材18および取付部19が一体に形成され、ホルダ16には受光素子20とテスト用赤外線LEDが収納され、ホルダ17には煙検出用赤外線LED21が収納される。遮光部材18は煙検出用赤外線LED21から照射される赤外光が受光素子20に直接入射しないように遮光する。取付部19には検煙部カバー11に形成された突起部22が挿入され、検煙部本体5に検煙部カバー11が脱着自在に取り付けられる。」(例えば、特許文献1参照)というものが提案されている。

As a conventional photoelectric smoke detector, for example, “a

従来の光電式煙感知器(例えば、特許文献1参照)における検煙部は、周縁部に壁体(ラビリンス部材)が形成された煙流入部内に、発光素子(煙検出用赤外線LED)及び受光素子が設けられていた。つまり、従来の光電式煙感知器は、発光素子と受光素子が設けられた実装部と、煙流入部とが分けられていなかった。したがって、調理場所やホテルの部屋の浴室等で発生した湯気が検煙部に流入すると、誤報してしまうという問題点があった。 A smoke detector in a conventional photoelectric smoke detector (for example, see Patent Document 1) includes a light emitting element (infrared LED for smoke detection) and a light receiving portion in a smoke inflow portion in which a wall (labyrinth member) is formed at the peripheral portion. An element was provided. That is, in the conventional photoelectric smoke detector, the mounting portion provided with the light emitting element and the light receiving element is not separated from the smoke inflow portion. Therefore, when steam generated in a cooking place or a bathroom of a hotel room flows into the smoke detector, there is a problem that a false alarm is generated.

本発明は、上記のような課題を解決するためになされたものであり、検煙部に湯気が流入しても誤報を防止することができる光電式煙感知器を得ることを目的とする。 The present invention has been made to solve the above-described problems, and an object of the present invention is to obtain a photoelectric smoke detector that can prevent false alarms even if steam flows into the smoke detector.

本発明に係る光電式煙感知器は、検煙部と、該検煙部の出力信号に基づいて火災を判断する火災判別部と、を有し、前記火災判別部が火災と判断すると火災信号を出力する光電式煙感知器において、前記検煙部は、実装部と、煙流入部と、を備え、前記実装部は、該実装部の内部に光を照射する発光素子と、該発光素子から照射され、前記検煙部の煙粒子により生じる散乱光を受光する受光素子と、を有し、前記煙流入部は、該煙流入部に外光が入射することを防止する複数の壁体と、該壁体の間に形成された煙流入口と、を有し、前記実装部と前記煙流入部とは、前記煙流入部が下側になるように重ねて配置され、開口部で連通されているものである。 The photoelectric smoke detector according to the present invention has a smoke detector and a fire discriminating unit for judging a fire based on an output signal of the smoke detector, and when the fire discriminator judges a fire, a fire signal In the photoelectric smoke detector that outputs, the smoke detection unit includes a mounting unit and a smoke inflow unit, the mounting unit irradiates light inside the mounting unit, and the light emitting device And a light receiving element that receives scattered light generated by the smoke particles of the smoke detecting section, and the smoke inflow section has a plurality of wall bodies that prevent external light from entering the smoke inflow section. And a smoke inlet formed between the walls, and the mounting portion and the smoke inflow portion are arranged so that the smoke inflow portion is on the lower side, It is what is communicated.

また、前記実装部の高さ寸法は、前記煙流入部の高さ寸法よりも大きいものである。 Moreover, the height dimension of the said mounting part is larger than the height dimension of the said smoke inflow part.

