CN1163623A - Graft ethylene-vinyl acetate copolymer and resin composition containing the same - Google Patents

Graft ethylene-vinyl acetate copolymer and resin composition containing the same Download PDFInfo

- Publication number

- CN1163623A CN1163623A CN 96190944 CN96190944A CN1163623A CN 1163623 A CN1163623 A CN 1163623A CN 96190944 CN96190944 CN 96190944 CN 96190944 A CN96190944 A CN 96190944A CN 1163623 A CN1163623 A CN 1163623A

- Authority

- CN

- China

- Prior art keywords

- composition

- vinyl

- vinyl acetate

- acetate copolymer

- glycidyl

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Landscapes

- Compositions Of Macromolecular Compounds (AREA)

Abstract

A graft ethylene-vinyl acetate copolymer prepared by preparing an aqueous suspension containing 100 parts (by weight, the same applies hereinbelow) of an ethylenevinyl acetate copolymer (a), 0.1 to 50 parts of a specific glycidyl compound (b), 1 to 500 parts of a vinylic monomer (c) and 0.001 to 10 parts (per 100 parts of the total of the components (b) and (c)) of a radical polymerization initiator (d), impregnating the component (a) with the components (b) and (c), and polymerizing the components (b) and (c). The copolymer is excellent in thermal decomposition resistance, adhesion characteristics, compatibility with polyester or polyamide resins, and so on, and is well balanced among mechanical characteristics (such as impact characteristics, rigidity and strength), heat resistance, and moldability.

Description

Technical field

The present invention relates to graft modification ethene-vinyl acetate copolymer and resin combination thereof, more particularly, relate to and can be used as tackiness agent, graft modification ethene-vinyl acetate copolymer that the compatible improving agent of various modifiers, polymer blend uses, and be mixed with by it, mechanical characteristics excellences such as impact characteristics, rigidity, intensity, physicalies such as thermotolerance, plasticity isostatic resin combinations very simultaneously.

Background technology

Vinyl-vinyl acetate copolymer is owing to weathering resistance, ozone resistance, shock-resistant giving property excellence, while have than higher polarity of olefines elastomerics such as ethylene-propylene copolymer or ethylene-propylene-diene copolymers because of containing the vinyl-acetic ester composition, thereby can give this vinyl-vinyl acetate copolymer with fusible resin and wax class by fusion, can be used as far-ranging adherend is shown that the hot-melt adhesive of bond properties uses.But, the shortcoming of vinyl-vinyl acetate copolymer is, if use at high temperature then can cause thermolysis and produce acid, in this case, not only make the original degradation of vinyl-vinyl acetate copolymer, and can corrode the metal parts of using apptss such as fusion tank or melting mixing machine and become malodorous reason, thereby, the improvement of the heat-resisting decomposability of this resin that waits in expectation.

In addition, existing people attempts making vinyl-vinyl acetate copolymer and widely used polymkeric substance fusion such as polyethylene, polypropylene or polyvinyl chloride, and to make full use of its excellent weathering resistance, shock-resistant giving property, this fusion has reached and improved effect.Yet, for engineering plastics such as polymeric amide, polyester, the compatibility of vinyl-vinyl acetate copolymer is not so good, even fusion, not only can not reach desirable improvement, the mechanical characteristics of adulterant or the surface properties of adulterant molding are descended, and because aforesaid heat-resisting decomposability is low, cause thermolysis during fusion, also limited fusion with other polymkeric substance.

On the other hand, with polyethylene terephthalate, polybutylene terephthalate is the vibrin of representative, because physics, chemical property excellences such as mechanical characteristics, insulativity, shaping processability, thereby be widely used in fields such as trolley part, electrical electronic part, precision optical machinery parts, but wherein major part is to use the parts of injection molded manufactured.

But the purposes of vibrin has tendency advanced, that become privileged in recent years, except that the purposes that injection molded method goods are arranged earlier, also wishes the purposes development to the blow-moulding process goods that obtain large-scale hollow forming product with low cost.

Yet vibrin shrinks (draw-down) fierceness owing to fusion tension force, melt viscosity are low under the situation of blow molding, thereby can not obtain the molding of desired shape in fact with blow-moulding process.

And although vibrin has aforesaid excellent physical, chemical property, especially toughness such as shock-resistance is not so good, in order further to enlarge the purposes of this resin, also expects its improvement.

As improving one's methods of the melting characteristic of this type of vibrin, can consider to adopt the method for high-polymerization degree polyester, adopt the method for the polyester that side chain is arranged, or add the method etc. of various fillers, but the improvement effect of these methods is little, can not be satisfactory.

In addition, by in vibrin, mixing epoxy compounds or by in vibrin, mixing ethene and α, the multipolymer of beta-unsaturated acid glycidyl ester improves fusion tension force, improves the existing people's proposition of inotropic method, but effect can not be satisfactory, its shortcoming is the plasticity instability, is difficult to obtain uniform molding.

And then, Te Kaiping 05-112701 communique discloses and mixed vinylbenzene and α in vibrin, the method of the multipolymer of beta-unsaturated acid glycidyl ester and other vinyl monomer, Te Kaiping 05-301273 communique also discloses and has used specific polyester resin mixture and mix vinylbenzene and α, the method for the multipolymer of beta-unsaturated acid glycidyl ester and other vinyl monomer therein.Adopt these methods can improve this polyester and resin composition melt viscosity, improve the fusion tension force and the shrinkability of parison, but except that shock-resistance is low, the trend that fusion tension force, melt viscosity is descended and make the blow molding reduction is arranged under the situation of utilizing the molding that has been shaped again, thereby can not be satisfactory.

The purpose of this invention is to provide the heat-resisting decomposability of having improved vinyl-vinyl acetate copolymer, with the graft modification ethene-vinyl acetate copolymer of the binding property excellence of organic/inorganic polar material.

Another object of the present invention provides resin combination excellent, that be made up of polyamide resin and/or vibrin and graft modification ethene-vinyl acetate copolymer such as impact characteristics, rigidity, thermotolerance and shaping thing surface property.

Further purpose of the present invention provides excellences such as impact characteristics, tensile strength, fusion when being detained, and fusion tension force and melt viscosity descend fewly, can be preferably as uses such as blow molding material, by vibrin, graft modification ethene-vinyl acetate copolymer with contain the resin combination that the vinyl-based copolymer of glycidyl is formed.

Disclosure of the Invention

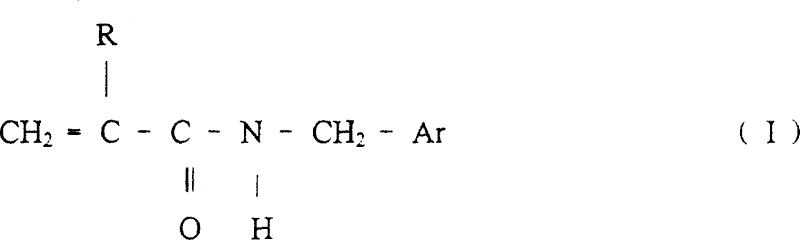

Promptly, a first aspect of the present invention content is graft modification ethene-vinyl acetate copolymer, it is a kind of aqeous suspension of preparation, wherein with respect to (a) vinyl-vinyl acetate copolymer 100 weight parts, contain the compound (b1) of (b) general formula (I) glycidyl that is shown with or the compound that glycidyl is arranged (b2) 0.1~50 weight part of forming by this compound (b1) and unsaturated glycidyl ester, (c) vinyl monomer 1~500 weight part, and become subtotaling 100 weight parts to contain (d) radical initiator 0.001~100 weight part with (c) with respect to (b) composition, make in this aqeous suspension (b) composition and (c) composition immerse in (a) composition, and make (b) composition and (c) composition be polymerized

Ar represents and the aromatic hydrocarbyl of at least one glycidoxypropyl bonded, 6~23 carbon atoms in the formula, and R represents hydrogen atom or methyl.

A second aspect of the present invention content is resin combination, and its composition is

(A) polyamide resin and/or vibrin 100 weight parts and

(B) graft modification ethene-vinyl acetate copolymer 1~100 weight part, described multipolymer is a kind of aqeous suspension of preparation, wherein with respect to (a) vinyl-vinyl acetate copolymer 100 weight parts, contain the compound (b1) of (b) general formula (I) glycidyl that is shown with or the compound that glycidyl is arranged (b2) 0.1~50 weight part of forming by this compound (b1) and unsaturated glycidyl ester, (c) vinyl monomer 1~500 weight part, and become subtotaling 100 weight parts to contain (d) radical initiator 0.001~100 weight part with (c) with respect to (b) composition, make in this aqeous suspension (b) composition and (c) composition immerse in (a) composition, and make (b) composition and (c) composition be polymerized

Ar represents and the aromatic hydrocarbyl of at least one glycidoxypropyl bonded, 6~23 carbon atoms in the formula, and R represents hydrogen atom or methyl.

A third aspect of the present invention content is resin combination, and its composition is

(A) vibrin 100 weight parts,

(B) graft modification ethene-vinyl acetate copolymer 1~100 weight part, described multipolymer is a kind of aqeous suspension of preparation, wherein with respect to (a) vinyl-vinyl acetate copolymer 100 weight parts, contain the compound (b1) of (b) general formula (I) glycidyl that is shown with or the compound that glycidyl is arranged (b2) 0.1~50 weight part of forming by this compound (b1) and unsaturated glycidyl ester, (c) vinyl monomer 1~500 weight part, and become subtotaling 100 weight parts to contain (d) radical initiator 0.001~100 weight part with (c) with respect to (b) composition, make in this aqeous suspension (b) composition and (c) composition immerse in (a) composition, and make (b) composition and (c) composition be polymerized

Ar represents the aromatic hydrocarbyl with at least one glycidoxypropyl bonded, 6~23 carbon atoms in the formula, R represent hydrogen atom or methyl and

(C) contain glycidyl vinyl-based copolymer 0.1~20 weight part, wherein 99~50% (weight) are at least a vinyl monomers of selecting a group that forms from vinylbenzene, alpha-methyl styrene, vinyl cyanide, methyl methacrylate, butyl methacrylate, bromostyrene, phenyl maleimide, and 1~50% (weight) is glycidyl methacrylate.

Implement optimal morphology of the present invention

Graft modification ethene-vinyl acetate copolymer as first aspect present invention, by being prepared as follows: prepare a kind of aqeous suspension, wherein contain vinyl-vinyl acetate copolymer as (a) composition, as the compound (b1) that contains glycidyl shown in the general formula (I) of (b) composition

(Ar represents the aromatic hydrocarbyl with at least one glycidoxypropyl bonded, 6~23 carbon atoms in the formula, R represents hydrogen atom or methyl) or the compound that contains glycidyl (b2) formed of this compound (b1) and unsaturated glycidyl ester, and the vinyl monomer of conduct (c) composition, and the radical initiator of conduct (d) composition, make in this aqeous suspension (b) composition and (c) composition immerse in (a) composition, and make (b) composition and (c) composition polymerization in (a) composition.

As the vinyl-vinyl acetate copolymer of (a) composition, better adopt by 50~99% (weight) ethene and 50~1% (weight) vinyl-acetic ester constitutes, JIS K6730 measures the melt flow rate (MFR) vinyl-vinyl acetate copolymer in 0.1~500g/10 minute scope.If beyond above-mentioned scope, the equilibrium of then heat-resisting decomposability, flowability, mechanical characteristics will worsen.

As being used to one of (b) composition that makes the modification of (a) composition, containing the compound (b1) of glycidyl, available general formula (I) expression,

(in the formula Ar represent that at least one glycidoxypropyl is arranged, the aromatic hydrocarbyl of 6~23 carbon atoms, R represents hydrogen atom or methyl) be the properties-correcting agent deutero-that has at least one acrylamido and glycidyl from intramolecularly respectively.So-called acrylamido except that acrylamido, also comprises the methacryloyl amido.

Such compound can be with open the method preparation described in the clear 60-130580 communique such as the spy.That is, aromatic hydrocarbons that can be by making at least one phenolic hydroxyl group and N hydroxymethyl acrylamide or N-methylol methacrylamide are after condensation in the presence of an acidic catalyst, and the method that makes hydroxyl change into glycidyl with 1,2 epoxy prapane prepares.

As the above-mentioned aromatic hydrocarbons that at least one phenolic hydroxyl group is arranged, can use the phenol compound of 6~23 carbon atoms.

As the specific examples of this oxybenzene compound, can enumerate such as phenol cresols, xylenol, isothymol, thymol, naphthols, Resorcinol, quinhydrones, pyrogallol, phenanthrol etc.Wherein be preferably the monobasic phenol of alkyl substituent.For example, under with 2 and the situation of N hydroxymethyl acrylamide, can obtain the compound shown in the structural formula (II) as initial substance.

As another kind of in (b) composition that is used for making the modification of (a) composition, with unsaturated glycidyl ester is the compound that contains glycidyl (b2) of representative, can enumerate glycidyl acrylate, glycidyl methacrylate, one and 2-glycidyl ester of methylene-succinic acid, one of butylene three acid, two and three-glycidyl ester, one and 2-glycidyl ester of citraconic acid, bridge-cis-two ring (2,2,1) heptan-5-alkene-2, one and 2-glycidyl ester of 3-diacid, one and 2-glycidyl ester of allyl group succsinic acid, to vinyl benzoic acid glycidyl ester etc., these can be used alone or in combination of two or more.From cost with to the dipping viewpoint of vinyl-vinyl acetate copolymer, wherein be preferably glycidyl methacrylate.

In addition, as the vinyl monomer of (c) composition, can enumerate, as vinylbenzene, o-methyl styrene, p-methylstyrene, a vinyl toluene, alpha-methyl styrene, Vinylstyrene etc. such as aromatic ethenyl compound; The alkyl carbon atoms number is 1~22 a alkyl methacrylate, as methyl methacrylate, Jia Jibingxisuanyizhi, isopropyl methacrylate, n-BMA, methacrylic tert-butyl acrylate, methacrylic acid 2-ethylhexyl, methacrylic acid stearyl ester etc.; The alkyl carbon atoms number is 1~22 a alkyl acrylate, as methyl acrylate, ethyl propenoate, isopropyl acrylate, n-butyl acrylate, tert-butyl acrylate, 2-EHA, stearyl acrylate ester etc.; The alkyl carbon atoms number is 1~22 a vinyl alkyl ethers, as vinyl methyl ether, EVE, vinyl n-propyl ether, vinyl isopropyl ether, vinyl isobutyl ether, vinyl n-pentyl ether, vinyl isoamyl ether, vinyl 2-ethylhexyl ether, vinyl octadecyl ether etc.; Unsaturated nitrile compound, as vinyl cyanide, methacrylonitrile etc.; The unsaturated acyl amine compound is as acrylamide, Methacrylamide etc.; Dialkyl maleate is as toxilic acid two n-pentyl esters, n-butyl maleate, toxilic acid diisoamyl ester, diisobutyl maleate, dimethyl maleate, toxilic acid di-n-propyl ester, dioctyl maleate, dinonyl maleate etc.; The alkyl carbon atoms number is 1~8 an allyl group alkyl oxide, as allyl ethyl ether, allyl group n-octyl ether etc.; Diolefin, as Dicyclopentadiene (DCPD), divinyl, isoprene, chloroprene, phenyl propadiene, cyclopentadiene, 1,5-norbornadiene, 1,1,1,5-cyclohexadiene, 1,3-cyclooctadiene etc.; And other vinyl monomer, as allyl methacrylate(AMA), vinylformic acid, methacrylic acid, toxilic acid, maleic anhydride, vinyl-acetic ester etc.These may be used alone, used in two or more.

In addition, radical initiator as (d) composition, can enumerate such as methyl ethyl ketone peroxide, di-t-butyl peroxide, 1,1-two (tert-butyl peroxy base)-3,3, the 5-trimethyl-cyclohexane, 4,4-two (tert-butyl peroxy base) n-butyl pentanoate, 2,5-dimethylhexane-2,5 two (hydroperoxide), α, α '-two (a tert-butyl peroxy base-sec.-propyl) benzene, 2,5-dimethyl-2,5-two (tert-butyl peroxy base) hexane, 2,5-dimethyl-2,5-two (tert-butyl peroxy base) hexene-3, organo-peroxide classes such as benzoyl peroxide, or such as 1,1 '-azo two (hexanaphthene-1-nitrile), 1-[(1-cyano group-1-methylethyl) azo] methane amide, 2-phenylazo-4-methoxyl group-2, the 4-methyl pentane nitrile, 2,2 '-azo two (2-methylbutyronitrile), 2,2 '-Diisopropyl azodicarboxylate, 2,2 '-azo two (2,4, the 4-trimethylpentane), 2,2 '-azo two (2-acetyl Ethylene Oxide), 2,2 '-azo two azo compounds such as (2-acetyl oxygen butane), these compounds may be used singly or in combination of two or more.In addition, these initiators can be according to such as various polymerizing conditions such as polymerization process, polymerization temperature, times, or according to the molecular weight of resulting polymkeric substance, viscosity etc., select desirable compound.

Specific examples as graft modification ethene of the present invention-vinyl acetate copolymer polymerization process, can enumerate such as preparation and contain (a) composition, (b) composition, (c) composition and (d) aqeous suspension of composition, make in this aqeous suspension (b) composition and (c) composition be impregnated in (a) composition, make (b) composition and (c) composition polymeric method again.

(a) composition in the aqeous suspension, (b) composition and (c) components in proportions be, for (a) composition 100 weight parts, (b) composition is 0.1~50 weight part, is preferably 0.1~30 weight part, (c) composition is 1~500 weight part, is preferably 1~200 weight part, is more preferably 1~100 weight part; And with respect to above-mentioned (b) composition became subtotaling 100 weight parts with (c) for, (d) composition was 0.001~10 weight part, more fortunately in the scope of 0.05~5 weight part.Under the situation that (b) components in proportions is Duoed than above-mentioned scope, mobile decline caused gelation sometimes, can cause heat-resisting decomposability, binding property to reduce under a few cases.And under the situation that (c) components in proportions is Duoed than above-mentioned scope, because the polymerization to each other of superfluous vinyl monomer becomes main body, thereby excessively cohesion, molten sticking, caking etc. take place in the aqeous suspension during polymerization, and (b) composition causes (b) composition that the graft reaction amount of (a) composition is reduced to the dipping decline of (a) composition under a few cases.In addition, under the situation that (d) components in proportions is Duoed than above-mentioned scope, can cause that (a) composition is excessively crosslinked, under a few cases, can make polymerization insufficient.

Graft modification ethene-vinyl acetate copolymer of the present invention also can use with the composition forms that contains unmodified vinyl-vinyl acetate copolymer.In this case, the content of unmodified vinyl-vinyl acetate copolymer is in the scope of 0~95% (weight), better 0~80% (weight).

As second aspect present invention is polyamide resin in the resin combination formed of (A) polyamide resin and/or vibrin and above-mentioned (B) graft modification ethene-vinyl acetate copolymer, the purpose so long as can be used for being shaped, just be not particularly limited, as its specific examples, can enumerate with aliphatic amino acid, lactan, diamines and dicarboxylic acid is the polymkeric substance that main component obtains by condensation reaction, or introduces the copoly type polymeric amide etc. of a small amount of aromatic component or other aliphatics composition in above-mentioned aliphatics composition.As above-mentioned aliphatic amino acid, can enumerate 6-aminocaprolc acid, the amino undecanoic acid of 11-, 12 amino dodecanoic acid etc.As described lactan, can enumerate ε-Ji Neixianan, omega-lauric lactam etc.As described diamines, can enumerate 1,4-butanediamine, 1,6-hexanediamine, 1,11-undecane diamines, 1,12-dodecane diamines etc.

As described dicarboxylic acid, can enumerate hexanodioic acid, nonane diacid, sebacic acid, dodecanedioic acid, diglycollic acid etc.

As above-mentioned polyamide resin, can enumerate polycaprolactam (nylon-6), poly hexamethylene adipamide-1,6-hexanediamine (nylon-66), poly hexamethylene adipamide-1,4-butanediamine (nylon-46), poly-dodecane acid amides (PA-12) and these mixture etc.

In addition, vibrin in the resin combination of forming as of the present invention, (A) polyamide resin and/or vibrin and above-mentioned (B) graft modification ethene-vinyl acetate copolymer, can enumerate that can to become ester derivative and glycol or its ester derivative with aromatic dicarboxylic acid or its be polymkeric substance and even the multipolymer that main component obtains by condensation reaction, or the ring-opening polymerization polymer of lactone etc.

As described aromatic dicarboxylic acid, can enumerate terephthalic acid, m-phthalic acid, phthalic acid, 2,6-naphthalene dicarboxylic acids, two (to carboxyl phenyl) methane, anthracene dicarboxylic acid, 4,4 '-diphenyl dicarboxylic acid, 4,4 '-the phenyl ether dicarboxylic acid, or the become ester derivative of these acid, or these mixture etc.In addition, as the become ester derivative of described aromatic dicarboxylic acid, can enumerate become ester derivative from described aromatic carboxylic acid specific examples.These aromatic carboxylic acids or its can become ester derivative may be used alone, used in two or more.

As described glycol, can enumerate the aliphatic diol of 2~10 carbon atoms, i.e. ethylene glycol, 1, ammediol, 1,4-butyleneglycol, neopentyl glycol, 1,5-pentanediol, 1,6-hexylene glycol, 1,8-ethohexadiol, cyclohexane diol etc., or the long chain diol of molecular weight 400~6000, i.e. polyoxyethylene glycol, poly--1, ammediol, poly--1,4-butyleneglycol etc., and composition thereof etc.

As the one-tenth ester derivative of described glycol, can enumerate the one-tenth ester derivative that derives from above-mentioned glycol specific examples.These glycol or its become ester derivative may be used alone, used in two or more.

Specific examples as described vibrin, can enumerate polyethylene terephthalate, Poly(Trimethylene Terephthalate), polybutylene terephthalate, poly terephthalic acid 1,6-hexylene glycol ester, poly--2, the mixture of 6-naphthalene dicarboxylic acids glycol ester, polyethylene terephthalate and polybutylene terephthalate etc.

The mix proportions scope of polyamide resin, vibrin and graft modification ethene-vinyl acetate copolymer is among the present invention, polyamide resin 0~100 weight part, vibrin 100~0 weight parts, and for polyamide resin and vibrin add up to 100 weight parts, graft modification ethene-vinyl acetate copolymer is 1~100 weight part, is preferably 1~50 weight part.If mix proportions exceeds above-mentioned scope, just then the balance of physicalies such as thermotolerance, shock-resistance, rigidity, plasticity and surface property can not be satisfactory.

As a third aspect of the present invention promptly above-mentioned (A) vibrin, (C) in the resin combination of above-mentioned (B) graft modification ethene-vinyl acetate copolymer and the vinyl-based copolymer composition that (C) contains glycidyl contains the vinyl-based copolymer of glycidyl, specifically, can enumerate from vinylbenzene, alpha-methyl styrene, vinyl cyanide, methyl methacrylate, butyl methacrylate, bromostyrene, at least a vinyl monomer of selecting in a group that phenyl maleimide is formed 99~50% (weight), better 99~75% (weight) and glycidyl methacrylate 1~50% (weight), the multipolymer that better 1~25% (weight) copolymerization forms.If the content of glycidyl methacrylate is lower than above-mentioned scope, then blow molding decline, and if be higher than above-mentioned scope, then the shaping of resin combination is mobile significantly descends.

(A) vibrin, (B) graft modification ethene-vinyl acetate copolymer and the mix proportions scope that (C) contains the vinyl-based copolymer of glycidyl are among the present invention, for (A) vibrin 100 weight parts, (B) graft modification ethene-vinyl acetate copolymer 1~100 weight part, better 1~50 weight part, (C) contain vinyl-based copolymer 0.1~20 weight part of glycidyl, better 0.2~10 weight part.If mix proportions exceeds above-mentioned scope, just then the balance of physicalies such as fusion tension force, melt viscosity, shaping flowability, shock-resistance, rigidity and surface property can not be satisfactory.

As second, third aspect of the present invention i.e. (A) polyamide resin and/or vibrin and (B) resin combination of graft modification ethene-vinyl acetate copolymer composition, and (A) vibrin, (B) graft modification ethene-vinyl acetate copolymer and (C) contain the preparation method of the resin combination that the vinyl-based copolymer of glycidyl forms, can by such as make with stirrer etc. each composition uniform mixing then melting mixing prepare.

The method of melting mixing is not particularly limited, and can use extrusion machine, hot-rolling, Brabender

Known blending machines such as (Brabender), Banbury mixer carry out melting mixing.

As the filler that adds in the resin combination of the present invention, can enumerate silica, talcum, mica, glass fibre, granulated glass sphere, Hollow Glass Sphere, neutral clay class, carbon fiber, aromatic polyamide fibre, aromatic polyester fiber, vinylon fiber, carbonizedfibres, silicon carbide fiber, sapphire whisker, potassium titanate fiber, steel fiber etc.These fillers may be used alone, two or more kinds can also be used.

State in the use under the situation of filler, the ratio in resin combination of the present invention can be to use 1~100 weight part, better 10~50 weight parts for resinous principle 100 weight parts.Be lower than the effect that can't reach filler under the situation of above-mentioned scope, and be higher than mobile decline that be shaped under the situation of above-mentioned scope.

In addition, as the fire retardant that can be used in the resin combination of the present invention, can enumerate tetrabromo-bisphenol, 2,2-two (4-hydroxyl-3, the 5-dibromo phenyl) propane, hexabromobenzene, isocyanuric acid three (2,3-dibromo propyl ester), 2, halogenated flame such as 2-two (4-hydroxy ethoxy-3,5-dibromo phenyl) propane, decabromodiphynly oxide, bromo polyphosphate, chloro polyphosphate, chloroparaffin; Phosphorus type flame retardants such as ammonium phosphate, tricresyl phosphate (hydroxy toluene ester), triethyl phosphate, tricresyl phosphate (chloroethene ester), tricresyl phosphate (β-chloroethene ester), tricresyl phosphate (dichloro propyl ester), phosphoric acid hydroxy toluene ester phenyl ester, phosphoric acid (diformazan phenyl ester) diphenyl ester, acid phosphoric acid ester, nitrogenous phosphorus compound; Red phosphorus, stannic oxide, ANTIMONY TRIOXIDE SB 203 99.8 PCT, zirconium hydroxide, barium metaborate, aluminium hydroxide, magnesium hydroxide, etc. inorganic combustion inhibitor; Brominated Polystyrene, bromo be poly--and alpha-methyl styrene, bromo polycarbonate, bromo poly epoxy resin, chlorinated polyethylene, chloro be poly--polymer fire retardants such as alpha-methyl styrene, chlorinated polycarbonates, chloro poly epoxy resin.These fire retardants may be used alone, two or more kinds can also be used.

Stating in the use under the situation of fire retardant, for resinous principle 100 weight parts in the resin combination of the present invention, can be the ratio of 1~50 weight part, better 1~30 weight part.Can't reach the effect that invests flame retardant resistance being lower than under the situation of described scope, and be higher than that can causing under the situation of described scope is shaped and mobilely worsen, mechanical property descends.

In the resin combination of the present invention, also can add stablizer in case of necessity, can improve reactive catalyzer of graft modification ethene-vinyl acetate copolymer etc.

As described stablizer, with regard to oxidation inhibitor, can enumerate such as 2,4-two (positive hot sulfenyl)-6-(4-hydroxyl-3,5-di-tert-butyl amido)-1,3,5-triazines, [3-(3 for tetramethylolmethane four, the 5-di-tert-butyl-hydroxy phenyl) propionic ester], 2,2-sulphur diethylidene two [3-(3, the 5-di-tert-butyl-hydroxy phenyl) propionic ester], 3-(3, the 5-di-tert-butyl-hydroxy phenyl) propionic acid octadecane ester, 2,2-sulphur two (4-methyl-6-tert butyl phenol), 1,3,5-trimethylammonium-2,4,6-three (3, the 5-di-tert-butyl-4-hydroxyl benzyl) phenol compound and thio-ether type compounds such as benzene, or 4,4 '-biphenyl phosphonous acid four (2,4-di-t-butyl phenyl ester), phosphonous acid three Phosphorus compounds such as (2,4-di-t-butyl phenyl ester); And with regard to photostabilizer, can enumerate Succinic acid dimethylester-1-(2-hydroxyethyl)-4-hydroxyl-2,2,6,6-tetramethyl piperidine polycondensate, it is poly-that [[6-(1,1,3, the 3-tetramethyl butyl) imino--1,3,5-triazine-2,4-two bases] [(2,2,6,6-tetramethyl--4-piperidyl) hexylidene (2 imino-), 2,6, the 6-tetramethyl-piperidyl) imino-]], 2-(3, the 5-di-tert-butyl-4-hydroxyl benzyl)-2-n-butylmalonic acid two (1,2,2,6,6-pentamethyl--4-piperidines ester) hindered amine compound such as, these compounds can be used alone or in combination of two or more.The usage quantity of stablizer is for resin combination 100 weight parts of the present invention, in the scope of 0.01~20 weight part.The stablizer additive effect can not be satisfactory under the situation of above-mentioned scope being lower than, and can cause under the situation of above-mentioned scope that mechanical property descends being higher than.

Be not particularly limited as described catalyzer, it generally is the combination of from the compound of the reaction that can promote carboxyl, hydroxyl, ester group and glycidyl, selecting one or more, but be preferably Phosphorus compounds such as aminated compounds, phosphonium salt, phosphine such as tertiary amine, quaternary ammonium salt, or imidazoles.In these compounds, from the Phosphorus compound of the viewpoint of heat-resistant stability is good especially, concrete can enumerate phosphonium salt classes such as bromination Si Zheng Ding Ji Phosphonium, chlorination Si Zheng Ding Ji Phosphonium, iodate three normal-butyl Jia Ji Phosphonium, chlorination three normal-butyl Bian Ji Phosphonium, bromination three normal-butyl Xi Bing Ji Phosphonium, phosphine classes such as triphenyl phosphine.The usage quantity of catalyzer is for resin combination 100 weight parts of the present invention, at 0.001~2 weight part, more fortunately in the scope of 0.005~1 weight part.Can not reach the reaction facilitation effect being lower than under the situation of above-mentioned scope, and can cause under the situation of above-mentioned scope that mechanical property descends being higher than.

In addition, in the resin combination of the present invention, can also in the scope of not damaging speciality of the present invention, add pigment, static inhibitor, nucleus formation agent or the present invention's thermoplasticity crystalline resin, non-crystalline resin in addition in case of necessity.

Below be described more specifically the present invention with embodiment, but the present invention just is not limited to these embodiment, can make various changes in the scope that does not deviate from essence of the present invention.

In addition, in the following description, except as otherwise noted, otherwise " part " and " % " represents " weight part " and " weight % " respectively.

Embodiment 1

The preparation of graft modification ethene-vinyl acetate copolymer (MEV1)

In withstand voltage closed reactor,, sneak into vinyl-vinyl acetate copolymer (Polychemical of Mitsui Du Pont corporate system, EVAFLEX360 for 4200 parts of pure water

: ethyl acetate content 25%, melt flow rate (MFR) 2g/10 minute) 1400 parts, 400 parts of vinylbenzene, N-[4-(2, the 3-glycidoxy)-3, the 5-dimethyl benzyl] 200 parts of acrylamides, 1,1-two (tert-butyl peroxy base)-3,3,6.0 parts of 5-trimethyl-cyclohexanes, tribasic calcium phosphate (Ca

3(PO

4)

2) 30 parts and emulsifying agent (Kao Corporation's system, LATEMULPS

) 1.0 parts, mix, obtain aqeous suspension.This aqueous solution, further stirred 3 hours at 110 ℃ after 1 hour 100 ℃ of stirrings, and polymerization is stopped.The particulate that obtains is washed, is removed tribasic calcium phosphate and LATEMUL PS after drying, obtains graft modification ethene-vinyl acetate copolymer (MEV1).

Embodiment 2

The preparation of graft modification ethene-vinyl acetate copolymer (MEV2)

In withstand voltage closed reactor,, sneak into vinyl-vinyl acetate copolymer (Polychemical of Mitsui Du Pont corporate system, EVAFLEX260 for 4200 parts of pure water

: vinyl acetate content 28%, melt flow rate (MFR) 6g/10 minute) 1600 parts, 200 parts of methyl methacrylates, 150 parts of vinylbenzene, N-[4-(2, the 3-glycidoxy)-3, the 5-dimethyl benzyl] 50 parts of acrylamides, 1,1-two (tert-butyl peroxy base)-3,3,4.0 parts of 5-trimethyl-cyclohexanes, 30 parts of tribasic calcium phosphates and emulsifying agent (Kao Corporation's system, LATEMUL PS

) 1.0 parts, mix, obtain aqeous suspension.This aqueous solution, further stirred 3 hours at 110 ℃ after 1 hour 100 ℃ of stirrings, and polymerization is stopped.Tribasic calcium phosphate washed, removes by the particulate that obtains and LATEMUL PS is dry afterwards, obtains graft modification ethene-vinyl acetate copolymer (MEV2).

Embodiment 3

The preparation of graft modification ethene-vinyl acetate copolymer (MEV3)

In withstand voltage closed reactor, for 4200 parts of pure water, (Polychemical of Mitsui Du Pont corporate system, EVAFLEX 260 to sneak into vinyl-vinyl acetate copolymer

: vinyl acetate content 28%, melt flow rate (MFR) 6g/10 minute) 1400 parts, 300 parts of vinylbenzene, N-[4-(2, the 3-glycidoxy)-3, the 5-dimethyl benzyl] 100 parts of 200 parts of acrylamides, glycidyl methacrylate, 1,1-two (tert-butyl peroxy base)-3,3,6.0 parts of 5-trimethyl-cyclohexanes, 30 parts of tribasic calcium phosphates and emulsifying agent (Kao Corporation's system, LATEMUL PS

) 1.0 parts, mix, obtain aqeous suspension.This aqueous solution, further stirred 3 hours at 110 ℃ after 1 hour 100 ℃ of stirrings, and polymerization is stopped.Tribasic calcium phosphate washed, removes by the particulate that obtains and LATEMUL PS is dry afterwards, obtains graft modification ethene-vinyl acetate copolymer (MEV3).

Embodiment 4

The preparation of graft modification ethene-vinyl acetate copolymer (MEV4)

In withstand voltage closed reactor, for 4200 parts of pure water, (Polychemical of Mitsui Du Pont corporate system, EVAFLEX 360 to sneak into vinyl-vinyl acetate copolymer

: vinyl acetate content 25%, melt flow rate (MFR) 2g/10 minute) 1800 parts, 100 parts of vinylbenzene, N-[4-(2, the 3-glycidoxy)-3, the 5-dimethyl benzyl] 100 parts of acrylamides, 1,1-two (tert-butyl peroxy base)-3,3,6.0 parts of 5-trimethyl-cyclohexanes, 30 parts of tribasic calcium phosphates and emulsifying agent (the system LATEMUL PS of Kao Corporation

) 1.0 parts, mix, obtain aqeous suspension.This aqueous solution, further stirred 3 hours at 110 ℃ after 1 hour 100 ℃ of stirrings, and polymerization is stopped.Tribasic calcium phosphate washed, removes by the particulate that obtains and LATEMUL PS is dry afterwards, obtains graft modification ethene-vinyl acetate copolymer (MEV4).

Comparative example 1

(Polychemical of Mitsui Du Pont corporate system, EVAFLEX 360 for the vinyl-vinyl acetate copolymer that uses among the embodiment

: vinyl acetate content 25%, melt flow rate (MFR) 2g/10 minute) former state use (being called for short EV1).

Comparative example 2

(Polychemical of Mitsui Du Pont corporate system, EVAFLEX 260 for the vinyl-vinyl acetate copolymer that uses among the embodiment

: vinyl acetate content 28%, melt flow rate (MFR) 6g/10 minute) former state use (being called for short EV2).

Comparative example 3

Removing among the embodiment 1 and not adding N-[4-(2, the 3-glycidoxy)-3,5-dimethyl benzyl] all the other carry out acrylamide equally outward, obtain graft modification ethene-vinyl acetate copolymer (EV3).

Estimate graft modification ethene-vinyl acetate copolymer (MEV1~MEV4) and the heat-resisting decomposability of the EV1~EV3 of comparative example 1~3 preparation and of the foregoing description 1~4 preparation to the bond strength of aluminium in order to following method.The results are shown in Table 1.

(1) heat-resisting decomposability: in air, sample is heated to 255 ℃ with 10 ℃/minute heat-up rate, and then continues heating 1 hour at 255 ℃, measures the weight decrement of this moment with TGA (thermogravimetry).

(2) bond strength: after being processed into pulverous each sample and evenly packing between 2 pieces of aluminium bases (thick 0.2mm, wide 25mm, long 100mm), at 200 ℃ with 5kg/cm

2Add thermo compression, make test piece.Use this test piece, measure T word stripping strength according to JISK6854.Table 1

| Weight decrement (wt%) | T word stripping strength (Kgf/25mm) | |

| Embodiment 1 embodiment 2 embodiment 3 embodiment 4 | ????1.3 ????1.5 ????1.7 ????1.0 | ?????7.9 ?????8.5 ?????9.1 ?????7.1 |

| Comparative example 1 comparative example 2 comparative examples 3 | ????4.0 ????3.5 ????9.2 | ?????0.4 ?????0.2 ?????0.6 |

Embodiment 5~10

Use the catalysts of following material, prepare resin combination by the combination and the mix proportions of each composition shown in the table 2 as each composition, polyamide resin, vibrin, graft modification ethene-vinyl acetate copolymer, glass fibre and the graft modification ethene-vinyl acetate copolymer of resin combination of the present invention.

Polyamide resin:

Nylon-66 (emerging product corporate system UBE 2020 B of space portion

, be called for short Ny66 in the table).

Vibrin:

Polybutylene terephthalate (Polyplastic corporate system 800FP

, be called for short PBT in the table).

Graft modification ethene-vinyl acetate copolymer:

Graft modification ethene-the vinyl acetate copolymer (MEV1, MEV2, MEV3, MEV4) of embodiment 1,2,3,4 preparations.

Glass fibre:

The system EC03T-187H/P of NEG limited-liability company

(being called for short GF in the table).

Catalysts:

Xiuization 4-butyl-phosphonium (the Aldrich corporate system is called for short TBPB in the table).

Resin combination and test piece prepare by the following method.At first, in ratio shown in the table 2 each composition is done fusion after, in the 45mm twin-screw extruder,, carry out granulation at 275 ℃ of melting mixings of barrel zone temperature.This pellet vacuum-drying, obtain desirable resin combination after, in injection molding machine, carry out injection molded for 80 ℃ in 280 ℃ of barrel zone temperatures, die temperature, make test piece.

Then, the evaluation of each test piece is undertaken by following project and method, and the results are shown in Table 2.

(1) impact characteristics:, measure 23 ℃ notched izod (Izod) impact value according to ASTM D256.

(2) curved characteristic:, measure flexural strength and bending modulus according to ASTM D790.

(3) thermal distorsion temperature: measure according to ASTM D648.

(4) shaping thing surface property: by the standard evaluation of three grades of following A, B, C.

A: there are not shrinkage cavity, fin line, ripple on the molding surface, good;

B: occur shrinkage cavity, fin line or ripple on the molding surface;

C: observe on the molding surface and peel off.

Comparative example 4 and 5

Except that not using graft modification ethene-vinyl acetate copolymer,, carry out the evaluating characteristics same with embodiment according to method making resin combination and the test piece same with embodiment.The results are shown in Table 2 for the mix proportions of each composition, evaluating characteristics.

Comparative example 6 and 7

Remove with ethylene-methyl methacrylate glycidyl ester copolymer (sumitomo chemical company system, BONDFASTE

, be called for short BF in the table) or the EV3 of comparative example 3 preparation replace outside graft modification ethene-vinyl acetate copolymer, use with the same method of embodiment and make resin combination and test piece, carry out the evaluating characteristics same with embodiment.The results are shown in Table 2 for the mix proportions of each composition and evaluating characteristics.Table 2

| Mix proportions | The characteristic of resin combination (molding) | ||||||||

| ?????????????(A) | ??(B) | Cantilever-type impact strength Kgcm/cm | Bending modulus Kg/cm 2 | Heat-drawn wire; Underload ℃ | Shaping thing surface property | ||||

| ????Ny66 | ????BT F | MEV and other resin | GF | TBPB | |||||

| Embodiment 5 | ?????100 | ?????0 | 10 MEV1 | - | - | 15.8 | 27900 | 197 | A |

| Embodiment 6 | ??????70 | ????30 | 10 MEV2 | - | - | 15.1 | 27500 | 186 | A |

| Embodiment 7 | ??????50 | ????50 | 30 MEV2 | - | 0.05 | 34.3 | 22000 | 153 | A |

| Embodiment 8 | ??????30 | ????70 | 10 MEV4 | - | 0.07 | 11.8 | 26100 | 177 | A |

| Embodiment 9 | ???????0 | ???100 | 25 MEV3 | - | - | 82.0 | 17800 | 150 | A |

| Embodiment 10 | ???????0 | ???100 | 10 MEV1 | 30 | - | 12.5 | 71000 | 203 | A |

| Comparative example 4 | ??????70 | ????30 | - | - | - | 3.3 | 29700 | 195 | C |

| Comparative example 5 | ??????50 | ????50 | - | - | - | 2.1 | 29100 | 190 | C |

| Comparative example 6 | ??????50 | ????50 | 30?BF | - | 0.05 | Tackify significantly and can't be shaped (injection volume deficiency) | |||

| Comparative example 7 | ???????0 | ???100 | 10?EV3 | 30 | - | 6.8 | 68200 | 185 | C |

Embodiment 11~14

Is the catalysts of vibrin, graft modification ethene-vinyl acetate copolymer, the vinyl-based copolymer that contains glycidyl, glass fibre and graft modification ethene-vinyl acetate copolymer with following material as each composition of resin combination of the present invention, prepares resin combination by the combination and the mix proportions of each composition shown in the table 3.

Vibrin:

Polybutylene terephthalate (Polyplastic corporate system JULANEX 2002

, be called for short PBT in the table);

Graft modification ethene-vinyl acetate copolymer:

Graft modification ethene-the vinyl acetate copolymer (MEV1, MEV3, MEV4) of embodiment 1,3,4 preparations;

The vinyl-based copolymer that contains glycidyl;

Styrene-acrylonitrile-glycidyl methacrylate copolymer (system BLENMER CP-20SA of Nof Corp.

, be called for short CP in the table);

Glass fibre:

The system EC03T-187H/P of NEG limited-liability company

(being called for short GF in the table).

Catalysts:

Xiuization 4-butyl-phosphonium (the Aldrich corporate system is called for short TBPB in the table).

Resin combination and test piece prepare by the following method.At first, in ratio shown in the table 3 each composition is done fusion after, in the 45mm twin-screw extruder,, carry out granulation at 240 ℃ of melting mixings of barrel zone temperature.After this pellet vacuum-drying obtains desirable resin combination, in injection molding machine, carry out injection molded for 60 ℃, make test piece in 250 ℃ of barrel zone temperatures, die temperature.

Then, the evaluation of each resin combination, test piece is undertaken by following project and method, and the results are shown in Table 3.

(1) melt viscosity: use capillary rheometer, this resin combination input is heated in 255 ℃ the cylinder and adds heat retention after 5 minutes, measure the melt viscosity when from the mould of diameter 1mm, flowing out with 1216/ second velocity of shear.

(2) add heat retention stability; Residence time except that 255 ℃ in above-mentioned (1) is to measure melt viscosity with the same manner 25 minutes, and the melt viscosity of measuring with above-mentioned (1) is 100%, obtains the percentage of this moment.

(3) fusion tension force: use capillary rheometer, this resin combination input is heated in 255 ℃ the cylinder and adds heat retention after 5 minutes, the load when measuring with velocity of shear effusive resin combination from the mould of diameter 1mm of 12/ second with 1m/ minute speed drawing.

(4) impact characteristics:, measure 23 ℃ notched izod impact value according to ASTM D256.

(5) the anti-characteristic of opening:, measure the tensile rupture elongation according to ASTM D638.

Comparative example 8

Use the vibrin that uses among the embodiment 11 separately, use the method making test piece same, carry out the evaluating characteristics same with embodiment with embodiment.The results are shown in Table 3 for evaluating characteristics.

Comparative example 9

Except that not using graft modification ethene-vinyl acetate copolymer, make resin combination and test piece with method similarly to Example 11, carry out the performance evaluation same with embodiment.The results are shown in Table 3 for the mix proportions of each composition and evaluating characteristics.

Comparative example 10

Except that the EV3 that uses comparative example 3 preparations replaces graft modification ethene-vinyl acetate copolymer, use with the same method of embodiment to prepare resin combination and test piece, carry out the evaluating characteristics same with embodiment.The results are shown in Table 3 for the mix proportions of each composition and evaluating characteristics.

Comparative example 11

Remove and use ethylene-methyl methacrylate glycidyl ester copolymer (sumitomo chemical company system, BONDFASTE

, be called for short BF in the table) replace outside graft modification ethene-vinyl acetate copolymer, use with the same method of embodiment to prepare resin combination and test piece, carry out the evaluating characteristics same with embodiment.The results are shown in Table 3 for the mix proportions of each composition and performance evaluation.(table 3)

| Mix proportions | The characteristic of resin combination (molding) | |||||||||

| (A) | (B) | (C) | The melt viscosity pool | Add heat retention stability % | Fusion tension force g | Cantilever-type impact strength kgcm/cm | Tensile rupture elongation % | |||

| PBT | MEV and other resin | CP | CF | TBPB | ||||||

| Embodiment 11 | 100 | 20 MEV1 | 2.0 | - | 6540 | 99 | 23.6 | 49 | 195 | |

| Embodiment 12 | 100 | 10 MEV3 | 1.5 | - | 0.03 | 6950 | 105 | 24.1 | 13 | 183 |

| Embodiment 13 | 100 | 10 MEV4 | 1.5 | - | 0.03 | 5910 | 95 | 12.5 | 12 | 110 |

| Embodiment 14 | 100 | 10 MEV3 | 1.5 | 10 | 0.03 | 7570 | 101 | 22.6 | 13 | - |

| Comparative example 8 | 100 | - | - | - | - | 3100 | 40 | 0.1 | 2 | 195 |

| Comparative example 9 | 100 | - | 1.5 | - | 0.03 | 3200 | 45 | 3.6 | 3 | 52 |

| Comparative example 10 | 100 | 10 EV3 | 1.5 | - | - | 2800 | 38 | 1.5 | 5 | 26 |

| Comparative example 11 | 100 | 10 BF | 1.5 | 10 | 0.03 | 12900 | 49 | 21.0 | 8 | 125 |

The possibility of utilizing on the industry

Such as above detailed description, according to graft modification ethene-vinyl acetate copolymer of the present invention heat-resisting decomposability, and the adhesion characteristic of polar material and with the aspects such as compatibility of the engineering plastics classes such as polyamide or mylar be excellent, can be widely used in modification purposes, the polymer blend of various adhesive applications or various resins compatible improver purposes, can reach distinctive excellent effect.

In addition, among the present invention (A) polyamide and/or mylar and (B) resin combination that forms of graft modification ethene-vinyl acetate copolymer be excellent aspect the mechanical properties such as impact characteristics, rigidity, intensity, simultaneously, the balance of the physical property such as heat resistance and formability also is good, thereby can obtain being suitable for as the formed products such as various auto parts and components, mechanical part, electric component, electronic unit etc.

And then, (A) mylar among the present invention, (B) graft modification ethene-vinyl acetate copolymer and the resin combination that (C) is formed by the vinyl-based copolymer of glycidyl, aspect melting tension force, melt viscosity, melting characteristics such as stability when adding heat retention, be excellent, simultaneously, the balance of the physical property such as impact characteristics, formability also is good, can obtain being suitable for as such as the formed products of various parts, mechanical part, electric component, electronic unit etc. etc., thereby the present invention has reached excellent peculiar effect.

Claims (12)

1. graft modification ethene-vinyl acetate copolymer, it is a kind of aqeous suspension of preparation, wherein with respect to (a) vinyl-vinyl acetate copolymer 100 weight parts, contain the compound (b1) of (b) general formula (I) glycidyl that is shown with or the compound that glycidyl is arranged (b2) 0.1~50 weight part of forming by this compound (b1) and unsaturated glycidyl ester, (c) vinyl monomer 1~500 weight part, and become subtotaling 100 weight parts to contain (d) radical initiator 0.001~10 weight part with (c) with respect to (b) composition, make in this aqeous suspension (b) composition and (c) composition immerse in (a) composition, and make (b) composition and (c) composition be polymerized

Ar represents and the aromatic hydrocarbyl of at least one glycidoxypropyl bonded, 6~23 carbon atoms in the formula, and R represents hydrogen atom or methyl.

2. the described graft modification ethene-vinyl acetate copolymer of claim 1, wherein the vinyl-vinyl acetate copolymer of (a) composition is 0.1~500g/10 minute vinyl-vinyl acetate copolymer by ethene 50-99% (weight) and vinyl-acetic ester 50-1% (weight) constitutes, JIS K6370 measures melt flow rate (MFR).

4. any one described graft modification ethene-vinyl acetate copolymer in the claim 1~3 is a glycidyl methacrylate by unsaturated glycidyl ester compound that form, that contain glycidyl (b2) in (b) composition wherein.

5. claim 1 or 2 described graft modification ethene-vinyl acetate copolymers, wherein (b) composition is a compound 1~99% (weight) shown in the structural formula (II) and the mixture of glycidyl methacrylate 99~1% (weight).

6. any one described graft modification ethene-vinyl acetate copolymer in the claim 1~5, wherein the vinyl monomer of (c) composition is select from following composition one group at least a: aromatic ethenyl compound, the alkyl carbon atoms number is 1~22 a alkyl acrylate, the alkyl carbon atoms number is 1~22 a alkyl methacrylate, the alkyl carbon atoms number is 1~22 a vinyl alkyl ethers, vinyl alcohol, unsaturated nitrile compound, unsaturated amino compounds, the alkyl carbon atoms number is 1~9 a toxilic acid dialkyl, and the alkyl carbon atoms number is 1~8 an allyl group alkyl oxide, allyl acrylate, diolefin, maleic anhydride, toxilic acid, vinylformic acid, methacrylic acid, vinyl-acetic ester.

7. resin combination is become to be grouped into (B) by following (A) composition:

(A) polyamide resin and/or vibrin 100 weight parts;

(B) graft modification ethene-vinyl acetate copolymer 1~100 weight part, it is a kind of aqeous suspension of preparation, wherein with respect to (a) vinyl-vinyl acetate copolymer 100 weight parts, contain the compound (b1) of (b) general formula (I) glycidyl that is shown with or the compound that glycidyl is arranged (b2) 0.1~50 weight part of forming by this compound (b1) and unsaturated glycidyl ester, (c) vinyl monomer 1~500 weight part, and become subtotaling 100 weight parts to contain (d) radical initiator 0.001~100 weight part with (c) with respect to (b) composition, make in this aqeous suspension (b) composition and (c) composition immerse in (a) composition, and make (b) composition and (c) composition be polymerized

Ar represents and the aromatic hydrocarbyl of at least one glycidoxypropyl bonded, 6~23 carbon atoms in the formula, and R represents hydrogen atom or methyl.

8. resin combination is become to be grouped into (C) by following (A) composition, (B) composition:

(A) vibrin 100 weight parts;

(B) graft modification ethene-vinyl acetate copolymer 1~100 weight part, it is a kind of aqeous suspension of preparation, wherein with respect to (a) vinyl-vinyl acetate copolymer 100 weight parts, contain the compound (b1) of (b) general formula (I) glycidyl that is shown with or the compound that glycidyl is arranged (b2) 0.1~50 weight part of forming by this compound (b1) and unsaturated glycidyl ester, (c) vinyl monomer 1~500 weight part, and become subtotaling 100 weight parts to contain (d) radical initiator 0.001~100 weight part with (c) with respect to (b) composition, make in this aqeous suspension (b) composition and (c) composition immerse in (a) composition, and make (b) composition and (c) composition be polymerized

Ar represents and the aromatic hydrocarbyl of at least one glycidoxypropyl bonded, 6~23 carbon atoms in the formula, and R represents hydrogen atom or methyl.

(C) contain vinyl-based copolymer 0.1~20 weight part of glycidyl, its composition is at least a vinyl monomer 99~50% (weight) and the glycidyl methacrylate of selecting a group that forms from vinylbenzene, alpha-methyl styrene, vinyl cyanide, methyl methacrylate, butyl methacrylate, bromostyrene and phenyl maleimide 1~50% (weight).

9. the described resin combination of claim 7, wherein polyamide resin is polycaprolactam (nylon-6), poly hexamethylene adipamide-1,6-hexanediamine (nylon-66), poly-dodecane acid amides (nylon 12), poly hexamethylene adipamide-1,4-butanediamine (nylon-46), or its two or more mixture.

10. claim 7 or 8 described resin combinations, wherein vibrin is polyethylene terephthalate, polybutylene terephthalate or these mixture.

11. resin combination, wherein with respect to described resin combination 100 weight parts of claim 7~10, at least a filler 1~100 weight part of selecting a group that fusion is formed from silica, talcum, mica, glass fibre, granulated glass sphere, Hollow Glass Sphere, neutral clay class, carbon fiber, aromatic polyamide fibre, aromatic polyester fiber, vinylon fiber, carbonizedfibres, silicon carbide fiber, sapphire whisker, potassium titanate fiber, steel fiber.

12. resin combination, wherein add up to 100 weight parts with respect to the resinous principle in the described resin combination of claim 7~11, at least a fire retardant 1~50 weight part that fusion is selected from a group of following composition: tetrabromo-bisphenol, 2,2-two (4-hydroxyl-3, the 5-dibromo phenyl) propane, hexabromobenzene, isocyanuric acid three (2,3-dibromo propyl ester), 2, halogenated flame such as 2-two (4-hydroxy ethoxy-3,5-dibromo phenyl) propane, decabromodiphynly oxide, bromo polyphosphate, chloro polyphosphate, chloroparaffin; Phosphorus type flame retardants such as ammonium phosphate, tricresyl phosphate (hydroxy toluene ester), triethyl phosphate, tricresyl phosphate (chloroethene ester), tricresyl phosphate (β-chloroethene ester), tricresyl phosphate (dichloro propyl ester), phosphoric acid hydroxy toluene ester phenyl ester, xylenylphosphate diphenyl ester, acid phosphoric acid ester, nitrogenous phosphorus compound; Mineral-type fire retardants such as red phosphorus, stannic oxide, ANTIMONY TRIOXIDE SB 203 99.8 PCT, zirconium hydroxide, barium metaborate, aluminium hydroxide, magnesium hydroxide; Brominated Polystyrene, bromo be poly--and alpha-methyl styrene, bromo polycarbonate, bromo poly epoxy resin, chlorinated polyethylene, chloro be poly--polymer fire retardants such as alpha-methyl styrene, chlorinated polycarbonates, chloro poly epoxy resin.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 96190944 CN1163623A (en) | 1995-06-30 | 1996-06-26 | Graft ethylene-vinyl acetate copolymer and resin composition containing the same |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP188181/95 | 1995-06-30 | ||

| CN 96190944 CN1163623A (en) | 1995-06-30 | 1996-06-26 | Graft ethylene-vinyl acetate copolymer and resin composition containing the same |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN1163623A true CN1163623A (en) | 1997-10-29 |

Family

ID=5128176

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN 96190944 Pending CN1163623A (en) | 1995-06-30 | 1996-06-26 | Graft ethylene-vinyl acetate copolymer and resin composition containing the same |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN1163623A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109867917A (en) * | 2017-12-01 | 2019-06-11 | 江南大学 | A kind of toughness PET antimicrobial composite material and preparation method thereof |

-

1996

- 1996-06-26 CN CN 96190944 patent/CN1163623A/en active Pending

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109867917A (en) * | 2017-12-01 | 2019-06-11 | 江南大学 | A kind of toughness PET antimicrobial composite material and preparation method thereof |

| CN109867917B (en) * | 2017-12-01 | 2022-02-11 | 江南大学 | Tough PET (polyethylene terephthalate) antibacterial composite material and preparation method thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR101812934B1 (en) | Thermoplastic molding compounds based on styrene copolymers and polyamides having improved weathering resistance | |

| CN1247551A (en) | Tough reinforced polyesters with improved flow | |

| CN1376182A (en) | Process for improving the toughness of PCT formulations by adding rubber impact modifiers | |

| WO2007018201A1 (en) | Thermoplastic elastomer composition | |

| JP5915251B2 (en) | Curable resin composition and cured product thereof | |

| CN1137936C (en) | Impact-resistant thermoplastic resin composition | |

| CN1320054C (en) | Thermoplastic polyester resin composition and molded object obtained therefrom | |

| CN1125120C (en) | Thermoplastic resin composition contg. hard dispersion phase | |

| CN1182440A (en) | Grafted polyolefinic resin and composition thereof | |

| CN1182448A (en) | Molding resin composition | |

| EP0779307A1 (en) | Graft ethylene-vinyl acetate copolymer and resin composition containing the same | |

| CN1163623A (en) | Graft ethylene-vinyl acetate copolymer and resin composition containing the same | |

| CN1282679C (en) | Heat and oil resistant thermoplastic elastomer | |

| JPH0717826B2 (en) | Impact resistant polyester resin composition | |

| CN1130389A (en) | Thermoplastic polyester resin composition | |

| CN1111263A (en) | Graft-modified polyolefin resin composition and thermoplastic resin composition containing the same | |

| CN1020738C (en) | Polymer composition | |

| JP3309553B2 (en) | Glass fiber reinforced polyethylene terephthalate-based composition and injection-molded article comprising the same | |

| JP2542147B2 (en) | Polyamide resin composition with excellent impact resistance | |

| JP2583231B2 (en) | Impact resistant polyester resin composition | |

| CN1260290C (en) | Polystyrene resin composition for chip plastic card | |

| JP2022143428A (en) | Resin composition and molding | |

| CN1160408C (en) | Moulding compositions based on ABS polymerizates | |

| JPH09316291A (en) | Thermoplastic resin molding and its production | |

| JPH01306460A (en) | Thermoplastic molding compound |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C01 | Deemed withdrawal of patent application (patent law 1993) | ||

| WD01 | Invention patent application deemed withdrawn after publication |