EP2236651A1 - Thermal barrier coating system for a high Titanium content superalloy substrate and method for applying the substrate with the thermal barrier system - Google Patents

Thermal barrier coating system for a high Titanium content superalloy substrate and method for applying the substrate with the thermal barrier system Download PDFInfo

- Publication number

- EP2236651A1 EP2236651A1 EP09004849A EP09004849A EP2236651A1 EP 2236651 A1 EP2236651 A1 EP 2236651A1 EP 09004849 A EP09004849 A EP 09004849A EP 09004849 A EP09004849 A EP 09004849A EP 2236651 A1 EP2236651 A1 EP 2236651A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- layer

- bondcoat

- thermal barrier

- substrate

- bondcoat layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C28/00—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D

- C23C28/30—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer

- C23C28/32—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer including at least one pure metallic layer

- C23C28/321—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer including at least one pure metallic layer with at least one metal alloy layer

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C28/00—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D

- C23C28/30—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer

- C23C28/34—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer including at least one inorganic non-metallic material layer, e.g. metal carbide, nitride, boride, silicide layer and their mixtures, enamels, phosphates and sulphates

- C23C28/345—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer including at least one inorganic non-metallic material layer, e.g. metal carbide, nitride, boride, silicide layer and their mixtures, enamels, phosphates and sulphates with at least one oxide layer

- C23C28/3455—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer including at least one inorganic non-metallic material layer, e.g. metal carbide, nitride, boride, silicide layer and their mixtures, enamels, phosphates and sulphates with at least one oxide layer with a refractory ceramic layer, e.g. refractory metal oxide, ZrO2, rare earth oxides or a thermal barrier system comprising at least one refractory oxide layer

Definitions

- the invention relates to a thermal barrier coating system for a high Titanium content superalloy substrate and a method for applying the substrate with the thermal barrier system.

- An internal combustion engine in particular a gas turbine, is desirably operated at a combustion temperature which is close to the maximum allowable temperature of hot gas bearing internal pars of the gas turbine in order to obtain a high thermal efficiency.

- parts down stream of a combustion are subject to high temperatures.

- the hot gas bearing parts are provided with measures protecting the parts from excessive heat.

- the ceramic thermal barrier coating with a metallic bondcoat layer which is located between the ceramic thermal barrier coating and the surface of the hot gas bearing part.

- the hot gas bearing part is highly stressed and therefore manufactured with a high Titanium content superalloy, since the higher Titanium content results in a higher volume fraction of strengthening Gamma prime particles in the superalloy.

- Titanium diffuses from the substrate through the metallic bondcoat layer and forms Titanium rich inclusions at the interface between the metallic bondcoat layer and the ceramic thermal barrier coating. These inclusions affect the bonding capability of the metallic bondcoat layer. Therefore, the lifespan of the ceramic thermal barrier coating is reduced and consequently the life cycle of the highly stressed parts is limited.

- a remedy to overcome this problem is to reduce the Titanium content in the highly stressed parts.

- this remedy can reduce the stability of these highly stressed parts.

- the thermal barrier coating system for a high Titanium content superalloy substrate comprises a first bondcoat layer being applied to the substrate surface and adhering thereon, a second bondcoat layer being applied to the first bondcoat layer and adhering thereon, and a thermal barrier topcoat layer made of a ceramic material and being applied to the second bondcoat layer and adhering thereon in such a way that the surface of said substrate is protected from corrosion, oxidation and high temperature thermal exposure, wherein the first bondcoat layer and the second bondcoat layer are made of metal material alloys having similar compositions but different phase structures so that the combination of both bondcoat layers is to inhibit diffusion of Titanium from the substrate material into the second bondcoat layer surface beneath the topcoat layer and to keep bondcoat functions.

- the first bondcoat layer and the second bondcoat layer provide a two-bondcoat layer to be arranged between the substrate and the thermal barrier topcoat layer.

