CN114648494B - Pesticide suspending agent production control system based on factory digitization - Google Patents

Pesticide suspending agent production control system based on factory digitization Download PDFInfo

- Publication number

- CN114648494B CN114648494B CN202210191429.8A CN202210191429A CN114648494B CN 114648494 B CN114648494 B CN 114648494B CN 202210191429 A CN202210191429 A CN 202210191429A CN 114648494 B CN114648494 B CN 114648494B

- Authority

- CN

- China

- Prior art keywords

- degree

- average gray

- concentric circles

- uniformity

- sand mill

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 26

- 239000000575 pesticide Substances 0.000 title claims abstract description 25

- 239000000375 suspending agent Substances 0.000 title claims abstract description 22

- 239000004576 sand Substances 0.000 claims abstract description 127

- 239000002994 raw material Substances 0.000 claims abstract description 62

- 238000000227 grinding Methods 0.000 claims abstract description 60

- 230000000694 effects Effects 0.000 claims abstract description 31

- 238000005070 sampling Methods 0.000 claims abstract description 29

- 238000012545 processing Methods 0.000 claims abstract description 22

- 238000013528 artificial neural network Methods 0.000 claims abstract description 17

- 238000001228 spectrum Methods 0.000 claims description 51

- 238000000034 method Methods 0.000 claims description 29

- 239000002245 particle Substances 0.000 claims description 26

- 238000012549 training Methods 0.000 claims description 14

- 238000004364 calculation method Methods 0.000 claims description 11

- 230000008569 process Effects 0.000 claims description 8

- 238000002372 labelling Methods 0.000 claims description 4

- 239000000725 suspension Substances 0.000 claims 1

- 230000008859 change Effects 0.000 description 4

- 238000010586 diagram Methods 0.000 description 4

- 239000008187 granular material Substances 0.000 description 4

- 238000007670 refining Methods 0.000 description 4

- 238000004458 analytical method Methods 0.000 description 3

- 238000002156 mixing Methods 0.000 description 2

- 210000002569 neuron Anatomy 0.000 description 2

- 239000000843 powder Substances 0.000 description 2

- 239000004546 suspension concentrate Substances 0.000 description 2

- 239000002699 waste material Substances 0.000 description 2

- SMZOUWXMTYCWNB-UHFFFAOYSA-N 2-(2-methoxy-5-methylphenyl)ethanamine Chemical compound COC1=CC=C(C)C=C1CCN SMZOUWXMTYCWNB-UHFFFAOYSA-N 0.000 description 1

- NIXOWILDQLNWCW-UHFFFAOYSA-N 2-Propenoic acid Natural products OC(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 239000000084 colloidal system Substances 0.000 description 1

- 238000010835 comparative analysis Methods 0.000 description 1

- 238000010924 continuous production Methods 0.000 description 1

- 239000002270 dispersing agent Substances 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 230000000750 progressive effect Effects 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 230000003595 spectral effect Effects 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06T—IMAGE DATA PROCESSING OR GENERATION, IN GENERAL

- G06T7/00—Image analysis

- G06T7/0002—Inspection of images, e.g. flaw detection

- G06T7/0004—Industrial image inspection

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01N—PRESERVATION OF BODIES OF HUMANS OR ANIMALS OR PLANTS OR PARTS THEREOF; BIOCIDES, e.g. AS DISINFECTANTS, AS PESTICIDES OR AS HERBICIDES; PEST REPELLANTS OR ATTRACTANTS; PLANT GROWTH REGULATORS

- A01N25/00—Biocides, pest repellants or attractants, or plant growth regulators, characterised by their forms, or by their non-active ingredients or by their methods of application, e.g. seed treatment or sequential application; Substances for reducing the noxious effect of the active ingredients to organisms other than pests

- A01N25/02—Biocides, pest repellants or attractants, or plant growth regulators, characterised by their forms, or by their non-active ingredients or by their methods of application, e.g. seed treatment or sequential application; Substances for reducing the noxious effect of the active ingredients to organisms other than pests containing liquids as carriers, diluents or solvents

- A01N25/04—Dispersions, emulsions, suspoemulsions, suspension concentrates or gels

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06N—COMPUTING ARRANGEMENTS BASED ON SPECIFIC COMPUTATIONAL MODELS

- G06N3/00—Computing arrangements based on biological models

- G06N3/02—Neural networks

- G06N3/08—Learning methods

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06T—IMAGE DATA PROCESSING OR GENERATION, IN GENERAL

- G06T2207/00—Indexing scheme for image analysis or image enhancement

- G06T2207/20—Special algorithmic details

- G06T2207/20081—Training; Learning

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06T—IMAGE DATA PROCESSING OR GENERATION, IN GENERAL

- G06T2207/00—Indexing scheme for image analysis or image enhancement

- G06T2207/20—Special algorithmic details

- G06T2207/20084—Artificial neural networks [ANN]

