EP0522304B1 - Natural cellulosic fibers treated with inorganic metal compounds and polycarboxylic acids - Google Patents

Natural cellulosic fibers treated with inorganic metal compounds and polycarboxylic acids Download PDFInfo

- Publication number

- EP0522304B1 EP0522304B1 EP19920109925 EP92109925A EP0522304B1 EP 0522304 B1 EP0522304 B1 EP 0522304B1 EP 19920109925 EP19920109925 EP 19920109925 EP 92109925 A EP92109925 A EP 92109925A EP 0522304 B1 EP0522304 B1 EP 0522304B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- acid

- water

- fiber

- metal compound

- natural cellulose

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000835 fiber Substances 0.000 title claims description 59

- 150000002736 metal compounds Chemical class 0.000 title claims description 51

- 239000002253 acid Substances 0.000 title claims description 46

- 150000007513 acids Chemical class 0.000 title claims description 18

- 229920003043 Cellulose fiber Polymers 0.000 claims description 45

- 238000000034 method Methods 0.000 claims description 38

- 150000003839 salts Chemical class 0.000 claims description 32

- 229910052751 metal Inorganic materials 0.000 claims description 30

- 239000002184 metal Substances 0.000 claims description 30

- 229920000742 Cotton Polymers 0.000 claims description 29

- JIAARYAFYJHUJI-UHFFFAOYSA-L zinc dichloride Chemical compound [Cl-].[Cl-].[Zn+2] JIAARYAFYJHUJI-UHFFFAOYSA-L 0.000 claims description 26

- 239000011592 zinc chloride Substances 0.000 claims description 13

- 235000005074 zinc chloride Nutrition 0.000 claims description 13

- 150000001875 compounds Chemical class 0.000 claims description 12

- GGAUUQHSCNMCAU-ZXZARUISSA-N (2s,3r)-butane-1,2,3,4-tetracarboxylic acid Chemical compound OC(=O)C[C@H](C(O)=O)[C@H](C(O)=O)CC(O)=O GGAUUQHSCNMCAU-ZXZARUISSA-N 0.000 claims description 11

- OFOBLEOULBTSOW-UHFFFAOYSA-N Malonic acid Chemical compound OC(=O)CC(O)=O OFOBLEOULBTSOW-UHFFFAOYSA-N 0.000 claims description 8

- 229910052725 zinc Inorganic materials 0.000 claims description 7

- 239000011701 zinc Substances 0.000 claims description 7

- UGZADUVQMDAIAO-UHFFFAOYSA-L zinc hydroxide Chemical compound [OH-].[OH-].[Zn+2] UGZADUVQMDAIAO-UHFFFAOYSA-L 0.000 claims description 7

- 229940007718 zinc hydroxide Drugs 0.000 claims description 7

- 229910021511 zinc hydroxide Inorganic materials 0.000 claims description 7

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 claims description 6

- MUBZPKHOEPUJKR-UHFFFAOYSA-N Oxalic acid Chemical compound OC(=O)C(O)=O MUBZPKHOEPUJKR-UHFFFAOYSA-N 0.000 claims description 6

- KRKNYBCHXYNGOX-UHFFFAOYSA-N citric acid Chemical compound OC(=O)CC(O)(C(O)=O)CC(O)=O KRKNYBCHXYNGOX-UHFFFAOYSA-N 0.000 claims description 6

- VZCYOOQTPOCHFL-UHFFFAOYSA-N trans-butenedioic acid Natural products OC(=O)C=CC(O)=O VZCYOOQTPOCHFL-UHFFFAOYSA-N 0.000 claims description 6

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 claims description 5

- 238000010438 heat treatment Methods 0.000 claims description 5

- 229910052684 Cerium Inorganic materials 0.000 claims description 4

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims description 4

- VZCYOOQTPOCHFL-OWOJBTEDSA-N Fumaric acid Chemical compound OC(=O)\C=C\C(O)=O VZCYOOQTPOCHFL-OWOJBTEDSA-N 0.000 claims description 4

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 claims description 4

- TWRXJAOTZQYOKJ-UHFFFAOYSA-L Magnesium chloride Chemical compound [Mg+2].[Cl-].[Cl-] TWRXJAOTZQYOKJ-UHFFFAOYSA-L 0.000 claims description 4

- QCWXUUIWCKQGHC-UHFFFAOYSA-N Zirconium Chemical compound [Zr] QCWXUUIWCKQGHC-UHFFFAOYSA-N 0.000 claims description 4

- WNLRTRBMVRJNCN-UHFFFAOYSA-N adipic acid Chemical compound OC(=O)CCCCC(O)=O WNLRTRBMVRJNCN-UHFFFAOYSA-N 0.000 claims description 4

- ZMIGMASIKSOYAM-UHFFFAOYSA-N cerium Chemical compound [Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce][Ce] ZMIGMASIKSOYAM-UHFFFAOYSA-N 0.000 claims description 4

- 229910052802 copper Inorganic materials 0.000 claims description 4

- 239000010949 copper Substances 0.000 claims description 4

- 150000004679 hydroxides Chemical class 0.000 claims description 4

- VZCYOOQTPOCHFL-UPHRSURJSA-N maleic acid Chemical compound OC(=O)\C=C/C(O)=O VZCYOOQTPOCHFL-UPHRSURJSA-N 0.000 claims description 4

- 239000011976 maleic acid Substances 0.000 claims description 4

- BDJRBEYXGGNYIS-UHFFFAOYSA-N nonanedioic acid Chemical compound OC(=O)CCCCCCCC(O)=O BDJRBEYXGGNYIS-UHFFFAOYSA-N 0.000 claims description 4

- CYIDZMCFTVVTJO-UHFFFAOYSA-N pyromellitic acid Chemical compound OC(=O)C1=CC(C(O)=O)=C(C(O)=O)C=C1C(O)=O CYIDZMCFTVVTJO-UHFFFAOYSA-N 0.000 claims description 4

- CXMXRPHRNRROMY-UHFFFAOYSA-N sebacic acid Chemical compound OC(=O)CCCCCCCCC(O)=O CXMXRPHRNRROMY-UHFFFAOYSA-N 0.000 claims description 4

- TYFQFVWCELRYAO-UHFFFAOYSA-N suberic acid Chemical compound OC(=O)CCCCCCC(O)=O TYFQFVWCELRYAO-UHFFFAOYSA-N 0.000 claims description 4

- 229920002994 synthetic fiber Polymers 0.000 claims description 4

- 239000012209 synthetic fiber Substances 0.000 claims description 4

- ARCGXLSVLAOJQL-UHFFFAOYSA-N trimellitic acid Chemical compound OC(=O)C1=CC=C(C(O)=O)C(C(O)=O)=C1 ARCGXLSVLAOJQL-UHFFFAOYSA-N 0.000 claims description 4

- 229910052726 zirconium Inorganic materials 0.000 claims description 4

- 244000025254 Cannabis sativa Species 0.000 claims description 3

- 235000012766 Cannabis sativa ssp. sativa var. sativa Nutrition 0.000 claims description 3

- 235000012765 Cannabis sativa ssp. sativa var. spontanea Nutrition 0.000 claims description 3

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 claims description 3

- 229910052787 antimony Inorganic materials 0.000 claims description 3

- WATWJIUSRGPENY-UHFFFAOYSA-N antimony atom Chemical compound [Sb] WATWJIUSRGPENY-UHFFFAOYSA-N 0.000 claims description 3

- 235000009120 camo Nutrition 0.000 claims description 3

- 235000005607 chanvre indien Nutrition 0.000 claims description 3

- 229910017052 cobalt Inorganic materials 0.000 claims description 3

- 239000010941 cobalt Substances 0.000 claims description 3

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 claims description 3

- 239000000194 fatty acid Substances 0.000 claims description 3

- 239000011487 hemp Substances 0.000 claims description 3

- VTHJTEIRLNZDEV-UHFFFAOYSA-L magnesium dihydroxide Chemical compound [OH-].[OH-].[Mg+2] VTHJTEIRLNZDEV-UHFFFAOYSA-L 0.000 claims description 3

- 239000000347 magnesium hydroxide Substances 0.000 claims description 3

- 229910001862 magnesium hydroxide Inorganic materials 0.000 claims description 3

- WPBNNNQJVZRUHP-UHFFFAOYSA-L manganese(2+);methyl n-[[2-(methoxycarbonylcarbamothioylamino)phenyl]carbamothioyl]carbamate;n-[2-(sulfidocarbothioylamino)ethyl]carbamodithioate Chemical compound [Mn+2].[S-]C(=S)NCCNC([S-])=S.COC(=O)NC(=S)NC1=CC=CC=C1NC(=S)NC(=O)OC WPBNNNQJVZRUHP-UHFFFAOYSA-L 0.000 claims description 3

- 239000000203 mixture Substances 0.000 claims description 3

- 229910052759 nickel Inorganic materials 0.000 claims description 3

- 229910052709 silver Inorganic materials 0.000 claims description 3

- 239000004332 silver Substances 0.000 claims description 3

- 239000001124 (E)-prop-1-ene-1,2,3-tricarboxylic acid Substances 0.000 claims description 2

- BJEPYKJPYRNKOW-REOHCLBHSA-N (S)-malic acid Chemical compound OC(=O)[C@@H](O)CC(O)=O BJEPYKJPYRNKOW-REOHCLBHSA-N 0.000 claims description 2

- RTBFRGCFXZNCOE-UHFFFAOYSA-N 1-methylsulfonylpiperidin-4-one Chemical compound CS(=O)(=O)N1CCC(=O)CC1 RTBFRGCFXZNCOE-UHFFFAOYSA-N 0.000 claims description 2

- ODGCZQFTJDEYNI-UHFFFAOYSA-N 2-methylcyclohex-3-ene-1,2-dicarboxylic acid Chemical compound OC(=O)C1(C)C=CCCC1C(O)=O ODGCZQFTJDEYNI-UHFFFAOYSA-N 0.000 claims description 2

- CTJFNNZDSZIGOM-UHFFFAOYSA-N 3-methylcyclohex-2-ene-1,1,2-tricarboxylic acid Chemical compound CC1=C(C(O)=O)C(C(O)=O)(C(O)=O)CCC1 CTJFNNZDSZIGOM-UHFFFAOYSA-N 0.000 claims description 2

- UITKHKNFVCYWNG-UHFFFAOYSA-N 4-(3,4-dicarboxybenzoyl)phthalic acid Chemical compound C1=C(C(O)=O)C(C(=O)O)=CC=C1C(=O)C1=CC=C(C(O)=O)C(C(O)=O)=C1 UITKHKNFVCYWNG-UHFFFAOYSA-N 0.000 claims description 2

- JVERADGGGBYHNP-UHFFFAOYSA-N 5-phenylbenzene-1,2,3,4-tetracarboxylic acid Chemical compound OC(=O)C1=C(C(O)=O)C(C(=O)O)=CC(C=2C=CC=CC=2)=C1C(O)=O JVERADGGGBYHNP-UHFFFAOYSA-N 0.000 claims description 2

- FEWJPZIEWOKRBE-JCYAYHJZSA-N Dextrotartaric acid Chemical compound OC(=O)[C@H](O)[C@@H](O)C(O)=O FEWJPZIEWOKRBE-JCYAYHJZSA-N 0.000 claims description 2

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 claims description 2

- 229910019142 PO4 Inorganic materials 0.000 claims description 2

- KDYFGRWQOYBRFD-UHFFFAOYSA-N Succinic acid Natural products OC(=O)CCC(O)=O KDYFGRWQOYBRFD-UHFFFAOYSA-N 0.000 claims description 2

- FEWJPZIEWOKRBE-UHFFFAOYSA-N Tartaric acid Natural products [H+].[H+].[O-]C(=O)C(O)C(O)C([O-])=O FEWJPZIEWOKRBE-UHFFFAOYSA-N 0.000 claims description 2

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 claims description 2

- 229940091181 aconitic acid Drugs 0.000 claims description 2

- 239000001361 adipic acid Substances 0.000 claims description 2

- 235000011037 adipic acid Nutrition 0.000 claims description 2

- BJEPYKJPYRNKOW-UHFFFAOYSA-N alpha-hydroxysuccinic acid Natural products OC(=O)C(O)CC(O)=O BJEPYKJPYRNKOW-UHFFFAOYSA-N 0.000 claims description 2

- 150000004645 aluminates Chemical class 0.000 claims description 2

- JFCQEDHGNNZCLN-UHFFFAOYSA-N anhydrous glutaric acid Natural products OC(=O)CCCC(O)=O JFCQEDHGNNZCLN-UHFFFAOYSA-N 0.000 claims description 2

- NIDNOXCRFUCAKQ-UHFFFAOYSA-N bicyclo[2.2.1]hept-5-ene-2,3-dicarboxylic acid Chemical compound C1C2C=CC1C(C(=O)O)C2C(O)=O NIDNOXCRFUCAKQ-UHFFFAOYSA-N 0.000 claims description 2

- KDYFGRWQOYBRFD-NUQCWPJISA-N butanedioic acid Chemical compound O[14C](=O)CC[14C](O)=O KDYFGRWQOYBRFD-NUQCWPJISA-N 0.000 claims description 2

- 150000004649 carbonic acid derivatives Chemical class 0.000 claims description 2

- GTZCVFVGUGFEME-IWQZZHSRSA-N cis-aconitic acid Chemical compound OC(=O)C\C(C(O)=O)=C\C(O)=O GTZCVFVGUGFEME-IWQZZHSRSA-N 0.000 claims description 2

- 235000015165 citric acid Nutrition 0.000 claims description 2

- IFDVQVHZEKPUSC-UHFFFAOYSA-N cyclohex-3-ene-1,2-dicarboxylic acid Chemical compound OC(=O)C1CCC=CC1C(O)=O IFDVQVHZEKPUSC-UHFFFAOYSA-N 0.000 claims description 2

- QYQADNCHXSEGJT-UHFFFAOYSA-N cyclohexane-1,1-dicarboxylate;hydron Chemical compound OC(=O)C1(C(O)=O)CCCCC1 QYQADNCHXSEGJT-UHFFFAOYSA-N 0.000 claims description 2

- STZIXLPVKZUAMV-UHFFFAOYSA-N cyclopentane-1,1,2,2-tetracarboxylic acid Chemical compound OC(=O)C1(C(O)=O)CCCC1(C(O)=O)C(O)=O STZIXLPVKZUAMV-UHFFFAOYSA-N 0.000 claims description 2

- 235000014113 dietary fatty acids Nutrition 0.000 claims description 2

- 229930195729 fatty acid Natural products 0.000 claims description 2

- 150000004665 fatty acids Chemical class 0.000 claims description 2

- 239000001530 fumaric acid Substances 0.000 claims description 2

- 229910052742 iron Inorganic materials 0.000 claims description 2

- 229910052749 magnesium Inorganic materials 0.000 claims description 2

- 239000011777 magnesium Substances 0.000 claims description 2

- 229910001629 magnesium chloride Inorganic materials 0.000 claims description 2

- 239000001630 malic acid Substances 0.000 claims description 2

- 235000011090 malic acid Nutrition 0.000 claims description 2

- 150000002739 metals Chemical class 0.000 claims description 2

- 235000006408 oxalic acid Nutrition 0.000 claims description 2

- UFOIOXZLTXNHQH-UHFFFAOYSA-N oxolane-2,3,4,5-tetracarboxylic acid Chemical compound OC(=O)C1OC(C(O)=O)C(C(O)=O)C1C(O)=O UFOIOXZLTXNHQH-UHFFFAOYSA-N 0.000 claims description 2

- 235000021317 phosphate Nutrition 0.000 claims description 2

- 150000003013 phosphoric acid derivatives Chemical class 0.000 claims description 2

- 150000004760 silicates Chemical class 0.000 claims description 2

- 239000011975 tartaric acid Substances 0.000 claims description 2

- 235000002906 tartaric acid Nutrition 0.000 claims description 2

- UFDHBDMSHIXOKF-UHFFFAOYSA-N tetrahydrophthalic acid Natural products OC(=O)C1=C(C(O)=O)CCCC1 UFDHBDMSHIXOKF-UHFFFAOYSA-N 0.000 claims description 2

- 229910052718 tin Inorganic materials 0.000 claims description 2

- GTZCVFVGUGFEME-UHFFFAOYSA-N trans-aconitic acid Natural products OC(=O)CC(C(O)=O)=CC(O)=O GTZCVFVGUGFEME-UHFFFAOYSA-N 0.000 claims description 2

- 238000004519 manufacturing process Methods 0.000 claims 2

- 150000003863 ammonium salts Chemical class 0.000 claims 1

- XAEFZNCEHLXOMS-UHFFFAOYSA-M potassium benzoate Chemical compound [K+].[O-]C(=O)C1=CC=CC=C1 XAEFZNCEHLXOMS-UHFFFAOYSA-M 0.000 claims 1

- 159000000000 sodium salts Chemical class 0.000 claims 1

- 239000004744 fabric Substances 0.000 description 94

- 239000007864 aqueous solution Substances 0.000 description 29

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 21

- 230000000052 comparative effect Effects 0.000 description 19

- 238000005406 washing Methods 0.000 description 17

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 15

- 238000007598 dipping method Methods 0.000 description 10

- QTBSBXVTEAMEQO-UHFFFAOYSA-N Acetic acid Chemical compound CC(O)=O QTBSBXVTEAMEQO-UHFFFAOYSA-N 0.000 description 9

- 239000000243 solution Substances 0.000 description 9

- 238000005303 weighing Methods 0.000 description 8

- 238000010521 absorption reaction Methods 0.000 description 7

- 239000000126 substance Substances 0.000 description 7

- -1 alkali metal salt Chemical class 0.000 description 6

- VSCWAEJMTAWNJL-UHFFFAOYSA-K aluminium trichloride Chemical compound Cl[Al](Cl)Cl VSCWAEJMTAWNJL-UHFFFAOYSA-K 0.000 description 6

- ORTQZVOHEJQUHG-UHFFFAOYSA-L copper(II) chloride Chemical compound Cl[Cu]Cl ORTQZVOHEJQUHG-UHFFFAOYSA-L 0.000 description 6

- 239000007789 gas Substances 0.000 description 6

- 229910021645 metal ion Inorganic materials 0.000 description 6

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 5

- 239000003513 alkali Substances 0.000 description 5

- 229910052783 alkali metal Inorganic materials 0.000 description 5

- 230000000844 anti-bacterial effect Effects 0.000 description 5

- 239000002781 deodorant agent Substances 0.000 description 5

- 230000001877 deodorizing effect Effects 0.000 description 5

- CDBYLPFSWZWCQE-UHFFFAOYSA-L Sodium Carbonate Chemical compound [Na+].[Na+].[O-]C([O-])=O CDBYLPFSWZWCQE-UHFFFAOYSA-L 0.000 description 4

