CN211663670U - Size-adjustable assembled tray - Google Patents

Size-adjustable assembled tray Download PDFInfo

- Publication number

- CN211663670U CN211663670U CN201922061568.5U CN201922061568U CN211663670U CN 211663670 U CN211663670 U CN 211663670U CN 201922061568 U CN201922061568 U CN 201922061568U CN 211663670 U CN211663670 U CN 211663670U

- Authority

- CN

- China

- Prior art keywords

- tray

- sub

- buckle

- connecting strip

- supporting legs

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Stackable Containers (AREA)

Abstract

The utility model relates to the technical field of machinery. The size-adjustable assembled tray comprises a tray body, wherein the tray body comprises two sub-trays and a connecting mechanism for connecting the two sub-trays; the two sub-trays are respectively a left sub-tray and a right sub-tray which are arranged in a left-right mirror symmetry manner; the connecting mechanism comprises a left connecting strip and a right connecting strip which are arranged on the left and right, and the left connecting strip and the right connecting strip are in sliding connection with each other by taking the front and back directions as sliding directions; a left side buckling group used for clamping supporting legs of the left side sub-tray is arranged on the left side of the left side connecting strip; the right side of the right connecting strip is provided with a right clamping group used for clamping the supporting legs of the right sub-tray; the connecting mechanism further comprises two elastic buckles arranged front and back, and the two elastic buckles clamp and fix the left sub-tray, the left connecting strip, the right connecting strip and the right sub-tray. This patent is convenient for put the space according to not equidimension article and difference, carries out independent assortment and dismantlement.

Description

Technical Field

The utility model relates to the technical field of machinery, concretely relates to commodity circulation transportation tray.

Background

The logistics transportation pallet is used as important loading, unloading, storing and transporting equipment in the logistics transportation process and is usually matched with a forklift for use.

At present, the logistics transportation tray is generally made of plastics and wood simply, the width of the tray is fixed, the size of the tray cannot be adjusted according to field requirements, and the logistics transportation tray is not flexible to use.

SUMMERY OF THE UTILITY MODEL

To the problem that prior art exists, the utility model provides a size adjustable assembled tray has solved the problem of above at least one.

The technical scheme of the utility model is that: the size-adjustable assembled tray comprises a tray body and is characterized in that the tray body comprises two sub-trays and a connecting mechanism for connecting the two sub-trays;

the two sub-trays are respectively a left sub-tray and a right sub-tray which are arranged in a left-right mirror symmetry manner;

the connecting mechanism comprises a left connecting strip and a right connecting strip which are arranged on the left and right sides, and the left connecting strip and the right connecting strip are in sliding connection by taking the front-back direction as the sliding direction;

a left side buckling group used for clamping and connecting the supporting legs of the left side sub-tray is arranged on the left side of the left side connecting strip;

the right side of the right connecting strip is provided with a right clamping group used for clamping the supporting legs of the right sub-tray;

the connecting mechanism further comprises two elastic buckles arranged front and back, and the two elastic buckles clamp and fix the left sub-tray, the left connecting strip, the right connecting strip and the right sub-tray.

This patent is through optimizing the structure of traditional integration tray, and the improvement is the detachable construction of two sub-trays and coupling mechanism combinations, is convenient for carry out independent assortment and dismantlement according to not equidimension article and the space of putting of difference.

When the device is used, the left sub-tray and the right sub-tray can be independently used, or the left sub-tray and the right sub-tray can be combined for use after being connected through the connecting mechanism,

further preferably, the elastic buckle is a U-shaped metal wire buckle.

Further preferably, the left sub-tray comprises a top plate, six supporting legs arranged at the outer edge of the top plate and two bottom plates arranged left and right;

the six supporting legs are respectively three supporting legs positioned on the left side and three supporting legs positioned on the right side, and the cross section area of the cross section of each of the three supporting legs positioned on the left side is larger than that of the cross section of each of the three supporting legs positioned on the right side;

the bottom plate positioned on the left side in the two bottom plates is connected with the three supporting legs positioned on the left side;

the bottom plate on the right side of the two bottom plates is connected with the three supporting legs on the right side.

The combination of the three supporting legs on the right side and the three supporting legs on the left side of the right side sub-tray is facilitated.

Preferably, the left side buckle group and the right side buckle group are arranged on the left side connecting strip and the right side connecting strip respectively in a left-right mirror symmetry structure;

the left side buckle group comprises two buckle units which are arranged up and down, each buckle unit is provided with four left side buckles, the four left side buckles are sequentially arranged along the length direction of the left side connecting strip, and adjacent left side buckles in the four left side buckles are of a front-back mirror symmetry structure;

each buckle unit is a first buckle, a second buckle, a third buckle and a fourth buckle which are sequentially arranged from front to back;

the three supporting legs on the right side of the left side sub-tray are a first supporting leg, a second supporting leg and a third supporting leg in sequence from front to back;

the first buckle is clamped at the rear side of the first supporting leg, the second buckle and the third buckle are respectively clamped at the front side and the rear side of the second supporting leg, and the third buckle is clamped at the front side of the third supporting leg;

the elastic buckle is arranged between the two buckle units.

The relative fixation in the front, back, left and right directions is convenient to ensure.

Preferably, the left buckle comprises a first bending part, a second bending part, a third bending part and a fourth bending part which are connected in sequence;

the first bending part is an installation part, and an installation hole is formed in the installation part;

the second bending part is a connecting part for connecting the first bending part and the third bending part;

the third bending part is bent towards the mounting part in an inclined way;

the fourth bending part is a limiting part used for abutting against the supporting leg, and the limiting part and the mounting part are arranged in parallel.

When being convenient for push left side sub-tray with the left side connecting strip towards the left side, left side buckle and the sub-tray joint in left side. When the right connecting strip is pushed into the right sub-tray backwards, the right buckle is clamped with the right sub-tray.

Further preferably, two reinforcing strips with the length direction being left and right are detachably connected above the tray body, and the reinforcing strips are arranged on the outer edge of the tray body.

Support intensity when being convenient for improve later stage tray body and supporting the use of fork truck.

Further preferably, the reinforcing bar is detachably connected with the left side sub-tray and the right side sub-tray through screws.

Or the front end and the rear end of the left sub-tray and the right sub-tray are respectively fixed with a positioning strip, and the width of the section of each positioning strip increases progressively from bottom to top;

the bottom of the reinforcing strip is provided with a sliding groove matched with the positioning strip.

Drawings

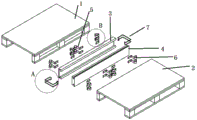

Fig. 1 is an exploded view of embodiment 1 of the present invention;

fig. 2 is a schematic structural diagram of embodiment 1 of the present invention;

fig. 3 is a schematic structural diagram of another view angle according to embodiment 1 of the present invention;

FIG. 4 is an enlarged view of a portion of FIG. 1;

FIG. 5 is an enlarged view of a portion of the structure shown at B in FIG. 1;

fig. 6 is a schematic structural diagram of embodiment 2 of the present invention.

In the figure: 1 is left side sub-tray, 2 is right side sub-tray, and 3 is the left side connecting strip, and 4 are the right side connecting strip, and 5 are left side buckle group, and 6 are right side buckle group, and 7 are elastic buckle, and 11 are for strengthening the strip, and 51 are the left side buckle.

Detailed Description

The present invention will be further described with reference to the accompanying drawings.

In specific embodiment 1, referring to fig. 1 to 5, a size-adjustable assembly type tray includes a tray body, and the tray body includes two sub-trays and a connecting mechanism for connecting the two sub-trays; the two sub-trays are respectively a left sub-tray 1 and a right sub-tray 2 which are arranged in a left-right mirror symmetry manner; the connecting mechanism comprises a left connecting strip 3 and a right connecting strip 4 which are arranged on the left and right, and the left connecting strip 3 and the right connecting strip 4 are in sliding connection by taking the front and back direction as the sliding direction; a left clamping group 5 for clamping supporting legs of the left sub-tray 1 is arranged on the left side of the left connecting strip 3; a right clamping group 6 for clamping the supporting legs of the right sub-tray 2 is arranged on the right side of the right connecting strip 4; the connecting mechanism further comprises two elastic buckles 7 arranged front and back, and the two elastic buckles 7 clamp and fix the left sub-tray 1, the left connecting strip 3, the right connecting strip 4 and the right sub-tray 2.

This patent is through optimizing the structure of traditional integration tray, and the improvement is the detachable construction of two sub-trays and coupling mechanism combinations, is convenient for carry out independent assortment and dismantlement according to not equidimension article and the space of putting of difference.

When the device is used, the left sub-tray 1 and the right sub-tray 2 can be independently used, or the left sub-tray 1 and the right sub-tray 2 can be combined for use after being connected through a connecting mechanism,

referring to fig. 4, the resilient catch 7 is a U-shaped wire catch.

The left sub-tray 1 comprises a top plate, six supporting legs arranged on the outer edge of the top plate and two bottom plates arranged left and right; the six supporting legs are respectively three supporting legs positioned on the left side and three supporting legs positioned on the right side, and the cross section area of the cross section of each of the three supporting legs positioned on the left side is larger than that of the cross section of each of the three supporting legs positioned on the right side; the bottom plate positioned on the left side in the two bottom plates is connected with the three supporting legs positioned on the left side; the bottom plate on the right side of the two bottom plates is connected with the three supporting legs on the right side. The combination of the three supporting feet on the right side and the three supporting feet on the left side of the right sub-tray 2 is facilitated.

The left side buckle group 5 and the right side buckle group 6 are arranged on the left side connecting strip and the right side connecting strip respectively in a left-right mirror symmetry structure; the left side buckle group 5 comprises eight left side buckles 51, the eight left side buckles 51 are divided into two buckle units which are arranged up and down, each buckle unit is provided with four left side buckles, the four left side buckles are sequentially arranged along the length direction of the left side connecting strip, and adjacent left side buckles in the four left side buckles are of a front-back mirror symmetry structure; the elastic buckle is arranged between the two buckle units. The relative fixation in the front, back, left and right directions is convenient to ensure. The upper end and the lower end of each of the two buckling units are respectively abutted against the top plate and the bottom plate.

Referring to fig. 5, the left buckle 51 includes a first bending portion, a second bending portion, a third bending portion, and a fourth bending portion connected in sequence; the first bending part is an installation part, and an installation hole is formed in the installation part; the second bending part is a connecting part for connecting the first bending part and the third bending part; the first bending part and the third bending part are respectively arranged at two sides of the first bending part in the left-right direction, and the third bending part is obliquely bent towards the mounting part; the fourth bending part is a limiting part used for abutting against the supporting leg, and the limiting part is arranged in parallel with the mounting part. When being convenient for push left side sub-tray with the left side connecting strip towards the left side, left side buckle and the sub-tray joint in left side. When the right connecting strip is pushed into the right sub-tray backwards, the right buckle is clamped with the right sub-tray. The first bending part, the second bending part and the third bending part are connected to form a 2-shaped structure.

The foregoing is only a preferred embodiment of the present invention, and it should be noted that, for those skilled in the art, a plurality of improvements and decorations can be made without departing from the principle of the present invention, and these improvements and decorations should also be regarded as the protection scope of the present invention.

Claims (4)

1. The size-adjustable assembled tray comprises a tray body and is characterized in that the tray body comprises two sub-trays and a connecting mechanism for connecting the two sub-trays;

the two sub-trays are respectively a left sub-tray and a right sub-tray which are arranged in a left-right mirror symmetry manner;

the connecting mechanism comprises a left connecting strip and a right connecting strip which are arranged on the left and right sides, and the left connecting strip and the right connecting strip are in sliding connection by taking the front-back direction as the sliding direction;

a left side buckling group used for clamping and connecting the supporting legs of the left side sub-tray is arranged on the left side of the left side connecting strip;

the right side of the right connecting strip is provided with a right clamping group used for clamping the supporting legs of the right sub-tray;

the connecting mechanism further comprises two elastic buckles arranged front and back, and the two elastic buckles clamp and fix the left sub-tray, the left connecting strip, the right connecting strip and the right sub-tray.

2. The modular size tray of claim 1, wherein: the left sub-tray comprises a top plate, six supporting legs arranged at the outer edge of the top plate and two bottom plates arranged left and right;

the six supporting legs are respectively three supporting legs positioned on the left side and three supporting legs positioned on the right side, and the cross section area of the cross section of each of the three supporting legs positioned on the left side is larger than that of the cross section of each of the three supporting legs positioned on the right side;

the bottom plate positioned on the left side in the two bottom plates is connected with the three supporting legs positioned on the left side;

the bottom plate on the right side of the two bottom plates is connected with the three supporting legs on the right side.

3. The modular size tray of claim 2, wherein: the left side buckle group and the right side buckle group are arranged on the left side connecting strip and the right side connecting strip respectively in a left-right mirror symmetry structure;

the left side buckle group comprises two buckle units which are arranged up and down, each buckle unit is provided with four left side buckles, the four left side buckles are sequentially arranged along the length direction of the left side connecting strip, and adjacent left side buckles in the four left side buckles are of a front-back mirror symmetry structure;

each buckle unit is a first buckle, a second buckle, a third buckle and a fourth buckle which are sequentially arranged from front to back;

the three supporting legs on the right side of the left side sub-tray are a first supporting leg, a second supporting leg and a third supporting leg in sequence from front to back;

the first buckle is clamped at the rear side of the first supporting leg, the second buckle and the third buckle are respectively clamped at the front side and the rear side of the second supporting leg, and the third buckle is clamped at the front side of the third supporting leg;

the elastic buckle is arranged between the two buckle units.

4. The modular size tray of claim 3, wherein: the left buckle comprises a first bending part, a second bending part, a third bending part and a fourth bending part which are connected in sequence;

the first bending part is an installation part, and an installation hole is formed in the installation part;

the second bending part is a connecting part for connecting the first bending part and the third bending part;

the third bending part is bent towards the mounting part in an inclined way;

the fourth bending part is a limiting part used for abutting against the supporting leg, and the limiting part and the mounting part are arranged in parallel.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201922061568.5U CN211663670U (en) | 2019-11-26 | 2019-11-26 | Size-adjustable assembled tray |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201922061568.5U CN211663670U (en) | 2019-11-26 | 2019-11-26 | Size-adjustable assembled tray |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN211663670U true CN211663670U (en) | 2020-10-13 |

Family

ID=72733705

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201922061568.5U Active CN211663670U (en) | 2019-11-26 | 2019-11-26 | Size-adjustable assembled tray |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN211663670U (en) |

-

2019

- 2019-11-26 CN CN201922061568.5U patent/CN211663670U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8739986B2 (en) | Retail cart | |

| US10106294B2 (en) | Transport rack and/or storage rack, and arrangement of a transport rack and/or storage rack on a floor plate | |

| US3840242A (en) | Transport rack | |

| CA1236222A (en) | Carrier for self-supporting sheet-like articles such as printed circuit boards | |

| US6974140B2 (en) | Modular multiple dolly moving system | |

| US8646618B2 (en) | Flexible shelving system | |

| US20100307998A1 (en) | Stop wall structure for removably mounting to a metal-wire shelf | |

| US8196761B2 (en) | Easily assembled shelving system of small overall size | |

| CA2451695A1 (en) | Pallet rack with camber beams | |

| US2687310A (en) | Mobile sheet rack | |

| CN211663670U (en) | Size-adjustable assembled tray | |

| US10232870B2 (en) | Bracket and caster lift for shopping cart | |

| US8777204B2 (en) | Cutting support | |

| JP5401688B2 (en) | desk | |

| JPS5816503Y2 (en) | Assembly type aluminum alloy flat pallet | |

| CN104210792A (en) | Inverted nesting rack with storage middle rack | |

| KR101379311B1 (en) | Leg using table | |

| US20050139131A1 (en) | Foldable shelf and drawers | |

| US6802267B1 (en) | Easily assembled pallet | |

| JP6270258B2 (en) | desk | |

| US20150027645A1 (en) | Barricade assembly with foldable legs | |

| JP2002095531A (en) | Furniture | |

| JP6079954B2 (en) | Furniture with a top plate | |

| CN217295300U (en) | Insect-proof wood tray | |

| CN210901897U (en) | Light desk of dismantling |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CP01 | Change in the name or title of a patent holder | ||

| CP01 | Change in the name or title of a patent holder |

Address after: 201908 a, No. 1258, yueluo Road, Baoshan District, Shanghai Patentee after: Shanghai Miaohang Packaging Technology Co.,Ltd. Address before: 201908 a, No. 1258, yueluo Road, Baoshan District, Shanghai Patentee before: Shanghai Miaohang Packaging Technology Co.,Ltd. |