Landscapes

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Theoretical Computer Science (AREA)

- Health & Medical Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Quality & Reliability (AREA)

- Dispersion Chemistry (AREA)

- Plant Pathology (AREA)

- Dentistry (AREA)

- Wood Science & Technology (AREA)

- Zoology (AREA)

- Environmental Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Computer Vision & Pattern Recognition (AREA)

- Pest Control & Pesticides (AREA)

- Agronomy & Crop Science (AREA)

- Toxicology (AREA)

- Artificial Intelligence (AREA)

- Biomedical Technology (AREA)

- Biophysics (AREA)

- Computational Linguistics (AREA)

- Data Mining & Analysis (AREA)

- Evolutionary Computation (AREA)

- Molecular Biology (AREA)

- Computing Systems (AREA)

- General Engineering & Computer Science (AREA)

- Mathematical Physics (AREA)

- Software Systems (AREA)

- Disintegrating Or Milling (AREA)

Abstract

The invention relates to the technical field of intelligent control, in particular to a pesticide suspending agent production control system based on factory digitization, which is a control system capable of realizing comprehensive factory control and can realize centralized control of a plurality of sand mills in a pesticide suspending agent production factory, such as: distributed digital control. The system comprises: the system comprises an image acquisition module, a data processing module and an intelligent control module; the image acquisition module is used for acquiring a sampling image of the raw material before processing by each sand mill; the data acquisition module is used for analyzing each sampling image to acquire an average gray sequence; the data processing module is used for obtaining the grain refinement degree and the uniformity degree of the corresponding raw materials according to each average gray sequence; the intelligent control module is used for calculating the optimal coarse and fine sand proportion required by the grinding effect of different sand mills according to the neural network, so that the multiple sand mills are subjected to distributed control according to the optimal coarse and fine sand proportion, and the efficiency in the production process is effectively improved.

Description

Technical Field

The invention relates to the technical field of intelligent control, in particular to a pesticide suspending agent production control system based on factory digitization.

Background

In China, the processing of the pesticide suspension concentrate basically adopts an ultrafine grinding method, and the production process of the pesticide suspension concentrate forms a set of basic modes after more than 20 years of research, namely: proportioning, pre-grinding powder, grinding by sand mill, blending, mixing and packaging. The main processing equipment used in the superfine grinding method comprises three types: firstly, the pre-crushing equipment: ball or colloid mills; secondly, ultrafine crushing equipment: sand mills, most commonly used as vertical open sand mills; and thirdly, a high-speed mixer and a homogenizer which mainly play a role of homogenizing.

At present, when a pesticide suspending agent is processed by using a sand mill, a multistage series continuous production process flow is generally adopted, the grinding medium particles of each sand mill in the multistage series are different, coarse and fine sand with different proportions is required to be added into the sand mill when raw materials are ground, but the coarse and fine sand proportion is closely related to the grinding effect of each sand mill, and the grinding effect of the sand mill is poor because the coarse and fine sand proportion is improper when the multistage series sand mill is intensively controlled, and even the waste of the raw materials can be caused.

Disclosure of Invention

In order to solve the above technical problems, the present invention aims to provide a plant-based digital pesticide suspension agent production control system, which comprises the following modules:

the image acquisition module is used for sampling the raw materials before being processed by each sand mill connected in series in multiple stages and acquiring a sampling image of each raw material sample; acquiring a frequency spectrum image corresponding to each raw material sample according to the sampling image;

the data acquisition module is used for making a plurality of concentric circles in each frequency spectrum image, acquiring the average gray value on the circumference of each concentric circle, and forming an average gray sequence according to the average gray values on the circumferences of the plurality of concentric circles;

the data processing module is used for acquiring the grain refinement degree and the uniformity degree of the corresponding raw material sample according to the average gray sequence of each frequency spectrum image, and acquiring the grinding effect of each sand mill according to the grain refinement degree and the uniformity degree;

the intelligent control module is used for acquiring a plurality of grinding data in the actual processing process of the raw materials as training samples, wherein the grinding data comprises the grain refinement degree, the uniformity degree and different coarse-fine sand proportions in each sand mill; and training a neural network by using the training sample, obtaining optimal coarse-fine sand ratios corresponding to different grinding effects according to the trained neural network, and controlling the coarse-fine sand ratio in each sand mill according to the optimal coarse-fine sand ratios.

Preferably, the method for making a plurality of concentric circles in each spectrum image in the data acquisition module includes:

and taking the central point of each frequency spectrum image as a circular point, and making a plurality of concentric circles in the frequency spectrum images based on the circular point.