- Titanium diffusion from the substrate to the thermal barrier topcoat layer is reduced without deteriorating the bondcoat functions such as oxidation and corrosion protection as well as bonding the thermal barrier topcoat layer.

- the combination of both layers is to reduce the Titanium diffusion and to keep bondcoat functions, so that an early failure of the ceramic thermal barrier layer is prevented.

- first bondcoat layer and the second bondcoat layer comprise the same chemical elements.

- first bondcoat layer has a Gamma prime phase structure and the second bondcoat layer preferably has a Beta phase structure.

- the second bondcoat layer has a Gamma prime phase structure and the first bondcoat layer has a Beta phase structure.

- thermal barrier topcoat layer is manufactured by an electronic beam physical vapour deposition method.

- the method for applying the substrate with the thermal barrier system comprises the steps:

- the first bondcoat layer and the second bondcoat layer comprise the same chemical elements.

- the first bondcoat layer has preferably a Gamma prime phase structure and the second bondcoat layer has preferably a Beta phase structure.

- the second bondcoat layer has preferably a Gamma prime phase structure and the first bondcoat layer has preferably a Beta phase structure.

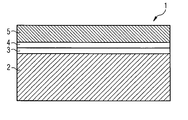

- FIG. 1 shows a cut out of a cross section of the inventive thermal barrier coating system.

- a thermal barrier coating system 1 comprises a first bondcoat layer 3, a second bondcoat layer 4 and a thermal barrier topcoat layer 5.

- the thermal barrier coating system 1 is applied to the surface of a substrate 2.

- the substrate 2 is for example a hot gas bearing part of a gas turbine and is manufactured from a high Titanium content superalloy.

- the first bondcoat layer 3 is applied to the substrate 2 surface and adheres thereon.

- the second bondcoat layer 4 is applied and adheres thereon.

- the thermal barrier topcoat layer 5 is made of a ceramic material and is applied to the second bondcoat 4 layer and adheres thereon. By means of the thermal barrier topcoat layer 5 the surface of the substrate 2 is protected from corrosion and oxidation caused by hot gas contacting the free surface of the thermal barrier topcoat layer 5.

- the first bondcoat layer 3 and the second bondcoat layer 4 are made of metal material alloys having similar compositions but different phase structures, wherein the first bondcoat layer 3 and the second bondcoat layer 4 comprise the same chemical elements. Further, the first bondcoat layer 3 has a Gamma prime phase structure and the second bondcoat layer 4 has a Beta phase structure, or, alternatively, the second bondcoat layer 4 has a Gamma prime phase structure and the first bondcoat layer 3 has a Beta phase structure.

- the thermal barrier topcoat layer 5 is applied to the second bondcoat layer 4 by an electronic beam physical vapour deposition method.

- the first bondcoat layer 3 and the second bondcoat layer 4 provide a two-bondcoat layer which is arranged between the substrate 2 and the thermal barrier topcoat layer 5.

- the Titanium diffusion from the substrate to the thermal barrier topcoat layer is reduced by means of the two-layer bondcoat layer, wherein the bondcoat functions, in particular the oxidation and the corrosion protection, as well as bonding the thermal barrier topcoat layer 5 are not deteriorated.

- the bondcoat layer containing Gamma prime phase is to inhibit diffusion of Titanium from the substrate 2 material into the second bondcoat surface beneath the topcoat 5.

- the bondcoat layer containing Beta phase is more active on corrosion and oxidation protection than the gamma prime one.

- the second bondcoat layer 4 is to keep bonding functions in order to attach the thermal barrier coating system 1 to the substrate 1. Thus, an early failure of the ceramic thermal barrier layer 5 is prevented.

Landscapes

- Chemical & Material Sciences (AREA)

- Inorganic Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Ceramic Engineering (AREA)

- Other Surface Treatments For Metallic Materials (AREA)

Abstract

Thermal barrier coating system for a high Titanium content superalloy substrate and method for applying the substrate with the thermal barrier system

A thermal barrier coating system for a high Titanium content superalloy substrate comprises a first bondcoat layer being applied to the substrate surface and adhering thereon, a second bondcoat layer being applied to the first bondcoat layer and adhering thereon, and a thermal barrier topcoat layer made of a ceramic material and being applied to the second bondcoat layer and adhering thereon in such a way that the surface of said substrate is protected from corrosion, oxidation and high temperature thermal exposure, wherein the first bondcoat layer and the second bondcoat layer are made of metal material alloys having similar compositions but different phase structures so that the combination of both bondcoat layers is to inhibit diffusion of Titanium from the substrate material into the second bondcoat layer surface beneath the topcoat layer and to keep bondcoat functions.

Description

- The invention relates to a thermal barrier coating system for a high Titanium content superalloy substrate and a method for applying the substrate with the thermal barrier system.

- An internal combustion engine, in particular a gas turbine, is desirably operated at a combustion temperature which is close to the maximum allowable temperature of hot gas bearing internal pars of the gas turbine in order to obtain a high thermal efficiency. In particular parts down stream of a combustion are subject to high temperatures. In order to increase the maximum allowable operating temperature the hot gas bearing parts are provided with measures protecting the parts from excessive heat. In particular, it is common to protect the hot gas bearing parts with a protective coating on basis of a ceramic thermal barrier coating with a thermal insulation and a corrosion and oxidation protection function.

- It is common to provide the ceramic thermal barrier coating with a metallic bondcoat layer which is located between the ceramic thermal barrier coating and the surface of the hot gas bearing part. During operation the hot gas bearing part is highly stressed and therefore manufactured with a high Titanium content superalloy, since the higher Titanium content results in a higher volume fraction of strengthening Gamma prime particles in the superalloy. However, when the rich Titanium superalloy hot gas bearing part is applied with the thermal barrier coating, Titanium diffuses from the substrate through the metallic bondcoat layer and forms Titanium rich inclusions at the interface between the metallic bondcoat layer and the ceramic thermal barrier coating. These inclusions affect the bonding capability of the metallic bondcoat layer. Therefore, the lifespan of the ceramic thermal barrier coating is reduced and consequently the life cycle of the highly stressed parts is limited.

- A remedy to overcome this problem is to reduce the Titanium content in the highly stressed parts. However, disadvantageously this remedy can reduce the stability of these highly stressed parts.

- It is an object of the invention to provide a thermal barrier coating system for a high Titanium content superalloy substrate and a method for applying the substrate with the thermal barrier system, wherein the substrate has a long life cycle and a high stability.

- According to the invention the thermal barrier coating system for a high Titanium content superalloy substrate comprises a first bondcoat layer being applied to the substrate surface and adhering thereon, a second bondcoat layer being applied to the first bondcoat layer and adhering thereon, and a thermal barrier topcoat layer made of a ceramic material and being applied to the second bondcoat layer and adhering thereon in such a way that the surface of said substrate is protected from corrosion, oxidation and high temperature thermal exposure, wherein the first bondcoat layer and the second bondcoat layer are made of metal material alloys having similar compositions but different phase structures so that the combination of both bondcoat layers is to inhibit diffusion of Titanium from the substrate material into the second bondcoat layer surface beneath the topcoat layer and to keep bondcoat functions.

- Therefore, the first bondcoat layer and the second bondcoat layer provide a two-bondcoat layer to be arranged between the substrate and the thermal barrier topcoat layer. By means of the two-layer bondcoat layer Titanium diffusion from the substrate to the thermal barrier topcoat layer is reduced without deteriorating the bondcoat functions such as oxidation and corrosion protection as well as bonding the thermal barrier topcoat layer. The combination of both layers is to reduce the Titanium diffusion and to keep bondcoat functions, so that an early failure of the ceramic thermal barrier layer is prevented.

- It is preferred that the first bondcoat layer and the second bondcoat layer comprise the same chemical elements. Further, preferably the first bondcoat layer has a Gamma prime phase structure and the second bondcoat layer preferably has a Beta phase structure. Alternatively, it is preferred that the second bondcoat layer has a Gamma prime phase structure and the first bondcoat layer has a Beta phase structure. Additionally, it is preferred that the thermal barrier topcoat layer is manufactured by an electronic beam physical vapour deposition method.

- According to the invention the method for applying the substrate with the thermal barrier system comprises the steps:

- applying a first metallic bondcoat layer on the surface of the substrate and applying a second metallic bondcoat layer on the first metallic bondcoat layer, wherein the first bondcoat layer and the second bondcoat layer have similar compositions but different phase structures; applying a ceramic thermal barrier topcoat layer by an electronic beam physical vapour deposition method.

- Preferably the first bondcoat layer and the second bondcoat layer comprise the same chemical elements. As a first alternative the first bondcoat layer has preferably a Gamma prime phase structure and the second bondcoat layer has preferably a Beta phase structure. As a second alternative, the second bondcoat layer has preferably a Gamma prime phase structure and the first bondcoat layer has preferably a Beta phase structure.

- In the following the invention is explained on the basis of a preferred embodiment with reference to the drawing. In the drawing

Fig. 1 shows a cut out of a cross section of the inventive thermal barrier coating system. - According to

Fig. 1 a thermal barrier coating system 1 comprises a first bondcoat layer 3, asecond bondcoat layer 4 and a thermalbarrier topcoat layer 5. The thermal barrier coating system 1 is applied to the surface of asubstrate 2. Thesubstrate 2 is for example a hot gas bearing part of a gas turbine and is manufactured from a high Titanium content superalloy. - The first bondcoat layer 3 is applied to the

substrate 2 surface and adheres thereon. On the surface of the first bondcoat layer 3 thesecond bondcoat layer 4 is applied and adheres thereon. The thermalbarrier topcoat layer 5 is made of a ceramic material and is applied to thesecond bondcoat 4 layer and adheres thereon. By means of the thermalbarrier topcoat layer 5 the surface of thesubstrate 2 is protected from corrosion and oxidation caused by hot gas contacting the free surface of the thermalbarrier topcoat layer 5. - The first bondcoat layer 3 and the

second bondcoat layer 4 are made of metal material alloys having similar compositions but different phase structures, wherein the first bondcoat layer 3 and thesecond bondcoat layer 4 comprise the same chemical elements. Further, the first bondcoat layer 3 has a Gamma prime phase structure and thesecond bondcoat layer 4 has a Beta phase structure, or, alternatively, thesecond bondcoat layer 4 has a Gamma prime phase structure and the first bondcoat layer 3 has a Beta phase structure. The thermalbarrier topcoat layer 5 is applied to thesecond bondcoat layer 4 by an electronic beam physical vapour deposition method. - The first bondcoat layer 3 and the

second bondcoat layer 4 provide a two-bondcoat layer which is arranged between thesubstrate 2 and the thermalbarrier topcoat layer 5. The Titanium diffusion from the substrate to the thermal barrier topcoat layer is reduced by means of the two-layer bondcoat layer, wherein the bondcoat functions, in particular the oxidation and the corrosion protection, as well as bonding the thermalbarrier topcoat layer 5 are not deteriorated. The bondcoat layer containing Gamma prime phase is to inhibit diffusion of Titanium from thesubstrate 2 material into the second bondcoat surface beneath thetopcoat 5. The bondcoat layer containing Beta phase is more active on corrosion and oxidation protection than the gamma prime one. Thesecond bondcoat layer 4 is to keep bonding functions in order to attach the thermal barrier coating system 1 to the substrate 1. Thus, an early failure of the ceramicthermal barrier layer 5 is prevented.

Claims (9)

- Thermal barrier coating system for a high Titanium content superalloy substrate (2), comprising a first bondcoat layer (3) being applied to the substrate (2) surface and adhering thereon, a second bondcoat layer (4) being applied to the first bondcoat layer (3) and adhering thereon, and a thermal barrier topcoat layer (5) made of a ceramic material and being applied to the second bondcoat (4) layer and adhering thereon in such a way that the surface of said substrate (2) is protected from corrosion, oxidation and high temperature thermal exposure, wherein the first bondcoat layer (3) and the second bondcoat layer (4) are made of metal material alloys having similar compositions but different phase structures so that the combination of both bondcoat layers (3, 4) is to inhibit diffusion of Titanium from the substrate (2) material into the second bondcoat layer (4) surface beneath the topcoat layer (5) and to keep bondcoat functions.

- Thermal barrier coating system according to claim 1, wherein the first bondcoat layer (3) and the second bondcoat layer (4) comprise the same chemical elements.

- Thermal barrier coating system according to claim 1 or 2, wherein the first bondcoat layer (3) has a Gamma prime phase structure and the second bondcoat layer (4) has a Beta phase structure.

- Thermal barrier coating system according to claim 1 or 2, wherein the second bondcoat layer (4) has a Gamma prime phase structure and the first bondcoat layer (3) has a Beta phase structure.

- Thermal barrier coating system according any of claims 1 to 4, wherein the thermal barrier topcoat layer (5) is manufactured by an electronic beam physical vapour deposition method.

- Method for applying a substrate with a thermal barrier system according to any of claims 1 to 5, comprising the steps:- applying a first metallic bondcoat layer (3) on the surface of the substrate and applying a second metallic bondcoat layer (4) on the first metallic bondcoat layer, wherein the first bondcoat layer (3) and the second bondcoat layer (4) have similar compositions but different phase structures;- applying a ceramic thermal barrier topcoat layer (5) by an electronic beam physical vapour deposition method.

- Method according to claim 6, wherein the first bondcoat layer (3) and the second bondcoat layer (4) comprise the same chemical elements.

- Method according to claim 6 or 7, wherein the first bondcoat layer (3) has a Gamma prime phase structure and the second bondcoat layer (4) has a Beta phase structure.

- Thermal barrier coating system according to claim 6 or 7, wherein the second bondcoat layer (4) has a Gamma prime phase structure and the first bondcoat layer (3) has a Beta phase structure.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP09004849A EP2236651A1 (en) | 2009-04-01 | 2009-04-01 | Thermal barrier coating system for a high Titanium content superalloy substrate and method for applying the substrate with the thermal barrier system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP09004849A EP2236651A1 (en) | 2009-04-01 | 2009-04-01 | Thermal barrier coating system for a high Titanium content superalloy substrate and method for applying the substrate with the thermal barrier system |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP2236651A1 true EP2236651A1 (en) | 2010-10-06 |

Family

ID=40801820

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09004849A Withdrawn EP2236651A1 (en) | 2009-04-01 | 2009-04-01 | Thermal barrier coating system for a high Titanium content superalloy substrate and method for applying the substrate with the thermal barrier system |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP2236651A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2021146231A1 (en) * | 2020-01-17 | 2021-07-22 | Lockheed Martin Corporation | Thermal protection system for lightweight hypersonic missile fin |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1260608A1 (en) * | 2001-05-25 | 2002-11-27 | ALSTOM (Switzerland) Ltd | Method of depositing a MCrAIY bond coating |

| EP1327702A1 (en) * | 2002-01-10 | 2003-07-16 | ALSTOM (Switzerland) Ltd | Mcraiy bond coating and method of depositing said mcraiy bond coating |

| EP1491650A1 (en) * | 2003-06-26 | 2004-12-29 | ALSTOM Technology Ltd | A method of depositing a coating system |

| EP1767667A2 (en) * | 2005-09-26 | 2007-03-28 | General Electric Company | Gamma prime phase-containing nickel aluminide coating |

| US20070190354A1 (en) * | 2006-02-13 | 2007-08-16 | Taylor Thomas A | Low thermal expansion bondcoats for thermal barrier coatings |

-

2009

- 2009-04-01 EP EP09004849A patent/EP2236651A1/en not_active Withdrawn

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1260608A1 (en) * | 2001-05-25 | 2002-11-27 | ALSTOM (Switzerland) Ltd | Method of depositing a MCrAIY bond coating |

| EP1327702A1 (en) * | 2002-01-10 | 2003-07-16 | ALSTOM (Switzerland) Ltd | Mcraiy bond coating and method of depositing said mcraiy bond coating |

| EP1491650A1 (en) * | 2003-06-26 | 2004-12-29 | ALSTOM Technology Ltd | A method of depositing a coating system |

| EP1767667A2 (en) * | 2005-09-26 | 2007-03-28 | General Electric Company | Gamma prime phase-containing nickel aluminide coating |

| US20070190354A1 (en) * | 2006-02-13 | 2007-08-16 | Taylor Thomas A | Low thermal expansion bondcoats for thermal barrier coatings |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2021146231A1 (en) * | 2020-01-17 | 2021-07-22 | Lockheed Martin Corporation | Thermal protection system for lightweight hypersonic missile fin |

| US11306387B2 (en) | 2020-01-17 | 2022-04-19 | Lockheed Martin Corporation | Thermal protection system for lightweight hypersonic missile fin |

| GB2606327A (en) * | 2020-01-17 | 2022-11-02 | Lockheed Corp | Thermal protection system for lightweight hypersonic missile fin |

| GB2606327B (en) * | 2020-01-17 | 2023-05-10 | Lockheed Corp | Thermal protection system for lightweight hypersonic missile fin |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US20210324506A1 (en) | Thermal barrier coating for gas turbine engine components | |

| US8596985B2 (en) | Method of protecting a component against hot corrosion and a component protected by said method | |

| CA2905343C (en) | Composite coatings and methods therefor | |

| US8277195B2 (en) | Coated turbine component and method of coating a turbine component | |

| JP2006193830A (en) | Multilayered environmental barrier coating and related article | |

| US20120272653A1 (en) | Internal combustion engine hot gas path component with powder metallurgy structure | |

| CA2772227C (en) | Component for a turbomachine and method for manufacturing such a component | |

| JPH11506500A (en) | Erosion and corrosion protection coatings for hot components | |

| KR102568312B1 (en) | Contoured protective coatings for compressor parts of gas turbines | |

| US20120223127A1 (en) | Components and methods of forming protective coating systems on components | |

| CN101298199A (en) | Multi-layered thermal barrier coating | |

| ATE543926T1 (en) | BIMETALLIC BONDING LAYER FOR A THERMAL INSULATION COATING ON A SUPER ALLOY | |

| US20090053554A1 (en) | Thermal barrier coating system for thermal mechanical fatigue resistance | |

| US20220081750A1 (en) | Silicon oxycarbide-based environmental barrier coating | |

| US7402347B2 (en) | In-situ formed thermal barrier coating for a ceramic component | |

| US11492692B2 (en) | Thermal barrier coating with high corrosion resistance | |

| EP2845925B1 (en) | Turbine engine, engine structure, and method of forming an engine structure with thermal barrier coating protection | |

| EP2236651A1 (en) | Thermal barrier coating system for a high Titanium content superalloy substrate and method for applying the substrate with the thermal barrier system | |

| US20160222804A1 (en) | A component for a turbomachine and a method for construction of the component | |

| US20190024243A1 (en) | Turbine engine part coated with a protective ceramic coating, method for manufacturing and for using such a part | |

| EP2857637A1 (en) | Turbine airfoil and corresponding method of manufacturing | |

| EP3048183B1 (en) | Corrosion resistant coating application method | |

| JP2013142387A (en) | Creep resistant coating for ceramic turbine blade | |

| JPH11268175A (en) | Ceramic heat-shielding coating | |

| EP2339051A1 (en) | Article having thermal barrier coating |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA RS |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20110407 |