- 229910052782 aluminium Inorganic materials 0.000 description 4

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 4

- 238000001035 drying Methods 0.000 description 4

- 230000000694 effects Effects 0.000 description 4

- 238000011156 evaluation Methods 0.000 description 4

- 229920000728 polyester Polymers 0.000 description 4

- 239000000047 product Substances 0.000 description 4

- 230000002035 prolonged effect Effects 0.000 description 4

- 229910052723 transition metal Inorganic materials 0.000 description 4

- 150000003624 transition metals Chemical class 0.000 description 4

- TUSDEZXZIZRFGC-UHFFFAOYSA-N 1-O-galloyl-3,6-(R)-HHDP-beta-D-glucose Natural products OC1C(O2)COC(=O)C3=CC(O)=C(O)C(O)=C3C3=C(O)C(O)=C(O)C=C3C(=O)OC1C(O)C2OC(=O)C1=CC(O)=C(O)C(O)=C1 TUSDEZXZIZRFGC-UHFFFAOYSA-N 0.000 description 3

- VHUUQVKOLVNVRT-UHFFFAOYSA-N Ammonium hydroxide Chemical compound [NH4+].[OH-] VHUUQVKOLVNVRT-UHFFFAOYSA-N 0.000 description 3

- 239000001263 FEMA 3042 Substances 0.000 description 3

- LRBQNJMCXXYXIU-PPKXGCFTSA-N Penta-digallate-beta-D-glucose Natural products OC1=C(O)C(O)=CC(C(=O)OC=2C(=C(O)C=C(C=2)C(=O)OC[C@@H]2[C@H]([C@H](OC(=O)C=3C=C(OC(=O)C=4C=C(O)C(O)=C(O)C=4)C(O)=C(O)C=3)[C@@H](OC(=O)C=3C=C(OC(=O)C=4C=C(O)C(O)=C(O)C=4)C(O)=C(O)C=3)[C@H](OC(=O)C=3C=C(OC(=O)C=4C=C(O)C(O)=C(O)C=4)C(O)=C(O)C=3)O2)OC(=O)C=2C=C(OC(=O)C=3C=C(O)C(O)=C(O)C=3)C(O)=C(O)C=2)O)=C1 LRBQNJMCXXYXIU-PPKXGCFTSA-N 0.000 description 3

- 235000011114 ammonium hydroxide Nutrition 0.000 description 3

- 239000011248 coating agent Substances 0.000 description 3

- 238000000576 coating method Methods 0.000 description 3

- 229960003280 cupric chloride Drugs 0.000 description 3

- 238000005342 ion exchange Methods 0.000 description 3

- 239000007788 liquid Substances 0.000 description 3

- CMOAHYOGLLEOGO-UHFFFAOYSA-N oxozirconium;dihydrochloride Chemical compound Cl.Cl.[Zr]=O CMOAHYOGLLEOGO-UHFFFAOYSA-N 0.000 description 3

- 239000011347 resin Substances 0.000 description 3

- 229920005989 resin Polymers 0.000 description 3

- HVTHJRMZXBWFNE-UHFFFAOYSA-J sodium zincate Chemical compound [OH-].[OH-].[OH-].[OH-].[Na+].[Na+].[Zn+2] HVTHJRMZXBWFNE-UHFFFAOYSA-J 0.000 description 3

- 235000015523 tannic acid Nutrition 0.000 description 3

- LRBQNJMCXXYXIU-NRMVVENXSA-N tannic acid Chemical compound OC1=C(O)C(O)=CC(C(=O)OC=2C(=C(O)C=C(C=2)C(=O)OC[C@@H]2[C@H]([C@H](OC(=O)C=3C=C(OC(=O)C=4C=C(O)C(O)=C(O)C=4)C(O)=C(O)C=3)[C@@H](OC(=O)C=3C=C(OC(=O)C=4C=C(O)C(O)=C(O)C=4)C(O)=C(O)C=3)[C@@H](OC(=O)C=3C=C(OC(=O)C=4C=C(O)C(O)=C(O)C=4)C(O)=C(O)C=3)O2)OC(=O)C=2C=C(OC(=O)C=3C=C(O)C(O)=C(O)C=3)C(O)=C(O)C=2)O)=C1 LRBQNJMCXXYXIU-NRMVVENXSA-N 0.000 description 3

- 229940033123 tannic acid Drugs 0.000 description 3

- 229920002258 tannic acid Polymers 0.000 description 3

- 238000010998 test method Methods 0.000 description 3

- IVORCBKUUYGUOL-UHFFFAOYSA-N 1-ethynyl-2,4-dimethoxybenzene Chemical compound COC1=CC=C(C#C)C(OC)=C1 IVORCBKUUYGUOL-UHFFFAOYSA-N 0.000 description 2

- XYHKNCXZYYTLRG-UHFFFAOYSA-N 1h-imidazole-2-carbaldehyde Chemical compound O=CC1=NC=CN1 XYHKNCXZYYTLRG-UHFFFAOYSA-N 0.000 description 2

- GWYFCOCPABKNJV-UHFFFAOYSA-M 3-Methylbutanoic acid Natural products CC(C)CC([O-])=O GWYFCOCPABKNJV-UHFFFAOYSA-M 0.000 description 2

- 239000005749 Copper compound Substances 0.000 description 2

- JPVYNHNXODAKFH-UHFFFAOYSA-N Cu2+ Chemical compound [Cu+2] JPVYNHNXODAKFH-UHFFFAOYSA-N 0.000 description 2

- VEXZGXHMUGYJMC-UHFFFAOYSA-N Hydrochloric acid Chemical compound Cl VEXZGXHMUGYJMC-UHFFFAOYSA-N 0.000 description 2

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 description 2

- NBIIXXVUZAFLBC-UHFFFAOYSA-N Phosphoric acid Chemical class OP(O)(O)=O NBIIXXVUZAFLBC-UHFFFAOYSA-N 0.000 description 2

- QAOWNCQODCNURD-UHFFFAOYSA-N Sulfuric acid Chemical compound OS(O)(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-N 0.000 description 2

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 2

- 125000002723 alicyclic group Chemical group 0.000 description 2

- 125000001931 aliphatic group Chemical group 0.000 description 2

- 150000001340 alkali metals Chemical class 0.000 description 2

- WNROFYMDJYEPJX-UHFFFAOYSA-K aluminium hydroxide Chemical compound [OH-].[OH-].[OH-].[Al+3] WNROFYMDJYEPJX-UHFFFAOYSA-K 0.000 description 2

- ANBBXQWFNXMHLD-UHFFFAOYSA-N aluminum;sodium;oxygen(2-) Chemical compound [O-2].[O-2].[Na+].[Al+3] ANBBXQWFNXMHLD-UHFFFAOYSA-N 0.000 description 2

- 229910021529 ammonia Inorganic materials 0.000 description 2

- 239000000908 ammonium hydroxide Substances 0.000 description 2

- 125000003118 aryl group Chemical group 0.000 description 2

- GWYFCOCPABKNJV-UHFFFAOYSA-N beta-methyl-butyric acid Natural products CC(C)CC(O)=O GWYFCOCPABKNJV-UHFFFAOYSA-N 0.000 description 2

- 230000000903 blocking effect Effects 0.000 description 2

- 125000003178 carboxy group Chemical group [H]OC(*)=O 0.000 description 2

- 150000001880 copper compounds Chemical class 0.000 description 2

- 229910001431 copper ion Inorganic materials 0.000 description 2

- ZZBBCSFCMKWYQR-UHFFFAOYSA-N copper;dioxido(oxo)silane Chemical compound [Cu+2].[O-][Si]([O-])=O ZZBBCSFCMKWYQR-UHFFFAOYSA-N 0.000 description 2

- 239000003599 detergent Substances 0.000 description 2

- 230000000855 fungicidal effect Effects 0.000 description 2

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 2

- 229910052500 inorganic mineral Inorganic materials 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- BDAGIHXWWSANSR-UHFFFAOYSA-N methanoic acid Natural products OC=O BDAGIHXWWSANSR-UHFFFAOYSA-N 0.000 description 2

- 235000010755 mineral Nutrition 0.000 description 2

- 239000011707 mineral Substances 0.000 description 2

- 229910052750 molybdenum Inorganic materials 0.000 description 2

- 239000011733 molybdenum Substances 0.000 description 2

- 229910001388 sodium aluminate Inorganic materials 0.000 description 2

- 229910000029 sodium carbonate Inorganic materials 0.000 description 2

- 238000005507 spraying Methods 0.000 description 2

- 239000002344 surface layer Substances 0.000 description 2

- 229910052719 titanium Inorganic materials 0.000 description 2

- 239000010936 titanium Substances 0.000 description 2

- 238000002834 transmittance Methods 0.000 description 2

- GETQZCLCWQTVFV-UHFFFAOYSA-N trimethylamine Chemical compound CN(C)C GETQZCLCWQTVFV-UHFFFAOYSA-N 0.000 description 2

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 2

- 229910052721 tungsten Inorganic materials 0.000 description 2

- 239000010937 tungsten Substances 0.000 description 2

- 229910052720 vanadium Inorganic materials 0.000 description 2

- GPPXJZIENCGNKB-UHFFFAOYSA-N vanadium Chemical compound [V]#[V] GPPXJZIENCGNKB-UHFFFAOYSA-N 0.000 description 2

- 239000002759 woven fabric Substances 0.000 description 2

- 150000003752 zinc compounds Chemical class 0.000 description 2

- RNFJDJUURJAICM-UHFFFAOYSA-N 2,2,4,4,6,6-hexaphenoxy-1,3,5-triaza-2$l^{5},4$l^{5},6$l^{5}-triphosphacyclohexa-1,3,5-triene Chemical compound N=1P(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP=1(OC=1C=CC=CC=1)OC1=CC=CC=C1 RNFJDJUURJAICM-UHFFFAOYSA-N 0.000 description 1

- OSWFIVFLDKOXQC-UHFFFAOYSA-N 4-(3-methoxyphenyl)aniline Chemical compound COC1=CC=CC(C=2C=CC(N)=CC=2)=C1 OSWFIVFLDKOXQC-UHFFFAOYSA-N 0.000 description 1