Preferably, the method for acquiring the average gray-scale value on the circumference of each concentric circle in the data acquisition module includes:

and acquiring the perimeter of each concentric circle and the sum of gray values corresponding to all pixel points on the circumference of the concentric circle, wherein the ratio of the sum of the gray values to the perimeter is the average gray value.

Preferably, the method for obtaining the grain refinement degree of the corresponding raw material sample according to the average gray sequence of each spectrum image in the data processing module includes:

labeling according to the radius of the concentric circles, and obtaining the grain refinement degree of the raw material sample according to the label of each concentric circle and the average gray sequence, wherein the grain refinement degree of the raw material sample is as follows:

wherein XD represents the degree of particle refinement; max (pu) represents the maximum average gray value in the average gray sequence; min (pu) represents the minimum mean gray value in the mean gray sequence; pu (Chinese character) i Representing the average gray value corresponding to the ith concentric circle; k/2 represents the number of concentric circles.

Preferably, the method for acquiring, in the data processing module, the uniformity degree of the corresponding raw material sample according to the average gray sequence of each of the spectrum images further includes:

and acquiring the label of the concentric circle corresponding to the maximum average gray value in the average gray sequence, and obtaining the uniformity degree according to the label corresponding to the maximum average gray value and the number of all the concentric circles.

Preferably, the method for obtaining the degree of uniformity in the data processing module according to the labels corresponding to the maximum average gray-scale value and the number of all the concentric circles further includes:

the degree of uniformity is related to a calculation state of each of the concentric circles, which is obtained from a difference between an average gray value and a maximum average gray value of the concentric circles, and when the difference is greater than a preset threshold, the calculation state of the concentric circles is 0, and when the difference is less than the preset threshold, the calculation state of the concentric circles is 1.

Preferably, the method for obtaining the grinding effect of each sand mill according to the grain refinement degree and the uniformity degree in the data processing module comprises the following steps:

and respectively obtaining the grain refinement degree and the uniformity degree corresponding to the raw material sample before and after grinding by the sand mill, wherein the variable quantity of the grain refinement degree and the uniformity degree before and after grinding by the sand mill is the grinding effect.

The invention has the following beneficial effects: the embodiment of the invention is a control system capable of realizing comprehensive factory control, which can realize centralized control of a plurality of sand mills in a pesticide suspending agent production factory, such as: distributed digital control; firstly, acquiring frequency spectrum images corresponding to raw materials before and after grinding of each sand mill; making a plurality of concentric circles in each frequency spectrum image, forming an average gray sequence according to the average gray value on the circumference of each concentric circle, further calculating the grain refinement degree and the uniformity degree of the corresponding raw materials according to the average gray sequence, wherein the difference between the grain refinement degree and the uniformity degree before and after grinding of each sand mill is the grinding effect of the sand mill; the particle thinning degree and the uniformity degree of the raw materials are analyzed through the frequency spectrum image corresponding to each raw material, so that the result obtained by analysis is more reliable; the method comprises the steps of taking the grain refining degree and the uniformity degree of raw materials before and after grinding of a plurality of sand mills and the coarse sand and fine sand proportion in each sand mill as training samples, training a neural network by using the training samples, calculating the optimal coarse sand and fine sand proportion corresponding to different grinding effects according to the trained neural network, and carrying out distributed control on the sand mills connected in series in multiple stages based on the optimal coarse sand and fine sand proportion. Based on the actual conditions, a plurality of sand mills are controlled in a centralized manner in the production process, so that the feasibility of raw material treatment is improved, and the waste is reduced.

Drawings

In order to more clearly illustrate the embodiments of the present invention or the technical solutions and advantages of the prior art, the drawings used in the description of the embodiments or the prior art will be briefly described below, it is obvious that the drawings in the following description are only some embodiments of the present invention, and other drawings can be obtained by those skilled in the art without creative efforts.

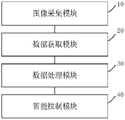

Fig. 1 is a system block diagram of a plant-based digital pesticide suspension agent production control system according to an embodiment of the present invention;

fig. 2 is a schematic diagram of an equipment location according to an embodiment of the present invention.

Detailed Description

In order to further illustrate the technical means and effects of the present invention adopted to achieve the predetermined objects, the following detailed description of the embodiments, structures, features and effects of a plant-based digital pesticide suspension agent production control system according to the present invention will be provided with reference to the accompanying drawings and preferred embodiments. In the following description, the different references to "one embodiment" or "another embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics may be combined in any suitable manner in one or more embodiments.

Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs.

The embodiment of the invention is suitable for centralized control of the multistage series connection sand mills in the production process of the pesticide suspending agent, the grinding effect of each sand mill is further obtained by calculating the grain refining degree and the uniformity degree of the raw materials before and after grinding the raw materials by each sand mill, the relation between the grinding effect of each sand mill and the corresponding coarse-fine sand proportion in the sand mill is obtained according to the neural network, and therefore the optimal coarse-fine sand proportion corresponding to each sand mill is obtained according to the preset grinding effect, the centralized control of the plurality of sand mills in the production process is realized, and the success rate of raw material treatment is improved.

The following describes a specific scheme of a factory-digitization-based pesticide suspending agent production control system provided by the invention in detail by combining with the accompanying drawings.

Referring to fig. 1, a block diagram of a system for controlling production of pesticide suspension agent based on factory digitization according to an embodiment of the present invention is shown, wherein the system comprises the following modules:

the image acquisition module 10 is used for sampling the raw materials before being processed by each sand mill connected in series in multiple stages and acquiring a sampling image of each raw material sample; and acquiring a frequency spectrum image corresponding to each raw material sample according to the sampling image.

In the production process of the pesticide suspending agent, the pesticide raw material, the carrier, the dispersing agent and the like are required to be mixed firstly, then the mixture is ground by using a sand mill, the size and the uniformity of ground particles have great influence on the quality of the subsequent suspending agent, and therefore the grinding effect after grinding treatment by the sand mill needs to be detected.

In order to realize intelligent and digital control in the production process, in the embodiment of the present invention, cameras and sampling platforms are disposed between the sand mills connected in series in multiple stages for analysis, please refer to fig. 2, which is a schematic diagram of equipment positions, showing a sand mill YM1, a sand mill YM2, a sand mill YM3, a sand mill YM4, a camera P1, a camera P2, a camera P3, a camera P4, a camera P5, a sampling platform T1, a sampling platform T2, a sampling platform T3, a sampling platform T4, and a sampling platform T5.

Specifically, the raw material before being processed by each sand mill is sampled to obtain a raw material sample, and in the embodiment of the invention, the weight of the raw material sample sampled five times is equal by default so as to ensure the accuracy of subsequent comparative analysis; the raw material samples obtained through sampling are placed on the sampling platforms, the sampling platforms vibrate to enable the raw material samples to be evenly distributed, and then the corresponding sampling images are obtained through the cameras corresponding to the sampling platforms.

Furthermore, because the sampling image is fully distributed with mixed particles, the proportion of high-frequency information and low-frequency information in the sampling image can be changed due to the size and the dimension of the particles, and the grinding effect is analyzed through the change of the frequency spectrum image; according to the method and the device, the spectrum image corresponding to the sampling image of each raw material sample is obtained by using a two-dimensional discrete Fourier transform algorithm, and subsequent analysis is performed based on the spectrum image corresponding to each raw material sample.

The data obtaining module 20 is configured to make a plurality of concentric circles in each spectrum image, obtain an average gray value on the circumference of each concentric circle, and form an average gray sequence according to the average gray values on the circumferences of the plurality of concentric circles.

Specifically, a spectrum image corresponding to each raw material sample is obtained from the image acquisition module 10, and a plurality of concentric circles are made in the spectrum image based on a central point of each spectrum image as a dot; taking a spectrum image corresponding to any raw material sample as an example, obtaining a central point of the spectrum image, and making a plurality of concentric circles in the spectrum image by taking the central point as a circular point; in the embodiment of the invention, the number of concentric circles in the spectrum image is determined by the transverse dimension of the spectrum image, and if the transverse dimension of the spectrum image is K, the number of concentric circles in the spectrum image is K/2.

Further, the circumference of each concentric circle and the sum of gray values corresponding to all pixel points on the circumference of the concentric circle are obtained, and the ratio of the sum of gray values to the circumference is an average gray value, and then the average gray value is calculated as:

wherein Pu represents the mean gray value; h is m Expressing the gray value of the mth pixel point on the circumference of the concentric circle; m represents the number of pixel points on the circumference of the concentric circle; r represents the radius of the concentric circle; and pi represents the circumferential ratio.

By analogy, the average gray value of the pixel points on the periphery of K/2 concentric circles in one spectrum image can be obtained, in the embodiment of the invention, the average gray value sequence is formed by sorting the concentric circles from small to large according to the radius of each concentric circle and labeling the concentric circles:

Pu={Pu 1 ,Pu 2 ,...,Pu K/2 }

wherein, pu 1 Expressing the average gray value of the pixel points on the circumference of the 1 st concentric circle, namely the average gray value of the pixel points on the circumference of the concentric circle with the smallest radius; pu (Pu) powder 2 Representing the average gray value of the pixel points on the circumference of the 2 nd concentric circle;Pu K/2 and expressing the average gray value of the pixel points on the circumference of the K/2 th concentric circle.

