CN114909189A - Novel adsorption type compression energy storage system - Google Patents

Novel adsorption type compression energy storage system Download PDFInfo

- Publication number

- CN114909189A CN114909189A CN202210532858.7A CN202210532858A CN114909189A CN 114909189 A CN114909189 A CN 114909189A CN 202210532858 A CN202210532858 A CN 202210532858A CN 114909189 A CN114909189 A CN 114909189A

- Authority

- CN

- China

- Prior art keywords

- energy storage

- working fluid

- storage system

- energy

- heat

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000004146 energy storage Methods 0.000 title claims abstract description 66

- 238000007906 compression Methods 0.000 title claims abstract description 65

- 230000006835 compression Effects 0.000 title claims abstract description 48

- 238000001179 sorption measurement Methods 0.000 title claims abstract description 45

- 239000012530 fluid Substances 0.000 claims abstract description 104

- 239000002440 industrial waste Substances 0.000 claims abstract description 12

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 35

- 238000003795 desorption Methods 0.000 claims description 21

- 239000002918 waste heat Substances 0.000 claims description 16

- 238000010438 heat treatment Methods 0.000 claims description 15

- 230000000274 adsorptive effect Effects 0.000 claims 1

- 238000000034 method Methods 0.000 description 14

- 230000008569 process Effects 0.000 description 13

- 230000000694 effects Effects 0.000 description 9

- 238000003860 storage Methods 0.000 description 7

- 230000005611 electricity Effects 0.000 description 5

- 239000007789 gas Substances 0.000 description 5

- 239000003463 adsorbent Substances 0.000 description 4

- 238000006243 chemical reaction Methods 0.000 description 4

- 238000005516 engineering process Methods 0.000 description 3

- 238000010248 power generation Methods 0.000 description 3

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 2

- 239000006096 absorbing agent Substances 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 238000012983 electrochemical energy storage Methods 0.000 description 2

- HBBGRARXTFLTSG-UHFFFAOYSA-N Lithium ion Chemical compound [Li+] HBBGRARXTFLTSG-UHFFFAOYSA-N 0.000 description 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 1

- 229910021536 Zeolite Inorganic materials 0.000 description 1

- BNOODXBBXFZASF-UHFFFAOYSA-N [Na].[S] Chemical compound [Na].[S] BNOODXBBXFZASF-UHFFFAOYSA-N 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 239000002156 adsorbate Substances 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- HNPSIPDUKPIQMN-UHFFFAOYSA-N dioxosilane;oxo(oxoalumanyloxy)alumane Chemical compound O=[Si]=O.O=[Al]O[Al]=O HNPSIPDUKPIQMN-UHFFFAOYSA-N 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 229910021389 graphene Inorganic materials 0.000 description 1

- 238000009776 industrial production Methods 0.000 description 1

- 238000007689 inspection Methods 0.000 description 1

- 229910001416 lithium ion Inorganic materials 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 238000004064 recycling Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 239000000741 silica gel Substances 0.000 description 1

- 229910002027 silica gel Inorganic materials 0.000 description 1

- 238000010792 warming Methods 0.000 description 1

- 239000010457 zeolite Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D15/00—Adaptations of machines or engines for special use; Combinations of engines with devices driven thereby

- F01D15/10—Adaptations for driving, or combinations with, electric generators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01K—STEAM ENGINE PLANTS; STEAM ACCUMULATORS; ENGINE PLANTS NOT OTHERWISE PROVIDED FOR; ENGINES USING SPECIAL WORKING FLUIDS OR CYCLES

- F01K27/00—Plants for converting heat or fluid energy into mechanical energy, not otherwise provided for

- F01K27/02—Plants modified to use their waste heat, other than that of exhaust, e.g. engine-friction heat

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F03—MACHINES OR ENGINES FOR LIQUIDS; WIND, SPRING, OR WEIGHT MOTORS; PRODUCING MECHANICAL POWER OR A REACTIVE PROPULSIVE THRUST, NOT OTHERWISE PROVIDED FOR

- F03G—SPRING, WEIGHT, INERTIA OR LIKE MOTORS; MECHANICAL-POWER PRODUCING DEVICES OR MECHANISMS, NOT OTHERWISE PROVIDED FOR OR USING ENERGY SOURCES NOT OTHERWISE PROVIDED FOR

- F03G4/00—Devices for producing mechanical power from geothermal energy

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F03—MACHINES OR ENGINES FOR LIQUIDS; WIND, SPRING, OR WEIGHT MOTORS; PRODUCING MECHANICAL POWER OR A REACTIVE PROPULSIVE THRUST, NOT OTHERWISE PROVIDED FOR

- F03G—SPRING, WEIGHT, INERTIA OR LIKE MOTORS; MECHANICAL-POWER PRODUCING DEVICES OR MECHANISMS, NOT OTHERWISE PROVIDED FOR OR USING ENERGY SOURCES NOT OTHERWISE PROVIDED FOR

- F03G6/00—Devices for producing mechanical power from solar energy

- F03G6/071—Devices for producing mechanical power from solar energy with energy storage devices

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D20/00—Heat storage plants or apparatus in general; Regenerative heat-exchange apparatus not covered by groups F28D17/00 or F28D19/00

- F28D20/0034—Heat storage plants or apparatus in general; Regenerative heat-exchange apparatus not covered by groups F28D17/00 or F28D19/00 using liquid heat storage material

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E70/00—Other energy conversion or management systems reducing GHG emissions

- Y02E70/30—Systems combining energy storage with energy generation of non-fossil origin

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Sustainable Energy (AREA)

- Sustainable Development (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Engine Equipment That Uses Special Cycles (AREA)

Abstract

The invention provides a novel adsorption type compression energy storage system, which comprises an energy storage system, wherein working fluid flows in the energy storage system in a circulating manner; an energy storage device; a thermally compressed component; a second heat exchanger; the expander is connected with a generator; a precooler that converts the working fluid state to a hot compressed component; wherein the working fluid flows through the hot compression component, the accumulator, the second heat exchanger, the expander, the precooler and returns to the hot compression component in sequence. The hot compression component performs a hot compression process by absorbing heat provided by industrial waste heat, so that working media in the system are converted into low-temperature high-pressure fluid to be stored in the energy accumulator; and when the power consumption peak period is reached, the energy storage device is opened, and the second heat exchanger absorbs the heat released by the renewable energy source to heat the working fluid, so that the working fluid applies work to the expansion machine, the generator generates power, and the energy is recycled.

Description

Technical Field

The invention relates to the technical field of energy storage systems, in particular to a novel adsorption type compression energy storage system.

Background

With the depletion of global fossil energy and the increasing prominence of global warming problems, countries in the world are energetically developing renewable energy technologies. Because renewable energy has the problem of intermittence and volatility, the large-scale use of the renewable energy is greatly limited, and simultaneously, a large amount of industrial waste heat in the nature cannot be reasonably utilized, and the energy storage technology is widely concerned as an effective measure for solving the problems.

At present, physical energy storage (such as pumped storage and compressed air energy storage) is adopted as a more applied energy storage mode, and the energy storage mode is large in scale, long in service life and long in energy storage period, but is limited by geographical conditions and depends on a large-scale air storage chamber; electrochemical energy storage (such as lead-acid batteries, flow batteries, sodium-sulfur batteries, lithium ion batteries and the like) is high in energy density and response speed, but the electrochemical energy storage is short in service life and high in cost.

Therefore, the currently developed energy storage technologies all have some defects, and a new energy storage system with low cost, long service life and high efficiency needs to be researched and developed urgently.

Disclosure of Invention

The invention solves the problems of high cost, short service life and low efficiency of the energy storage system in the prior art.

In order to solve the problems, the invention provides a novel adsorption type compression energy storage system, which comprises an energy storage system, wherein a working fluid circularly flows in the energy storage system; an accumulator for storing a working fluid; the hot compression component is used for absorbing industrial waste heat to provide heat of the waste heat, performing a hot compression process, and converting working media in the system into low-temperature and high-pressure fluid to be stored in the energy accumulator; a second heat exchanger for absorbing heat released by a renewable energy source to heat the working fluid; the expander is connected with a generator; a precooler that converts the working fluid state to the hot compression component; wherein the working fluid flows sequentially through the hot compression component, the accumulator, the second heat exchanger, the expander, the precooler, and back to the hot compression component.

Compared with the prior art, the technical effect that this scheme of adoption can reach: the hot compression component absorbs heat provided by industrial waste heat to perform a hot compression process, and converts working media in the system into low-temperature high-pressure fluid and temporarily stores the fluid in the energy accumulator; and when the system is in a power utilization peak period, the energy storage device is opened, and the heat released by the renewable energy is absorbed by the second heat exchanger to heat the working fluid, so that the working fluid acts on the expansion machine, the generator generates electricity, the energy is recycled, and compared with the traditional pumped storage and compressed air storage forms, the system is low in equipment cost, compact in structure and convenient to operate.

In this embodiment, the thermal compression member includes: a first coil through which a waste heat fluid passes; the adsorption structure is used for desorbing industrial waste heat, performing a thermal compression process and converting working media in an energy storage system into working fluid to the energy accumulator; wherein the first coil is coupled with the adsorption structure.

The technical effect after adopting this technical scheme does, through first coil pipe and adsorption structure coupling, guarantees that the absorptive industry waste heat of first coil pipe can enter into adsorption structure, through absorbing the heat that industry waste heat provided, carries out the hot compression process to turn into the high-pressure fluid of low temperature and temporarily storage in the accumulator with the working medium in the system, the follow-up energy reuse of being convenient for.

In this embodiment, the adsorption structure includes: one end of the adsorption air inlet pipe is connected with one end of the precooler; one end of the desorption air outlet pipe is connected with the energy storage device; at least one adsorber, the adsorber is located adsorb between intake pipe and the desorption outlet duct.

The technical effect after the technical scheme is adopted is that the number of the adsorbers is four, each adsorber is filled with the adsorbent and used for carrying out adsorption and desorption processes, and the adsorbers carry out desorption reaction by absorbing heat provided by waste heat and carry out a thermal compression process. Therefore, the inlet and the outlet of the adsorber are respectively connected with the adsorption air inlet pipe and the desorption air outlet pipe.

In this embodiment, the adsorber includes: a hot water inlet and a cold water inlet connected to the outlet end of the first coil; the hot water outlet and the cold water outlet are connected with the inlet end of the first coil.

The technical effect after the technical scheme is adopted is that cold water and hot water in the first coil pipe enter the absorber through the cold water inlet and the hot water inlet, the absorber is heated or cooled by the cold water and the hot water in the first coil pipe, and the cold water and the hot water in the first coil pipe flow back to the first coil pipe through the hot water outlet and the cold water outlet.

In this embodiment, the second heat exchanger includes: a second coil through which passes a renewable energy heating fluid; a heat exchanger body for absorbing the heating fluid and heating the working fluid.

The technical effect after the technical scheme is adopted is that the second coil pipe is coupled with the heat exchanger main body, so that the regenerated energy heat absorbed by the second coil pipe is ensured to heat the working fluid, the state of the working fluid is ensured to be changed, the subsequent expander can be acted, the power generation of the generator is ensured, and the energy reutilization is realized.

In this embodiment, the inlet and the outlet of the accumulator are respectively connected with a first check valve and a second check valve, the first check valve is connected with the hot compression component, and the second check valve is connected with the second heat exchanger.

The technical effect after adopting this technical scheme does, in order to guarantee that the energy storage can temporary storage working fluid, so set up first check valve and second check valve, and the working fluid volume that first check valve control flowed into in the energy storage, and the working fluid volume that the second check valve control flowed out from the energy storage has guaranteed that working fluid volume is in stable within range.

In this embodiment, a pressure gauge is further connected to the top of the accumulator.

The technical effect after adopting this technical scheme does, can monitor the pressure value in the energy storage through the manometer for pressure in the energy storage guarantees in normal within range, and when pressure was unusual, operating personnel can in time shut down and carry out the inspection and whether produce reasons such as revealing.

In this embodiment, the renewable energy source is solar energy or geothermal energy.

The technical effect after the technical scheme is adopted is that in daily life or industry, a part of geothermal energy is wasted in the floor heating use process, a part of solar energy is wasted in the solar panel use process, the solar energy or the geothermal energy is utilized to heat the working fluid, so that the state of the working fluid is changed, the subsequent expander can do work, the power generation of the generator is guaranteed, and the energy reutilization is realized.

In the present embodiment, the states of the working fluid include a working fluid in a low-temperature high-pressure state, a working fluid in a high-temperature high-pressure state, and a working fluid in a low-temperature low-pressure state.

The technical effect after the technical scheme is adopted is that the working fluid is in a low-temperature high-pressure state when flowing through the hot compression component, is in a high-temperature high-pressure state when flowing through the second heat exchanger, and is in a low-temperature low-pressure state when flowing through the precooler, so that the working fluid is ensured to circularly flow in the energy storage system.

Compared with the prior art, the invention also has the following beneficial effects: 1. the adsorption structure is heated by other waste heat such as industrial waste heat, and the desorbed gas is stored in the energy storage device in a low-temperature and high-pressure mode, so that the cost of the energy storage process is low;

2. the invention uses new energy such as solar energy, geothermal energy and the like to heat the released low-temperature high-pressure gas, and the low-temperature high-pressure gas is converted into electric energy through the expander and the generator and is used for adjusting the electricity utilization pressure of the electricity utilization peak.

3. The invention replaces a mechanical compressor with a hot compression part, and utilizes the hot compression part to increase the pressure of the circulating working medium so as to store the circulating working medium in a high-pressure gas form, thereby utilizing the waste heat, saving the electric energy and achieving the purposes of energy saving and environmental protection.

Drawings

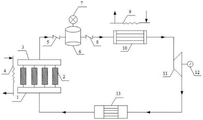

Fig. 1 is a schematic structural diagram of a novel adsorption type compression energy storage system according to the present invention.

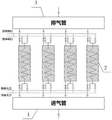

Fig. 2 is a schematic view of the principle of the thermocompression unit of the present invention.

Description of reference numerals: 1. adsorbing an air inlet pipe; 2. an adsorber; 3. a desorption gas outlet pipe; 4. a first coil pipe; 5. a first check valve; 6. an energy storage device; 7. a pressure gauge; 8. a second check valve; 9. a second coiled tube; 10. a heat exchanger main body; 11. an expander; 12. a generator; 13. a precooler.

Detailed Description

In order to make the aforementioned objects, features and advantages of the present invention comprehensible, a specific embodiment thereof is described in detail with reference to fig. 1.

[ first embodiment ] A method for manufacturing a semiconductor device

Referring to fig. 1, the invention discloses a novel adsorption type compression energy storage system, which comprises an energy storage system, wherein a working fluid circularly flows in the energy storage system; an accumulator 6, the accumulator 6 being for storing a working fluid; the hot compression component absorbs heat provided by industrial waste heat to perform a hot compression process, so that working media in the system are converted into low-temperature high-pressure fluid to be stored in the energy storage device 6; a second heat exchanger for absorbing heat released by a renewable energy source to heat the working fluid; an expander 11, wherein a generator 12 is connected to the expander 11; a precooler 13, said precooler 13 converting said working fluid state to said hot compression components; wherein the working fluid flows in sequence through the hot compression component, the accumulator 6, the second heat exchanger, the expander 11, the precooler 13 and back to the hot compression component.

In the embodiment, working fluid circularly flows in the energy storage system, and the energy is transferred by the circular flow of the working fluid; the energy storage 6 is a high-pressure energy storage 6 capable of temporarily storing the working fluid for use in the subsequent secondary use of energy, and the working fluid stored in the energy storage 6 is a working fluid in a low-temperature high-pressure state, and is in a gaseous state.

And the hot compression component is used for carrying out a hot compression process by absorbing heat provided by industrial waste heat, and converting working media in the system into low-temperature high-pressure fluid to be stored in the energy storage device 6. The waste heat fluid can be from waste heat released by industrial production, and the waste heat can be recycled.

The second heat exchanger can absorb the heat released by the renewable energy source and is used for heating the working fluid, and in life, the renewable energy source can be preferably geothermal energy and solar energy; a part of geothermal energy is wasted in the floor heating using process, and a part of solar energy is wasted in the solar panel using process, and the solar energy or the geothermal energy is utilized to heat the working fluid, so that the energy is recycled.

The working fluid applies work to the expansion machine 11, so that the expansion machine 11 drives the generator 12 to generate electricity, the generator 12 can supply power when the electricity consumption peak is too large, and secondary utilization of energy is guaranteed.

The working fluid after performing work flows out of the expander 11 and then flows into the precooler 13 to be cooled, and the working fluid changes its state and flows into the hot compression component again to perform the next cycle.

The working medium of the system is selected from one or more of CO2, R134a, R32 and R245 fa.

[ second embodiment ]

Referring to fig. 1, the thermal compression member includes: a first coil 4, wherein the first coil 4 is used for allowing waste heat fluid to pass through; the adsorption structure is used for carrying out a thermal compression process, and converting working media in the system into low-temperature high-pressure fluid to be stored in the energy accumulator 6; wherein the first coil 4 is coupled to the adsorption structure.

In this embodiment, through first coil pipe 4 and adsorption structure coupling, guarantee that the industrial waste heat that first coil pipe 4 absorbed can enter into adsorption structure, adsorption structure carries out the hot compression process through the heat that absorbs industrial waste heat and provide, turns into the high-pressure fluid of low temperature with the working medium in the system, temporarily stores working fluid in accumulator 6, the follow-up energy reuse of being convenient for. The adsorption structure performs a desorption reaction by absorbing heat provided by the waste heat, and stores the working fluid in a low-temperature and high-pressure state in the energy storage 6 through a thermal compression process.

[ third embodiment ]

Referring to fig. 1, the adsorption structure includes: an adsorption air inlet pipe 1, wherein one end of the adsorption air inlet pipe 1 is connected with one end of the precooler 13; a desorption outlet pipe 3, wherein one end of the desorption outlet pipe 3 is connected with the energy storage device 6; at least one adsorber 2, adsorber 2 is located adsorb the intake pipe 1 with desorption outlet duct 3 between.

In the present embodiment, the ratio of the outlet pressure of desorption outlet pipe 3 to the inlet pressure of adsorption inlet pipe 11 is generally 2 or more for a common working fluid. The number of the adsorbers 2 is four, each adsorber is filled with an adsorbent and used for carrying out adsorption and desorption processes, and the inlet and the outlet of the adsorber 2 are respectively connected with the adsorption air inlet pipe 1 and the desorption air outlet pipe 3. The adsorption structure absorbs heat provided by waste heat to perform desorption reaction, and the working fluid in a low-temperature and high-pressure state is stored in the energy storage device 6 through a thermal compression process.

Wherein, the adsorbent comprises one or more of active carbon, graphene, silica gel and zeolite and is used for carrying out adsorption and desorption processes.

[ fourth example ] A

Referring to fig. 1, the second heat exchanger includes: a second coil 9, said second coil 9 being for the passage of a renewable energy heating fluid; a heat exchanger body 10 for absorbing the heating fluid and heating the working fluid by the heat exchanger body 10.

In this embodiment, the second coil 9 is coupled to the heat exchanger main body 10, so as to ensure that the renewable energy absorbed by the second coil 9 heats the working fluid, ensure that the state of the working fluid changes and can apply work to the subsequent expander 11, ensure power generation of the generator 12, and realize energy recycling. The renewable energy source may preferably be geothermal energy, solar energy.

[ fifth embodiment ]

The adsorber comprises: a hot water inlet and a cold water inlet connected to the outlet ends of the first coils 4; a hot water outlet and a cold water outlet, which are connected to the inlet end of the first coil 4.

The cold water and the hot water in the first coil 4 enter the adsorber 2 through the cold water inlet and the hot water inlet, the adsorber 2 is heated or cooled by the cold water and the hot water in the first coil 4, and the cold water and the hot water in the first coil 4 flow back to the first coil 4 through the hot water outlet and the cold water outlet.

[ sixth embodiment ]

Referring to fig. 1, a first check valve 5 and a second check valve 8 are connected to an inlet and an outlet of the accumulator 6, respectively, the first check valve 5 is connected to the hot compression part, and the second check valve 8 is connected to the second heat exchanger.

In the present embodiment, in order to ensure that the accumulator 6 can temporarily store the working fluid, the first check valve 5 and the second check valve 8 are provided, the first check valve 5 controls the amount of the working fluid flowing into the accumulator 6, and the second check valve 8 controls the amount of the working fluid flowing out from the accumulator 6, ensuring that the amount of the working fluid is within a stable range.

Referring to fig. 1, a pressure gauge 7 is further connected to the top of the energy accumulator 6.

In this embodiment, can monitor the pressure value in the energy storage ware 6 through manometer 7 for pressure in the energy storage ware 6 guarantees in normal within range, and when pressure was unusual, operating personnel can in time shut down and carry out and inspect whether produce reasons such as reveal.

Referring to fig. 1, the renewable energy source is solar energy or geothermal energy.

In the present embodiment, in life, the renewable energy source may preferably be geothermal energy, solar energy; a part of geothermal energy is wasted in the floor heating using process, and a part of solar energy is wasted in the solar panel using process, and the solar energy or the geothermal energy is utilized to heat the working fluid, so that the energy is recycled.

Referring to fig. 1, states of the working fluid include a working fluid in a low temperature and high pressure state, a working fluid in a high temperature and high pressure state, and a working fluid in a low temperature and low pressure state.

In the present embodiment, the working fluid in a low-temperature and high-pressure state when flowing through the hot compression component, the working fluid in a high-temperature and high-pressure state when flowing through the second heat exchanger, and the working fluid in a low-temperature and low-pressure state when flowing through the precooler 13 ensure that the working fluid circulates in the energy storage system.

[ tenth embodiment ]

Referring to fig. 1, the adsorber 2 in the hot compression component performs a desorption reaction by absorbing heat provided by waste heat, and through a hot compression process, for a common working fluid, a ratio of an outlet pressure of the desorption outlet pipe 3 to an inlet pressure of the adsorption inlet pipe 1 is generally greater than or equal to 2, at this time, the working fluid in a low-temperature and high-pressure working state is stored in the accumulator 6 through the first check valve 5, and at this time, the second check valve 8 is in a closed state.

When the power consumption peak is in, the second check valve 8 is opened, the working fluid in the working state of low temperature and high pressure flows through the second heat exchanger, the heat provided by the renewable energy is absorbed, the working state is changed into the working fluid in the high temperature and high pressure, and then the working fluid flows through the expansion machine 11 to do work, so that the generator 12 is driven to generate power, and the problem of the power consumption peak pressure is solved. The working fluid after the work is discharged from the expander 11, and then flows into the precooler 13 to be cooled, and the working fluid in the low-temperature and low-pressure working state is returned to the hot compression part to be subjected to the next cycle.

In this embodiment, the thermo-compression component is an extremely important component of the system, and the working principle thereof is shown in fig. 2. Like the processes of suction, compression, discharge and re-expansion of mechanical compression, thermal compression can be divided into four processes of cooling adsorption, heating pressure rise, heating desorption and cooling pressure reduction. Four adsorbers in the unit, one of which is maintained at all times desorbed during operation, andand each adsorber is continuously subjected to one of four processes. The temperature of the waste heat hot water is assumed to be T hin The function is to heat the adsorbent in the adsorber, so that the working medium (adsorbate) is desorbed, and the working medium at the outlet of the device is changed into a state with pressure of P2 and temperature of T2 through the adsorption and compression process of the thermal compression part. Taking CO2 working medium as an example, the ratio of the outlet pressure to the inlet pressure of the hot compression part is about 2, and the outlet pressure is increased by about 2 times relative to the inlet of the device at the moment, so that the device is in a state of low temperature and high pressure.

Flow m in the system is (Hhin-Hhout) m h /(H 2 -H 1 ) After the circulating working medium is compressed by the hot compression part, the circulating working medium is stored in the energy accumulator 6 through the first check valve 5, and in order to prevent the pressure of the energy accumulator from being too high, the pressure gauge 7 is installed on the upper part of the energy accumulator, and the internal pressure of the energy accumulator is observed at any time.

When the power consumption is in peak, the power consumption to be provided is assumed to be P, and then P is m (h) 6 -h 7 ). Assuming that there is no pressure loss in the storage and release of the working fluid through the accumulator 6, the heat provided to the system by the solar or geothermal energy through the second coil 9 is Q, and the enthalpy h of the working fluid at the inlet of the expander 11 is h 6 =h 5 + Q/m. At the same time, the compound is formed by P ═ m ═ h (h) 6 -h 7 ) Can obtain h 7 . Meanwhile, the pressure P1 of the working medium at the inlet of the hot compression device is given, and P1 is P7, so that working medium at the outlet states P7 and T7 of the expansion machine 11 is obtained. The working fluid then flows through the precooler 13 for the next cycle.

Although the present invention is disclosed above, the present invention is not limited thereto. Various changes and modifications may be effected therein by one skilled in the art without departing from the spirit and scope of the invention as defined in the appended claims.

Claims (9)

1. The novel adsorption type compression energy storage system is characterized by comprising an energy storage system, wherein a working fluid flows in the energy storage system in a circulating manner;

an accumulator (6), the accumulator (6) being for storing a working fluid;

the hot compression component is used for absorbing heat provided by industrial waste heat, performing a hot compression process and converting working media in an energy storage system into the working fluid to the energy storage device (6);

a second heat exchanger for absorbing heat released by a renewable energy source to heat the working fluid;

an expander (11), wherein a generator (12) is connected to the expander (11);

a precooler (13), said precooler (13) converting the working fluid state to the hot compression component;

wherein the working fluid flows through the hot compression component, the energy storage (6), the second heat exchanger, the expander (11), the precooler (13) and back to the hot compression component in sequence.

2. The novel adsorptive compressed energy storage system according to claim 1, wherein the thermal compression component comprises:

a first coil (4), wherein the first coil (4) is used for waste heat fluid to pass through; the first coil (4) comprises an outlet end and an inlet end;

the adsorption structure is used for desorbing industrial waste heat, performing a thermal compression process and converting working media in an energy storage system into working fluid to the energy accumulator (6);

wherein the first coil (4) is coupled with the adsorption structure.

3. The novel adsorption type compressed energy storage system according to claim 2, wherein the adsorption structure comprises:

an adsorption air inlet pipe (1), wherein one end of the adsorption air inlet pipe (1) is connected with one end of the precooler (13);

a desorption outlet pipe (3), wherein one end of the desorption outlet pipe (3) is connected with the energy storage device (6);

at least one adsorber (2), adsorber (2) are located adsorb intake pipe (1) with desorption outlet duct (3) between.

4. A new adsorption type compressed energy storage system according to claim 3, characterized in that the adsorber (2) comprises:

a hot water inlet and a cold water inlet connected to the outlet end of the first coil (4);

a hot water outlet and a cold water outlet, the hot water outlet and the cold water outlet being connected to the inlet end of the first coil (4).

5. The novel adsorption type compression energy storage system according to claim 1, wherein the second heat exchanger comprises:

a second coil (9), said second coil (9) being passed by a renewable energy heating fluid;

a heat exchanger body (10), the heat exchanger body (10) for absorbing the heating fluid and heating the working fluid.

6. A new adsorption type compression energy storage system according to claim 1, characterized in that the inlet and outlet of the energy storage device (6) are connected with a first check valve (5) and a second check valve (8), respectively, the first check valve (5) is connected with the hot compression component, and the second check valve (8) is connected with the second heat exchanger.

7. The novel adsorption type compressed energy storage system according to claim 1, wherein a pressure gauge (7) is further connected to the top of the energy storage device (6).

8. The system of claim 1, wherein the renewable energy source is solar energy or geothermal energy.

9. The novel adsorption type compression energy storage system according to claim 1, wherein the working fluid states include a low temperature and high pressure working fluid, a high temperature and high pressure working fluid, and a low temperature and low pressure working fluid.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210532858.7A CN114909189A (en) | 2022-05-11 | 2022-05-11 | Novel adsorption type compression energy storage system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210532858.7A CN114909189A (en) | 2022-05-11 | 2022-05-11 | Novel adsorption type compression energy storage system |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN114909189A true CN114909189A (en) | 2022-08-16 |

Family

ID=82769211

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210532858.7A Pending CN114909189A (en) | 2022-05-11 | 2022-05-11 | Novel adsorption type compression energy storage system |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114909189A (en) |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0689019B1 (en) * | 1994-06-20 | 1999-07-28 | L'air Liquide, Societe Anonyme Pour L'etude Et L'exploitation Des Procedes Georges Claude | Process and apparatus for producing gaseous oxygen under pressure |

| CN103527271A (en) * | 2013-10-21 | 2014-01-22 | 上海交通大学 | Passive low-temperature heat energy organic matter working medium electricity generation method |

| EP2730328A1 (en) * | 2012-11-08 | 2014-05-14 | Hitachi Ltd. | Solid CO2 adsorbent material system |

| CN107605559A (en) * | 2017-08-04 | 2018-01-19 | 上海柯来浦能源科技有限公司 | Heat engine hydrogen reaction bed combined cycle system |

-

2022

- 2022-05-11 CN CN202210532858.7A patent/CN114909189A/en active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0689019B1 (en) * | 1994-06-20 | 1999-07-28 | L'air Liquide, Societe Anonyme Pour L'etude Et L'exploitation Des Procedes Georges Claude | Process and apparatus for producing gaseous oxygen under pressure |

| EP2730328A1 (en) * | 2012-11-08 | 2014-05-14 | Hitachi Ltd. | Solid CO2 adsorbent material system |

| CN103527271A (en) * | 2013-10-21 | 2014-01-22 | 上海交通大学 | Passive low-temperature heat energy organic matter working medium electricity generation method |

| CN107605559A (en) * | 2017-08-04 | 2018-01-19 | 上海柯来浦能源科技有限公司 | Heat engine hydrogen reaction bed combined cycle system |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Cabeza et al. | Review on sorption materials and technologies for heat pumps and thermal energy storage | |

| Li et al. | Progress in the development of solid–gas sorption refrigeration thermodynamic cycle driven by low-grade thermal energy | |

| Deng et al. | A review of thermally activated cooling technologies for combined cooling, heating and power systems | |

| WO2019096132A1 (en) | Hydrated magnesium hydride energy system | |

| CN102758690A (en) | Efficient high-pressure liquid air energy storage/release system | |

| JP2013510257A (en) | Supercritical air energy storage system | |

| CN102758748A (en) | High-pressure liquid air energy storage/release system | |

| CN105114138A (en) | Low-temperature energy storage power generation system and running method thereof | |

| ElBahloul et al. | Recent advances in multistage sorption thermal energy storage systems | |

| CN110118160B (en) | Solar supercritical carbon dioxide Brayton cycle system | |

| OH et al. | Fuel cell waste heat powered adsorption cooling systems | |

| CN104457020B (en) | Method for improving efficiency of compressed air energy storage system by utilizing compressed heat refrigeration | |

| CN102679617B (en) | Compression-driven adsorption refrigeration method and heat pump system | |

| CN102261764A (en) | Composite refrigerating system | |

| CN114909189A (en) | Novel adsorption type compression energy storage system | |

| CN103075835B (en) | Novel absorption type refrigeration and power-generation combining device | |

| CN114345079B (en) | Temperature and pressure swing adsorption device and method for capturing carbon dioxide in flue gas | |

| CN216044241U (en) | Multi-connected liquid supply air energy storage system | |

| CN116122928A (en) | Combined cooling and power system combining compressed air energy storage and compression absorption refrigeration | |

| CN202792681U (en) | Compression-drive adsorption refrigeration heat pump system | |

| KR102272896B1 (en) | Adsorption heat pump system using low temperature heat source | |

| CN107677002B (en) | Low-grade heat-driven absorption type chemical reaction refrigeration heat pump circulating device and method | |

| CN109973152B (en) | Piston hydrogen energy work system | |

| CN218722401U (en) | Carbon dioxide energy storage and adsorption type heat pump combined power generation system | |

| TW201512537A (en) | Compressed air energy storage system |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication |

Application publication date: 20220816 |