EP0378943A1 - Compressor housing with an adaptable inner diameter for a turbo machine - Google Patents

Compressor housing with an adaptable inner diameter for a turbo machine Download PDFInfo

- Publication number

- EP0378943A1 EP0378943A1 EP89403573A EP89403573A EP0378943A1 EP 0378943 A1 EP0378943 A1 EP 0378943A1 EP 89403573 A EP89403573 A EP 89403573A EP 89403573 A EP89403573 A EP 89403573A EP 0378943 A1 EP0378943 A1 EP 0378943A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- casing

- bellows

- turbomachine

- compressor

- shells

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D11/00—Preventing or minimising internal leakage of working-fluid, e.g. between stages

- F01D11/08—Preventing or minimising internal leakage of working-fluid, e.g. between stages for sealing space between rotor blade tips and stator

- F01D11/14—Adjusting or regulating tip-clearance, i.e. distance between rotor-blade tips and stator casing

- F01D11/20—Actively adjusting tip-clearance

- F01D11/22—Actively adjusting tip-clearance by mechanically actuating the stator or rotor components, e.g. moving shroud sections relative to the rotor

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T403/00—Joints and connections

- Y10T403/21—Utilizing thermal characteristic, e.g., expansion or contraction, etc.

Definitions

- the present invention relates to a turbomachine compressor casing provided with a device for controlling its internal diameter in order to ensure minimum objective radial clearance between rotor and compressor stator.

- Adjustments of clearances in operation can thus be obtained by the use of thermal means, calling in particular on circulations of hot or cold air flows with adjustable flow rates as a function of determined parameters of operation of the turbomachine or of measurements. direct, these air flows are usually used to control the expansion / retraction of mechanical parts. Examples of these solutions are given by FR-A-2,534,982, FR-A-2,535,795 or FR-A-2,540,560.

- mechanical means are used to vary the diameter of the housings or fixed parts located opposite the rotors or rotating parts of the turbomachine. This principle is for example applied by FR-A-2 577 282 or FR-A-2 591 674.

- the object of the invention is to solve the problems mentioned above without incurring the drawbacks of the known prior solutions and in particular by allowing an advantageous application to the turbomachine compressor casings in two half-shells.

- said complementary flexible connection means consist of a number N of flexible connection elements, each flexible element being associated with a bellows, being moreover hingedly fixed at each of its ends respectively on each casing half-shell. , on either side of the assembly flanges and forming a C element spanning said bellows.

- said complementary flexible connection means consist of N pairs of lever arms, each articulated at a first end on a casing half-shell in the vicinity of the assembly flange and its second end being secured to a radially outer casing by means of an elastic flange.

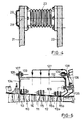

- a turbomachine compressor casing 1, schematically represented in FIG. 1, comprises, on the one hand, a radially external casing 2 comprising at each end of the radial flanges, respectively 3 and 4 , oriented towards the outside and assembled by any known means, such as bolts 5 and 6, with the flanges 7 and 8 of an adjacent casing and, on the other hand, an internal envelope 9, radially spaced from the previous one and which supports, according to a method of construction known per se in the production of axial compressors, a number of circular rows of fixed blades forming stator stages 10, 11, 12 which are three in number in the example shown in the Figure 1 and between which are interposed stages of movable blades 13, 14, 15 of the compressor rotor.

- the external 2 and internal 9 envelopes are connected together, in a manner also known, by telescopic devices 16 with pins and grooves, at the level of radial lugs such as 17 and 18.

- These connecting devices 16 are regularly distributed and six in number , for example in the embodiment shown in Figure 1, are arranged in two longitudinally spaced series.

- the inner casing 9 of the casing consists of two half-shells 19 and 20 assembled together by remarkable means in accordance with the invention, constituting a device for controlling the internal diameter of the casing 1 of the compressor and shown in detail in the figures. 2 to 5.

- Each half-shell 19 and 20 comprises, at each end, a longitudinal flange, respectively 21 and 22, located in the compressor assembled in a horizontal plane.

- the flanges 21 and 22 of the half-shells are slightly spaced and in the space thus provided, a bellows 23 is arranged, as shown in the detail. enlarged in Figure 4.

- the bellows 23 is secured at each end, respectively to one of the flanges 21 and 22 of the half-shells 19 and 20 of the housing. Spanning the bellows 23 and the flanges 21 and 22, a flexible connecting element 24, having the general shape of a C is further articulated at each of its ends 25 and 26, directly on a half-shell, respectively 19 and 20

- the bellows 23 and the flexible elements 24 in the same number are, for example, four in number, in the embodiment shown in FIGS. 1 to 5.

- An air supply duct, symbolized at 27, supplies each bellows 23 in air taken downstream of the compressor. As shown in Figure 4, the air inlet into the bellows 23 can be through an orifice 28 drilled in the flange 21 and through a chamber 29 formed at the inlet.

- the seal between the two half-shells 19 and 20 is ensured by longitudinal tongues 30 arranged in the grooves provided in the thickness of the half-shells at their connection. Furthermore, safety devices each comprising a rod 31 forming a spacer between the flanges 21 and 22, and visible in FIGS. 4 and 5 are arranged so as to ensure a minimum internal diameter of the compressor housing.

- the operating mode of the device for controlling the internal diameter of the casing according to the invention is as follows. Between the outer 2 and inner 9 casing casings, an air sampling carried out, for example, upstream of the casing 1 ensures a pressure P1. In each bellows 23, the supply 25 brings an air pressure P2. Each increase in flow pressure at the outlet of the compressor activates the control device and increases the internal diameter of the casing 1. The deformation and the elongation of the bellows 23 in fact exert moments on each flange 21 or 22 of the internal casing 9 of housing.

- the half-shells 19 and 20 are deformed only in bending and an increase in diameter is obtained without ovalization, the half-shells 19 and 20 being separated by the bellows 23 while the flexible elements 24 retain them. Furthermore, in the telescopic connections 16 between the inner casing 9 and the outer casing 2 of the casing, a clearance is provided between the pins and the grooves, to allow non-radial movement of the pins in the grooves.

- Figures 6 to 10 show a second embodiment of the invention for which , references increased by a hundred compared to those which were used in the description of the first mode will be given to designate parts or elements identical or of function analogous to those of the first mode.

- the casing 101 of the turbomachine compressor is composed of an external casing 102, between two flanges 103 and 104, connected to the flanges 107 and 108 by bolts 105 and 106 and an internal casing 109 in two half-shells 119 and 120, carrying stator stages of fixed blades 110, 111, 112 and 112a between rotor stages of movable blades 113, 114, 115, 115a and 115b.

- the two half-shells 119 and 120 also include the longitudinal flanges 121 and 122 slightly spaced and connected by bellows 123, supplied with air taken downstream from the compressor by a pipe 127.

- the variant applied in this second embodiment relates to the complementary flexible connection means between the two flanges 121 and 122 of the two half-shells 119 and 120 of the internal envelope 109 of the compressor housing according to the invention.

- said flexible connection means are constituted at each bellows 123, two lever arms 124a and 124b.

- Each lever-arm 124a or 124b has one of its ends, respectively 125 and 126, articulated directly on a half-shell, respectively 119 and 120 and their other end 125a or 126a is secured to the outer casing 102 of the casing by a flange elastic 32.

- the bellows 123 and the pairs associated with the same number of lever arms 124a and 124b are six in number.

- the operating mode of the device for controlling the internal diameter of the casing is the same as that which was previously described for the first embodiment, with reference to FIGS. 1 to 5.

- Another particularity of the second embodiment concerning the assembly of the assembly As shown in the detail in FIG. 10, elements 33 are used to hold the lever arms 124a or 124b in the docking position during the positioning of the elastic flange 32, these elements 33 then being eliminated.

- the device for controlling the internal diameter of the compressor casing according to the invention can be combined with additional arrangements.

- watertight walls, respectively 34 and 35 or 134 and 135, are arranged at each end of the casing, between the internal envelopes 9 or 109 and the external 2 or 102, thus forming a sealed enclosure between the two envelopes.

- the air pressure P1 prevailing in this enclosure can then also be controlled by adding a valve to the air sample taken upstream of the casing and which supplies the enclosure, the control device for this valve, not shown in drawing, which can, for example, be controlled by an operating parameter of the turbomachine or a measurement of the real clearance in operation between the rotor and the compressor stator.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

Abstract

Un carter de compresseur comporte une enveloppe interne (9) en deux demi-coquilles (19, 20) assemblées par brides (21, 22). Des soufflets cylindriques (23) disposés entre les brides (21, 22) sont déformés en fonction d'une pression interne P2 fournie par une alimentation en air prélevé (27) à l'aval du compresseur d'où il résulte un pilotage du diamètre interne du carter. Une liaison souple complémentaire (24) est disposée entre les deux demi-coquilles (19, 20).A compressor housing comprises an internal casing (9) in two half-shells (19, 20) assembled by flanges (21, 22). Cylindrical bellows (23) disposed between the flanges (21, 22) are deformed as a function of an internal pressure P2 supplied by a supply of withdrawn air (27) downstream of the compressor from which results in control of the diameter internal of the housing. A complementary flexible connection (24) is arranged between the two half-shells (19, 20).

Description

La présente invention concerne un carter de compresseur de turbomachine muni d'un dispositif de pilotage de son diamètre interne afin d'assurer un jeu radial objectif minimal entre rotor et stator de compresseur.The present invention relates to a turbomachine compressor casing provided with a device for controlling its internal diameter in order to ensure minimum objective radial clearance between rotor and compressor stator.

