JP2006172824A - Electric connector - Google Patents

Electric connector Download PDFInfo

- Publication number

- JP2006172824A JP2006172824A JP2004361556A JP2004361556A JP2006172824A JP 2006172824 A JP2006172824 A JP 2006172824A JP 2004361556 A JP2004361556 A JP 2004361556A JP 2004361556 A JP2004361556 A JP 2004361556A JP 2006172824 A JP2006172824 A JP 2006172824A

- Authority

- JP

- Japan

- Prior art keywords

- metal shell

- electrical connector

- connector

- contact

- contact spring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Landscapes

- Details Of Connecting Devices For Male And Female Coupling (AREA)

- Coupling Device And Connection With Printed Circuit (AREA)

Abstract

Description

この発明は、基板とケーブル等とを電気的に連結する電気コネクタに関し、特に高速伝送用中継コネクタとして使用され、かつ電磁波による中継部分の障害防止機能を具えた電気コネクタに関する。 The present invention relates to an electrical connector that electrically connects a board and a cable or the like, and more particularly to an electrical connector that is used as a high-speed transmission relay connector and has a function of preventing failure of a relay portion due to electromagnetic waves.

従来から、コンピュータあるいは携帯電話等の電子機器内にはケーブルと基板とを電気的に接続する装置として電気コネクタが使用されている。 Conventionally, an electrical connector is used as an apparatus for electrically connecting a cable and a board in an electronic apparatus such as a computer or a mobile phone.

特に高速伝送用中継コネクタとして使用され、かつ電磁波による中継部分の障害防止機能を具えた電気コネクタとして、シールド機能を有する金属シェルを具えた電気コネクタが知られている。 In particular, an electrical connector having a metal shell having a shielding function is known as an electrical connector that is used as a relay connector for high-speed transmission and has a function of preventing failure of a relay portion due to electromagnetic waves.

図6は上述したシールド機能を有する金属シェルを具えた従来の電気コネクタ1の要部断面図で、特に図示せぬ相手側のプラグコネクタが電気的に接続されるソケットコネクタを示している。

FIG. 6 is a cross-sectional view of a main part of a conventional

この電気コネクタ1は図面に垂直な方向に沿って所定のピッチで配設された複数本の導電端子2と、この導電端子2を位置決め収容した絶縁ハウジング3と、この絶縁ハウジング3の周囲を覆うように配設されたシールド機能を有する金属シェル4とから構成されている。

The

また上述した絶縁ハウジング3内には、図示せぬ相手側プラグコネクタの金属シェルと接続するため、独立した別部材である金属製のグランドプレート5が配設されている。

Further, in the insulating housing 3 described above, a

なお、このグランドプレート5と前記金属シェル4とは電気的に接触しており、相手側プラグコネクタの金属シェルから前記グランドプレート5に伝達されたグランド信号は、電気的に接触した前記金属シェル4を介し基板のグランド接続端子等へ伝達されるようになっている。

The

なお、図6で符号7は図示せぬ相手側プラグコネクタが嵌合する嵌合孔で、前記導電端子2の接点2aと前記グランドプレート5の接点5aはいずれも前記嵌合孔7内に突出している。

In FIG. 6,

なお、上述した独立した別部材であるグランドプレートを有する従来の金属シェルを具えた電気コネクタは特許第3451393号にも記載されている。

ところで、上述した従来の電気コネクタ1によると、グランド信号を伝達するグランドプレート5を独立部品として製造し、これを使用するため、電気コネクタ1全体としての部品点数が多く、このため製造工程も煩雑となってコストアップの要因となっていた。また、グランドプレート5と金属シェル4とは電気的に接触する構造であるから接触不良等が起き易く、このためグランド信号が安定して伝達できない虞もある。

By the way, according to the conventional

この発明は、上述した事情に鑑み、部品点数が少なく、しかも安定してグランド信号を伝達することがでる電気コネクタを提供することを目的とする。 In view of the circumstances described above, an object of the present invention is to provide an electrical connector that has a small number of components and can stably transmit a ground signal.

上述した課題を解決するため、この発明では、導電端子を配設した絶縁ハウジングと、該絶縁ハウジングを囲繞する金属シェルとを少なくとも具えた電気コネクタにおいて、前記金属シェルに相手側コネクタの金属シェルと接触する接触バネを一体に形成するようにしている。 In order to solve the above-described problem, according to the present invention, in an electrical connector including at least an insulating housing provided with a conductive terminal and a metal shell surrounding the insulating housing, the metal shell of the mating connector is connected to the metal shell. The contact springs that come into contact with each other are formed integrally.

上述した、本願発明に係る電気コネクタによると、相手側コネクタの金属シェルと接触してグランド信号を伝達するグランドプレートとしての機能を、金属シェルと一体に形成された接触バネにより行なうようにしたから、全体としての部品点数が少なくなり、このため製造工程を減少して安価に電気コネクタを提供することが出来る。また接触バネが金属シェルと一体に形成されているから接触不良もなく、グランド信号を安定して金属シェルに伝達することも出来る。 According to the electrical connector according to the present invention described above, the function as a ground plate for transmitting a ground signal in contact with the metal shell of the mating connector is performed by the contact spring formed integrally with the metal shell. As a result, the number of parts as a whole is reduced, so that the manufacturing process can be reduced and the electrical connector can be provided at a low cost. Further, since the contact spring is formed integrally with the metal shell, there is no contact failure, and the ground signal can be stably transmitted to the metal shell.

以下、この発明に係る電気コネクタの一実施例を詳述する。 Hereinafter, an embodiment of the electrical connector according to the present invention will be described in detail.

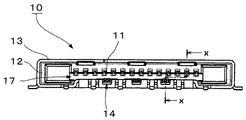

図1はこの発明に係る電気コネクタ10の概念斜視図である。

FIG. 1 is a conceptual perspective view of an

なおこの電気コネクタ10も後述する相手側のプラグコネクタが電気的に接続されるソケットコネクタを示している。

The

この電気コネクタ10も従来と同様に長手方向に沿って所定のピッチで配設された複数本の導電端子11と、この導電端子11を位置決め収容した矩形状の絶縁ハウジング12と、この絶縁ハウジング12の周囲を覆うように配設されたシールド機能を有する金属シェル13とから構成されている。

The

一方、上述した金属シェル13は、ハウジング12を除いた概念斜視図で示す図2のように全体が矩形状で、かつ環状に形成されている。

On the other hand, the

そして、正面13aの下面には、当該金属シェル13と一体に後述する相手側コネクタの金属シェルと接触する接触バネ14が所定のピッチで複数個(実施例では3個)形成されている。

A plurality of contact springs 14 (three in the embodiment) are formed on the lower surface of the

この接触バネ14は上下方向へ向け弾性的に変位することができる舌片14aにより形成され、その先端14bは後述する相手側コネクタの金属シェルとの接触をより一層確実にするため二股状になっている。

This

また、電気コネクタ10の正面図で示す図3のように、接触バネ14は上方に位置する導電端子11と対向する位置に形成されており、このため後述する相手側コネクタを導電端子11と接触バネ14との間、即ち嵌合部17の間で挟持する構造となっている。

Further, as shown in FIG. 3, which is a front view of the

また、図2で示すように、前記接触バネ14に隣接する位置の金属シェル13には相手側コネクタの嵌挿を容易にするとともに、金属シェル13の断面係数を高めてその剛性を向上させる湾曲した舌片15が複数個形成され、またこの舌片15間には、図示せぬ基板側のグランド端子と接続するグランド端子16が形成されている。

Further, as shown in FIG. 2, the

なお、金属シェル13の両側方にも図示せぬ基板のグランド端子と接続する矩形状のグランド端子18が形成されている。

A

なお、図4は図3のXX線拡大断面図である。 4 is an enlarged sectional view taken along line XX of FIG.

この図4に示す位置から図5で示すように、相手側コンタクト、即ち相手側のプラグコネクタ20を嵌合部17内に嵌装して接続させると、その導電端子である同軸ケーブル21の中心導体22が導電端子11の接続端子11aと接触し、また金属シェル13の接触バネ14が同軸ケーブル21の外部導体23と接触した金属シェル24に圧接して接触することとなる。

When the mating contact, that is, the

したがって、相手側のプラグコネクタ20の嵌合片25およびその上下面に配設された中心導体22と金属シェル24は、導電端子11と接触バネ14との間に挟持され、このため接触バネ14の弾性定数を適宜設定すれば、相手側のプラグコネクタ20の金属シェル24との接触圧を最適に設定して安定したグランド信号伝達を行なうことが出来る。

Therefore, the

この発明は、部品点数が少なく、しかも安定してグランド信号を伝達する電気コネクタに適している。 The present invention is suitable for an electrical connector that has a small number of parts and stably transmits a ground signal.

10…電気コネクタ

11…導電端子

12…絶縁ハウジング

13…金属シェル

14…接触バネ

DESCRIPTION OF

Claims (3)

前記金属シェルに、相手側コネクタの金属シェルと接触する接触バネを一体に形成するようにしたことを特徴とする電気コネクタ。

In an electrical connector comprising at least an insulating housing provided with conductive terminals and a metal shell surrounding the insulating housing,

An electrical connector characterized in that a contact spring that contacts the metal shell of the mating connector is formed integrally with the metal shell.

The electrical connector according to claim 1, wherein the contact spring and the conductive terminal are formed at positions facing each other.

The electrical connector according to claim 1, wherein a tip of the contact spring is formed in a bifurcated shape.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004361556A JP4605591B2 (en) | 2004-12-14 | 2004-12-14 | Electrical connector |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004361556A JP4605591B2 (en) | 2004-12-14 | 2004-12-14 | Electrical connector |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006172824A true JP2006172824A (en) | 2006-06-29 |

| JP4605591B2 JP4605591B2 (en) | 2011-01-05 |

Family

ID=36673351

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004361556A Expired - Fee Related JP4605591B2 (en) | 2004-12-14 | 2004-12-14 | Electrical connector |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4605591B2 (en) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008123933A (en) * | 2006-11-15 | 2008-05-29 | I-Pex Co Ltd | Connector device |

| JP2009199891A (en) * | 2008-02-21 | 2009-09-03 | Kel Corp | Cable connector |

| CN101933199A (en) * | 2007-11-29 | 2010-12-29 | 莫列斯公司 | Wire to board connector with multiple contact points |

| JP2013041679A (en) * | 2011-08-11 | 2013-02-28 | Hirose Electric Co Ltd | Electric connector device and connector used for the same |

| US8721366B2 (en) | 2012-02-01 | 2014-05-13 | Japan Aviation Electronics Industry, Limited | Connector |

| US9893448B2 (en) | 2015-11-18 | 2018-02-13 | Dai-Ichi Seiko Co., Ltd. | Electrical connector having a shell plate with an intermediate connecting portion joined to a wiring board |

| JP2019192604A (en) * | 2018-04-27 | 2019-10-31 | ヒロセ電機株式会社 | connector |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103715572B (en) * | 2012-09-29 | 2016-12-21 | 春源科技(深圳)有限公司 | Connectors for coaxial cables assembly and plate terminal adapter |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS61184285U (en) * | 1985-05-10 | 1986-11-17 | ||

| JPH0312367U (en) * | 1989-06-21 | 1991-02-07 | ||

| JPH11329598A (en) * | 1998-05-20 | 1999-11-30 | Amp Japan Ltd | Shield type connector assembly |

| JP2001110527A (en) * | 1999-09-29 | 2001-04-20 | Molex Inc | Shielded connector |

| JP2003007408A (en) * | 2001-06-22 | 2003-01-10 | Iriso Denshi Kogyo Kk | Electric connector |

| JP2003288967A (en) * | 2002-03-25 | 2003-10-10 | Molex Inc | Electric connector |

-

2004

- 2004-12-14 JP JP2004361556A patent/JP4605591B2/en not_active Expired - Fee Related

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS61184285U (en) * | 1985-05-10 | 1986-11-17 | ||

| JPH0312367U (en) * | 1989-06-21 | 1991-02-07 | ||

| JPH11329598A (en) * | 1998-05-20 | 1999-11-30 | Amp Japan Ltd | Shield type connector assembly |

| JP2001110527A (en) * | 1999-09-29 | 2001-04-20 | Molex Inc | Shielded connector |

| JP2003007408A (en) * | 2001-06-22 | 2003-01-10 | Iriso Denshi Kogyo Kk | Electric connector |

| JP2003288967A (en) * | 2002-03-25 | 2003-10-10 | Molex Inc | Electric connector |

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008123933A (en) * | 2006-11-15 | 2008-05-29 | I-Pex Co Ltd | Connector device |

| CN101933199A (en) * | 2007-11-29 | 2010-12-29 | 莫列斯公司 | Wire to board connector with multiple contact points |

| JP2009199891A (en) * | 2008-02-21 | 2009-09-03 | Kel Corp | Cable connector |

| JP2013041679A (en) * | 2011-08-11 | 2013-02-28 | Hirose Electric Co Ltd | Electric connector device and connector used for the same |

| US8851922B2 (en) | 2011-08-11 | 2014-10-07 | Hirose Electric Co., Ltd. | Electrical connector device and connector used in the electrical connector device |

| KR101493842B1 (en) * | 2011-08-11 | 2015-02-16 | 히로세덴끼 가부시끼가이샤 | Electric connector device and receptacle connector used therein |

| US8721366B2 (en) | 2012-02-01 | 2014-05-13 | Japan Aviation Electronics Industry, Limited | Connector |

| TWI472095B (en) * | 2012-02-01 | 2015-02-01 | Japan Aviation Electron | Connector |

| US9893448B2 (en) | 2015-11-18 | 2018-02-13 | Dai-Ichi Seiko Co., Ltd. | Electrical connector having a shell plate with an intermediate connecting portion joined to a wiring board |

| JP2019192604A (en) * | 2018-04-27 | 2019-10-31 | ヒロセ電機株式会社 | connector |

| JP7100489B2 (en) | 2018-04-27 | 2022-07-13 | ヒロセ電機株式会社 | connector |

Also Published As

| Publication number | Publication date |

|---|---|

| JP4605591B2 (en) | 2011-01-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4287107B2 (en) | Coaxial connector for interconnecting printed circuit boards | |

| KR101471283B1 (en) | Electrical connector for use with a circuit board | |

| US7753689B1 (en) | Plug connector with right angle cover | |

| CN104795654B (en) | Terminal, electric connector and electric coupler component | |

| KR20120022624A (en) | Electrical connector and circuit board assembly | |

| US7878850B2 (en) | Cable connector assembly with grounding device | |

| CN112913090B (en) | Coaxial connector device | |

| US20100184330A1 (en) | Cable connector assembly | |

| JP4605591B2 (en) | Electrical connector | |

| KR20160101520A (en) | Receptacle connector | |

| JP4803761B2 (en) | Connector device | |

| JPH11251001A (en) | Coaxial connector assembled body | |

| JP4726019B2 (en) | Connector device | |

| JP5787081B2 (en) | Connector device | |

| KR102317945B1 (en) | Receptacle | |

| JP5182327B2 (en) | Electrical connector and electrical connector assembly | |

| JP2006221863A (en) | Electric connector for cable, and its manufacturing method | |

| WO2023190261A1 (en) | Connector and connector device | |

| JP5144714B2 (en) | Connector device | |

| JP3134220B2 (en) | Coaxial connector | |

| JP3083796B2 (en) | Composite connector | |

| JP2011003393A (en) | Connector device | |

| JP2024110293A (en) | Electrical connector device, receptacle connector, and plug connector | |

| JP2006100105A (en) | Cable side connector | |

| JP2018181701A (en) | Connector device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20071129 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100323 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100330 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100514 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100713 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100826 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100921 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100929 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4605591 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131015 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131015 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131015 Year of fee payment: 3 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313111 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131015 Year of fee payment: 3 |

|

| R360 | Written notification for declining of transfer of rights |

Free format text: JAPANESE INTERMEDIATE CODE: R360 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131015 Year of fee payment: 3 |

|

| R370 | Written measure of declining of transfer procedure |

Free format text: JAPANESE INTERMEDIATE CODE: R370 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131015 Year of fee payment: 3 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313111 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131015 Year of fee payment: 3 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131015 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |