CN216815088U - Quick cooling tower - Google Patents

Quick cooling tower Download PDFInfo

- Publication number

- CN216815088U CN216815088U CN202122788727.9U CN202122788727U CN216815088U CN 216815088 U CN216815088 U CN 216815088U CN 202122788727 U CN202122788727 U CN 202122788727U CN 216815088 U CN216815088 U CN 216815088U

- Authority

- CN

- China

- Prior art keywords

- cooling tower

- groove

- block

- clamping

- fixedly connected

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Structure Of Emergency Protection For Nuclear Reactors (AREA)

Abstract

The utility model discloses a rapid cooling tower which comprises a cooling tower, a protective shell, a cover plate, a fixing piece and a fixing block, wherein the bottom of the protective shell is fixedly connected with the top of the cooling tower, the cover plate is arranged at the top of the protective shell, the front side of the cover plate is fixedly connected with the fixing piece, the rear side of the fixing block is fixedly connected with the protective shell, and the top of the fixing block is provided with a positioning groove. Through setting up the cooling tower, the protecting crust, the apron, the stationary blade, the fixed block, the constant head tank, the locating piece, square groove, chucking mechanism, chucking groove and drive mechanism's cooperation is used, the effect of convenient use has been reached, current quick cooling tower when idle has been solved, because do not install the device to the top protection, thereby lead to too much dust to get into the inner chamber of quick cooling tower, need the user to clear up, not only brought the trouble for the user, the problem of the unnecessary waste time of user has still been wasted.

Description

Technical Field

The utility model belongs to the technical field of cooling towers, and particularly relates to a rapid cooling tower.

Background

Along with the development of society now, because the rapid cooling tower can be quick with the water cooling, so the rapid cooling tower is also very common, it is more in the aspect of being used for air conditioner cooling system or mill's processing mostly, it is convenient to have brought for the user, but current rapid cooling tower is when idle, owing to do not install the device to the top protection, thereby lead to too much dust to get into the inner chamber of rapid cooling tower, it clears up to need the user, not only brought the trouble for the user, the unnecessary wasted time of user has still been wasted.

SUMMERY OF THE UTILITY MODEL

Aiming at the problems in the prior art, the utility model provides a rapid cooling tower which has the advantage of convenient use, and solves the problems that when the conventional rapid cooling tower is idle, excessive dust enters an inner cavity of the rapid cooling tower due to the fact that a device for protecting the top is not installed, and the excessive dust needs to be cleaned by a user, so that troubles are brought to the user, and time which is unnecessarily wasted by the user is wasted.

The utility model discloses a rapid cooling tower, which comprises a cooling tower, a protective shell, an cover plate, a fixing piece and a fixing block, wherein the bottom of the protective shell is fixedly connected with the top of the cooling tower, the cover plate is arranged on the top of the protective shell, the front side of the cover plate is fixedly connected with the fixing piece, the rear side of the fixing piece is fixedly connected with the protective shell, the top of the fixing block is provided with a positioning groove, the inner cavity of the positioning groove is provided with a positioning block, the inner cavity of the positioning block is provided with a square groove, the inner cavity of the square groove is provided with a clamping mechanism matched with the fixing block, the inner wall of the positioning groove is provided with a clamping groove matched with the clamping mechanism, and the inner cavity of the square groove is provided with a transmission mechanism matched with the clamping mechanism.

Preferably, the clamping mechanism comprises a clamping block, a pushing block is arranged on one side, away from the clamping groove, of the clamping block, a connecting sheet is movably connected to the rear side of the pushing block, the surface of the clamping block is matched with the inner cavity of the clamping groove, and the connecting sheet is matched with the transmission mechanism.

Preferably, the transmission mechanism comprises a pull rod, the bottom of the pull rod is fixedly connected with a connecting rod, a fixing rod is arranged in an inner cavity of the connecting rod, the top and the bottom of the fixing rod penetrate through the connecting rod and are fixedly connected with the inner wall of the square groove, and the front side of the connecting rod is movably connected with the connecting sheet.

Preferably, the spring is sleeved on the surface of the fixing rod, the bottom of the spring is fixedly connected with the connecting rod, the top of the spring is fixedly connected with the inner wall of the square groove, and the connecting rod is movably connected with the connecting sheet through the rotating shaft.

Preferably, the inner wall of the square groove is provided with a sliding groove, the inner cavity of the sliding groove is provided with a sliding rod, the front side of the sliding rod is fixedly connected with the push block, and the connecting sheet is movably connected with the push block through a rotating shaft.

Preferably, the inner wall of the square groove is provided with a limiting groove, an inner cavity of the limiting groove is matched with the clamping blocks for use, one sides of the two clamping blocks opposite to each other are fixedly connected with tension springs, and one sides of the tension springs far away from the clamping blocks are fixedly connected with the inner wall of the square groove.

Compared with the prior art, the utility model has the following beneficial effects:

1. according to the utility model, through the matched use of the cooling tower, the protective shell, the cover plate, the fixing block, the positioning groove, the positioning block, the square groove, the clamping mechanism, the clamping groove and the transmission mechanism, the pull rod is pulled, then the cover plate is reset, the positioning block is inserted into the inner cavity of the positioning groove to be positioned and clamped, finally the pull rod is loosened, and the adjustment is completed, so that the effect of convenient use is achieved, and the problems that when the existing rapid cooling tower is idle, excessive dust enters the inner cavity of the rapid cooling tower due to the fact that a device for protecting the top part is not installed, the cleaning needs to be carried out by a user, troubles are brought to the user, and time which is not wasted by the user is wasted are solved.

2. According to the clamping mechanism, the clamping mechanism is arranged, and the clamping block can drive the positioning block to clamp and fix the clamping groove by matching the clamping block, so that the clamping block can be positioned better.

3. According to the utility model, by arranging the transmission mechanism, the pull rod can drive the connecting rod to move by matching with the pull rod, so that the connecting sheet can move better.

4. According to the utility model, the spring is arranged, and the pull rod can be better reset after being used through the matching use of the spring, so that the connecting rod can better drive the connecting sheet to move.

5. According to the utility model, by arranging the sliding groove and the sliding rod, the pushing block can better move through the matching use of the sliding groove and the sliding rod, so that the connecting sheet can better drive the pushing block to move.

6. According to the utility model, by arranging the limiting groove and the tension spring, the clamping block can not deviate in the moving process through the matching use of the limiting groove and the tension spring, so that the clamping block can be better reset.

Drawings

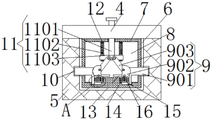

FIG. 1 is a schematic diagram of a structure provided by an embodiment of the present invention;

FIG. 2 is a front cross-sectional view of a portion of a structure provided by an embodiment of the present invention;

fig. 3 is an enlarged view of a portion a of fig. 2 according to an embodiment of the present invention.

In the figure: 1. a cooling tower; 2. a protective shell; 3. a cover plate; 4. a fixing sheet; 5. a fixed block; 6. positioning a groove; 7. positioning blocks; 8. a square groove; 9. a chucking mechanism; 901. a clamping block; 902. a push block; 903. connecting sheets; 10. a clamping groove; 11. a transmission mechanism; 1101. a pull rod; 1102. a connecting rod; 1103. fixing the rod; 12. a spring; 13. a chute; 14. a slide bar; 15. a limiting groove; 16. a tension spring.

Detailed Description

In order to further understand the contents, features and effects of the present invention, the following embodiments are illustrated and described in detail with reference to the accompanying drawings.

The structure of the present invention will be described in detail below with reference to the accompanying drawings.

As shown in fig. 1 to 3, the rapid cooling tower provided in an embodiment of the present invention includes a cooling tower 1, a protective shell 2, a cover plate 3, a fixing piece 4 and a fixing block 5, the bottom of the protective shell 2 is fixedly connected to the top of the cooling tower 1, the cover plate 3 is disposed at the top of the protective shell 2, the front side of the cover plate 3 is fixedly connected to the fixing piece 4, the rear side of the fixing block 5 is fixedly connected to the protective shell 2, the top of the fixing block 5 is provided with a positioning slot 6, an inner cavity of the positioning slot 6 is provided with a positioning block 7, an inner cavity of the positioning block 7 is provided with a square slot 8, an inner cavity of the square slot 8 is provided with a clamping mechanism 9 used in cooperation with the fixing block 5, an inner wall of the positioning slot 6 is provided with a clamping slot 10 used in cooperation with the clamping mechanism 9, and an inner cavity of the square slot 8 is provided with a transmission mechanism 11 used in cooperation with the clamping mechanism 9.

Referring to fig. 2, the clamping mechanism 9 includes a clamping block 901, a pushing block 902 is disposed on a side of the clamping block 901 away from the clamping groove 10, a connecting piece 903 is movably connected to a rear side of the pushing block 902, a surface of the clamping block 901 cooperates with an inner cavity of the clamping groove 10, and the connecting piece 903 cooperates with the transmission mechanism 11.

Adopt above-mentioned scheme: through setting up chucking mechanism 9, can use through the cooperation of fixture block 901, let fixture block 901 drive locating piece 7 carry out the chucking fixedly to chucking groove 10, make the better location of fixture block 901.

Referring to fig. 2, the transmission mechanism 11 includes a pull rod 1101, a connecting rod 1102 is fixedly connected to the bottom of the pull rod 1101, a fixing rod 1103 is disposed in an inner cavity of the connecting rod 1102, the top and the bottom of the fixing rod 1103 both penetrate through the connecting rod 1102 and are fixedly connected to the inner wall of the square groove 8, and the front side of the connecting rod 1102 is movably connected to the connecting piece 903.

Adopt above-mentioned scheme: through setting up drive mechanism 11, can use through the cooperation of pull rod 1101, let pull rod 1101 drive connecting rod 1102 move, make the better removal that moves of connection piece 903.

Referring to fig. 2, a spring 12 is sleeved on the surface of the fixing rod 1103, the bottom of the spring 12 is fixedly connected with a connecting rod 1102, the top of the spring 12 is fixedly connected with the inner wall of the square groove 8, and the connecting rod 1102 is movably connected with the connecting piece 903 through a rotating shaft.

Adopt above-mentioned scheme: through setting up spring 12, can use through the cooperation of spring 12, let pull rod 1101 can be better after using reset, make the better drive connection piece 903 of connecting rod 1102 remove.

Referring to fig. 2, a sliding groove 13 is formed in the inner wall of the square groove 8, a sliding rod 14 is arranged in the inner cavity of the sliding groove 13, the front side of the sliding rod 14 is fixedly connected with a push block 902, and a connecting piece 903 is movably connected with the push block 902 through a rotating shaft.

Adopt above-mentioned scheme: through setting up spout 13 and slide bar 14, can use through the cooperation of spout 13 with slide bar 14, let ejector pad 902 better remove, make the better drive ejector pad 902 of connection piece 903 remove.

Referring to fig. 2, a limiting groove 15 is formed in the inner wall of the square groove 8, an inner cavity of the limiting groove 15 is matched with the two clamping blocks 901 for use, the tension springs 16 are fixedly connected to one sides of the two clamping blocks 901 opposite to each other, and one side of each tension spring 16 far away from the corresponding clamping block 901 is fixedly connected to the inner wall of the square groove 8.

Adopt above-mentioned scheme: through setting up spacing groove 15 and extension spring 16, can use through the cooperation of spacing groove 15 with extension spring 16, let fixture block 901 can not appear squinting at the in-process that removes, make better the resetting of fixture block 901.

The working principle of the utility model is as follows:

when the positioning device is used, the pull rod 1101 is pulled, the connecting rod 1102 drives the connecting piece 903 to move through the rotating shaft, the connecting rod 1102 moves while being matched with the fixing rod 1103 and extrudes the spring 12, the spring 12 is stressed, the connecting piece 903 drives the push block 902 to move through the rotating shaft along with the movement of the connecting piece 903, the push block 902 moves while driving the slide rod 14, the slide rod 14 moves better through the matching of the sliding groove 13, at the moment, the tension spring 16 releases the tension force, the clamping block 901 moves through the matching of the limiting groove 15, then the cover plate 3 is reset, the positioning block 7 is inserted into the inner cavity of the positioning groove 6 to be positioned and clamped, finally, the pull rod 1101 is loosened, at the moment, the spring 12 releases the elastic force, the connecting rod 1102 better drives the pull rod 1101 to reset, and the connecting piece 903 is driven by the connecting rod 1102 to reset through the rotating shaft, connecting piece 903 can drive ejector pad 902 through the pivot and reset, and along with the resetting of ejector pad 902, ejector pad 902 can extrude fixture block 901, lets fixture block 901 reset, can stimulate extension spring 16 when fixture block 901 resets, lets extension spring 16 atress, makes the better inner chamber with chucking groove 10 of fixture block 901 carry out the chucking, adjusts the completion.

In summary, the following steps: this quick cooling tower, through setting up cooling tower 1, protecting crust 2, apron 3, the stationary blade 4, the fixed block 5, the constant head tank 6, locating piece 7, square groove 8, chucking mechanism 9, chucking groove 10 and drive mechanism 11's cooperation is used, the effect of convenient use has been reached, current quick cooling tower when idle has been solved, because do not install the device to the top protection, thereby lead to too much dust to get into the inner chamber of quick cooling tower, it clears up to need the user, not only bring the trouble for the user, the problem of the unnecessary wasted time of user has still been wasted.

It is noted that, herein, relational terms such as first and second, and the like may be used solely to distinguish one entity or action from another entity or action without necessarily requiring or implying any actual such relationship or order between such entities or actions. Also, the terms "comprises," "comprising," or any other variation thereof, are intended to cover a non-exclusive inclusion, such that a process, method, article, or apparatus that comprises a list of elements does not include only those elements but may include other elements not expressly listed or inherent to such process, method, article, or apparatus. Although embodiments of the present invention have been shown and described, it will be appreciated by those skilled in the art that changes, modifications, substitutions and alterations can be made in these embodiments without departing from the principles and spirit of the utility model, the scope of which is defined in the appended claims and their equivalents.

Claims (6)

1. The utility model provides a quick cooling tower, includes cooling tower (1), protecting crust (2), apron (3), stationary blade (4) and fixed block (5), its characterized in that: the bottom of the protective shell (2) is fixedly connected with the top of the cooling tower (1), the cover plate (3) is arranged at the top of the protective shell (2), the front side of the cover plate (3) is fixedly connected with the fixing plate (4), the rear side of the fixing block (5) is fixedly connected with the protective shell (2), the top of the fixed block (5) is provided with a positioning groove (6), the inner cavity of the positioning groove (6) is provided with a positioning block (7), a square groove (8) is arranged in the inner cavity of the positioning block (7), a clamping mechanism (9) matched with the fixing block (5) is arranged in the inner cavity of the square groove (8), the inner wall of the positioning groove (6) is provided with a clamping groove (10) matched with the clamping mechanism (9), the inner cavity of the square groove (8) is provided with a transmission mechanism (11) matched with the clamping mechanism (9).

2. A rapid cooling tower as recited in claim 1, wherein: the clamping mechanism (9) comprises a clamping block (901), a pushing block (902) is arranged on one side, away from the clamping groove (10), of the clamping block (901), a connecting piece (903) is movably connected to the rear side of the pushing block (902), the surface of the clamping block (901) is matched with the inner cavity of the clamping groove (10) for use, and the connecting piece (903) is matched with the transmission mechanism (11) for use.

3. A rapid cooling tower as recited in claim 2, wherein: the transmission mechanism (11) comprises a pull rod (1101), the bottom of the pull rod (1101) is fixedly connected with a connecting rod (1102), a fixing rod (1103) is arranged in an inner cavity of the connecting rod (1102), the top and the bottom of the fixing rod (1103) penetrate through the connecting rod (1102) and are fixedly connected with the inner wall of the square groove (8), and the front side of the connecting rod (1102) is movably connected with the connecting piece (903).

4. A rapid cooling tower as recited in claim 3, wherein: the surface cover of dead lever (1103) is equipped with spring (12), the bottom and connecting rod (1102) fixed connection of spring (12), the top and the inner wall fixed connection of square groove (8) of spring (12), connecting rod (1102) is through pivot and connection piece (903) swing joint.

5. A rapid cooling tower as recited in claim 2, wherein: the inner wall of the square groove (8) is provided with a sliding groove (13), an inner cavity of the sliding groove (13) is provided with a sliding rod (14), the front side of the sliding rod (14) is fixedly connected with the push block (902), and the connecting piece (903) is movably connected with the push block (902) through a rotating shaft.

6. A rapid cooling tower as recited in claim 2, wherein: the inner wall of the square groove (8) is provided with a limiting groove (15), the inner cavity of the limiting groove (15) is matched with the clamping blocks (901) for use, one side, opposite to the two clamping blocks (901), of each clamping block (901) is fixedly connected with a tension spring (16), and one side, far away from the clamping blocks (901), of each tension spring (16) is fixedly connected with the inner wall of the square groove (8).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202122788727.9U CN216815088U (en) | 2021-11-15 | 2021-11-15 | Quick cooling tower |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202122788727.9U CN216815088U (en) | 2021-11-15 | 2021-11-15 | Quick cooling tower |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN216815088U true CN216815088U (en) | 2022-06-24 |

Family

ID=82050173

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202122788727.9U Active CN216815088U (en) | 2021-11-15 | 2021-11-15 | Quick cooling tower |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN216815088U (en) |

-

2021

- 2021-11-15 CN CN202122788727.9U patent/CN216815088U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN115555449A (en) | Stamping die and stamping method | |

| CN216815088U (en) | Quick cooling tower | |

| CN218202536U (en) | Hot bending device for glass processing | |

| CN214927023U (en) | Clean effectual ya keli board hot bending machine | |

| CN215975948U (en) | Heat treatment tempering discharging cooling device for mask forging | |

| CN110948543B (en) | Gauze production and processing is with tailorring sword convenient to press gauze | |

| CN215898224U (en) | Novel power control equipment based on comprehensive energy | |

| CN215957443U (en) | Dragon fruit is planted and is used big-arch shelter heat abstractor | |

| CN115106424A (en) | Stamping device of irregular C-shaped piece for automobile accessory production | |

| CN215962224U (en) | Chemical extraction device with good separation effect | |

| CN216705163U (en) | Artificial intelligence technology development auxiliary device | |

| CN216094824U (en) | Gravel and sand screening plant for building engineering | |

| CN215636085U (en) | Protection fixing device of video monitoring equipment | |

| CN220944611U (en) | Gearbox front casing grinding device | |

| CN216273167U (en) | Livestock-raising sewage treatment plant | |

| CN215748005U (en) | Screw rod supporting device for gantry machining center | |

| CN219573936U (en) | Visual inspection auxiliary device | |

| CN216614957U (en) | Opener is used in cotton production and processing | |

| CN215683813U (en) | Forestry is fixing device for seedling cultivation | |

| CN219988110U (en) | Intelligent infrared numerical control cutting machine for building stone machining | |

| CN216217949U (en) | Communication display screen that first aid kit and AED used | |

| CN216096045U (en) | New energy automobile is positioner for clod wash section bar based on high heat dissipating ability | |

| CN216433099U (en) | Device for measuring water flow and check assembly thereof | |

| CN216914970U (en) | Camera hot pressing module | |

| CN216844014U (en) | Liquid level alarm for multi-parameter intelligent control system and mounting structure thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |