CN115982837A - Multi-system coupling dynamics modeling method for multi-propeller tilt-wing rotor aircraft - Google Patents

Multi-system coupling dynamics modeling method for multi-propeller tilt-wing rotor aircraft Download PDFInfo

- Publication number

- CN115982837A CN115982837A CN202211459321.9A CN202211459321A CN115982837A CN 115982837 A CN115982837 A CN 115982837A CN 202211459321 A CN202211459321 A CN 202211459321A CN 115982837 A CN115982837 A CN 115982837A

- Authority

- CN

- China

- Prior art keywords

- wing

- coordinate system

- blade

- model

- nacelle

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 230000008878 coupling Effects 0.000 title claims abstract description 53

- 238000010168 coupling process Methods 0.000 title claims abstract description 53

- 238000005859 coupling reaction Methods 0.000 title claims abstract description 53

- 238000000034 method Methods 0.000 title claims abstract description 44

- 239000011159 matrix material Substances 0.000 claims description 40

- 239000013598 vector Substances 0.000 claims description 29

- 230000033001 locomotion Effects 0.000 claims description 15

- 238000013016 damping Methods 0.000 claims description 11

- 230000008569 process Effects 0.000 claims description 6

- 239000000284 extract Substances 0.000 claims description 3

- 238000004458 analytical method Methods 0.000 description 21

- 230000014509 gene expression Effects 0.000 description 17

- 238000006073 displacement reaction Methods 0.000 description 11

- 230000004044 response Effects 0.000 description 11

- 238000011160 research Methods 0.000 description 10

- 238000013461 design Methods 0.000 description 9

- 238000011161 development Methods 0.000 description 9

- 238000009795 derivation Methods 0.000 description 8

- 238000005516 engineering process Methods 0.000 description 8

- 238000004364 calculation method Methods 0.000 description 7

- 238000005452 bending Methods 0.000 description 3

- 230000008901 benefit Effects 0.000 description 3

- 238000006243 chemical reaction Methods 0.000 description 3

- 239000006185 dispersion Substances 0.000 description 3

- 230000001052 transient effect Effects 0.000 description 3

- 238000007664 blowing Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 230000005489 elastic deformation Effects 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 238000012360 testing method Methods 0.000 description 2

- 230000007704 transition Effects 0.000 description 2

- 230000009471 action Effects 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 230000007123 defense Effects 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

- 230000009466 transformation Effects 0.000 description 1

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T90/00—Enabling technologies or technologies with a potential or indirect contribution to GHG emissions mitigation

Landscapes

- Aerodynamic Tests, Hydrodynamic Tests, Wind Tunnels, And Water Tanks (AREA)

Abstract

The application provides a multi-system coupling dynamics modeling method for a multi-paddle tiltrotor wing aircraft, which comprises the following steps: step 1: establishing coordinate systems of all systems and relations among the coordinate systems; step 2: establishing an aerodynamic model according to a machine body coordinate system, a wing deformation coordinate system and a blade deformation coordinate system; and step 3: establishing a high aspect ratio wing dynamic model according to a wing deformation coordinate system; and 4, step 4: according to the undeformed coordinate system of the wing, establishing a nacelle kinetic model; and 5: according to the blade deformation coordinate system, a rotor wing dynamic model is established; step 6: and establishing a multi-propeller/nacelle/high-aspect-ratio wing coupling system kinetic equation according to the high-aspect-ratio wing kinetic model, the nacelle kinetic model and the rotor wing kinetic model.

Description

Technical Field

The invention belongs to a helicopter dynamics modeling and analyzing technology, and particularly relates to a multi-system coupling dynamics modeling method for a multi-propeller/tilt-wing rotorcraft.

Background

The limitation of maximum flight speed of helicopters of conventional configuration has increasingly become a barrier to their greater role in war. In recent years, along with the rise of comprehensive national strength of China and the continuous promotion of development advocates of 'one-by-one' in China, the 'frontier-frontier' of national safety and benefits is greatly expanded, and the military protection capability construction requirement that the conventional configuration helicopter is low in speed and short in range and cannot meet the future safety and benefits of China is increasingly highlighted. The high speed and the long distance are the inevitable trend of the development of the future rotor craft, and are effective ways for improving the comprehensive strength of China and the fighting capacity of our army. Therefore, the development of high-speed, long-range rotorcraft is imperative.

The high-speed rotor aircraft is a novel structure rotor aircraft which breaks through the speed limit of the conventional helicopter structure and reaches the speed of more than 400 kilometers per hour. Its main features are high speed and high battle efficiency. The united states, europe, and russia have been devoting tremendous enthusiasm to research into high-speed gyroplanes and have made various degrees of progress. In a report of technical and innovation for supporting 2030 superiority, issued by the national defense science committee (DSB) in 2013, the high-speed rotorcraft is listed as one of the best choices for keeping the military superiority of the U.S. army in the future, which is also the first future development direction for the U.S. army to clarify the rotorcraft after the 21 st century.

The multi-propeller/tilt-wing rotor aircraft comprehensively utilizes concepts of distributed rotors and tilt wings, the aerodynamic layout adopts the tilt-wing layout, a plurality of rotor units driven in a distributed mode are distributed on front and rear wings, the configuration has vertical take-off and landing, fixed-point hovering and high-speed forward flying capabilities, the flying speed and the operational radius can be improved by more than one time compared with those of a conventional helicopter, and the multi-propeller/tilt-wing rotor aircraft is one of important development directions of future high-speed new-configuration rotor aircraft. Research institutions such as NASA, boeing, france airbus and the like in the united states begin to lay out and occupy space in advance, a great deal of advance research work is carried out on the aircraft with the configuration, and major stage breakthrough is obtained successively. The dynamic design technology in the core technology of the multi-paddle/tilt wing rotor aircraft is key, the existing basic of the multi-paddle/tilt wing rotor aircraft in China is weak in the aspect of the dynamic design technology, and relevant basic research needs to be urgently developed to master the mechanism and the rule of aeroelastic coupling dynamics.

Disclosure of Invention

The technical problems to be solved by the invention are as follows: the method is used for modal analysis and stability analysis of coupling systems of multi-propeller/tilt-wing rotor aircrafts, tilt-rotor aircrafts, distributed high-speed rotorcrafts and other aircrafts, can be used for aeroelastic response analysis of the aircrafts, and provides key technical support for developing model design and modification development.

The technical scheme is as follows: a multi-system coupling dynamics modeling method for a multi-rotor/tiltrotor rotorcraft, the method comprising:

step 1: establishing coordinate systems of all systems and relations among the coordinate systems;

step 2: establishing an aerodynamic model according to a machine body coordinate system, a wing deformation coordinate system and a blade deformation coordinate system;

and step 3: establishing a high aspect ratio wing dynamic model according to a wing deformation coordinate system;

and 4, step 4: establishing a nacelle dynamic model according to an undeformed wing coordinate system;

and 5: according to the blade deformation coordinate system, a rotor wing dynamic model is established;

step 6: and establishing a multi-propeller/nacelle/high-aspect-ratio wing coupling system kinetic equation according to the high-aspect-ratio wing kinetic model, the nacelle kinetic model and the rotor wing kinetic model.

Further, step 1 specifically includes:

establishing a relation among an inertia coordinate system, a body coordinate system, a wing undeformed coordinate system, a wing deformed coordinate system, a hub non-rotating coordinate system, a hub rotating coordinate system, a blade undeformed coordinate system, a blade deformed coordinate system and the coordinate systems of the coordinate systems.

Further, step 3 comprises:

Step 34: according to the virtual deformation energy U of the wing w Wing, wing virtual kinetic energy T w And wing external force virtual work W w And constructing a dynamic model of the wing with high aspect ratio

Further, step 5 comprises:

Further, step 4 comprises:

according to the undeformed coordinate system of the wing, using a formulaEstablishing a nacelle kinetic model; and extracts the quality matrix of the nacelle, based on the comparison of the value of the reference value>

Further, step 6 comprises:

establishing a multi-propeller/nacelle/high-aspect-ratio wing coupling system kinetic equation according to the high-aspect-ratio wing kinetic model, the nacelle kinetic model and the rotor kinetic model

Further, step 2 comprises:

establishing an aerodynamic model of the wing according to the wing deformation coordinate system;

and establishing an aerodynamic model of the body according to a body coordinate system.

Further, step 2 comprises:

establishing a blade model according to a blade deformation coordinate system; and then, according to the blade model and the relation between the coordinate systems of the hub rotation coordinate system and the blade deformation coordinate system, the aerodynamic force model of the rotor wing is established by summing the blade number.

The invention has the beneficial effects that: the invention discloses a multi-system coupling dynamics modeling method for a multi-propeller/tilt-wing rotor aircraft, which is used for establishing a multi-propeller/nacelle/high aspect ratio wing coupling system dynamics equation aiming at the characteristics of the dynamics problem of the multi-propeller/tilt-wing rotor aircraft. The modeling method can be applied to the fundamental research of dynamics such as modal analysis, stability analysis and aeroelastic response analysis of a multi-propeller/tilt-wing rotor aircraft coupling system, and can also be directly popularized to aeroelastic coupling stability design analysis of various advanced rotor aircrafts, tilt-rotor aircrafts, distributed high-speed rotor aircrafts and the like.

Drawings

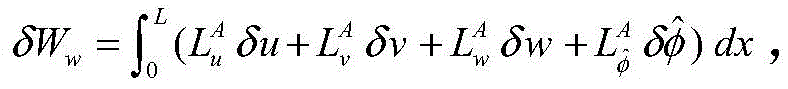

Figure 1 is a wing to rotor hub coordinate system to which the present invention relates;

FIG. 2 is a schematic view of a flexible wing according to the present invention;

FIG. 3 is a schematic aerodynamic view of a section of an airfoil according to the invention;

FIG. 4 is a schematic view of a nacelle configuration to which the present invention relates;

FIG. 5 is a blade unit and node distribution diagram according to the present invention;

fig. 6 is a schematic diagram of the distribution of degrees of freedom of the blade according to the present invention.

Detailed Description

In order to maintain excellent vertical take-off and landing and hovering performances of the multi-paddle/tilt-wing rotor craft, and simultaneously break through the speed limit of a helicopter with a traditional configuration, high-speed flight (up to 600 km/h) is realized, the multi-paddle/tilt-wing configuration comprehensively utilizes the advantages of various technologies, but at the same time, inherent problems and defects of various technologies are inevitably inherited, and new problems are generated even after the multi-paddle/tilt-wing rotor craft is synthesized. The aeroelastic instability and the overhigh vibration generated by the coupling of the distributed multi-propeller and the high-aspect-ratio wing are key dynamic problems to be faced by the multi-propeller tilt rotor aircraft, in particular to the problems of transient aeroelastic response/load in the wing tilt transition process, the rotation flutter stability in the high-speed forward flight axial flow state and the like.

The multi-propeller/tilt wing rotor craft adopts a high aspect ratio wing design, the wing structure is obviously deformed, meanwhile, concentrated loads and concentrated mass/inertia caused by distributed multi-propeller exist on the wing, and the multi-propeller/tilt wing rotor craft has complex aerodynamic/elastic/inertial coupling characteristics in a transition state and a high-speed forward flight state. As a new configuration type rotor aircraft, the research work of related coupling dynamics is basically blank aiming at a multi-paddle/tilt wing rotor aircraft and a similar tilt rotor aircraft. Therefore, a theoretical calculation method is researched aiming at the problem of complex aeroelastic coupling dynamics between the multi-propeller and high-aspect-ratio tilting wings, modal characteristics, aeroelastic response and stability characteristics of different flight states of the multi-propeller and high-aspect-ratio tilting wings are mastered, and the method is of great importance to the dynamic design of the multi-propeller/tilting wing rotor aircraft. However, the research on the aeroelastic coupling dynamics of the multi-propeller/tilt-rotor wing solves the basic performance problems of the coupling modal characteristics, the motion characteristics and the like of the structural large deformation wing and the distributed multi-propeller, and the method is carried out on the basis of mastering multi-system coupling dynamics modeling methods of the multi-propeller and tilt-rotor wing and the like, and has important significance for the development of the high-speed rotor aircraft dynamics design technology of the multi-propeller tilt-rotor configuration.

The research technical result has wide application prospect, has profound influence on the technical development of the high-speed rotor craft in China, strongly supports the development of the advanced high-speed rotor craft in China, has great significance, and can be directly popularized and applied to the aeroelastic coupling stability design analysis of various advanced rotor craft, tilt rotor aircraft, distributed high-speed rotor craft and the like. The basic research of the multi-propeller/tilt-wing rotor aircraft dynamics has wide market space and application prospect, and the multi-system coupling dynamics modeling method of the multi-propeller/tilt-wing rotor aircraft has the important function.

Example one

The technical scheme of the invention is as follows: firstly, describing the motion of a rotor, a wing and a nacelle in different coordinate systems, respectively establishing a finite element model of the structure dynamics of an isolated rotor blade, an elastic wing and the nacelle, and adopting a quasi-constant or constant aerodynamic model to model the aerodynamic force. Based on a medium deformation beam theory and a quasi-steady/non-steady aerodynamic model, a rotor blade kinetic equation, a nacelle kinetic equation and an elastic wing kinetic equation are established through a Hamilton variational principle, the equations are subjected to space dispersion by adopting a finite element method, a matrix dimension is expanded according to the number of degrees of freedom, matrix elements corresponding to the degrees of freedom of the same node are superposed to obtain a multi-paddle/nacelle/high-aspect-ratio wing coupling system kinetic equation, and a method for solving a stability model is provided.

The application provides a multi-system coupling dynamics modeling method for a multi-paddle/tilt wing rotorcraft, which comprises the following steps:

step 1: and establishing coordinate transformation relations among coordinate systems of the systems and among the coordinate systems.

The system coordinate system comprises an inertia coordinate system, a body coordinate system, a wing undeformed coordinate system, a wing deformed coordinate system, a hub non-rotating coordinate system, a hub rotating coordinate system, a blade undeformed coordinate system and a blade deformed coordinate system.

Step 2: and establishing an aerodynamic model.

Because the coupling stability and the aeroelastic response of the multi-paddle/nacelle/high-aspect-ratio wing coupling system are related to aerodynamic force, different aerodynamic force models need to be considered for different dynamics analysis, and a quasi-steady aerodynamic force model, an unsteady aerodynamic force model, a dynamic inflow model and an ONERA model are adopted for aerodynamic force calculation of a rotor, and the three models can be comprehensively applied to more accurately calculate aerodynamic load in stability analysis, dynamic response analysis and transient response analysis. A blowing test model is adopted for aerodynamic force calculation of the engine body, the horizontal tail, the vertical tail and the tilt wing due to the influence of rotor wing downwash.

And 3, step 3: and establishing a dynamic model of the high aspect ratio wing.

The multi-propeller tilting high-aspect-ratio wing considers elastic deformation, is described by adopting a beam model, the root part of the wing is connected to a fuselage through a tilting hinge, a plurality of rigid-body nacelles are distributed on the wing, the movement of the wing is superposed by bending and twisting of an elastic shaft, the wing model is established by adopting a medium-deformation beam theory, the virtual deformation energy, the virtual kinetic energy and the external virtual work of the high-aspect-ratio wing are established, and the dynamic equation of the elastic wing is deduced.

And 4, step 4: and establishing a nacelle kinetic model.

The nacelle-power device is rigidly connected to the elastic wing, and a plurality of rigid nacelles are distributed and mounted on the elastic wing structure, which is equivalent to the existence of multi-point mass and inertia, neglects the influence of aerodynamic resistance and only considers kinetic energy. And obtaining a velocity vector through a space position vector of any point on the nacelle, finally obtaining virtual kinetic energy of the nacelle through integration, and deducing a nacelle kinetic equation.

And 5: and (4) establishing a rotor wing dynamic model.

For a rotor system of a multi-paddle/tilt wing rotor aircraft, a rotor dynamic model considering the movement influence of an elastic wing is established based on the Hamilton variation principle. The paddle adopts a 15-degree-of-freedom nonlinear medium-deformation beam unit, elastic motions such as flapping, shimmy, torsion and axial stretching are considered, and the paddle deforms along an elastic shaft at any section r in the unfolding direction: axial displacement u, shimmy direction displacement v, flapping direction displacement w and torsional deformation phi, and structural and inertial coupling thereof, calculating blade virtual deformation energy, virtual kinetic energy and aerodynamic virtual work, and deriving a rotor kinetic equation.

Step 6: and (3) derivation of a dynamic equation of a multi-paddle/nacelle/high-aspect-ratio wing coupling system.

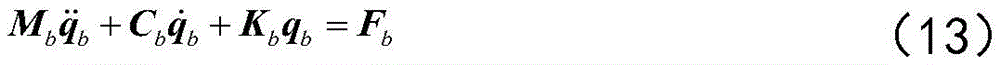

According to a dynamic model of a wing, a nacelle and a rotor system, a Hamilton principle is adopted, mass damping rigidity matrixes of the rotor system, the nacelle and an elastic wing are assembled into a multi-system coupling model, force vectors of the rotor and the wing corresponding to the degree of freedom are assembled into force vectors of multi-system coupling, and then a dynamic equation of the rotor/nacelle/wing coupling system model can be obtained. Converting the coupling dynamic equation into a state equation, solving the characteristic value of the state equation by adopting a characteristic value method, wherein the real part of the characteristic value represents the damping of the system, and the imaginary part represents the frequency of the system. And the stability of the coupling system can be judged according to the real part of the characteristic value.

Example two

The multi-system coupling dynamics modeling method of the multi-rotor/tilt-wing rotorcraft according to the present invention is further described in detail with reference to the accompanying drawings.

Step 1: establishing coordinate systems of each system and the relationship between the coordinate systems.

The system coordinate system comprises an inertial coordinate system, a fuselage coordinate system, a wing undeformed coordinate system, a wing deformed coordinate system, a hub non-rotating coordinate system, a hub rotating coordinate system, a blade undeformed coordinate system and a blade deformed coordinate system.

To facilitate the description of the spatial position and kinematic deformations of the wings, nacelle and rotating blades, a series of reference coordinate systems need to be established. Establishing the relationship between the coordinate systems of the systems as follows: the system comprises an inertial coordinate system, a body coordinate system, a wing undeformed coordinate system, a wing deformed coordinate system, a hub non-rotating coordinate system, a hub rotating coordinate system, a blade undeformed coordinate system and a blade deformed coordinate system. The coordinate system of the wing and the rotor hub is shown in figure 1, and the coordinate (O) is defined on the tilting axis of the undeformed wing i ,X i ,Y i ,Z i Denoted with the index i below. The coordinate system of the deformed wing is { O } w ,X w ,Y w ,Z w And the deformation angle of the three directions is different from the undeformed coordinate system and is marked by the following mark w. Wing forward tilting alpha around tilting axis p Angle, defining a helicopter mode tilt angle of 0 °. A rotor hub coordinate system defined at the center of the universal hinge as { O } H ,X H ,Y H ,Z H H, identified below with the index h. The rotational coordinate system is { O } r ,X r ,Y r ,Z r And, rotating psi azimuth angle relative to the hub coordinate system Kh axis, denoted by the subscript r. Marking a lower standard beta mark of a blade flapping coordinate system, and offsetting a flapping hinge relative to the center of a hub by e β There is a motion beta flap angle. Zeta mark and offset e under the pendulum-vibration coordinate system βζ There is a motion zeta shimmy angle. The method for establishing the coordinate system of the deformation and the non-deformation of the wing and the coordinate system conversion relation refer to the method for establishing the coordinate system of the deformation and the non-deformation of the blade of the conventional helicopter and the coordinate system conversion relation. The establishment of other coordinate systems and the coordinate system conversion relation are consistent with the conventional helicopter.

Step 2: and establishing an aerodynamic model according to the body coordinate system, the wing deformation coordinate system and the blade deformation coordinate system.

Specifically, the step 2 comprises the steps of establishing an aerodynamic model of the wing according to a wing deformation coordinate system; establishing a blade model according to a blade deformation coordinate system; then, according to the blade model and the relation between the coordinate systems of the hub rotation coordinate system and the blade deformation coordinate system, the aerodynamic force model of the rotor wing is established by summing the blade number; and establishing a pneumatic force model of the machine body according to a machine body coordinate system.

Because the coupling stability and aeroelastic response of the multi-propeller/nacelle/high-aspect-ratio wing coupling system are related to aerodynamic force, different aerodynamic force models need to be considered for different dynamic analysis, and a quasi-steady aerodynamic force model, an unsteady aerodynamic force model, a dynamic inflow model and an ONERA model are adopted for aerodynamic force calculation of the rotor, and the three models can be comprehensively applied to more accurately calculate aerodynamic load in stability analysis, dynamic response analysis and transient response analysis. A blowing test model is adopted for aerodynamic force calculation of the engine body, the horizontal tail, the vertical tail and the tilt wing due to the influence of rotor wing downwash.

And step 3: and establishing a high aspect ratio wing dynamic model according to the wing deformation coordinate system.

The multi-propeller tilting high-aspect-ratio wing considers elastic deformation, is described by a beam model, the root part of the wing is connected to a fuselage through a tilting hinge, a plurality of rigid-body nacelles are distributed on the wing, and the schematic view of the wing is shown in figure 2. Wing chord length of c w Half span length of y TW And ep is the offset between the mounting position of the tilting hinge and the elastic shaft of the wing. The movement of the wing is superimposed by the bending and torsion of the elastic shaft. The method comprises the steps of establishing a wing model by adopting a medium deformation beam theory, establishing virtual deformation energy, virtual kinetic energy and external virtual work of the wing with a large aspect ratio, and deducing an elastic wing kinetic equation.

Specifically, step 3 includes:

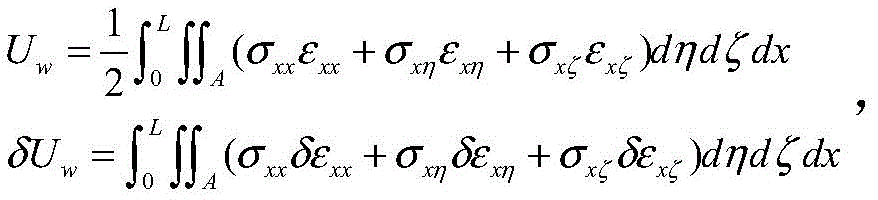

The elastic wing model is built by adopting the medium deformation beam theory, namely, assuming that the wing is an anisotropic beam, medium deformation and small strain are generated, and the method is based on the principle thatStress, strain of wing and elastic modulus constant Q of its material ij The relation between the two can obtain the deformation energy of the wing after integrating along the section and the spanwise direction of the wing, and the corresponding virtual deformation energy can be obtained by solving the variation of the deformation energy, and the expression form is as follows:

The kinetic energy of the wing depends on the speed of the wing itself, and the expression and corresponding variation thereof are:

speed of any point on the wingDepending on the time derivative of the position vector of the point in the inertial system. The radial position of the wing x and the displacement of the section of the wing x are defined as { x + u, v, w }, wherein ue, v, w correspond to the radial, chordwise and vertical displacements of the wing section; the third part is the position vector of any point in the section under the coordinate system of the morphing wing, and the position vector is defined as {0, eta, zeta }. And (3) deriving the speed of any point of the wing under the body coordinate system by deriving the position vector of any point on the wing under the body coordinate system, and substituting the speed expression into the wing kinetic energy variational expression (2) to obtain the virtual kinetic energy of the wing.

Compared with the complex unsteady aerodynamic environment of a rotor wing, the aerodynamic environment of the wing is much simpler, so that the aerodynamic load blade unsteady aerodynamic model for describing the section of the wing by adopting a quasi-steady aerodynamic model adopts a lifting line theory, the aerodynamic force action point of the quasi-steady aerodynamic model is at the quarter chord length, and the aerodynamic load on the wing section is calculated by using the air flow speed at the quarter chord length. The aerodynamic profile of the airfoil is shown in figure 2.

To calculate the aerodynamic load of the airfoil section, the relative velocity V of the airfoil section and the air is obtained from the forward flight velocity V W And velocity V caused by elastic movement of wing b And (4) forming. Obtaining the velocity vector V of any point on the wing according to the derivation of the displacement vector of any point on the wing under the body coordinate system to the time b The method can obtain the incoming flow velocity of the wing section under a deformed wing coordinate system by combining the forward flying speed, can derive and obtain wing aerodynamic force and moment according to a force and moment equation, and can derive wing aerodynamic virtual work under an undeformed wing coordinate system according to a coordinate system relationship, wherein the expression is as follows:

step 34: according to the virtual deformation energy U of the wing w Virtual kinetic energy T of wing w And wing external force virtual work W w Building dynamic model of high aspect ratio wing

And (4) derivation of dynamic equations of the elastic wing. According to the distribution of the lifting propellers and the thrust propellers on the wing and the calculation efficiency, the wing is divided into four sections of space beam units, and the wing unit matrix is assembled according to a finite element method, so that the mass matrix, the damping matrix, the rigidity matrix and the force vector of the whole wing can be obtained.

After discretization, the variation expression of the wing energy is as follows:

wherein q is w Is the total degree of freedom vector, M, of the wing w 、C w And K w Respectively, mass, damping and stiffness matrix of the wing, F w Is the load vector. .

And 4, step 4: according to the undeformed coordinate system of the wing, using a formulaEstablishing a nacelle kinetic model; and extracts the quality matrix of the nacelle, based on the comparison of the value of the reference value>

The nacelle-power device of the multi-propeller tiltrotor aircraft is rigidly connected to the flexible wing, the configuration of the nacelle-power device is shown in fig. 4, a plurality of rigid nacelles are distributed and mounted on the flexible wing structure, namely, multipoint mass and inertia exist, the influence of aerodynamic resistance is ignored, and only the influence of kinetic energy is considered, so that the nacelle part only contributes to a mass matrix of the system. The method comprises the steps of establishing a nacelle model, firstly converting a space position vector of any point on the nacelle into an inertial coordinate system, then obtaining a first derivative of time to obtain a velocity vector, and finally obtaining the virtual kinetic energy of the nacelle through volume division.

According to the basic theory of multi-body dynamics, the vector of any position of the distributed nacelle under the undeformed coordinate system of the wing can be obtained, and the velocity vector is derived, so that the virtual kinetic energy of the nacelle can be obtained:

extracting a quality matrix of the nacelle:

wherein q is i Representing the nacelle freedom of motion. Calculating structural characteristic parameters of a rigid nacelle in the multi-propeller tilt rotor aircraft to form a 6 x 6 mass matrix, and coupling the nacelle mass matrix to a total mass matrix of the wing according to the distribution of the nacelle on the wing so as to analyze the influence of multi-point suspension on the structural mode of the wing with a large aspect ratio.

And 5: and establishing a rotor wing dynamic model according to the blade deformation coordinate system.

For a rotor system of a multi-paddle/tilt wing rotor aircraft, a rotor dynamic model considering the movement influence of an elastic wing is established based on the Hamilton variation principle. The paddle adopts a 15-degree-of-freedom nonlinear medium-deformation beam unit, elastic motions such as flapping, shimmy, torsion and axial stretching are considered, and the paddle deforms along an elastic shaft at any section r in the unfolding direction: axial displacement u, shimmy direction displacement v, flapping direction displacement w and torsional deformation phi, and structural and inertial coupling thereof, calculating blade virtual deformation energy, virtual kinetic energy and aerodynamic virtual work, and deriving a rotor kinetic equation.

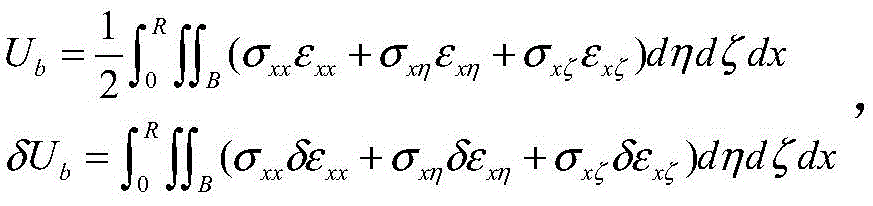

The derivation process is consistent with the derivation process of the virtual deformation energy of the wings, and the elastic blade model is established by adopting the medium deformation beam theory, namely, the blade is assumed to be an anisotropic beam, medium deformation and small strain are generated, and the stress and the strain of the blade and the elastic modulus constant Q of the material of the blade are determined according to the stress and the strain of the blade ij The relation between the two is integrated along the section and the span direction of the blade, so that the deformation energy of the blade can be obtained, and the variation of the deformation energy is obtained to obtain the corresponding virtual deformation energy, wherein the expression form is as follows:

The derivation process is also consistent with the derivation process of the virtual kinetic energy of the wing, the kinetic energy of the blade depends on the speed of the blade, and the expression and the corresponding variation are as follows:

speed of any point on the bladeDepending on the time derivative of the position vector of the point in the inertial system. The radial position of the blade x and the displacement of the section of the blade x are defined as { x + u, v, w }, wherein ue, v, w correspond to the radial, chordal and vertical displacements of the blade section; the third part is the position vector of any point in the section under the coordinate system of the deformed blade, and the position vector is defined as {0, eta, zeta }. And (3) obtaining the speed of any point of the blade under the body coordinate system by deducing the position vector of any point of the blade under the body coordinate system and carrying out time derivation, and substituting the speed expression into the blade kinetic energy variational expression (2) to obtain the blade virtual kinetic energy.

And (5) establishing an aerodynamic model according to the second step. For rotor aerodynamic force calculation, a quasi-stationary aerodynamic force model, an unsteady aerodynamic force model, a dynamic inflow model or an ONERA model are adopted, blade aerodynamic force is built, and aerodynamic force virtual work of the blades can be obtained according to the aerodynamic load of each section of the blades multiplied by the virtual displacement of the section and integrated along the whole blades. The aerodynamic virtual work expression on the single blade is as follows:

After finite element dispersion of the blade, the dimensionless energy expression is as follows:

and substituting the expressions of the virtual deformation energy, the virtual kinetic energy and the external virtual work into the above expression to obtain the discretized aeroelastic equation of motion of the blade.

The blade is divided into several medium deformation beam units, each unit containing 15 degrees of freedom, as shown in fig. 5. Each cell has 2 outer nodes and 3 inner nodes, each external node contains 6 degrees of freedom, which in turn is: u, v ', w'),The inner node has only one degree of freedom, wherein the central node of the unit is the torsional degree of freedom, and the node at the trisection point of the unit is the axial deformation degree of freedom.

For the ith beam unit, shape function interpolation is utilized, and any point x in the ith beam unit is i Can be expressed as:

wherein s = x i /l i ,l i Is the unit length. H is the shape function of the degree of freedom of the unit flapping and shimmy bending, H u Andis a form function of the axial stretch and torsion degrees of freedom. q. q.s i Total degree of freedom column vector for a single cell:

will delta U i -δT i -δW i Written as a matrix expression:

wherein M is i 、C i And K i Sequentially setting mass, damping and rigidity matrixes of the ith unit, wherein the mass, damping and rigidity matrixes are linear matrixes; f i Is a phaseThe corresponding load vector includes linear and non-linear portions.

Assuming that the blade is divided into five units, the degrees of freedom of the single blade are numbered as shown in fig. 6. The whole blade has 51 degrees of freedom. After discretization, the expression of the blade energy variation is as follows:

the boundary conditions of equation (12) vary from blade root connection form to blade root connection form. Setting corresponding boundary conditions according to the dispersed energy expression, and obtaining the aeroelastic differential equation of the single blade:

to N b And summing the blade blades to obtain a dynamic equation of a pair of rotors.

Step 6: establishing a multi-propeller/nacelle/high-aspect-ratio wing coupling system kinetic equation according to the high-aspect-ratio wing kinetic model, the nacelle kinetic model and the rotor kinetic model

After an elastic wing kinetic equation, a nacelle kinetic equation and a rotor blade kinetic equation are established, a half-span multi-propeller/high-aspect-ratio wing coupling system kinetic matrix equation can be obtained according to the Hamilton energy principle.

M of rotor system b 、C b 、K b 、F b M of matrix and nacelle p And M of a flexible wing w 、C w 、K w 、F w And performing matrix grouping to obtain M, C, K and F matrixes of the rotor/nacelle/wing coupling system model. The grouping mode is to expand the matrix dimension according to the number of the degrees of freedom and superpose the matrix elements corresponding to the degrees of freedom of the same node to obtain the quality moment of the whole modelThe array, the damping matrix and the rigidity matrix adopt the same mode for the force vector, and the force vector of the rotor wing system and the force vector of the wing correspond to the degree of freedom group set to obtain the force vector of the half-spread model rotor wing/wing coupling system.

Expressing the dynamic equation of the half-span multi-paddle/high-aspect-ratio wing coupling system model in a matrix form as follows:

wherein the degree of freedom q is as follows:

q={u w1 、v w1 、v' w1 、w w1 、w' w1 、φ w1 、…、v wn 、v' wn 、w wn 、w' wn 、

φ wn 、u bm 、v bm 、v' bm 、w bm 、w' bm 、φ bm } (15)

in the above formula, the subscripts n and m denote the number of discrete elements of the wing and blade, respectively.

Converting the coupling dynamic equation into a state equation, solving the characteristic value of the state equation by adopting a characteristic value method, wherein the real part of the characteristic value represents the damping of the system, and the imaginary part represents the frequency of the system. And the stability of the coupling system can be judged according to the real part of the characteristic value.

In summary, the present application provides a multi-system coupling dynamics modeling method for a multi-rotor/tilt-wing rotorcraft, and belongs to the helicopter dynamics modeling and analysis technology. Aiming at the characteristics of the dynamics problem of a multi-propeller/tilt wing rotor wing aircraft, the motions of a rotor wing, a wing and a nacelle are described in different coordinate systems, a finite element model of the structure dynamics of an isolated rotor wing blade, an elastic wing and the nacelle is respectively established, and a quasi-constant or non-constant aerodynamic model is adopted to model the aerodynamic force. Based on a medium deformation beam theory and a quasi-constant/non-constant aerodynamic model, a rotor blade kinetic equation, a nacelle kinetic equation and an elastic wing kinetic equation are established through a Hamilton variational principle, the equations are subjected to space dispersion by adopting a finite element method, the matrix dimension is expanded according to the number of degrees of freedom, and matrix elements corresponding to the degrees of freedom of the same node are superposed to obtain a multi-paddle/nacelle/high-aspect-ratio wing coupling system kinetic equation. And finally, solving the characteristic value through a characteristic value method, and judging the stability of the coupling system through characteristic value solution. The modeling method can be applied to fundamental dynamics researches such as mode analysis, stability analysis and aeroelastic response analysis of a multi-propeller/tilt-wing rotor craft, and can also be directly popularized to aeroelastic coupling stability design analysis of various advanced rotor crafts, tilt-rotor aircrafts, distributed high-speed rotor aircrafts and the like.

Claims (8)

1. A multi-system coupling dynamics modeling method for a multi-paddle tiltrotor rotor aircraft is characterized by comprising the following steps:

step 1: establishing coordinate systems of all systems and relations among the coordinate systems;

step 2: establishing an aerodynamic model according to a machine body coordinate system, a wing deformation coordinate system and a blade deformation coordinate system;

and step 3: establishing a high aspect ratio wing dynamic model according to a wing deformation coordinate system;

and 4, step 4: establishing a nacelle dynamic model according to an undeformed wing coordinate system;

and 5: according to the blade deformation coordinate system, a rotor wing dynamic model is established;

step 6: and establishing a multi-propeller/nacelle/high-aspect-ratio wing coupling system kinetic equation according to the high-aspect-ratio wing kinetic model, the nacelle kinetic model and the rotor wing kinetic model.

2. The method according to claim 1, wherein step 1 specifically comprises:

establishing a relation among an inertia coordinate system, a body coordinate system, a wing undeformed coordinate system, a wing deformed coordinate system, a hub non-rotating coordinate system, a hub rotating coordinate system, a blade undeformed coordinate system, a blade deformed coordinate system and the coordinate systems of the coordinate systems.

3. The method of claim 2, wherein step 3 comprises:

step 31: using formulasCalculating to obtain the virtual deformation energy U of the wing W Wherein A is the cross-sectional area of the airfoil, L is the span length of the airfoil, σ xx For axial stress, σ xη And σ xζ For engineering shear stress,. Epsilon xx For axial strain,. Epsilon xη And ε xζ Engineering shear strain;

step 32: using formulasCalculating to obtain the virtual kinetic energy T of the wing w Where ρ is w Is wing mass density, V w The speed of any point on the wing;

step 33: using formulasCalculating the external force virtual work W of the wing w Wherein, in the process,for external loads on an undeformed flexible shaft along the wing>Is the moment along the undeformed elastic axis of the wing;

step 34: according to the virtual deformation energy U of the wing w Virtual kinetic energy T of wing w And wing external force virtual work W w And constructing a dynamic model of the wing with high aspect ratioWherein N is w Total number of wing elements, q w Is the column vector of total degrees of freedom of the wing, M w 、C w 、K w 、F w The matrix is a total mass matrix, a damping matrix, a rigidity matrix and a force matrix of the wing.

4. The method of claim 2, wherein step 5 comprises:

step 51: using formulasCalculating blade virtual deformation energy U b Wherein R is the radius of the blade, and B is the section area of the blade;

step 52: using a formulaCalculating blade virtual kinetic energy T b Where ρ is s The mass density of the blade is shown, and V is the speed of any point on the blade; />

Step 53: using formulasCalculating blade aerodynamic virtual work W b Wherein S and T are external force loads along the non-deformed elastic axis of the blade in the lateral direction and the vertical direction respectively, and M is φa Is the moment along the undeformed elastic axis of the blade;

5. The method of claim 1, wherein step 4 comprises:

according to the undeformed coordinate system of the wing, using a formulaEstablishing a nacelle kinetic model; and extracts the quality matrix of the nacelle, based on the comparison of the value of the reference value>Where ρ is p Denotes the bulk density of the nacelle, V denotes the volume of the nacelle, V pi Representing the speed of any point on the nacelle, q i Representing the degree of freedom of movement of the nacelle, M pi A nacelle quality matrix is represented.

6. The method of claim 1, wherein step 6 comprises:

establishing a multi-propeller/nacelle/high-aspect-ratio wing coupling system kinetic equation according to the high-aspect-ratio wing kinetic model, the nacelle kinetic model and the rotor kinetic modelWherein q is the total degree of freedom of the system, and M, C, K and F are respectively a total mass matrix, a damping matrix, a rigidity matrix and a force matrix of the system.

7. The method of claim 2, wherein step 2 comprises:

establishing an aerodynamic model of the wing according to the wing deformation coordinate system;

and establishing a pneumatic force model of the machine body according to a machine body coordinate system.

8. The method of claim 2, wherein step 2 comprises:

establishing a blade model according to a blade deformation coordinate system; and then, according to the blade model and the relation between the coordinate systems of the hub rotation coordinate system and the blade deformation coordinate system, the aerodynamic force model of the rotor wing is established by summing the blade number.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211459321.9A CN115982837A (en) | 2022-11-17 | 2022-11-17 | Multi-system coupling dynamics modeling method for multi-propeller tilt-wing rotor aircraft |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211459321.9A CN115982837A (en) | 2022-11-17 | 2022-11-17 | Multi-system coupling dynamics modeling method for multi-propeller tilt-wing rotor aircraft |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115982837A true CN115982837A (en) | 2023-04-18 |

Family

ID=85965418

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211459321.9A Pending CN115982837A (en) | 2022-11-17 | 2022-11-17 | Multi-system coupling dynamics modeling method for multi-propeller tilt-wing rotor aircraft |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115982837A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN118194447A (en) * | 2024-05-20 | 2024-06-14 | 浙江大学 | Structural design optimization method and system for tilting duct aircraft wing |

-

2022

- 2022-11-17 CN CN202211459321.9A patent/CN115982837A/en active Pending

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN118194447A (en) * | 2024-05-20 | 2024-06-14 | 浙江大学 | Structural design optimization method and system for tilting duct aircraft wing |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Johnson | Rotorcraft aeromechanics | |

| CN105260492A (en) | Synthetic modeling method of rotor and airframe coupling dynamics modality | |

| Yeo et al. | Comparison of CAMRAD II and RCAS predictions of tiltrotor aeroelastic stability | |

| CN113868771B (en) | Flight dynamics modeling method considering structure and aerodynamic nonlinearity | |

| Yuan et al. | Aeroelasticity and structural optimization of composite helicopter rotor blades with swept tips | |

| Soykasap et al. | Performance enhancement of a composite tilt-rotor using aeroelastic tailoring | |

| Heeg et al. | Whirl flutter and the development of the NASA X-57 Maxwell | |

| CN115982837A (en) | Multi-system coupling dynamics modeling method for multi-propeller tilt-wing rotor aircraft | |

| Cole et al. | Transonic dynamics tunnel aeroelastic testing in support of aircraft development | |

| Hoover et al. | Whirl flutter stability and its influence on the design of the distributed electric propeller aircraft X-57 | |

| CN112149232B (en) | Rigid-elastic coupling modeling method for flight dynamics of heavy helicopter | |

| CN112597582B (en) | Tandem helicopter rotor and fuselage coupling stability modeling method | |

| CN112632695B (en) | Ground resonance modeling and analyzing method for transverse double-rotor helicopter | |

| CN114186334B (en) | Rotor wing aeroelastic coupling calculation method introducing full elastic boundary condition | |

| Halder et al. | Free-wake based nonlinear aeroelastic modeling of cycloidal rotor | |

| CN116305512A (en) | Distributed multi-rotor aircraft aeroelastic analysis method | |

| Vijayanandh et al. | Material optimization of a contra–Rotating propeller for a rotary wing unmanned aerial vehicle | |

| Li et al. | Aeroelastic modelling and stability analysis of tiltrotor aircraft in conversion flight | |

| Huang et al. | Aerodynamic Design of Fixed-wing Mode for A Ducted-fan Tiltrotor UAV by Digital DATCOM | |

| Quesada et al. | Influence of nonlinear aerodynamic effects on high aspect ratio aircraft model | |

| Stanisławski | Effectiveness of the compound helicopter configuration in rotorcraft performance increase | |

| van't Hoff et al. | Design of a Tiltrotor Semi-Span Wind Tunnel Model for Whirl Flutter Investigations | |

| Srinivas et al. | Formulation of a comprehensive aeroelastic analysis for tilt-rotor aircraft | |

| Jrad et al. | Elastic Axis Determination and Extraction of Vibration Mode Shapes of a Light Weight Composite Aircraft | |

| CN117521251A (en) | Paddle fluid-solid coupling method based on POD reduced order model |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |