CN203134528U - Wiring clamping strip for transformer - Google Patents

Wiring clamping strip for transformer Download PDFInfo

- Publication number

- CN203134528U CN203134528U CN 201320084687 CN201320084687U CN203134528U CN 203134528 U CN203134528 U CN 203134528U CN 201320084687 CN201320084687 CN 201320084687 CN 201320084687 U CN201320084687 U CN 201320084687U CN 203134528 U CN203134528 U CN 203134528U

- Authority

- CN

- China

- Prior art keywords

- section

- transformer

- clamping section

- clamping

- block section

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 230000001154 acute effect Effects 0.000 claims abstract description 6

- 229910001220 stainless steel Inorganic materials 0.000 claims abstract description 5

- 239000010935 stainless steel Substances 0.000 claims abstract description 5

- 239000004677 Nylon Substances 0.000 description 5

- 239000002184 metal Substances 0.000 description 5

- 229920001778 nylon Polymers 0.000 description 5

- 238000010276 construction Methods 0.000 description 2

- 230000036461 convulsion Effects 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Landscapes

- Coils Or Transformers For Communication (AREA)

Abstract

The utility model discloses a wiring clamping strip for a transformer. The wiring clamping strip for the transformer comprises a long-strip-shaped horizontal strip body, one end of the horizontal strip body is provided with a fixed connecting section and a fixed base part, the other end of the horizontal strip body is provided with a first clamping section, a second clamping section and a third clamping section, and an acute angle is formed between the arranged direction of the first clamping section and the arranged direction of the second clamping section. According to the wiring clamping strip for the transformer, the first clamping section, the second clamping section and the third clamping section are integrally formed by stainless steel, due to the fact that the acute angle is formed between the arranged direction of the first clamping section and the arranged direction of the second clamping section, a connecting wire cable can be clamped between the first clamping section and the second clamping section, when workers works, the wire cable can be drawn by certain strength, and filed operation is greatly facilitated. The wiring clamping strip for the transformer is simple in structure, convenient to use and low in cost.

Description

Technical Field

The present invention relates to a high voltage electrical apparatus, more precisely, a terminal strip for a transformer.

Background

The connecting cable of the existing high-voltage transformer is usually fixed by utilizing a nylon buckle or a metal ring buckle, if the cable needs to be replaced or a new connecting terminal is introduced, the original nylon buckle or the metal ring buckle needs to be cut off, so that waste is caused, in addition, the existing nylon buckle or the metal ring buckle adopts a completely locked structure, and once the nylon buckle or the metal ring buckle is buckled, the nylon buckle or the metal ring buckle is difficult to pull, so that certain trouble is caused for worker construction.

Disclosure of Invention

The utility model discloses solve the technical problem that prior art exists to a wiring card strip for transformer is provided.

The above technical problem of the present invention can be solved by the following technical solutions:

the utility model provides a wiring card strip for transformer, wiring card strip for transformer contain a long banding horizontal bar main part, the one end of horizontal bar main part be equipped with a fixed connection section and a fixed basal portion, the other end of horizontal bar main part is equipped with a first block section, a second block section and a third block section, the direction that sets up of first block section with second block section one-tenth acute angle, the direction that sets up of second block section with third block section one-tenth right angle.

As a preferred embodiment of the present invention, the arrangement direction of the first engaging section and the second engaging section form an angle of 45 °.

As the preferred embodiment of the present invention, the horizontal bar main body is integrally formed by stainless steel.

The utility model discloses a wiring card strip for transformer utilizes stainless steel integrated into one piece's first block section, second block section and third block section, because the setting direction of first block section becomes an acute angle with second block section, can be with the connecting cable block between first block section and second block section, can apply certain dynamics during the workman's construction and just can twitch the cable, has made things convenient for the field operation greatly. The wiring clamping strip for the transformer is simple in structure, convenient to use and low in cost.

Drawings

In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the drawings used in the description of the embodiments or the prior art will be briefly described below, it is obvious that the drawings in the following description are only some embodiments of the present invention, and for those skilled in the art, other drawings can be obtained according to these drawings without creative efforts.

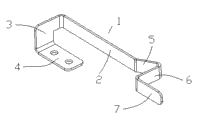

Fig. 1 is a schematic perspective view of a terminal strip for a transformer according to the present invention;

fig. 2 is a perspective view of the terminal block strip for the transformer of fig. 1, from another perspective;

wherein,

1. a terminal strip for a transformer; 2. a cross bar body; 3. a fixed connection section; 4. a fixed base; 5. a first engaging section; 6. a second clamping section; 7. and a third clamping section.

Detailed Description

The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the scope of the present invention can be more clearly and clearly defined.

As shown in fig. 1 to 2, the utility model discloses a terminal block strip 1 for transformer contains a long banding horizontal bar main part 2, and the one end of this horizontal bar main part 2 is equipped with a fixed connection section 3 and a fixed basal portion 4, and the other end of horizontal bar main part 2 is equipped with a first block section 5, a second block section 6 and a third block section 7, and the direction that sets up of this first block section 5 becomes an acute angle with this second block section 6, and the direction that sets up of this second block section 6 becomes a right angle with this third block section 7.

The first engaging segment 5 is disposed at an angle of 45 ° with respect to the second engaging segment 6.

The horizontal bar main body 2 is integrally formed by stainless steel.

The above description is only for the specific embodiments of the present invention, but the scope of the present invention is not limited thereto, and any changes or substitutions that are not thought of through the creative work should be covered within the scope of the present invention. Therefore, the protection scope of the present invention should be subject to the protection scope defined by the claims.

Claims (3)

1. The utility model provides a wiring card strip for transformer, characterized in that, wiring card strip (1) for transformer contain a long banding horizontal main part (2), the one end of horizontal main part (2) be equipped with a fixed connection section (3) and a fixed basal portion (4), the other end of horizontal main part (2) is equipped with a first block section (5), a second block section (6) and a third block section (7), the setting direction of first block section (5) with second block section (6) become an acute angle, the setting direction of second block section (6) with third block section (7) become a right angle.

2. The terminal strip according to claim 1, wherein the first engaging section (5) is arranged at an angle of 45 ° with respect to the second engaging section (6).

3. The terminal strip according to claim 2, wherein the cross-bar body (2) is integrally formed of stainless steel.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201320084687 CN203134528U (en) | 2013-02-25 | 2013-02-25 | Wiring clamping strip for transformer |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201320084687 CN203134528U (en) | 2013-02-25 | 2013-02-25 | Wiring clamping strip for transformer |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN203134528U true CN203134528U (en) | 2013-08-14 |

Family

ID=48942479

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN 201320084687 Expired - Fee Related CN203134528U (en) | 2013-02-25 | 2013-02-25 | Wiring clamping strip for transformer |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN203134528U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105321679A (en) * | 2015-10-16 | 2016-02-10 | 苏州腾冉电气设备股份有限公司 | Connection structure for outgoing cable of transformer |

-

2013

- 2013-02-25 CN CN 201320084687 patent/CN203134528U/en not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105321679A (en) * | 2015-10-16 | 2016-02-10 | 苏州腾冉电气设备股份有限公司 | Connection structure for outgoing cable of transformer |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN201690167U (en) | Bus bar for fixing wire harness | |

| CN203134528U (en) | Wiring clamping strip for transformer | |

| CN204144470U (en) | Binding clip | |

| CN208189819U (en) | A kind of earthing clamp | |

| CN204692768U (en) | A kind of reused wiring harness ribbon | |

| CN203232971U (en) | Lightning-protection grounding cable connector for distribution transformer | |

| CN203910983U (en) | Compression type rapid binding post | |

| CN105135059A (en) | Multipurpose electric cable bundling device | |

| CN204282927U (en) | A kind of electric pole pull rope | |

| CN203180115U (en) | Rapid wiring device of wires | |

| CN203326130U (en) | Grounding pricker for cable overhaul | |

| CN209401855U (en) | A kind of soft graphite grounding body wire clamp | |

| CN203010012U (en) | Wire-fixing edge clamp | |

| CN203131220U (en) | Wall nail for fixing electric wire | |

| CN204597009U (en) | Automobile starter eyelet terminal | |

| NZ607726A (en) | Securing device | |

| CN204289761U (en) | 180 degree of anti-rotation terminals | |

| CN204230796U (en) | A kind of wire harnesses | |

| CN207234135U (en) | A kind of aerospace connectors tail clamp fixing device | |

| CN108011336A (en) | Integral type cable hook | |

| CN218040542U (en) | Automobile wire harness multi-joint dividing and guiding device | |

| CN207121050U (en) | Electric power cable wire harness apparatus | |

| CN204035421U (en) | A kind of multi-functional cable is cut | |

| CN211428800U (en) | Reusable cable tie | |

| CN202261735U (en) | Headphone clip |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20130814 Termination date: 20140225 |