- QTBSBXVTEAMEQO-UHFFFAOYSA-M Acetate Chemical compound CC([O-])=O QTBSBXVTEAMEQO-UHFFFAOYSA-M 0.000 description 1

- QGZKDVFQNNGYKY-UHFFFAOYSA-O Ammonium Chemical compound [NH4+] QGZKDVFQNNGYKY-UHFFFAOYSA-O 0.000 description 1

- 241000894006 Bacteria Species 0.000 description 1

- 239000004135 Bone phosphate Substances 0.000 description 1

- VEXZGXHMUGYJMC-UHFFFAOYSA-M Chloride anion Chemical compound [Cl-] VEXZGXHMUGYJMC-UHFFFAOYSA-M 0.000 description 1

- RWSOTUBLDIXVET-UHFFFAOYSA-N Dihydrogen sulfide Chemical compound S RWSOTUBLDIXVET-UHFFFAOYSA-N 0.000 description 1

- BDAGIHXWWSANSR-UHFFFAOYSA-M Formate Chemical compound [O-]C=O BDAGIHXWWSANSR-UHFFFAOYSA-M 0.000 description 1

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 1

- LSDPWZHWYPCBBB-UHFFFAOYSA-N Methanethiol Chemical compound SC LSDPWZHWYPCBBB-UHFFFAOYSA-N 0.000 description 1

- 108010088249 Monogen Proteins 0.000 description 1

- 229910002651 NO3 Inorganic materials 0.000 description 1

- NHNBFGGVMKEFGY-UHFFFAOYSA-N Nitrate Chemical compound [O-][N+]([O-])=O NHNBFGGVMKEFGY-UHFFFAOYSA-N 0.000 description 1

- 239000004677 Nylon Substances 0.000 description 1

- QFWJMRCADKAQLV-UHFFFAOYSA-N O.[O-2].[Zn+2].[O-2].[Al+3] Chemical compound O.[O-2].[Zn+2].[O-2].[Al+3] QFWJMRCADKAQLV-UHFFFAOYSA-N 0.000 description 1

- ZLMJMSJWJFRBEC-UHFFFAOYSA-N Potassium Chemical compound [K] ZLMJMSJWJFRBEC-UHFFFAOYSA-N 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- 239000004115 Sodium Silicate Substances 0.000 description 1

- 241000191967 Staphylococcus aureus Species 0.000 description 1

- QAOWNCQODCNURD-UHFFFAOYSA-L Sulfate Chemical compound [O-]S([O-])(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-L 0.000 description 1

- FMRLDPWIRHBCCC-UHFFFAOYSA-L Zinc carbonate Chemical compound [Zn+2].[O-]C([O-])=O FMRLDPWIRHBCCC-UHFFFAOYSA-L 0.000 description 1

- 229910026551 ZrC Inorganic materials 0.000 description 1

- OTCHGXYCWNXDOA-UHFFFAOYSA-N [C].[Zr] Chemical compound [C].[Zr] OTCHGXYCWNXDOA-UHFFFAOYSA-N 0.000 description 1

- RRXGIIMOBNNXDK-UHFFFAOYSA-N [Mg].[Sn] Chemical compound [Mg].[Sn] RRXGIIMOBNNXDK-UHFFFAOYSA-N 0.000 description 1

- 229910001854 alkali hydroxide Inorganic materials 0.000 description 1

- 150000008044 alkali metal hydroxides Chemical class 0.000 description 1

- 150000001447 alkali salts Chemical class 0.000 description 1

- 229910052784 alkaline earth metal Inorganic materials 0.000 description 1

- 150000001342 alkaline earth metals Chemical class 0.000 description 1

- 229910000147 aluminium phosphate Inorganic materials 0.000 description 1

- 150000001450 anions Chemical class 0.000 description 1

- 150000001463 antimony compounds Chemical class 0.000 description 1

- 239000002585 base Substances 0.000 description 1

- 239000011324 bead Substances 0.000 description 1

- 239000011203 carbon fibre reinforced carbon Chemical group 0.000 description 1

- BVKZGUZCCUSVTD-UHFFFAOYSA-N carbonic acid Chemical class OC(O)=O BVKZGUZCCUSVTD-UHFFFAOYSA-N 0.000 description 1

- 125000002915 carbonyl group Chemical group [*:2]C([*:1])=O 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- RCJVRSBWZCNNQT-UHFFFAOYSA-N dichloridooxygen Chemical compound ClOCl RCJVRSBWZCNNQT-UHFFFAOYSA-N 0.000 description 1

- IJKVHSBPTUYDLN-UHFFFAOYSA-N dihydroxy(oxo)silane Chemical class O[Si](O)=O IJKVHSBPTUYDLN-UHFFFAOYSA-N 0.000 description 1

- XPPKVPWEQAFLFU-UHFFFAOYSA-N diphosphoric acid Chemical class OP(O)(=O)OP(O)(O)=O XPPKVPWEQAFLFU-UHFFFAOYSA-N 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 239000003063 flame retardant Substances 0.000 description 1

- 235000019253 formic acid Nutrition 0.000 description 1

- 229910052732 germanium Inorganic materials 0.000 description 1

- GNPVGFCGXDBREM-UHFFFAOYSA-N germanium atom Chemical compound [Ge] GNPVGFCGXDBREM-UHFFFAOYSA-N 0.000 description 1

- 125000005843 halogen group Chemical group 0.000 description 1

- 229910000037 hydrogen sulfide Inorganic materials 0.000 description 1

- 230000007062 hydrolysis Effects 0.000 description 1

- 238000006460 hydrolysis reaction Methods 0.000 description 1

- FAHBNUUHRFUEAI-UHFFFAOYSA-M hydroxidooxidoaluminium Chemical compound O[Al]=O FAHBNUUHRFUEAI-UHFFFAOYSA-M 0.000 description 1

- GUCFCORTBHEGRE-UHFFFAOYSA-N iron zinc zirconium Chemical compound [Fe][Zr][Zn] GUCFCORTBHEGRE-UHFFFAOYSA-N 0.000 description 1

- 238000004898 kneading Methods 0.000 description 1

- 229960002337 magnesium chloride Drugs 0.000 description 1

- 229940050906 magnesium chloride hexahydrate Drugs 0.000 description 1

- 150000002681 magnesium compounds Chemical class 0.000 description 1

- DHRRIBDTHFBPNG-UHFFFAOYSA-L magnesium dichloride hexahydrate Chemical compound O.O.O.O.O.O.[Mg+2].[Cl-].[Cl-] DHRRIBDTHFBPNG-UHFFFAOYSA-L 0.000 description 1

- 229940091250 magnesium supplement Drugs 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- VLAPMBHFAWRUQP-UHFFFAOYSA-L molybdic acid Chemical compound O[Mo](O)(=O)=O VLAPMBHFAWRUQP-UHFFFAOYSA-L 0.000 description 1

- 239000004745 nonwoven fabric Substances 0.000 description 1

- 229920001778 nylon Polymers 0.000 description 1

- 150000007524 organic acids Chemical class 0.000 description 1

- 235000005985 organic acids Nutrition 0.000 description 1

- RVTZCBVAJQQJTK-UHFFFAOYSA-N oxygen(2-);zirconium(4+) Chemical compound [O-2].[O-2].[Zr+4] RVTZCBVAJQQJTK-UHFFFAOYSA-N 0.000 description 1

- 229920002635 polyurethane Polymers 0.000 description 1

- 239000004814 polyurethane Substances 0.000 description 1

- 229910052700 potassium Inorganic materials 0.000 description 1

- 239000011591 potassium Substances 0.000 description 1

- 229940005657 pyrophosphoric acid Drugs 0.000 description 1

- 239000012266 salt solution Substances 0.000 description 1

- RMAQACBXLXPBSY-UHFFFAOYSA-N silicic acid Chemical class O[Si](O)(O)O RMAQACBXLXPBSY-UHFFFAOYSA-N 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 235000012239 silicon dioxide Nutrition 0.000 description 1

- 229910052708 sodium Inorganic materials 0.000 description 1

- 239000011734 sodium Substances 0.000 description 1

- NTHWMYGWWRZVTN-UHFFFAOYSA-N sodium silicate Chemical compound [Na+].[Na+].[O-][Si]([O-])=O NTHWMYGWWRZVTN-UHFFFAOYSA-N 0.000 description 1

- 229910052911 sodium silicate Inorganic materials 0.000 description 1

- 238000003756 stirring Methods 0.000 description 1

- 150000004763 sulfides Chemical class 0.000 description 1

- LLZRNZOLAXHGLL-UHFFFAOYSA-J titanic acid Chemical compound O[Ti](O)(O)O LLZRNZOLAXHGLL-UHFFFAOYSA-J 0.000 description 1

- WQEVDHBJGNOKKO-UHFFFAOYSA-K vanadic acid Chemical compound O[V](O)(O)=O WQEVDHBJGNOKKO-UHFFFAOYSA-K 0.000 description 1

- 239000011667 zinc carbonate Substances 0.000 description 1

- 235000004416 zinc carbonate Nutrition 0.000 description 1

- 229910000010 zinc carbonate Inorganic materials 0.000 description 1

- 150000003755 zirconium compounds Chemical class 0.000 description 1

- 229910001928 zirconium oxide Inorganic materials 0.000 description 1

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M11/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising

- D06M11/32—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with oxygen, ozone, ozonides, oxides, hydroxides or percompounds; Salts derived from anions with an amphoteric element-oxygen bond

- D06M11/36—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with oxygen, ozone, ozonides, oxides, hydroxides or percompounds; Salts derived from anions with an amphoteric element-oxygen bond with oxides, hydroxides or mixed oxides; with salts derived from anions with an amphoteric element-oxygen bond

- D06M11/44—Oxides or hydroxides of elements of Groups 2 or 12 of the Periodic Table; Zincates; Cadmates

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M11/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising

- D06M11/32—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with oxygen, ozone, ozonides, oxides, hydroxides or percompounds; Salts derived from anions with an amphoteric element-oxygen bond

- D06M11/36—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with oxygen, ozone, ozonides, oxides, hydroxides or percompounds; Salts derived from anions with an amphoteric element-oxygen bond with oxides, hydroxides or mixed oxides; with salts derived from anions with an amphoteric element-oxygen bond

- D06M11/45—Oxides or hydroxides of elements of Groups 3 or 13 of the Periodic Table; Aluminates

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M11/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising

- D06M11/32—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with oxygen, ozone, ozonides, oxides, hydroxides or percompounds; Salts derived from anions with an amphoteric element-oxygen bond

- D06M11/36—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with oxygen, ozone, ozonides, oxides, hydroxides or percompounds; Salts derived from anions with an amphoteric element-oxygen bond with oxides, hydroxides or mixed oxides; with salts derived from anions with an amphoteric element-oxygen bond

- D06M11/47—Oxides or hydroxides of elements of Groups 5 or 15 of the Periodic Table; Vanadates; Niobates; Tantalates; Arsenates; Antimonates; Bismuthates

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M11/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising

- D06M11/68—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with phosphorus or compounds thereof, e.g. with chlorophosphonic acid or salts thereof

- D06M11/70—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with phosphorus or compounds thereof, e.g. with chlorophosphonic acid or salts thereof with oxides of phosphorus; with hypophosphorous, phosphorous or phosphoric acids or their salts

- D06M11/71—Salts of phosphoric acids

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M11/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising

- D06M11/68—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with phosphorus or compounds thereof, e.g. with chlorophosphonic acid or salts thereof

- D06M11/72—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with phosphorus or compounds thereof, e.g. with chlorophosphonic acid or salts thereof with metaphosphoric acids or their salts; with polyphosphoric acids or their salts; with perphosphoric acids or their salts

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M11/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising

- D06M11/73—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with carbon or compounds thereof

- D06M11/76—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with carbon or compounds thereof with carbon oxides or carbonates

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M16/00—Biochemical treatment of fibres, threads, yarns, fabrics, or fibrous goods made from such materials, e.g. enzymatic

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M2101/00—Chemical constitution of the fibres, threads, yarns, fabrics or fibrous goods made from such materials, to be treated

- D06M2101/02—Natural fibres, other than mineral fibres

- D06M2101/04—Vegetal fibres

- D06M2101/06—Vegetal fibres cellulosic

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M2200/00—Functionality of the treatment composition and/or properties imparted to the textile material

- D06M2200/25—Resistance to light or sun, i.e. protection of the textile itself as well as UV shielding materials or treatment compositions therefor; Anti-yellowing treatments

Definitions

- the present invention relates to natural cellulose fibers having an inorganic metal compound therein, and a process for producing such fibers.

- copper compounds have antibacterial activity and fungicidal activity

- oxides of zirconium, cerium and the like have ability to absorb ultraviolet rays

- zirconium oxide and carbide have the nature of releasing heat by absorbing light.

- the metal compound is admixed with the material for preparing the synthetic fibers, so that the fibers can be given the desired function to a satisfactory extent, whereas the kneading method is in no way applicable to natural fibers such as natural cellulose fibers.

- heretofore proposed for treating natural cellulose fibers is a method of coating the surface of cellulose fibers with polyurethane or like resin containing a metal compound to cause the fibers to support the metal compound thereon (Examined Japanese Patent Publication HEI 2-10274, etc.), a method of causing cellulose fibers to support thereon the reaction product of a transition metal and tannic acid (Unexamined Japanese Patent Publications HEI 1-292169 and HEI 1-266275, etc.) and the like.

- these methods are unable to prepare natural cellulose fibers capable of retaining the imparted function for a prolonged period of time.

- the finished fibers are hard, have a poor hand and are low in washing fastness such that the deodorant properties become halved or lower when the fibers are washed repeatedly about 10 times.

- the transition metal becomes inevitably released from the fibers, for example, owing to hydrolysis when the fibers are repeatedly washed.

- the functional fibers afforded by this method are also low in washing fasteness.

- the deodorant properties become halved or lower if the fibers are repeatedly washed about 10 times.

- An object of the present invention is to provide natural cellulose fibers capable of retaining for a prolonged period of time functions imparted thereto by various metal compounds.

- Another object of the invention is to provide a process for producing such natural cellulose fibers.

- the present invention provides a natural cellulose fiber having a water-insoluble inorganic metal compound incorporated therein and having at least one heat-treated polycarboxylic acid combined therewith, the polycarboxylic acid being selected from the group consisting of polycarboxylic acids and partial salts thereof. It also provides a process for producing a natural cellulose fiber having a water-insoluble inorganic metal compound incorporated therein, the process comprising the steps of impregnating a natural cellulose fiber with a treating solution containing a water-soluble inorganic metal compound and a polycarboxylic acid, heating the fiber and insolubilizing the water-soluble inorganic metal compound incorporated in the fiber.

- the natural cellulose fiber of the present invention is characterized in that the cellulose fiber has an inorganic metal compound incorporated therein.

- fibers are coated with a resin containing a particulate metal compound admixed therewith, or a third substance, such as tannic acid, which is adsorbable by or reactive with fibers and which is caused to form a complex with a metal ion, hence the necessity of using an intermediary substance.

- the present invention does not require any support medium such as resin or other chemical substance because the natural cellulose fiber has incorporated therein an insoluble metal compound as converted from a metal ion within the fiber.

- the metal compound incorporating cellulose fiber of the present invention is less likely to release the metal compound even when repeatedly washed. The metal compound is not merely deposited on the cellulose fiber but behaves as if enclosed in the noncrystalline structure of the fiber.

- Examples of natural cellulose fibers for use in the present invention are cotton and hemp fibers. Such fibers may be in the form of a blend with polyester or like synthetic fibers. The fibers are not limited specifically in form but can be in any form such as yarns, woven fabrics, knitted fabrics or nonwoven fabrics.

- the inorganic metal compound to be incorporated into cellulose fibers is not limited specifically insofar as it is insoluble in water.

- useful inorganic metal compounds are hydroxides, carbonates, phosphates, silicates, aluminates and zirconates of metals such as copper, silver, zinc zirconium iron, cobalt, nickel, manganese, cerium, magnesium tin and antimony. At least one of these metal compounds is incorporated into the cellulose fiber.

- 0.01 to 10 wt. %, preferably 0.1 to 5 wt. %, of the metal compound is incorporated in the cellulose fiber.

- the natural cellulose fiber of the present invention is produced by causing a metal ion to penetrate into a natural cellulose fiber and converting the metal ion to a water-insoluble inorganic metal compound.

- a metal ion to penetrate into a natural cellulose fiber and converting the metal ion to a water-insoluble inorganic metal compound.

- the particulars of the process differ as will be described below.

- the process generally comprises a first bath treatment for impregnating the cellulose fiber to be treated with a water-soluble metal salt and a second bath treatment for insolubilizing the water-soluble metal salt in the fiber.

- the fiber is treated with an aqueous solution of the water-soluble metal salt so as to be impregnated with the metal salt.

- the fiber is treated with the metal salt solution, for example, by dipping, padding, spraying or coating.

- the dipping or padding method is suitable to practice.

- the dipping method is practiced by dipping the fiber in an aqueous solution containing the metal salt in an amount of 0.01 to 10 wt. % calculated as the metal concerned at room temperature to 100°C for 3 seconds to 10 minutes.

- the treatment conditions differ with the kind of fiber, and optimum conditions for the fiber to be treated are used.

- the fiber While the dipped fiber is subjected to the second bath treatment, the fiber may be washed with water and dried before the second bath treatment. Since the metal salt is soluble in water according to the invention, it is desired that the dipping treatment be changed over to the second bath treatment by way of the drying step only.

- the padding method is especially suited to woven fabrics and knitted fabrics. Stated more specifically when the padding method is resorted to, the fiber is treated as immersed in an aqueous solution containing the metal salt in an amount of 0.01 to 10 wt. % calculated as the metal at room temperature to 100°C for 3 seconds to 10 minutes, and is thereafter squeezed as by a mangle to a predetermined uniform ratio. This treatment is conducted under conditions optimum for the fiber and suitably selected.

- the padded fiber may be washed with water and dried prior to the second bath treatment to be subsequently conducted. Like the dipping method, the padding method is preferably followed by the drying step only before the second bath treatment.

- an aqueous solution of alkali, acid or alkali metal salt is caused to act on the water-soluble metal salt impregnating the fiber or deposited thereon to convert the water-soluble metal salt to a water-insoluble metal compound.

- This treatment can be carried out also by dipping, padding, spraying, coating or like method.

- the dipping or padding method is suitable to practice.

- the dipping method is usable for fibers of any form, while the padding method is suited to woven or knitted fabrics.

- the padding method is practiced by dipping the fiber subjected to the first bath treatment in an aqueous solution containing 0.01 to 10 wt. % of an alkali, acid or alkali metal salt at room temperature to 70°C for 3 seconds to 5 minutes, and thereafter squeezing the dipped fiber as by a mangle to a predetermined uniform ratio.

- the treatment is conducted under suitably selected conditions which are optimum for the fiber.

- the padded and squeezed fiber is then soaped or washed with water to completely remove the alkali, acid or alkali metal salt, and is thereafter dried, whereby a natural cellulose fiber of the invention is prepared which has a water-insoluble inorganic metal compound incorporated therein as if enclosed in the amorphous region of the fiber.

- the metal of the metal compound to be incorporated into the fiber is a transition metal, such as copper, silver, iron, cobalt, nickel, manganese, zinc, titanium, zirconium, cerium, vanadium, molybdenum or tungsten, germanium, aluminum or magnesium

- the water-soluble metal salt present in the first bath is preferably in the form of the chloride, oxychloride, sulfate, nitrate or like mineral acid salt of the metal, or the acetate, formate or like organic acid salt of the metal, while an aqueous solution of alkali is used as the second bath.

- useful alkalis are hydroxides of alkali metals, hydroxides of alkaline earth metals, ammonium hydroxide and the like, among which sodium hydroxide is preferred.

- the metal of the metal compound to be incorporated into the fiber is an metal element such as zinc, titanium, zirconium, vanadium, molybdenum, tungsten, aluminum, silicon, tin or antimony

- an aqueous solution which contains as an anion the oxide of the metal element prepared by dissolving the element or a salt thereof with an alkali hydroxide or ammonium hydroxide, and to use an aqueous solution of acid as the second bath.

- useful acids are hydrochloric acid, sulfuric acid and like mineral acids, formic acid, acetic acid and like water-soluble organic acids, etc., among which acetic acid is desirable.

- the natural cellulose fiber to be treated can be impregnated with a water-soluble metal salt using the first bath and thereafter passed through an aqueous solution of another water-soluble metal salt serving as the second bath to form a water-insoluble inorganic metal salt in the fiber.

- the water-soluble metal salt for use in the first bath is any water-soluble metal salt other than the salts of alkali metals.

- the water-soluble metal salt for use in the second bath is any inorganic metal salt which becomes insoluble in water when reacting with the metal salt of the first bath.

- salts examples include alkali salts of carbonic acid, phosphoric acid, pyrophosphoric acid, metasilicic acid, silicic acid, zincic acid, aluminic acid, titanic acid, molybdic acid, vanadic acid, zirconic acid and the like, alkali sulfides, etc.

- the metal compound incorporated in the fiber imparts to the fiber deodorizing, antibacterial and fungicidal effects when the compound is, for example, a zinc or copper compound, a deodorizing effect when the compound is an aluminum or magnesium compound, effects to accumulate heat, block ultraviolet rays and radiate far infrared rays when the compound is a zirconium compound, or flame retardant effect when the compound is an antimony compound.

- An enhanced deodorant effect is available when at least one member selected from polycarboxylic acids and partial salts thereof is used in combination with the water-soluble inorganic metal compound.

- partial salt of polycarboxylic acid used herein refers to a salt thereof having at least one free carboxyl group remaining after the reaction of all carboxyl groups with a base.

- polycarboxylic acids are straight-chain or branched-chain aliphatic polycarboxylic acids, alicyclic polycarboxylic acids, aromatic polycarboxylic acids, etc. These acids may be those having a hydroxyl group, halogen atom, carbonyl group or carbon-carbon double bond.

- polycarboxylic acids are oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, suberic acid, azelaic acid, sebacic acid, corresponding branched fatty acids, maleic acid, fumaric acid, cyclohexanedicarboxylic acid and corresponding position isomers and like aliphatic dibasic acids; tetrahydrophthalic acid, nadic acid and like alicyclic dibasic acids; tricarbaryl acid, aconitic acid, methylcyclohexenetricarboxylic acid and like tribasic acids; butanetetracarboxylic acid, cyclopentanetetracarboxylic acid, tetrahydrofurantetracarboxylic acid, an ene adduct of methyltetrahydrophthalic acid with maleic acid and like tetrabasic acids; malic acid, tartaric acid, citric acid and like hydroxy-fatty acids,

- Useful metal ions constituting a partial salt of polycarboxylic acid are sodium, potassium, ammonium, etc.

- the polycarboxylic acid or partial salt thereof is used in combination with the water-soluble metal compound

- the polycarboxylic acid or partial salt is impregnated into and deposited on the cellulose fiber together with the water-soluble metal compound and heat-treated and then the water-soluble metal compound is insolubilized, or alternatively the water-soluble metal compound is insolublized first and the treated cellulose fiber is dipped in an aqueous solution of polycarboxylic acid or the like, followed by heat treatment.

- the present invention provides natural cellulose fibers capable of retaining for a prolonged period of time the functions imparted thereto by various metal compounds.

- the natural cellulose fiber of the present invention which has the insoluble inorganic metal compound incorporated therein, is excellent in washing fastness, therefore less likely to release the metal compound even if washed repeatedly and capable of retaining the function imparted by the metal compound for a prolonged period of time.

- the natural cellulose fiber of the invention is fully satisfactory also in hand.

- a cotton fabric weighing 120 g/m 2 was scoured, bleached and mercerized.

- the fabric was then dipped in an aqueous solution containing 1.16% of zinc chloride, thereafter squeezed with a mangle and dried at 100° C to incorporate zinc chloride into the cotton fabric.

- the fabric was subsequently dipped in an aqueous solution containing 1.0% of sodium hydroxide for 3 seconds, then squeezed with the mangle, washed with water immediately after squeezing and dried to obtain a cotton fabric having zinc hydroxide incorporated therein.

- the fabric was found to contain 4100 mg/kg of zinc hydroxide by the atomic absorption method.

- a polyester/cotton blended yarn fabric weighing 150 g/m 2 was bleached in the usual manner, then dyed, dipped in an aqueous solution containing 1.6% of zinc chloride and thereafter squeezed with a mangle. Subsequently, the fabric was dipped in an aqueous solution containing 1.0% of sodium hydroxide for 3 seconds, then squeezed with the mangle, further dipped in an aqueous solution containing 6.9% of butanetetracarboxylic acid and 1.2% of sodium carbonate and thereafter squeezed with the mangle. The fabric was dried at 120° C and cured at 160°C for 2 minutes to obtain a butanetetracarboxylic acid crosslinked fabric having zinc hydroxide incorporated therein. The fabric was found to contain 3100 mg/kg of zinc hydroxide by the atomic absorption method.

- Example 1 The same fabric as in Example 1 was treated in the same manner as in Example 1 except that the treating solutions were free from zinc chloride or butanetetracarboxylic acid.

- a cotton fabric weighing 120 g/m 2 was scoured, bleached and mercerized.

- the fabric was then dipped in an aqueous solution containing 10% of aluminum chloride, thereafter squeezed with a mangle and dried at 60°C to incorporate aluminum chloride into the fabric.

- the fabric was dipped in an aqueous solution containing 1.0% of sodium hydroxide for 3 seconds, then squeezed with the mangle, washed with water immediately after squeezing and dried to obtain a cotton fabric having aluminum hydroxide incorporated therein.

- the weight of the fabric measured indicated that the fabric contained 18500 mg/kg of aluminum hydroxide.

- a cotton fabric weighing 120 g/m 2 was scoured, bleached and mercerized.

- the fabric was then dipped in an aqueous solution containing 20% of zirconium oxychloride, thereafter squeezed with a mangle and dried at 50°C to incorporate zirconium oxychloride into the fabric.

- the fabric was dipped in an aqueous solution containing 1.0% of sodium hydroxide for 3 seconds, then squeezed with the mangle, washed with water immediately after squeezing and dried to obtain a cotton fabric having zirconium hydroxide incorporated therein.

- the weight of the fabric measured indicated that the fabric contained 43000 mg/kg of zirconium hydroxide.

- a cotton fabric weighing 120 g/m 2 was scoured, bleached and mercerized.

- the fabric was then dipped in an aqueous solution containing 0.45% of magnesium chloride hexahydrate and thereafter squeezed with a mangle. Subsequently, the fabric was dipped in an aqueous solution containing 0.5% of sodium hydroxide for 3 seconds, further dipped in an aqueous solution containing 2.5% of butanetetracarboxylic acid and 0.45% of sodium carbonate and thereafter squeezed with the mangle.

- the fabric was dried at 120°C and cured at 160°C for 2 minutes to obtain a butanetetracarboxylic acid crosslinked fabric having magnesium hydroxide incorporated therein.

- the fabric was found to have a magnesium hydroxide content of 1200 mg/kg by the atomic absorption method.

- Example 2 The same cotton fabric as used in Example 2 was treated in the same manner as in Example 2 except that the treating solutions were free from magnesium chloride or butanetetracarboxylic acid.

- a cotton fabric weighing 120 g/m 2 was scoured, bleached and mercerized.

- the fabric was then dipped for 3 minutes in an aqueous solution of sodium zincate which was prepared in advance by mixing together 5% zinc carbonate and 30% sodium hydroxide with stirring.

- the fabric was squeezed with a mangle and dried at 100°C to obtain a cotton fabric having sodium zincate incorporated therein.

- the fabric was dipped in 0.4% aqueous solution of acetic acid for 3 seconds, squeezed with the mangle, washed with water and dried to obtain a cotton fabric having zinc hydroxide incorporated therein.

- the fabric was found to have a zinc hydroxide content of 25700 mg/kg by the atomic absorption method.

- a cotton fabric weighing 120 g/m 2 was scoured, bleached and mercerized.

- the fabric was then dipped in an aqueous solution containing 1% of cupric chloride, thereafter squeezed with a mangle and dried at 80°C to incorporate cupric chloride into the fabric.

- the fabric was dipped in an aqueous solution containing 1.0% of sodium silicate for 3 seconds, then squeezed with the mangle, washed with water immediately after squeezing and dried to obtain a cotton fabric having cupric silicate incorporated therein.

- the fabric was found to have a cupric silicate content of 4800 mg/kg by the atomic absorption method.

- a cotton fabric weighing 120 g/m 2 was scoured, bleached and mercerized.

- the fabric was then dipped in an aqueous solution containing 8% of zinc chloride, thereafter squeezed with a mangle and dried at 80° C to incorporate zinc chloride into the fabric.

- the fabric was dipped in an aqueous solution containing 1.0% of sodium aluminate for 3 seconds, then squeezed with the mangle, washed with water immediately after squeezing and dried to obtain a cotton fabric having incorporated therein zinc aluminate (aluminum oxide zinc oxide hydrate).

- the fabric was found to have a zinc aluminate content of 38100 mg/kg by the atomic absorption method.

- the untreated fabric 1 was dipped in an aqueous solution containing 1.16% of zinc chloride, squeezed with a mangle and dried at 100°C to obtain a cotton fabric having zinc chloride incorporated therein.

- the fabric was found to have a zinc chloride content of 5600 mg/kg by the atomic absorption method.

- a gaseous or liquid compound releasing an offensive odor and having a specified concentration was then injected into the flask from its top using a microsyringe and allowed to stand for 60 minutes.

- the compound, when liquid, was evaporated by heating with a hot air gun and thereafter allowed to stand.

- the same gas or liquid was also injected into a flask containing no fabric sample and allowed to stand. After standing, the gas concentration was measured using a Kitagawa gas sensor tube.

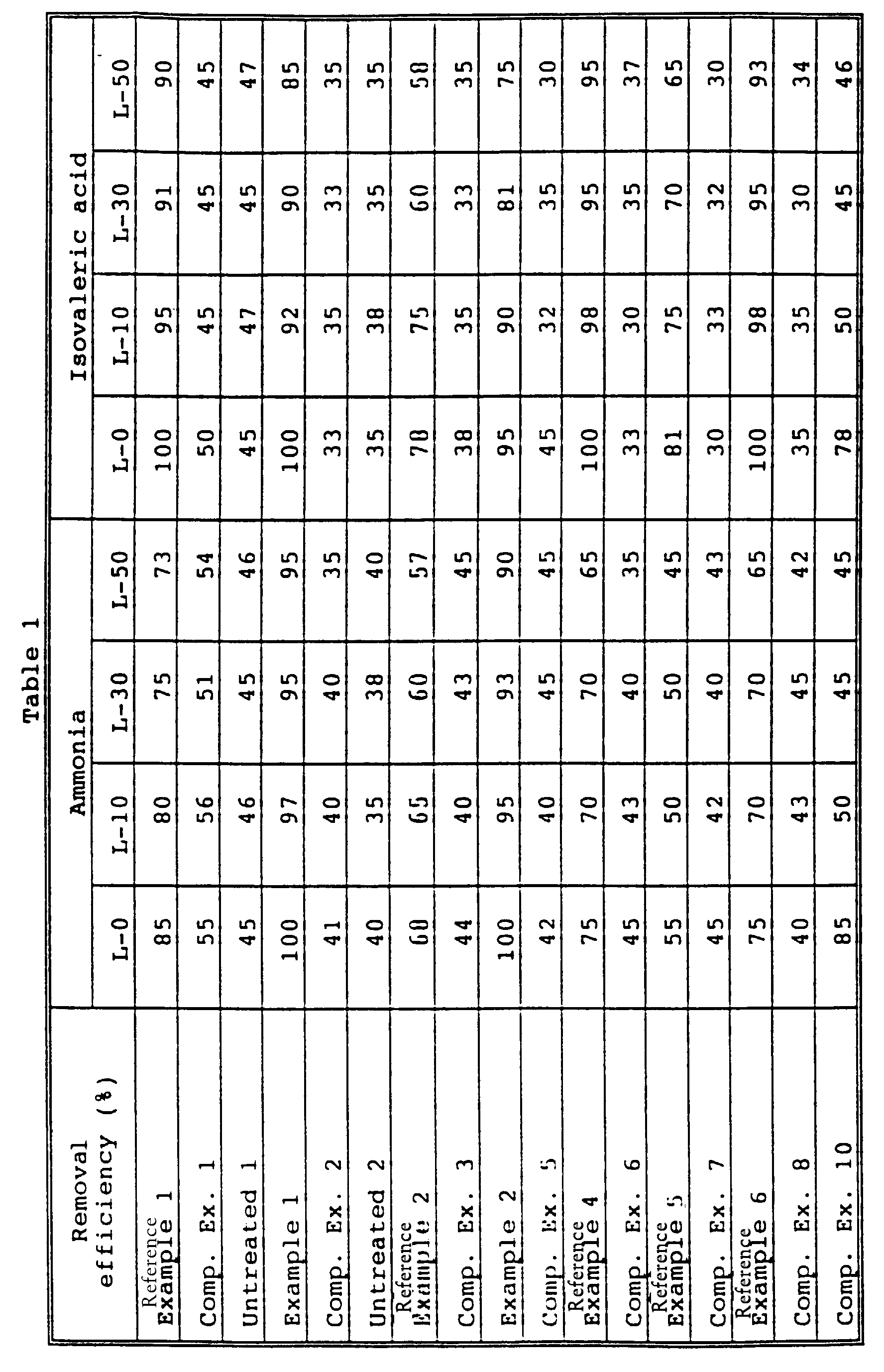

- Removal efficiency(%) A-B A x 100 wherein A is the gas concentration (ppm) in the flask containing no fabric, and B is the gas concentration (ppm) in the flask containing the fabric to be tested.

- Example 1, 1 and Reference Examples 1 and 4 to 6, and the fabrics obtained in Comparative Examples 1, 2 and 6 to 8 were tested for antibacterial property by the 5 following method.

- Test bacterium Staphylococcus aureus IAM12082

- Test method Clear zone test was conducted according to AATCC TEST METHOD 90. The number of cells was measured according to AATCC TEST METHOD 100.

- Table 3 shows the result of the clear zone test.

- Table 4 shows the result of cell number measurement.

- UV-GL-58 product of San Gabriel, U.S.A.

- a UV intensity meter (UM-1, product of Minolta Camera Co., Ltd.) was placed immediately below the lamp, with the sensor portion of the meter covered with the fabric to be tested, and the intensity of ultraviolet rays passing through the fabric was measured.

- the UV sensors used were UM-36 for long wavelengths and UM-25 for short wavelengths to measure the intensity in the respective wavelength ranges.

- the transmittance (%) was calculated from the following equation.

- Transmittance (%) I 1 I 2 x 100 wherein I 1 is the intensity of ultraviolet rays (mw/cm 2 ) passing through the fabric, and I 2 is the intensity of ultraviolet rays (mw/cm 2 ) impinging on the sensor in the absence of fabric.

- Table 5 shows the result obtained. Table 5 UM-25 UM-36 L-0 L-10 L-0 L-10 Reference Example 3 7.8 8.2 30.1 31.2 Comp. Ex. 4 16.0 17.9 44.8 45.9 Untreated 1 16.7 17.6 45.1 46.2

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Biochemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Microbiology (AREA)

- Chemical Or Physical Treatment Of Fibers (AREA)

- Treatments For Attaching Organic Compounds To Fibrous Goods (AREA)

Description

- The present invention relates to natural cellulose fibers having an inorganic metal compound therein, and a process for producing such fibers.

- It is known for long to deodorize ammonia, hydrogen sulfide, mercaptan, trimethylamine or like substance having an offensive odor by reacting the substance with zinc, aluminum, copper or like metal compound and thereby converting the substance to another substance.

- On the other hand, copper compounds have antibacterial activity and fungicidal activity, oxides of zirconium, cerium and the like have ability to absorb ultraviolet rays, and zirconium oxide and carbide have the nature of releasing heat by absorbing light. Methods have been provided of imparting various functions to fibers by utilizing these known properties of such metal compounds.

- Attempts have been made to knead the metal compound with a material such as nylon or polyester and make the mixture into synthetic fibers having such a function. With this method, the metal compound is admixed with the material for preparing the synthetic fibers, so that the fibers can be given the desired function to a satisfactory extent, whereas the kneading method is in no way applicable to natural fibers such as natural cellulose fibers.

- Accordingly, heretofore proposed for treating natural cellulose fibers is a method of coating the surface of cellulose fibers with polyurethane or like resin containing a metal compound to cause the fibers to support the metal compound thereon (Examined Japanese Patent Publication HEI 2-10274, etc.), a method of causing cellulose fibers to support thereon the reaction product of a transition metal and tannic acid (Unexamined Japanese Patent Publications HEI 1-292169 and HEI 1-266275, etc.) and the like. However, these methods are unable to prepare natural cellulose fibers capable of retaining the imparted function for a prolonged period of time. When the former method is practiced using, for example, a zinc compound as the metal compound to obtain deodorant fibers, the finished fibers are hard, have a poor hand and are low in washing fastness such that the deodorant properties become halved or lower when the fibers are washed repeatedly about 10 times. With the latter method wherein the tannic acid is used to attach the transition metal to the cellulose fibers, the transition metal becomes inevitably released from the fibers, for example, owing to hydrolysis when the fibers are repeatedly washed. Thus, the functional fibers afforded by this method are also low in washing fasteness. In fact, when the latter method is practiced using a zinc compound as the metal compound in the same manner as above to obtain deodorant fibers, the deodorant properties become halved or lower if the fibers are repeatedly washed about 10 times.

- Further Unexamined Japanese Patent Publication SHO 55-137210 discloses bactericidal fibers prepared by attaching copper ion to an ion exchange group present in the surface layer of fibers having ion exchange ability, and causing the copper ion to form a water-insoluble compound as incorporated in the surface layer. Nevertheless, the invention of the publication is not applicable as it is to natural cellulose fibers since the hydroxyl group of natural cellulose fibers has no ion exchange ability. When we treated natural cellulose fibers according to the invention as disclosed in the publication by impregnating the fibers with a water-soluble metal salt, drying the fibers and washing the fibers with water, we found that almost all the metal ions were washed away. This indicates that the disclosed technique is unable to basically overcome the conventional drawback.

- An object of the present invention is to provide natural cellulose fibers capable of retaining for a prolonged period of time functions imparted thereto by various metal compounds.

- Another object of the invention is to provide a process for producing such natural cellulose fibers.

- Other features of the invention will become apparent from the following description.

- The present invention provides a natural cellulose fiber having a water-insoluble inorganic metal compound incorporated therein and having at least one heat-treated polycarboxylic acid combined therewith, the polycarboxylic acid being selected from the group consisting of polycarboxylic acids and partial salts thereof. It also provides a process for producing a natural cellulose fiber having a water-insoluble inorganic metal compound incorporated therein, the process comprising the steps of impregnating a natural cellulose fiber with a treating solution containing a water-soluble inorganic metal compound and a polycarboxylic acid, heating the fiber and insolubilizing the water-soluble inorganic metal compound incorporated in the fiber.

- The natural cellulose fiber of the present invention is characterized in that the cellulose fiber has an inorganic metal compound incorporated therein. With the prior art, fibers are coated with a resin containing a particulate metal compound admixed therewith, or a third substance, such as tannic acid, which is adsorbable by or reactive with fibers and which is caused to form a complex with a metal ion, hence the necessity of using an intermediary substance. The present invention, however, does not require any support medium such as resin or other chemical substance because the natural cellulose fiber has incorporated therein an insoluble metal compound as converted from a metal ion within the fiber. The metal compound incorporating cellulose fiber of the present invention is less likely to release the metal compound even when repeatedly washed. The metal compound is not merely deposited on the cellulose fiber but behaves as if enclosed in the noncrystalline structure of the fiber.

- Examples of natural cellulose fibers for use in the present invention are cotton and hemp fibers. Such fibers may be in the form of a blend with polyester or like synthetic fibers. The fibers are not limited specifically in form but can be in any form such as yarns, woven fabrics, knitted fabrics or nonwoven fabrics.

- The inorganic metal compound to be incorporated into cellulose fibers is not limited specifically insofar as it is insoluble in water. Examples of useful inorganic metal compounds are hydroxides, carbonates, phosphates, silicates, aluminates and zirconates of metals such as copper, silver, zinc zirconium iron, cobalt, nickel, manganese, cerium, magnesium tin and antimony. At least one of these metal compounds is incorporated into the cellulose fiber.

- According to the invention, 0.01 to 10 wt. %, preferably 0.1 to 5 wt. %, of the metal compound is incorporated in the cellulose fiber.

- The natural cellulose fiber of the present invention is produced by causing a metal ion to penetrate into a natural cellulose fiber and converting the metal ion to a water-insoluble inorganic metal compound. Depending on the kind of metal compound to be incorporated into the fiber, the particulars of the process differ as will be described below.

- The process generally comprises a first bath treatment for impregnating the cellulose fiber to be treated with a water-soluble metal salt and a second bath treatment for insolubilizing the water-soluble metal salt in the fiber.

- In the first bath treatment, the fiber is treated with an aqueous solution of the water-soluble metal salt so as to be impregnated with the metal salt. The fiber is treated with the metal salt solution, for example, by dipping, padding, spraying or coating. The dipping or padding method is suitable to practice.

- More specifically, the dipping method is practiced by dipping the fiber in an aqueous solution containing the metal salt in an amount of 0.01 to 10 wt. % calculated as the metal concerned at room temperature to 100°C for 3 seconds to 10 minutes. The treatment conditions differ with the kind of fiber, and optimum conditions for the fiber to be treated are used. While the dipped fiber is subjected to the second bath treatment, the fiber may be washed with water and dried before the second bath treatment. Since the metal salt is soluble in water according to the invention, it is desired that the dipping treatment be changed over to the second bath treatment by way of the drying step only.

- The padding method is especially suited to woven fabrics and knitted fabrics. Stated more specifically when the padding method is resorted to, the fiber is treated as immersed in an aqueous solution containing the metal salt in an amount of 0.01 to 10 wt. % calculated as the metal at room temperature to 100°C for 3 seconds to 10 minutes, and is thereafter squeezed as by a mangle to a predetermined uniform ratio. This treatment is conducted under conditions optimum for the fiber and suitably selected. The padded fiber may be washed with water and dried prior to the second bath treatment to be subsequently conducted. Like the dipping method, the padding method is preferably followed by the drying step only before the second bath treatment.

- In the second bath treatment, an aqueous solution of alkali, acid or alkali metal salt is caused to act on the water-soluble metal salt impregnating the fiber or deposited thereon to convert the water-soluble metal salt to a water-insoluble metal compound. This treatment can be carried out also by dipping, padding, spraying, coating or like method. The dipping or padding method is suitable to practice. The dipping method is usable for fibers of any form, while the padding method is suited to woven or knitted fabrics.

- More specifically, the padding method is practiced by dipping the fiber subjected to the first bath treatment in an aqueous solution containing 0.01 to 10 wt. % of an alkali, acid or alkali metal salt at room temperature to 70°C for 3 seconds to 5 minutes, and thereafter squeezing the dipped fiber as by a mangle to a predetermined uniform ratio. The treatment is conducted under suitably selected conditions which are optimum for the fiber.

- The padded and squeezed fiber is then soaped or washed with water to completely remove the alkali, acid or alkali metal salt, and is thereafter dried, whereby a natural cellulose fiber of the invention is prepared which has a water-insoluble inorganic metal compound incorporated therein as if enclosed in the amorphous region of the fiber.

- In the case where the metal of the metal compound to be incorporated into the fiber is a transition metal, such as copper, silver, iron, cobalt, nickel, manganese, zinc, titanium, zirconium, cerium, vanadium, molybdenum or tungsten, germanium, aluminum or magnesium, the water-soluble metal salt present in the first bath is preferably in the form of the chloride, oxychloride, sulfate, nitrate or like mineral acid salt of the metal, or the acetate, formate or like organic acid salt of the metal, while an aqueous solution of alkali is used as the second bath. Examples of useful alkalis are hydroxides of alkali metals, hydroxides of alkaline earth metals, ammonium hydroxide and the like, among which sodium hydroxide is preferred.

- In the case where the metal of the metal compound to be incorporated into the fiber is an metal element such as zinc, titanium, zirconium, vanadium, molybdenum, tungsten, aluminum, silicon, tin or antimony, it is desirable to use as the first bath an aqueous solution which contains as an anion the oxide of the metal element prepared by dissolving the element or a salt thereof with an alkali hydroxide or ammonium hydroxide, and to use an aqueous solution of acid as the second bath. Examples of useful acids are hydrochloric acid, sulfuric acid and like mineral acids, formic acid, acetic acid and like water-soluble organic acids, etc., among which acetic acid is desirable.

- Alternatively, the natural cellulose fiber to be treated can be impregnated with a water-soluble metal salt using the first bath and thereafter passed through an aqueous solution of another water-soluble metal salt serving as the second bath to form a water-insoluble inorganic metal salt in the fiber. The water-soluble metal salt for use in the first bath is any water-soluble metal salt other than the salts of alkali metals. The water-soluble metal salt for use in the second bath is any inorganic metal salt which becomes insoluble in water when reacting with the metal salt of the first bath. Examples of such salts are alkali salts of carbonic acid, phosphoric acid, pyrophosphoric acid, metasilicic acid, silicic acid, zincic acid, aluminic acid, titanic acid, molybdic acid, vanadic acid, zirconic acid and the like, alkali sulfides, etc.

- The metal compound incorporated in the fiber imparts to the fiber deodorizing, antibacterial and fungicidal effects when the compound is, for example, a zinc or copper compound, a deodorizing effect when the compound is an aluminum or magnesium compound, effects to accumulate heat, block ultraviolet rays and radiate far infrared rays when the compound is a zirconium compound, or flame retardant effect when the compound is an antimony compound.

- An enhanced deodorant effect is available when at least one member selected from polycarboxylic acids and partial salts thereof is used in combination with the water-soluble inorganic metal compound. The term "partial salt of polycarboxylic acid" used herein refers to a salt thereof having at least one free carboxyl group remaining after the reaction of all carboxyl groups with a base.

- Examples of useful polycarboxylic acids are straight-chain or branched-chain aliphatic polycarboxylic acids, alicyclic polycarboxylic acids, aromatic polycarboxylic acids, etc. These acids may be those having a hydroxyl group, halogen atom, carbonyl group or carbon-carbon double bond.

- Specific examples of these polycarboxylic acids are oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, suberic acid, azelaic acid, sebacic acid, corresponding branched fatty acids, maleic acid, fumaric acid, cyclohexanedicarboxylic acid and corresponding position isomers and like aliphatic dibasic acids; tetrahydrophthalic acid, nadic acid and like alicyclic dibasic acids; tricarbaryl acid, aconitic acid, methylcyclohexenetricarboxylic acid and like tribasic acids; butanetetracarboxylic acid, cyclopentanetetracarboxylic acid, tetrahydrofurantetracarboxylic acid, an ene adduct of methyltetrahydrophthalic acid with maleic acid and like tetrabasic acids; malic acid, tartaric acid, citric acid and like hydroxy-fatty acids; trimellitic acid, pyromellitic acid, biphenyltetracarboxylic acid, benzophenonetetracarboxylic acid, diphenylsulfonetetracarboxylic acid and like aromatic polycarboxylic acids; etc. Of these polycarboxylic acids, butanetetracarboxylic acid is preferred.

- Useful metal ions constituting a partial salt of polycarboxylic acid are sodium, potassium, ammonium, etc.

- When a polycarboxylic acid or partial salt thereof is used in combination with the water-soluble metal compound, the polycarboxylic acid or partial salt is impregnated into and deposited on the cellulose fiber together with the water-soluble metal compound and heat-treated and then the water-soluble metal compound is insolubilized, or alternatively the water-soluble metal compound is insolublized first and the treated cellulose fiber is dipped in an aqueous solution of polycarboxylic acid or the like, followed by heat treatment.