Field of the invention

The present invention relates to a photothermographic recording

material comprising a photo-addressable thermally developable

element comprising a species which increases the infrared

sensitivity thereof.

Background of the invention.

Thermal imaging or thermography is a recording process wherein

images are generated by the use of thermal energy.

In thermography three approaches are known:

Thermographic materials of type 1 become photothermographic when

a photosensitive agent is present which after exposure to UV,

visible or IR light is capable of catalyzing or participating in a

thermographic process bringing about changes in colour or optical

density. Examples of photothermographic materials are the so called

"Dry Silver" photographic materials of the 3M Company, which are

reviewed by D.A. Morgan in "Handbook of Imaging Science", edited by

A.R. Diamond, page 43, published by Marcel Dekker in 1991.

In US-P 5,441,866 it is stated that: "While many of such dyes

(dyes which impart spectral sensitivity to a gelatino silver halide

element) provide spectral sensitization in photothermographic

formulations the dye sensitization is often very inefficient and it

is not possible to translate the performance of a dye in gelatino

silver halide elements to photothermographic elements."

US-P 5,441,866 discloses a heat-developable photothermographic

element comprising a preferably hydrophobic binder, supersensitizer,

preferably selected from the group consisting of aromatic,

heterocyclic mercapto or disulfide compounds, and a spectrally

sensitizing amount of an infrared absorbing dye having the central

nucleus:

wherein R

1 represents a (CH

2)

n-COO

- group of from 1-20 carbon atoms,

or an alkyl group of from 1 to 20 carbon atoms; and n is an integer

from 1 to 20; and EP-A 616 014 discloses a heptamethine cyanine dye

characterised in that both nitrogen atoms of the cyanine chromophore

bear a 5 carboxyalkyl substituent comprising an alkyl chain of at

least five carbon atoms, which may be used in conjunction with

supersensitizers such as 2-mercaptobenzimidazoles, metal chelating

agents and pyridine, pyrimidine and triazine derivatives.

US-P 4,873,184 discloses a spectrally sensitized silver halide

photothermographic emulsion layer comprising a reducible silver

source material as 20 to 70% by weight of said emulsion layer,

photosensitive silver halide, and a reducing agent for silver ion,

said silver halide having no latent image therein and being present

as 1.5 to 7.0% by weight of said emulsion layer and said emulsion

layer having a speed increasing effective amount of a metal

complexing agent therein in an amount equal to 0.4 to 40% by weight

of total silver in said emulsion.

WO 96/33442A discloses a heat developable, photothermographic

element comprising a support bearing at least one photosensitive,

image-forming layer comprising: (a) a photosensitive silver halide;

(b) a non-photosensitive, reducible silver source; (c) a reducing

agent for silver ions; (d) a binder; and (e) a spectrally

sensitizing amount of a compound having the central nucleus:

wherein: X is independently a thioalkyl group of from 1 to 20 carbon

atoms; n is independently 0, 1 or 2 with the total of n's being at

least 1; R

1 and R

2 represent an alkyl group of from 1 to 20 carbon

atoms other than carboxy-substituted alkyl; and A

- is an anion.

The detailed descriptions and invention examples of US-P

4,873,184, US-P 5,441,866 and WO 96/33442 are all confined to photo-addressable

thermally developable elements coated from non-aqueous

media. This reflects the standard teaching over such

photothermographic materials, but for economic, safety and

ecological reasons, it is desirable to coat such materials from

aqueous media. However, the extrapolation of materials technology

for photothermographic materials based on organic silver

salts/silver halide/reducing agent-systems coated from non-aqueous

media is by no means self-evident as is borne out by the inventors'

investigation of the spectral sensitization of such

photothermographic materials coated from aqueous media.

Objects of the invention.

It is a first object of the invention to provide a

photothermographic recording material with a high infra-red

sensitivity and excellent image-forming properties.

It is a second object of the invention to provide a

photothermographic recording material comprising a photo-addressable

thermally developable element based on a substantially light-insensitive

organic silver salt, photosensitive silver halide in

catalytic association therewith and an organic reducing agent for

the organic silver salt, which is produceable without necessitating

intermediate drying of the organic silver salt.

It is a third object of the invention to provide a photo-addressable

thermally developable element with excellent image-forming

properties, which can be coated from aqueous media.

It is a yet a still further object of the invention to provide a

recording process for a photothermographic recording material with

the above improved characteristics.

Further objects and advantages of the invention will become

apparent from the description hereinafter.