Diverses solutions ont été proposées dans le but de maintenir en fonctionnement, entre les rotors de turbomachine et les stators associés et notamment, entre les extrémités des aubes mobiles et la paroi interne d'un carter enveloppant les couronnes desdites aubes, des jeux radiaux aussi réduits que possible afin d'assurer les performances de la machine et notamment un bon rendement et une valeur réduite de consommation spécifique, mais toutefois des jeux suffisants afin d'éviter, notamment dans des conditions transitoires d'accélération ou de décélération et quelle que soit la succession de ces séquences, toute interférence mécanique dommageable entre partie fixe et partie tournante de la turbomachine. Les ajustements de jeux en fonctionnement peuvent ainsi être obtenus grâce à la mise en oeuvre de moyens thermiques, faisant appel notamment à des circulations de flux d'air chauds ou froids à débits réglables en fonction de paramètres déterminés de fonctionnement de la turbomachine ou de mesures directes, ces débits d'air étant habituellement utilisés pour piloter les dilatations/rétractions de pièces mécaniques. Des exemples de ces solutions sont donnés par FR-A-2 534 982, FR-A-2 535 795 ou FR-A-2 540 560.Various solutions have been proposed in order to maintain in operation, between the turbomachine rotors and the associated stators and in particular, between the ends of the movable blades and the internal wall of a casing enveloping the crowns of said blades, also reduced radial clearances. as possible in order to ensure the performance of the machine and in particular a good yield and a reduced value of specific consumption, but nevertheless sufficient clearances in order to avoid, in particular in transient conditions of acceleration or deceleration and whatever the succession of these sequences, any damaging mechanical interference between the fixed part and the rotating part of the turbomachine. Adjustments of clearances in operation can thus be obtained by the use of thermal means, calling in particular on circulations of hot or cold air flows with adjustable flow rates as a function of determined parameters of operation of the turbomachine or of measurements. direct, these air flows are usually used to control the expansion / retraction of mechanical parts. Examples of these solutions are given by FR-A-2,534,982, FR-A-2,535,795 or FR-A-2,540,560.

Selon d'autres solutions, des moyens mécaniques sont utilisés pour faire varier le diamètre des carters ou parties fixes situés en regard des rotors ou parties tournantes de turbomachine. Ce principe est par exemple appliqué par FR-A-2 577 282 ou FR-A-2 591 674.According to other solutions, mechanical means are used to vary the diameter of the housings or fixed parts located opposite the rotors or rotating parts of the turbomachine. This principle is for example applied by FR-A-2 577 282 or FR-A-2 591 674.

Ces solutions antérieures connues ne donnent pas toutefois entière satisfaction dans toutes les applications. Des prélèvements d'air, souvent relativement importants, nécessités par la mise en oeuvre des solutions utilisant des moyens thermiques font perdre aux performances du moteur une part non négligeable de l'apport de ces dispositions. Par ailleurs, les moyens mécaniques envisagés présentent les inconvénients d'occasionner un accroissement de masse, ce qui est particulièrement préjudiciable pour les applications aéronautiques, et de nécessiter des montages complexes. Particulièrement, dans l'application à des compresseurs de turbomachine comportant des carters en deux demi-coquilles assemblées par des brides, la mise en oeuvre des solutions connues s'avère délicate et difficile à réaliser.These known prior solutions are however not entirely satisfactory in all applications. Air samples, often relatively large, required by the implementation of solutions using thermal means make the engine performance lose a significant part of the contribution of these provisions. Furthermore, the mechanical means envisaged have the drawbacks of causing an increase in mass, which is particularly detrimental for aeronautical applications, and of requiring complex assemblies. In particular, in the application to turbomachine compressors comprising casings in two half-shells assembled by flanges, the implementation of known solutions proves to be delicate and difficult to carry out.

En conséquence le but de l'invention est de résoudre les problèmes évoqués ci-dessus sans encourir les inconvénients des solutions antérieures connues et particulièrement en permettant une application avantageuse aux carters de compresseur de turbomachine en deux demi-coquilles. Ces résultats sont obtenus au moyen d'un carter de compresseur de turbomachine comportant au moins une enveloppe radialement interne, composée de deux demi-coquilles portant des brides d'assemblage et muni d'un dispositif de pilotage de son diamètre interne en fonction des conditions de fonctionnement de la turbomachine caractérisé en ce que une pluralité N de soufflets déformables, de longueur variable, sont fixés entre les deux dites brides de carter, les reliant entre elles, une pression variable P₂ étant maintenue à l'intérieur de chaque soufflet au moyen d'une canalisation de prélèvement d'air à l'extrémité aval du compresseur et en ce que des moyens complémentaires sont disposés entre les deux demi-coquilles assurant entre elles une liaison souple.Consequently, the object of the invention is to solve the problems mentioned above without incurring the drawbacks of the known prior solutions and in particular by allowing an advantageous application to the turbomachine compressor casings in two half-shells. These results are obtained by means of a turbomachine compressor casing comprising at least one radially internal envelope, composed of two half-shells carrying assembly flanges and provided with a device for controlling its internal diameter as a function of the conditions. operating mode of the turbomachine characterized in that a plurality N of deformable bellows, of variable length, are fixed between the two said casing flanges, connecting them together, a variable pressure P₂ being maintained inside each bellows by means an air intake pipe at the downstream end of the compressor and in that complementary means are arranged between the two half-shells ensuring a flexible connection between them.

Avantageusement, lesdits moyens complémentaires de liaison souple sont constitués par un nombre N d'éléments souples de liaison, chaque élément souple étant associé à un soufflet, étant en outre fixé de manière articulée à chacune de ses extrémités respectivement sur chaque demi-coquille de carter, de part et d'autre des brides d'assemblage et formant un élément en C enjambant ledit soufflet.Advantageously, said complementary flexible connection means consist of a number N of flexible connection elements, each flexible element being associated with a bellows, being moreover hingedly fixed at each of its ends respectively on each casing half-shell. , on either side of the assembly flanges and forming a C element spanning said bellows.

Selon un autre mode avantageux de réalisation, lesdits moyens complémentaires de liaison souple sont constitués par N paires de bras-leviers, chacun articulé à une première extrémité sur une demi-coquille de carter au voisinage de la bride d'assemblage et sa deuxième extrémité étant solidarisée à une enveloppe radialement externe du carter au moyen d'une bride élastique.According to another advantageous embodiment, said complementary flexible connection means consist of N pairs of lever arms, each articulated at a first end on a casing half-shell in the vicinity of the assembly flange and its second end being secured to a radially outer casing by means of an elastic flange.

D'autres caractéristiques et avantages de l'invention seront mieux compris à la lecture de la description qui va suivre de deux modes de réalisation de l'invention, en référence aux dessins annexés sur lesquels

- - la figure 1 représente, selon une demi-vue partielle schématique, en coupe par un plan longitudinal passant par l'axe de rotation de la turbomachine, un compresseur dont le carter est muni d'un dispositif de pilotage de son diamètre interne, suivant un premier mode de réalisation de l'invention :

- - la figure 2 représente un détail agrandi du carter de compresseur représenté sur la figure 1, selon une vue partielle schématique en coupe par un plan passant par la ligne II-II de la figure 3 ;

- - La figure 3 représente, dans une vue suivant F1 de la figure 2, un détail de réalisation du dispositif de pilotage du diamètre interne du carter de compresseur représenté sur la figure 1 ;

- - la figure 4 représente un détail agrandi d'un élément du dispositif de pilotage du diamètre interne du carter de compresseur, représenté sur la figure 2 ;

- - la figure 5 représente un détail de réalisation d'un dispositif de sécurité entrant dans le dispositif d'assemblage des deux demi-coquilles de l'enveloppe interne du carter de compresseur représenté sur la figure 1;

- - la figure 6 représente, selon une demi-vue partielle schématique, en coupe par un plan longitudinal passant par l'axe de rotation de la turbomachine, analogue à celle de la figure 1, un compresseur dont le carter est muni d'un dispositif de pilotage de son diamètre interne, suivant un deuxième mode de réalisation de l'invention ;

- - la figure 7 représente un détail agrandi du carter de compresseur représenté sur la figure 6, selon une vue analogue à celle de la figure 2 ;

- - la figure 8 représente, dans une vue suivant F2 de la figure 7, analogue à celle de la figure 3, un détail de réalisation du dispositif de pilotage du diamètre interne du carter de compresseur représenté sur la figure 6 ,

- - la figure 9 représente un détail de réalisation d'un dispositif de sécurité, analogue à celui qui est représenté sur la figure 5 dans le premier mode de réalisation de l'invention et entrant dans le dispositif d'assemblage des deux demi-coquilles de l'enveloppe interne du carter de compresseur représenté sur la figure 6 ;

- - la figure 10 représente un détail d'un dispositif utilisé pour le montage du dispositif de pilotage du diamètre interne de carter de compresseur représenté sur la figure 7.

- - Figure 1 shows, in a partial schematic half-view, in section through a longitudinal plane passing through the axis of rotation of the turbomachine, a compressor whose casing is provided with a device for controlling its internal diameter, according to a first embodiment of the invention:

- - Figure 2 shows an enlarged detail of the compressor housing shown in Figure 1, in a schematic partial view in section through a plane passing through the line II-II of Figure 3;

- - Figure 3 shows, in a view along F1 of Figure 2, a detail of the device for controlling the internal diameter of the compressor housing shown in Figure 1;

- - Figure 4 shows an enlarged detail of an element of the device for controlling the internal diameter of the compressor housing, shown in Figure 2;

- - Figure 5 shows a detail of a safety device entering the assembly device of the two half-shells of the inner casing of the compressor housing shown in Figure 1;

- - Figure 6 shows, in a partial schematic half-view, in section through a longitudinal plane passing through the axis of rotation of the turbomachine, similar to that of Figure 1, a compressor whose housing is provided with a device piloting its internal diameter, according to a second embodiment of the invention;

- - Figure 7 shows an enlarged detail of the compressor housing shown in Figure 6, in a view similar to that of Figure 2;

- FIG. 8 represents, in a view along F2 of FIG. 7, similar to that of FIG. 3, a detail of embodiment of the device for controlling the internal diameter of the compressor casing shown in FIG. 6,

- - Figure 9 shows a detail of an embodiment of a safety device, similar to that which is shown in Figure 5 in the first embodiment of the invention and entering the device for assembling the two half-shells of the inner casing of the compressor housing shown in Figure 6;

- FIG. 10 represents a detail of a device used for mounting the device for controlling the internal diameter of the compressor casing shown in FIG. 7.

Un carter 1 de compresseur de turbomachine, schématiquement représenté sur la figure 1, selon un premier mode de réalisation de l'invention, comporte, d'une part, une enveloppe radialement externe 2 comportant à chaque extrémité des brides radiales, respectivement 3 et 4, orientées vers l'extérieur et assemblées par tout moyen connu, tels que des boulons 5 et 6, avec les brides 7 et 8 d'un carter adjacent et, d'autre part, une enveloppe interne 9, radialement espacée de la précédente et qui supporte, selon un mode de construction connu en soi dans la réalisation de compresseurs axiaux, un certain nombre de rangées circulaires d'aubes fixes formant des étages statoriques 10, 11, 12 qui sont au nombre de trois dans l'exemple représenté sur la figure 1 et entre lesquels sont intercalés des étages d'aubes mobiles 13, 14, 15 du rotor de compresseur. Les enveloppes externe 2 et interne 9 sont reliées entre elles, de manière également connue, par des dispositifs télescopiques 16 à pions et rainures, au niveau de pattes radiales telles que 17 et 18. Ces dispositifs 16 de liaison régulièrement répartis et au nombre de six, par exemple dans le mode de réalisation représenté sur la figure 1, sont disposés suivant deux séries longitudinalement espacées.A

L'enveloppe interne 9 de carter est constituée de deux demi-coquilles 19 et 20 assemblées entre elles par des moyens remarquables conformes à l'invention, constituant un dispositif de pilotage du diamètre interne du carter 1 de compresseur et représentés en détails sur les figures 2 à 5. Chaque demi-coquille 19 et 20 comporte, à chaque extrémité, une bride longitudinale, respectivement 21 et 22, situées dans le compresseur assemblé dans un plan horizontal. Conformément à l'invention, au lieu d'être liées rigidement et directement entre elles, les brides 21 et 22 des demi-coquilles sont légèrement espacées et dans l'espace ainsi ménagé, est disposé un soufflet 23, tel que représenté sur le détail agrandi de la figure 4. Le soufflet 23 est solidarisé à chaque extrémité, respectivement à l'une des brides 21 et 22 des demicoquilles 19 et 20 de carter. Enjambant le soufflet 23 et les brides 21 et 22, un élément souple 24 de liaison, présentant la forme générale d'un C est en outre articulé à chacune de ses extrémités 25 et 26, directement sur une demi-coquille, respectivement 19 et 20. Les soufflets 23 et les éléments souples 24 en même nombre sont, par exemple, au nombre de quatre, dans le mode de réalisation représenté sur les figures 1 à 5. Un canalisation d'alimentation en air, symbolisée en 27, alimente chaque soufflet 23 en air prélevé à l'aval du compresseur. Comme représenté sur la figure 4, l'arrivée d'air dans le soufflet 23 peut se faire à travers un orifice 28 percé dans la bride 21 et au travers d'une chambre 29 ménagée à l'entrée. L'étanchéité entre les deux demi-coquilles 19 et 20 est assurée par des languettes longitudinales 30 disposées dans les rainures prévues dans l'épaisseur des demi-coquilles au niveau de leur liaison. Par ailleurs, des dispositifs de sécurité comportant chacun une tige 31 formant entretoise entre les brides 21 et 22, et visible sur les figures 4 et 5 sont disposés de manière à assurer un diamètre interne minimal du carter de compresseur.The

Le mode de fonctionnement du dispositif de pilotage du diamètre interne de carter conforme à l'invention, qui vient d'être décrit, est le suivant. Entre les enveloppes externe 2 et interne 9 de carter, un prélèvement d'air effectué, par exemple, à l'amont du carter 1 assure une pression P1. Dans chaque soufflet 23, l'alimentation 25 amène une pression d'air P2. Chaque augmentation de pression du flux à la sortie du compresseur actionne le dispositif de pilotage et augmente le diamètre interne du carter 1. La déformation et l'allongement des soufflets 23 exercent en effet des moments sur chaque bride 21 ou 22 de l'enveloppe interne 9 de carter. Les demi-coquilles 19 et 20 sont déformées uniquement en flexion et on obtient une augmentation de diamètre sans ovalisation, les demi-coquilles 19 et 20 étant écartées par les soufflets 23 tandis que les éléments souples 24 les retiennent. Par ailleurs, dans les liaisons télescopiques 16 entre enveloppe interne 9 et enveloppe externe 2 de carter, un jeu est ménagé entre pions et rainures, pour permettre un déplacement non radial des pions dans les rainures.The operating mode of the device for controlling the internal diameter of the casing according to the invention, which has just been described, is as follows. Between the outer 2 and inner 9 casing casings, an air sampling carried out, for example, upstream of the

De même, une chûte de pression du flux à la sortie du compresseur ramène le diamètre interne du carter à sa valeur initiale. Le pilotage du diamètre interne de carter assurant le jeu objectif entre les extrémités d'aubes mobiles du rotor et le diamètre correspondant du carter est ainsi effectué sans consommation d'énergie.Similarly, a drop in flow pressure at the outlet of the compressor brings the internal diameter of the casing back to its initial value. The control of the internal diameter of the housing ensuring the objective clearance between the ends of the movable blades of the rotor and the corresponding diameter of the housing is thus carried out without energy consumption.

Diverses variantes de réalisation peuvent être apportées au premier mode de réalisation de l'invention qui a été décrit ci-dessus en référence aux figures 1 à 5. Notamment, les figures 6 à 10 représentent un deuxième mode de réalisation de l'invention pour lequel, des références augmentées d'une centaine par rapport à celles qui ont été utilisées dans la description du premier mode seront données pour désigner des pièces ou éléments identiques ou de fonction analogue à ceux du premier mode. Ainsi et de manière analogue, le carter 101 de compresseur de turbomachine est composé d'une enveloppe externe 102, entre deux brides 103 et 104, liées aux brides 107 et 108 par des boulons 105 et 106 et d'une enveloppe interne 109 en deux demi-coquilles 119 et 120, portant des étages statoriques d'aubes fixes 110, 111, 112 et 112a entre des étages rotoriques d'aubes mobiles 113, 114, 115, 115a et 115b. Les deux demi-coquilles 119 et 120 comportent également les brides longitudinales 121 et 122 légèrement espacées et reliées par des soufflets 123, alimentés en air prélevé en aval du compresseur par une canalisation 127. On retrouve également les languettes 130 d'étanchéité ainsi que les dispositifs de sécurité à tiges 131 visibles sur les figures 8 et 9. La variante appliquée dans ce deuxième mode de réalisation concerne les moyens complémentaires de liaison souple entre les deux brides 121 et 122 des deux demi-coquilles 119 et 120 de l'enveloppe interne 109 du carter de compresseur conforme à l'invention. Comme cela est représenté plus particulièrement sur les figures 7 et 8, lesdits moyens de liaison souple sont constitués au niveau de chaque soufflet 123, de deux bras-leviers 124a et 124b. Chaque bras-levier 124a ou 124b a une de ses extrémités, respectivement 125 et 126, articulée directement sur une demi-coquille, respectivement 119 et 120 et leur autre extrémité 125a ou 126a est solidarisée à l'enveloppe externe 102 de carter par une bride élastique 32. Dans le deuxième mode de réalisation représenté sur les figures 6 à 10, les soufflets 123 et les paires associées en même nombre de bras-leviers 124a et 124b sont au nombre de six.Various variant embodiments can be made to the first embodiment of the invention which has been described above with reference to Figures 1 to 5. In particular, Figures 6 to 10 show a second embodiment of the invention for which , references increased by a hundred compared to those which were used in the description of the first mode will be given to designate parts or elements identical or of function analogous to those of the first mode. Thus and in a similar manner, the casing 101 of the turbomachine compressor is composed of an

Le mode de fonctionnement du dispositif de pilotage du diamètre interne de carter est dans ce deuxième mode de réalisation le même que celui qui a été précédemment décrit pour le premier mode de réalisation, en référence aux figures 1 à 5. On notera une autre particularité du deuxième mode de réalisation concernant le montage de l'ensemble. Comme représenté sur le détail de la figure 10, on utilise des éléments 33 pour maintenir les bras-leviers 124a ou 124b en position d'accostage pendant le positionnement de la bride élastique 32, ces éléments 33 étant ensuite éliminés.In this second embodiment, the operating mode of the device for controlling the internal diameter of the casing is the same as that which was previously described for the first embodiment, with reference to FIGS. 1 to 5. Another particularity of the second embodiment concerning the assembly of the assembly. As shown in the detail in FIG. 10,

Dans le premier, comme dans le deuxième mode de réalisation, le dispositif de pilotage du diamètre interne du carter de compresseur conforme à l'invention peut être combiné avec des dispositions complémentaires. Comme représenté sur la figure 1 pour le premier mode et sur la figure 6 pour le deuxième mode, des parois étanches, respectivement 34 et 35 ou 134 et 135, sont disposées à chaque extrémité du carter, entre les enveloppes interne 9 ou 109 et externe 2 ou 102, formant ainsi une enceinte étanche entre les deux enveloppes. La pression d'air P1 régnant dans cette enceinte peut ensuite être également pilotée en adjoignant une vanne sur le prélèvement d'air effectué à l'amont du carter et qui alimente l'enceinte, le dispositif de commande de cette vanne, non représenté au dessin, pouvant, par exemple, être asservi à un paramètre de fonctionnement de la turbomachine ou à une mesure du jeu réel en fonctionnement entre rotor et stator de compresseur.In the first, as in the second embodiment, the device for controlling the internal diameter of the compressor casing according to the invention can be combined with additional arrangements. As shown in FIG. 1 for the first mode and in FIG. 6 for the second mode, watertight walls, respectively 34 and 35 or 134 and 135, are arranged at each end of the casing, between the

Claims (7)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8816888A FR2640687B1 (en) | 1988-12-21 | 1988-12-21 | COMPRESSOR HOUSING OF A TURBOMACHINE WITH STEERING OF ITS INTERNAL DIAMETER |

| FR8816888 | 1988-12-21 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0378943A1 true EP0378943A1 (en) | 1990-07-25 |

| EP0378943B1 EP0378943B1 (en) | 1992-06-10 |

Family

ID=9373220

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89403573A Expired - Lifetime EP0378943B1 (en) | 1988-12-21 | 1989-12-20 | Compressor housing with an adaptable inner diameter for a turbo machine |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US5017088A (en) |

| EP (1) | EP0378943B1 (en) |

| DE (1) | DE68901768T2 (en) |

| FR (1) | FR2640687B1 (en) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2653171B1 (en) * | 1989-10-18 | 1991-12-27 | Snecma | TURBOMACHINE COMPRESSOR CASING PROVIDED WITH A DEVICE FOR DRIVING ITS INTERNAL DIAMETER. |

| US6691519B2 (en) | 2000-02-18 | 2004-02-17 | Siemens Westinghouse Power Corporation | Adaptable modular gas turbine power plant |

| US7125223B2 (en) * | 2003-09-30 | 2006-10-24 | General Electric Company | Method and apparatus for turbomachine active clearance control |

| US7260892B2 (en) * | 2003-12-24 | 2007-08-28 | General Electric Company | Methods for optimizing turbine engine shell radial clearances |

| DE102004058487A1 (en) * | 2004-12-04 | 2006-06-14 | Mtu Aero Engines Gmbh | gas turbine |

| US10190499B2 (en) | 2012-12-28 | 2019-01-29 | United Technologies Corporation | Axial tension system for a gas turbine engine case |

| US10309409B2 (en) * | 2016-05-26 | 2019-06-04 | Rolls-Royce Corporation | Impeller shroud with pneumatic piston for clearance control in a centrifugal compressor |

| US10458429B2 (en) * | 2016-05-26 | 2019-10-29 | Rolls-Royce Corporation | Impeller shroud with slidable coupling for clearance control in a centrifugal compressor |

| WO2018045351A1 (en) * | 2016-09-01 | 2018-03-08 | Additive Rocket Corporation | Additive manufactured combustion engine |

| US10704560B2 (en) | 2018-06-13 | 2020-07-07 | Rolls-Royce Corporation | Passive clearance control for a centrifugal impeller shroud |

| US10962024B2 (en) | 2019-06-26 | 2021-03-30 | Rolls-Royce Corporation | Clearance control system for a compressor shroud assembly |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2458676A1 (en) * | 1979-06-06 | 1981-01-02 | Mtu Muenchen Gmbh | SEALING DEVICE FOR THE PERIPHERAL INTERVAL OF AN AXIAL FLUX TURBOMACHINE |

| GB2050527A (en) * | 1979-05-29 | 1981-01-07 | Gen Motors Corp | Turbine blade tip seal assembly |

| FR2509373A1 (en) * | 1981-07-11 | 1983-01-14 | Rolls Royce | ADJUSTABLE WRAPPING CROWN FOR MOBILE BLADES OF A GAS TURBINE ENGINE |

| GB2169962A (en) * | 1985-01-22 | 1986-07-23 | Rolls Royce | Blade tip clearance control |

| GB2195715A (en) * | 1986-10-08 | 1988-04-13 | Rolls Royce Plc | Rotor blade tip-shroud |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH397360A (en) * | 1961-11-28 | 1965-08-15 | Licentia Gmbh | Rotor seal with radially movable sealing ring segments, especially for turbo machines |

| GB2024336A (en) * | 1978-05-30 | 1980-01-09 | Rolls Royce | Gas turbine rotor tip clearance control apparatus |

| JPS5820904A (en) * | 1981-07-29 | 1983-02-07 | Hitachi Ltd | Seal structure of tip of moving blade for gas turbine |

| FR2534982A1 (en) * | 1982-10-22 | 1984-04-27 | Snecma | Control device for the tolerances of a high-pressure compressor |

| FR2535795B1 (en) * | 1982-11-08 | 1987-04-10 | Snecma | DEVICE FOR SUSPENSION OF STATOR BLADES OF AXIAL COMPRESSOR FOR ACTIVE CONTROL OF GAMES BETWEEN ROTOR AND STATOR |

| FR2540560B1 (en) * | 1983-02-03 | 1987-06-12 | Snecma | DEVICE FOR SEALING MOBILE BLADES OF A TURBOMACHINE |

| JPS61152907A (en) * | 1984-12-27 | 1986-07-11 | Toshiba Corp | Seal part gap regulating device for turbine |

| FR2577282B1 (en) * | 1985-02-13 | 1987-04-17 | Snecma | TURBOMACHINE HOUSING ASSOCIATED WITH A DEVICE FOR ADJUSTING THE GAME BETWEEN ROTOR AND STATOR |

| FR2591674B1 (en) * | 1985-12-18 | 1988-02-19 | Snecma | DEVICE FOR ADJUSTING THE RADIAL CLEARANCES BETWEEN ROTOR AND STATOR OF A COMPRESSOR |

| JPS62142808A (en) * | 1985-12-18 | 1987-06-26 | Toshiba Corp | Clearance control device for gas turbine |

-

1988

- 1988-12-21 FR FR8816888A patent/FR2640687B1/en not_active Expired - Lifetime

-

1989

- 1989-12-20 DE DE8989403573T patent/DE68901768T2/en not_active Expired - Fee Related

- 1989-12-20 EP EP89403573A patent/EP0378943B1/en not_active Expired - Lifetime

- 1989-12-21 US US07/454,650 patent/US5017088A/en not_active Expired - Fee Related

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2050527A (en) * | 1979-05-29 | 1981-01-07 | Gen Motors Corp | Turbine blade tip seal assembly |

| FR2458676A1 (en) * | 1979-06-06 | 1981-01-02 | Mtu Muenchen Gmbh | SEALING DEVICE FOR THE PERIPHERAL INTERVAL OF AN AXIAL FLUX TURBOMACHINE |

| FR2509373A1 (en) * | 1981-07-11 | 1983-01-14 | Rolls Royce | ADJUSTABLE WRAPPING CROWN FOR MOBILE BLADES OF A GAS TURBINE ENGINE |

| GB2169962A (en) * | 1985-01-22 | 1986-07-23 | Rolls Royce | Blade tip clearance control |

| GB2195715A (en) * | 1986-10-08 | 1988-04-13 | Rolls Royce Plc | Rotor blade tip-shroud |

Non-Patent Citations (2)

| Title |

|---|

| PATENT ABSTRACTS OF JAPAN vol. 10, no. 353 (M-539)(2409) 28 novembre 1986, & JP-A-61 152907 (TOSHIBA) 11 juillet 1986, * |

| PATENT ABSTRACTS OF JAPAN vol. 7, no. 98 (M-210)(1243) 26 avril 1983, & JP-A-58 20904 (HITACHI SEISAKUSHO) 07 février 1983, * |

Also Published As

| Publication number | Publication date |

|---|---|

| US5017088A (en) | 1991-05-21 |

| FR2640687A1 (en) | 1990-06-22 |

| DE68901768T2 (en) | 1993-01-14 |

| FR2640687B1 (en) | 1991-02-08 |

| EP0378943B1 (en) | 1992-06-10 |

| DE68901768D1 (en) | 1992-07-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1382817B1 (en) | Pump driving system in a turbo-engine | |

| EP4069944B1 (en) | Electrical connection of an electrical machine in an aircraft turbine engine | |

| FR2490722A1 (en) | AIR GASKETS FOR TURBOMACHINES | |

| EP3870810B1 (en) | Fan module equipped with an electrical machine for a turbomachine of an aircraft | |

| FR3027053B1 (en) | AIRCRAFT TURBOMACHINE STATOR | |

| EP0378943B1 (en) | Compressor housing with an adaptable inner diameter for a turbo machine | |

| EP0424253B1 (en) | Turbomachine compressor casing with device for controlling its internal diameter | |

| CA2951196A1 (en) | A turbine engine comprising a drive system for a device such as an accessories case | |

| WO2020084241A1 (en) | Aircraft turbine engine equipped with an electrical machine | |

| FR2993631A1 (en) | DEVICE FOR BLIND CONNECTION BETWEEN FLUID, ELECTRICAL OR SIMILAR POWER SUPPLIES AND A RECEIVER CONTROL MECHANISM | |

| BE1024982A1 (en) | TURBOMACHINE COMPRESSOR WITH AUBES WITH VARIABLE SHIFT | |

| WO2020084219A1 (en) | Aircraft turbine engine equipped with an electrical machine | |

| EP4069948B1 (en) | Electric module for an aircraft turbomachine | |

| EP4069946B1 (en) | Electrical connection for an electric machine in an aircraft turbine engine | |

| FR3086341A1 (en) | REDUCING TURBOMACHINE FOR AN AIRCRAFT | |

| EP4069945B1 (en) | Rigid bar for electrically connecting a machine in an aircraft turbine engine | |

| FR2965247A1 (en) | HYDRAULIC DEVICE FOR CHANGING PROPELLER PITCH | |

| FR3119199A1 (en) | DISCHARGE PIPE WITH PERFECTED SEALING | |

| EP3290657B1 (en) | Stator with adjustable vanes for the compressor of an axial turbine engine | |

| BE1026063B1 (en) | MOTOR DRIVE OF COMPRESSOR VARIABLE TIMING SYSTEM FOR TURBOMACHINE | |

| EP4214403B1 (en) | Electrical connection of an electrical machine in an aircraft turbine engine | |

| FR3086001A1 (en) | AIRCRAFT PROPULSION SYSTEM WITH BLOWER PROVIDED AT REAR END OF FUSELAGE | |

| FR3126021A1 (en) | PASSAGE OF SERVITUDES IN AN AIRCRAFT TURBOMACHINE EXHAUST CASING | |

| FR3137131A1 (en) | TURBOMACHINE MODULE EQUIPPED WITH A FLUIDIC CONNECTION | |

| FR3118093A1 (en) | Turbine blade, in particular for a counter-rotating turbine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19900109 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE FR GB |

|

| 17Q | First examination report despatched |

Effective date: 19911115 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB |

|

| REF | Corresponds to: |

Ref document number: 68901768 Country of ref document: DE Date of ref document: 19920716 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19921123 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19930226 Year of fee payment: 4 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19931220 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19931220 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19940831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19940901 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |