【0001】

【発明の属する技術分野】

本発明は、貯湯槽の外部に設けたヒーターにより貯湯槽内の水を加熱する給湯装置に関するものである。

【0002】

【従来の技術】

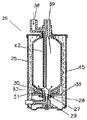

従来より、貯湯槽の外部に設けたヒーターにより貯湯槽内の水を加熱する給湯装置は知られており、例えば特開平7−180909号に見られるものは、図6に示すような構造をしている。図6において、給湯装置26の給水口38から入った水は、給水パイプ42を通って貯湯槽25に導かれ、貯湯槽25内の湯を出湯口39へと押し出す。貯湯槽25の底面中心部には、排水口27が設けられており、外周には固定ナット28と螺合するネジが、また内周には排水管29と螺合するネジが、各々設けられている。

【0003】

貯湯槽25の外部に設けられ貯湯槽25内の水を加熱するための電気ヒーターユニット30は、電気ヒーター31と伝熱板32より成る。伝熱板32は、略円盤状のアルミニウム合金で成型されており、上面は貯湯槽25の底面と同一形状で、下面には電気ヒーター31を装着できる溝を備えている。電気ヒーター31は、円筒の棒状シーズヒーターで、伝熱板32の溝に圧入して熱伝導の良好な状態で装着されている。また、伝熱板32の中心部には、貯湯槽25の排水口27が貫通する孔が設けられている。電気ヒーターユニット30は、貯湯槽25の排水口27に挿入された後、グラスウールなどの難燃材料より成る円盤状の断熱材33を介して貯湯槽25の底面に圧接されるように、固定ナット28で取り付けられる。

【0004】

上記構成において貯湯槽25内の水は、電気ヒーターユニット30に通電されることにより底面より加熱されて高温の湯に沸き上げられる。なお、貯湯槽25に設けられた温度調節器45に基づいて電気ヒーターユニット30が通電制御されることにより、貯湯槽25内の湯温は一定に保たれる。また、電気ヒーターユニット30が発する高熱は、断熱材33でカットされるので排水管29などに伝わることはない。

【0005】

【発明が解決しようとする課題】

貯湯槽25内の水は、電気ヒーターユニット30への通電による温度上昇と自然放熱による温度下降とを繰り返すが、貯湯槽25はこれに連動して膨張・収縮する。ここで、電気ヒーターユニット30は断熱材33を介して貯湯槽25の底面に圧接されるように固定ナット28で取り付けられるため、断熱材33は、貯湯槽25が膨張した際に圧縮変形しまう。そして、貯湯槽25の膨張・収縮が繰り返されると、断熱材33は永久変形して薄くなってしまうことがあった。この場合は、電気ヒーターユニット30の伝熱板32が貯湯槽25の底面から離れてしまうことになる。その結果、電気ヒーターユニット30の熱が貯湯槽25へ伝わりにくくなり、放熱ロスが大きくなってお湯が温まりにくくなる、という問題があった。

【0006】

本発明は、上記課題を解決するためになされたもので、本発明の目的は、貯湯槽の外部に設けた電気ヒーターユニットと貯湯槽の接触を確保し、放熱ロスを抑制することのできる給湯装置を提供することにある。

【0007】

【課題を解決するための手段およびその作用・効果】

上記課題を解決するために請求項1は、貯湯槽と、前記貯湯槽の底面中心部に突出し外周に雄ネジを有する給水口と、前記貯湯槽の底面に面接触すべく形成された伝熱部を有する電気ヒーターユニットと、前記電気ヒーターユニットの底面に接するように配置された断熱材と、前記給水口の雄ネジと螺合する雌ネジが内周に形成されるとともに前記断熱材の下面を支持する固定ナットとを備えた給湯装置において、前記固定ナットは、前記断熱材を介さずに前記電気ヒーターユニットの底面を支持するためのリブを備えていることとした。よって、固定ナットのリブにより、断熱材を介することなく電気ヒーターユニットを貯湯槽へ直接押し付けるように固定することができる。このため、貯湯槽の膨張・収縮に伴なう断熱材の変形に影響されることなく、電気ヒーターユニットと貯湯槽の接触を確保することができるので、放熱ロスを抑制できる。

【0008】

請求項2は、請求項1に記載の給湯装置において、前記固定ナットのリブに対する接触面積を減らすために、前記電気ヒーターユニットに除肉部を設けた。よって、電気ヒーターユニットから固定ナットへの不要な伝熱を抑えることができる。

【0009】

【発明の実施の形態】

以下、本発明の実施の形態を、図面により詳細に説明する。

【0010】

図1は、本発明の一実施形態を示す給湯装置1の構成図であり、図2はその部分断面図である。図1において、入水エルボ24から入った水は、接続継手2を経由し給水パイプ3を通って貯湯槽4に導かれ、貯湯槽4内の湯を貯湯槽上口6へと押し上げる。押し上げられた湯は、バイパス通路5(図2参照)により貯湯槽4を通ることなく供給される水と接続継手2で混合され、出湯エルボ7から図示しない給湯栓へ供給される。なお、貯湯槽4内の水の加熱に伴って上昇する貯湯槽4内の圧力を逃がすため、貯湯槽4の上部に逃し弁8を設けている。また給水パイプ3には、使用しない時や修理時に貯湯槽4内の水を抜くための排水栓11を備えている。

【0011】

図2に示すように、貯湯槽4の底面中心部には、円筒状に突出し外周に雄ネジを有する給水口12が設けられている。後述するように、貯湯槽4の下部には、電気ヒーターユニット13と断熱材17が、固定ナット14で取り付けられている。なお、給水パイプ3と給水口12の接続部は、Oリング23によりシールされている。

【0012】

上記構成において貯湯槽4内の水は、電気ヒーターユニット13に通電されることにより底面より加熱されて高温の湯に沸き上げられる。なお、貯湯槽4に設けられた貯湯温度検出手段9(図1参照)の検出温度に基づいて電気ヒーターユニット13が通電制御されることにより、貯湯槽4内の湯温は一定に保たれる。もし、水が入っていない場合に空焚きされようとした場合には、安全のため過昇温度検出手段10(図1参照)により通電が停止されるようにしている。

【0013】

図3は、電気ヒーターユニット13の固定方法を示す図である。図3に示すように電気ヒーターユニット13は、アルミニウムダイキャストで略円盤状に形成されており、中心部には貯湯槽4の給水口12が貫通する孔が設けられている。また、電気ヒーターユニット13の底面と側面を囲んで放熱を防止するための断熱材17は、グラスウールなどの難燃材料でできており、中心部には、やはり貯湯槽4の給水口12が貫通する孔が設けられている。

【0014】

組み立ての際には、貯湯槽4の給水口12に電気ヒーターユニット13と断熱材17を順に挿入し、最後に、固定ナット14の内周の雌ネジを給水口12の外周の雄ネジと螺合させて固定する。固定ナット14は、図3に示すようにフランジ16とリブ15を備えている。そして図2から明らかなように、固定ナット14のフランジ16は断熱材17の下面を支持し、リブ15は断熱材17を介すことなく電気ヒーターユニット13の底面を支持している。

【0015】

また、電気ヒーターユニット13の上面は、図4の正面図および図5の断面図に示すように、貯湯槽4の底面に面接触して(図2参照)貯湯槽4に熱を伝える伝熱部18が外周部に形成されるとともに、内周部には貯湯槽4の底面に接触しない非伝熱部19を備えている。そして、非伝熱部19には4箇所の除肉部20が形成されており、その結果残った4箇所の梁部21の先端の下面を固定ナット14のリブ15が支持する。なお、4箇所の梁部21の先端の上面には、固定ナット14のリブ15による固定の際の変形を防ぐためのリブ22を設けている。

【0016】

さて、貯湯槽4内の水は、電気ヒーターユニット13への通電による温度上昇と自然放熱による温度下降とを繰り返すが、貯湯槽4はこれに連動して膨張・収縮する。ここで電気ヒーターユニット13は、固定ナット14のリブ15により断熱材17を介することなく貯湯槽4へ直接押し付けられて固定されているため、貯湯槽4の膨張・収縮に伴なう断熱材17の変形に影響されることなく、電気ヒーターユニット13と貯湯槽4の接触を確保することができるので、放熱ロスを抑制できる。

【0017】

また、電気ヒーターユニット13に除肉部20を形成したことにより、固定ナット14のリブ15と接触するのは、電気ヒーターユニット13のうち梁部21の先端のみであるので接触面積は小さい。このため、電気ヒーターユニット13から固定ナット14のリブ15への不要な伝熱を抑えることができ、Oリング23などの耐熱性能が低い他の部品への伝熱も抑制する。また、電気ヒーターユニット13の除肉部20は、貯湯槽4の膨張・収縮の際に生じる電気ヒーターユニット13の弾性変形を助け、破損を防止する役割も果たす。

【0018】

なお、本実施例において電気ヒーターユニット13は、複雑な形状を安価に形成できることからアルミニウムダイキャストを用いたが、他の材料で形成してもよい。また、電気ヒーターユニット13の除肉部20と梁部21は各4箇所設けたが、除肉部20と梁部21の形状や数は、固定ナット14のリブ15に対する接触面積を減らすという目的に沿った範囲であれば任意に設定して構わない。

【図面の簡単な説明】

【図1】本発明の一実施形態を示す給湯装置1の構成図

【図2】給湯装置1の断面図

【図3】電気ヒーターユニット13の固定方法を示す図

【図4】電気ヒーターユニット13の正面図

【図5】電気ヒーターユニット13の断面図

【図6】従来の給湯装置26の構成図

【符号の説明】

1…給湯装置

2…接続継手

3…給水パイプ

4…貯湯槽

5…バイパス通路

6…貯湯槽上口

7…出側エルボ

8…逃し弁

9…貯湯温度検出手段

10…過昇温度検出手段

11…排水栓

12…給水口

13…電気ヒーターユニット

14…固定ナット

15…リブ

16…フランジ

17…断熱材

18…伝熱部

19…非伝熱部

20…除肉部

21…梁部

22…リブ

23…Oリング

24…入水エルボ

25…貯湯槽

26…給湯装置

27…排水口

28…固定ナット

29…排水管

30…電気ヒーターユニット

31…電気ヒーター

32…伝熱板

33…断熱材

38…給水口

39…出湯口

42…給水パイプ

45…温度調節器[0001]

TECHNICAL FIELD OF THE INVENTION

TECHNICAL FIELD The present invention relates to a hot water supply device that heats water in a hot water tank by a heater provided outside the hot water tank.

[0002]

[Prior art]

2. Description of the Related Art Conventionally, a hot water supply device for heating water in a hot water storage tank by a heater provided outside the hot water storage tank is known. For example, a hot water supply apparatus disclosed in JP-A-7-180909 has a structure as shown in FIG. ing. In FIG. 6, water that has entered from a water supply port 38 of a hot water supply device 26 is guided to a hot water tank 25 through a water supply pipe 42, and pushes hot water in the hot water tank 25 to a hot water outlet 39. A drain port 27 is provided at the center of the bottom surface of the hot water storage tank 25, a screw that is screwed with the fixing nut 28 is provided on the outer periphery, and a screw that is screwed with the drain pipe 29 is provided on the inner periphery. ing.

[0003]

An electric heater unit 30 provided outside the hot water storage tank 25 for heating water in the hot water storage tank 25 includes an electric heater 31 and a heat transfer plate 32. The heat transfer plate 32 is formed of a substantially disc-shaped aluminum alloy, has an upper surface having the same shape as the bottom surface of the hot water storage tank 25, and has a groove on the lower surface in which the electric heater 31 can be mounted. The electric heater 31 is a cylindrical rod-shaped sheathed heater, which is press-fitted into a groove of the heat transfer plate 32 and is mounted with good heat conduction. In the center of the heat transfer plate 32, a hole through which the drain port 27 of the hot water storage tank 25 penetrates is provided. After the electric heater unit 30 is inserted into the drain port 27 of the hot water tank 25, the fixing nut is pressed against the bottom surface of the hot water tank 25 via a disc-shaped heat insulating material 33 made of a flame-retardant material such as glass wool. Mounted at 28.

[0004]

In the above configuration, the water in the hot water storage tank 25 is heated from the bottom by being energized to the electric heater unit 30 and is heated to high-temperature hot water. The electric temperature of the electric heater unit 30 is controlled based on the temperature controller 45 provided in the hot water storage tank 25, so that the temperature of the hot water in the hot water storage tank 25 is kept constant. Further, the high heat generated by the electric heater unit 30 is not transmitted to the drain pipe 29 or the like because it is cut by the heat insulating material 33.

[0005]

[Problems to be solved by the invention]

The water in the hot water storage tank 25 repeats a temperature rise due to energization of the electric heater unit 30 and a temperature decrease due to natural heat radiation, and the hot water tank 25 expands and contracts in conjunction with this. Here, since the electric heater unit 30 is attached with the fixing nut 28 so as to be pressed against the bottom surface of the hot water storage tank 25 via the heat insulating material 33, the heat insulating material 33 is compressed and deformed when the hot water storage tank 25 expands. When the expansion and contraction of the hot water storage tank 25 are repeated, the heat insulating material 33 may be permanently deformed and become thin. In this case, the heat transfer plate 32 of the electric heater unit 30 is separated from the bottom surface of the hot water storage tank 25. As a result, there is a problem that the heat of the electric heater unit 30 is not easily transmitted to the hot water storage tank 25, the heat loss is increased, and the hot water is hardly heated.

[0006]

The present invention has been made to solve the above problems, and an object of the present invention is to provide a hot water supply system capable of ensuring contact between an electric heater unit provided outside a hot water storage tank and the hot water storage tank and suppressing heat radiation loss. It is to provide a device.

[0007]

[Means for Solving the Problems and Their Functions and Effects]

In order to solve the above-mentioned problem, a first aspect of the present invention is a hot water storage tank, a water supply port protruding from the center of the bottom surface of the hot water storage tank and having a male screw on the outer periphery, and a heat transfer formed to make surface contact with the bottom surface of the hot water storage tank. An electric heater unit having a portion, a heat insulating material arranged to be in contact with a bottom surface of the electric heater unit, and a female screw screwed with a male screw of the water supply port formed on an inner periphery and a lower surface of the heat insulating material And a fixing nut for supporting the heater, wherein the fixing nut is provided with a rib for supporting a bottom surface of the electric heater unit without interposing the heat insulating material. Therefore, the electric heater unit can be fixed so as to be directly pressed against the hot water storage tank without the intervention of the heat insulating material by the rib of the fixing nut. For this reason, the contact between the electric heater unit and the hot water storage tank can be ensured without being affected by the deformation of the heat insulating material due to expansion and contraction of the hot water storage tank, so that heat dissipation loss can be suppressed.

[0008]

According to a second aspect, in the hot water supply apparatus according to the first aspect, the electric heater unit is provided with a wall-thinning portion in order to reduce a contact area of the fixing nut with a rib. Therefore, unnecessary heat transfer from the electric heater unit to the fixing nut can be suppressed.

[0009]

BEST MODE FOR CARRYING OUT THE INVENTION

Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0010]

FIG. 1 is a configuration diagram of a hot water supply apparatus 1 showing one embodiment of the present invention, and FIG. 2 is a partial cross-sectional view thereof. In FIG. 1, water entering from a water inlet elbow 24 is guided to a hot water storage tank 4 through a water supply pipe 3 via a connection joint 2, and pushes hot water in the hot water storage tank 4 to a hot water tank upper opening 6. The pushed-up hot water is mixed with water supplied by the bypass passage 5 (see FIG. 2) without passing through the hot water storage tank 4 at the connection joint 2, and supplied from the tapping elbow 7 to a hot water tap (not shown). Note that a relief valve 8 is provided above the hot water storage tank 4 in order to release the pressure in the hot water storage tank 4 that rises with the heating of the water in the hot water storage tank 4. The water supply pipe 3 is provided with a drain plug 11 for draining water from the hot water storage tank 4 when not in use or when repairing.

[0011]

As shown in FIG. 2, a water supply port 12 is provided at the center of the bottom surface of the hot water storage tank 4 and has a cylindrical shape and has a male screw on the outer periphery. As will be described later, an electric heater unit 13 and a heat insulating material 17 are attached to a lower portion of the hot water storage tank 4 with a fixing nut 14. The connection between the water supply pipe 3 and the water supply port 12 is sealed by an O-ring 23.

[0012]

In the above configuration, the water in the hot water storage tank 4 is heated from the bottom by being energized to the electric heater unit 13 and is heated to high-temperature hot water. The electric heater unit 13 is controlled to be energized based on the temperature detected by the hot water storage temperature detecting means 9 (see FIG. 1) provided in the hot water storage tank 4, so that the temperature of the hot water in the hot water storage tank 4 is kept constant. . If there is no water in the tank, and if it is attempted to heat the battery without power, the power supply is stopped by the overheated temperature detecting means 10 (see FIG. 1) for safety.

[0013]

FIG. 3 is a diagram illustrating a method of fixing the electric heater unit 13. As shown in FIG. 3, the electric heater unit 13 is formed in a substantially disc shape by aluminum die-casting, and has a central portion provided with a hole through which the water supply port 12 of the hot water storage tank 4 penetrates. Further, a heat insulating material 17 for preventing heat radiation around the bottom and side surfaces of the electric heater unit 13 is made of a flame-retardant material such as glass wool, and the water supply port 12 of the hot water storage tank 4 also passes through the center. Holes are provided.

[0014]

When assembling, the electric heater unit 13 and the heat insulating material 17 are sequentially inserted into the water supply port 12 of the hot water tank 4, and finally, the female screw on the inner circumference of the fixing nut 14 is screwed with the male screw on the outer circumference of the water supply port 12. And fix them together. The fixing nut 14 includes a flange 16 and a rib 15 as shown in FIG. 2, the flange 16 of the fixing nut 14 supports the lower surface of the heat insulating material 17, and the rib 15 supports the bottom surface of the electric heater unit 13 without the heat insulating material 17.

[0015]

Further, as shown in the front view of FIG. 4 and the cross-sectional view of FIG. 5, the upper surface of the electric heater unit 13 is in surface contact with the bottom surface of the hot water storage tank 4 (see FIG. 2), and heat is transmitted to the hot water storage tank 4. The portion 18 is formed on the outer peripheral portion, and the inner peripheral portion is provided with a non-heat transfer portion 19 that does not contact the bottom surface of the hot water storage tank 4. The non-heat transfer portion 19 is formed with four thinned portions 20, and the ribs 15 of the fixing nut 14 support the lower surfaces of the tips of the remaining four beam portions 21 as a result. Note that ribs 22 are provided on the upper surfaces of the tips of the four beam portions 21 to prevent deformation when the fixing nut 14 is fixed by the ribs 15.

[0016]

By the way, the water in the hot water storage tank 4 repeats a temperature rise due to energization of the electric heater unit 13 and a temperature decrease due to natural heat radiation, and the hot water storage tank 4 expands and contracts in conjunction with this. Here, since the electric heater unit 13 is directly pressed and fixed to the hot water storage tank 4 without the intermediary of the heat insulating material 17 by the rib 15 of the fixing nut 14, the heat insulating material 17 accompanying the expansion and contraction of the hot water storage tank 4 is provided. Since the contact between the electric heater unit 13 and the hot water storage tank 4 can be ensured without being affected by the deformation of the water heater, the heat radiation loss can be suppressed.

[0017]

In addition, since the thinned portion 20 is formed in the electric heater unit 13, only the tip of the beam portion 21 of the electric heater unit 13 comes into contact with the rib 15 of the fixing nut 14, so that the contact area is small. For this reason, unnecessary heat transfer from the electric heater unit 13 to the rib 15 of the fixing nut 14 can be suppressed, and heat transfer to other parts having low heat resistance such as the O-ring 23 can also be suppressed. In addition, the thinned portion 20 of the electric heater unit 13 assists the elastic deformation of the electric heater unit 13 generated when the hot water storage tank 4 expands and contracts, and also serves to prevent breakage.

[0018]

In this embodiment, the electric heater unit 13 is made of aluminum die-cast because a complicated shape can be formed at a low cost. However, the electric heater unit 13 may be made of another material. Although the thinning portion 20 and the beam portion 21 of the electric heater unit 13 are provided at four places, the shape and number of the thinning portion 20 and the beam portion 21 are intended to reduce the contact area of the fixing nut 14 with the rib 15. May be arbitrarily set as long as it is within the range.

[Brief description of the drawings]

FIG. 1 is a configuration diagram of a water heater 1 showing an embodiment of the present invention. FIG. 2 is a cross-sectional view of the water heater 1. FIG. 3 is a diagram showing a method of fixing the electric heater unit 13. FIG. FIG. 5 is a cross-sectional view of the electric heater unit 13. FIG. 6 is a configuration diagram of a conventional water heater 26.

DESCRIPTION OF SYMBOLS 1 ... Hot water supply apparatus 2 ... Connection joint 3 ... Water supply pipe 4 ... Hot water tank 5 ... Bypass passage 6 ... Hot water tank upper opening 7 ... Outlet elbow 8 ... Relief valve 9 ... Hot water storage temperature detecting means 10 ... Excess temperature detecting means 11 ... Drain plug 12 ... water supply port 13 ... electric heater unit 14 ... fixed nut 15 ... rib 16 ... flange 17 ... heat insulating material 18 ... heat transfer part 19 ... non-heat transfer part 20 ... thinning part 21 ... beam part 22 ... rib 23 ... O-ring 24 ... Water inlet elbow 25 ... Hot water tank 26 ... Hot water supply 27 ... Drain port 28 ... Fixed nut 29 ... Drain pipe 30 ... Electric heater unit 31 ... Electric heater 32 ... Heat transfer plate 33 ... Insulation material 38 ... Water supply port 39 ... Hot water outlet 42: water supply pipe 45: temperature controller