本発明においては、検煙部は、発光素子と受光素子が設けられた実装部と煙流入部とが分けられている。また、実装部と煙流入部とは、煙流入部が下側になるように重ねて配置され、開口部で連通されている。このため、煙流入部に流入した湯気は、粒子の質量が大きいため慣性が大きい。よって、流動状態を変化させにくいので、実装部にほとんど流入することなく煙流入部を通過する。一方、煙流入部に流入した煙は、粒子の質量が小さいため慣性が小さい。よって、流動状態を変化させやすいので、開口部を介して実装部に流入する。そして、発光素子から照射された光がこの実装部に流入した煙によって散乱されたときの散乱光を受光素子が受光し、火災判断部が火災を判断する。したがって、検煙部(煙流入部)に湯気が流入しても誤報することなく、火災を判断することができる光電式煙感知器を得ることができる。 In the present invention, the smoke detecting section is divided into a mounting section provided with a light emitting element and a light receiving element and a smoke inflow section. Further, the mounting portion and the smoke inflow portion are arranged so that the smoke inflow portion is on the lower side, and communicated with each other through the opening. For this reason, the steam flowing into the smoke inflow portion has a large inertia because the mass of the particles is large. Therefore, since it is difficult to change the flow state, it passes through the smoke inflow portion with almost no flow into the mounting portion. On the other hand, the smoke flowing into the smoke inflow portion has a small inertia because the mass of the particles is small. Therefore, since the flow state is easily changed, it flows into the mounting portion through the opening. Then, the light receiving element receives the scattered light when the light emitted from the light emitting element is scattered by the smoke flowing into the mounting part, and the fire determining part determines a fire. Therefore, it is possible to obtain a photoelectric smoke detector that can determine a fire without erroneous reporting even if steam flows into the smoke detector (smoke inlet).

また、実装部の高さ寸法が前記煙流入部の高さ寸法よりも大きくなっているので、煙流入部に流入した煙は、より実装部に流入しやすくなる。したがって、光電式煙感知器はより精度良く火災を判断することができる。 Moreover, since the height dimension of the mounting part is larger than the height dimension of the smoke inflow part, the smoke that has flowed into the smoke inflow part is more likely to flow into the mounting part. Therefore, the photoelectric smoke detector can determine a fire with higher accuracy.

実施の形態.

以下の実施の形態では、光電式煙感知器の構成に押し釦スイッチやブザー等の警報装置を設けた火災警報器に本発明を実施した場合について説明する。

Embodiment.

In the following embodiments, a case will be described in which the present invention is applied to a fire alarm device in which an alarm device such as a push button switch or a buzzer is provided in the configuration of the photoelectric smoke detector.

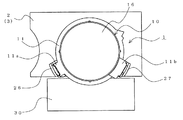

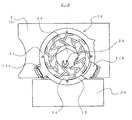

図1は本発明の実施の形態に係る火災警報器の検煙部を示す縦断面図、図2はこの検煙部の底面図、図3はこの検煙部の右側面図、図4は図1のA−A断面図、及び図5は図1のB−B断面図である。これら図1〜図5は、縮尺を一部異ならせて示している。以下、これら図1〜図5を用いて、本実施の形態に係る火災警報器について説明する。なお、以下の説明では、図1の上下左右方向に合わせて説明する。 1 is a longitudinal sectional view showing a smoke detector of a fire alarm device according to an embodiment of the present invention, FIG. 2 is a bottom view of the smoke detector, FIG. 3 is a right side view of the smoke detector, and FIG. AA sectional view of FIG. 1 and FIG. 5 are BB sectional views of FIG. These FIG. 1 to FIG. 5 show the scales partially different. Hereinafter, the fire alarm device according to the present embodiment will be described with reference to FIGS. In the following description, description will be made in accordance with the vertical and horizontal directions in FIG.

火災警報器100の検煙部1は、煙流入部10及び実装部20等から構成されている。煙流入部10は、略円筒形状をしており、板部材11及び壁体12等から構成されている。板部材11は略円板状をしており、略中心部に開口部13が形成されている。また、板部材11の外周部には、後述する発光素子ホルダ26及び受光素子ホルダ27のそれぞれの対応する位置に凸部11a及び凸部11bが形成されている。この板部材11における下面側の周縁部には、複数の例えば略J字状の壁体12が、所定の間隔を空けて、略円環状に立設されている。これにより、煙流入部10は、上面部が板部材11によって覆われるように略円筒状に形成されている。壁体12は、煙流入部10へ外光が入射することを防止している。また、各壁体12間に形成された空間(所定の間隔)は、煙流入部10に煙が流入するための煙流入口14となっている。煙流入部10の下面側開口部は蓋体16により閉塞されており、煙流入部10内が暗箱となっている。また、煙流入部10の側面部には、煙流入口14から虫が侵入することを防止するため、防虫網(図示せず)が設けられている。

The

煙流入部10の上方には、実装部20が設けられている。この実装部20は、光学台21、発光素子22、受光素子23及び遮光部材24等から構成されている。光学台21は下部が開口した略円筒形状となっており、発光素子22を収納するための発光素子ホルダ26、及び受光素子23を収納するための受光素子ホルダ27が設けられている。これら発光素子ホルダ26及び受光素子ホルダ27の外側端部は、光学台21の外周部から突出するように設けられている。煙流入部10が実装部20の下方に設けられた状態においては、暗箱となっている煙流入部10が光学台21の開口部を閉塞する。これにより、光学台21内も暗箱となっている。また、煙流入部10が実装部20の下方に設けられた状態において、煙流入部10と実装部20とは、開口部13を介して連通している。なお、本実施の形態では、実装部20の高さ寸法が煙流入部10の高さ寸法よりも大きくなっている。

A

発光素子ホルダ26には、例えばフック等からなる一対の保持部材26aが設けられている。これら保持部材26aに挟持されて、発光素子22は発光素子ホルダ26に収納されている。このとき、発光素子22のリード部は、略直角に曲げられており、発光素子ホルダ26に形成された貫通孔26bに挿通され、光学台21の上面部から突出している。

The light

受光素子23は、シールドケース28内に設けられ、このシールドケース28と共に受光素子ホルダ27に収納されている。シールドケース28は、上部及び受光素子23の受光部と対向する範囲が開口した、略角筒形状をしている。このシールドケース28には例えば押さえ片等からなる保持部材28aが設けられており、受光素子23は、シールドケース28の側面部と保持部材28aに挟持され、シールドケース28内に設けられている。シールドケース28の上部には凸部28bが形成されており、この凸部28bを回路基板2に形成された開口部に挿通させて半田付けすることによって、シールドケース28及び受光素子23は固定されている。

The

発光素子22及び受光素子23が光学台21内に収納された状態において、発光素子22はその照射範囲22bが光学台21の略中心部を向くように設けられており、受光素子23はその受光範囲23bが光学台21の略中心部を向くように設けられている。また、発光素子22の光軸22aと受光素子23の光軸23aは、側面視において略平行となり、平面視において所定の角度をなすように設けられている。つまり、発光素子22の照射範囲22bと受光素子23の受光範囲23bとの重合部である煙検出部25で煙を検出する。より詳しくは、発光素子22から照射された光がこの煙検出部25に進入する煙によって散乱される光を、受光素子23は受光する。

In a state where the

また、発光素子22の光軸22aと受光素子23の光軸23aとのなす角度が鋭角となる側の光学台21には、遮光部材24が立設されている。この遮光部材24の平面視における断面形状は、例えば略六角形状をしており、光学台21の中心部側の角部を略コ字状に切り欠いた形状となっている。これにより、遮光部材24には、エッジ部24a及びエッジ部24bが形成されている。エッジ部24aは、発光素子22の照射した光を受光素子23が直接受光することを防止している。エッジ部24bは、エッジ部24aで乱反射した光を受光素子23が受光することを防止している。

Further, a

実装部20は、回路基板2の下面部に実装されている。この回路基板2には複数の電気部品(図示せず)が実装されており、これら電気部品が火災判別部3を構成する。実装部20が回路基板2に実装された状態においては、発光素子22及び受光素子23と火災判別部3は電気的に接続されている。そして、火災判別部3は、受光素子23が検出する受光量に基づいて火災が発生したか否かを判別する。受光素子23が検出する受光量は、例えば電圧等によって火災判別部3に出力される。

The mounting

検煙部1及び回路基板2は、煙流入部10への通気性が確保された筐体(図示せず)内に設けられ、火災警報器100を構成する。そして、この火災警報器100は、例えば家屋、ビル及びホテルの室内等の監視空間に設置される。火災警報器100が監視空間の天井面に取り付けられた状態においては、火災警報器100は、図1に示すように、煙流入部10が下側となって設置される。

The

火災警報器100は、例えばリチウム電池である電池30を駆動源としている。つまり、電池30は、検煙部1の発光素子22や回路基板2の火災判別部3等に電源供給する。この電池30は、発光素子22の光軸22aと受光素子23の光軸23aとのなす角度が鋭角となる側の回路基板2の側方に設けられている。また、この電池30は、実装部20の上面部と側面部の一部を切り欠くようにして設けられている。つまり、電池30を収納する電池収納部は、実装部20の上面部と側面部の一部を切り欠くようにして設けられている。実装部20の上面部と側面部の一部を切り欠くようにして電池30(電池収納部)を設けることにより、火災警報器100を小型化、薄型化することができる。なお、実装部20の切り欠かれた部分は、外光が入射するのを防止するため、閉塞されている。

The fire alarm device 100 uses, for example, a

なお、電池30(電池収納部)は、必ずしも本実施の形態に示す位置に設けられる必要はなく、実装部20の煙検出機能に支障がない部分を切り欠くようにして設けられていればよい。つまり、電池30(電池収納部)は、実装部20における発光素子22の煙検出部25までの照射範囲22b及び受光素子23の前記煙検出部25までの受光範囲23bを避けた部分を切り欠くように形成すればよい。発光素子22の光軸22aと受光素子23の光軸23aとのなす角度が鋭角となる側は、煙検出部25が遮光部材24により隔てられているので、電池30(電池収納部)を設けることによる実装部20の煙検出機能への影響が最も少ない場所である。このため、本実施の形態では、発光素子22の光軸22aと受光素子23の光軸23aとのなす角度が鋭角となる側の実装部20の上面部と側面部の一部を切り欠くようにして、電池30(電池収納部)を設けている。

In addition, the battery 30 (battery storage part) does not necessarily need to be provided at the position shown in the present embodiment, and may be provided so as to cut out a part that does not hinder the smoke detection function of the mounting

(動作説明)

続いて、本実施の形態に係る火災警報器100の動作について説明する。

図6は、本発明の実施の形態に係る火災警報器の検煙部を示す縦断面図である。なお、この図6は図4のC−C断面図となっている。また、図6(a)は、検煙部1に煙が流入した状態を示す縦断面図であり、検煙部1内の煙の流れを破線の矢印で示している。また、図6(b)は、検煙部1に湯気が流入した状態を示す縦断面図であり、検煙部1内の湯気の流れを破線の矢印で示している。

(Description of operation)

Then, operation | movement of the fire alarm device 100 which concerns on this Embodiment is demonstrated.

FIG. 6 is a longitudinal sectional view showing the smoke detector of the fire alarm according to the embodiment of the present invention. 6 is a cross-sectional view taken along the line CC of FIG. FIG. 6A is a longitudinal cross-sectional view showing a state where smoke has flowed into the

図6(a)に示すように、火災により発生した煙は、監視空間の天井面等に沿って流れ、検煙部1の煙流入部10に流入する。このとき、遮光部材24は実装部20のみに設けられている。つまり、煙流入部10に遮光部材24が設けられていない。また、発光素子22及び受光素子23等も煙流入部10に設けられていない。したがって、遮光部材24等が煙流入部10に流入する煙の流れを遮らず、煙流入部10の煙流入特性が向上する。なお、遮光部材24は必ずしも実装部20のみに設けられている必要はなく、煙流入部10の煙流入特性が低下しない範囲において、遮光部材24の先端部が煙流入部10内に挿入されていてもよい。先端部が煙流入部10内に挿入するような長さに遮光部材24を設けることにより、発光素子22が照射する光を受光素子23が直接受光することを、より確実に防止することができる。

As shown in FIG. 6A, smoke generated by the fire flows along the ceiling surface of the monitoring space and flows into the

煙は粒子の質量が小さいため慣性が小さい。よって、流動状態を変化させやすいので、煙流入部10に流入した煙は、開口部13を通って実装部20へ流入する。実装部20に煙が流入すると、この煙によって発光素子22の照射した光が散乱する。この散乱光は受光素子23によって受光される。つまり、受光素子23の受光量が変化する。そして受光素子23は、受光量に応じた検出値(電圧等)を火災判別部3に出力する。この検出値に基づいて、火災判別部3は火災が発生したか否かを判別する。火災が発生したと判断すると、火災判別部3は、LED等の発光素子やブザー等の警報装置(図示せず)によって火災が発生したことを周囲に警報する。なお、本実施の形態では実装部20の高さ寸法が煙流入部10の高さ寸法よりも大きくなっているので、煙流入部10に流入した煙は実装部20へ流入しやすくなっている。このため、火災判別部3(火災警報器100)は、精度よく火災を判断することができる。

Smoke has low inertia because of its small particle mass. Therefore, since the flow state is easily changed, the smoke that has flowed into the

一方、図6(b)に示すように、湯気は粒子の質量が大きいため慣性が大きい。よって、流動状態を変化させにくいので、煙流入部10に流入した湯気は、ほとんど実装部10に流入することなく流入部10を通過する。このため、実装部20内では、発光素子22の照射した光が湯気によって散乱することはない(又は少ない)。したがって、煙流入部10(検煙部1)に湯気が流入しても、火災判別部3は(火災警報器100)火災であると誤判断することがない。

On the other hand, as shown in FIG. 6B, steam has a large inertia because the mass of the particles is large. Therefore, since it is difficult to change the flow state, the steam that has flowed into the

このように構成された火災警報器100においては、検煙部1は、発光素子22と受光素子23が設けられた実装部20と煙流入部10とが分けられている。また、実装部20と煙流入部10とは、煙流入部10が下側になるように重ねて配置され、開口部13で連通されている。このため、煙流入部10に湯気が流入しても誤報することなく、火災を判断することができる火災警報器100を得ることができる。

In the fire alarm 100 configured as described above, the

また、実装部20の高さ寸法が煙流入部10の高さ寸法よりも大きくなっているので、煙流入部10に流入した煙は実装部20へ流入しやすくなっている。このため、火災判別部3(火災警報器100)は、精度よく火災を判断することができる。

Moreover, since the height dimension of the mounting

さらに、火災警報器100が天井面と略直交する側壁面に向きを変えて設置されても、煙と湯気はそれぞれ図6(a),(b)の通りに流動するので、天井面取付時と同様な効果が得られる。 Furthermore, even if the fire alarm 100 is installed with its orientation changed to a side wall surface that is substantially orthogonal to the ceiling surface, smoke and steam flow as shown in FIGS. 6 (a) and 6 (b). The same effect can be obtained.

なお、本実施の形態では散乱光式の火災警報器100に本発明を実施したが、減光式の火災警報器に本発明を実施してもよい。また、火災感知器に本発明を実施することももちろん可能である。 In the present embodiment, the present invention is applied to the scattered light type fire alarm device 100. However, the present invention may be applied to a dimming type fire alarm device. It is of course possible to implement the present invention on a fire detector.

1 検煙部、2 回路基板、3 火災判別部、10 煙流入部、11 板部材、11a 凸部、11b 凸部、12 壁体、13 開口部、14 煙流入口、16 蓋体、20 実装部、21 光学台、22 発光素子、22a 光軸、22b 照射範囲、23 受光素子、23a 光軸、23b 照射範囲、24 遮光部材、24a エッジ部、24b エッジ部、25 煙検出部、26 発光素子ホルダ、26a 保持部材、26b 貫通孔、27 受光素子ホルダ、28 シールドケース、28a 保持部材、28b 凸部、30 電池、100 火災警報器。

DESCRIPTION OF

Claims (2)

前記検煙部は、実装部と、煙流入部と、を備え、

前記実装部は、

該実装部の内部に光を照射する発光素子と、該発光素子から照射され、前記検煙部の煙粒子により生じる散乱光を受光する受光素子と、を有し、

前記煙流入部は、

該煙流入部に外光が入射することを防止する複数の壁体と、該壁体の間に形成された煙流入口と、を有し、

前記実装部と前記煙流入部とは、

前記煙流入部が下側になるように重ねて配置され、

開口部で連通されていることを特徴とする光電式煙感知器。 In a photoelectric smoke detector that has a smoke detector and a fire discriminator that judges a fire based on an output signal of the smoke detector, and outputs a fire signal when the fire discriminator judges a fire,

The smoke detector includes a mounting part and a smoke inflow part,

The mounting part is

A light-emitting element that irradiates light inside the mounting part; and a light-receiving element that receives the scattered light that is emitted from the light-emitting element and is generated by the smoke particles of the smoke detector part,

The smoke inlet is

A plurality of walls that prevent external light from entering the smoke inlet, and a smoke inlet formed between the walls;

The mounting portion and the smoke inflow portion are

Arranged so that the smoke inflow part is on the lower side,

A photoelectric smoke detector characterized in that it communicates with an opening.

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008256064A JP2010086378A (en) | 2008-10-01 | 2008-10-01 | Photoelectric smoke detector |

| KR1020090082802A KR20100037539A (en) | 2008-10-01 | 2009-09-03 | Photoelectric smoke sensor |

| CN2009101619770A CN101713733B (en) | 2008-10-01 | 2009-09-10 | Photoelectric smoke sensor |

| TW098131614A TWI442346B (en) | 2008-10-01 | 2009-09-18 | Photoelectric smoke detector |

| US12/566,269 US8232885B2 (en) | 2008-10-01 | 2009-09-24 | Photoelectric smoke detector |

| EP09252336A EP2172916B1 (en) | 2008-10-01 | 2009-10-01 | Photoelectric smoke detector |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008256064A JP2010086378A (en) | 2008-10-01 | 2008-10-01 | Photoelectric smoke detector |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2010086378A true JP2010086378A (en) | 2010-04-15 |

Family

ID=42250256

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008256064A Pending JP2010086378A (en) | 2008-10-01 | 2008-10-01 | Photoelectric smoke detector |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2010086378A (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2014016268A (en) * | 2012-07-10 | 2014-01-30 | Asahi Kasei Electronics Co Ltd | Gas sensor |

| JP2019212180A (en) * | 2018-06-08 | 2019-12-12 | ホーチキ株式会社 | sensor |

| JP2020135780A (en) * | 2019-02-26 | 2020-08-31 | 能美防災株式会社 | Smoke detector |

| JP2021152902A (en) * | 2015-10-28 | 2021-09-30 | ホーチキ株式会社 | Fire alarm device |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS54136984U (en) * | 1978-03-15 | 1979-09-22 | ||

| JPS5724539U (en) * | 1980-07-15 | 1982-02-08 | ||

| JPH11118713A (en) * | 1997-10-16 | 1999-04-30 | Matsushita Electric Works Ltd | Photoelectric smoke detector |

-

2008

- 2008-10-01 JP JP2008256064A patent/JP2010086378A/en active Pending

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS54136984U (en) * | 1978-03-15 | 1979-09-22 | ||

| JPS5724539U (en) * | 1980-07-15 | 1982-02-08 | ||

| JPH11118713A (en) * | 1997-10-16 | 1999-04-30 | Matsushita Electric Works Ltd | Photoelectric smoke detector |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2014016268A (en) * | 2012-07-10 | 2014-01-30 | Asahi Kasei Electronics Co Ltd | Gas sensor |

| JP2021152902A (en) * | 2015-10-28 | 2021-09-30 | ホーチキ株式会社 | Fire alarm device |

| JP7134290B2 (en) | 2015-10-28 | 2022-09-09 | ホーチキ株式会社 | fire alarm |

| JP2019212180A (en) * | 2018-06-08 | 2019-12-12 | ホーチキ株式会社 | sensor |

| JP7128664B2 (en) | 2018-06-08 | 2022-08-31 | ホーチキ株式会社 | sensor |

| JP2020135780A (en) * | 2019-02-26 | 2020-08-31 | 能美防災株式会社 | Smoke detector |

| JP7364342B2 (en) | 2019-02-26 | 2023-10-18 | 能美防災株式会社 | Smoke detectors |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| TWI442346B (en) | Photoelectric smoke detector | |

| JP5660794B2 (en) | Photoelectric smoke detector | |

| CA2796976C (en) | Smoke detector | |

| KR101733714B1 (en) | Detector | |

| EP2685437B1 (en) | Fire sensor | |

| JP2012014330A (en) | Heat-smoke composite type sensor | |

| JP2011215689A (en) | Photoelectric smoke sensor | |

| JP2010086378A (en) | Photoelectric smoke detector | |

| JP5637718B2 (en) | Photoelectric smoke detector | |

| JP5046552B2 (en) | Photoelectric smoke detector | |

| JP5153709B2 (en) | Photoelectric smoke detector | |

| JP5637717B2 (en) | Photoelectric smoke detector | |

| JP5534696B2 (en) | Photoelectric smoke detector | |

| JP2010238095A (en) | Photoelectric smoke sensor | |

| JP4999812B2 (en) | Fire alarm | |

| JP2010086381A (en) | Photoelectric smoke detector | |

| JP5874026B2 (en) | Battery fire detector | |

| JP5426929B2 (en) | Photoelectric smoke detector | |

| JP2018088201A (en) | Fire sensor | |

| JP5117820B2 (en) | Photoelectric smoke detector | |

| JP2009140078A (en) | Photoelectric smoke sensor | |

| CN210006175U (en) | Smoke alarm | |

| JP5887522B2 (en) | Smoke fire detector | |

| JP2011210212A (en) | Insect screen for smoke sensor and photoelectric smoke sensor | |

| JP2020016978A (en) | Fire detector |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100323 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100910 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20101005 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20101201 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20110628 |