DE102018206334A1 - Fuel delivery device for cryogenic fuels - Google Patents

Fuel delivery device for cryogenic fuels Download PDFInfo

- Publication number

- DE102018206334A1 DE102018206334A1 DE102018206334.6A DE102018206334A DE102018206334A1 DE 102018206334 A1 DE102018206334 A1 DE 102018206334A1 DE 102018206334 A DE102018206334 A DE 102018206334A DE 102018206334 A1 DE102018206334 A1 DE 102018206334A1

- Authority

- DE

- Germany

- Prior art keywords

- valve element

- fuel

- cold

- suction

- pump

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000000446 fuel Substances 0.000 title claims abstract description 77

- 238000007789 sealing Methods 0.000 claims abstract description 27

- 230000006835 compression Effects 0.000 claims description 7

- 238000007906 compression Methods 0.000 claims description 7

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 4

- 238000002485 combustion reaction Methods 0.000 description 3

- 238000011010 flushing procedure Methods 0.000 description 3

- 238000001704 evaporation Methods 0.000 description 2

- 230000008020 evaporation Effects 0.000 description 2

- 239000003345 natural gas Substances 0.000 description 2

- BUHVIAUBTBOHAG-FOYDDCNASA-N (2r,3r,4s,5r)-2-[6-[[2-(3,5-dimethoxyphenyl)-2-(2-methylphenyl)ethyl]amino]purin-9-yl]-5-(hydroxymethyl)oxolane-3,4-diol Chemical compound COC1=CC(OC)=CC(C(CNC=2C=3N=CN(C=3N=CN=2)[C@H]2[C@@H]([C@H](O)[C@@H](CO)O2)O)C=2C(=CC=CC=2)C)=C1 BUHVIAUBTBOHAG-FOYDDCNASA-N 0.000 description 1

- CYJRNFFLTBEQSQ-UHFFFAOYSA-N 8-(3-methyl-1-benzothiophen-5-yl)-N-(4-methylsulfonylpyridin-3-yl)quinoxalin-6-amine Chemical compound CS(=O)(=O)C1=C(C=NC=C1)NC=1C=C2N=CC=NC2=C(C=1)C=1C=CC2=C(C(=CS2)C)C=1 CYJRNFFLTBEQSQ-UHFFFAOYSA-N 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 210000003746 feather Anatomy 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 239000007792 gaseous phase Substances 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 238000010926 purge Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M21/00—Apparatus for supplying engines with non-liquid fuels, e.g. gaseous fuels stored in liquid form

- F02M21/02—Apparatus for supplying engines with non-liquid fuels, e.g. gaseous fuels stored in liquid form for gaseous fuels

- F02M21/0218—Details on the gaseous fuel supply system, e.g. tanks, valves, pipes, pumps, rails, injectors or mixers

- F02M21/0221—Fuel storage reservoirs, e.g. cryogenic tanks

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D19/00—Controlling engines characterised by their use of non-liquid fuels, pluralities of fuels, or non-fuel substances added to the combustible mixtures

- F02D19/02—Controlling engines characterised by their use of non-liquid fuels, pluralities of fuels, or non-fuel substances added to the combustible mixtures peculiar to engines working with gaseous fuels

- F02D19/021—Control of components of the fuel supply system

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D19/00—Controlling engines characterised by their use of non-liquid fuels, pluralities of fuels, or non-fuel substances added to the combustible mixtures

- F02D19/02—Controlling engines characterised by their use of non-liquid fuels, pluralities of fuels, or non-fuel substances added to the combustible mixtures peculiar to engines working with gaseous fuels

- F02D19/025—Failure diagnosis or prevention; Safety measures; Testing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M21/00—Apparatus for supplying engines with non-liquid fuels, e.g. gaseous fuels stored in liquid form

- F02M21/02—Apparatus for supplying engines with non-liquid fuels, e.g. gaseous fuels stored in liquid form for gaseous fuels

- F02M21/0218—Details on the gaseous fuel supply system, e.g. tanks, valves, pipes, pumps, rails, injectors or mixers

- F02M21/023—Valves; Pressure or flow regulators in the fuel supply or return system

- F02M21/0236—Multi-way valves; Multiple valves forming a multi-way valve system

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M21/00—Apparatus for supplying engines with non-liquid fuels, e.g. gaseous fuels stored in liquid form