Since the brightness at the center of the spectrum image is always the maximum, in the embodiment of the present invention, the average gray-scale value of the concentric circles at the center point of the spectrum image is defaulted to zero, that is, pu is 1 =0。

And the data processing module 30 is configured to obtain a particle refinement degree and a uniformity degree of the corresponding raw material sample according to the average gray sequence of each spectrum image, and obtain a grinding effect of each sand mill according to the particle refinement degree and the uniformity degree.

Specifically, the low-frequency information in the spectrum image represents a flat area, and the high-frequency information represents an edge area, and when the size of particles in the collected sampling image is smaller, the number of particles is larger and the number of edge pixels is larger under the same quality, so that the high-frequency component value represented in the spectrum image is higher.

The smaller the size of the raw material particles in the sampled image is, the higher the corresponding particle refinement degree is, the larger the corresponding average gray value of the concentric circles is and the smaller the distance between the concentric circles and the dots is, the higher the particle refinement degree is; therefore, the particle refinement degree is calculated according to the average gray sequence of the concentric circles obtained in the data acquisition module 20 as follows:

wherein XD represents the degree of particle refinement; max (pu) represents the maximum average gray value in the average gray sequence; min (pu) represents the minimum mean gray value in the mean gray sequence; pu (pure acrylic acid) i Representing the average gray value corresponding to the ith concentric circle; k/2 represents the number of concentric circles; k denotes the lateral size of the spectral image.

Further, labels of concentric circles corresponding to the maximum average gray value in the average gray sequence are obtained, and the uniformity degree is obtained according to the labels corresponding to the maximum average gray value and the number of all the concentric circles; the degree of uniformity is related to the calculation state of each concentric circle, which is obtained from the difference between the average gray value and the maximum average gray value of the concentric circle, and is 0 when the difference is greater than a preset threshold, and is 1 when the difference is less than the preset threshold. The specific method for obtaining the uniformity is as follows:

first, the average gray sequence obtained in the data acquisition module 20 is normalized, so that the value range of all the average gray values in the average gray sequence is [0,1].

Then, selecting the concentric circle corresponding to the maximum normalized average gray value in the average gray sequence, and marking the label corresponding to the position of the concentric circle as i max Then the degree of uniformity is calculated as:

wherein JD represents the degree of homogeneity; i denotes the ith concentric circle number; i.e. i max Representing the concentric circle label corresponding to the maximum average gray value in the average gray sequence; k/2 represents the number of concentric circles; t is t i Indicating the calculation state of the average gray value corresponding to the ith concentric circle.

Specifically, the method for determining the calculation state of the average gray value corresponding to each concentric circle comprises the following steps:

wherein, t i Representing the calculation state of the average gray value corresponding to the ith concentric circle; qu u max Representing the maximum average gray value in the normalized average gray sequence; qu u i Expressing the ith average gray value in the normalized average gray sequence; k is a preset threshold.

Preferably, an empirical value k =0.3 is taken in the embodiment of the present invention.

Based on the method for obtaining the same grain refinement degree and uniformity degree of the raw material sample corresponding to one spectrum image, the grain refinement degree and uniformity degree corresponding to the raw material sample before and after grinding of each sand mill are respectively obtained, and the variation of the grain refinement degree and uniformity degree before and after grinding of the sand mill is the grinding effect. Specifically, the particle refinement degree and the uniformity degree of the raw material sample corresponding to the front and back corresponding frequency spectrum images of each sand mill are obtained, the change of the raw material sample before and after grinding is obtained according to the front and back two frequency spectrum images of the sand mill, and the particle fineness degree is changed as follows:

ΔD=XD h -XD q

wherein Δ D represents the degree of particle fineness variation; XD h Representing the degree of particle fineness corresponding to a previous frequency spectrum image of the current sand mill; XD q And the degree of particle fineness corresponding to a next frequency spectrum image of the current sand mill is shown.

Further, the degree of uniformity varies as:

ΔJ=JD h -JD q

wherein Δ J represents the degree of uniformity variation; JD h Representing the corresponding uniformity degree of a previous frequency spectrum image of the current sand mill; JD q Indicating the corresponding uniformity degree of the next frequency spectrum image of the current sand mill.

The grinding effect of each sand mill is [ Delta D, delta J ] obtained by the change of the degree of particle fineness and the change of the degree of uniformity.

The intelligent control module 40 is used for acquiring a plurality of grinding data in the actual processing process of the raw materials as training samples, wherein the grinding data comprises the grain refinement degree, the uniformity degree and different coarse and fine sand proportions in each sand mill; training the neural network by using the training sample, obtaining the optimal coarse sand proportion corresponding to different grinding effects according to the trained neural network, and controlling the coarse sand proportion in each sand mill by using the optimal coarse sand proportion.

The grinding effect of each sand mill in the pesticide suspending agent processing process can be obtained from the data processing module 30; when raw materials with different particle fineness degrees and uniformity degrees pass through a sand mill with the same coarse sand proportion, the obtained particle fineness degrees and uniformity degrees after grinding are different, in order to accurately obtain the relationship among the particle fineness, the uniformity degree and the coarse sand proportion, the embodiment of the invention adopts a deep neural network technology to realize digital twinning of the sand mill, the deep neural network adopts a fully-connected network structure, the number of neurons in an input layer is 3, and the number of neurons in an output layer is 2; the training data set is grinding data obtained in the actual grinding process before and after grinding of the sand mill, the grinding data specifically includes grain refinement degree and uniformity degree before and after grinding of the sand mill and actual coarse-fine sand proportion in each sand mill, and the specific training process is as follows:

(1) The input of the deep neural network is the grain refinement degree of the raw materials, the uniformity degree of the raw materials and the coarse sand and fine sand proportion;

(2) The output of the deep neural network is the grain refinement degree and the uniformity degree after the grinding of the sand mill;

(3) The loss function is a mean square error loss function.

The coarse sand proportion and the fine sand proportion are parameters of the sand mill and are adjusted manually, and the coarse sand proportion and the fine sand proportion are calculated by the following method:

wherein bl represents the coarse-fine sand proportion in the sand mill; zs c Represents the mass of the grit; zs is x Indicating the quality of the fine sand.

And subsequently, the corresponding grain refinement degree and the uniformity degree can be obtained according to the sampling image of the raw material sample, and the grain refinement degree and the uniformity degree after grinding in the sand mill at different grain refinement sand ratios are obtained by carrying out ergodic reasoning through a deep neural network by continuously changing the grain refinement sand ratio in the sand mill.

When the intelligent control to pesticide suspending agent production in-process sand mill, at first acquire the target granule that grinds the raw materials and refine degree and target uniform degree, then calculate the granule of current raw materials and refine degree and uniform degree, refine degree, target uniform degree and current granule and refine degree, current uniform degree with the target granule and do the difference respectively and obtain the target sanding effect of whole multistage series connection sand mill unit and do:

[ΔD z ,ΔJ z ]

wherein, Δ D z Representing the variation of the grain refinement degree corresponding to the multistage series sanding unit; delta J z Indicating that the degree of uniformity to which the multi-level sanding unit corresponds varies.

Furthermore, because the multistage series connection sanding unit in the embodiment of the invention comprises four sanding machine devices, the average grinding effect of each sanding machine obtained according to the target grinding effect of the whole multistage series connection sanding unit is as follows:

[ΔD z /4,ΔJ z /4]

wherein, Δ D z Representing the variation of the grain refinement degree corresponding to the multistage series sanding unit; delta J z Indicating that the degree of uniformity to which the multi-level sanding unit corresponds varies.

And (3) obtaining the optimal coarse-fine sand proportion when each sand mill needs to achieve the corresponding grinding effect according to the ergodic calculation of the trained deep neural network, adjusting the coarse-fine sand proportion in the sand mill according to the obtained optimal coarse-fine sand proportion, and finally realizing the intelligent control of each sand mill.

In summary, in the embodiment of the present invention, sampling images of front and rear raw materials of each sand mill connected in series in multiple stages are obtained, a corresponding spectrum image is obtained based on each sampling image, a central point of each spectrum image is used as a circular point to make multiple concentric circles, and an average gray value of each concentric circle is further obtained according to gray values of all pixel points on the circumference of each concentric circle; obtaining average gray values corresponding to all concentric circles in a spectrum image to form an average gray value sequence; labeling the concentric circles based on the radius of each concentric circle from small to large, and obtaining the grain refinement degree and the uniformity degree of the raw material sample corresponding to the frequency spectrum image according to the label of each concentric circle and the corresponding average gray value; the method comprises the steps of obtaining the grain refining degree and the uniformity degree corresponding to a raw material sample before and after grinding of each sand mill to obtain the grinding effect of the sand mill, further obtaining the grain refining degree and the uniformity degree based on a deep neural network and the relation between coarse sand proportion and fine sand proportion in the sand mill, and further obtaining the optimal coarse sand proportion under the premise of the known grinding effect.

It should be noted that: the precedence order of the above embodiments of the present invention is only for description, and does not represent the merits of the embodiments. And specific embodiments thereof have been described above. Other embodiments are within the scope of the following claims. In some cases, the actions or steps recited in the claims may be performed in a different order than in the embodiments and still achieve desirable results. In addition, the processes depicted in the accompanying figures do not necessarily require the particular order shown, or sequential order, to achieve desirable results. In some embodiments, multitasking and parallel processing may also be possible or may be advantageous.

The embodiments in the present specification are described in a progressive manner, and the same and similar parts among the embodiments are referred to each other, and each embodiment focuses on the differences from the other embodiments.

The above description is only for the purpose of illustrating the preferred embodiments of the present invention and should not be taken as limiting the scope of the present invention, which is intended to cover any modifications, equivalents, improvements, etc. within the spirit and scope of the present invention.

Claims (6)

1. A plant-digitization-based pesticide suspending agent production control system, which is characterized by comprising the following modules:

the image acquisition module is used for sampling the raw materials before the treatment of each sand mill connected in series in multiple stages and acquiring a sampling image of each raw material sample; acquiring a frequency spectrum image corresponding to each raw material sample according to the sampling image;

the data acquisition module is used for making a plurality of concentric circles in each frequency spectrum image, acquiring the average gray value on the circumference of each concentric circle, and forming an average gray sequence according to the average gray values on the circumferences of the plurality of concentric circles;

the data processing module is used for acquiring the grain refinement degree and the uniformity degree of the raw material sample according to the average gray sequence of each frequency spectrum image and acquiring the grinding effect of each sand mill according to the grain refinement degree and the uniformity degree;

the intelligent control module is used for acquiring a plurality of grinding data in the actual processing process of the raw materials as training samples, wherein the grinding data comprises the grain refinement degree, the uniformity degree and different coarse-fine sand proportions in each sand mill; training a neural network by using the training sample, obtaining optimal coarse-fine sand ratios corresponding to different grinding effects according to the trained neural network, and controlling the coarse-fine sand ratio in each sand mill according to the optimal coarse-fine sand ratios;

the method for obtaining the grinding effect of each sand mill in the data processing module according to the particle refinement degree and the uniformity degree comprises the following steps:

respectively obtaining the grain refinement degree and the uniformity degree corresponding to the raw material sample before and after grinding by the sand mill, wherein the variation of the grain refinement degree and the uniformity degree before and after grinding by the sand mill is the grinding effect.

2. The factory digitization based pesticide suspension production control system as claimed in claim 1, wherein the method of making multiple concentric circles in each of the spectrum images in the data acquisition module comprises:

and taking the central point of each frequency spectrum image as a circular point, and making a plurality of concentric circles in the frequency spectrum image based on the circular point.

3. The factory digitization-based pesticide suspension agent production control system as claimed in claim 1, wherein the method for acquiring the average gray scale value on the circumference of each concentric circle in the data acquisition module comprises:

and acquiring the perimeter of each concentric circle and the sum of gray values corresponding to all pixel points on the circumference of the concentric circle, wherein the ratio of the sum of the gray values to the perimeter is the average gray value.

4. The factory digitization based pesticide suspension agent production control system as claimed in claim 1, wherein the method for obtaining the particle refinement degree of the corresponding raw material sample according to the average gray sequence of each spectrum image in the data processing module comprises:

labeling according to the radius of the concentric circles, and obtaining the grain refinement degree of the raw material sample according to the label of each concentric circle and the average gray sequence, wherein the grain refinement degree of the raw material sample is as follows:

wherein,indicating the degree of grain refinement;representing a maximum average gray value in the average gray sequence;representing a minimum average gray value in the average gray sequence;is shown asAverage gray values corresponding to the concentric circles;indicating the number of concentric circles.

5. The factory-digitization-based pesticide suspension agent production control system according to claim 4, wherein the method for acquiring the uniformity degree of the corresponding raw material sample in the data processing module according to the average gray sequence of each spectrum image further comprises:

and acquiring the label of the concentric circle corresponding to the maximum average gray value in the average gray sequence, and obtaining the uniformity degree according to the label corresponding to the maximum average gray value and the number of all the concentric circles.

6. The factory digitization-based pesticide suspension agent production control system as claimed in claim 5, wherein the method for obtaining the degree of uniformity in the data processing module according to the number of the concentric circles and the label corresponding to the maximum mean gray value further comprises:

the degree of uniformity is related to a calculation state of each of the concentric circles, which is obtained from a difference between an average gray value and a maximum average gray value of the concentric circles, and when the difference is greater than a preset threshold, the calculation state of the concentric circles is 0, and when the difference is less than the preset threshold, the calculation state of the concentric circles is 1.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210191429.8A CN114648494B (en) | 2022-02-28 | 2022-02-28 | Pesticide suspending agent production control system based on factory digitization |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210191429.8A CN114648494B (en) | 2022-02-28 | 2022-02-28 | Pesticide suspending agent production control system based on factory digitization |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN114648494A CN114648494A (en) | 2022-06-21 |

| CN114648494B true CN114648494B (en) | 2022-12-06 |

Family

ID=81992751

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210191429.8A Active CN114648494B (en) | 2022-02-28 | 2022-02-28 | Pesticide suspending agent production control system based on factory digitization |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114648494B (en) |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2021203618A1 (en) * | 2020-04-08 | 2021-10-14 | 浙江啄云智能科技有限公司 | Image sample generating method and system, and target detection method |

| CN113777033A (en) * | 2021-08-18 | 2021-12-10 | 长沙长泰机器人有限公司 | Raw sliver defect detection method and device based on machine vision |

| CN114051098A (en) * | 2021-11-23 | 2022-02-15 | 河南牧业经济学院 | Intelligent acquisition method and platform for visual images |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SG10201405182WA (en) * | 2014-08-25 | 2016-03-30 | Univ Singapore Technology & Design | Method and system |

| CN106340239B (en) * | 2016-10-21 | 2019-04-05 | 复旦大学 | The optical anti-counterfeiting mark and preparation method thereof that silver nano-grain is formed on titanium dioxide single crystalline surface |

| CN113227755A (en) * | 2018-08-28 | 2021-08-06 | Essenlix 公司 | Assay accuracy improvement |

| CN112743445A (en) * | 2021-02-02 | 2021-05-04 | 河南科技学院 | Chemical mechanical polishing detection device and detection method thereof |

| CN113105249B (en) * | 2021-03-01 | 2023-06-02 | 东阳富仕特磁业有限公司 | Gyromagnetic ferrite preparation method and gyromagnetic ferrite ball milling production line |

| CN113705590B (en) * | 2021-10-28 | 2022-02-22 | 江苏南通元辰钢结构制造有限公司 | Steel structure intelligent polishing control method based on artificial intelligence |

| CN113962333A (en) * | 2021-12-01 | 2022-01-21 | 北京工业大学 | Model training method, fine particulate matter concentration prediction device and electronic equipment |

-

2022

- 2022-02-28 CN CN202210191429.8A patent/CN114648494B/en active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2021203618A1 (en) * | 2020-04-08 | 2021-10-14 | 浙江啄云智能科技有限公司 | Image sample generating method and system, and target detection method |

| CN113777033A (en) * | 2021-08-18 | 2021-12-10 | 长沙长泰机器人有限公司 | Raw sliver defect detection method and device based on machine vision |

| CN114051098A (en) * | 2021-11-23 | 2022-02-15 | 河南牧业经济学院 | Intelligent acquisition method and platform for visual images |

Also Published As

| Publication number | Publication date |

|---|---|

| CN114648494A (en) | 2022-06-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110174334B (en) | Coarse aggregate form quality detection system and method | |

| CN112419397B (en) | Ore granularity grading method and system based on image and deep neural network | |

| CN210269521U (en) | Coarse aggregate form quality detection system | |

| CN111539920B (en) | Automatic detection method for fermented grain quality in white spirit brewing process | |

| CN114648494B (en) | Pesticide suspending agent production control system based on factory digitization | |

| CN108227664A (en) | Control of product quality equipment and method of quality control based on sample data training | |

| CN102855641A (en) | Fruit level classification system based on external quality | |

| US20230166985A1 (en) | Systems and Methods for Treating Wastewater | |

| Iglesias et al. | Automatic characterization of iron ore by digital microscopy and image analysis | |

| CN113706566B (en) | Edge detection-based perfuming and spraying performance detection method | |

| CN117428199B (en) | Alloy powder atomizing device and atomizing method | |

| JP2021170373A (en) | Water quality analysis method | |

| CN115294106B (en) | Method for detecting uniformity of particles in latex solution | |

| CN113743424A (en) | DBSCAN cluster analysis method for extracting characteristic points of full tailings dynamic flocculation sedimentation image | |

| CN115179194A (en) | Mold machining control method based on big data | |

| JP2001523311A (en) | Method and apparatus for controlling a multi-stage sorter | |

| CN115900586B (en) | Real-time monitoring device and real-time monitoring method for morphology of reclaimed sand particles | |

| CN117237799A (en) | Tea fresh leaf grading method based on image recognition | |

| CN114462543A (en) | Screening method for producing recycled asphalt concrete | |

| WO2023097664A1 (en) | Robot-assisted intelligent inverse design for automatic nanocrystal characterization acceleration material | |

| CN114863277A (en) | Machine vision-based method for rapidly detecting irregular particle group overrun particles | |

| CN112966705A (en) | Adaboost-based agricultural irrigation drip irrigation head quality online identification method | |

| CN118204275B (en) | Phosphogypsum impurity removal method and phosphogypsum impurity removal system based on visual detection technology | |

| CN113100207A (en) | Accurate formula pesticide application robot system based on wheat disease information and pesticide application method | |

| CN117752020A (en) | Efficient continuous production method of fermented feed |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |