CN202087671U - Simple precise die - Google Patents

Simple precise die Download PDFInfo

- Publication number

- CN202087671U CN202087671U CN2011200258551U CN201120025855U CN202087671U CN 202087671 U CN202087671 U CN 202087671U CN 2011200258551 U CN2011200258551 U CN 2011200258551U CN 201120025855 U CN201120025855 U CN 201120025855U CN 202087671 U CN202087671 U CN 202087671U

- Authority

- CN

- China

- Prior art keywords

- die

- gear ring

- stripper

- punch

- pressing plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Punching Or Piercing (AREA)

Abstract

The utility model discloses a simple precise die which relates to a stamping die and comprises an upper die base, a lower die base, a die handle, a guide sleeve, a guide pillar, a male die, a female die and a gear ring platen, wherein the male die is provided with a stripper plate which is provided with a stripper bolt, and a stripper spring is sheathed on the stripper bolt; the gear ring platen is ring-shaped, and an annular groove, matched with the gear ring platen, is arranged at the position of the lower surface of the stripper plate, corresponding to the male module; the gear ring platen is sheathed on the male die in an annular way and is fixedly connected the an annular groove by a bolt, a toothed bulge is arranged at the lower surface of the gear ring platen, and the lower surface of the toothed bulge is lower than the lower surface of the stripper plate; and the female die is internally provided with a top plate, a top rod is arranged at the lower surface of the top plate, and a top piece spring is sheathed and connected on the top rod. The simple precise die can enlarge pressure on a material belt in stamping, leads the material belt in a state of three-way pressure stress, and prevents the material belt from being vaulted and bent, thus enhancing the precision of products, improving the quality of sections, and realizing the great practicability.

Description

Technical field

The utility model relates to a kind of diel, relates in particular to a kind of simple and easy fine blanking die.

Background technology

Stamping die is a kind of industrial production common equipment, it can carry out processing and forming such as punching and blanking, existing stamping die is when the thin material of punching press, strip is in free state, and when punching or blanking, strip is easy to wrinkling, influence the precision of product, increased percent defective, even adopt stripper to suppress discharging and push piece, also because can not prevent inadequately that to the pressure of strip the stopping materials strip vault is curved.When using existing stamping die punching press in addition, strip only is subjected to the pressure of punch, and shearing can appear in the strip at the cutting edge place tears phenomenon, and the product section has only the euphotic belt about 1/3, and all the other are coarse fracture belt, and cross section quality is poor.

Summary of the invention

At the problem that above-mentioned prior art exists, the utility model provides a kind of simple and easy fine blanking die, in the time of can increasing punching press to the pressure of strip, allow strip be in the state of three-dimensional compressive stress, anti-stopping materials strip vault is curved, improves the precision and the cross section quality of product, and is very practical.

The technical solution of the utility model is: a kind of simple and easy fine blanking die, comprise upper bolster, die shoe, die shank, guide pin bushing, guide pillar, punch and die, punch is fixedly connected on the upper bolster below by punch retainer, be provided with backing plate between punch and the upper bolster, punch is provided with stripper, stripper is provided with the discharging screw, be socketed with the discharging spring on the discharging screw, also comprise the gear ring pressing plate, the gear ring pressing plate is the annular plate, the position that the stripper lower surface is corresponding with punch has the annular groove with gear ring pressing plate coupling, the gear ring pressing plate is located on the punch and by screw and is fixedly connected in the annular groove, the lower surface of gear ring pressing plate is provided with detent projection, and the lower surface of detent projection is lower than the lower surface of stripper; Be provided with top board in the die, the upper surface of top board is higher than the upper surface of die, and the lower surface of top board is provided with push rod, is socketed with the head part spring on the push rod.

As preferably, described discharging spring is a disc spring.

As preferably, be provided with ball in the gap that guide pin bushing and guide pillar cooperate.

The beneficial effects of the utility model are: gear ring pressing plate of the present utility model can strengthen the pressure to strip when punching press, can not produce the elasticity vault and bend up wrinkle, has improved the precision of product.Strip is in the stress state of three dimension stress during punching press under the effect of gear ring pressing plate, top board, punch and die, only produces plasticity and shears, and phenomenon is torn in the shearing in the time of general stamping-out can not occurring.Whole stamping-out section all is the euphotic belt of shearing, and cross section quality is good.Discharging spring employing disc spring can further increase the pressure to strip.The ball that is provided with in the gap that guide pin bushing and guide pillar cooperate can improve the positioning accuracy of upper bolster and die shoe, and is very practical.

Description of drawings

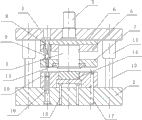

Fig. 1 is a structural representation of the present utility model.

The specific embodiment

As a kind of embodiment of the present utility model, as shown in Figure 1, a kind of simple and easy fine blanking die, comprise upper bolster 1, die shoe 2, die shank 3, guide pin bushing 11, guide pillar 12, punch 4 and die 10, in the present embodiment, die 10 is fixedly connected on die shoe 2 upper surfaces by hold-down screw 16, is provided with stop pin 17 in die 10 and the die shoe 2.Punch 4 is fixedly connected on upper bolster 1 below by punch retainer 5, be provided with backing plate 6 between punch 4 and the upper bolster 1, punch 4 is provided with stripper 7, stripper 7 is provided with discharging screw 8, be socketed with discharging spring 9 on the discharging screw 8, in the present embodiment, as preferably, described discharging spring 9 is a disc spring.Also comprise gear ring pressing plate 13, gear ring pressing plate 13 is the annular plate, stripper 7 lower surfaces and punch 4 corresponding positions have the annular groove with gear ring pressing plate 13 couplings, gear ring pressing plate 13 is located on the punch 4 and by screw and is fixedly connected in the annular groove, the lower surface of gear ring pressing plate 13 is provided with detent projection, and the lower surface of detent projection is lower than the lower surface of stripper 7; Be provided with top board 14 in the die 10, the upper surface of top board 14 is higher than the upper surface of die 10, and the lower surface of top board 14 is provided with push rod 15, is socketed with the head part spring on the push rod 15.

In the present embodiment, as preferably, be provided with ball in the gap that guide pin bushing 11 and guide pillar 12 cooperate.Guiding accuracy when allowing guide pin bushing 11 along guide pillar 12 slips is higher, has improved the precision of stamping-out.

Claims (3)

1. simple and easy fine blanking die, comprise upper bolster, die shoe, die shank, guide pin bushing, guide pillar, punch and die, punch is fixedly connected on the upper bolster below by punch retainer, be provided with backing plate between punch and the upper bolster, punch is provided with stripper, stripper is provided with the discharging screw, be socketed with the discharging spring on the discharging screw, it is characterized in that: also comprise the gear ring pressing plate, the gear ring pressing plate is the annular plate, the position that the stripper lower surface is corresponding with punch has the annular groove with gear ring pressing plate coupling, the gear ring pressing plate is located on the punch and by screw and is fixedly connected in the annular groove, the lower surface of gear ring pressing plate is provided with detent projection, and the lower surface of detent projection is lower than the lower surface of stripper; Be provided with top board in the die, the upper surface of top board is higher than the upper surface of die, and the lower surface of top board is provided with push rod, is socketed with the head part spring on the push rod.

2. a kind of simple and easy fine blanking die according to claim 1 is characterized in that: described discharging spring is a disc spring.

3. a kind of simple and easy fine blanking die according to claim 1 and 2 is characterized in that: be provided with ball in the gap that guide pin bushing and guide pillar cooperate.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011200258551U CN202087671U (en) | 2011-01-26 | 2011-01-26 | Simple precise die |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011200258551U CN202087671U (en) | 2011-01-26 | 2011-01-26 | Simple precise die |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202087671U true CN202087671U (en) | 2011-12-28 |

Family

ID=45362771

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2011200258551U Expired - Fee Related CN202087671U (en) | 2011-01-26 | 2011-01-26 | Simple precise die |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202087671U (en) |

Cited By (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102641938A (en) * | 2012-05-14 | 2012-08-22 | 昆山电子羽电业制品有限公司 | Stamping die for stamping parts |

| CN102764816A (en) * | 2012-07-20 | 2012-11-07 | 江苏华灿电讯股份有限公司 | Base station antenna reflecting plate cutting and punching combined fixture |

| CN102773341A (en) * | 2012-07-20 | 2012-11-14 | 苏州吴中经济开发区搏宇模具加工厂 | Special shape punching die of mobile phone integrated chip |

| CN102836923A (en) * | 2012-09-29 | 2012-12-26 | 无锡市亚青机械厂 | Crane bent plate press forming mold structure |

| CN102989860A (en) * | 2012-12-06 | 2013-03-27 | 无锡透平叶片有限公司 | Cold cutting die for titanium alloy precision-forged blade |

| CN103071721A (en) * | 2013-01-14 | 2013-05-01 | 山西惠丰机械工业有限公司 | Reciprocating fine blanking die |

| CN103182416A (en) * | 2011-12-29 | 2013-07-03 | 上海众大汽车配件有限公司 | Steel floor tile part blanking mold |

| CN103317022A (en) * | 2013-06-23 | 2013-09-25 | 苏州腾行精密模具有限公司 | Pushing ruler mould |

| CN103521594A (en) * | 2013-10-18 | 2014-01-22 | 芜湖环球汽车配件有限公司 | Lifting type sheet metal part punching device |

| CN103611783A (en) * | 2013-11-18 | 2014-03-05 | 梧州恒声电子科技有限公司 | T iron hole-drawing die |

| CN103707042A (en) * | 2013-12-27 | 2014-04-09 | 哈尔滨固泰电子有限责任公司 | Rivet pressing type dismounting device of shell body of non-contact electronic horn |

| CN103752693A (en) * | 2013-12-23 | 2014-04-30 | 柳州职业技术学院 | Stamping die of middle door guide track pulley fixing plate |

| CN103846342A (en) * | 2012-12-04 | 2014-06-11 | 昆山平成电子科技有限公司 | Simple precision die |

| CN103949525A (en) * | 2014-04-30 | 2014-07-30 | 成都海凌达机械有限公司 | Mechanism for punching sheet metal component |

| CN103969102A (en) * | 2014-05-29 | 2014-08-06 | 哈尔滨理工大学 | Plastic-disk sample preparation device and sample preparation method |

| CN104416056A (en) * | 2013-08-28 | 2015-03-18 | 法因图尔国际控股股份公司 | Tool and method for producing stamped parts |

| CN104588476A (en) * | 2014-12-22 | 2015-05-06 | 威海华邦精冲技术有限公司 | Single-position combined fine blanking die for machining car synchronous conical gear ring and method thereof |

| CN104907384A (en) * | 2015-06-18 | 2015-09-16 | 宁波富邦精业集团股份有限公司 | Aluminum sheet machining device |

| CN105195592A (en) * | 2015-10-10 | 2015-12-30 | 重庆量健机械有限公司 | Blanking lower die |

| CN108941310A (en) * | 2018-05-23 | 2018-12-07 | 华中科技大学鄂州工业技术研究院 | A kind of manufacturing process and equipment improving fine part tooth tip thickness |

| CN109570304A (en) * | 2018-11-30 | 2019-04-05 | 山东南山铝业股份有限公司 | Constant temperature shaping and punching device and its system |

| CN110270625A (en) * | 2019-01-02 | 2019-09-24 | 上海宇飞金属制品有限公司 | Double acting die set device |

| CN111168764A (en) * | 2020-02-15 | 2020-05-19 | 杭州欧亚机械制造有限公司 | Edge cutting method and edge cutting device for plant fiber molded product |

-

2011

- 2011-01-26 CN CN2011200258551U patent/CN202087671U/en not_active Expired - Fee Related

Cited By (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103182416A (en) * | 2011-12-29 | 2013-07-03 | 上海众大汽车配件有限公司 | Steel floor tile part blanking mold |

| CN102641938A (en) * | 2012-05-14 | 2012-08-22 | 昆山电子羽电业制品有限公司 | Stamping die for stamping parts |

| CN102764816A (en) * | 2012-07-20 | 2012-11-07 | 江苏华灿电讯股份有限公司 | Base station antenna reflecting plate cutting and punching combined fixture |

| CN102773341A (en) * | 2012-07-20 | 2012-11-14 | 苏州吴中经济开发区搏宇模具加工厂 | Special shape punching die of mobile phone integrated chip |

| CN102836923A (en) * | 2012-09-29 | 2012-12-26 | 无锡市亚青机械厂 | Crane bent plate press forming mold structure |

| CN103846342A (en) * | 2012-12-04 | 2014-06-11 | 昆山平成电子科技有限公司 | Simple precision die |

| CN102989860A (en) * | 2012-12-06 | 2013-03-27 | 无锡透平叶片有限公司 | Cold cutting die for titanium alloy precision-forged blade |

| CN103071721A (en) * | 2013-01-14 | 2013-05-01 | 山西惠丰机械工业有限公司 | Reciprocating fine blanking die |

| CN103071721B (en) * | 2013-01-14 | 2015-12-02 | 山西惠丰机械工业有限公司 | Reciprocal fine-blanking die |

| CN103317022A (en) * | 2013-06-23 | 2013-09-25 | 苏州腾行精密模具有限公司 | Pushing ruler mould |

| CN104416056A (en) * | 2013-08-28 | 2015-03-18 | 法因图尔国际控股股份公司 | Tool and method for producing stamped parts |

| CN104416056B (en) * | 2013-08-28 | 2018-03-16 | 法因图尔国际控股股份公司 | For manufacturing the mould and method of stamping parts |

| CN103521594A (en) * | 2013-10-18 | 2014-01-22 | 芜湖环球汽车配件有限公司 | Lifting type sheet metal part punching device |

| CN103611783A (en) * | 2013-11-18 | 2014-03-05 | 梧州恒声电子科技有限公司 | T iron hole-drawing die |

| CN103611783B (en) * | 2013-11-18 | 2015-06-03 | 梧州恒声电子科技有限公司 | T iron hole-drawing die |

| CN103752693A (en) * | 2013-12-23 | 2014-04-30 | 柳州职业技术学院 | Stamping die of middle door guide track pulley fixing plate |

| CN103707042A (en) * | 2013-12-27 | 2014-04-09 | 哈尔滨固泰电子有限责任公司 | Rivet pressing type dismounting device of shell body of non-contact electronic horn |

| CN103949525A (en) * | 2014-04-30 | 2014-07-30 | 成都海凌达机械有限公司 | Mechanism for punching sheet metal component |

| CN103949525B (en) * | 2014-04-30 | 2015-09-30 | 成都海凌达机械有限公司 | A kind of mechanism for sheet metal component punching press |

| CN103969102A (en) * | 2014-05-29 | 2014-08-06 | 哈尔滨理工大学 | Plastic-disk sample preparation device and sample preparation method |

| CN103969102B (en) * | 2014-05-29 | 2017-11-14 | 哈尔滨哈普电气技术有限责任公司 | Plastic disks formula sample preparation device and method for making sample |

| CN104588476A (en) * | 2014-12-22 | 2015-05-06 | 威海华邦精冲技术有限公司 | Single-position combined fine blanking die for machining car synchronous conical gear ring and method thereof |

| CN104907384A (en) * | 2015-06-18 | 2015-09-16 | 宁波富邦精业集团股份有限公司 | Aluminum sheet machining device |

| CN105195592A (en) * | 2015-10-10 | 2015-12-30 | 重庆量健机械有限公司 | Blanking lower die |

| CN108941310A (en) * | 2018-05-23 | 2018-12-07 | 华中科技大学鄂州工业技术研究院 | A kind of manufacturing process and equipment improving fine part tooth tip thickness |

| CN109570304A (en) * | 2018-11-30 | 2019-04-05 | 山东南山铝业股份有限公司 | Constant temperature shaping and punching device and its system |

| CN110270625A (en) * | 2019-01-02 | 2019-09-24 | 上海宇飞金属制品有限公司 | Double acting die set device |

| CN111168764A (en) * | 2020-02-15 | 2020-05-19 | 杭州欧亚机械制造有限公司 | Edge cutting method and edge cutting device for plant fiber molded product |

| CN111168764B (en) * | 2020-02-15 | 2024-06-25 | 杭州欧亚机械制造有限公司 | Plant fiber molded product trimming method and trimming device |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN202087671U (en) | Simple precise die | |

| CN202498152U (en) | Simple fine blanking die | |

| CN203002940U (en) | Novel fine blanking die | |

| CN202803935U (en) | Flip-over type punching blanking die | |

| CN203076444U (en) | Simple fine blanking die with gear ring pressing plate | |

| CN202779359U (en) | Precise stamping die with gear ring pressing plate | |

| CN203427108U (en) | Novel fine blanking die | |

| CN102728719A (en) | Composite cold punching die | |

| CN202943164U (en) | Simple fine blanking die | |

| CN102019319A (en) | Mold structure of L-shaped connecting sheet for cable bridge | |

| CN203076410U (en) | Blanking die for lock cushion punching | |

| CN201736461U (en) | Anti-rotation stamping die | |

| CN202137266U (en) | USB iron casing die | |

| CN203140588U (en) | Integral die for punching machine | |

| CN204603042U (en) | The Minitype punching mould of material lift protection | |

| CN103464600A (en) | High-efficiency stamping die structure | |

| CN204470403U (en) | A kind of fast ram Bending Mould | |

| CN203875198U (en) | Stamping die | |

| CN203470612U (en) | Compensation shearing die for punching plate | |

| CN103846342A (en) | Simple precision die | |

| CN215467400U (en) | Non-cross-cutting type bending and stamping equipment | |

| CN204545146U (en) | Elongated needle class tearing notch blanking die | |

| CN204365797U (en) | Mosquito-repellent incense machine box-shaped cavity edger | |

| CN103272919A (en) | Perforating die structure for ribbon retainer | |

| CN204247797U (en) | Thick material no waste mine die cutting die |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20111228 Termination date: 20130126 |