- F02M21/02—Apparatus for supplying engines with non-liquid fuels, e.g. gaseous fuels stored in liquid form for gaseous fuels

- F02M21/0218—Details on the gaseous fuel supply system, e.g. tanks, valves, pipes, pumps, rails, injectors or mixers

- F02M21/023—Valves; Pressure or flow regulators in the fuel supply or return system

- F02M21/0242—Shut-off valves; Check valves; Safety valves; Pressure relief valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M21/00—Apparatus for supplying engines with non-liquid fuels, e.g. gaseous fuels stored in liquid form

- F02M21/02—Apparatus for supplying engines with non-liquid fuels, e.g. gaseous fuels stored in liquid form for gaseous fuels

- F02M21/0218—Details on the gaseous fuel supply system, e.g. tanks, valves, pipes, pumps, rails, injectors or mixers

- F02M21/0245—High pressure fuel supply systems; Rails; Pumps; Arrangement of valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B15/00—Pumps adapted to handle specific fluids, e.g. by selection of specific materials for pumps or pump parts

- F04B15/06—Pumps adapted to handle specific fluids, e.g. by selection of specific materials for pumps or pump parts for liquids near their boiling point, e.g. under subnormal pressure

- F04B15/08—Pumps adapted to handle specific fluids, e.g. by selection of specific materials for pumps or pump parts for liquids near their boiling point, e.g. under subnormal pressure the liquids having low boiling points

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B23/00—Pumping installations or systems

- F04B23/04—Combinations of two or more pumps

- F04B23/08—Combinations of two or more pumps the pumps being of different types

- F04B23/10—Combinations of two or more pumps the pumps being of different types at least one pump being of the reciprocating positive-displacement type

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B49/00—Control, e.g. of pump delivery, or pump pressure of, or safety measures for, machines, pumps, or pumping installations, not otherwise provided for, or of interest apart from, groups F04B1/00 - F04B47/00

- F04B49/22—Control, e.g. of pump delivery, or pump pressure of, or safety measures for, machines, pumps, or pumping installations, not otherwise provided for, or of interest apart from, groups F04B1/00 - F04B47/00 by means of valves

- F04B49/24—Bypassing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B53/00—Component parts, details or accessories not provided for in, or of interest apart from, groups F04B1/00 - F04B23/00 or F04B39/00 - F04B47/00

- F04B53/08—Cooling; Heating; Preventing freezing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B53/00—Component parts, details or accessories not provided for in, or of interest apart from, groups F04B1/00 - F04B23/00 or F04B39/00 - F04B47/00

- F04B53/10—Valves; Arrangement of valves

- F04B53/102—Disc valves

- F04B53/1032—Spring-actuated disc valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B53/00—Component parts, details or accessories not provided for in, or of interest apart from, groups F04B1/00 - F04B23/00 or F04B39/00 - F04B47/00

- F04B53/10—Valves; Arrangement of valves

- F04B53/1087—Valve seats

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B53/00—Component parts, details or accessories not provided for in, or of interest apart from, groups F04B1/00 - F04B23/00 or F04B39/00 - F04B47/00

- F04B53/10—Valves; Arrangement of valves

- F04B53/109—Valves; Arrangement of valves inlet and outlet valve forming one unit

- F04B53/1092—Valves; Arrangement of valves inlet and outlet valve forming one unit and one single element forming both the inlet and outlet closure member

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B53/00—Component parts, details or accessories not provided for in, or of interest apart from, groups F04B1/00 - F04B23/00 or F04B39/00 - F04B47/00

- F04B53/10—Valves; Arrangement of valves

- F04B53/1097—Valves; Arrangement of valves with means for lifting the closure member for pump cleaning purposes

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B53/00—Component parts, details or accessories not provided for in, or of interest apart from, groups F04B1/00 - F04B23/00 or F04B39/00 - F04B47/00

- F04B53/16—Casings; Cylinders; Cylinder liners or heads; Fluid connections

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B7/00—Piston machines or pumps characterised by having positively-driven valving

- F04B7/0042—Piston machines or pumps characterised by having positively-driven valving with specific kinematics of the distribution member

- F04B7/0053—Piston machines or pumps characterised by having positively-driven valving with specific kinematics of the distribution member for reciprocating distribution members

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B7/00—Piston machines or pumps characterised by having positively-driven valving

- F04B7/0076—Piston machines or pumps characterised by having positively-driven valving the members being actuated by electro-magnetic means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D41/00—Electrical control of supply of combustible mixture or its constituents

- F02D41/0025—Controlling engines characterised by use of non-liquid fuels, pluralities of fuels, or non-fuel substances added to the combustible mixtures

- F02D41/0027—Controlling engines characterised by use of non-liquid fuels, pluralities of fuels, or non-fuel substances added to the combustible mixtures the fuel being gaseous

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M2200/00—Details of fuel-injection apparatus, not otherwise provided for

- F02M2200/16—Sealing of fuel injection apparatus not otherwise provided for

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M2200/00—Details of fuel-injection apparatus, not otherwise provided for

- F02M2200/50—Arrangements of springs for valves used in fuel injectors or fuel injection pumps

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M59/00—Pumps specially adapted for fuel-injection and not provided for in groups F02M39/00 -F02M57/00, e.g. rotary cylinder-block type of pumps

- F02M59/20—Varying fuel delivery in quantity or timing

- F02M59/36—Varying fuel delivery in quantity or timing by variably-timed valves controlling fuel passages to pumping elements or overflow passages

- F02M59/366—Valves being actuated electrically

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M59/00—Pumps specially adapted for fuel-injection and not provided for in groups F02M39/00 -F02M57/00, e.g. rotary cylinder-block type of pumps

- F02M59/44—Details, components parts, or accessories not provided for in, or of interest apart from, the apparatus of groups F02M59/02 - F02M59/42; Pumps having transducers, e.g. to measure displacement of pump rack or piston

- F02M59/46—Valves

- F02M59/466—Electrically operated valves, e.g. using electromagnetic or piezoelectric operating means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B15/00—Pumps adapted to handle specific fluids, e.g. by selection of specific materials for pumps or pump parts

- F04B15/06—Pumps adapted to handle specific fluids, e.g. by selection of specific materials for pumps or pump parts for liquids near their boiling point, e.g. under subnormal pressure

- F04B15/08—Pumps adapted to handle specific fluids, e.g. by selection of specific materials for pumps or pump parts for liquids near their boiling point, e.g. under subnormal pressure the liquids having low boiling points

- F04B2015/081—Liquefied gases

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/10—Internal combustion engine [ICE] based vehicles

- Y02T10/30—Use of alternative fuels, e.g. biofuels

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Health & Medical Sciences (AREA)

- Biomedical Technology (AREA)

- Details Of Reciprocating Pumps (AREA)

- Fuel-Injection Apparatus (AREA)

Abstract

Kraftstofffördereinrichtung (100) für kryogene Kraftstoffe mit einem Tank (30), einer Hochdruckförderpumpe (1) und einer Zulaufleitung (18), über welche Zulaufleitung (18) der Hochdruckförderpumpe (1) kryogener Kraftstoff aus dem Tank (30) zuführbar ist. Die Hochdruckförderpumpe (1) weist ein Pumpengehäuse (2) auf, in dem ein mit der Zulaufleitung (18) verbundener Ansaugraum (50) ausgebildet ist, welcher Ansaugraum (50) mittels eines Verbindungskanals (26) mit einem Hochdruckraum (12) verbindbar ist. Zum Öffnen und Schließen des Verbindungskanals (26) ist ein Saugventil (14) in dem Pumpengehäuse (2) angeordnet, wobei das Saugventil (14) ein entlang einer Längsachse (28) der Hochdruckförderpumpe (1) bewegliches Saugventilelement (140) umfasst. Das Saugventilelement (140) wirkt mit einem ersten Dichtsitz (25) zusammen, wobei koaxial zu dem Saugventilelement (140) ein Kaltfahrventilelement (66) angeordnet ist, an welchem Kaltfahrventilelement (660) der erste Dichtsitz (25) ausgebildet ist. Außerdem ist sowohl das Kaltfahrventilelement (660) als auch das Saugventilelement (140) jeweils als mittels eines Elektromagneten (6) hubbeweglicher Magnetanker (66', 140') ausgebildet. Fuel feed device (100) for cryogenic fuels with a tank (30), a high pressure feed pump (1) and a supply line (18), via which feed line (18) of the high pressure feed pump (1) cryogenic fuel from the tank (30) can be supplied. The high-pressure feed pump (1) has a pump housing (2) in which a suction space (50) connected to the feed line (18) is formed, which suction space (50) can be connected to a high-pressure space (12) by means of a connecting channel (26). For opening and closing the connecting channel (26), a suction valve (14) is arranged in the pump housing (2), wherein the suction valve (14) comprises a suction valve element (140) movable along a longitudinal axis (28) of the high-pressure feed pump (1). The suction valve element (140) interacts with a first sealing seat (25), wherein a cold-shunt valve element (66) is arranged coaxially to the suction valve element (140), on which cold-shunt valve element (660) the first sealing seat (25) is formed. In addition, both the cold shuttle valve element (660) and the suction valve element (140) are in each case designed as a magnet armature (66 ', 140') which can be lifted by means of an electromagnet (6).

Description

Die Erfindung betrifft eine Kraftstofffördereinrichtung für kryogene Kraftstoffe. Diese Kraftstofffördereinrichtung findet beispielsweise Anwendung bei Brennkraftmaschinen von Kraftfahrzeugen mit einem kryogenen Kraftstoff-Antrieb, insbesondere mit Erdgas.The invention relates to a fuel delivery device for cryogenic fuels. This fuel delivery device is used, for example, in internal combustion engines of motor vehicles with a cryogenic fuel drive, in particular with natural gas.

Stand der TechnikState of the art

In der nicht vorveröffentlichten Schrift

Wird die Hochdruckpumpe nach einer Betriebspause wieder in Betrieb genommen, weist diese typischerweise Umgebungstemperatur auf. Der kryogene Kraftstoff aus dem Tank weist jedoch eine Speichertemperatur von beispielsweise -160°C auf, so dass dieser bei einer Förderung in den Pumpenkopf der Hochdruckpumpe sofort verdampft. Daher ist in der Hochdruckpumpe der

Vorteile der ErfindungAdvantages of the invention

Die erfindungsgemäße Kraftstofffördereinrichtung mit den kennzeichnenden Merkmalen des Anspruchs 1 weist den Vorteil auf, dass in einfacher und kostengünstiger Weise die Funktion des Kaltfahrventils in den Niederdruckspeicher integriert ist, ohne die Funktion der Hochdruckförderpumpe zu beeinträchtigen.The fuel delivery device according to the invention with the characterizing features of

Dazu weist die Kraftstofffördereinrichtung für kryogene Kraftstoffe einen Tank, eine Hochdruckförderpumpe und eine Zulaufleitung auf, über welche Zulaufleitung der Hochdruckförderpumpe kryogener Kraftstoff aus dem Tank zuführbar ist. Die Hochdruckförderpumpe weist ein Pumpengehäuse auf, in dem ein mit der Zulaufleitung verbundener Ansaugraum ausgebildet ist. Der Ansaugraum ist mittels eines Verbindungskanals mit einem Hochdruckraum verbindbar, wobei zum Öffnen und Schließen des Verbindungskanals ein Saugventil in dem Pumpengehäuse angeordnet ist. Das Saugventil umfasst ein entlang einer Längsachse der Hochdruckförderpumpe bewegliches Saugventilelement, welches mit einem ersten Dichtsitz zusammenwirkt. Weiterhin ist koaxial zu dem Saugventilelement ein Kaltfahrventilelement angeordnet, an welchem Kaltfahrventilelement der erste Dichtsitz ausgebildet ist. Darüber hinaus ist sowohl das Kaltfahrventilelement als auch das Saugventilelement jeweils als mittels eines Elektromagneten hubbeweglicher Magnetanker ausgebildet.For this purpose, the fuel delivery device for cryogenic fuels to a tank, a high-pressure pump and a supply line, via which supply line of the high-pressure pump cryogenic fuel from the tank can be fed. The high-pressure feed pump has a pump housing in which a suction space connected to the feed line is formed. The suction chamber is connectable by means of a connecting channel with a high-pressure chamber, wherein a suction valve is arranged in the pump housing for opening and closing the connecting channel. The suction valve comprises a suction valve element which is movable along a longitudinal axis of the high-pressure feed pump and which cooperates with a first sealing seat. Furthermore, coaxial with the suction valve element, a cold drive valve element is arranged, on which cold drive valve element of the first sealing seat is formed. In addition, both the cold-shut valve element and the suction valve element are each designed as a lifting magnet by means of an electromagnet.

So kann in einfacher Weise ein Kaltfahrventil bauraumoptimiert zur Durchspülung der Hochdruckförderpumpe in die Hochdruckförderpumpe integriert werden, ohne dass deren Funktion oder die Lebensdauer der verwendeten Bauteile beeinträchtigt werden. Weiterhin wird die Funktion des Kaltfahrens verbessert, da zusätzlich zum hydraulischen Druck des kryogenen Kraftstoffs die magnetische Kraft des Elektromagneten einen schnellen Öffnungshub des Saugventilelements gewährleistet.Thus, in a simple manner, a cold-driving valve can be integrated in a space-optimized manner for purging the high-pressure feed pump into the high-pressure feed pump without impairing its function or the service life of the components used. Furthermore, the function of the cooling is improved, since in addition to the hydraulic pressure of the cryogenic fuel, the magnetic force of the electromagnet ensures a fast opening stroke of the Saugventilelements.

In erster vorteilhafter Weiterbildung ist es vorgesehen, dass ein Ankerteller des Kaltfahrventilelements mit dem Elektromagneten wirkverbunden ist. So kann die Hubbewegung des Kaltfahrventilelements mittels des Elektromagneten präzise gesteuert werden.In a first advantageous embodiment, it is provided that an anchor plate of the cold-vehicle valve element is operatively connected to the electromagnet. Thus, the stroke movement of the cold retard valve element can be precisely controlled by means of the electromagnet.

In weiterer Ausgestaltung der Erfindung ist es vorteilhaft vorgesehen, dass das Saugventilelement Längsnuten aufweist, durch welche Längsnuten bei geöffnetem ersten Dichtsitz kryogener Kraftstoff aus dem Ansaugraum in den Hochdruckraum strömen kann. So kann in einfacher und bauraumsparender Weise ein Durchfluss von kryogenem Kraftstoff in der Hochdruckförderpumpe ermöglicht werden.In a further embodiment of the invention, it is advantageously provided that the suction valve element has longitudinal grooves through which longitudinal grooves with open first sealing seat cryogenic fuel from the suction chamber can flow into the high-pressure chamber. Thus, a flow of cryogenic fuel in the high-pressure feed pump can be made possible in a simple and space-saving manner.

In vorteilhafter Weiterbildung ist es vorgesehen, dass das Kaltfahrventilelement eine Ausnehmung aufweist, in welcher Ausnehmung eine Feder angeordnet ist, welche Feder sich zwischen dem Kaltfahrventilelement und dem Saugventilelement abstützt und das Saugventilelement mit einer Kraft in Richtung des ersten Dichtsitzes beaufschlagt. Vorteilhafterweise ist der Verbindungskanal in der Ausnehmung des Kaltfahrventilelements ausgebildet und das Saugventil in der Ausnehmung des Kaltfahrventilelements aufgenommen. So kann in einfacher Weise das Kaltfahrventilelement in die Hochdruckförderpumpe integriert werden, ohne zusätzlichen Bauraum zu beanspruchen.In an advantageous embodiment, it is provided that the cold drive valve element has a recess in which recess a spring is arranged, which spring is supported between the cold drive valve element and the suction valve element and the suction valve element is acted upon by a force in the direction of the first sealing seat. Advantageously, the connecting channel is formed in the recess of the cold-actuated valve element and the suction valve is received in the recess of the cold-actuated valve element. Thus, the cold shuttle valve element can be integrated into the high-pressure feed pump in a simple manner, without requiring additional space.

In weiterer Ausgestaltung der Erfindung ist es vorteilhaft vorgesehen, dass das Saugventilelement einen Ankerteller aufweist, an welchem Ankerteller Anformungen ausgebildet sind, welche Anformungen in Ausnehmungen des Ankertellers des Kaltfahrventilelements eingreifbar sind. Durch optimierte räumliche Anordnung des Ankertellers des Saugventilelements zu dem Elektromagneten kann so in einfacher Weise die magnetische Kraft auf das Saugventilelement erhöht werden, so dass ein schnelleres Schalten erzielt wird.In a further embodiment of the invention, it is advantageously provided that the suction valve element has an anchor plate, on which anchor plate projections are formed, which projections are engageable in recesses of the anchor plate of the cold shuttle valve element. Through optimized Spatial arrangement of the anchor plate of the suction valve element to the electromagnet can be increased in a simple manner, the magnetic force on the suction valve element, so that a faster switching is achieved.

In vorteilhafter Weiterbildung ist an einem konisch verjüngtem Absatz des Pumpengehäuses ein zweiter Dichtsitz ausgebildet, der mit dem Kaltfahrventilelement zum Öffnen und Schließen einer Verbindung zwischen dem Hochdruckraum und der Rückführleitung zusammenwirkt und so ein Kaltfahrventil ausbildet. So ist in einfacher Weise die Rückführung von kryogenem Kraftstoff aus der Hochdruckförderpumpe in Richtung Tank gewährleistet.In an advantageous embodiment, a second sealing seat is formed on a conically tapered shoulder of the pump housing, which cooperates with the cold-driving valve element for opening and closing a connection between the high-pressure chamber and the return line and thus forms a cold running valve. Thus, in a simple manner, the return of cryogenic fuel from the high-pressure pump is ensured in the direction of the tank.

In weiterer Ausgestaltung der Erfindung ist es vorteilhaft vorgesehen, dass das Kaltfahrventilelement mittels einer Druckfeder mit einer Kraft in Richtung des zweiten Dichtsitzes beaufschlagt ist. Dadurch ist die Verbindung zwischen dem Hochdruckraum und der Rückführleitung schließbar.In a further embodiment of the invention, it is advantageously provided that the cold drive valve element is acted upon by means of a compression spring with a force in the direction of the second sealing seat. As a result, the connection between the high-pressure chamber and the return line can be closed.

In vorteilhafter Weiterbildung ist der erste Dichtsitz konisch ausgebildet. So wird eine verbesserte Funktion des Saugventils in der Hochdruckförderpumpe und damit eine Optimierung der Dichtheit am ersten Dichtsitz erzielt.In an advantageous embodiment, the first sealing seat is conical. Thus, an improved function of the suction valve in the high-pressure delivery pump and thus an optimization of the tightness at the first sealing seat is achieved.

In weiterer Ausgestaltung der Erfindung ist es vorteilhaft vorgesehen, dass der Hochdruckraum mit einer Rückführleitung verbindbar ist, welche mit dem Tank verbunden ist. Dadurch ist bei Öffnung der Rückführleitung ein Kraftstoffkreislauf zwischen der Hochdruckförderpumpe und dem Tank geschlossen.In a further embodiment of the invention, it is advantageously provided that the high-pressure chamber is connectable to a return line, which is connected to the tank. As a result, a fuel circuit between the high-pressure feed pump and the tank is closed when opening the return line.

In vorteilhafter Weiterbildung ist es vorgesehen, dass in der Längsbohrung ein längsbeweglicher Pumpenkolben angeordnet ist, welcher den Hochdruckraum begrenzt. Vorteilhafterweise ist der Pumpenkolben mittels einer Feder mit einer Kraft entgegen der Richtung des Ansaugraums beaufschlagt. Durch Längsbewegungen des Pumpenkolbens kann der kryogene Kraftstoff bei Betrieb komprimiert und durch die Hochdruckförderpumpe gefördert werden.In an advantageous embodiment, it is provided that in the longitudinal bore a longitudinally movable pump piston is arranged, which limits the high-pressure chamber. Advantageously, the pump piston is acted upon by means of a spring with a force against the direction of the suction chamber. By longitudinal movements of the pump piston, the cryogenic fuel can be compressed during operation and promoted by the high pressure pump.

In vorteilhafter Weiterbildung ist es vorgesehen, dass in dem Tank eine Vorförderpumpe angeordnet ist, welche Kraftstoff aus dem Tank über die Zulaufleitung in den Ansaugraum der Hochdruckförderpumpe fördert. Dies ermöglicht eine variable Anordnung der Hochdruckförderpumpe, so dass diese beispielsweise relativ nahe zum Tankbehälter, oder aber relativ nahe zur Brennkraftmaschine angeordnet werden kann.In an advantageous embodiment, it is provided that in the tank, a prefeed pump is arranged, which promotes fuel from the tank via the supply line into the suction of the high pressure pump. This allows a variable arrangement of the high-pressure feed pump, so that it can be arranged, for example, relatively close to the tank container, or relatively close to the internal combustion engine.

Figurenlistelist of figures

In der Zeichnung sind Ausführungsbeispiele einer erfindungsgemäßen Kraftstofffördereinrichtung dargestellt. Es zeigt

-

1a ein Ausführungsbeispiel einer erfindungsgemäßen Kraftstofffördereinrichtung im Längsschnitt, -

1b das Ausführungsbeispiel der erfindungsgemäßen Kraftstofffördereinrichtung aus der1a mit geöffneten Ventilen im Längsschnitt, -

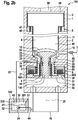

2a ein weiteres Ausführungsbeispiel einer erfindungsgemäßen Kraftstofffördereinrichtung im Längsschnitt, -

2b das Ausführungsbeispiel der erfindungsgemäßen Kraftstofffördereinrichtung aus der2a mit geöffneten Ventilen im Längsschnitt.

-

1a an embodiment of a fuel delivery device according to the invention in longitudinal section, -

1b the embodiment of the fuel delivery device according to the invention from the1a with opened valves in longitudinal section, -

2a a further embodiment of a fuel delivery device according to the invention in longitudinal section, -

2 B the embodiment of the fuel delivery device according to the invention from the2a with opened valves in longitudinal section.

Beschreibung der AusführungsbeispieleDescription of the embodiments

In der

Der Tank

Der Tank

Die Hochdruckförderpumpe

Weiterhin ist in der Längsbohrung

In dem Ansaugraum

Weiterhin weist das Kaltfahrventilelement

Mit seinem dem Ansaugraum

Der Ankerteller

Funktionsweise der KraftstofffördereinrichtungOperation of the fuel conveyor

Bei Betrieb der Kraftstofffördereinrichtung

Bei einem erstmaligen Betrieb oder einer Wiederaufnahme des Betriebs der Kraftstofffördereinrichtung

Zur Öffnung des zweiten Dichtsitzes

So kann die Hochdruckpumpe

ZITATE ENTHALTEN IN DER BESCHREIBUNG QUOTES INCLUDE IN THE DESCRIPTION

Diese Liste der vom Anmelder aufgeführten Dokumente wurde automatisiert erzeugt und ist ausschließlich zur besseren Information des Lesers aufgenommen. Die Liste ist nicht Bestandteil der deutschen Patent- bzw. Gebrauchsmusteranmeldung. Das DPMA übernimmt keinerlei Haftung für etwaige Fehler oder Auslassungen.This list of the documents listed by the applicant has been generated automatically and is included solely for the better information of the reader. The list is not part of the German patent or utility model application. The DPMA assumes no liability for any errors or omissions.

Zitierte PatentliteraturCited patent literature

- DE 102017219784 A1 [0002]DE 102017219784 A1 [0002]

- DE 102017219784 [0003]DE 102017219784 [0003]

Claims (13)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102018206334.6A DE102018206334A1 (en) | 2018-04-25 | 2018-04-25 | Fuel delivery device for cryogenic fuels |

| PCT/EP2019/058598 WO2019206600A1 (en) | 2018-04-25 | 2019-04-05 | Fuel delivery device for cryogenic fuels |

| CN201980027810.7A CN112005003B (en) | 2018-04-25 | 2019-04-05 | Fuel delivery device for cryogenic fuels |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102018206334.6A DE102018206334A1 (en) | 2018-04-25 | 2018-04-25 | Fuel delivery device for cryogenic fuels |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| DE102018206334A1 true DE102018206334A1 (en) | 2019-10-31 |

Family

ID=66182504

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| DE102018206334.6A Pending DE102018206334A1 (en) | 2018-04-25 | 2018-04-25 | Fuel delivery device for cryogenic fuels |

Country Status (3)

| Country | Link |

|---|---|

| CN (1) | CN112005003B (en) |

| DE (1) | DE102018206334A1 (en) |

| WO (1) | WO2019206600A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2021151941A1 (en) * | 2020-01-31 | 2021-08-05 | Robert Bosch Gmbh | Gas metering valve for internal combustion engines |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3715614A1 (en) * | 1987-05-11 | 1988-11-24 | Bosch Gmbh Robert | FUEL INJECTION PUMP |

| DE3934953A1 (en) * | 1989-10-20 | 1991-04-25 | Bosch Gmbh Robert | SOLENOID VALVE, ESPECIALLY FOR FUEL INJECTION PUMPS |

| RU2101547C1 (en) * | 1991-10-11 | 1998-01-10 | Катерпиллар Инк. | Drive and valve unit for hydraulically operated injector with electronic control |

| US5884488A (en) * | 1997-11-07 | 1999-03-23 | Westport Research Inc. | High pressure fuel supply system for natural gas vehicles |

| JP2000186649A (en) * | 1998-12-24 | 2000-07-04 | Isuzu Motors Ltd | Variable discharge quantity control type high pressure fuel pump |

| US8201754B2 (en) * | 2009-12-03 | 2012-06-19 | Caterpillar Inc. | Fluid injector with thermal load control |

| DE102010027745A1 (en) * | 2010-04-14 | 2011-10-20 | Robert Bosch Gmbh | high pressure pump |

| DE102011007376A1 (en) * | 2011-04-14 | 2012-10-18 | Robert Bosch Gmbh | Fuel supply device for fuel injection system of internal combustion engine, comprises high-pressure fuel pump that has pump element and through that fuel is supplied into high-pressure area, where injector is provided in high-pressure area |

| DE102011087701A1 (en) * | 2011-12-05 | 2013-06-06 | Robert Bosch Gmbh | Low pressure unit for a pump, in particular a high-pressure fuel pump of a fuel injection device |

| DE102017219784A1 (en) | 2017-11-07 | 2019-05-09 | Robert Bosch Gmbh | Cryogenic fuel fuel delivery system, method of operating a fuel delivery system for cryogenic fuels |

-

2018

- 2018-04-25 DE DE102018206334.6A patent/DE102018206334A1/en active Pending

-

2019

- 2019-04-05 WO PCT/EP2019/058598 patent/WO2019206600A1/en active Application Filing

- 2019-04-05 CN CN201980027810.7A patent/CN112005003B/en active Active

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2021151941A1 (en) * | 2020-01-31 | 2021-08-05 | Robert Bosch Gmbh | Gas metering valve for internal combustion engines |

| US11873784B2 (en) | 2020-01-31 | 2024-01-16 | Robert Bosch Gmbh | Gas metering valve for internal combustion engines |

Also Published As

| Publication number | Publication date |

|---|---|

| CN112005003A (en) | 2020-11-27 |

| WO2019206600A1 (en) | 2019-10-31 |

| CN112005003B (en) | 2022-07-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3478957B1 (en) | Valve for injecting gaseous fuel | |

| DE102011013702A1 (en) | Electromagnetic actuator | |

| EP1203151B1 (en) | Two-stage electromagnetic valve for an injector of internal combustion engines | |

| DE112009001971T5 (en) | Check valve with separate spherical spring guide | |

| EP1144843B1 (en) | Injector for a fuel injection system for internal combustion engines, with hydraulic prestressing of the pressure booster | |

| EP1123461B1 (en) | Compact-size injector for a common-rail-injection system utilized in internal combustion engines | |

| DE102009047559A1 (en) | fuel injector | |

| EP1970556B1 (en) | Injector | |

| DE102006003484A1 (en) | Device for injecting fuel | |

| DE102018206334A1 (en) | Fuel delivery device for cryogenic fuels | |

| DE19945785B4 (en) | Fuel injection system for internal combustion engines and method for injecting fuel into the combustion chamber of an internal combustion engine | |

| EP1939441A2 (en) | Fuel injector | |

| DE102018206331A1 (en) | Fuel delivery device for cryogenic fuels | |

| DE102012220027A1 (en) | Switching valve for common-rail fuel injector for injecting diesel into combustion chamber of internal combustion engine, has control space filled with fuel via hole, and closing element closing hole in position for pressure relief of space | |

| EP1413756B1 (en) | Fuel pump | |

| DE102019134775B4 (en) | solenoid valve | |

| DE102013210881A1 (en) | Electromagnetically controllable suction valve for a high-pressure pump | |

| DE102007026834A1 (en) | Electromagnetic control valve e.g. for internal combustion engine, has valve unit, full valve casing, inlet port, consumer connection and piston valve which is relocatable compared with valve casing | |

| DE19949525B4 (en) | Pressure intensifier for a fuel injection system for internal combustion engines with hydraulically assisted refilling | |

| DE10307003B3 (en) | IC engine fuel injection valve has actuator controlling displacement of valve needle spring biased into closure position for fuel injection bores | |

| DE102018203697A1 (en) | Fuel delivery device for cryogenic fuels | |

| DE102018200715A1 (en) | Fuel delivery device for cryogenic fuels | |

| DE102018211924A1 (en) | Fuel delivery device for cryogenic fuels | |

| DE102018213091A1 (en) | Valve device for a fuel delivery device for cryogenic fuels | |

| DE102019206322A1 (en) | Fuel delivery device for cryogenic fuels and method for a cold start-up process of a fuel delivery device |