CN202176453U - Eccentric ring wind power mechanism - Google Patents

Eccentric ring wind power mechanism Download PDFInfo

- Publication number

- CN202176453U CN202176453U CN 201120208230 CN201120208230U CN202176453U CN 202176453 U CN202176453 U CN 202176453U CN 201120208230 CN201120208230 CN 201120208230 CN 201120208230 U CN201120208230 U CN 201120208230U CN 202176453 U CN202176453 U CN 202176453U

- Authority

- CN

- China

- Prior art keywords

- wind

- plate

- ring

- driving

- vertical shaft

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 230000000712 assembly Effects 0.000 claims abstract description 17

- 238000000429 assembly Methods 0.000 claims abstract description 17

- 238000005096 rolling process Methods 0.000 claims description 15

- 238000005192 partition Methods 0.000 claims description 9

- 238000007667 floating Methods 0.000 claims description 8

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 8

- 238000003756 stirring Methods 0.000 claims description 6

- 238000005516 engineering process Methods 0.000 description 3

- 238000010248 power generation Methods 0.000 description 3

- 230000005540 biological transmission Effects 0.000 description 2

- 230000003213 activating effect Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000005611 electricity Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F03—MACHINES OR ENGINES FOR LIQUIDS; WIND, SPRING, OR WEIGHT MOTORS; PRODUCING MECHANICAL POWER OR A REACTIVE PROPULSIVE THRUST, NOT OTHERWISE PROVIDED FOR

- F03D—WIND MOTORS

- F03D3/00—Wind motors with rotation axis substantially perpendicular to the air flow entering the rotor

- F03D3/06—Rotors

- F03D3/062—Rotors characterised by their construction elements

- F03D3/066—Rotors characterised by their construction elements the wind engaging parts being movable relative to the rotor

- F03D3/067—Cyclic movements

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E10/00—Energy generation through renewable energy sources

- Y02E10/70—Wind energy

- Y02E10/74—Wind turbines with rotation axis perpendicular to the wind direction

Landscapes

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Sustainable Development (AREA)

- Sustainable Energy (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Wind Motors (AREA)

Abstract

The utility model relates to an eccentric ring wind power mechanism which comprises a plurality of wind board assemblies, a connection driving assembly and a movable round ring capable of moving in the horizontal direction. The wind board assemblies are rotatablely arranged on the outer periphery of the connection driving assembly. Each wind board assembly is divided into an inner board and an outer board by taking the position connected with the connection driving assembly as the boundary. The area of each outer board is greater than the area of the corresponding inner board. The movable round ring is provided with a guide slot. The end part of the inner board of each wind board assembly is provided with an inner board roller. The inner board rollers are rotatablely connected with the guide slot. When the wind board assemblies are acted by the wind, the wind board assemblies drive the connection driving assembly to rotate, the positions of the wind board assemblies are relatively fixed, and the inner boards of the wind board assemblies can provide pressures for the movable round ring, wherein the larger are openings of the wind board assemblies opened, the higher the pressures provided for the movable round ring are; and the position of the movable round ring depends on the resultant force of the pressures provided for the movable round ring by the wind board assemblies, so that the wind board assemblies are always kept at the most reasonable windage position, and thus, the utilization efficiency of wind energy is improved.

Description

Technical Field

The utility model relates to a wind power equipment, more specifically say, relate to an eccentric ring formula wind-force mechanism.

Background

In the present day that petrochemical and coal-fired energy sources are gradually withered, wind power generation or power output has become one of the key directions of human energy development. The data indicate that the total amount of globally exploitable wind energy resources is about many times the total amount of human energy demand. The richness and natural reproducibility of wind energy is the most attractive reason.

Wind power technology has originated in europe, where the development and initiatives for wind power in countries such as denmark, the netherlands, germany have been in history for over 20 years. Since the birth of the wind power generation technology, the wind power generation technology is continuously improved, and the wind turbines which are commonly used at present can be summarized into two types:

1) the vertical axis of the wind wheel of the horizontal axis wind turbine is parallel to the airflow direction. The horizontal axis wind turbine mainly comprises a tower, a horizontal axis wind wheel, a gearbox (an accelerating gearbox), a generator, a wind aligning device, a control system and other components. The wind wheel is used for converting wind energy into mechanical energy, and is formed by mounting blades with good air flow performance on a wheel shaft, and the low-speed rotating wind wheel is accelerated by an accelerating gearbox through a transmission mechanism so as to transmit power to a generator. The horizontal shaft wind turbine has the main advantages that: the wind wheel can be erected at a place higher than the ground, the influence of ground disturbance on the dynamic characteristics of the wind wheel is reduced, the higher the wind wheel is erected from the ground, the larger the wind power is, the higher the generated energy is increased along with the increase of the height, the starting wind speed is low, and the wind wheel can be automatically started. The defects are that the design of the blade profile and the manufacture of the wind wheel are complex; and an additional wind aligning device is needed to adjust the wind aligning direction of the blades of the wind wheel, so that the design difficulty and the cost are increased.

2) The vertical axis wind turbine has the vertical axis perpendicular to the ground or airflow direction. The vertical axis wind turbine is usually arranged in a place close to the ground, and a tower and a wind aligning device are not needed; the vertical shaft wind turbine is driven to rotate by wind, and the generator is driven to rotate by the gearbox. The wind wheel has the advantages that no wind aligning device is needed when the direction of the airflow is changed, and the gyroscopic force of the wind wheel when the wind wheel aligns to the wind is reduced. The structure is relatively simple, and the cost is low. However, the vertical axis wind turbine has a lower wind energy utilization rate than that of the horizontal axis, the wind wheel is greatly influenced by the ground by the airflow close to the ground, and the wind plates of the vertical axis wind turbine are usually fixedly arranged, so that the wind power cannot be received more fully, the conversion efficiency of the wind energy is low, and the actual requirements cannot be met.

SUMMERY OF THE UTILITY MODEL

The to-be-solved technical problem of the utility model is to provide an eccentric ring formula wind power mechanism of wind energy utilization efficiency height, simple structure.

The utility model provides a technical scheme that its technical problem adopted is: an eccentric ring type wind power mechanism is constructed, and comprises a plurality of wind plate assemblies and a connecting driving assembly driven by the wind plate assemblies to output power;

the wind plate assembly is rotatably arranged on the periphery of the connecting driving assembly, and is divided into an inner plate and an outer plate by taking the position of connecting the connecting driving assembly as a boundary, and the area of the outer plate is larger than that of the inner plate;

the eccentric ring type wind power mechanism also comprises a movable circular ring which can translate in the horizontal direction; the movable circular ring is provided with a guide groove; an inner plate rolling shaft is arranged at the end part of an inner plate of the air plate assembly and is rotatably connected with the guide groove;

the wind plate component drives the connecting driving component to rotate, and the position of the connecting driving component is relatively fixed.

In the eccentric ring type wind power mechanism of the utility model, the eccentric ring wind power mechanism also comprises a vertical shaft which is vertically arranged;

the connecting and driving components comprise two groups which are respectively arranged at the upper end and the lower end of the vertical shaft; the axis of the connecting and driving component is fixedly connected with the vertical shaft to drive the vertical shaft to rotate;

the inner plate is one side of the wind plate assembly close to the vertical shaft, and the outer plate is one side far away from the vertical shaft.

In the eccentric ring type wind power mechanism of the present invention, the connecting driving assembly includes a plurality of driving connecting rods respectively disposed at the upper and lower ends of the vertical shaft;

each driving connecting rod corresponds to one air plate assembly, the inner end of each driving connecting rod is fixedly connected with the vertical shaft, and the outer end of each driving connecting rod is provided with a connecting hole;

the upper side and the lower side of the wind plate component are provided with wind plate rolling shafts, and the wind plate rolling shafts on the two sides are respectively rotatably inserted into the corresponding connecting holes of the driving connecting rod.

In the eccentric ring type wind power mechanism of the utility model, the eccentric ring type vertical wind power mechanism further comprises an inner fixed ring positioned at the inner side of the movable ring; the inner fixed ring can rotate relative to the driving connecting rod, and the position of the inner fixed ring is relatively fixed;

the inner fixed ring and the vertical shaft are arranged concentrically and are positioned at the same horizontal position with the movable ring.

The utility model discloses an in the eccentric ring formula wind-force mechanism, the width of inner panel plus the radial length of internal fixation ring is greater than the vertical axis arrives the length of aerofoil roller bearing.

In the eccentric ring type wind power mechanism of the utility model, the outer end of the driving connecting rod is fixedly provided with an outer fixed ring; the connecting hole is arranged on the outer fixing ring.

In the eccentric ring type wind power mechanism of the utility model, the width of the inner plate and the length of the diameter of the movable ring are larger than the diameter of the outer fixed ring; or,

the width of the inner plate and the length of the diameter of the movable circular ring are equal to the diameter of the outer fixed circular ring, a plurality of partitions are arranged in the movable circular ring, the partitions are the same in size, and the number of the partitions is equal to the number of the wind plates.

The utility model discloses an among the eccentric ring formula wind-force mechanism, the cambered surface sum length of aerofoil subassembly is more than or equal to the girth of external fixation ring, and the inner panel roller bearing can break away from the guide way of activity ring, end to end can constitute a drum.

In the eccentric ring type wind power mechanism of the utility model, the wind plate component comprises a resistance type wind plate or a lift type wind plate; the wind plate is a solar cell wind plate; and bearings are arranged on the peripheries of the inner plate rolling shafts and/or the wind plate rolling shafts.

The utility model discloses an among the eccentric ring formula wind-force mechanism, eccentric ring formula wind-force mechanism still includes fixed mounting and is in connect the body that revolves of drive assembly downside, the water stirring spare is installed to the body downside that revolves.

Implement the utility model discloses following beneficial effect has: when the wind plate assembly is subjected to wind, the wind plate assembly is driven to be connected with the driving assembly to rotate, meanwhile, the inner plate of the wind plate assembly can provide pressure for the movable circular ring, the larger the wind plate assembly is opened, the larger the pressure is provided for the movable circular ring, the resultant force of the pressure provided by the wind plate assembly for the movable circular ring determines the position of the movable circular ring, so that the wind plate assembly is always kept at the most reasonable wind receiving position, and the utilization efficiency of wind energy is improved; in addition, various wind aligning devices of the horizontal shaft wind turbine in the prior art are not needed, and the structure is simple and reasonable.

Drawings

The invention will be further explained with reference to the drawings and examples, wherein:

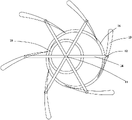

FIG. 1 is a schematic top view of a first embodiment of an eccentric ring wind turbine according to the present invention;

FIG. 2 is a schematic partial cross-sectional view of a first embodiment of an eccentric ring wind power plant according to the present invention;

FIG. 3 is an enlarged partial view of portion A of FIG. 2;

fig. 4 is a schematic top view of a lift-type wind-receiving member according to a first embodiment of the eccentric ring type wind-power mechanism of the present invention;

FIG. 5 is a schematic top view of a second embodiment of an eccentric ring wind turbine according to the present invention;

fig. 6 is a schematic top view of a third embodiment of an eccentric ring wind turbine according to the present invention.

Detailed Description

As shown in fig. 1 to 4, the first embodiment of the eccentric ring type wind power mechanism of the present invention, used as a wind power machine, includes a vertical shaft 11 vertically disposed, two sets of connecting driving components respectively disposed at the upper and lower ends of the vertical shaft 11, and a plurality of wind plate components.

The vertical shaft 11 is arranged in the vertical direction and is driven to rotate by a connecting driving assembly. The output of the vertical shaft 11 may drive a generator or other power machine to convert wind energy into kinetic energy for output. The wind plate component is used as a wind receiving piece 13, is pushed by wind to be connected with the driving component to rotate, and comprises a wind plate rolling shaft 12 arranged in parallel with the vertical shaft 11 and the wind receiving piece 13 fixedly combined with the wind plate rolling shaft 12. The wind board assembly may adopt various wind board assemblies of the prior art, such as the windsurfing board assembly disclosed in chinese utility model patent No. 200920133508.3. The windward member 13 of the windboard assembly may be a drag type windboard or a lift type windboard (as shown in fig. 4). Of course, the wind receiving member 13 of the wind plate assembly can also be made of a solar cell panel, so that the wind plate assembly can be combined with solar energy to generate electricity.

The connection driving assembly, as a power transmission assembly, is connected between the vertical shaft 11 and the wind plate assembly, and may include two sets separately disposed at the upper and lower ends of the vertical shaft 11, and one of the sets is described below as an example. The axis of the connecting driving component is fixedly connected with the vertical shaft 11, and the outer end of the connecting driving component is connected with the wind plate component.

In this embodiment, the connecting driving assembly includes a plurality of driving links 14 respectively disposed at upper and lower ends of the vertical shaft 11. The number of the driving connecting rods 14 corresponds to that of the wind plate assemblies, the inner ends of the driving connecting rods 14 are fixedly connected with the vertical shaft 11, and the outer ends of the driving connecting rods are connected with the wind plate assemblies. The outer end of the driving connecting rod 14 is provided with a connecting hole 15, and the wind plate rollers 12 on the upper side and the lower side of the wind plate assembly can be rotatably inserted into the corresponding connecting holes 15 of the driving connecting rod 14 on the upper side and the lower side, so that the wind plate assembly can push the driving connecting rod 14 to rotate, and can also rotate around the wind plate rollers 12.

It is understood that the periphery of the flap rollers 12 may be provided with bearings or the like to reduce friction between the flap rollers 12 and the connecting holes 15 of the driving link 14.

In order to keep the wind plate assembly at a reasonable wind facing position all the time during the rotation process, the eccentric ring type wind power mechanism is also provided with a movable circular ring 16 which can translate in the horizontal direction. In this embodiment, the movable rings 16 are disposed on both upper and lower sides of the wind plate assembly, respectively, but only one of them may be disposed as required.

Each movable ring 16 is provided with a guide groove 17; correspondingly, an inner plate roller 18 is provided at an end of an inner plate of the damper assembly, and the inner plate roller 18 is rotatably inserted into the guide groove 17. It is understood that a bearing may be further provided on the outer periphery of the inner plate roller 18 to reduce friction between the inner plate roller 18 and the guide groove 17.

In the present embodiment, the damper assembly is divided into an inner plate on the side close to the vertical shaft 11 and an outer plate on the side far from the vertical shaft 11, with the position of the driving assembly (i.e., the line connecting the damper rollers 12 on the upper and lower sides) as a boundary; moreover, the area of the outer plate is larger than that of the inner plate, so that the wind area of the outer plate is always larger than that of the inner plate, and resultant force for pushing the movable ring 16 to reach a proper position and pushing the connecting driving assembly to rotate is formed.

When the air plate assemblies are subjected to wind, each air plate assembly gives pressure to the movable circular ring 16, the larger the opening of the air plate assembly gives the pressure to the movable circular ring 16 is, and the resultant force of the pressure given by the air plate assembly to the movable circular ring 16 determines the position of the movable circular ring 16. When the wind plate assembly rotates around the vertical shaft 11, the inner plate rolling shaft 18 is inserted into the guide groove 17 and is guided by the guide groove 17, so that the wind receiving angle of the wind plate assembly is changed, the wind plate assembly is always kept at the most reasonable wind receiving position, and the utilization efficiency of wind energy is improved.

Further, an inner fixed ring 19 fixedly connected to the driving link 14 is further provided inside the movable ring 16 in order to restrain the movable ring 16, support the driving link 14, and the like. The inner stationary ring 19 is arranged concentrically with the vertical axis 11 and is located at the same horizontal position as the movable ring 16. The width of the inner plate of the air plate component and the length of the radius of the fixed circular ring are larger than the length from the vertical shaft 11 to the air plate roller 12, so that the movable circular ring 16 can be ensured not to exceed the limit position, and the air plate of the air plate component is prevented from being blown over.

In order to reduce the friction between the movable ring 16 and the inner fixed ring 19, a bearing of the inner fixed ring 19 can be fixedly arranged on the outer circumference of the inner fixed ring 19. Alternatively, the inner stationary ring 19 may be provided to include an inner race and an outer race that are separately coupled, and rolling elements such as balls or rollers may be provided between the inner race and the outer race.

As shown in fig. 5, the second embodiment of the eccentric ring type wind power mechanism of the present invention is different from the first embodiment in that an external fixing ring 20 fixedly provided at the outer end of the driving link 14 is used instead of the internal fixing ring 19, and the connecting hole 15 is provided on the external fixing ring 20 so that the wind plate assembly is rotatably inserted and mounted on the external fixing ring 20. Moreover, the outer fixed ring 20 and the movable ring 16 are in the same horizontal position, so that the movable ring 16 can only horizontally move in the outer fixed ring 20, and the function of limiting the movable ring 16 is achieved.

To prevent the aerofoil assembly from being blown over, the width of the inner plate plus the length of the diameter of the mobile ring 16 is greater than the diameter of the outer fixed ring 20. Or the width of the inner plate plus the diameter of the movable ring 16 is equal to the diameter of the outer fixed ring 20, and at this time, a plurality of partitions are arranged in the movable ring 16, the partitions have the same size, and the number of the partitions is equal to the number of the wind plates.

Furthermore, the total length of the cambered surfaces of the wind plate components is designed to be larger than or equal to the perimeter of the outer fixed rings 20, so that the wind plate components can be sequentially arranged between the upper outer fixed ring 20 and the lower outer fixed ring 20 when not rotating, the inner plate rolling shafts 18 can be separated from the guide grooves 1 of the movable rings 16 and are connected end to form a cylinder, and thus, when the wind speed is too high, the wind turbine is prevented from being damaged.

It will be appreciated that, in combination with the first and second embodiments described above as a third embodiment, both the inner fixing ring 19 and the outer fixing ring 20 may be provided, as shown in fig. 6.

In the fourth example of the eccentric ring type wind power mechanism of the present invention, the difference from the above embodiment is that a rotary float is fixedly mounted on the lower side of the connecting drive component. The rotary floating body can be made into a hollow circular ring body, and sufficient buoyancy is provided to support the whole wind turbine, so that the whole mechanism can be used on water. The connection between the rotary floating body and the connecting driving component can refer to the Chinese utility model patent ZL200920134710.8, and of course, other connection modes can be adopted without limitation.

In the fifth embodiment of the present invention, the eccentric ring type wind power mechanism can be used as a wind power water activating machine, and is different from the above embodiments in that a rotary floating body is fixedly mounted on the lower side of the connecting driving assembly, and a water stirring member is fixedly mounted on the lower side of the rotary floating body. The connection structure of the water stirring piece and the rotary floating body can refer to Chinese patent ZL200920134813.4, and of course, other connection modes can be adopted, as long as the wind plate component can drive the connection driving component to rotate, and then the rotary floating body is driven to rotate, and the water stirring piece is driven to stir water.

Claims (10)

1. An eccentric ring type wind power mechanism comprises a plurality of wind plate assemblies and a connecting driving assembly driven by the wind plate assemblies to output power;

the wind plate assembly is rotatably arranged on the periphery of the connecting driving assembly, and is divided into an inner plate and an outer plate by taking the position of connecting the connecting driving assembly as a boundary, wherein the area of the outer plate is larger than that of the inner plate;

the eccentric ring type wind power mechanism also comprises a movable circular ring which can translate in the horizontal direction; the movable circular ring is provided with a guide groove; an inner plate rolling shaft is arranged at the end part of an inner plate of the air plate assembly and is rotatably connected with the guide groove;

the wind plate component drives the connecting driving component to rotate, and the position of the connecting driving component is relatively fixed.

2. The eccentric ring wind power mechanism of claim 1, further comprising a vertically disposed vertical shaft;

the connecting and driving components comprise two groups which are respectively arranged at the upper end and the lower end of the vertical shaft; the axis of the connecting and driving component is fixedly connected with the vertical shaft to drive the vertical shaft to rotate;

the inner plate is one side of the wind plate assembly close to the vertical shaft, and the outer plate is one side far away from the vertical shaft.

3. The eccentric ring type wind power mechanism according to claim 2, wherein the connection driving assembly comprises a plurality of driving connecting rods respectively arranged at the upper and lower ends of the vertical shaft;

each driving connecting rod corresponds to one air plate assembly, the inner end of each driving connecting rod is fixedly connected with the vertical shaft, and the outer end of each driving connecting rod is provided with a connecting hole;

the upper side and the lower side of the wind plate component are provided with wind plate rolling shafts, and the wind plate rolling shafts on the two sides are respectively rotatably inserted into the corresponding connecting holes of the driving connecting rod.

4. The eccentric ring type wind turbine according to claim 3, further comprising an inner fixed ring inside the movable ring; the inner fixed ring can rotate relative to the driving connecting rod, and the position of the inner fixed ring is relatively fixed;

the inner fixed ring and the vertical shaft are arranged concentrically and are positioned at the same horizontal position with the movable ring.

5. An eccentric ring wind power mechanism according to claim 4, characterized in that the width of the inner plate plus the length of the radius of the inner stationary ring is larger than the length of the vertical shaft to the aerofoil roller.

6. An eccentric ring type wind power mechanism according to any of claims 3 to 5, wherein the outer end of the driving connecting rod is fixedly provided with an outer fixing ring; the connecting hole is arranged on the outer fixing ring.

7. The eccentric ring type wind power mechanism according to claim 6, wherein the width of the inner plate plus the length of the diameter of the movable ring is greater than the diameter of the outer stationary ring; or,

the width of the inner plate and the length of the diameter of the movable circular ring are equal to the diameter of the outer fixed circular ring, a plurality of partitions are arranged in the movable circular ring, the partitions are the same in size, and the number of the partitions is equal to the number of the wind plates.

8. The eccentric ring type wind power mechanism according to claim 7, wherein the total length of the cambered surfaces of the wind plate components is greater than or equal to the circumference of the outer fixed ring, and the inner plate rollers can be separated from the guide grooves of the movable ring and can be connected end to form a cylinder.

9. The eccentric annular wind power plant of claim 7, wherein the wind plate assembly comprises a drag type wind plate or a lift type wind plate; the wind plate is a solar cell wind plate; and bearings are arranged on the peripheries of the inner plate rolling shafts and/or the wind plate rolling shafts.

10. The eccentric ring type wind power mechanism according to claim 1, further comprising a rotary floating body fixedly installed at the lower side of the connecting driving assembly, and a water stirring member is installed at the outer lower side of the rotary floating body.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201120208230 CN202176453U (en) | 2011-06-20 | 2011-06-20 | Eccentric ring wind power mechanism |

| PCT/CN2012/070558 WO2012174864A1 (en) | 2011-06-20 | 2012-01-19 | Eccentric ring wind power mechanism |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201120208230 CN202176453U (en) | 2011-06-20 | 2011-06-20 | Eccentric ring wind power mechanism |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202176453U true CN202176453U (en) | 2012-03-28 |

Family

ID=45866337

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN 201120208230 Expired - Fee Related CN202176453U (en) | 2011-06-20 | 2011-06-20 | Eccentric ring wind power mechanism |

Country Status (2)

| Country | Link |

|---|---|

| CN (1) | CN202176453U (en) |

| WO (1) | WO2012174864A1 (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103899474A (en) * | 2014-03-04 | 2014-07-02 | 哈尔滨工程大学 | Telescopic variable blade device |

| CN104329219A (en) * | 2014-10-29 | 2015-02-04 | 西北工业大学 | Sistan fan propeller |

| CN104595121A (en) * | 2014-12-03 | 2015-05-06 | 王长波 | Wind driven generator |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2019113675A1 (en) * | 2017-12-15 | 2019-06-20 | Wind-Do Energy Inc. | Design of blades for darrieus wind turbines |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2800551A1 (en) * | 1978-01-07 | 1979-07-12 | Kiehn Paul | Wind or water turbine unit - has hollow cylindrical rotor with sliding vanes turning about eccentric core |

| SU1437570A1 (en) * | 1986-10-24 | 1988-11-15 | Ч.-К.А.Нудревич | Windmill |

| JPH11141453A (en) * | 1997-11-10 | 1999-05-25 | Kaoru Nishimura | Wind force device |

| JP4658768B2 (en) * | 2005-02-04 | 2011-03-23 | 株式会社別川製作所 | Rotor blade and power generator using the rotor blade |

| KR100938669B1 (en) * | 2008-12-23 | 2010-01-25 | 최말희 | Eccentric type wind turbine |

-

2011

- 2011-06-20 CN CN 201120208230 patent/CN202176453U/en not_active Expired - Fee Related

-

2012

- 2012-01-19 WO PCT/CN2012/070558 patent/WO2012174864A1/en active Application Filing

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103899474A (en) * | 2014-03-04 | 2014-07-02 | 哈尔滨工程大学 | Telescopic variable blade device |

| CN104329219A (en) * | 2014-10-29 | 2015-02-04 | 西北工业大学 | Sistan fan propeller |

| CN104329219B (en) * | 2014-10-29 | 2017-01-18 | 西北工业大学 | Sistan fan propeller |

| CN104595121A (en) * | 2014-12-03 | 2015-05-06 | 王长波 | Wind driven generator |

| WO2016086880A1 (en) * | 2014-12-03 | 2016-06-09 | 王长波 | Wind power generator |

| CN104595121B (en) * | 2014-12-03 | 2017-09-05 | 王长波 | Wind-driven generator |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2012174864A1 (en) | 2012-12-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8922047B2 (en) | Wind turbine | |

| CN103089547B (en) | Balanced vertical-axis large wind power generation unit | |

| KR101581336B1 (en) | Rotatable individual generation device | |

| CN202176453U (en) | Eccentric ring wind power mechanism | |

| CN102400854A (en) | Vertical axis wind turbine | |

| WO2021023004A1 (en) | Horizontal shaft wind-driven power generator | |

| US20120061972A1 (en) | Vertical-axis wind turbine | |

| CN203796490U (en) | Transmission gear based vertical-axis wind turbine with movable blades | |

| KR20090102282A (en) | A vertical axis wind turbin with rotate on it's own axis type wind plane | |

| CN202300829U (en) | Double-blade wind driven generator | |

| CN104329219A (en) | Sistan fan propeller | |

| KR20140142500A (en) | Turbine and power generating apparatus having the same | |

| CN201065812Y (en) | Tornado type wind power machine | |

| KR101363889B1 (en) | Vertical shaft wind power generation | |

| CN202300833U (en) | Vertical-shaft loose-leaf wind turbine | |

| KR20110004803A (en) | Wind power apparatus | |

| CN202176454U (en) | Vertical shaft wind power rotating generating system | |

| CN201144763Y (en) | Vertical shaft wind power generator wind wheel | |

| CN201090373Y (en) | Counter-rotating wind motor | |

| CN202991350U (en) | Balanced type perpendicular-shaft large-sized wind-power generator set | |

| RU2722982C1 (en) | Rotary windmill | |

| CN219549022U (en) | Wind turbine and wind power plant | |

| CN217300786U (en) | Sliding slewing bearing for wind generating set | |

| CN204553087U (en) | Vertical axis wind power generation structure | |

| CN116591903B (en) | Wind collection energy storage and communication integrated single-pipe tower and management control system |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20120328 Termination date: 20140620 |

|

| EXPY | Termination of patent right or utility model |