Summary of the invention

According to the present invention a photothermographic

recording material is provided comprising a support and a photo-addressable

thermally developable element includingprising a

substantially light-insensitive organic silver salt, photosensitive

silver halide in catalytic association with the substantially light-insensitive

organic silver salt and spectrally sensitized to infra-red

light with a dye, a supersensitizer for the dye, a reducing

agent in thermal working relationship with the substantially light-insensitive

organic silver salt and a binder, characterized in that

the binder comprises a water soluble polymer, a water-dispersible

polymer or a water soluble polymer and a water-dispersible polymer

and the dye corresponds to the general formula (I):

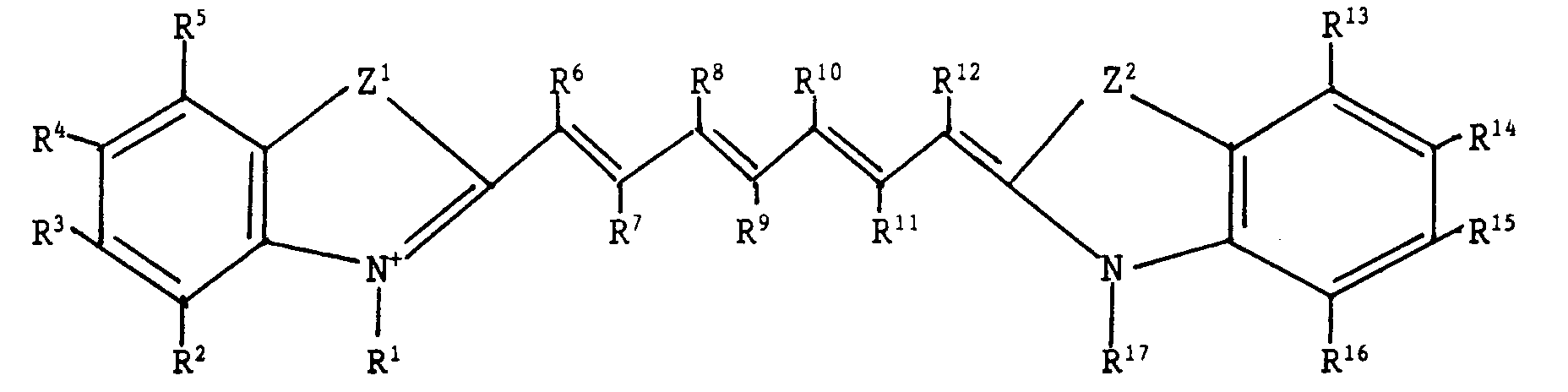

wherein Z

1 and Z

2 independently represent S, O or Se; R

1 and R

17 are

independently each an alkyl or sulfo-alkyl group which may be

substituted with at least one fluorine, chlorine, bromine, iodine or

an alkoxy-, aryloxy- or ester-group; R

2, R

3, R

4, R

5, R

13, R

14, R

15 and

R

16 are independently each hydrogen, chlorine, bromine, fluorine, a

nitro-group, a cyano-group or a keto-, sulfo-, carboxy-, ester-,

sulfonamide-, amide-, dialkylamino-, alkyl-, alkenyl-, heteroaromatic,

aryl-, alkoxy- or aryloxy-group, which groups may be

substituted; or each of R

2 together with R

3, R

3 together with R

4, R

4

together with R

5, R

13 together with R

14, R

14 together with R

15 and R

15

together with R

16 may independently constitute the atoms necessary to

complete a benzene ring which may be substituted; R

6, R

7, R

8, R

9, R

10,

R

11 and R

12 independently represent hydrogen, an alkyl group, a

substituted alkyl group, chlorine, fluorine, bromine, iodine, a

disubstituted amino group, wherein the substituents may constitute

the atoms necessary to form a 5-ring atom or 6-ring atom

heterocyclic ring, or each of R

6 together with R

8, R

8 together with

R

10, R

10 together with R

12 and R

9 together with R

11 may independently

constitute the atoms necessary to complete a 5-atom or 6-atom

carbocyclic or heterocyclic ring which may be substituted; R

7

together with R

9 may independently constitute the atoms necessary to

complete a 5-atom heterocyclic ring, a 6-atom heterocyclic ring or a

5-atom carbocyclic ring which may be substituted; each of R

1 together

with R

6 and R

12 together with R

17 may independently constitute the

atoms necessary to complete a 5-atom or 6-atom heterocyclic ring

which may be substituted; and X

- represents an anion.

A process is also provided producing a photothermographic

recording material, as referred to above, comprising the steps of:

(i) producing an aqueous dispersion or aqueous dispersions

comprising the substantially light-insensitive organic silver salt,

the photosensitive silver halide spectrally sensitized to infra-red

light with the dye, the supersensitizer for the dye, the reducing

agent and the binder; (ii) coating the aqueous dispersion or aqueous

dispersions onto a support.

A recording process for a photothermographic recording material

is further provided comprising the steps of: imagewise exposing to

infrared actinic radiation a photothermographic recording material

as referred to above or produced as referred to above and overall

heating of the photothermographic recording material.

Preferred embodiments of the present invention are disclosed in

the detailed description of the invention.

Detailed description of the invention.

Aqueous

The term aqueous for the purposes of the present invention

includes mixtures of water with water-miscible organic solvents such

as alcohols e.g. methanol, ethanol, 2-propanol, butanol, iso-amyl

alcohol, octanol, cetyl alcohol etc; glycols e.g. ethylene glycol;

glycerine; N-methyl pyrrolidone; methoxypropanol; and ketones e.g.

2-propanone and 2-butanone etc.

Spectral sensitizer

According to the present invention the photothermographic

material comprises a photo-addressable thermally developable element

comprising a dye corresponding to the general formula (I).

In a particularly preferred embodiment, according to the present

invention, in formula (I) R1 and R17 each independently represent an

alkyl group consisting of 1 to 6 carbon atoms.

In an especially preferred embodiment, according to the present

invention, the dye corresponds to the formula

Suitable infra-red sensitizing dyes for photosensitive silver

halide, according to the present invention, are the N-alkyl

benzothiazole heptamethine cyanine dyes:

the N-alkylsulfo benzothiazole heptamethine cyanine dyes:

Suitable supersensitizers for use with the dyes, used in the

present invention, are disclosed in EP-A's 559 228 and 587 338 and

in the US-P's 3,877,943 and 4,873,184.

In a particularly preferred embodiment, as used in the present

invention, the supersensitizer is a compound selected from the group

consisting of stilbene compounds, hydrazine compounds and triazine

compounds.

Particularly preferred stilbene supersensitizers, according to

the present invention, are:

According to the present invention the photo-addressable

thermally developable element includes a binder comprising a water-soluble

binder, a water-dispersible binder or a mixture of a water

soluble binder and a water-dispersible binder. An important

prerequisite in the choice of binders and binder-mixtures is their

ability to form a continuous layer with the other ingredients

present.

The water-dispersible binder can be any water-insoluble polymer

e.g. water-insoluble cellulose derivatives, polymers derived from

α,β-ethylenically unsaturated compounds such as polyvinyl chloride,

after-chlorinated polyvinyl chloride, copolymers of vinyl chloride

and vinylidene chloride, copolymers of vinyl chloride and vinyl

acetate, polyvinyl acetate and partially hydrolyzed polyvinyl

acetate, polyvinyl alcohol, polyvinyl acetals that are made from

polyvinyl alcohol as starting material in which only a part of the

repeating vinyl alcohol units may have reacted with an aldehyde,

preferably polyvinyl butyral, copolymers of acrylonitrile and

acrylamide, polyacrylic acid esters, polymethacrylic acid esters,

polystyrene and polyethylene or mixtures thereof. It should be

noted that there is no clear cut transition between a polymer

dispersion and a polymer solution in the case of very small polymer

particles resulting in the smallest particles of the polymer being

dissolved and those slightly larger being in dispersion.

Suitable water-soluble polymers, according to the present

invention, are: polyvinyl alcohol, polyacrylamide, polyacrylic acid,

polymethacrylic acid, polyethyleneglycol, proteins, such as gelatin

and modified gelatins such as phthaloyl gelatin, polysaccharides,

such as starch, gum arabic and dextran and water-soluble cellulose

derivative.

To improve the layer-forming properties of water-soluble and

water-dispersible polymers, plasticizers can be incorporated into

the polymers, water-miscible solvents can be added to the dispersion

medium and mixtures of water-soluble polymers, mixtures of water-dispersible

polymers, or mixtures of water-soluble and water-dispersible

polymers may be used.

Photo-addressable thermally developable element

The photo-addressable thermally developable element, according

to the present invention, comprises a substantially light-insensitive

organic silver salt, photosensitive silver halide in

catalytic association therewith and an organic reducing agent in

thermal working relationship with the substantially light-insensitive

organic silver salt and a water soluble or water-dispersible

binder. The element may include a layer system with the

silver halide in catalytic association with the substantially light-insensitive

organic silver salt, spectral sensitizer optionally

together with a supersensitizer in intimate sensitizing association

with the silver halide particles and the other ingredients active in

the thermal development process or pre- or post-development

stabilization of the element being in the same layer or in other

layers with the proviso that the organic reducing agent and the

toning agent, if present, are in thermal working relationship with

the substantially light-insensitive organic silver salt i.e. during

the thermal development process the reducing agent and the toning

agent, if present, are able to diffuse to the substantially light-insensitive

organic silver salt.

Light-insensitive organic silver salts

Preferred substantially light-insensitive organic silver salts

produced using the process according to the present invention and

used in the photothermographic materials, according to the present

invention, are silver salts of organic carboxylic acids having as

their organic group: aryl, aralkyl, alkaryl or alkyl. For example

aliphatic carboxylic acids known as fatty acids, wherein the

aliphatic carbon chain has preferably at least 12 C-atoms, e.g.

silver laurate, silver palmitate, silver stearate, silver

hydroxystearate, silver oleate and silver behenate, which silver

salts are also called "silver soaps". Silver salts of modified

aliphatic carboxylic acids with thioether group, as described e.g.

in GB-P 1,111,492, may likewise be used to produce a thermally

developable silver image.

In a preferred embodiment, according to the present invention,

the substantially light-insensitive organic silver salt is a silver

salt of a fatty acid.

The term substantially light-insensitive organic silver salt for

the purposes of the present invention also includes mixtures of

organic silver salts.

Binder to organic silver salt ratio

The binder to organic silver salt weight ratio is preferably in

the range of 0.2 to 6, and the thickness of the recording layer is

preferably in the range of 1 to 50 µm.

Production of particles of organic silver salt

Particles of the organic silver salts are prepared by the

reaction of a soluble silver salt with the organic carboxylic acid

or a salt thereof.

According to a process, according to the present invention, the

suspension of particles of a substantially light-insensitive organic

silver salt may be produced by simultaneous metered addition of an

aqueous solution or suspension of an organic carboxylic acid, or its

salt, and an aqueous solution of a silver salt to an aqueous liquid

and the metered addition of the aqueous solution or suspension of

the organic carboxylic acid or its salt; and/or the aqueous solution

of the silver salt is regulated by the concentration of silver ions

or the concentration of anions of the silver salt in the aqueous

liquid as disclosed in EP-A 754 969.

Photosensitive silver halide

The photosensitive silver halide used in the present invention

may be employed in a range of 0.1 to 35 mol percent of substantially

light-insensitive organic silver salt, with the range of 0.5 to 20

mol percent being preferred and the range of 1 to 12 mol percent

being particularly preferred.

The silver halide may be any photosensitive silver halide such

as silver bromide, silver iodide, silver chloride, silver

bromoiodide, silver chlorobromoiodide, silver chlorobromide etc. The

silver halide may be in any form which is photosensitive including,

but not limited to, cubic, orthorhombic, tabular, tetrahedral,

octagonal etc. and may have epitaxial growth of crystals thereon.

The silver halide used in the present invention may be employed

without modification. However, it may be chemically sensitized with

a chemical sensitizing agent such as a compound containing sulphur,

selenium, tellurium etc., or a compound containing gold, platinum,

palladium, iron, ruthenium, rhodium or iridium etc., a reducing

agent such as a tin halide etc., or a combination thereof. The

details of these procedures are described in T.H. James, "The Theory

of the Photographic Process", Fourth Edition, Macmillan Publishing

Co. Inc., New York (1977). Chapter 5, pages 149 to 169.

According to a preferred embodiment used in the present

invention, particles of the photosensitive silver halide are non-aggregating

in the photo-addressable thermally developable element

and are uniformly distributed over and between particles of the

substantially light-insensitive organic silver salt, at least 80% by

number of the particles having a diameter, determined by

transmission electron microscopy, of ≤40nm.

Emulsion of organic silver salt and photosensitive silver halide

The silver halide may be added to the photo-addressable

thermally developable element in any fashion which places it in

catalytic proximity to the substantially light-insensitive organic

silver salt. Silver halide and the substantially light-insensitive

organic silver salt which are separately formed, i.e. ex-situ or

"preformed", in a binder can be mixed prior to use to prepare a

coating solution, but it is also effective to blend both of them for

a long period of time. Furthermore, it is effective to use a process

which comprises adding a halogen-containing compound to the organic

silver salt to partially convert the substantially light-insensitive

organic silver salt to silver halide as disclosed in US-P 3,457,075.

The aqueous emulsion of the organic silver salt optionally

including photosensitive silver halide can, according to the present

invention, also be produced from particles of the organic silver

salt optionally containing photosensitive silver halide by

dispersing the particles in water in the presence of non-ionic or

anionic surfactants or a mixture of non-ionic and anionic

surfactants using any dispersion technique known to one skilled in

the art such as ball milling, dispersion in a impingement mill

(rotor-stator mixer), dispersion in a microfluidizer etc. A

combination of dispersion techniques may also be used, for example

using a first technique to produce a predispersion and a second

technique to produce a fine dispersion.

Onium halides and polyhalides

According to the present invention photosensitive silver halide

particles produced by reacting an aqueous dispersion of particles of

the substantially light-insensitive organic silver salt with at

least one onium salt with halide or polyhalide anions may be

present. Onium cations, according to the present invention, may be

polymeric or non-polymeric. Preferred non-polymeric onium salts for

partial conversion of particles of substantially light-insensitive

organic silver salt into photosensitive silver halides according to

the present invention are:

- PC01 =

- 3-(triphenyl-phosphonium)propionic acid bromide

perbromide

- PC02 =

- 3-(triphenyl-phosphonium)propionic acid bromide

- PC03 =

- 3-(triphenyl-phosphonium)propionic acid iodide

The onium salts are present in quantities of between 0.1 and

35mol % with respect to the quantity of substantially light-insensitive

organic silver salt of organic, with quantities between

0.5 and 20mol% being preferred and with quantities between 1 and

12mol % being particularly preferred.

Organic reducing agent

Suitable organic reducing agents for the reduction of the

substantially light-insensitive organic heavy metal salts are

organic compounds containing at least one active hydrogen atom

linked to O, N or C. Particularly suitable organic reducing agents

for the reduction of the substantially light-insensitive organic

silver salt, an organic reducing agent for the substantially light-insensitive

organic silver salt are non-sulfo-substituted 6-membered

aromatic or heteroaromatic ring compounds with at least three

substituents one of which is a hydroxy group at a first carbon atom

and a second of which is a hydroxy or amino-group substituted on a

second carbon atom one, three or five ring atoms removed in a system

of conjugated double bonds from the first carbon atom in the

compound, in which (i) the third substituent may be part of an

annelated carbocyclic or heterocyclic ring system; (ii) the third

substituent or a further substituent is not an aryl- or oxo-aryl-group

whose aryl group is substituted with hydroxy-, thiol- or

amino-groups; and (iii) the third substituent or a further

substituent is a non-sulfo-electron withdrawing group if the second

substituent is an amino-group.

Particularly preferred reducing agents are substituted catechols

or substitued hydroquinones with 3-(3',4'-dihydroxyphenyl)-propionic

acid, 3',4'-dihydroxy-butyrophenone, methyl gallate, ethyl gallate

and 1,5-dihydroxy-naphthalene being especially preferred.

During the thermal development process the reducing agent must

be present in such a way that it is able to diffuse to the

substantially light-insensitive organic silver salt particles so

that reduction of the substantially light-insensitive organic silver

salt can take place.

Auxiliary reducing agents

The above mentioned reducing agents, regarded as primary or main

reducing agents, may be used in conjunction with so-called auxiliary

reducing agents. Auxiliary reducing agents that may be used in

conjunction with the above mentioned primary reducing agents are

sulfonyl hydrazide reducing agents such as disclosed in US-P

5,464,738, trityl hydrazides and formyl-phenyl-hydrazides such as

disclosed in US-P 5,496,695 and organic reducing metal salts, e.g.

stannous stearate described in US-P 3,460,946 and 3,547,648.

Thermal solvents

The above mentioned binders or mixtures thereof may be used in

conjunction with waxes or "heat solvents" also called "thermal

solvents" or "thermosolvents" improving the reaction speed of the

redox-reaction at elevated temperature.

By the term "heat solvent" in this invention is meant a non-hydrolyzable

organic material which is in a solid state in the

recording layer at temperatures below 50°C, but becomes a

plasticizer for the recording layer where thermally heated and/or a

liquid solvent for at least one of the redox-reactants, e.g. the

reducing agent for the substantially light-insensitive organic

silver salt, at a temperature above 60°C.

Toning agents

In order to obtain a neutral black image tone in the higher

densities and neutral grey in the lower densities,

photothermographic materials according to the present invention may

contain one or more toning agents. The toning agents should be in

thermal working relationship with the substantially light-insensitive

organic silver salts and reducing agents during thermal

processing. Any known toning agent from thermography or

photothermography may be used.

Suitable toning agents are succinimide and the phthalimides and

phthalazinones within the scope of the general formulae described in

US-P 4,082,901 and the toning agents described in US-P 3,074,809,

US-P 3,446,648 and US-P 3,844,797. Particularly useful toning agents

are the heterocyclic toner compounds of the benzoxazine dione or

naphthoxazine dione type as described in GB-P 1,439,478 and US-P

3,951,660.

Stabilizers and antifoggants

In order to obtain improved shelf-life and reduced fogging,

stabilizers and antifoggants may be incorporated into the

photothermographic materials of the present invention. Examples of

suitable stabilizers and antifoggants and their precursors, which

can be used alone or in combination, include the thiazolium salts

described in US-P 2,131,038 and 2,694,716; the azaindenes described

in US-P 2,886,437 and 2,444,605; the urazoles described in US-P

3,287,135; the sulfocatechols described in US-P 3,235,652; the

oximes described in GB-P 623,448; the thiuronium salts described in

US-P 3,220,839; the palladium, platinum and gold salts described in

US-P 2,566,263 and 2,597,915; the tetrazolyl-thio-compounds

described in US-P 3,700,457; the mesoionic 1,2,4-triazolium-3-thiolate

stablizer precursors described in US-P 4,404,390 and

4,351,896; the tribromomethyl ketone compounds described in EP-A 600

587; the combination of isocyanate and halogenated compounds

described in EP-A 600 586; the vinyl sulfone and β-halo sulfone

compounds described in EP-A 600 589; and those compounds mentioned

in this context in Chapter 9 of "Imaging Processes and Materials,

Neblette's 8th edition", by D. Kloosterboer, edited by J. Sturge, V.

Walworth and A. Shepp. page 279, Van Nostrand (1989); in Research

Disclosure 17029 published in June 1978; and in the references cited

in all these documents.

Surfactants

Non-ionic, cationic or anionic surfactants may be used,

according to the present invention, to produce dispersions of

particles of the substantially light-insensitive organic silver salt

in aqueous media and to disperse water-dispersible binders, such as

polymer latexes, in aqueous media. In a preferred embodiment used

in the present invention the surfactant is a sulfonate e.g. alkyl,

aryl, alkaryl or aralkyl sulfonate, with alkyl and alkaryl

sulfonates being particularly preferred e.g.:

Additional ingredients

In addition to the ingredients the photothermographic material

may contain other additives such as free organic carboxylic acids,

surface-active agents, antistatic agents, e.g. non-ionic antistatic

agents including a fluorocarbon group as e.g. in

F3C(CF2)6CONH(CH2CH2O)-H, silicone oil, e.g. BAYSILONE Öl A (tradename

of BAYER AG - GERMANY), ultraviolet light absorbing compounds, white

light reflecting and/or ultraviolet radiation reflecting pigments,

silica, and/or optical brightening agents.

Antihalation dyes

According to a preferred embodiment of the present invention,

the photothermographic recording material further comprises an

antihalation or acutance dye which absorbs light which has passed

through the photosensitive layer, thereby preventing its reflection.

Such dyes may be incorporated into the photo-addressable thermally

developable element or in any other layer comprising the

photothermographic recording material of the present invention. The

antihalation dye may also be bleached either thermally during the

thermal development process or photo-bleached after removable after

the thermal development process and it may be contained in a layer

which can be removed subsequent to the exposure process. Suitable

antihalation dyes for use with infra-red light are described in the

EP-A's 377 961 and 652 473, the EP-B's 101 646 and 102 781 and the

US-P's 4,581,325 and 5,380,635.

Support

The support for the photothermographic recording material

according to the present invention may be transparent, translucent

or opaque, e.g. having a white light reflecting aspect and is

preferably a thin flexible carrier made e.g. from paper,

polyethylene coated paper or transparent resin film, e.g. made of a

cellulose ester, e.g. cellulose triacetate, corona and flame treated

polypropylene, polystyrene, polymethacrylic acid ester,

polycarbonate or polyester, e.g. polyethylene terephthalate or

polyethylene naphthalate as disclosed in GB 1,293,676, GB 1,441,304

and GB 1,454,956. For example, a paper base substrate is present

which may contain white reflecting pigments, optionally also applied

in an interlayer between the recording material and the paper base

substrate.

The support may be in sheet, ribbon or web form and subbed if

needs be to improve the adherence to the thereon coated heat-sensitive

recording layer.

Suitable subbing layers for improving the adherence of the

thermosensitive element and the antistatic layer outermost backing

layer of the present invention for polyethylene terephthalate

supports are described e.g. in GB-P 1,234,755, US-P 3,397,988;

3,649,336; 4,123,278 and US-P 4,478,907 which relates to subbing

layers applied from aqueous dispersion of sulfonated copolyesters,

and further the subbing layers described in Research Disclosure

published in Product Licensing Index, July 1967, p. 6.

Suitable pretreatments of hydrophobic resin supports are, for

example, treatment with a corona discharge and/or attack by

solvent(s), thereby providing a micro-roughening.

Protective layer

According to a preferred embodiment of the photothermographic

recording material of the present invention, the photo-addressable

thermally developable element is provided with a protective layer.

The protective layer preferably comprises a binder, which may be

solvent soluble (hydrophobic), solvent dispersible, water soluble

(hydrophilic) or water dispersible. Among the hydrophobic binders

polycarbonates as described in EP-A 614 769 are particularly

preferred. Suitable hydrophilic binders are, for example, gelatin,

polyvinylalcohol, cellulose derivatives or other polysaccharides,

hydroxyethylcellulose, hydroxypropylcellulose etc., with hardenable

binders being preferred and polyvinylalcohol being particularly

preferred.

A protective layer according to the present invention may be

crosslinked. Crosslinking can be achieved by using crosslinking

agents such as described in WO 95/12495 for protective layers. A

protective layer used in the present invention may include in

addition at least one solid lubricant having a melting point below

150°C and at least one liquid lubricant in a binder, wherein at

least one of the lubricants is a phosphoric acid derivative, further

dissolved lubricating material and/or particulate material, e.g.

talc particles, optionally protruding from the outermost layer. The

lubricant may be applied with or without a polymeric binder. Such

protective layers may also comprise particulate material, e.g. talc

particles, optionally protruding from the protective outermost layer

as described in WO 94/11198. Other additives can also be

incorporated in the protective layer e.g. colloidal particles such

as colloidal silica.

Antistatic layer

In a preferred embodiment the recording material of the present

invention an antistatic layer is applied to the outermost layer on

the side of the support not coated with the photo-addressable

thermally developable element. Suitable antistatic layers therefor

are described in EP-A's 444 326, 534 006 and 644 456, US-P's

5,364,752 and 5,472,832 and DOS 4125758.

Coating techniques

The coating of any layer of the photothermographic materials of

the present invention may proceed by any coating technique e.g. such

as described in Modern Coating and Drying Technology, edited by

Edward D. Cohen and Edgar B. Gutoff, (1992) VCH Publishers Inc. 220

East 23rd Street, Suite 909 New York, NY 10010, U.S.A.

Recording process

Photothermographic materials, according to the present

invention, may be exposed with infrared radiation at wavelengths

between 700 and 1100nm with the image either being obtained by

pixel-wise exposure with a finely focussed light source, such as an

IR wavelength laser or an IR-laser diode, e.g. emitting at 780nm,

830nm or 850nm; or by direct exposure to the object itself or an

image therefrom illuminated with IR light.

For the thermal development of image-wise exposed photothermographic

recording materials, according to the present invention, any

sort of heat source can be used that enables the recording materials

to be uniformly heated to the development temperature in a time

acceptable for the application concerned e.g. contact heating,

radiative heating, microwave heating etc.

According to the present invention a photothermographic

recording process is, in which only heat and the photothermographic

recording material are involved in the thermal development process

and the heat is supplied by conduction, convection or radiation.

Applications

The photothermographic recording materials of the present

invention can be used for both the production of transparencies and

reflection type prints. This means that the support will be

transparent or opaque, e.g. having a white light reflecting aspect.

For example, a paper base substrate is present which may contain

white reflecting pigments, optionally also applied in an interlayer

between the recording material and the paper base substrate. Should

a transparent base be used, the base may be colourless or coloured,

e.g. has a blue colour.

In the hard copy field photothermographic recording materials on

a white opaque base are used, whereas in the medical diagnostic

field black-imaged transparencies are widely used in inspection

techniques operating with a light box.

The following ingredients in addition to those mentioned above

were used in the photothermographic recording materials of the

examples and comparative examples illustrating this invention:

the following supersensitizers in addition to those mentioned above:

- * SS-08:

- 2-mercaptobenzimidazole;

- * SS-09:

- 2-mercaptobenzothiazole-5-[N-(4'-chlorophenyl)]sulfonamide.

the following IR-sensitizing dye according to US-P 5,441,866:

the following IR-sensitizing dyes according to EP-A 616 014:

and the latex binder:

- BINDER 01:

- copolymer consisting of 45% by weight of

methylmethacrylate, 45% by weight of butadiene and 10%

by weight of itaconic acid.

The following examples and comparative examples illustrate the

present invention. The percentages and ratios used in the examples

are by weight unless otherwise indicated.

COMPARATIVE EXAMPLES 1 to 5

Extrapolation of the state of the art regarding photothermographic

materials with IR-spectral sensitizers disclosed in US-P 5,441,866

and EP-A 616 014 to photothermographic materials with photo-addressable

thermally developable elements coated from aqueous

media:

Silver behenate dispersion

Silver behenate was prepared by dissolving 34g (0.1 moles) of

behenic acid in 340mL of 2-propanol at 65°C, converting the behenic

acid to sodium behenate by adding 400mL of 0.25M aqueous sodium

hydroxide to the stirred behenic acid solution and finally adding

250mL of 0.4M aqueous silver nitrate the silver behenate

precipitating out. This was filtered off and then washed with a

mixture of 10% by volume of 2-propanol and 90% by volume of

deionized water to remove residual sodium nitrate.

After drying at 45°C for 12h, the silver behenate was dispersed

in deionized water with the anionic dispersion agents Ultravon™ W

and Mersolat™ H to produce, after rapid mixing using a high speed

impingement mill (rotor-stator mixer) to obtain a paste and

homogenization with a microfluidizer, a finely divided and stable

dispersion containing 20% by weight of silver behenate, 2.1% by

weight of Ultravon™ W and 0.203% by weight of Mersolat™ H. The pH of

the resulting dispersion was adjusted to about 6.5.

The following ingredients were then added with stirring to 3.0g

of the silver behenate dispersion: 2g of a 2.22% by weight aqueous

solution of 3-(triphenyl-phosphonium)propionic acid bromide (PC02),

corresponding to a concentration of 8 mol% of PC02 with respect to

silver behenate, at a pH of 4 to accomplish in situ conversion of

part of the silver behenate to silver bromide. After 10 minutes

further stirring, the supersensitizer was added with stirring as a

solution in water and/or methanol, as specified in table 1,

immediately followed by the IR-spectral sensitizer as a solution or

dispersion in water and/or methanol as specified in table 1. After

stirring for a further 15 minutes 2g of a 30% by weight

concentration of BINDER 01 at a pH of 4 was added with stirring

followed by 2g of a 4.5% by weight aqueous solution of 3-(3',4'-dihydroxyphenyl)propionic

acid.

| Comparative example number | IR-sensitizer | supersensitizer |

| | code | Weight of solution [g] | Conc. of solution [% by wt] | code | Weight of solution [g] | Conc. of solution [% by wt] |

| 1 | SENSI C01 | 0.180 | 0.3 (MeOH) | - | - | - |

| 2 | SENSI C01 | 0.180 | 0.3 (MeOH) | SS-08 | 0.2 | 2 (MeOH) |

| 3 | SENSI C02 | 0.270 | 0.2 (MeOH) | - | - | - |

| 4 | SENSI C02 | 0.270 | 0.2 (MeOH) | SS-08 | 0.4 | 2 (MeOH) |

| 5 | SENSI C02 | 0.270 | 0.2 (MeOH) | SS-09 | 0.8 | 1 (MeOH) |

A subbed polyethylene terephthalate support having a thickness

of 100µm was doctor blade-coated with the silver behenate/silver

bromide dispersion at a blade setting of 90µm. After drying for

several minutes at 40°C on the coating bed, the emulsion layer was

dried for 1 hour in a hot air oven at 40°C.

Image-wise exposure and thermal processing

The photothermographic materials of COMPARATIVE EXAMPLES 1 to 5

were exposed to a beam of a 836nm diode laser type HL 8318G from

HITACHI with a nominal power of 12.8mW focussed to give a spot

diameter (1/e2) of 115µm , scanned at a speed of 5m/s with a pitch of

63µm and an overlap of 30% through a wedge filter with optical

density varying between 0 and 3.3 in optical density steps of 0.15.

The maximum exposure (filter optical density = 0) was about 50J/m2.

Thermal processing was carried out on a heated metal block for 5

to 15s at 105 to 115°C, as specified in table 2. The maximum and

minimum optical densities, Dmax and Dmin, of the images were measured

in transmission with a MacBeth™ TR924 densitometer through a visible

filter.

The D

max- and D

min-values obtained upon image-wise exposure and

thermal processing of the photothermographic recording materials of

COMPARATIVE EXAMPLES 1 to 5 together with the IR-sensitizer,

supersensitizer, molar ratio of supersensitizer to IR-sensitizer and

the thermal processing conditions used are summarized in table 2.

| Comparative example number | IR-sensitizer code | supersensitizer code | moles supersensitizer /mol IR-sensitizer | thermal processing conditions |

| | | | | temperature [°C] | time [s] | Dmax | Dmin |

| 1 | SENSI C01 | - | - | 105 | 15 | 0.20 | 0.20 |

| 2 | SENSI C01 | SS-08 | 36 : 1 | 105 | 15 | 0.24 | 0.14 |

| 3 | SENSI C02 | - | - | 105 | 15 | 0.25 | 0.25 |

| 4 | SENSI C02 | SS-08 | 74 : 1 | 105 | 15 | 0.13 | 0.13 |

| 5 | SENSI C02 | SS-09 | 31 : 1 | 105 | 15 | 0.65 | 0.12 |

A comparison of the results obtained for the photothermographic

recording materials of COMPARATIVE EXAMPLES 1 and 2 coated from

aqueous media, shows that no sensitization was observed with SENSI

C01 and that no supersensitization was observed with the

supersensitizer SS-08. A comparison of the results obtained for the

photothermographic recording materials of COMPARATIVE EXAMPLES 4 and

5 with those for COMPARATIVE EXAMPLE 3, shows that no sensitization

was observed with SENSI C02 and that little supersensitization was

observed with the supersensitizers SS-08 and SS-09.

These results show that the state of the art regarding infra-red

sensitization of photothermographic recording materials as

represented by example 1 of US-P 5,441,586 and example 3 of EP-A 616

014 cannot be readily extrapolated to such materials coated from

aqueous media.

INVENTION EXAMPLES 1 to 4 and COMPARATIVE EXAMPLES 6 to 8

Infra-red sensitization with dyes and supersensitizers according to

the present invention:

A dispersion of silver behenate was prepared as described for

COMPARATIVE EXAMPLES 1 to 5 and the photothermographic emulsion

prepared also as described for COMPARATIVE EXAMPLES 1 to 5 except

that the IR-sensitizer, IR-sensitizer solution, weight of IR-sensitizer

solution, supersensitizer, sensitizer solution and weight

of supersensitizer solution used for each photothermographic

emulsion is as given in table 3.

| Invention example number | IR-sensitizer | supersensitizer |

| | code | Weight of solution [g] | Conc. of solution [% by wt] | code | Weight of solution [g] | Conc. of solution [% by wt] |

| 1 | SENSI 01 | 0.18 | 0.3 (MeOH) | SS-01 | 1.2 | 0.25 (MeOH) |

| 2 | SENSI 01 | 0.18 | 0.3 (MeOH) | SS-09 | 0.8 | 1.0 (MeOH) |

| 3 | SENSI 02 | 0.18 | 0.3 (MeOH) | SS-01 | 1.2 | 0.25 (MeOH) |

| 4 | SENSI 06 | 0.046 | 0.3 (MeOH) | SS-01 | 1.2 | 0.25 (MeOH) |

| Comparative example number |

| 6 | SENSI 01 | 0.18 | 0.3 (MeOH) | - | - | - |

| 7 | SENSI 02 | 0.18 | 0.3 (MeOH) | - | - | - |

| 8 | SENSI 06 | 0.046 | 0.3 (MeOH) | - | - | - |

The photothermographic emulsions of INVENTION EXAMPLES 1 to 4

and COMPARATIVE EXAMPLES 6 to 8 were coated as described for

COMPARATIVE EXAMPLES 1 to 5 and then image-wise exposed, thermally

processed and the resulting images evaluated as described for

COMPARATIVE EXAMPLES 1 to 5.

The D

max- and D

min-values obtained upon image-wise exposure and

thermal processing of the photothermographic recording materials of

INVENTION EXAMPLES 1 to 4 and COMPARATIVE EXAMPLES 6 to 8 together

with the IR-sensitizer, supersensitizer, molar ratio of

supersensitizer to IR-sensitizer and the thermal processing

conditions used are summarized in table 4.

| Invention example number | IR-sensitizer code | supersensitizer code | moles supersensitizer /mol IR-sensitizer | thermal processink conditions |

| | | | | temperature [°C] | time [s] | Dmax | Dmin |

| 1 | SENSI 01 | SS-01 | 3 : 1 | 105 | 15 | 1.59 | 0.17 |

| 2 | SENSI 01 | SS-09 | 25 : 1 | 105 | 15 | 0.89 | 0.12 |

| 3 | SENSI 02 | SS-01 | 4 : 1 | 105 | 15 | 0.75 | 0.15 |

| 4 | SENSI 06 | SS-01 | 18 : 1 | 105 | 15 | 0.58 | 0.15 |

| Comparative example number |

| 6 | SENSI 01 | - | - | 105 | 15 | 0.30 | 0.30 |

| 7 | SENSI 02 | - | - | 105 | 15 | 0.15 | 0.15 |

| 8 | SENSI 06 | - | - | 105 | 15 | 0.25 | 0.25 |

The results in table 4 show that the IR-sensitizer dyes of the

present invention are efficiently supersensitized by stilbene-supersensitizers

(SS-01, SS-02, SS-03, SS-04 and SS-07) and

mercapto-supersensitizers (SS-09), being examples of the general

class of supersensitizers, in photothermographic recording materials

comprising photo-addressable thermally developable elements coated

from aqueous media.

Having described in detail preferred embodiments of the current

invention, it will now be apparent to those skilled in the art that

numerous modifications can be made therein without departing from

the scope of the invention as defined in the following claims.