CN201732292U - Safety monitoring system of dangerous goods logistics - Google Patents

Safety monitoring system of dangerous goods logistics Download PDFInfo

- Publication number

- CN201732292U CN201732292U CN201020296511XU CN201020296511U CN201732292U CN 201732292 U CN201732292 U CN 201732292U CN 201020296511X U CN201020296511X U CN 201020296511XU CN 201020296511 U CN201020296511 U CN 201020296511U CN 201732292 U CN201732292 U CN 201732292U

- Authority

- CN

- China

- Prior art keywords

- subsystem

- dangerous

- monitor

- distribution

- control subsystem

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P90/00—Enabling technologies with a potential contribution to greenhouse gas [GHG] emissions mitigation

- Y02P90/02—Total factory control, e.g. smart factories, flexible manufacturing systems [FMS] or integrated manufacturing systems [IMS]

Landscapes

- Warehouses Or Storage Devices (AREA)

Abstract

The embodiment of the utility model provides a safety monitoring system of dangerous goods logistics, which comprises a storage monitoring subsystem, a stowage management subsystem, a handling monitoring subsystem, a storage in-out management subsystem, an on-the-way real-time monitoring subsystem, a key node monitoring subsystem, an event processing subsystem, an emergency management subsystem and a dangerous goods logistics monitoring center management platform, wherein the storage monitoring subsystem, the stowage management subsystem, the handling monitoring subsystem, the storage in-out management subsystem, the on-the-way real-time monitoring subsystem, the key node monitoring subsystem, the emergency management subsystem and the dangerous goods logistics monitoring center management platform are respectively connected with the event processing subsystem, and the emergency management subsystem is respectively connected with the dangerous goods logistics monitoring center management platform and the event processing subsystem. The safety monitoring system monitors the various processes of the dangerous goods logistics through corresponding specific monitoring systems, thereby reducing the risk degree of dangerous goods logistics and improving the efficiency of the dangerous goods logistics.

Description

Technical field

The utility model relates to a kind of logistics security monitoring and regulation technique field, and specifically, what relate to is a kind of dangerous-article physical-distribution safety monitoring system.

Background technology

Along with the quickening of China's process of industrialization, the storage and the freight volume of dangerous material sharply increase.China every year, the dangerous material by road transport surpassed 300,000,000 tons.According to Ministry of Communications's data statistics, hazardous materials transportation accounts for year more than 30% of shipping total amount, and in rising trend.Meanwhile, dangerous cargo storage happens occasionally with shipping accident, and accident frequency and the extent of injury are more and more serious.Therefore, how strengthening the dangerous material storage is an important problems with the supervision of transporting.

Application number be " 200810035543 " Chinese utility model patent utility model based on the dangerous-article physical-distribution intelligent supervision system and method for radio-frequency (RF) identification.Its practical novel dangerous-article packing condition monitoring system of installing in dangerous-article packing is gathered the dangerous material physical state in real time and is write in the outer RFID label of container; Adopt in dangerous material vehicle-mounted monitoring system, each monitoring station and the way inspection post in the logistics overall process, the RFID label information to be read and write in real time, and with the integrated supervising platform dynamic exchange of dangerous-article physical-distribution dangerous-article physical-distribution information, status information, security information, vehicle running state information; Adopt the integrated supervising platform of dangerous-article physical-distribution to realize the centralized supervisory of logistics progress and provide the long-distance user to inquire about in real time, the dangerous-article physical-distribution intelligent monitoring of form multistage real-time monitoring, in time report to the police synchronously, fault being handled automatically, logic distributes unified, the complete distribution multilevel monitor of realizing the dangerous-article physical-distribution process, process real-time follow-up, fault processing and remote live inquiry automatically.

The application number monitoring security of major petrochemical hazard installations system that has been " 200820150794.X " Chinese patent utility model, this system comprises Surveillance center's database, network security module, software automated back-up module, expansion module, mobile command car, gps satellite positioning and tracking device, UPS power supply, described Surveillance center database is connected with network security module, software automated back-up module, expansion module, UPS power supply respectively, and described Surveillance center database is connected with mobile command car, gps satellite positioning and tracking device by wireless communication networks.

Application number for " 200910304657.6 " Chinese patent utility model a kind of monitoring method that is used for operation states of intelligent tanks for dangerous chemical transportation disclosed.It is made up of signal pre-processing module and running status judging module.Signal pre-processing module comprises that the filtering of signal and characteristic information extract, and the running status judging module adopts the method for finite state machine that characteristic information is merged, thereby judges the running status of dangerization product.At corresponding signal post-processing mechanism of different state design and alarm mechanism, can realize rapid reaction on this basis to dangerization product peril of transportation situation.

Application number relates to a kind of danger product supervisory system and its implementation for " 200710075594.2 " Chinese patent utility model; the monitoring terminal of this system is used for gathering the status data that is installed at sensors such as valve member cavity dangerous material leak sensor, liquid level, pressure, humiture, acceleration, space; again with image data to uploading to device end; simultaneously described device end upload the data to Surveillance center by the GPS global positioning system GPRS wireless system for transmitting data of unifying, and realizes the real-time local and remote monitoring to the hazardous materials transportation process.The related communication protocol device of the utility model can solve the problem of complicated eurypalynous data security reliable transmission between monitoring terminal and the device end.

Application number has been " 200720149467.8 " Chinese patent utility model a kind of fireworks and firecrackers production storage place and haulage vehicle security monitoring and supervisory systems, belong to safety production monitoring and regulation technique field, this system comprises: various sensors, camera, alarm and the monitoring and early warning main frame etc. that are installed in production scene and warehouse; Be installed in Vehicle Controller, global location module, vehicle crash sensor, temperature sensor, humidity sensor, alarm, display screen and receiving short message equipment etc. on the haulage vehicle; Be installed in the network switch, monitoring server, data server, the webserver, fire wall, three screen control and monitor console, receiving short message equipment and the alarms etc. of Surveillance center; Be installed in the network switch, supervision server, data server, the webserver, fire wall, giant-screen and the alarm etc. of supervision center.

By above patent and article as can be seen, existing at present dangerous-article physical-distribution supervisory system is separated enforcement with many dangerous material storage, carrying and hazardous materials transportation are monitored of method.This causes the disconnection of monitoring in the dangerous-article physical-distribution overall process.Dangerous-article physical-distribution is subjected to division managements such as public security, traffic, quality inspection, environmental protection, health simultaneously simultaneously.And existing dangerous-article physical-distribution supervisory system opening is relatively poor.

The utility model content

The purpose of the utility model embodiment is to provide a kind of dangerous-article physical-distribution safety monitoring system and method, finishes the monitoring to the dangerous-article physical-distribution overall process, reduces the hazard level of dangerous-article physical-distribution, improves the efficient of dangerous-article physical-distribution.

The utility model embodiment provides a kind of dangerous-article physical-distribution safety monitoring system, comprise: the storage Monitor And Control Subsystem, the prestowage ADMINISTRATION SUBSYSTEM, the loading and unloading Monitor And Control Subsystem, warehouse room entry/exit management subsystem, real-time Monitor And Control Subsystem in transit, the key node Monitor And Control Subsystem, the event handling subsystem, contingency management subsystem and dangerous-article physical-distribution Surveillance center management platform, described storage Monitor And Control Subsystem, the prestowage ADMINISTRATION SUBSYSTEM, the loading and unloading Monitor And Control Subsystem, warehouse room entry/exit management subsystem, real-time Monitor And Control Subsystem in transit, the key node Monitor And Control Subsystem links to each other with described event handling subsystem respectively with dangerous-article physical-distribution Surveillance center management platform, described contingency management subsystem links to each other with described dangerous-article physical-distribution Surveillance center's management platform and described event handling subsystem respectively, wherein: described storage Monitor And Control Subsystem is used for the environment of dangerous goods store and dangerous material state are monitored, and monitor data is sent to described event handling subsystem; Described prestowage ADMINISTRATION SUBSYSTEM is used for distributing according to the dangerous material type the various items of transit link, and assignment information is sent to described event handling subsystem; Described loading and unloading Monitor And Control Subsystem is used for being responsible for the security monitoring of dangerous material cargo handling process, and monitor message is sent to the event handling subsystem; Relevant information when described warehouse room entry/exit management subsystem is used to discern vehicle and goes out to put in storage, and be sent to the event handling subsystem; Described real-time Monitor And Control Subsystem in transit is used for the relevant information of real-time collection vehicle transportation, and sends to described event handling subsystem; Described key node Monitor And Control Subsystem is used for discerning the relevant information of vehicle automatically and being sent to described event handling subsystem when the trans-regional transportation of vehicle; Described event handling subsystem is used for the information that described storage Monitor And Control Subsystem, prestowage ADMINISTRATION SUBSYSTEM, loading and unloading Monitor And Control Subsystem, warehouse room entry/exit management subsystem, real-time Monitor And Control Subsystem in transit, key node Monitor And Control Subsystem send is carried out analyzing and processing, find the anomalous event in the dangerous-article physical-distribution process, result is sent to described dangerous-article physical-distribution Surveillance center management platform; Described contingency management subsystem is used to receive the related data of described event handling subsystem, formulates the fault handling plan, and described fault handling plan is sent to described dangerous-article physical-distribution Surveillance center management platform; Described dangerous-article physical-distribution Surveillance center management platform is used to finish data normalization to be handled and storage, the visual control to the dangerous-article physical-distribution overall process, all kinds of warning and fault handling, and responsible and each public sector's information platform carry out exchanges data.

Preferably, storage Monitor And Control Subsystem among the utility model embodiment comprises warehouse environment sensor, camera head, dangerous material state sensor and acoustic-optic alarm, described warehouse environment sensor, dangerous material state sensor and the described acoustic-optic alarm drawn together links to each other with described event handling subsystem respectively, and described camera head links to each other with described dangerous-article physical-distribution Surveillance center management platform by described event handling subsystem.

Preferably, prestowage ADMINISTRATION SUBSYSTEM among the utility model embodiment comprises prestowage administrative unit, route calculation unit and electronic tag, described electronic tag is attached on the haulage vehicle, information in the output information that comprises described prestowage administrative unit and route calculation unit in the described electronic tag, described electronic tag can be sent to described event handling subsystem.

Preferably, loading and unloading Monitor And Control Subsystem among the utility model embodiment comprises the attitude monitoring device, wireless launcher, locating read-write device and acoustic-optic alarm, described attitude monitoring device and described wireless launcher are arranged on the dangerous articles package container, described attitude monitoring device links to each other with described wireless launcher and described acoustic-optic alarm respectively, described locating read-write device is arranged in the warehouse, described attitude monitoring device is used for detecting the attitude of dangerous articles package container at cargo handling process, when described attitude during greater than the safety coefficient set, notify described acoustic-optic alarm to report to the police, described attitude monitoring device also is used for finishing the positioning function of described dangerous articles package container at cargo handling process with described locating read-write device.

Preferably, the warehouse room entry/exit management subsystem among the utility model embodiment comprises frequency read/write, and described frequency read/write is used for reading the data in the described electronic tag when haulage vehicle goes out to put in storage, and described data are sent to described event handling subsystem.

Preferably, in transit real-time Monitor And Control Subsystem among the utility model embodiment comprises global position system GPS car-mounted terminal, car inner sensor, described attitude monitoring means and described electronic tag, described GPS car-mounted terminal is used to receive the state of the described dangerous articles package container that the environment inside car information of being gathered from described car inner sensor, described attitude monitoring means gathered and the information in the described electronic tag, and the information that receives is sent to described event handling subsystem.

Preferably, key node Monitor And Control Subsystem among the utility model embodiment comprises the frequency read/write that is arranged on key node, when the described key node of haulage vehicle process, read the information in the described electronic tag and this information is sent to described event handling subsystem by described frequency read/write.

Preferably, the GPS car-mounted terminal among the utility model embodiment also is used for by wireless network the information in the described electronic tag of being gathered being sent to described event handling subsystem when haulage vehicle process key node.

Preferably, event handling subsystem among the utility model embodiment also is used for producing the control corresponding incident in the dangerous-article physical-distribution overall process according to various external informations and controls described storage Monitor And Control Subsystem, prestowage ADMINISTRATION SUBSYSTEM, loading and unloading Monitor And Control Subsystem, warehouse room entry/exit management subsystem, real-time Monitor And Control Subsystem in transit and key node Monitor And Control Subsystem, and adjusts the corresponding work flow of dangerous-article physical-distribution according to event type.

The utility model embodiment reduces the hazard level of dangerous-article physical-distribution by each process of dangerous-article physical-distribution specifically monitored system with correspondence is monitored it, improves the efficient of dangerous-article physical-distribution.

Description of drawings

In order to be illustrated more clearly in the utility model embodiment or technical scheme of the prior art, the accompanying drawing of required use is done to introduce simply in will describing embodiment below, apparently, accompanying drawing in describing below only is embodiment more of the present utility model, for those of ordinary skills, under the prerequisite of not paying creative work, can also obtain other accompanying drawing according to these accompanying drawings.

The structural representation of a kind of dangerous-article physical-distribution safety monitoring system that Fig. 1 provides for the utility model embodiment;

The structural representation of a kind of Monitor And Control Subsystem of storing in a warehouse that Fig. 2 provides for the utility model embodiment;

The structural representation of a kind of prestowage ADMINISTRATION SUBSYSTEM that Fig. 3 provides for the utility model embodiment;

A kind of structural representation that loads and unloads Monitor And Control Subsystem that Fig. 4 provides for the utility model embodiment;

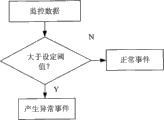

The event handling schematic flow sheet of a kind of event handling subsystem that Fig. 5 provides for the utility model embodiment.

Embodiment

Below in conjunction with the accompanying drawing among the utility model embodiment, the technical scheme among the utility model embodiment is clearly and completely described, obviously, described embodiment only is the utility model part embodiment, rather than whole embodiment.Based on the embodiment in the utility model, those of ordinary skills are not making the every other embodiment that is obtained under the creative work prerequisite, all belong to the scope of the utility model protection.

Be illustrated in figure 1 as the structural representation of a kind of dangerous-article physical-distribution safety monitoring system that the utility model embodiment provides, this system comprises: storage Monitor And Control Subsystem 110, prestowage ADMINISTRATION SUBSYSTEM 120, loading and unloading Monitor And Control Subsystem 130, warehouse room entry/exit management subsystem 140, real-time Monitor And Control Subsystem 150 in transit, key node Monitor And Control Subsystem 160, event handling subsystem 170, contingency management subsystem 180 and dangerous-article physical-distribution Surveillance center management platform 190, the Monitor And Control Subsystem 110 of wherein storing in a warehouse, prestowage ADMINISTRATION SUBSYSTEM 120, loading and unloading Monitor And Control Subsystem 130, warehouse room entry/exit management subsystem 140, real-time Monitor And Control Subsystem 150 in transit, key node Monitor And Control Subsystem 160 links to each other with event handling subsystem 170 respectively with dangerous-article physical-distribution Surveillance center management platform 190, and contingency management subsystem 180 links to each other with dangerous-article physical-distribution Surveillance center management platform 190 and event handling subsystem 170 respectively.

Storage Monitor And Control Subsystem 110 is used for the environment and the dangerous material state of dangerous goods store are monitored, and monitor data is sent to described event handling subsystem 170.

As an embodiment of the present utility model, as shown in Figure 2, storage Monitor And Control Subsystem 110 comprises warehouse environment sensor 111, camera head 112, dangerous material state sensor 113 and acoustic-optic alarm 114, warehouse environment sensor 111, dangerous material state sensor 113 and acoustic-optic alarm 114 link to each other with event handling subsystem 170 respectively, and camera head 112 links to each other with dangerous-article physical-distribution Surveillance center management platform 190 by event handling subsystem 170.

In the present embodiment, warehouse environment sensor 111 can comprise temperature sensor, humidity sensor, pressure transducer, in the smoke transducer etc. one or more, specifically can carry out being determined according to the character of dangerous material, it can gather the store in a warehouse temperature of environment of living in of dangerous material, humidity, pressure, information such as smog and image, dangerous material state sensor 113 can obtain the various physical state parameters in the dangerous material, in the present embodiment, dangerous material state sensor 113 is such as being mounted in dangerous goods container temperature inside sensor, pressure transducer, liquid level sensor etc., it can detected temperatures, pressure, liquid level etc., warehouse environment sensor 111 and dangerous material state sensor 113 are sent to event handling subsystem 170 with the information of being gathered by wired or wireless mode, judge and handle by 170 pairs of these information of event handling subsystem, if unusual condition, then can carry out onsite alarming by the acoustic-optic alarm in the warehouse 114, also this warning can be reported contingency management subsystem 180 respectively with dangerous-article physical-distribution Surveillance center management platform 190, provide processing scheme by contingency management subsystem 180, and by dangerous-article physical-distribution Surveillance center management platform 190 notice related management personnel.Managerial personnel also can see the real-time monitored picture of warehouse photographic device inside 112 by dangerous-article physical-distribution Surveillance center management platform 190 in addition, so that the floor manager scheduling.

Prestowage ADMINISTRATION SUBSYSTEM 120 is used for distributing according to the dangerous material type the various items of transit link, and assignment information is sent to event handling subsystem 170.

As an embodiment of the present utility model, as shown in Figure 3, prestowage ADMINISTRATION SUBSYSTEM 120 comprises prestowage administrative unit 121, route calculation unit 122 and electronic tag 123.The dangerous material type that wherein prestowage administrative unit 121 can be ordered according to customer order, determine same haulage vehicle can not mix the dangerous material that carry, carry and relatively to be prone to accidents if such dangerous material mix, and can be the safe freight volume of this time transportation distribution transport vehicle, driver and definite haulage vehicle.Route calculation unit 122 can and transport the destination according to institute's peril of transportation product kind, vehicle condition, weather condition, calculates optimum traffic route.Electronic tag 123 is attached on the haulage vehicle, this electronic tag internal memory contains the output information of prestowage ADMINISTRATION SUBSYSTEM 120 and route calculation unit 122, such as vehicle ID, driver information, dangerous material kind, dangerous material freight volume, traffic route etc., before haulage vehicle was dispatched a car, the information in this electronic tag can be sent to event handling subsystem 1

70, conveniently carry out tracking and monitoring and maintenance of information.

Loading and unloading Monitor And Control Subsystem 130 is used for being responsible for the security monitoring of dangerous material cargo handling process, and monitor message is sent to event handling subsystem 170.

As an embodiment of the present utility model, as shown in Figure 4, loading and unloading Monitor And Control Subsystem 130 comprises attitude monitoring device 131, wireless launcher 132, locating read-write device 133 and acoustic-optic alarm (not illustrating), attitude monitoring device 131 and wireless launcher 132 are arranged on the dangerous articles package container, attitude monitoring device 131 links to each other with wireless launcher 132 and acoustic-optic alarm respectively, attitude monitoring device 131 is used for detecting the attitude of dangerous articles package container at cargo handling process, when described attitude during greater than the safety coefficient set, the notice acoustic-optic alarm is reported to the police, this acoustic-optic alarm can be installed in the dangerous goods container, also can be installed in the somewhere in warehouse, attitude monitoring device 131 can utilize wireless launcher 132 to drive this acoustic-optic alarm.Attitude monitoring device 131 also is used for finishing the positioning function of dangerous articles package container at cargo handling process with locating read-write device 133 in addition, such as, when carrying dangerous articles package container in the warehouse, when by locating read-write device 133, locating read-write device 133 can be determined the position of this dangerous articles package container, simultaneously can be by voice suggestion or other means, restriction operating personnel's violation operation reduces and avoids the generation of loading and unloading accident.

Relevant information when warehouse room entry/exit management subsystem 140 is used to discern vehicle and goes out to put in storage, and be sent to event handling subsystem 170.

As an embodiment of the present utility model, warehouse room entry/exit management subsystem 140 can comprise a frequency read/write, this frequency read/write can be installed in the place, gateway in warehouse, be used for when haulage vehicle is come in and gone out the warehouse, reading the data in the electronic tag on the haulage vehicle, and these data are sent to event handling subsystem 170, event handling subsystem 170 can produce the warehouse-in incident successively, and is monitored to dangerous-article physical-distribution Surveillance center management platform 190 this reporting events.

Real-time Monitor And Control Subsystem 150 in transit is used for the relevant information of real-time collection vehicle transportation, and sends to event handling subsystem 170.

As an embodiment of the present utility model, real-time Monitor And Control Subsystem 150 in transit comprises GPS car-mounted terminal 151, car inner sensor 152 and attitude monitoring device 131, the GPS car-mounted terminal is used to receive the state of the environment inside car information of being gathered from car inner sensor 152, dangerous articles package container that attitude monitoring device 131 is gathered, and the information in the electronic tag 123, then these information are merged and encode, the data after will encoding by GPRS or 3G wireless data transmission channel again are sent to event handling subsystem 170.In the present embodiment, car inner sensor 152 can comprise one or more in temperature sensor, humidity sensor, pressure transducer, the smoke transducer etc.

As another embodiment of the present utility model, GPS car-mounted terminal 151 can also receive real-time road condition information and the schedule information that event handling subsystem 170 is sent, so that the driver in time adjusts traffic route.

Key node Monitor And Control Subsystem 160 is used for discerning the relevant information of vehicle automatically and being sent to event handling subsystem 170 when the trans-regional transportation of vehicle.

As an embodiment of the present utility model, key node Monitor And Control Subsystem 160 comprises the frequency read/write that is arranged on key node, when this key node of haulage vehicle process, read the information in the electronic tag and this information is sent to event handling subsystem 170 by this frequency read/write, event handling subsystem 170 can produce the dangerous material goods by the key node incident according to this information.

As another embodiment of the present utility model, the function of key node Monitor And Control Subsystem 160 also can be finished by real-time Monitor And Control Subsystem 150 in transit, such as when haulage vehicle passes through key node, GPS car-mounted terminal 151 sends to event handling subsystem 170 by GPRS or 3G wireless network with the information in the electronic tag of being gathered 123, GPS car-mounted terminal 151 can also obtain relevant car speed information etc. by GPS in addition, and will be somebody's turn to do the information that gets access to by GPS and also be sent to event handling subsystem 170, the information in electronic tag 123 is as the key node incident.

Dangerous-article physical-distribution Surveillance center management platform 190 is used to finish data normalization and handles and storage, the visual control to the dangerous-article physical-distribution overall process, all kinds of warning and fault handling, and be responsible for and each public sector's information platform carry out exchanges data, specifically, dangerous-article physical-distribution Surveillance center management platform 190 can be by the exchanges data of carrying out of exchanges data subsystem and public sector's information platform.

The utility model embodiment reduces the hazard level of dangerous-article physical-distribution by each process of dangerous-article physical-distribution specifically monitored system with correspondence is monitored it, improves the efficient of dangerous-article physical-distribution.

Above-described specific embodiment; the purpose of this utility model, technical scheme and beneficial effect are further described; institute is understood that; the above only is a specific embodiment of the utility model; and be not used in and limit protection domain of the present utility model; all within spirit of the present utility model and principle, any modification of being made, be equal to replacement, improvement etc., all should be included within the protection domain of the present utility model.

Claims (9)

1. dangerous-article physical-distribution safety monitoring system, it is characterized in that, described system comprises: the storage Monitor And Control Subsystem, the prestowage ADMINISTRATION SUBSYSTEM, the loading and unloading Monitor And Control Subsystem, warehouse room entry/exit management subsystem, real-time Monitor And Control Subsystem in transit, the key node Monitor And Control Subsystem, the event handling subsystem, contingency management subsystem and dangerous-article physical-distribution Surveillance center management platform, described storage Monitor And Control Subsystem, the prestowage ADMINISTRATION SUBSYSTEM, the loading and unloading Monitor And Control Subsystem, warehouse room entry/exit management subsystem, real-time Monitor And Control Subsystem in transit, the key node Monitor And Control Subsystem links to each other with described event handling subsystem respectively with dangerous-article physical-distribution Surveillance center management platform, described contingency management subsystem links to each other with described dangerous-article physical-distribution Surveillance center's management platform and described event handling subsystem respectively, wherein:

Described storage Monitor And Control Subsystem is used for the environment of dangerous goods store and dangerous material state are monitored, and monitor data is sent to described event handling subsystem;

Described prestowage ADMINISTRATION SUBSYSTEM is used for distributing according to the dangerous material type the various items of transit link, and assignment information is sent to described event handling subsystem;

Described loading and unloading Monitor And Control Subsystem is used for being responsible for the security monitoring of dangerous material cargo handling process, and monitor message is sent to described event handling subsystem;

Relevant information when described warehouse room entry/exit management subsystem is used to discern vehicle and goes out to put in storage, and be sent to described event handling subsystem;

Described real-time Monitor And Control Subsystem in transit is used for the relevant information of real-time collection vehicle transportation, and is sent to described event handling subsystem;

Described key node Monitor And Control Subsystem is used for discerning the relevant information of vehicle automatically and being sent to described event handling subsystem when the trans-regional transportation of vehicle;

Described event handling subsystem is used for the information that described storage Monitor And Control Subsystem, prestowage ADMINISTRATION SUBSYSTEM, loading and unloading Monitor And Control Subsystem, warehouse room entry/exit management subsystem, real-time Monitor And Control Subsystem in transit, key node Monitor And Control Subsystem send is carried out analyzing and processing, find the anomalous event in the dangerous-article physical-distribution process, result is sent to described dangerous-article physical-distribution Surveillance center management platform;

Described contingency management subsystem is used to receive the related data of described event handling subsystem, formulates the fault handling plan, and described fault handling plan is sent to described dangerous-article physical-distribution Surveillance center management platform;

Described dangerous-article physical-distribution Surveillance center management platform is used to finish data normalization to be handled and storage, the visual control to the dangerous-article physical-distribution overall process, all kinds of warning and fault handling, and responsible and each public sector's information platform carry out exchanges data.

2. dangerous-article physical-distribution safety monitoring system as claimed in claim 1, it is characterized in that, described storage Monitor And Control Subsystem comprises warehouse environment sensor, camera head, dangerous material state sensor and acoustic-optic alarm, described warehouse environment sensor, dangerous material state sensor and described acoustic-optic alarm link to each other with described event handling subsystem respectively, and described camera head links to each other with described dangerous-article physical-distribution Surveillance center management platform by described event handling subsystem.

3. dangerous-article physical-distribution safety monitoring system as claimed in claim 1, it is characterized in that, described prestowage ADMINISTRATION SUBSYSTEM comprises prestowage administrative unit, route calculation unit and electronic tag, described electronic tag is attached on the haulage vehicle, information in the output information that comprises described prestowage administrative unit and route calculation unit in the described electronic tag, described electronic tag can be sent to described event handling subsystem.

4. dangerous-article physical-distribution safety monitoring system as claimed in claim 3, it is characterized in that, described loading and unloading Monitor And Control Subsystem comprises the attitude monitoring device, wireless launcher, locating read-write device and acoustic-optic alarm, described attitude monitoring device and described wireless launcher are arranged on the dangerous articles package container, described attitude monitoring device links to each other with described wireless launcher and described acoustic-optic alarm respectively, described locating read-write device is arranged in the warehouse, described attitude monitoring device is used for detecting the attitude of dangerous articles package container at cargo handling process, when described attitude during greater than the safety coefficient set, notify described acoustic-optic alarm to report to the police, described attitude monitoring device also is used for finishing the positioning function of described dangerous articles package container at cargo handling process with described locating read-write device.

5. dangerous-article physical-distribution safety monitoring system as claimed in claim 3, it is characterized in that, described warehouse room entry/exit management subsystem comprises frequency read/write, described frequency read/write is used for reading the data in the described electronic tag when haulage vehicle goes out to put in storage, and described data are sent to described event handling subsystem.

6. dangerous-article physical-distribution safety monitoring system as claimed in claim 4, it is characterized in that, described real-time Monitor And Control Subsystem in transit comprises global position system GPS car-mounted terminal, car inner sensor, described attitude monitoring means and described electronic tag, described GPS car-mounted terminal is used to receive the state of the described dangerous articles package container that the environment inside car information of being gathered from described car inner sensor, described attitude monitoring means gathered and the information in the described electronic tag, and the information that receives is sent to described event handling subsystem.

7. dangerous-article physical-distribution safety monitoring system as claimed in claim 3, it is characterized in that, described key node Monitor And Control Subsystem comprises the frequency read/write that is arranged on key node, when the described key node of haulage vehicle process, read the information in the described electronic tag and this information is sent to described event handling subsystem by described frequency read/write.

8. dangerous-article physical-distribution safety monitoring system as claimed in claim 6, it is characterized in that, described GPS car-mounted terminal also is used for by wireless network the information in the described electronic tag of being gathered being sent to described event handling subsystem when haulage vehicle process key node.

9. dangerous-article physical-distribution safety monitoring system as claimed in claim 1, it is characterized in that, described event handling subsystem also is used for producing the control corresponding incident in the dangerous-article physical-distribution overall process according to various external informations and controls described storage Monitor And Control Subsystem, prestowage ADMINISTRATION SUBSYSTEM, loading and unloading Monitor And Control Subsystem, warehouse room entry/exit management subsystem, real-time Monitor And Control Subsystem in transit and key node Monitor And Control Subsystem, and adjusts the corresponding work flow of dangerous-article physical-distribution according to event type.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201020296511XU CN201732292U (en) | 2010-08-18 | 2010-08-18 | Safety monitoring system of dangerous goods logistics |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201020296511XU CN201732292U (en) | 2010-08-18 | 2010-08-18 | Safety monitoring system of dangerous goods logistics |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN201732292U true CN201732292U (en) | 2011-02-02 |

Family

ID=43523450

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201020296511XU Expired - Lifetime CN201732292U (en) | 2010-08-18 | 2010-08-18 | Safety monitoring system of dangerous goods logistics |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN201732292U (en) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101943902A (en) * | 2010-08-18 | 2011-01-12 | 北京物资学院 | Safety monitoring system and method for dangerous goods logistics |

| CN102509137A (en) * | 2011-11-18 | 2012-06-20 | 上海佳依佳信息科技有限公司 | Hazardous material logistics intelligent monitoring system |

| CN107358383A (en) * | 2017-06-15 | 2017-11-17 | 成都华药共享网络科技有限公司 | Logistics freight transport system |

| CN107896253A (en) * | 2017-11-24 | 2018-04-10 | 上海璞玫信息科技有限公司 | A kind of dangerous material port area storing and transporting security supervisory systems |

| CN109269565A (en) * | 2018-10-18 | 2019-01-25 | 杭州电子科技大学 | A kind of hazardous materials transportation monitoring device and monitoring method based on position control |

-

2010

- 2010-08-18 CN CN201020296511XU patent/CN201732292U/en not_active Expired - Lifetime

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101943902A (en) * | 2010-08-18 | 2011-01-12 | 北京物资学院 | Safety monitoring system and method for dangerous goods logistics |

| CN101943902B (en) * | 2010-08-18 | 2012-01-11 | 北京物资学院 | Safety monitoring system and method for dangerous goods logistics |

| CN102509137A (en) * | 2011-11-18 | 2012-06-20 | 上海佳依佳信息科技有限公司 | Hazardous material logistics intelligent monitoring system |

| CN107358383A (en) * | 2017-06-15 | 2017-11-17 | 成都华药共享网络科技有限公司 | Logistics freight transport system |

| CN107358383B (en) * | 2017-06-15 | 2021-03-26 | 成都华药共享网络科技有限公司 | Logistics freight system |

| CN107896253A (en) * | 2017-11-24 | 2018-04-10 | 上海璞玫信息科技有限公司 | A kind of dangerous material port area storing and transporting security supervisory systems |

| CN109269565A (en) * | 2018-10-18 | 2019-01-25 | 杭州电子科技大学 | A kind of hazardous materials transportation monitoring device and monitoring method based on position control |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101943902B (en) | Safety monitoring system and method for dangerous goods logistics | |

| AU2019232022B2 (en) | Methods and apparatus to monitor and manage loading docks and facility operations | |

| CN103514708B (en) | Based on the logistics transportation intelligence short message information alarming apparatus of the Big Dipper and GIS | |

| US7455225B1 (en) | Method and system for monitoring and controlling goods while in transit | |

| CN101276422B (en) | System and method for intelligent monitoring of dangerous articles physical distribution based on radio frequency discrimination | |

| CN201732292U (en) | Safety monitoring system of dangerous goods logistics | |

| CN110262355A (en) | Intelligent mine management system and method based on intelligent mine control platform | |

| CN101719233A (en) | Cold-chain logistics management system | |

| CN103198338A (en) | Logistics transportation monitoring system and method based on Internet of things | |

| CN103294013A (en) | System and method for entirely supervising hazardous chemical substance transportation | |

| WO2007149629A1 (en) | Intelligent railyard monitoring system | |

| CN111352380A (en) | On-line monitoring system for hazardous chemical substance transport vehicle | |

| CN109269565A (en) | A kind of hazardous materials transportation monitoring device and monitoring method based on position control | |

| CN202677151U (en) | Whole-journey supervision system for hazardous chemical substance transportation | |

| CN202306254U (en) | Logistic real-time monitoring system | |

| CN109573839A (en) | A kind of monitoring method and device of articles from the storeroom | |

| CN204808030U (en) | Warehouse monitored control system based on thing networking | |

| CN109902984A (en) | A kind of safety monitoring system of dangerous goods logistics | |

| CN107102577A (en) | A kind of multifunctional environmental sanitation vehicle car-mounted terminal | |

| CN212649610U (en) | Visual vehicle-mounted monitoring equipment based on mobile communication network technology and carrying vehicle | |

| KR20070019509A (en) | Real-time safety patrol control system of industry plant using Radio Frequency IDentification | |

| CN111652564A (en) | Intelligent remote monitoring management system for containers | |

| CN211531093U (en) | Internet of things card, dispatching center device and logistics information service system | |

| CN111762229A (en) | Method for supervising full life cycle of railway dangerous cargo transportation | |

| CN203950347U (en) | For tracking means and the logistic track system of logistic track system |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| AV01 | Patent right actively abandoned |

Granted publication date: 20110202 Effective date of abandoning: 20120111 |