CN210744387U - PCB type power supply and signal mixed cascade line - Google Patents

PCB type power supply and signal mixed cascade line Download PDFInfo

- Publication number

- CN210744387U CN210744387U CN201921791625.9U CN201921791625U CN210744387U CN 210744387 U CN210744387 U CN 210744387U CN 201921791625 U CN201921791625 U CN 201921791625U CN 210744387 U CN210744387 U CN 210744387U

- Authority

- CN

- China

- Prior art keywords

- plug

- pcb

- control box

- outer die

- power

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Connector Housings Or Holding Contact Members (AREA)

Abstract

The utility model discloses a PCB formula power and signal load in mixture cascade line relates to connector, wire rod cross technical field. The utility model discloses a flat line, the skeleton, module plug PCB board and control box plug PCB board, the one end of module plug PCB board one side and the both ends of control box plug PCB board one side all weld the run-on bus female, the opposite side of module plug PCB board and the opposite side of control box plug PCB board have welded respectively that the module plug is arranged female and the control box plug is arranged female, the central point of skeleton puts and has seted up the rectangle through-hole, the inside of rectangle through-hole is equipped with that the control box plug is arranged female or the module plug is arranged female, circular through-hole has all been seted up at the both ends of rectangle through-hole, the inside of circular through-hole is equipped with female terminal of power, the inside parcel of flat line has winding. The utility model discloses a series of designs make the external dimension of device become littleer, utilize PCB to realize the cascade of signal and power.

Description

Technical Field

The utility model relates to a connector, wire rod are alternately technical field, and more specifically says, relates to a PCB formula power and signal loads in mixture cascade line.

Background

The application of LED front maintenance module in market has been very extensive, and the customer adopts power + signal to load in mixture flat winding displacement also fairly much, but if according to a module corresponds a plug and inserts the control box again, sometimes the control box will be done very big, also do not benefit to the full power performance of power in the control box simultaneously, the cost is increased, consequently demand a section can enough reduce the control box size on the market, can exert mains power again, can also realize signal transmission's product, the utility model discloses a new solution is proposed to above problem.

SUMMERY OF THE UTILITY MODEL

1. Technical problem to be solved

To the problem that exists among the prior art, the utility model aims to provide a PCB formula power and signal load in mixture cascade line to solve the technical problem who mentions in the background art.

2. Technical scheme

In order to solve the above problems, the utility model adopts the following technical proposal.

A PCB type power supply and signal mixed cascading line comprises a flat line, a framework, a module plug PCB and a control box plug PCB, wherein connecting row nuts are welded at one end of one side of the module plug PCB and at two ends of one side of the control box plug PCB, a module plug row nut and a control box plug row nut are respectively welded at the other side of the module plug PCB and at the other side of the control box plug PCB, a rectangular through hole is formed in the central position of the framework, a control box plug row nut or a module plug row nut is assembled inside the rectangular through hole, circular through holes are formed at two ends of the rectangular through hole, a power supply female terminal is assembled inside the circular through hole, a flat line and a power supply line are wrapped inside the flat line, the flat line is connected with the connecting row nuts through compression joint, the power supply line is connected with the power supply female terminal through welding, an inner mold is formed outside the framework through rubber coating and injection molding, the outer side of the inner die is secondarily formed with an outer die through rubber coating, the outer die is provided with a middle outer die and an end outer die, and net tails are fixed at two ends of the middle outer die and one end of the end outer die.

Preferably, the surface of the framework and the positions at the tops of the two circular through holes are both fixed with limit keys, and the limit keys and the framework are integrally formed through injection molding.

In any of the above schemes, preferably, the flat wire is wrapped with a common flat cable, two sides of the flat wire are respectively provided with a power line, and the flat cable and the power lines are wrapped with a layer of PVC glue.

In any of the above schemes, preferably, the middle outer mold and the end outer mold respectively include a control box plug PCB and a module plug PCB, the two PCBs have different internal circuits, and signals are controlled and cascaded through the difference of the two PCBs.

In any of the above schemes, preferably, both ends of the middle outer die and the end outer die are provided with screw holes, and hand-screwed screws or common screws are assembled as required.

In any of the above schemes, preferably, the power lines in the flat wires are welded through the power female terminal in the plug to realize current series connection and cascade connection.

In any of the above schemes, preferably, the middle plug and the end plug are respectively integrally encapsulated with the flat wire through the framework, the inner die, the middle outer die and the end outer die, so that the requirement of water resistance inside the plug is met.

3. Advantageous effects

Compared with the prior art, the utility model has the advantages of:

(1) the utility model discloses when the equipment, earlier arrange female with the module plug row mother with the control box plug and weld respectively in one side of control box plug PCB board and module plug PCB board, the winding displacement of flat line centre crimping respectively is female at the connector row again, then will connect female the welding of connector row and get into inside the skeleton at the both ends of control box plug PCB board opposite side and the one end of module plug PCB opposite side, last whole gets into the skeleton with its assembly, weld the power cord of flat line both sides in the one end of power female terminal respectively, the mode of rethread injection molding is with skeleton and wire rod and terminal parcel in the inside of centre form, then wrap up the outside at the centre form with the mode of moulding plastics with centre external mold or end external mold and net tail, just so constituted a PCB formula cascade line. The series connection and jumper connection of signals are realized by using the module PCBs and the PCBs in the plugs, so that the information transmission and cascade connection between a plurality of modules and the control box are realized, and meanwhile, the direct current connection of each module belongs to the same control box, so that the cascade connection of a power supply is realized, the number of the connections is reduced, the control range of the control box is expanded, and the appearance size of the device is smaller;

(2) the utility model discloses when the equipment, adopt flat line and female ripe technology of row's line crimping row, through PCB switching signal, consequently reduced the welded degree of difficulty, reduced the height of plug, make the whole size greatly reduced of product, still the cost is reduced simultaneously.

(3) The utility model discloses the product designs according to row female + hat spring terminal plug class design mode when designing, divide into skeleton, centre form, external mold, realizes the constitution and the waterproof sealing of plug, makes the product can use in the open air.

Drawings

FIG. 1 is an overall structure diagram of the present invention;

fig. 2 is a structural view of the inner mold of the present invention;

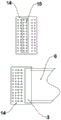

fig. 3 is a structural diagram of the connection between the module plug row bus and the framework of the present invention;

FIG. 4 is a structural diagram of the framework of the present invention;

fig. 5 is a connecting structure diagram of the control box plug PCB board, the control box plug row bus and the connecting row bus of the present invention;

fig. 6 is a connecting structure diagram of the module plug PCB board, the module plug row bus bar and the connecting row bus bar of the present invention;

fig. 7 is the utility model discloses female, the female or the module plug PCB board of control box plug PCB board and the female or the female connection structure picture of module plug row of control box plug row.

The reference numbers in the figures illustrate:

1. an intermediate outer mold; 2. end external molds; 3. connecting the row nuts; 4. a power supply female terminal; 5. a net tail; 6. flat wires; 7. a framework; 8. a rectangular through hole; 9. a circular through hole; 10. an inner mold; 11. a limiting key; 12. a control box plug PCB board; 13. arranging a control box plug in a female manner; 14. a module plug PCB board; 15. the module plug is arranged in a female manner.

Detailed Description

The technical solution in the embodiment of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiment of the present invention; obviously, the described embodiments are only a part of the embodiments of the present invention, and not all embodiments, and all other embodiments obtained by those skilled in the art without any inventive work are within the scope of the present invention based on the embodiments of the present invention.

In the description of the present invention, it should be noted that the terms "upper", "lower", "inner", "outer", "top/bottom", and the like indicate orientations or positional relationships based on the orientations or positional relationships shown in the drawings, and are only for convenience of description and simplification of description, but do not indicate or imply that the device or element referred to must have a specific orientation, be constructed in a specific orientation, and be operated, and thus, should not be construed as limiting the present invention. Furthermore, the terms "first" and "second" are used for descriptive purposes only and are not to be construed as indicating or implying relative importance.

In the description of the present invention, it should be noted that, unless explicitly stated or limited otherwise, the terms "mounted," "disposed," "sleeved/connected," "connected," and the like are used in a broad sense, and for example, "connected," may be fixedly connected, detachably connected, or integrally connected, mechanically connected, electrically connected, directly connected, indirectly connected through an intermediate medium, or connected between two elements.

The specific embodiment is as follows:

referring to fig. 1-7, a PCB type power and signal mixed-loading cascade connection line comprises a flat wire 6, a frame 7, a module plug PCB 14 and a control box plug PCB 12, wherein one end of one side of the module plug PCB 14 and two ends of one side of the control box plug PCB 12 are welded with a connecting bar nut 3, the other side of the module plug PCB 14 and the other side of the control box plug PCB 12 are welded with a module plug bar nut 15 and a control box plug bar nut 13, respectively, a rectangular through hole 8 is formed at the center of the frame 7, a control box plug bar nut 13 or a module plug bar nut 15 is assembled in the rectangular through hole 8, circular through holes 9 are formed at two ends of the rectangular through hole 8, a power supply terminal 4 is assembled in the circular through hole 9, a flat wire and a power line are wrapped in the flat wire 6, two power lines are crimped and located at two sides of the flat wire, and the flat wire is connected with the connecting bar nut 3, the power cord is connected with a power female terminal 4 through welding, the outer side of the framework 7 is provided with an inner die 10 through rubber coating injection molding, the outer side of the inner die 10 is provided with an outer die through rubber coating secondary molding, the outer die is provided with a middle outer die 1 and an end outer die 2, and both ends of the middle outer die 1 and one end of the end outer die 2 are fixed with net tails 5.

In this embodiment, in order to effectively prevent the erroneous insertion, the surface of the frame 7 and the positions at the tops of the two circular through holes 9 are both fixed with a limit key 11, and the limit key 11 and the frame 7 are integrally formed by injection molding.

In this embodiment, the flat wire 6 includes a common flat cable, two sides of which are respectively provided with a power line, and the flat cable and the power line are both wrapped by a layer of PVC glue, so that the flat wire can be used outdoors, and the flat cable is protected.

In this embodiment, the end outer mold 2 of the middle outer mold 1 includes a control box plug PCB 12 and a module plug PCB 14, respectively, the two PCBs have different internal circuits, and signals are controlled and cascaded through the different internal circuits of the two PCBs.

In the embodiment, in order to facilitate the installation of the plug in use, both ends of the middle outer die 1 and the end outer die 2 are provided with screw through holes, and hand screws or ordinary screws are assembled as required.

In the embodiment, the power wires in the flat wires 6 are welded through the power female terminal 4 in the plug to realize current series connection and cascade connection.

In the embodiment, the middle plug and the end plug are respectively and integrally encapsulated with the flat wire 6 through the framework 7, the inner die 10, the middle outer die 1 and the end outer die 2, so that the waterproof requirement of the plug is met.

The working principle is as follows:

during assembly, firstly, a control box plug row bus 13 and a module plug row bus 15 are respectively welded on one side of a control box plug PCB 12 and one side of a module plug PCB 14, then flat cables in the middle of a plurality of flat wires 6 are respectively crimped on a connecting row bus 3, then the flat cables are welded on one end of the other side of the module plug PCB 14 and two ends of the other side of the control box plug PCB 12, finally the whole flat cables are assembled into the framework 7, power lines on two sides of the flat wires 6 are welded on one end of a power supply female terminal 4, the framework 7, wires and terminals are wrapped in the inner die 10 in an injection molding mode, and then the middle outer die 1 or the end outer die 2 and the net tail 5 are wrapped in the outer side of the inner die 10 in an injection molding mode. In actual production, the PCB is designed into two types of green and blue respectively, and the two types are easy to identify in processing, namely, the green is the module plug PCB 14, and the blue is the control box plug PCB 12.

When the plug is used, signals and current on the control box PCB enter the control box plug row female 13 and the power source female terminal 4 in the oppositely-inserted middle plug through the row pins welded on the control box PCB and the power source male terminal, on one hand, the signals enter the connected control box plug PCB 12, then respectively enter the connecting row female 3 on the other side of the control box plug PCB 12 according to circuits on the PCB, enter the connecting row female 3 connected with the module plug PCB 14 in the end plug through the connection of the row wires, then enter the module plug row female 15 along the module plug PCB 14, and finally enter the oppositely-connected module PCB row pins to enter the module. On the other hand, after the current enters the power female terminal 4 in the middle plug, the current respectively enters the power female terminal 4 in the end plug along the power line, and finally enters the module through the power male terminal on the module PCB which is butted with the power female terminal.

The above is only a preferred embodiment of the present invention; the scope of the present invention is not limited thereto. Any person skilled in the art should also be able to cover the technical scope of the present invention by replacing or changing the technical solution and the improvement concept of the present invention with equivalents and modifications within the technical scope of the present invention.

Claims (7)

1. A PCB type power supply and signal mixed-loading cascade line comprises a flat wire (6), a framework (7), a module plug PCB (14) and a control box plug PCB (12), and is characterized in that one end of one side of the module plug PCB (14) and two ends of one side of the control box plug PCB (12) are both welded with a connecting row bus (3), and the other side of the module plug PCB (14) and the other side of the control box plug PCB (12) are respectively welded with a module plug row bus (15) and a control box plug row bus (13);

a rectangular through hole (8) is formed in the center of the framework (7), a control box plug row bus (13) or a module plug row bus (15) is assembled inside the rectangular through hole (8), circular through holes (9) are formed in two ends of the rectangular through hole (8), a power supply bus terminal (4) is assembled inside the circular through hole (9), a flat cable and a power supply wire are wrapped inside the flat wire (6), the flat cable is connected with the connecting row bus (3) in a compression joint mode, and the power supply wire is connected with the power supply bus terminal (4) in a welding mode;

the outer side of the framework (7) is provided with an inner die (10) through encapsulation and injection molding, the outer side of the inner die (10) is provided with an outer die through encapsulation and secondary molding, the outer die is provided with a middle outer die (1) and an end outer die (2), and the two ends of the middle outer die (1) and one end of the end outer die (2) are both fixed with net tails (5).

2. A PCB-type power and signal mixed-loading cascade line according to claim 1, wherein: the surface of skeleton (7) and the position that is located the top of two circular through-holes (9) all are fixed with spacing key (11), spacing key (11) and skeleton (7) are through moulding plastics integrated into one piece.

3. A PCB-type power and signal mixed-loading cascade line according to claim 1, wherein: the flat wire (6) is wrapped by a common flat cable, two sides of the flat wire are respectively provided with a single power line, and the flat cable and the power lines are wrapped by a layer of PVC glue.

4. A PCB-type power and signal mixed-loading cascade line according to claim 1, wherein: the middle outer die (1) end outer die (2) respectively comprises a control box plug PCB (12) and a module plug PCB (14), the two PCBs have different internal circuits, and signals are controlled and cascaded through the difference of the two PCBs.

5. A PCB-type power and signal mixed-loading cascade line according to claim 1, wherein: screw holes are formed in the two ends of the middle outer die (1) and the two ends of the end outer die (2), and hand-screwed screws or ordinary screws are assembled according to needs.

6. A PCB-type power and signal mixed-loading cascade line according to claim 1, wherein: and a power wire in the flat wire (6) is welded through a power female terminal (4) in the plug to realize current series connection and cascade connection.

7. A PCB-type power and signal mixed-loading cascade line according to claim 1, wherein: the middle plug and the end plug are respectively integrally wrapped with a flat wire (6) through a framework (7), an inner die (10), a middle outer die (1) and an end outer die (2), and the waterproof requirement of the plug is met.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921791625.9U CN210744387U (en) | 2019-10-24 | 2019-10-24 | PCB type power supply and signal mixed cascade line |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921791625.9U CN210744387U (en) | 2019-10-24 | 2019-10-24 | PCB type power supply and signal mixed cascade line |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN210744387U true CN210744387U (en) | 2020-06-12 |

Family

ID=70982182

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201921791625.9U Expired - Fee Related CN210744387U (en) | 2019-10-24 | 2019-10-24 | PCB type power supply and signal mixed cascade line |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN210744387U (en) |

-

2019

- 2019-10-24 CN CN201921791625.9U patent/CN210744387U/en not_active Expired - Fee Related

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN210744387U (en) | PCB type power supply and signal mixed cascade line | |

| CN2874838Y (en) | Cable connector module | |

| CN104900438A (en) | No-overhanging pin patch type silica gel elastic button | |

| CN210744353U (en) | Wire rod type power supply and signal mixed loading cascade line | |

| CN203562616U (en) | Double-layer combined connector | |

| CN219393756U (en) | Novel potential bridging structure | |

| CN207800955U (en) | A kind of double-row terminal welding adapter of electric connector | |

| CN216672602U (en) | Multi-power supply system distribution unit | |

| CN210744369U (en) | Bus-bar relay type power supply and signal mixed cascade line | |

| CN205960232U (en) | Electric connector | |

| CN212462203U (en) | Robot connecting wire | |

| CN210744385U (en) | Power and signal mixed flat wire | |

| CN203445351U (en) | Improved structure for multi-port straight-through type RJ45 connector | |

| CN210200515U (en) | Copper conducting bar assembling and fixing structure for transformer and transformer thereof | |

| CN206850090U (en) | The pin power outlet of integral type three | |

| CN204156151U (en) | A kind of wire and cable connector | |

| CN220122258U (en) | Communication line suitable for connection between battery monitoring modules | |

| CN210744212U (en) | Power and signal mixed shielding flat wire | |

| CN204668209U (en) | A kind of without the SMD silicone elastomer button of overhanging pin | |

| CN215870110U (en) | Serial-type leading wire structure with punching press terminal | |

| CN201478558U (en) | Anti-glue injection structure of cable connector | |

| CN117175307A (en) | General design method for front maintenance module wire harness of LED display screen | |

| CN210744386U (en) | Power and signal mixed round wire | |

| CN221574533U (en) | Electric power cabinet structure | |

| CN105047838B (en) | Battery flat group |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20200612 Termination date: 20201024 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |