CN215680594U - Flow guide structure of molded case circuit breaker - Google Patents

Flow guide structure of molded case circuit breaker Download PDFInfo

- Publication number

- CN215680594U CN215680594U CN202121216228.6U CN202121216228U CN215680594U CN 215680594 U CN215680594 U CN 215680594U CN 202121216228 U CN202121216228 U CN 202121216228U CN 215680594 U CN215680594 U CN 215680594U

- Authority

- CN

- China

- Prior art keywords

- trench

- arc

- chamber

- flow guide

- communicated

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Arc-Extinguishing Devices That Are Switches (AREA)

Abstract

The utility model provides a moulded case circuit breaker's water conservancy diversion structure, it includes base (1) and bottom plate (2), explosion chamber installation cavity (a) is constituteed in base (1) and bottom plate (2), and explosion chamber (3) dress is in the explosion chamber installation cavity (a), its characterized in that: at least one side end of the arc extinguish chamber mounting cavity (a) is provided with a flow guide groove (b), the flow guide groove (b) enables the arc extinguish chamber cavity (a) to be communicated with the outside, so that high-temperature gas generated when the arc extinguish chamber (3) extinguishes electric arcs can be discharged along the flow guide groove (b). This moulded case circuit breaker's water conservancy diversion structure sets up the guiding gutter on the bottom plate, UNICOM's explosion chamber cavity and exterior space, and the guiding gutter setting is behind the explosion chamber for the high-temperature gas that the arc extinguishing produced can be in time smooth discharge.

Description

Technical Field

The utility model belongs to the technical field of molded case circuit breakers, and particularly relates to a flow guide structure of a molded case circuit breaker, which is used for conveniently and smoothly discharging high-temperature gas generated during arc extinction.

Background

The circuit breaker is an important part in a distribution electrical appliance, is mainly used for an industrial low-voltage power system, and is used for connecting and disconnecting current in a power grid circuit and protecting lines and power supply equipment from damage caused by faults of overload, undervoltage, short circuit, single-phase grounding and the like. The function of the circuit breaker to break overload or short-circuit current is mainly accomplished by an arc extinguishing chamber installed in the circuit breaker. When fault current occurs in the circuit and the current value exceeds the set protection range of the circuit breaker, the tripping mechanism is driven to act, so that the movable contact and the fixed contact of the circuit breaker are quickly disconnected, and at the moment, the air medium is discharged due to the voltage between the movable contact and the fixed contact, so that high-temperature electric arc is generated. During the combustion process, the arc on the one hand causes a sharp rise in the air temperature in the arc quenching device, so that the air ionization is accelerated. On the other hand, the electric arc is divided into a plurality of short arcs by a plurality of arc isolating grid pieces under the pushing of the magnetic field and the fluid effect in the arc extinguishing chamber, the deionization effect of the electric arc is enhanced by the metal arc isolating pieces, the electric arc is reduced, the voltage is rapidly increased, and the electric arc is extinguished.

The back of current traditional explosion chamber generally with external UNICOM, the high temperature gas that produces after high temperature electric arc extinguishes can follow the passageway discharge circuit breaker at explosion chamber back, but under some circumstances, the explosion chamber position changes the back, and the back of explosion chamber does not directly and external UNICOM, leads to the high temperature gas that produces after high temperature electric arc extinguishes can not in time discharge circuit breaker, sometimes can ionize once more, takes place to burn out incident such as circuit breaker product.

SUMMERY OF THE UTILITY MODEL

The utility model aims to solve the technical defect that the back of the existing arc extinguish chamber is not directly communicated with the outside, so that high-temperature gas generated after high-temperature electric arc is extinguished cannot be discharged out of the circuit breaker in time, and safety accidents are easy to occur.

Technical scheme

In order to achieve the technical purpose, the utility model provides a diversion structure of a molded case circuit breaker, which comprises a base and a bottom plate, wherein the base and the bottom plate form an arc extinguish chamber installation cavity, and the arc extinguish chamber is arranged in the arc extinguish chamber installation cavity, and the diversion structure is characterized in that: at least one side end of the arc extinguish chamber mounting cavity is provided with a diversion trench, and the diversion trench enables the arc extinguish chamber cavity to be communicated with the outside, so that high-temperature gas generated when the arc extinguish chamber extinguishes electric arcs can be discharged along the diversion trench.

Furthermore, the wiring terminal is located above two sides of the arc extinguish chamber mounting cavity, and the diversion trench is located below the wiring terminal.

Furthermore, the guiding gutter includes at least one groove that converges, converge the groove and be located on the bottom surface of a base side, on the bottom plate with converge the groove corresponding position and be provided with the collecting vat, converge the groove and be linked together with the collecting vat, the outside end of collecting vat is provided with gas outlet and external UNICOM.

Furthermore, the confluence groove is communicated with the arc extinguishing chamber cavity, and the gas flowing direction of the confluence groove is consistent with the arc spraying direction of the arc extinguishing chamber.

Furthermore, the bottom of the collecting groove is a slope, and an air outlet is formed in the bottom end of the slope and communicated with the outside.

Advantageous effects

According to the diversion structure of the molded case circuit breaker, the diversion groove is formed in the bottom plate and is communicated with the arc extinguishing chamber cavity and the external space, and the diversion groove is formed in the back of the arc extinguishing chamber and is used for discharging high-temperature gas generated by arc extinguishing in time and smoothly.

Drawings

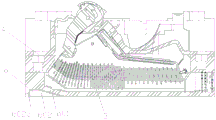

Fig. 1 is a schematic position diagram of a flow guide structure in an embodiment of the utility model.

Fig. 2 is a schematic diagram of the position of an arc chamber cavity in an embodiment of the utility model.

Fig. 3 is a schematic view of the positions of the current guiding structure and the terminal in an embodiment of the present invention.

Fig. 4 is a schematic view of the arc-extinguishing chamber in the embodiment of the present invention.

Detailed Description

The technical solutions of the present invention will be described clearly and completely with reference to the accompanying drawings, and it should be understood that the described embodiments are some, but not all embodiments of the present invention. All other embodiments, which can be derived by a person skilled in the art from the embodiments given herein without making any creative effort, shall fall within the protection scope of the present invention.

In the description of the present invention, it should be noted that the terms "inside", "outside", and the like indicate orientations or positional relationships based on the orientations or positional relationships shown in the drawings, which are only for convenience in describing the present invention and simplifying the description, but do not indicate or imply that the referred device or element must have a specific orientation, be constructed in a specific orientation, and operate, and thus, should not be construed as limiting the present invention. Furthermore, the terms "first," "second," and "third" are used for descriptive purposes only and are not to be construed as indicating or implying relative importance.

In the description of the present invention, it should be noted that, unless otherwise explicitly specified or limited, the terms "mounted" and "connected" are to be interpreted broadly, e.g., as being either fixedly connected, detachably connected, or integrally connected; can be mechanically or electrically connected; they may be connected directly or indirectly through intervening media, or they may be interconnected between two elements. The specific meanings of the above terms in the present invention can be understood in specific cases to those skilled in the art.

The present invention will be described in further detail below with reference to specific embodiments and with reference to the attached drawings.

Examples

As shown in the attached drawing 1, a diversion structure of a molded case circuit breaker comprises a base 1 and a bottom plate 2, wherein the base 1 and the bottom plate 2 form an arc extinguish chamber installation cavity a, an arc extinguish chamber 3 is installed in the arc extinguish chamber installation cavity a, as shown in the attached drawing 2, at least one side end of the arc extinguish chamber installation cavity a is provided with a diversion trench b, specifically, the diversion trench b can be arranged at a moving contact end and a stationary contact end, or both ends are arranged, and the embodiment is arranged at the moving contact end. The diversion trench b enables the arc extinguish chamber cavity a to be communicated with the outside, so that high-temperature gas generated when the arc extinguish chamber 3 extinguishes electric arcs can be discharged along the diversion trench b.

As shown in fig. 3, the connecting terminal 4 is located above two sides of the arc extinguish chamber mounting cavity a, and the diversion trench b is located below the connecting terminal 4. As shown in fig. 1 and 3, the diversion trench b includes at least one confluence trench b01, the confluence trench b01 is located on the bottom surface of one side end of the base 1, a collection trench b02 is arranged on the bottom plate 2 corresponding to the confluence trench b01, the confluence trench b01 is communicated with a collection trench b02, and an air outlet b02a is arranged at the outer side end of the collection trench b02 and communicated with the outside. The confluence groove b01 is communicated with the arc extinguishing chamber cavity a, and as shown in fig. 4, the gas flowing direction of the confluence groove b01 is consistent with the arc spraying direction of the arc extinguishing chamber 3. In this embodiment, the bottom of the collecting groove b02 is a slope, and the bottom end of the slope is provided with an air outlet b02a communicated with the outside.

Meanwhile, it should be noted that the width of the confluence groove b01 in this embodiment can be designed according to the size of the requirement, and the guiding groove b can be formed by one confluence groove b01 plus one collecting groove b02, or by N confluence grooves b01 plus one collecting groove b 02.

According to the diversion structure of the molded case circuit breaker, the diversion groove is formed in the bottom plate and is communicated with the arc extinguishing chamber cavity and the external space, the diversion groove is formed in the back of the arc extinguishing chamber, and high-temperature gas generated by arc extinguishing can be timely and smoothly discharged.

Finally, it should be noted that: the above embodiments are only used to illustrate the technical solution of the present invention, and not to limit the same; while the utility model has been described in detail and with reference to the foregoing embodiments, those skilled in the art will appreciate that; the technical solutions described in the foregoing embodiments may still be modified, or some or all of the technical features may be equivalently replaced; and the modifications or the substitutions do not make the essence of the corresponding technical solutions depart from the scope of the technical solutions of the embodiments of the present invention.

Claims (5)

1. The utility model provides a moulded case circuit breaker's water conservancy diversion structure, it includes base (1) and bottom plate (2), explosion chamber installation cavity (a) is constituteed in base (1) and bottom plate (2), and explosion chamber (3) dress is in the explosion chamber installation cavity (a), its characterized in that: at least one side end of the arc extinguish chamber mounting cavity body (a) is provided with a flow guide groove (b), the flow guide groove (b) enables the arc extinguish chamber mounting cavity body (a) to be communicated with the outside, so that high-temperature gas generated when the arc extinguish chamber (3) extinguishes electric arcs can be discharged along the flow guide groove (b).

2. The structure of claim 1, wherein: binding post (4) are located explosion chamber installation cavity (a) both sides top, guiding gutter (b) are located binding post (4) below.

3. The structure of claim 1, wherein: the diversion trench (b) comprises at least one confluence trench (b01), the confluence trench (b01) is located on the bottom surface of one side end of the base (1), a collecting trench (b02) is arranged on the bottom plate (2) corresponding to the confluence trench (b01), the confluence trench (b01) is communicated with a collecting trench (b02), and an air outlet (b02a) is arranged at the outer side end of the collecting trench (b02) and communicated with the outside.

4. The structure of claim 3, wherein: the confluence groove (b01) is communicated with the arc extinguishing chamber mounting cavity (a), and the gas flowing direction of the confluence groove (b01) is consistent with the arc spraying direction of the arc extinguishing chamber (3).

5. The structure of claim 3, wherein: the bottom of the collecting groove (b02) is a slope surface, and an air outlet (b02a) is formed in the bottom end of the slope surface and communicated with the outside.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202121216228.6U CN215680594U (en) | 2021-06-01 | 2021-06-01 | Flow guide structure of molded case circuit breaker |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202121216228.6U CN215680594U (en) | 2021-06-01 | 2021-06-01 | Flow guide structure of molded case circuit breaker |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN215680594U true CN215680594U (en) | 2022-01-28 |

Family

ID=79973575

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202121216228.6U Active CN215680594U (en) | 2021-06-01 | 2021-06-01 | Flow guide structure of molded case circuit breaker |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN215680594U (en) |

-

2021

- 2021-06-01 CN CN202121216228.6U patent/CN215680594U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN213184182U (en) | Switch electric appliance | |

| CN114068262A (en) | Low-voltage circuit breaker | |

| WO2022134743A1 (en) | Switch | |

| CN111092007A (en) | Frame-type circuit breaker striking arc extinguishing device and contact arc extinguishing system | |

| CN215680594U (en) | Flow guide structure of molded case circuit breaker | |

| CN113972118A (en) | Arc extinguishing chamber and switching device | |

| CN111863465A (en) | Double-station circuit breaker, direct-current combined electrical apparatus applied to double-station circuit breaker and working method of double-station circuit breaker | |

| CN213184178U (en) | Contact mechanism and switching device | |

| CN215527617U (en) | Circuit breaker structure capable of improving breaking capacity | |

| CN213424905U (en) | Plastic casing type circuit breaker | |

| CN216671541U (en) | Backflow gas discharging structure of miniature circuit breaker | |

| CN217280665U (en) | High-breaking-capacity universal circuit breaker diversion mechanism | |

| CN107546081B (en) | Arc extinguishing space sealing structure of circuit breaker | |

| CN112490094A (en) | Current-limiting air direct-current circuit breaker arc extinguishing device and arc extinguishing method thereof | |

| CN220439539U (en) | Novel lightning protection circuit breaker | |

| CN209962915U (en) | Arc extinguishing chamber | |

| CN221352666U (en) | Wire outlet structure from two side directions of fixed contact and moving contact of circuit breaker | |

| CN217035574U (en) | Quick arc control device | |

| CN217544513U (en) | Moving contact protection structure | |

| CN214203596U (en) | Contact matching structure of electrical switch | |

| CN221529855U (en) | Arc extinguishing structure of miniature circuit breaker | |

| CN220543821U (en) | Air-blowing arc-escaping channel arc-extinguishing structure of circuit breaker and circuit breaker | |

| CN221352643U (en) | Arc extinguishing structure of circuit breaker | |

| WO2020248556A1 (en) | Novel double-contact point plastic case circuit breaker | |

| CN211376574U (en) | Circuit breaker moving contact mounting structure |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |