GB2560956A - Femoral implant explantation chisel - Google Patents

Femoral implant explantation chisel Download PDFInfo

- Publication number

- GB2560956A GB2560956A GB1705073.3A GB201705073A GB2560956A GB 2560956 A GB2560956 A GB 2560956A GB 201705073 A GB201705073 A GB 201705073A GB 2560956 A GB2560956 A GB 2560956A

- Authority

- GB

- United Kingdom

- Prior art keywords

- chisel

- implant

- femoral implant

- elongate shaft

- cutter

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods, e.g. tourniquets

- A61B17/16—Bone cutting, breaking or removal means other than saws, e.g. Osteoclasts; Drills or chisels for bones; Trepans

- A61B17/1604—Chisels; Rongeurs; Punches; Stamps

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2/46—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2/46—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor

- A61F2/4603—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor for insertion or extraction of endoprosthetic joints or of accessories thereof

- A61F2/4607—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor for insertion or extraction of endoprosthetic joints or of accessories thereof of hip femoral endoprostheses

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2/46—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor

- A61F2/4603—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor for insertion or extraction of endoprosthetic joints or of accessories thereof

- A61F2002/4619—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor for insertion or extraction of endoprosthetic joints or of accessories thereof for extraction

Landscapes

- Health & Medical Sciences (AREA)

- Orthopedic Medicine & Surgery (AREA)

- Life Sciences & Earth Sciences (AREA)

- Oral & Maxillofacial Surgery (AREA)

- General Health & Medical Sciences (AREA)

- Transplantation (AREA)

- Engineering & Computer Science (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Surgery (AREA)

- Veterinary Medicine (AREA)

- Animal Behavior & Ethology (AREA)

- Public Health (AREA)

- Cardiology (AREA)

- Physical Education & Sports Medicine (AREA)

- Dentistry (AREA)

- Nuclear Medicine, Radiotherapy & Molecular Imaging (AREA)

- Vascular Medicine (AREA)

- Medical Informatics (AREA)

- Molecular Biology (AREA)

- Surgical Instruments (AREA)

- Prostheses (AREA)

Abstract

A femoral implant explantation chisel 10 for loosening a femur-implant medial interface during hip revision surgery comprising an elongate shaft 12 having a handle end 14 and a cutter end 16. The elongate shaft 12 comprising an implant-contacting guide surface 24 which extends along at least part of the elongate shaft 12 from the cutter end 16 for guiding the chisel 10 along a femoral implant to be extracted. The chisel 10 also comprises a cutter 18 which projects from a longitudinal edge of the implant contacting guide surface 24. The cutter 18 having an arcuate cutting edge 22 at or adjacent the cutter end 16 which extends laterally of a longitudinal extent of the elongate shaft 12. The guide surface 24 may be planar and may extend along a majority or all of the shaft 12. The shaft 12 may include a bone facing surface along the majority or all of the shaft 12. The curvature of the cutting edge 22 may have a constant radius. The cutter end 16 may be tapered, bevelled or chamfered. A method of loosening or separating a femoral implant using the femoral implant chisel 10 is also provided.

Description

(54) Title of the Invention: Femoral implant explantation chisel Abstract Title: Femoral implant explantation chisel (57) A femoral implant explantation chisel 10 for loosening a femur-implant medial interface during hip revision surgery comprising an elongate shaft 12 having a handle end 14 and a cutter end 16. The elongate shaft 12 comprising an implant-contacting guide surface 24 which extends along at least part of the elongate shaft 12 from the cutter end 16 for guiding the chisel 10 along a femoral implant to be extracted. The chisel 10 also comprises a cutter 18 which projects from a longitudinal edge of the implant contacting guide surface 24. The cutter 18 having an arcuate cutting edge 22 at or adjacent the cutter end 16 which extends laterally of a longitudinal extent of the elongate shaft 12. The guide surface 24 may be planar and may extend along a majority or all of the shaft 12. The shaft 12 may include a bone facing surface along the majority or all of the shaft 12. The curvature of the cutting edge 22 may have a constant radius. The cutter end 16 may be tapered, bevelled or chamfered. A method of loosening or separating a femoral implant using the femoral implant chisel 10 is also provided.

1/4

2/4

Figure 5

3/4

Figure 6a

Figure 6b

4/4

Figure 7

10’

Femoral Implant Explantation Chisel

The present invention relates to a femoral implant explantation chisel, particularly but not necessarily for use in the separation of a femur-implant medial interface during hip revision surgery. A method of loosening a femoral implant along a femur-implant medial interface during hip revision surgery is also provided.

When removing an un-cemented femoral hip prosthesis during revision surgery, various instruments are used to remove biological matter from the area around the prosthesis. Osseous tissue grows onto the stem of the prosthesis providing fixation of the implant after implantation. This must be removed when the stem requires explantation.

Typically, thin chisels are used to loosen the interface between the implant and the femur in an attempt to minimize damage to the osseous tissue of the femur, and in particular to the cortical wall thereof

There is adequate instrumentation available to loosen the interface on the lateral, posterior and anterior surfaces of the femoral hip prosthesis; however, the tools used to loosen the medial surface are inadequate.

Thin curved surgical chisels are currently used, but are unable to reach along the entire medial surface of a femoral prosthesis. Since the curvature of the medial surface changes towards the stem, the uniform curvature of such curved chisels can only penetrate a certain depth along the medial surface without then penetrating the cortical surface of the femur as the blade of the chisel curves back on itself. The osseous integration at the bottom of the stem of the femoral prosthesis cannot therefore presently be loosened, which then requires significant explantation forces to be utilised in order to remove the implant.

The present invention seeks to provide a tool which can loosen the biological material from a greater proportion of the medial surface of the femoral implant, without causing breaching of the cortical wall of the femur.

According to a first aspect of the invention, there is provided a femoral implant explantation chisel for loosening or separating a femur-implant medial interface during hip revision surgery, the femoral implant explantation chisel comprising: an elongate shaft having a handle end and a cutter end, the elongate shaft including an implantcontacting guide surface which extends along at least part of the elongate shaft from the cutter end for guiding the chisel along a femoral implant to be extracted; and a cutter which projects from a longitudinal edge of the implant-contacting guide surface, the cutter having an arcuate cutting edge at or adjacent to the cutter end and which extends laterally of a longitudinal extent of the elongate shaft.

By providing a cutter which curves laterally away from the main stem of the chisel, an implant-contacting guide surface can be provided which can be rested on the implant to be explanted by a surgeon. This allows the cutter to follow the femur-implant medial interface accurately, as the surgeon is able to reorient the chisel along the implant as it is urged towards the stem of the femoral implant. Such an arrangement results in a significantly reduced risk of damage to the cortical wall of the femur in use, allowing the surgeon to safely loosen all biological material from the medial surface of the implant.

Preferably, the implant-contacting guide surface may be planar. Furthermore, the implant-contacting guide surface may extend along at least a majority of the longitudinal extent of the elongate shaft, in which case the implant-contacting guide surface may extend along the full longitudinal extent of the elongate shaft.

The greater the extent of the implant-guide surface extending along the stem or shaft of the chisel, the greater the freedom of movement which will be available to the surgeon during explantation surgery. This ensures that loosening of the biological material at the very base of the stem of the femoral implant can be effected.

Optionally, the elongate shaft may include a bone-facing surface which is opposite to the implant-contacting guide surface, the bone-facing surface being planar and parallel to the implant-contacting guide surface. The bone-facing guide surface may extend along at least a majority of the longitudinal extent of the elongate shaft, in which case, the bone-facing guide surface may extend along the full longitudinal extent of the elongate shaft.

The bone-facing surface can be shaped which minimises the friction between the osseous tissue of the femur and the chisel as it is inserted into the femur-implant interface region. This further reduces the risk of damage to the femur during surgery.

Preferably, the implant-contacting guide surface may be an implant-anterior-surfacecontacting guide surface.

From an anatomical perspective, it is more straightforward for a surgeon to access the medial surface of the femoral implant by contacting the chisel with the anterior surface of the existing implant.

In one preferred embodiment, a curvature of the cutting edge may have a constant radius. Preferably, the cutter may have an arcuate cross-section in a plane perpendicular to a longitudinal direction of the elongate shaft.

The provision of a constant radius of the cutter and/or cutting edge allows for the chisel to closely follow the curvature of the medial surface of the implant, resulting in less bone damage during explantation surgery.

The cutter may further comprise a longitudinal cutting edge which is parallel or substantially parallel to the longitudinal direction of the elongate shaft.

A secondary cutting edge which is positioned on a longitudinal or side portion of the cutter reduces the drag experienced by the cutter as it is inserted at the femur-implant interface. This results in reduced damage to the surrounding tissue in the femur, as well as reducing the likelihood of the chisel snagging on biological material on any of the adjacent surfaces of the implant.

Optionally, the cutter end of the elongate shaft may be at least in part tapered, bevelled or chamfered. Additionally, or alternatively, the cutter may be at least in part tapered, bevelled or chamfered at an end which is distal to the handle end of the elongate shaft.

Shaping the leading edge of the chisel so as to eliminate sharp comers may reduce the risk of damaging the patient, and/or may also result in an easier insertion of the chisel during hip revision surgery.

Preferably, the chisel may further comprise a handle engagement element at the handle end of the elongate shaft. The handle engagement element may have a width which is greater than that of the elongate shaft.

The chisel may advantageously be provided as a hand-held tool, or could be readily engaged with one or more existing handles or grips. This could extend to computercontrolled operating machines which can precisely control the orientation of the chisel in use. The increased width of the handle engagement element may also advantageously act as a stop to prevent over-insertion of the chisel into the patient.

The elongate shaft may be formed as a contiguous plate, and/or the elongate shaft and cutter may be integrally formed with one another.

The provision of a shaft as a contiguous plate can ensure that the depth of the shaft is kept to a minimum, reducing friction with the implant and femur, which will result in as neat a cut as possible at the interface between the implant and the femur.

Preferably, the cutter may meet the elongate shaft at an angle between 90 degrees and 180 degrees, and more preferably at an angle between 120 degrees and 150 degrees.

The cutter is advantageously angled relative to a plane of the implant-contacting guide surface, as this will ensure a correct relative positioning of cutting edge to the anterior surface of the implant in use. This will make use of the chisel easier for the surgeon during hip revision surgery.

In one embodiment, the cutter may extend laterally from the longitudinal edge of the elongate shaft such that the cutter has a left-hand curvature. Alternatively, the cutter may extend laterally from the longitudinal edge of the elongate shaft such that the cutter has a right-hand curvature.

It is beneficial to provide complementary tools which can be used during hip revision surgery of either leg of a patient.

According to a second aspect of the invention, there is provided a method of loosening or separating a femoral implant along a femur-implant medial interface during hip revision surgery, the method comprising the steps of a] engaging an implant-contacting guide surface of a femoral implant explantation chisel, preferably in accordance with the first aspect of the invention, with a femoral implant such that the cutter is aligned with the femur-implant medial interface; and b] urging the implant-contacting guide surface along the femoral implant such that the arcuate cutting edge follows and separates the femur-implant medial interface.

Preferably, during step a], the implant-contacting guide surface may be engaged with an anterior surface of the femoral implant.

The ability of a surgeon to be able to loosen biological material along the entire medial surface of a femoral implant allows for the force required during the explantation to be significantly reduced. This results in less trauma to the patient undergoing hip revision surgery.

The invention will now be more particularly described, by way of example only, with reference to the accompanying drawings, in which:

Figure 1 shows an upper perspective representation of a first embodiment of a femoral implant explantation chisel, in accordance with the first aspect of the invention;

Figure 2 shows a lower perspective representation of the femoral implant explantation chisel of Figure 1;

Figure 3 shows a bottom plan representation of the femoral implant explantation chisel of Figure 1;

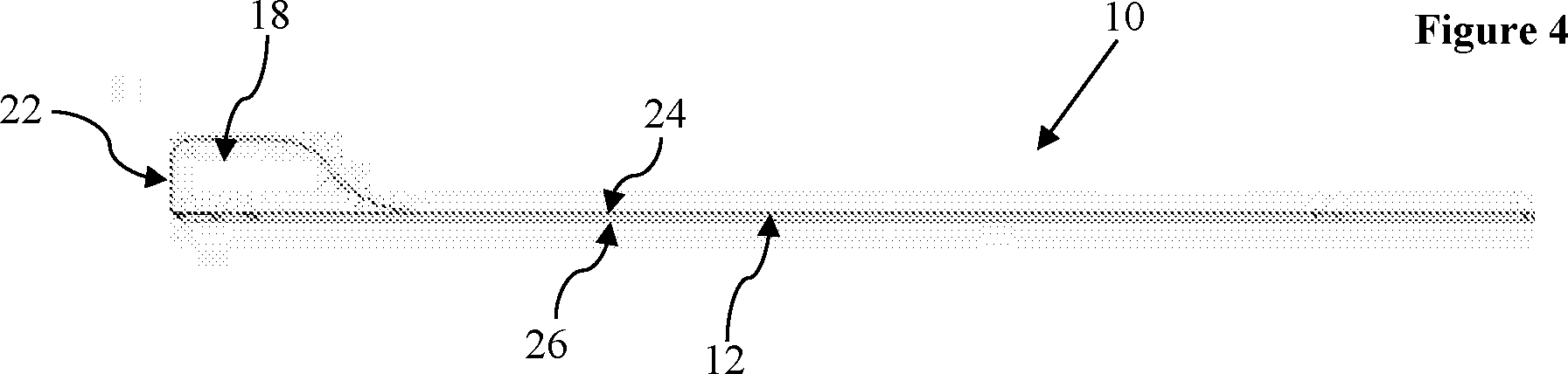

Figure 4 shows a side representation of the femoral implant explantation chisel of Figure 1;

Figure 5 shows a top plan representation of the femoral implant explantation chisel of Figure 1;

Figure 6a shows a cross-section through a femur having a femoral implant, using the femoral implant explantation chisel to loosen the femur and implant at the femurimplant medial interface in a first position;

Figure 6b shows the femoral implant explantation chisel in use as shown in Figure 6a, the femoral implant explantation chisel being in a second, more advanced position relative to the femoral implant; and

Figure 7 shows an upper perspective representation of a second embodiment of a femoral implant explantation chisel, in accordance with the first aspect of the invention.

Referring firstly to Figures 1 to 5, there is shown a femoral implant explantation chisel, indicated globally at 10, which can be used during hip revision surgery to loosen or break a femur-implant medial interface.

The femoral implant explantation chisel 10 comprises an elongate shaft 12 having first and second ends: a handle end 14 to which a handle or similar gripping or attachment means is connected or connectable for grasping or manipulation by a surgeon; and a cutter end 16, which defines a leading usable edge of the femoral implant explantation chisel 10 during a surgical procedure.

The femoral implant explantation chisel 10 also includes a cutter 18 which is connected to the elongate shaft 12 so as to extend laterally from one longitudinal edge 20 of the elongate shaft 12. The cutter 18 has an arcuate cutting edge 22 at or adjacent to the cutter end 16 of the elongate shaft 12 which is arranged to be able to cut along the femur-implant medial interface, as will be described in detail below.

The elongate shaft 12 includes an implant-contacting guide surface 24 which extends along at least part of the elongate shaft 12 from the cutter end 16. The implantcontacting guide surface 24 can be defined with respect to the curvature of the cutting edge 22; the implant-contacting guide surface 24 is the surface of the elongate shaft 12 towards which the direction of curvature of the cutting edge 22 is directed.

An opposite side of the elongate shaft 12 can therefore be deemed to have a bone-facing or -contacting surface 26, which may also act as a guide surface against osseous tissue. The bone-facing guide surface 26 can therefore be defined as being a surface of the elongate shaft 12 away from which the direction of curvature of the cutting edge 22 is directed.

The cutter 18 preferably has a cutter body having a shape having a corresponding curvature to the cutting edge 22, which is preferably arcuate in a plane perpendicular to a longitudinal extent of the elongate shaft 12, with the cutting edge 22 therefore being the leading edge of the cutter 18 when in use. Preferably, the cutting edge 22 is flush with an edge of the cutter end 16 of the elongate shaft 12, and the edge of the elongate shaft 12 could feasibly also be provided as a cutting edge.

The cutting edge 22, and preferably the body of the cutter 18, may have a tapered, chamfered or bevelled portion 28 which may assist with insertion of the femoral implant explantation chisel 10 along a femoral implant to be extracted. The cutter end 16 of the elongate shaft 12 may also have a tapered, chamfered or bevelled portion 30 for the same reason.

The body of the cutter 18 may have any shape or length along in the longitudinal direction of the elongate shaft 12. Here, the cutter 18 is formed as a curled element which is unitarily formed with the elongate shaft 12 having a length which exceeds a lateral extent of the cutting edge 22 so as to provide structural support to the cutting edge 22. A tapered, curved or sinusoidal trailing edge 32 is provided on the cutter 18 so as to avoid catching on the femoral implant or femur during explantation of the femoral implant explantation chisel 10.

The cutter 18 and/or cutting edge 22 are formed so as to meet the implant-contacting guide surface 24 and/or bone-facing guide surface 26 at an angle, which is preferably an angle between 90 degrees and 180 degrees, and more preferably an angle between 120 degrees and 150 degrees. Preferably, there is a contiguous junction along the longitudinal edge 20 where the cutter 18 meets the elongate shaft 12, such that the arc of the cutter 18 and/or cutting edge 22 meets the plane of the implant-contacting guide surface 24 so as to have a non-continuous gradient.

The body of the cutter 18 may therefore define two surfaces: an inner concave surface which faces the implant-contacting guide surface 24; and an outer convex surface which faces away from the implant-contacting guide surface 24.

In the depicted embodiment, an outermost edge 34 of the cutter 18 is provided so as to be parallel or substantially parallel to the longitudinal axis of the elongate shaft 12. Furthermore, the outermost edge 34 may be formed so as to include a longitudinal cutting edge, which may assist in reducing drag on the femoral implant explantation chisel 10 during insertion. The outermost projection of the body of the cutter 18 may also be uniform.

Preferably, the elongate shaft 12 is formed as a thin plate, having flat surfaces on both sides to form planar implant-contacting and bone-facing guide surfaces 24, 26. It is preferred that the implant-contacting and/or bone-facing guide surfaces 24, 26 are formed so as to span at least a majority of the longitudinal extent of the elongate shaft 12, and more preferably to span the entire longitudinal extent of the elongate shaft 12. This reduces the likelihood of the femoral implant explantation chisel 10 becoming wedged in the femur-implant interface.

The elongate shaft 12 may preferably be formed from a resiliently pliable biocompatible material, such as stainless steel. The cutter 18 and/or cutting edge 22 may be formed as a sharpened portion of the same material which forms the elongate shaft 12, or may alternatively be formed from a more hard-wearing or durable material which is suitable for cutting through osseous tissue. The elongate shaft 12 may preferably be formed so as to be at least in part flexible or deflectable, for example, by forming the elongate shaft 12 as a thin contiguous plate. This assists with the easy insertion of the femoral implant explantation chisel 10 into the femur-implant interface region. Preferably, the elongate shaft 12 may have a uniform depth and/or width along its longitudinal extent.

At the handle end 14 of the elongate shaft 12, there may be provided a handle engagement element 36, which may preferably have a width which is greater than that of the main body of the elongate shaft 12. This could be used to engage with a separate handle or extraction tool grip, but it will be apparent to the skilled person that the femoral implant explantation chisel 10 could be integrally formed so as to have a handle.

In use, the femoral implant explantation chisel 10 is utilised as one of several tools to extract an existing femoral implant 38, such as that shown in Figures 6a and 6b, from a femur 40, where there has been biological matter integration with the femoral implant 38. Due to the curvature of the medial surface 42 of the femoral implant 38, other chisels are unable to separate the femur and implant along the femur-implant medial interface without causing significant damage to the cortical walls of the femur.

The femoral implant explantation chisel 10 is placed such that the cutting edge 22 is aligned with an upper portion of the medial surface 42 of the femoral implant 38, with the implant-contacting guide surface 24 being placed onto an adjacent surface of the femoral implant 38. Preferably, this will be an anterior surface 44 of the femoral implant 38, making the implant-contacting guide surface 24 an implant-anteriorsurface-contact guide surface. It may, however, be feasible to use the posterior surface of the femoral implant 38 to achieve the same cut.

In non-cemented femoral implants, the anterior surface 44 is typically largely planar, which allows the implant-contacting guide surface 24 to rest against the anterior surface 44 in use, thereby providing a natural guide for the femoral implant explantation chisel

10. It will be appreciated that the implant-contacting guide surface 24 could be altered to accommodate contours in the shape of the anterior surface of the femoral implant 38, if necessary.

The surgeon performing the femoral implant extraction can then apply pressure or force to the femoral implant explantation chisel 10 so as to urge the cutting edge 22 along the femur-implant medial interface, separating the femur 40 and femoral implant 38. The implant-contacting guide surface 24, being the planar anterior surface 44 in this instance, means that the femoral implant explantation chisel 10 can be pivoted in use so that the curvature of the femur-implant medial interface is followed and separated, as can be seen from Figure 6b.

This is a significant improvement over curved chisels having a constant curvature, which cannot typically cut all of the way to the bottom of the stem 46 of the femoral implant 38. In combination with traditional chisels which are available for loosening the biological matter from the anterior, posterior and lateral surfaces of the femoral implant, much more separation between the femur and femoral implant can be achieved. In due course, this significantly reduces the force required to remove the femoral implant 38.

A second embodiment of the femoral implant explantation chisel 10’ is indicated in Figure 7. Identical or similar components to those described in relation to the first embodiment will be referred to using identical or similar reference numerals, and further detailed description is omitted for brevity.

The femoral implant explantation chisel 10’ is identical to the previously described chisel other than the cutter 18 extends laterally from an opposite longitudinal edge 20’ of the elongate shaft 12. The femoral implant explantation chisel 10’ is therefore a lefthand chisel suitable for loosening the medial surface of a left-leg femoral implant, rather than the right-hand chisel for right-leg femoral implants previously described.

The provision of a femoral implant explantation chisel which has an elongate shaft having a laterally extending cutter having an arcuate cutting edge allows for the medial surface of a femoral implant can be loosened of biological material along its entire extent. The chisel utilises one of the adjacent surfaces of the implant as a guide against which the chisel can be moved, which allows the cutting edge to closely follow the medial surface down to the very base of the stem of the femoral implant. This allows for a significant reduction in the force required to explant the femoral implant during hip revision surgery.

The words ‘comprises/comprising’ and the words ‘having/including’ when used herein with reference to the present invention are used to specify the presence of stated features, integers, steps or components, but do not preclude the presence or addition of one or more other features, integers, steps, components or groups thereof.

It is appreciated that certain features of the invention, which are, for clarity, described in the context of separate embodiments, may also be provided in combination in a single embodiment. Conversely, various features of the invention which are, for brevity, described in the context of a single embodiment, may also be provided separately or in any suitable sub-combination.

The embodiments described above are provided by way of examples only, and various other modifications will be apparent to persons skilled in the field without departing from the scope of the invention as defined herein.

Claims (23)

1. A femoral implant explantation chisel for loosening a femur-implant medial interface during hip revision surgery', the femoral implant explantation chisel comprising:

an elongate shaft having a handle end and a cutter end, the elongate shaft including an implant-contacting guide surface which extends along at least part of the elongate shaft from the cutter end for guiding the chisel along a femoral implant to be extracted; and a cutter which projects from a longitudinal edge of the implant-contacting guide surface, the cutter having an arcuate cutting edge at or adjacent to the cutter end and which extends laterally of a longitudinal extent of the elongate shaft.

2. A femoral implant explantation chisel as claimed in claim 1, wherein the implant-contacting guide surface is planar.

3. A femoral implant explantation chisel as claimed in claim 1 or claim 2, wherein the implant-contacting guide surface extends along at least a majority of the longitudinal extent of the elongate shaft.

4. A femoral implant explantation chisel as claimed in claim 3, wherein the implant-contacting guide surface extends along the full longitudinal extent of the elongate shaft.

5. A femoral implant explantation chisel as claimed in any one of the preceding claims, wherein the elongate shaft includes a bone-facing surface which is opposite to the implant-contacting guide surface, the bone-facing surface being planar and parallel to the implant-contacting guide surface.

6. A femoral implant explantation chisel as claimed in claim 5, wherein the bonefacing guide surface extends along at least a majority of the longitudinal extent of the elongate shaft.

7. A femoral implant explantation chisel as claimed in claim 6, wherein the bonefacing guide surface extends along the full longitudinal extent of the elongate shaft.

8. A femoral implant explantation chisel as claimed in any one of the preceding claims, wherein the implant-contacting guide surface is an implant-anterior-surfacecontacting guide surface.

9. A femoral implant explantation chisel as claimed in any one of the preceding claims, wherein a curvature of the cutting edge has a constant radius.

10. A femoral implant explantation chisel as claimed in any one of the preceding claims, wherein the cutter has an arcuate cross-section in a plane perpendicular to a longitudinal direction of the elongate shaft.

11. A femoral implant explantation chisel as claimed in any one of the preceding claims, wherein the cutter further comprises a longitudinal cutting edge which is parallel or substantially parallel to the longitudinal direction of the elongate shaft.

12. A femoral implant explantation chisel as claimed in any one of the preceding claims, wherein the cutter end of the elongate shaft is at least in part tapered, bevelled or chamfered.

13. A femoral implant explantation chisel as claimed in any one of the preceding claims, wherein the cutter is at least in part tapered, bevelled or chamfered at an end which is distal to the handle end of the elongate shaft.

14. A femoral implant explantation chisel as claimed in any one of the preceding claims, further comprising a handle engagement element at the handle end of the elongate shaft.

15. A femoral implant explantation chisel as claimed in claim 14, wherein the handle engagement element has a width which is greater than that of the elongate shaft.

16. A femoral implant explantation chisel as claimed in any one of the preceding claims, wherein the elongate shaft is formed as a contiguous plate.

17. A femoral implant explantation chisel as claimed in any one of the preceding claims, wherein the cutter meets the elongate shaft at an angle between 90 degrees and 180 degrees.

18. A femoral implant explantation chisel as claimed in claim 17, wherein the cutter meets the elongate shaft at an angle between 120 degrees and 150 degrees.

19. A femoral implant explantation chisel as claimed in any one of the preceding claims, wherein the elongate shaft and cutter are integrally formed with one another.

20. A femoral implant explantation chisel as claimed in any one of the preceding claims, wherein the cutter extends laterally from the longitudinal edge of the elongate shaft such that the cutter has a left-hand curvature.

21. A femoral implant explantation chisel as claimed in any one of claims 1 to 17, wherein the cutter extends laterally from the longitudinal edge of the elongate shaft such that the cutter has a right-hand curvature.

22. A method of loosening or separating a femoral implant along a femur-implant medial interface during hip revision surgery, the method comprising the steps of:

a] engaging an implant-contacting guide surface of a femoral implant explantation chisel as claimed in any one of the preceding claims with a femoral implant such that the cutter is aligned with the femur-implant medial interface; and

b] urging the implant-contacting guide surface along the femoral implant such that the arcuate cutting edge follows and separates the femur-implant medial interface.

23. A method as claimed in claim 22, wherein, during step a], the implantcontacting guide surface is engaged with an anterior surface of the femoral implant.

Intellectual

Property

Office

Application No: GB1705073.3 Examiner: Mr Tony Judge

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB1705073.3A GB2560956A (en) | 2017-03-30 | 2017-03-30 | Femoral implant explantation chisel |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB1705073.3A GB2560956A (en) | 2017-03-30 | 2017-03-30 | Femoral implant explantation chisel |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| GB201705073D0 GB201705073D0 (en) | 2017-05-17 |

| GB2560956A true GB2560956A (en) | 2018-10-03 |

Family

ID=58682808

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| GB1705073.3A Withdrawn GB2560956A (en) | 2017-03-30 | 2017-03-30 | Femoral implant explantation chisel |

Country Status (1)

| Country | Link |

|---|---|

| GB (1) | GB2560956A (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU201462U1 (en) * | 2020-08-24 | 2020-12-16 | Шароф Мажидович ДАВИРОВ | DAVIROV'S CHISEL FOR LOW-TRAUMATIC BONE OSTEOTOMY |

| EP4093339A4 (en) * | 2021-01-14 | 2023-07-19 | Simplex Designs, LLC | Prosthetic implant removal tool and tool set |

| US11890204B2 (en) | 2019-06-05 | 2024-02-06 | Simplex Designs, Llc | Implant removal tool |

| US11938032B2 (en) | 2019-06-05 | 2024-03-26 | Simplex Designs, Llc | Prosthetic implant removal tool and associated method |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SU902734A1 (en) * | 1980-03-20 | 1982-02-07 | Горьковский научно-исследовательский институт травматологии и ортопедии | Chisel |

| US6190390B1 (en) * | 1999-10-29 | 2001-02-20 | Howmedica Osteonics Corp. | Apparatus and method for creating a dome tibial osteotomy |

| US20100100097A1 (en) * | 2008-10-22 | 2010-04-22 | Wright Medical Technology, Inc. | Instruments for preparing bone implants |

| WO2011123954A1 (en) * | 2010-04-05 | 2011-10-13 | Ross Paul And Associates Ltd. | Medical implant extraction device |

-

2017

- 2017-03-30 GB GB1705073.3A patent/GB2560956A/en not_active Withdrawn

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SU902734A1 (en) * | 1980-03-20 | 1982-02-07 | Горьковский научно-исследовательский институт травматологии и ортопедии | Chisel |

| US6190390B1 (en) * | 1999-10-29 | 2001-02-20 | Howmedica Osteonics Corp. | Apparatus and method for creating a dome tibial osteotomy |

| US20100100097A1 (en) * | 2008-10-22 | 2010-04-22 | Wright Medical Technology, Inc. | Instruments for preparing bone implants |

| WO2011123954A1 (en) * | 2010-04-05 | 2011-10-13 | Ross Paul And Associates Ltd. | Medical implant extraction device |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11890204B2 (en) | 2019-06-05 | 2024-02-06 | Simplex Designs, Llc | Implant removal tool |

| US11938032B2 (en) | 2019-06-05 | 2024-03-26 | Simplex Designs, Llc | Prosthetic implant removal tool and associated method |

| RU201462U1 (en) * | 2020-08-24 | 2020-12-16 | Шароф Мажидович ДАВИРОВ | DAVIROV'S CHISEL FOR LOW-TRAUMATIC BONE OSTEOTOMY |

| EP4093339A4 (en) * | 2021-01-14 | 2023-07-19 | Simplex Designs, LLC | Prosthetic implant removal tool and tool set |

Also Published As

| Publication number | Publication date |

|---|---|

| GB201705073D0 (en) | 2017-05-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10321945B2 (en) | Method and implant system for sacroiliac joint fixation and fusion | |

| JP6184716B2 (en) | Orthopedic instrument for removing an implanted humeral stem component and method of use thereof | |

| CA2832349C (en) | Medical implant extraction device | |

| US20140236306A1 (en) | Methods and instruments for forming non-circular cartilage grafts | |

| US20060235520A1 (en) | Spinal implant apparatus, method and system | |

| GB2560956A (en) | Femoral implant explantation chisel | |

| US11938032B2 (en) | Prosthetic implant removal tool and associated method | |

| AU2013200534B2 (en) | Orthopaedic surgical saw assembly for removing an implanted glenoid component and method of using the same | |

| US9011458B2 (en) | Surgical instrument and method of disassembling a tibial prosthesis | |

| US20210353432A1 (en) | Prosthetic implant removal tool and tool set | |

| CN114302684B (en) | Implant removal tool | |

| WO2022140801A2 (en) | Prosthetic implant removal tool and associated method | |

| EP3282959B1 (en) | Sterile implant instruments and kits for flexible joint implants | |

| US11364050B2 (en) | Catheter placing instrument | |

| Gray | Total hip revision arthroplasty: Prosthesis and cement removal techniques | |

| KR101679754B1 (en) | Device for positioning Gigli saw | |

| CA3172424A1 (en) | Prosthetic implant removal tool and tool set | |

| US20240268839A1 (en) | Prosthetic implant revision tools | |

| CN116801839A (en) | Prosthetic implant removal tool and kit | |

| US20230397998A1 (en) | Orthopedic implant extraction device | |

| AU2015200417B2 (en) | Orthopaedic surgical saw assembly for removing an implanted glenoid component and method of using the same |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WAP | Application withdrawn, taken to be withdrawn or refused ** after publication under section 16(1) |