CN218943294U - Insertion part - Google Patents

Insertion part Download PDFInfo

- Publication number

- CN218943294U CN218943294U CN202120442596.6U CN202120442596U CN218943294U CN 218943294 U CN218943294 U CN 218943294U CN 202120442596 U CN202120442596 U CN 202120442596U CN 218943294 U CN218943294 U CN 218943294U

- Authority

- CN

- China

- Prior art keywords

- bend

- distal end

- stainless steel

- disposed

- channel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Endoscopes (AREA)

Abstract

The utility model discloses an electronic endoscope, which comprises an insertion part and an operation part which are sequentially connected with each other, wherein the insertion part comprises a front end part and a bending part, the distal end surface of the front end part is provided with an inclined surface, the inclined surface and the distal end surface of the front end part are crossed to form a ridge line, and the ridge line is parallel to the bending direction of the bending part. The electronic endoscope provided by the utility model can realize better trafficability aiming at the use environment with low cost.

Description

The present application is a divisional application of a chinese utility model patent application named "electronic endoscope" with application number 202021293159.4 and application date 2020, 07, 03.

Technical Field

The utility model relates to the field of medical instruments, in particular to an electronic endoscope.

Background

Retrograde cholangiopancreatography (ERCP, english full name: encoscopic Retrograde Cholangio-Pancreatography) refers to a technique of inserting a duodenal mirror into a duodenal drop portion, finding a duodenal papilla, inserting a contrast catheter into a papilla opening portion from a biopsy tube, and injecting a contrast agent, and then taking an x-ray image to display the cholangiopancreatography. Based on ERCP, can carry out intervention treatment such as duodenal papillary sphincterotomy, endoscopic nasal bile drainage, endoscopic internal bile drainage, endoscopic stone extraction and the like, and is welcomed by patients because of no need of operation and small trauma. Such interventions often require the insertion of an interventional instrument through the instrument channel of the duodenum scope (or referred to as the working channel, the forceps channel, etc.), through the duodenal papilla and into the biliary pancreatic duct. When the interventional instrument is an endoscope, the duodenum scope may be understood as a parent endoscope or a parent endoscope.

However, endoscopes currently marketed as interventional instruments are complex in structure and expensive and can only be reused. Accordingly, there is a need for an endoscope that can substantially perform the above-described functions as an interventional instrument, and that is also desirably low-cost.

Disclosure of Invention

The utility model aims to solve the problem of excessive cost of an endoscope used as an interventional therapy device. The utility model provides an electronic endoscope which can be used as an interventional therapy instrument and has lower cost.

In order to solve the above technical problems, an embodiment of the present utility model discloses an electronic endoscope, which includes an insertion portion and an operation portion that are sequentially connected to each other, the insertion portion includes a distal end portion and a bending portion, a distal end surface of the distal end portion has an inclined surface, the inclined surface and the distal end surface of the distal end portion intersect to form a ridge line, and the ridge line is parallel to a bending direction of the bending portion.

By adopting the technical scheme, the electronic endoscope provided by the utility model has good trafficability in the vertical direction perpendicular to the bending direction through the arrangement of the inclined surface; through active control of the bending direction, the electronic endoscope provided by the utility model has good trafficability in the bending direction; in addition, through the movement or rotation of the operation part, the electronic endoscope provided by the utility model can selectively utilize the inclined plane, or utilize the active control on the bending direction or simultaneously utilize the active control on the inclined plane and the bending direction to cooperate according to the actual situation so as to realize the trafficability in different scenes. Most importantly, the technical scheme has simple structure and can be manufactured at low cost.

The different scenarios above include at least a working channel (or instrument channel or forceps channel, etc.) through the mother endoscope or into the duodenal papilla. Namely, the electronic endoscope provided by the utility model has good trafficability when passing through a mother endoscope preset in a human body in advance; the electronic endoscope provided by the utility model has good trafficability when entering the duodenal papilla after passing through the female endoscope. The advantage of the above-described passability is achieved at low cost by the engagement with the operation portion.

Alternatively, the inclined surface faces the side surface of the operation portion.

Optionally, an instrument opening is formed in the shell of the operation part, and the inclined surface faces one side of the instrument opening.

Optionally, the bend includes a harness channel extending axially through the bend, an intersection of an axis of the harness channel and a distal end face of the bend being located at an eccentric location relative to the axis of the bend.

Optionally, a line between the intersection of the axis of the wire harness channel and the distal end face of the bend is parallel to the ridge.

Optionally, the front end portion includes the base, and the distal end of base is equipped with camera shooting unit and two lighting units, and two lighting units are located the both sides of camera shooting unit respectively.

Optionally, the bend comprises an auxiliary channel, the auxiliary channel being watertight.

Optionally, an intersection of the auxiliary channel and the distal end face of the front end portion is located in a region other than the inclined surface.

Alternatively, the number of the auxiliary channels is two, and the intersections of the two auxiliary channels and the distal end face of the front end portion are respectively close to the two illumination units.

Optionally, the insertion part further comprises a flexible pipe part, the front end part, the bending part and the flexible pipe part are all provided with working channels penetrating along the axial direction, and the working channels of the front end part, the bending part and the flexible pipe part are communicated through pipe fittings.

Drawings

Fig. 1 is a front view showing a structure of an electronic endoscope provided in an embodiment of the present utility model.

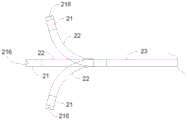

Fig. 2 is a bottom view showing a structure of an insertion portion according to an embodiment of the present utility model.

Fig. 3 is a left side view showing the structure of an insertion portion provided in an embodiment of the present utility model.

Fig. 4 shows a cross-sectional view along A-A in fig. 2.

Fig. 5 shows a bottom view of a bent state of the bent portion in the left-right direction thereof.

Fig. 6a shows a cross-sectional view along the junction of the front end portion and the curved portion of fig. 3B-B.

Fig. 6B shows a cross-sectional view along the junction of the bend and flexible pipe section of fig. 3B-B.

Fig. 6C shows a cross-sectional view along the junction of the front end portion and the curved portion of fig. 3C-C.

Fig. 6d shows a cross-sectional view along the junction of the bend and flexible pipe section of fig. 3C-C.

Fig. 7a is a perspective view showing an internal structure of an operation section according to an embodiment of the present utility model.

Fig. 7b is a front view showing an internal structure of an operation section provided in an embodiment of the present utility model.

Fig. 8a is a perspective view showing a part of the internal structure of an operation section according to an embodiment of the present utility model.

Fig. 8b is a front view showing a part of the internal structure of the operation section provided by an embodiment of the present utility model.

Fig. 9 is a perspective view showing a back surface structure of an operation portion according to an embodiment of the present utility model.

Fig. 10 is a perspective view showing the structure of a locking mechanism according to an embodiment of the present utility model.

Fig. 11 is a perspective view showing the structure of a petal-shaped block according to an embodiment of the present utility model.

Fig. 12 is a perspective view showing the structure of a control section according to an embodiment of the present utility model.

Fig. 13 is a perspective view showing a structure of a follower portion according to an embodiment of the present utility model.

Detailed Description

Further advantages and effects of the present utility model will become apparent to those skilled in the art from the disclosure of the present specification, by describing the embodiments of the present utility model with specific examples. While the description of the utility model will be described in connection with the preferred embodiments, it is not intended to limit the inventive features to the implementation. Rather, the purpose of the utility model described in connection with the embodiments is to cover other alternatives or modifications, which may be extended by the claims based on the utility model. The following description contains many specific details for the purpose of providing a thorough understanding of the present utility model. The utility model may be practiced without these specific details. Furthermore, some specific details are omitted from the description in order to avoid obscuring the utility model. It should be noted that, without conflict, the embodiments of the present utility model and features of the embodiments may be combined with each other.

It should be noted that in this specification, like reference numerals and letters denote like items in the following figures, and thus once an item is defined in one figure, no further definition or explanation thereof is necessary in the following figures.

In the description of the present embodiment, it should be noted that the azimuth or positional relationship indicated by the terms "upper", "lower", "inner", "bottom", etc. are based on the azimuth or positional relationship shown in the drawings, or the azimuth or positional relationship in which the inventive product is conventionally put in use, are merely for convenience of describing the present utility model and simplifying the description, and are not indicative or implying that the apparatus or element to be referred to must have a specific azimuth, be configured and operated in a specific azimuth, and therefore should not be construed as limiting the present utility model.

In the description of the present embodiment, the terms "near" and "far" are relative positional relationships, and when an operator operates an instrument to treat a target object, the side close to the operator is "near" and the side close to the target object is "far" along the instrument.

The terms "first," "second," and the like are used merely to distinguish between descriptions and are not to be construed as indicating or implying relative importance.

In the description of the present embodiment, it should also be noted that, unless explicitly specified and limited otherwise, the terms "disposed," "connected," and "connected" are to be construed broadly, and may be, for example, fixedly connected, detachably connected, or integrally connected; can be mechanically or electrically connected; can be directly connected or indirectly connected through an intermediate medium, and can be communication between two elements. The specific meaning of the above terms in the present embodiment can be understood in a specific case by those of ordinary skill in the art.

In the embodiments provided herein, the bends and/or flexible tubing portions of the embodiments provided herein involve multiple channels or lumens in order to perform some of the functions of an endoscope as an interventional procedure instrument. In this case, the "channel" or "cavity" is described mainly with respect to the bent portion and/or the flexible tube portion which are substantially solid. The channel or lumen involved in the bend and/or flexible tubing in embodiments provided by the present utility model may be a conduit or path if the bend and/or flexible tubing is not solid, such as being substantially hollow. That is, the channels or lumens in the bends and/or flexible tubing portions of the embodiments provided herein may also be tubing or paths so long as the desired paths for the respective components are provided.

For the purpose of making the objects, technical solutions and advantages of the present utility model more apparent, embodiments of the present utility model will be described in further detail below with reference to the accompanying drawings.

Retrograde cholangiopancreatography (ERCP, english full name: encoscopic Retrograde Cholangio-Pancreatography) refers to a technique of inserting a duodenal mirror into a duodenal drop portion, finding a duodenal papilla, inserting a contrast catheter into a papilla opening portion from a biopsy tube, and injecting a contrast agent, and then taking an x-ray image to display the cholangiopancreatography. Based on ERCP, can carry out intervention treatment such as duodenal papillary sphincterotomy, endoscopic nasal bile drainage, endoscopic internal bile drainage, endoscopic stone extraction and the like, and is welcomed by patients because of no need of operation and small trauma. Such interventions often require the insertion of an interventional instrument through the instrument channel of the duodenum scope (or referred to as the working channel, the forceps channel, etc.), through the duodenal papilla and into the biliary pancreatic duct. When the interventional instrument is an endoscope, the duodenum scope may be understood as a parent endoscope or a parent endoscope.

However, endoscopes currently marketed as interventional instruments are complex in structure and expensive, and bring about another problem while performing ERCP surgery and corresponding interventional therapy.

8.6.2019, U.S. New York Times published an article entitled "WhyAre These Medical Instruments So Tough to Sterilize" and the authors were Roni Caryn Rabin. Why is it so difficult to disinfect an endoscope that 36 krypton (36 kr. Com) translates into 50 thousands of patients per year? (B) A & lt- & gt. Writing in the article: in medical institutions around the world, it is necessary to use a snake-shaped duodenal mirror (duodenoscope) tool for diagnosis and treatment of pancreatic, bile duct, and other diseases. However, these fiber optic elements have a significant disadvantage: although it can be inserted through the mouth into the upper half of the small intestine and reused, it cannot be sterilized in a conventional manner. Typically, they are cleaned by hand and then placed in a dishwasher-like machine for cleaning again. During the re-cleaning process, special chemicals are also added to destroy microorganisms. Even if each procedure is strictly on demand, bacteria may remain on these devices and the patient may be infected accordingly. In fact, in many medical institutions in the united states and europe, cases of duodenal infection of patients occur, and up to hundreds of cases. However, according to a recent test, the relevant regulatory authorities have seriously underestimated their risk behind. Worse still, these devices can even cause the spread of drug-resistant infections, which are currently rarely cured.

Obviously, the above-mentioned problems are also present as an endoscope for an interventional instrument.

Therefore, there is a strong need for an endoscope that can perform the above-described functions of diagnosing and treating diseases such as pancreas and bile duct, and can avoid infection due to incomplete cleaning. In addition, it is important that the cost be low, otherwise the patient still has difficulty in using it. Obviously, as the cost is low to a certain extent, the endoscope with low cost can be used as a disposable endoscope, and the problem that secondary infection is caused by the fact that the endoscope cannot be thoroughly cleaned is thoroughly solved.

The utility model provides an electronic endoscope which can be used as an interventional therapy instrument for the ERCP operation and can achieve the aim, and a corresponding component which is contained in the electronic endoscope and can be independently manufactured and used.

For convenience of description of the orientation, the electronic endoscope 1 provided in the embodiment of the present utility model, in which the knob 3111 on the operation section 3 is located on the front surface of the operation section 3. The operation portion 3 is provided with an instrument opening 307, and the instrument opening 307 is located on a side surface of the operation portion 3. The inclined surface 211 faces the side surface of the operation portion 3. The inclined surface 211 faces the instrument well 307 side.

Fig. 1 is a front view showing a structure of an electronic endoscope provided in an embodiment of the present utility model. As shown in fig. 1, an electronic endoscope 1 according to an embodiment of the present utility model includes an elongated insertion portion 2 and an operation portion 3 provided on a proximal end side of the insertion portion 2. That is, the present utility model provides an electronic endoscope 1 including an insertion portion 2 and an operation portion 3 connected to each other.

Fig. 2 is a bottom view showing a structure of an insertion portion according to an embodiment of the present utility model. As shown in fig. 2, the insertion portion 2 is provided with a distal end portion 21, a bent portion 22, and a flexible tube portion 23 in this order from the distal end.

Fig. 3 is a left side view showing the structure of an insertion portion provided in an embodiment of the present utility model. As shown in fig. 3 in combination with fig. 1 and 2, the tip portion 21 of the insertion portion 2 is provided with a substantially cylindrical base 210. The base 210 is provided with an inclined surface 211 formed by cutting out a part of the underside of the distal end surface of the base 210. It will be appreciated by those skilled in the art that the "cut-out" is provided to facilitate visual understanding of the shape of the inclined surface 211, and is not a limitation of the formation process of the inclined surface 211.

Continuing as shown in fig. 3. The base 210 is further provided with a plurality of cavities penetrating through the base 210 along the axial direction, wherein the cavities comprise a cavity for fixing the camera unit 212, a cavity for fixing the illumination unit 213 and a working channel 214 for allowing a working instrument to pass through. Wherein, as shown in fig. 3, the base 210 is seen from the distal end side, and most of the area of the working channel 214 is located in the inclined surface 211.

By adopting the technical scheme, the electronic endoscope provided by the utility model has good trafficability in the vertical direction perpendicular to the bending direction through the arrangement of the inclined surface; through active control of the bending direction, the electronic endoscope provided by the utility model has good trafficability in the bending direction; in addition, through the movement or rotation of the operation part, the electronic endoscope provided by the utility model can selectively utilize the inclined plane, or utilize the active control on the bending direction or simultaneously utilize the active control on the inclined plane and the bending direction to cooperate according to the actual situation so as to realize the trafficability in different scenes. Most importantly, the technical scheme has simple structure and can be manufactured at low cost. The above low cost advantage is embodied in the various structures of the electronic endoscope provided by the present utility model.

The base 210 may also include an auxiliary channel 215, which auxiliary channel 215 allows clean water to pass through. It will be appreciated by those skilled in the art that this embodiment is provided by way of example only and is primarily intended to intuitively illustrate that the auxiliary channel 215 may be provided with corresponding features depending on the object being passed, i.e. when the auxiliary channel 215 is to be used as a channel for water, it should be substantially sealed and able to withstand a certain pressure, so as to ensure that the water is properly transported to the distal end of the base 210 and normally functions as a flush, etc., rather than to define the auxiliary channel 215 to only allow the passage of water. In the present embodiment, the auxiliary passages 215 are provided in two.

The above-described embodiment of the present utility model provides the insertion portion 2 of the electronic endoscope 1, wherein the intersection of the auxiliary channel 215 and the distal end face of the distal end portion 21 is located in a region other than the inclined surface 211.

The applicant found that the paired and symmetrical illumination units can make the image captured by the image capturing unit clearer and have less dead angle relative to one illumination unit. In this embodiment, therefore, on the base 210 where the actual product may be small in size, the illumination units 213 respectively located on both sides of the image pickup unit 212 are still provided. The applicant believes that it is worth at least providing the two lighting units 213 described above, even if the dimensions of the other cavities are forced to become smaller thereby.

The above-described embodiment of the present utility model provides the insertion section 2 of the electronic endoscope 1, in which two fixed illumination units 213 are located on both sides of the image pickup unit 212. The intersections of the two auxiliary passages 215 with the distal end faces of the front end portion 21 are close to the two illumination units 213, respectively.

The base 210 should be hard, and the definition of hard herein should be understood that when the electronic endoscope 1 provided in this embodiment works in a human body, the base 210 should be able to withstand corresponding pressure, and overcome corresponding resistance, so that the image pickup unit 212, the illumination unit 213, the working channel 214, and the auxiliary channel 215 provided thereon can be stably maintained. The base 210 may be made of a rigid plastic or other materials that meet the above requirements. Such as metals, surface glazed ceramics, melamine resins.

The insertion section 2 of the electronic endoscope 1 according to the above embodiment of the present utility model is provided with the imaging unit 212 provided at both ends of the cross section of the distal end portion 21 opposite to the working channel 214. The cross section is a section perpendicular to the axis of the front end portion 21.

Fig. 4 shows a cross-sectional view along A-A in fig. 2. Fig. 4 shows a schematic cross-sectional view of a bend 22 provided by an embodiment of the present utility model. In the present embodiment, the cross-sectional structures of the bending portion 22 and the flexible tube portion 23 are substantially the same, and are each provided with a cavity extending therethrough in the axial direction, including the cable passage 223 and the working passage 224. Auxiliary channels 225 may also be provided in accordance with the foregoing description. As previously described, the auxiliary passage 225 may be provided to have water tightness.

The arrangement of the inner structures of the bent portion 22 and the flexible tube portion 23 corresponds to the inner structure of the base 210. Specifically, the imaging unit 212 and the illumination unit 213 provided on the base 210 require the cable 24 such as an electric wire, a data wire, and the like to be provided to the bending portion 22 and the cable passage 223 in the flexible tube portion 23. Wherein the cable 24 is shown in this application as being electrically conductive to provide power or to transmit electronic data. The working channel 214 provided on the base 210 requires the bending portion 22 and the flexible tube portion 23 to be provided with corresponding working channels 224, so that the objects such as instruments needing to pass through the working channels 214 and 224 can pass through the flexible tube portion 23, the bending portion 22 and the base 210 from the proximal end to enter the human body or the detected object. When the auxiliary channel 215 is provided on the base 210, the bending portion 22 and the flexible tube portion 23 may be provided with corresponding auxiliary channels 225 as well and cooperate with the auxiliary channel 215.

The above-described embodiment of the present utility model provides the insertion portion 2 of the electronic endoscope 1, wherein the cable channel 223 is provided at both ends on the cross section of the bending portion 22 opposite to the working channel 224. The cross section is a section perpendicular to the axis of the front end portion 21.

As further shown in fig. 4, unlike the internal structure of the base 210, the inside of the bending portion 22 and the flexible tube portion 23 is further provided with a harness passage 226, which is provided mainly for the purpose of achieving bending control of the bending portion 22. The wire harness 20 may be placed in the wire harness passage 226, and the wire harness 20 sequentially passes through the operation portion 3, the flexible tube portion 23, the bending portion 22 from the operation mechanism 31 located at the operation portion 3, and is finally fixed at an eccentric position at the distal end of the bending portion 22. Thus, when the operator controls the operating mechanism 31 to tighten the wire harness 20, the wire harness 20 will act on the eccentric position of the distal end of the bent portion 22, so that the bent portion 22 is bent toward the eccentric position. That is, the bending direction of the bending portion 22 is determined by the arrangement position of the harness path 226 on the distal end face of the bending portion 22. The bending direction of the bending portion 22 can be controlled by setting the fixing point of the wire harness 20 at the distal end of the bending portion 22 at different eccentric positions. In order to achieve the bidirectional bending of the bending portion 22, in the present embodiment, the applicant sets two wire harnesses 20, and connects the proximal ends of the two wire harnesses 20 to the operating mechanism 31, and the distal ends extend along the above-described path and are respectively fixed at different eccentric positions of the distal end of the bending portion 22, achieving the bidirectional bending of the bending portion 22. In order to achieve a bending angle of the bending portion 22 in one direction as large as possible, the fixed positions of the two wire harnesses 20 at the distal ends of the bending portion 22 may be disposed opposite to each other. That is, the bending portion 22 includes two harness channels 226, and intersections of the two harness channels 226 and the distal end face of the bending portion 22 are provided at both right and left ends of the distal end face of the bending portion 22 in mirror image (fig. 4). In some embodiments, the distal end surface of the bending portion 22 may be disposed at a central position in the up-down direction, which is advantageous for achieving the maximum bending angle of the bending portion 22. In other words, the intersections of the two harness channels 226 and the distal end face of the bent portion 22 are symmetrically disposed with respect to a longitudinal section passing through the axis of the working channel 224.

Fig. 5 shows a bottom view of a bent state of the bent portion in the left-right direction thereof.

The insertion portion 2 of the electronic endoscope 1 provided by the above-described embodiment of the present utility model, wherein the bending portion 22 includes a cable passage 223 penetrating the bending portion 22, a working passage 224, and a harness passage 226, wherein an intersection of an axis of the harness passage 226 and a distal end face of the bending portion 22 is located at an eccentric position with respect to an axis of the bending portion 22. That is, the axis of the harness passage 226 does not coincide with the axis of the bent portion 22. When the auxiliary passages 225 are provided, the intersections of the two harness passages 226 and the distal end face of the bent portion 22 are close to the intersections of the two auxiliary passages 225 and the distal end face of the bent portion 22, respectively.

In the present utility model, the line connecting the intersection of the two harness channels 226 and the distal end face of the bent portion 22 is substantially parallel to the ridge line 216, so that the ridge line 216 can be ensured to be substantially parallel to the bending direction of the bent portion 22.

When the operator controls the harness 20 to bend the bending portion 22 to one side, the flexible tube portion 23 may also be bent at an angle. In the present embodiment, in order to make the control of the operator more accurate, the material of the flexible tube portion 23 is set to be harder with respect to the bending portion 22, so that when the operator controls the bending portion 22 to bend the front end portion 21 by the wire harness 20, the flexible tube portion 23 is not substantially bent, so that the position of the front end portion 21 can be easily controlled. In other embodiments, the material of the flexible tube portion 23 may be set to be the same as that of the bending portion 22 according to the purpose, so as to control the follow-up motion of the flexible tube portion 23 according to the motion of the bending portion 22 when necessary. In the above embodiment, although only the control of the bending portion 22 and the flexible tube portion 23 by the material selection is mentioned, it will be understood by those skilled in the art that the control of the bending angle of the bending portion 22 and the follow-up action of the flexible tube portion 23 may be achieved by controlling different specifications of the same material or providing different portions to different materials or different specifications of the same material. In order to achieve a relatively less flexible tube portion 23 and a relatively more flexible tube portion 22, one may consider the material of the inner and outer parts (e.g. outer cover, outer coating material, inner cover attached to the inner wall, inner coating material) attached to both, on the one hand, and on the other hand, the material of the tube replacing the channel or lumen, as well. At this time, since the pipe is used in place of the channel or the cavity, it is obviously provided inside the bent portion 22 and/or the flexible pipe portion 23. In addition, besides the materials, the structure of each component, such as a spring tube, can be realized.

The above-described embodiment of the present utility model provides the insertion portion 2 of the electronic endoscope 1, in which the material of the bending portion 22 or the material attached to the bending portion 22 is lower in rigidity, i.e., softer, and easier to bend than the material of the flexible tube portion 23 or the material attached to the flexible tube portion 23. Alternatively, the material or construction of the tubing disposed within the bend 22 is less rigid, i.e., softer, and more flexible, than the material or construction of the tubing within the flexible tubing portion 23. For example, the tubing may be supported by spring tubes, with more sparsely arranged spring tubes or smaller wire diameters being more easily bent.

In the case where two wire harnesses 20 are provided and two wire harness channels 226 are provided in the bending portion 22 and the flexible tube portion 23 as described above, one end of one wire harness 20 may be inserted into one wire harness channel 226 from the proximal end side of the flexible tube portion 23, sequentially passed through the flexible tube portion 23 and the bending portion 22 and projected from the distal end side of the bending portion 22 (at this time, the bending portion 22 is not yet connected to the front end portion 21), and then inserted into the other wire harness channel 226 from the distal end side of the bending portion 22 and projected from the proximal end side of the flexible tube portion 23. That is, one wire harness 20 is passed through the bending portion 22 and the harness passage 226 of the flexible tube portion 23 and formed into a U-shape in which an opening of the U-shape is located outside the proximal end of the flexible tube portion 23 and a closing of the U-shape is located outside the distal end of the bending portion 22. Then, the portion of the wire harness 20 located outside the distal end of the bent portion 22 at this time is fixed to the distal end face of the bent portion 22, for example, by bonding with glue or welding, so that quick installation of the wire harness 20 can be achieved. The installation method can remarkably improve the working efficiency.

The above-described embodiment of the present utility model provides a wire harness 20 for bending control of an electronic endoscope 1, a method of mounting to an insertion portion 2, the insertion portion 2 including a bending portion 22 and a flexible tube portion 23, the bending portion 22 and the flexible tube portion 23 each being provided with two harness passages 226 extending in an axial direction, the mounting method including:

inserting one end of one harness 20 into one harness passage 226 from the proximal end side of the flexible tube portion 23;

extending the one end of the wire harness 20 from the distal end of the bent portion 22;

inserting the one end of the wire harness 20 into the other wire harness channel 226 from the distal end of the bent portion 22;

extending the one end of the wire harness 20 from the proximal end of the flexible tube portion 23;

the portion of the wire harness 20 protruding from the distal end of the bent portion 22 is fixedly connected to the bent portion 22.

As an example of a use scenario of the embodiment provided by the present utility model, in ERCP endoscopic retrograde cholangiopancreatography, a mother endoscope is transorally inserted into the duodenum, and then the electronic endoscope provided by the present embodiment is inserted into the duodenal papilla (common opening of bile duct and main pancreatic duct in the duodenum) through an ocular endoscope, and various required operations are performed. The applicant has found that the electronic endoscope provided in this embodiment needs to pass through a corresponding channel (e.g. working channel, or referred to as instrument channel, or referred to as forceps channel, etc.) in the parent endoscope and be inserted into the duodenal papilla, and has high requirements on passability. Among them, since the distal end portion 21 in the present embodiment is located at the forefront of the advancement of the electronic endoscope 1, the passability thereof is most important. The applicant has found in practice that factors influencing the trafficability of the front end portion 21 mainly include the distal end shape of the front end portion 21 and the support of the front end portion 21 by the bent portion 22.

The distal end shape of the distal end portion 21 is one influencing factor that influences the trafficability of the distal end portion 21. As described above, in the present embodiment, the front end portion 21 includes the base 210, and the base 210 is provided with the inclined surface 211. As shown in fig. 3, the intersection of the inclined surface 211 and the distal end surface of the base 210 forms a ridge 216. The applicant has found that the ridge 216 may be arranged perpendicular to the axis of the base 210 and parallel to the bending direction of the bending portion 22, without requiring ease of operation and without increasing the cost of the electronic endoscope 1. When the electronic endoscope 1 provided by the present embodiment is passed in the corresponding channel of the female endoscope, the applicant has found that a better passability of the front end portion 21 can be achieved by the choice of material of the bending portion 22 and/or the flexible tube portion 23. Meanwhile, the applicant has found that, in order to increase the passability, it is also possible to provide the structure of the operation portion 3 (see later for detailed structure) so that the bending portion 22 and/or the flexible tube portion 23 are not unduly restrained by the wire harness 20 when being adaptively bent along with the structure of the corresponding passage of the female endoscope. When the front end portion 21 and the bending portion 22 of the electronic endoscope 1 provided in the present embodiment extend out of the parent endoscope, bending in the left-right direction (parallel to the ridge line 216) of the bending portion 22 can be achieved by controlling the aforementioned wire harness 20; bending in the up-down direction (perpendicular to the ridge line 216) can be easily achieved by rotating the whole electronic endoscope 1 located outside the body by a certain angle (the bending portion 22 rotates with it) and controlling bending with the wire harness 20, thereby making it possible to bend the bending portion 22 and/or the distal end portion 21 around the axial center. Thus, the trafficability can be ensured, and the cost can be reduced.

The insertion portion 2 of the electronic endoscope 1 provided in the above embodiment of the present utility model includes a distal end portion 21 and a bending portion 22, wherein the distal end surface of the distal end portion 21 has an inclined surface 211, the inclined surface 211 and the distal end surface of the distal end portion 21 intersect to form a ridge line 216, and the ridge line 216 is parallel to the bending direction of the bending portion 22.

The supporting force of the bent portion 22 on the distal end portion 21 is also a factor that affects the trafficability of the distal end portion 21. When the electronic endoscope 1 provided in the present embodiment is required to enter a tissue of a relatively narrow human body, such as a duodenal papilla, the support from the proximal end of the distal end portion 21 is important. If the support is too weak, it is difficult to successfully access against the resistance. The applicant has found that one of the alternatives for this is to improve the way in which the front end portion 21 and the curved portion 22 are connected. In this embodiment, the support is achieved from both the inner and outer supports. In fact, through a number of experiments, the applicant has found that the above-mentioned object of supporting can be achieved by providing the inner support alone, the outer support alone and both the inner and outer support.

Fig. 6a shows a cross-sectional view along the junction of the front end portion and the curved portion of fig. 3B-B. Fig. 6B shows a cross-sectional view along the junction of the bend and flexible pipe section of fig. 3B-B. Fig. 6C shows a cross-sectional view along the junction of the front end portion and the curved portion of fig. 3C-C. Fig. 6d shows a cross-sectional view along the junction of the bend and flexible pipe section of fig. 3C-C.

The inner support, as shown in fig. 6a, may be a stainless steel tube 201 with a flare (not shown) at its proximal end, its distal end being placed in the working channel 214 of the base 210, and its proximal end with the flare being placed in the working channel 224 of the bending section 22, and an interference fit being generally formed, so that the connection of the stainless steel tube 201 to the base 210 and the bending section 22 is more stable. And also more easily passes through the junction of the bend 22 and the base 210 due to the flare as the instrument is advanced along the working channel from the proximal end to the distal end. As shown in fig. 6c, a stainless steel tube 201a having a distal end disposed in the auxiliary passage 215 of the base 210 and a proximal end disposed in the distal end of the bent portion 22 may be further provided, so that the inner support function may be also provided on the premise of preventing water leakage between the bent portion 22 and the base 210.

The outer support is a stainless steel tube 202 that is provided outside to partially surround the base 210 and partially surround the distal end of the bent portion 22, as shown in fig. 6a and 6 c. The stainless steel tube 202 hoops the distal ends of the base 210 and the bent portion 22 together, thereby preventing leakage at the junction of the base 210 and the bent portion 22, and achieving the aforementioned support. In the above embodiment, when each stainless steel pipe is provided, it is necessary to consider the influence of the length thereof on the bending angle of the bending portion 22 at the same time. Through the applicant's trial and error, it is considered that the stainless steel pipe 201 having a gauge of 8 mm is easy to achieve both of the passing ability and the bending control. Wherein the portion extending into the base 210 may be less than 4 mm, or alternatively 2-3.5 mm. The stainless steel tube 202 may be 5-10 mm long, wherein 6 mm long is easy to achieve both passability and bend control, the portion covering the base 210 and the portion covering the bend 22 are about half of each other, and the portion covering the base 210 may be selected to be smaller than the portion covering the bend 22.

The insertion section 2 of the electronic endoscope 1 according to the above embodiment of the present utility model is provided in which the working channel 214 of the distal end portion 21 and the working channel 224 of the bending portion 22 are communicated with each other through a pipe member (stainless steel pipe 201 in this embodiment). The pipe member (stainless steel pipe 201) that communicates the working channel 214 of the front end portion 21 and the working channel 224 of the bent portion 22 has a flare that faces the bent portion 22 and is placed in the working channel 224 of the bent portion 22. The auxiliary passage 215 of the front end portion 21 and the auxiliary passage 225 of the bent portion 22 are communicated with each other through a pipe member (stainless steel pipe 201a in this embodiment). The outside of the pipe communicating with the auxiliary passage 215 of the front end portion 21 and the auxiliary passage 225 of the bent portion 22 is connected with the auxiliary passage 215 of the front end portion 21 and the auxiliary passage 225 of the bent portion 22 in a watertight manner. The tip portion 21 and the bent portion 22 are connected by a pipe member (stainless steel pipe 202 in this embodiment) that is crimped from the outside to the junction of the tip portion 21 and the bent portion 22.

Similarly, in order to achieve the engagement between the flexible tube portion 23 and the bending portion 22, or to achieve the support of the flexible tube portion 23 to the bending portion 22, the above-described manner of providing the inner and outer supports separately or providing the inner and outer supports simultaneously may be adopted. Since the cross-sectional configurations of the curved portion 22 and the flexible tube portion 23 are substantially identical, providing internal support, as shown in fig. 6b and 6d, a stainless steel tube 203 may be provided having its distal end disposed within the working channel 224 at the proximal end of the curved portion 22 and its proximal end disposed within the working channel 224 at the distal end of the flexible tube portion 23. Alternatively, a stainless steel tube 205 may be provided separately or additionally with a distal end disposed within the auxiliary channel 225 proximal to the bend 22 and a proximal end disposed within the auxiliary channel 225 distal to the flexible tube portion 23. The outer support is provided by a stainless steel tube 204 which partly surrounds the proximal end of the bent portion 22 and partly surrounds the distal end of the flexible tube portion 23, as shown in fig. 6b, 6 d. The stainless steel tube 204 may be a complete steel tube, a spring steel tube having an opening in the axial direction, or a steel tube made of a memory alloy or an open steel tube). When the stainless steel tube 204 has an axial opening, the installation efficiency can be improved. However, due to the presence of the opening, there is a high requirement for dimensional accuracy of the components joined by the stainless steel pipe 204, otherwise warping may occur at the end of the opening, and human tissue or the object to be inspected may be scratched after insertion into the human body or the object to be inspected, or the stability of installation may be affected, or the internal passage may be pressed. Thus, the selection may be based on a balance between cost and efficiency. The stainless steel tube 204 hoops the proximal end of the bent portion 22 and the distal end of the flexible tube portion 23 together, and as with the inner support described above, both prevents leakage from the joint and achieves the purpose of support. Also, the lengths of the stainless steel pipes 203, 204, 205 need to be considered to avoid affecting the bending angles of the bending portion 22 and the flexible pipe portion 23. Through the applicant's trial and error, it is believed that the stainless steel tube 203 may be 5-10 mm long, allowing for ease of both passability and bend control, about half of which extends into the bend 22. Stainless steel tube 204 may be 5-12 millimeters long, allowing for ease of both passability and bend control, with about half of it covering bend 22. Stainless steel tube 205 may be 5-10 mm long in size, allowing for ease of both passability and bend control, with approximately half of it extending into bend 22.

In addition, in the present embodiment, the harness passage 226 is also provided in the flexible tube portion 23 and the bending portion 22, so that the stainless steel tube 206 partially located in the harness passage 226 at the proximal end of the bending portion 22 and partially located in the harness passage 226 at the distal end of the flexible tube portion 23 can be provided, which can ensure sufficient smoothness when the control harness 20 passes through the joint portion, and can also function as the aforementioned support. The dimensions may be the same as those of the stainless steel tube previously described to provide internal support.

The above-described embodiment of the present utility model provides the insertion portion 2 of the electronic endoscope 1, in which the working channel 224 of the bending portion 22 and the working channel 224 of the flexible tube portion 23 are communicated with each other through a pipe member (stainless steel tube 203 in this embodiment). The harness passage 226 of the bent portion 22 and the harness passage 226 of the flexible pipe portion 23 are communicated with each other through a pipe member (stainless steel pipe 206 in this embodiment). The auxiliary passage 225 of the bent portion 22 and the auxiliary passage 225 of the flexible pipe portion 23 are communicated with each other through a pipe fitting (stainless steel pipe 205 in this embodiment). The outside of the pipe member (stainless steel pipe 205 in this embodiment) that communicates with the auxiliary passage 225 of the bending portion 22 and the auxiliary passage 225 of the flexible pipe portion 23 is connected with the auxiliary passage 225 of the bending portion 22 and the auxiliary passage 225 of the flexible pipe portion 23 in a watertight manner. The bending portion 22 and the flexible pipe portion 23 are connected by a pipe fitting (stainless steel pipe 204 in this embodiment) which is crimped from the outside to the joint of the bending portion 22 and the flexible pipe portion 23.

The bending portion 22 and the flexible tube portion 23 are made of a flexible material, which may be the same or the material of the bending portion 22 may be softer than the material of the flexible tube portion 23. In this example, an extrusion process was used.

In the embodiment provided by the utility model, the flexible material can beElastomers (polyether amide block copolymers composed of rigid polyamide and flexible polyether blocks). The stainless steel pipes can be fixedly connected with the flexible material in an adhesive mode. The stainless steel pipe arranged on the outer side can be fixedly connected with the hooped part on the inner side by using a press-holding process (using a press-holding machine) alone or combining the press-holding process and an adhesion process. In addition, the interconnection between the flexible materials may be achieved by a hot-melt method, and when the flexible materials are interconnected by a hot-melt method, the flexible materials after being cooled by a hot-melt process can provide sufficient support by themselves under a proper process, and a stainless steel pipe providing internal or external support may not be provided between the front end portion 21 and the bent portion 22, and between the bent portion 22 and the flexible pipe portion 23. That is, the fixing connection between the distal end portion 21 and the bent portion 22 and between the bent portion 22 and the flexible tube portion 23 can be achieved by the hot-melt process, and the necessary internal and external support can be provided. Of course, after hot melting, a rough surface is sometimes formed on the outer surface of the flexible material, and this rough surface may cause various problems after entering the human body; sometimes the flexible materials that are joined together by a hot melt process cannot withstand repeated bending during operation and may break at the joint. Thus, as will be appreciated by those skilled in the art, a lower cost hot melt process may be used in place of the stainless steel tube and a bonding or crimping process suitable for use between the stainless steel tube and the flexible material. However, if the support, roughened surface and bond strength are taken into consideration in combination, the various processes and structures described above may be applied or combined at different locations as desired.

It should be noted that, in the present embodiment, the inner and outer supports between the front end portion 21, the bending portion 22 and the flexible tube portion 23 are made of stainless steel tubes, and those skilled in the art will understand that the stainless steel tubes are only an alternative way, so long as the strength required by the inner and outer supports and other requirements for rust prevention, surface and the like required for entering the human body or the object to be detected can be satisfied, and supports made of other materials, such as polylactic acid, can be used.

Fig. 7a is a perspective view showing an internal structure of an operation section according to an embodiment of the present utility model. Fig. 7b is a front view showing an internal structure of an operation section provided in an embodiment of the present utility model. Fig. 8a is a perspective view showing a part of the internal structure of an operation section according to an embodiment of the present utility model. Fig. 8b is a front view showing a part of the internal structure of the operation section provided by an embodiment of the present utility model.

For clarity of illustration, fig. 8a and 8b have the control portion 311 and the follower portion 312 removed with respect to fig. 7a and 7 b.

As shown in fig. 7a and 7b, the insertion portion 2 and the operation portion 3 are connected by a sheath 32, the sheath 32 has a substantially conical shape, and a narrow portion 321 is provided in the middle. The lumen of the sheath 32 allows the insertion portion 2 to pass through, i.e. the proximal end of the insertion portion 2 protrudes into the operating portion 3 and beyond the proximal face of the sheath 32.

As shown in fig. 7b, the bottom end of the sheath 32 is H-shaped, and the narrow part of the H-shaped part is engaged with the corresponding protruding part on the housing to realize assembly. The narrow portion 321 in the middle of the sheath 32 may be fitted by engagement with a corresponding protruding portion of the housing 30.

As shown in fig. 7a, 7b, 8a, 8b, the operation portion 3 may be formed of a housing 30 having an internal cavity formed therein, and in this embodiment, an auxiliary port 306, an instrument port 307, a key port 308, and a knob port 301 are provided in the housing 30. When the operator holds the operation portion 3 with his left hand and finally controls the bending portion 22 with his right hand by controlling the corresponding member on the operation portion 3, the sheath 32 is opened substantially downward with respect to the operator, the instrument opening 307 is provided on the front side of the operation portion 3, and the opening is directed obliquely upward; knob port 301 is located on the right; the auxiliary port 306 is provided on the rear side of the operation unit 3, and the opening is directed obliquely upward. The knob opening 301 is circular, and is provided with a circular ring which coincides with the axis of the knob opening 301, and forms flanges extending to the inner side and the outer side of the housing 30 of the operation part 3, wherein the inwardly extending flanges are defined as inner flanges 3011, and the outwardly extending flanges are defined as outer flanges 3012. The operation unit 3 can be used for holding when an operator operates the electronic endoscope provided by the present utility model.

The operation unit 3 includes an operation mechanism 31. The operating mechanism 31 further includes a control portion 311, a follower portion 312, a lock member 313, and a harness restraint member 314. Referring to fig. 12, in the present embodiment, the control unit 311 includes a knob 3111 and a shaft 3112. The knob 3111 is disposed outside the housing 30, and a stopper 3113 is disposed on an inward end surface of the knob 3111. The rotation shaft 3112 coincides with the axis of the knob 3111, and one end of the rotation shaft 3112 is fixed to the knob 3111, and the other end is provided with teeth on the outer periphery, which are defined as tooth ends. Corresponding to the stopper 3113 provided on the inner end surface of the knob 3111, two other stoppers 3113 are provided on the outer side of the housing 30 as shown in fig. 9.

Referring to fig. 13, the follower 312 includes a follower ring 3121, and the follower ring 3121 approximates a hollow cylinder provided in the housing 30. The outer circumference of one end of the follower ring 3121 near the knob port 301 is provided with external teeth, defined as an external tooth end 3122; an inner circumference of one end remote from the knob opening 301 is provided with inner teeth, defined as an inner tooth end 3123. The outer tooth end 3122 of the follower ring 3121 has an inner diameter greater than the inner flange 3011 formed by the inward extension of the knob port 301 such that the outer tooth end 3122 of the follower ring 3121 may be sleeved over the inner flange 3011 and may be rotated. Three radially protruding circumferential annular pieces 3124 are provided on the follower ring 3121, and positioning holes 3125 are provided on the annular pieces 3124. In the present embodiment, the positioning holes 3125 provided on the different annular sheets 3124 overlap each other in circumferential position, that is, the axes of the positioning holes 3125 provided on the different annular sheets 3124 overlap.

The lock member 313 includes a lock mechanism 3131, a petal-shaped block 3132, and a lock block 3133. Referring to fig. 10, the locking mechanism 3131 further includes a circular ring 3134, a handle 3135, and a cross 3136.

In this embodiment, the ring 3134, the shank 3135, and the cross 3136 are fixedly connected to each other. As shown, the stem 3135 is disposed on one side of the annular ring 3134 and is substantially coplanar with the annular ring 3134, and the cross 3136 is disposed on the stem 3135 and extends toward the housing 30. Referring to fig. 9, a cross slot 302 is formed in the housing 30 and corresponds to the cross block 3136, and the cross block 3136 extends into the housing 30 through the cross slot 302 and is fixedly connected to the petal-shaped block 3132 located in the housing 30. The present embodiment achieves quick and stable mounting between the cross piece 3136 and the petal-shaped pieces 3132 by providing a groove in the outward end of the petal-shaped pieces 3132 that can engage with the cross piece 3136. The edge of the ring 3134 is provided with a positioning block 3137, and the positioning block 3137 extends from the outer edge of the inner side (toward the housing 30 side) end surface of the ring 3134 to the inner side (housing 30), and forms a step 3138 protruding outward with respect to the axis of the ring 3134 at the end of the extension.

The above embodiment of the present utility model provides the operation portion 3 of the electronic endoscope 1, wherein the cross block 3136 and the positioning block 3137 of the locking mechanism 3131 are located on the same side of the circular ring 3134.

A locking block 3133 is provided on an inner wall of the housing 30 and extends into the housing 30, and the side of the locking block 3133 facing the knob opening 301 is provided with a pointed protrusion 3139.

In addition, referring to fig. 9, the housing 30 is further provided with a slot 303, and positioning blocks 3137 disposed at the edge of the circular ring 3134 can respectively extend into the slot 303, and engage with the edges of the slot 303 through a step 3138 protruding from the terminal end of the positioning block 3137, so that the circular ring 3134 can be assembled on the housing 30. Thus, depending on the restriction of the slot 303 to the positioning block 3137 and the restriction of the cross slot 302 to the cross block 3136, the locking mechanism 3131 may be fitted to the housing 30 and may be rotated at a certain angle with respect to the housing 30. In order to make the rotation of the ring 3134 smoother, in this embodiment, the inner ring of the ring 3134 is sleeved on the outer flange 3012 of the knob opening 301. Otherwise, the rotation of the ring 3134 only depends on the cooperation of the positioning block 3137 and the slot 303, and undesired deflection may occur to affect the use.

The mutual position relation among the components is as follows: the tooth end of the rotation shaft 3112 passes through the outer flange 3012 of the knob opening 301, the inner flange 3011 of the knob opening 301, the outer tooth end 3122 of the follower ring 3121, and the inner tooth end 3123 of the follower ring 3121 in this order, meshes with the inner tooth end 3123 of the follower ring 3121, and protrudes in the axial direction from the end surface of the inner tooth end 3123 of the follower ring 3121. At this time, due to the arrangement of the outer flange 3012, the stopper 3113 provided on the inner end surface of the knob 3111 can be rotated along with the knob 3111 without touching the housing 30. When the knob 3111 is rotated, the stopper 3113 on the housing 30 controls the maximum rotation angle of the knob 3111 by restricting the movement range of the stopper 3113 on the inner end surface of the knob 3111.

Thus, as will be appreciated by those skilled in the art, in the unlocked state, an operator rotates knob 3111, knob 3111 rotates shaft 3112 fixedly connected thereto, and shaft 3112 rotates follower ring 3121 about inner flange 3011.

When the operator wants to realize locking, the operator moves the handle 3135, the handle 3135 drives the ring 3134 to rotate, the ring 3134, the positioning block 3137 and the cross block 3136 respectively rotate along the limitation of the outer flange 3012, the slot 303 and the cross slot 302 by a certain angle, and at this time, as shown in fig. 8b, the cross block 3136 drives the petal-shaped block 3132 in the housing 30 to move along the cross slot 302, the protruding part of the petal-shaped block 3132 presses the locking block 3133, so that the locking block 3133 is elastically deformed, and the pointed protrusion 3139 of the pointed protrusion is engaged with or meshed with the outer tooth end 3122 of the follower ring 3121, so that the follower ring 3121 cannot rotate, thereby realizing locking.

In other embodiments, the tooth end of the shaft 3112 is provided with a pin hole 3114 penetrating the shaft 3112 radially, and a pin 3115 penetrating the pin hole 3114 is further provided to prevent the follower ring 3121 from being separated from the shaft 3112 axially.

In other embodiments, the locking member 313 further comprises an annular groove 3130 for receiving a resilient gasket that is positioned within the annular groove 3130 and between the annular ring 3134 and the housing 30 in the completed state of the present utility model. The elastic washer 3130 can reduce noise generated when the circular ring 3134 rotates relative to the housing 30; and in the locked state, the contact between the circular ring 3134 and the housing 30 can be damped by increasing the friction force, so that the connection is more stable.

Those skilled in the art will appreciate that the elements of the present utility model are designated as cross-shaped blocks, petal-shaped blocks, wherein the description of the cross and petals is for ease of understanding the nomenclature of their function and are not limiting of their specific shape. As long as the transmission effect desired in the present application can be achieved, it is within the scope of the present application. As will be seen from figures 7a, 7b, 8a, 8b, the present embodiment controls the bending of the bending portion 22 by tightening and loosening the two harnesses 20 at the proximal end, as previously described. That is, the distal end of the wire harness 20 is fixed to the distal end of the bending portion 22, and the proximal end of the wire harness 20 sequentially passes through the bending portion 22, the flexible tube portion 23, and the sheath 32 to enter the housing 30 of the operation portion 3, sequentially passes through the wire harness restraining member 314 in the housing 30 of the operation portion 3, passes through at least two positioning holes 3125 provided on the ring piece 3124 of the follow-up ring 3121, and is fixed to the last passing positioning hole 3125 by welding or bonding. The applicant has found that positioning the proximal end of the harness 20 by passing through the positioning hole 3125 on one of the flaps 3124 and finally passing through and being secured to the positioning hole 3125 on the other flap 3124 provides for quick installation while providing for secure positioning of the proximal end of the harness 20 without affecting the action of the operating mechanism 31. In particular, one thin rod may be used to pass through all of the positioning holes 3125 after the wire harness 20 passes through at least two different positioning holes 3125, and glue may be applied at the positioning holes 3125 for further fastening. This allows for quick installation and secure positioning of the proximal end of the harness 20 without affecting the action of the operating mechanism 31.

The above embodiment of the present utility model provides the operation portion 3 of the electronic endoscope 1, wherein the proximal end of the wire harness 20 passes through the positioning hole 3125 of the middle ring piece 3124 of the follow-up ring 3121.

The above embodiment of the present utility model provides the operation portion 3 of the electronic endoscope 1, wherein the follower ring is provided with a thin rod for inserting the positioning hole 3125 through which the wire harness 20 passes and fixing the proximal end of the wire harness 20 to the positioning hole 3125.

In the present embodiment, the harness restraint member 314 includes one main wire passing plate 3141 and two sub wire passing plates 3142. The bus bar 3141 is disposed distally of the split bar 3142, and the split bar 3142 is disposed proximally of the bus bar 3141. Two positioning holes 3125 are provided in the middle of the bus bar 3141, through which the two wire harnesses 20 respectively pass; the edge of the bus board 3141 is provided with a slot with a downward opening, and the slot can be inserted into the plugboard 304 fixed on the inner wall of the shell 30, so that the position of the bus board 3141 relative to the shell 30 can be quickly fixed. The two wire dividing plates 3142 are respectively arranged in the two wire harness channels 305, each wire dividing plate 3142 is provided with a positioning hole 3125, the inner wall of each wire harness channel 305 is provided with a slot 3143, and the wire dividing plates 3142 are fixed on the shell 30 through the slots 3143 inserted into the inner wall of the wire harness channel 305. It will be appreciated by those skilled in the art that a higher installation efficiency can be achieved by inserting the wire harness 20 through the positioning hole 3125 and then inserting and fixing the main wire passing plate 3141 and the branch wire passing plate 3142.

The above embodiment of the present utility model provides the operation portion 3 of the electronic endoscope 1, wherein the housing 30 is provided with the harness aisle 305 therein. A total pass-through plate 3141 and/or a split pass-through plate 3142 are provided in the harness aisle 305. The bus bar 3141 and/or the split bar 3142 are provided with positioning holes 3125. The bus bar 3141 has two positioning holes 3125 that are up and down.

In addition, as described above, in order to make it easier for the insertion portion 2 to pass through the corresponding passage of the female endoscope, that is, to improve the passage of the insertion portion 2 with respect to the corresponding passage of the female endoscope as a use environment, the bending portion 22 and/or the flexible tube portion 23 may be adapted to bend in accordance with the structure of the corresponding passage of the female endoscope by providing the structure of the operation portion 3, without being unduly restricted by the wire harness 20. The applicant has found that in order to prevent the harness 20 from being too tight, which would interfere with the above-described passability, it is necessary to first maintain the harness 20 in a certain degree of slack. At this time, the wire harness 20 is disposed through the structure of the positioning holes 3125 on the total wire passing plate 3141 and the wire dividing plate 3142, or the wire harness 20 is disposed through the structure of the positioning holes 3125 on the ring piece 3124, so that interference or confusion between the wire harnesses 20 and surrounding components does not occur when the wire harness 20 is loosened. Thus, in operation, the wire harness 20 can be quickly brought into the operating state by simply turning the knob 3111, and the normal function is achieved.

The above embodiment of the present utility model provides the operation portion 3 of the electronic endoscope 1, wherein the length of the wire harness 20 provided in the housing 30 is longer than the path of the wire harness 20 in the housing 30.

As previously described, the housing 30 of the operating portion 3 is further provided with an auxiliary port 306 and an instrument port 307, and as also previously described, the insertion portion 2 extends proximally into the housing 30 of the operating portion 3 and protrudes from the proximal end face of the sheath 32. As can be seen from the foregoing, the flexible tube portion 23 protruding from the proximal end face of the sheath 32, specifically the insertion portion 2, is provided with a working channel 224, a cable channel 223, and a harness channel 226, and in other embodiments, an auxiliary channel 225 may be provided.

Wherein, the instrument port 307 is provided with a luer connector 3071 which is communicated with the working channel 224 of the flexible tube part 23 through a stainless steel tube 3072. A sheath 3061 is provided at the auxiliary port 306 and communicates with the auxiliary passage 225 of the flexible pipe portion 23 through a stainless steel pipe 3062 (a communication state between the auxiliary port 306 and the stainless steel pipe 3062 is not shown).

In other embodiments, the electronic control unit 33 is further disposed in the housing 30 of the operation portion 3, and the keys 331 of the electronic control unit 33 protrude from the key opening 308 on the housing 30 outside the housing 30 for the operator to use. The housing 30 of the operation part 3 may further be provided with an electronic output port 332, and the electronic control unit 33, the image pickup unit 212, the illumination unit 213, and the electronic output port 332 may perform power supply and data transmission as required through the cable 24.

While the utility model has been shown and described with reference to certain preferred embodiments thereof, it will be understood by those skilled in the art that the foregoing is a further detailed description of the utility model with reference to specific embodiments, and it is not intended to limit the practice of the utility model to those descriptions. Various changes in form and detail may be made therein by those skilled in the art, including a few simple inferences or alternatives, without departing from the spirit and scope of the present utility model.

Claims (14)

1. An insertion part for an electronic endoscope is characterized in that the insertion part is sequentially and continuously provided with a front end part, a bending part and a flexible pipe part from a distal end, the bending part and the flexible pipe part are provided with a cavity channel penetrating along an axial direction, the insertion part comprises a cable channel, a working channel and a wire harness channel, and the front end part, the bending part and the working channel of the flexible pipe part are communicated through a pipe fitting.

2. The insert of claim 1, wherein the front end portion includes a base having a working channel for allowing a working instrument to pass therethrough, a stainless steel tube being disposed between the working channel of the base and the working channel of the bend, a flare being disposed at a proximal end thereof, a distal end thereof being disposed within the working channel of the base, and a proximal end thereof being disposed within the working channel of the bend.

3. The insert of claim 2, wherein the length of the stainless steel tube disposed between the working channel of the base and the working channel of the bend is 8 millimeters.

4. The insert of claim 1, wherein the front end portion includes a base having an auxiliary passage provided thereon, the auxiliary passage having water tightness, the auxiliary passage of the base being in communication with the auxiliary passage of the bent portion through a stainless steel tube disposed distally in the auxiliary passage of the base and proximally in the distal end of the bent portion.

5. The insert of claim 1, wherein the front end portion includes a base, the base and a distal end of the bent portion being hooped by a stainless steel tube disposed on an outer side.

6. The insert of claim 5, wherein the stainless steel tube that hoops the base and the distal end of the bend is 5-10 millimeters in length.

7. The insert of claim 6, wherein the stainless steel tube that hoops the base and the distal end of the bend is 6 millimeters in length.

8. The insert of claim 1, wherein a stainless steel tube having a distal end disposed within the working channel at the proximal end of the bend and a proximal end disposed within the working channel at the distal end of the flexible tube is disposed between the working channel of the bend and the working channel of the flexible tube.

9. The insert of claim 8, wherein the stainless steel tube disposed between the bend and the working channel of the flexible tube portion has a length of 5-10 millimeters.

10. The insert of claim 1, wherein the bend and the flexible tube portion are provided with an auxiliary passage extending axially therethrough, and wherein a stainless steel tube is disposed between the bend and the auxiliary passage of the flexible tube portion with a distal end disposed within the auxiliary passage at a proximal end of the bend and a proximal end disposed within the auxiliary passage at a distal end of the flexible tube portion, the auxiliary passage being watertight.

11. The insert of claim 10, wherein the stainless steel tube disposed between the bend and the auxiliary channel of the flexible tube portion has a length of 5-10 millimeters.

12. The insert of claim 1, wherein an outer side between the bend and the flexible tube portion is provided with a stainless steel tube partially surrounding a proximal end of the bend and partially surrounding a distal end of the flexible tube portion.

13. The insert of claim 12, wherein the stainless steel tube disposed outside between the bend and the flexible tube portion has a length of 5-12 mm.

14. The insert of claim 1, wherein a stainless steel tube is disposed between the bend and the flexible tube portion partially within the harness channel at the proximal end of the bend and partially within the harness channel at the distal end of the flexible tube portion.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202120442596.6U CN218943294U (en) | 2020-07-03 | 2020-07-03 | Insertion part |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202021293159.4U CN212996344U (en) | 2020-07-03 | 2020-07-03 | Electronic endoscope |

| CN202120442596.6U CN218943294U (en) | 2020-07-03 | 2020-07-03 | Insertion part |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202021293159.4U Division CN212996344U (en) | 2020-07-03 | 2020-07-03 | Electronic endoscope |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN218943294U true CN218943294U (en) | 2023-05-02 |

Family

ID=75500355

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202021293159.4U Active CN212996344U (en) | 2020-07-03 | 2020-07-03 | Electronic endoscope |

| CN202120442497.8U Active CN218870249U (en) | 2020-07-03 | 2020-07-03 | Operating mechanism |

| CN202120442596.6U Active CN218943294U (en) | 2020-07-03 | 2020-07-03 | Insertion part |

Family Applications Before (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202021293159.4U Active CN212996344U (en) | 2020-07-03 | 2020-07-03 | Electronic endoscope |

| CN202120442497.8U Active CN218870249U (en) | 2020-07-03 | 2020-07-03 | Operating mechanism |

Country Status (1)

| Country | Link |

|---|---|

| CN (3) | CN212996344U (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113876284A (en) * | 2020-07-03 | 2022-01-04 | 杭州莱恩瑟特医疗技术有限公司 | Electronic endoscope |

| CN114305289A (en) * | 2020-09-28 | 2022-04-12 | 微创优通医疗科技(嘉兴)有限公司 | Endoscope handle, endoscope and endoscope system |

| CN113413116B (en) * | 2021-05-17 | 2022-04-26 | 杭州莱恩瑟特医疗技术有限公司 | Tip portion and electronic endoscope |

| CN113440094B (en) * | 2021-08-04 | 2023-03-31 | 中国人民解放军空军军医大学 | Gallbladder-protecting mirror for minimally invasive cystic duct exploration |

-

2020

- 2020-07-03 CN CN202021293159.4U patent/CN212996344U/en active Active

- 2020-07-03 CN CN202120442497.8U patent/CN218870249U/en active Active

- 2020-07-03 CN CN202120442596.6U patent/CN218943294U/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN218870249U (en) | 2023-04-18 |

| CN212996344U (en) | 2021-04-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN218943294U (en) | Insertion part | |

| JP5409898B2 (en) | Endoscope adapter | |

| US20150313450A1 (en) | Stopper for the Cables of a Bending Section of An Endoscope | |

| EP2574271B1 (en) | Closure device for end opening | |

| JPS5993413A (en) | Endoscope | |

| US11723523B2 (en) | One-piece elevator for a duodenoscope | |

| WO2016190011A1 (en) | Endoscope curved portion | |

| JP6250254B1 (en) | Instrument insertion aid | |

| WO2022001587A1 (en) | Electronic endoscope | |

| US20180014717A1 (en) | Adaptor for Multiple Types of Endoscope | |

| WO2017132057A1 (en) | Multi-element cover for a multi-camera endoscope | |

| US20130079593A1 (en) | Closure device for end opening and endoscope | |

| CN220898657U (en) | Suction nozzle switch, negative pressure suction assembly and endoscope | |

| US9144371B2 (en) | Drainage tube insertion tool | |

| CN113413116B (en) | Tip portion and electronic endoscope | |

| CN218606545U (en) | Meatus clamping assembly, operation part and electronic endoscope | |