CN114368508A - A pad pasting device that is used for solar PV modules to encapsulate POE photovoltaic glued membrane - Google Patents

A pad pasting device that is used for solar PV modules to encapsulate POE photovoltaic glued membrane Download PDFInfo

- Publication number

- CN114368508A CN114368508A CN202210136513.XA CN202210136513A CN114368508A CN 114368508 A CN114368508 A CN 114368508A CN 202210136513 A CN202210136513 A CN 202210136513A CN 114368508 A CN114368508 A CN 114368508A

- Authority

- CN

- China

- Prior art keywords

- frame

- frames

- supporting

- photovoltaic

- film

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B33/00—Packaging articles by applying removable, e.g. strippable, coatings

- B65B33/02—Packaging small articles, e.g. spare parts for machines or engines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B35/00—Supplying, feeding, arranging or orientating articles to be packaged

- B65B35/10—Feeding, e.g. conveying, single articles

- B65B35/24—Feeding, e.g. conveying, single articles by endless belts or chains

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B41/00—Supplying or feeding container-forming sheets or wrapping material

- B65B41/12—Feeding webs from rolls

- B65B41/16—Feeding webs from rolls by rollers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B61/00—Auxiliary devices, not otherwise provided for, for operating on sheets, blanks, webs, binding material, containers or packages

- B65B61/04—Auxiliary devices, not otherwise provided for, for operating on sheets, blanks, webs, binding material, containers or packages for severing webs, or for separating joined packages

- B65B61/06—Auxiliary devices, not otherwise provided for, for operating on sheets, blanks, webs, binding material, containers or packages for severing webs, or for separating joined packages by cutting

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P70/00—Climate change mitigation technologies in the production process for final industrial or consumer products

- Y02P70/50—Manufacturing or production processes characterised by the final manufactured product

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Photovoltaic Devices (AREA)

Abstract

The invention relates to a film sticking device, in particular to a film sticking device for a POE (polyolefin elastomer) photovoltaic adhesive film for packaging a solar photovoltaic module. The invention provides a film pasting device for a POE (Power over Ethernet) photovoltaic adhesive film for packaging a solar photovoltaic module, which can automatically complete the loading of a photovoltaic panel. The photovoltaic panels are stacked on the first supporting frame, the conveyor belt pushes the photovoltaic panels to move to the left side through the connecting blocks, the photovoltaic panels on the first supporting frame can be sequentially dropped onto the conveyor belt, the photovoltaic panels do not need to be manually placed one by one, film pasting can be continuously carried out, the purpose of automatic discharging is achieved, and therefore the overall working efficiency is improved.

Description

Technical Field

The invention relates to a film sticking device, in particular to a film sticking device for a POE (polyolefin elastomer) photovoltaic adhesive film for packaging a solar photovoltaic module.

Background

The photovoltaic packaging adhesive film is an important material in the solar photovoltaic technology industry, plays an important role in bonding a battery piece with photovoltaic glass and a back plate, and simultaneously has multiple functions of mechanical buffering and protection of a photovoltaic module, PID resistance of the module and ultraviolet resistance protection of the back plate, so that a layer of adhesive film is adhered to the surface of the solar photovoltaic module in the processing process of the solar photovoltaic module to protect the solar photovoltaic module.

The device comprises a first support and a conveying mechanism, wherein the two first supports are symmetrically arranged in parallel, the conveying mechanism is arranged between the two first supports, the conveying mechanism conveys the photovoltaic panels at intervals along the length direction of the first supports, the position corresponding to the photovoltaic panels is a film sticking station, the film sticking mechanism is arranged on the first supports and is positioned above the conveying mechanism, and the film sticking mechanism points to the film sticking station; the tip that keeps the film through blowing the membrane module is unsettled, and the rethread presss from both sides the membrane module and carries out the centre gripping and remove the film to the tip of film, again by the pad pasting subassembly with the film laminating on the photovoltaic board surface, but the conflict setting through pad pasting subassembly and cutting assembly simultaneously with the film cutting, has realized the automatic continuous pad pasting of film, has reduced the hand labor power, has improved pad pasting efficiency. Although above-mentioned patent has realized the automatic continuous pad pasting of film, has improved pad pasting efficiency, this patent still needs the manual work to place the photovoltaic board on conveying mechanism to be convenient for the photovoltaic board pad pasting, the manual work is placed the photovoltaic board and is difficult to guarantee that the photovoltaic board position is unified, the deviation easily appears when the pad pasting, and then leads to the pad pasting effect not good, the phenomenon that the pad pasting is complete appears not even, so will influence the use in photovoltaic board later stage, reduce the quality of photovoltaic board pad pasting.

Therefore, a film pasting device for a POE photovoltaic adhesive film for packaging a solar photovoltaic module, which can automatically complete the loading of a photovoltaic panel, needs to be designed.

Disclosure of Invention

In order to overcome the defects that the existing film pasting device needs to manually feed the photovoltaic panel, the position uniformity of the photovoltaic panel is difficult to ensure, and the film pasting quality of the photovoltaic panel is influenced, the technical problems of the invention are as follows: the film pasting device for the POE photovoltaic adhesive film for packaging the solar photovoltaic module can automatically complete the feeding of the photovoltaic panel.

The technical implementation scheme of the invention is as follows: the utility model provides a pad pasting device for solar PV modules encapsulation POE photovoltaic glued membrane, including the chassis, first support frame, the slide bar, promote the piece, transport mechanism and cutting mechanism, the chassis is totally two, be connected with first support frame between two chassis upsides, two chassis upsides all slidingtype are equipped with the slide bar, one side that two slide bars are close to each other all is connected with and promotes the piece, it is used for spacing glued membrane book to promote the piece, be connected with between two chassis and need not the manual work and carry out the transport mechanism that conveys to the photovoltaic board, the last cutting mechanism that need not the manual work and carry out the shearing to the glued membrane that is equipped with of transport mechanism.

Further, the transmission mechanism comprises a first fixed frame, a first connecting frame, a mounting frame, a motor and a rotating frame, the cylinder, the conveyer belt, the connecting block, the second support frame, gyro wheel and first carriage, two chassis top left sides all are equipped with first mount, be connected with first link between two first mounts, two chassis lower part right sides all are equipped with the mounting bracket, be equipped with the motor on the anterior mounting bracket, rear portion mounting bracket and two chassis upper portion left sides equal rotary type are equipped with the rotating turret, the front side of motor output shaft also is connected with the rotating turret, all be connected with the cylinder between two rotating turrets of the left and right sides, the cover has the conveyer belt between two cylinders, both sides all evenly are equipped with five connecting blocks about the conveyer belt, first link top left side is equipped with the second support frame, the last rotary type of rotating of second support frame is equipped with the gyro wheel, first link upper portion right side is equipped with first carriage.

Further, cutting mechanism is including the roof-rack, the second link, spacing, the elevator, the cutter, return spring and dead lever, both sides all are equipped with the roof-rack around every connecting block, upper portion roof-rack left side wall all has certain radian, and reset groove has all been opened on upper portion roof-rack right side, the roof-rack of lower part is the mirror image relation with the roof-rack on upper portion, first link top left side is connected with the second link, the second link top is equipped with spacing, the symmetry slidingtype is equipped with the elevator around on the spacing, all be connected with return spring between two elevator top right sides and the spacing, be connected with the cutter between two elevator bottoms, cutter and connecting block contact cooperation, one side that two elevators kept away from each other all is connected with the dead lever, two dead levers all with roof-rack contact cooperation.

Further comprises a supporting mechanism which is convenient for people to replace the adhesive film, the supporting mechanism comprises a return spring, a second fixing frame and a supporting block, ejector pin, a handle, compression spring and second carriage, all connect reset spring between the chassis of one side and homonymy that two promotion pieces kept away from each other, two reset spring all overlap on the slide bar of homonymy, be equipped with the second mount on the first support frame, second mount upside is equipped with the second carriage, it has lower silo to open in the middle of the second carriage, second mount downside slidingtype is equipped with the supporting shoe, two promotion pieces all cooperate with the contact of second carriage, the supporting shoe right side is equipped with the handle, all be connected with compression spring between both sides and the second mount around the supporting shoe bottom right side, both sides are equipped with the ejector pin around the supporting shoe top, the upside of two ejector pins is the inclined plane, and two ejector pins all cooperate with the promotion piece contact of homonymy.

Further, still including the unloading mechanism that can carry out the unloading to the glued membrane automatically, unloading mechanism is including the guide bar, the carriage, the sliding plate, gag lever post and fixed frame, the upper portion right side of two promotion pieces all is equipped with the guide bar, first support frame right side is equipped with the carriage, symmetrical slidingtype is equipped with the gag lever post around the left side of carriage upper portion, be connected with the sliding plate between two gag lever post right sides, sliding plate and carriage sliding fit, symmetrical division has the inclined groove around the sliding plate bottom, two guide bars all with the inclined groove sliding fit of homonymy, the carriage top is equipped with fixed frame.

Further, still including avoiding the direct discharge mechanism who falls on the conveyer belt of reel, discharge mechanism is including spacing frame, the dwang, torsion spring and rotation frame, the supporting shoe lower part is equipped with spacing frame, the equal rotary type in the anterior left and right sides of spacing frame is equipped with the dwang, all be connected with torsion spring between two dwangs and the spacing frame, be connected with the rotation frame between two dwang lower parts, it cooperates with spacing frame contact to rotate the frame, it has the one deck cushion to paste in the rotation frame, avoid the cylinder to drop for a long time inside rotating the frame, and then the frame is rotated in wearing and tearing.

Further, still including the mechanism that flattens that can make the glued membrane paste more level and smooth, the mechanism that flattens is equipped with the connecting plate including connecting plate, briquetting and extension spring at second carriage top, and connecting plate bottom slidingtype is equipped with the briquetting, all is connected with extension spring between both sides and the connecting plate around the briquetting top.

Furthermore, a layer of soft cushion is pasted in the rotating frame.

The invention provides a film sticking device for a POE (polyolefin elastomer) photovoltaic adhesive film for packaging a solar photovoltaic module, which has the following advantages: 1. the motor is used as a power source to drive the conveyor belt to rotate to convey the photovoltaic panel, the adhesive film is pulled by the leftmost photovoltaic panel to be uniformly adhered to the photovoltaic panel, and then the adhesive film is sequentially adhered to the rest photovoltaic panels, so that the adhering mode is more accurate compared with a mode of manually pulling the adhesive film to adhere, and the phenomenon of uneven adhesion caused by different pulling force is avoided;

2. the photovoltaic panels are stacked on the first supporting frame, the conveyor belt pushes the photovoltaic panels to move to the left side through the connecting blocks, the photovoltaic panels on the first supporting frame can sequentially fall onto the conveyor belt, the photovoltaic panels do not need to be manually placed one by one, film pasting can be continuously carried out, the purpose of automatic blanking is achieved, and the overall working efficiency is improved;

3. people place the adhesive film roll on the fixed frame, and then push the handle downwards to enable the ejector rod to drive the pushing block to move outwards without limiting the residual winding drum, so that the guide rod drives the sliding plate to move towards the right side, the adhesive film roll on the fixed frame automatically drops downwards to the supporting block and is limited by the pushing block, and the operation mode is more labor-saving and faster when the adhesive film is replaced;

4. the reel remaining on the pushing block falls onto the rotating frame through the blanking groove, so that the rotating frame is forced to rotate in an inclined state, the reel slides downwards to the ground, and the reel is prevented from falling on the conveying belt to damage the photovoltaic panel;

5. photovoltaic board will be through the briquetting extrusion after pasting the glued membrane, can flatten the glued membrane on the photovoltaic board, increase the roughness.

Drawings

Fig. 1 is a schematic perspective view of a first embodiment of the present invention.

Fig. 2 is a schematic perspective view of a second embodiment of the present invention.

Fig. 3 is a partial perspective view of the present invention.

Fig. 4 is a schematic perspective view of the conveying mechanism of the present invention.

Fig. 5 is a schematic view of a first partial body structure of the transfer mechanism of the present invention.

Fig. 6 is a schematic diagram of a second partial body structure of the transfer mechanism of the present invention.

Fig. 7 is a schematic perspective view of the cutting mechanism of the present invention.

Fig. 8 is a schematic perspective view of a part of the cutting mechanism of the present invention.

Fig. 9 is a schematic perspective view of the supporting mechanism of the present invention.

Fig. 10 is a schematic view of a first partially separated body structure of the support mechanism of the present invention.

Fig. 11 is a schematic view of a second partial structure of the supporting mechanism of the present invention.

Fig. 12 is a schematic perspective view of the feeding mechanism of the present invention.

Fig. 13 is a schematic view of a first partially separated body structure of the feeding mechanism of the present invention.

FIG. 14 is a schematic view of a second partial body structure of the present invention showing the liberation of the charge.

Fig. 15 is a schematic perspective view of the discharging mechanism of the present invention.

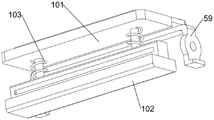

Fig. 16 is a schematic perspective view of the flattening mechanism of the present invention.

Fig. 17 is a schematic perspective view of a part of the flattening mechanism of the present invention.

The parts are labeled as follows: 1. the device comprises a base frame, 2, a first supporting frame, 3, a sliding rod, 4, a pushing block, 5, a conveying mechanism, 51, a first fixing frame, 52, a first connecting frame, 53, a mounting frame, 54, a motor, 55, a rotating frame, 56, a roller, 57, a conveying belt, 58, a connecting block, 59, a second supporting frame, 510, a roller, 511, a first supporting frame, 6, a cutting mechanism, 61, a top frame, 62, a second connecting frame, 63, a limiting frame, 64, a lifting block, 65, a cutter, 66, a return spring, 67, a fixing rod, 7, a supporting mechanism, 71, a return spring, 72, a second fixing frame, 73, a supporting block, 74, a top rod, 75, a handle, 76, a compression spring, 77, a second supporting frame, 8, a blanking mechanism, 81, a guide rod, 82, a connecting frame, 83, a sliding plate, 84, a limiting rod, 85, a fixing frame, 9, a discharging mechanism, 91, a limiting frame, 92, a sliding plate, a pushing block, 5, a conveying mechanism, a cutting mechanism, the device comprises a rotating rod 93, a torsion spring 94, a rotating frame 10, a flattening mechanism 101, a connecting plate 102, a pressing block 103 and an extension spring.

Detailed Description

It is to be noted that, in the case of the different described embodiments, identical components are provided with the same reference numerals or the same component names, wherein the disclosure contained in the entire description can be transferred to identical components having the same reference numerals or the same component names in a meaningful manner. The positional references selected in the description, such as upper, lower, lateral, etc., refer also to the directly described and illustrated figures and are to be read into the new position in the sense of a change in position.

Example 1

The utility model provides a pad pasting device for solar PV modules encapsulation POE photovoltaic glued membrane, show in fig. 1-3, including chassis 1, first support frame 2, slide bar 3, catch bar 4, transport mechanism 5 and cutting mechanism 6, chassis 1 is totally two, be connected with first support frame 2 between 1 upside of two chassis, 1 upsides of two chassis all slidingtype is equipped with and is used for spacing slide bar 3, one side that two slide bars 3 are close to each other all is connected with can carry out spacing catch bar 4 to the glued membrane book, be connected with transport mechanism 5 that can carry out the conveying to the photovoltaic board automatically between two chassis 1, be equipped with on transport mechanism 5 and carry out cutting mechanism 6 that cuts to the unnecessary glued membrane on the photovoltaic board.

As shown in fig. 1, 2, 4, 5 and 6, the transmission mechanism 5 includes a first fixing frame 51, a first connecting frame 52, a mounting frame 53, a motor 54, a rotating frame 55, a roller 56, a conveyor belt 57, a connecting block 58, a second supporting frame 59, a roller 510 and a first supporting frame 511, the first fixing frame 51 is welded on the left side of the top of each of the two bottom frames 1, the first connecting frame 52 is connected between the two first fixing frames 51, the mounting frame 53 is welded on the right side of the lower portion of each of the two bottom frames 1, the motor 54 is installed on the front mounting frame 53, the rotating frame 55 is rotatably installed on the rear mounting frame 53 and the left side of the upper portion of each of the two bottom frames 1, the rotating frame 55 is also connected on the front side of the output shaft of the motor 54, the roller 56 is connected between the two rotating frames 55 on the left and right sides, the conveyor belt 57 for conveying photovoltaic panels is sleeved between the two rollers 56, the upper and lower sides of the conveyor belt 57 are uniformly provided with five connecting blocks 58, the left side of the top of the first connecting frame 52 is provided with a second supporting frame 59, the second supporting frame 59 is rotatably provided with a roller 510 capable of limiting the adhesive film, and the right side of the upper part of the first connecting frame 52 is welded with a first supporting frame 511.

As shown in fig. 1, 2, 7 and 8, the cutting mechanism 6 includes a top frame 61, a second connecting frame 62, a limiting frame 63, lifting blocks 64, a cutter 65, a return spring 66 and a fixing rod 67, the top frame 61 is disposed on the front side and the rear side of each connecting block 58, the left side wall of the upper top frame 61 has a certain radian, the right side of the upper top frame 61 is provided with a reset groove, the top frame 61 on the lower portion and the top frame 61 on the upper portion are in a mirror image relationship, the left side of the top portion of the first connecting frame 52 is connected with the second connecting frame 62, the top portion of the second connecting frame 62 is welded with the limiting frame 63, the lifting blocks 64 are symmetrically disposed on the limiting frame 63 in a sliding manner, the return spring 66 is connected between the right side of the top portions of the two lifting blocks 64 and the limiting frame 63, the cutter 65 capable of cutting redundant adhesive films on the photovoltaic panel is connected between the bottom portions of the two lifting blocks 64, the cutter 65 is in contact with the connecting blocks 58, one side that two elevator blocks 64 kept away from each other all is connected with dead lever 67, and two dead levers 67 all cooperate with the contact of roof-rack 61.

When people need to paste an adhesive film on the surface of the photovoltaic panel, people can fix an adhesive film roll customized according to the size of the photovoltaic panel at a position between the two pushing blocks 4, drive the pushing blocks 4 to move outwards by pulling the sliding rod 3 outwards, align the adhesive film roll with the two pushing blocks 4 after the pushing blocks 4 move to a proper position, then move the sliding rod 3 inwards to drive the pushing blocks 4 to move and reset inwards, so that the pushing blocks 4 clamp the adhesive film roll, and further limit a winding drum of the adhesive film roll, then people place the photovoltaic panel on the conveyor belt 57, place the photovoltaic panel between every two connecting blocks 58, simultaneously place the photovoltaic panel on the first supporting frame 511 to enable the photovoltaic panel to be in contact with the conveyor belt 57, and place the first supporting frame 511 full, so that five photovoltaic panels in contact with the conveyor belt 57 can be provided, and people can pull one end of the adhesive film, so that the glue film roll rotates along the pushing block 4, one end of the glue film can penetrate through the lower part of the roller 510, the glue film is pasted on the surface of a first photovoltaic plate counted from left to right, the glue film is limited by the roller 510, then one can start the motor 54 to work, the output shaft of the motor 54 rotates to drive the two rotating frames 55 at the right part and the two rotating frames 56 at the right part to rotate, the conveyor belt 57 is driven by the right rotating frame 56, the two rotating frames 56 at the left side and the two rotating frames 55 at the left side rotate, the conveyor belt 57 rotates to drive the connecting block 58 to rotate, so that the connecting block 58 pushes the photovoltaic plate to move along with the conveyor belt 57 to the left side, the first photovoltaic plate can pull one end of the glue film to move and elongate to the left side, the glue film is in contact with the surface of a second photovoltaic plate due to the limitation of the roller 510 and then pasted on the surface of the second photovoltaic plate, the connecting block 58 moves to the left side and is also in contact with the glue film, because the adhesive film is a customized adhesive film, the adhesive film in contact with the connecting block 58 will not have adhesive property, only the adhesive film part in contact with the photovoltaic panel has adhesive property, and so on, the adhesive film can be contacted with the next photovoltaic panel and adhered by moving the photovoltaic panel stained with the adhesive film to achieve the purpose of adhering the film, and the bottommost photovoltaic panel in the first supporting frame 511 is pushed by the connecting block 58 to move left to leave a gap, the photovoltaic panels in the first supporting frame 511 will slide down one grid in sequence, so that the second photovoltaic panels from bottom to top in the first supporting frame 511 fall onto the conveyor belt 57, and so on in sequence, people only need to add the photovoltaic panel into the first supporting frame 511, and will drive the top frame 61 to move to the left while the connecting block 58 moves to the left, the top frame 61 corresponds to the size of the photovoltaic panel, the top frame 61 moves to the left to push the fixing rod 67 to move upwards by means of the self cambered surface, and then drive the lifting block 64 and the cutter 65 to move upwards, the lifting block 64 moves upwards to compress the return spring 66, the top frame 61 moves towards the left side continuously to move towards the left side along with the fixed rod 67, when the top frame 61 moves to the reset groove of itself to be aligned with the fixed rod 67, the lifting block 64 drives the cutter 65 to move downwards under the reset action of the return spring 66 to reset, so that the cutter 65 cuts the adhesive film, the right wall of the photovoltaic panel is adhered downwards and is contacted with the connecting block 58, thus cutting off the redundant adhesive film on the photovoltaic panel, the adhered photovoltaic panel is driven by the conveyor belt 57 to move towards the left side to the limit and then falls onto a material transferring tool, people can collect the photovoltaic panel with the film adhered on the material transferring tool, the leftover materials on the photovoltaic panel with the film adhered are required to be cut, the conveyor belt 57 drives the photovoltaic panel and the connecting block 58 to move towards the left side continuously, make roof-rack 61 continue to move left and promote dead lever 67, unnecessary part is cuted on the photovoltaic board after gluing the glued membrane to alright the above-mentioned operation of repetition, roof-rack 61 corresponds with each photovoltaic board, can guarantee that each photovoltaic board is pasting the epimembranal back, can both cut the glued membrane through cutter 65, need not the manual work and cut, after the glued membrane book on promotion piece 4 all used, people can pause motor 54, make conveyer belt 57 no longer convey the photovoltaic board, people can drive promotion piece 4 outside lateral movement to outside pulling slide bar 3, make remaining glued membrane reel drop, people can repeat above-mentioned operation and place new glued membrane book again, and then carry on spacingly through promotion piece 4, alright the above-mentioned operation of repetition glues glued membrane one end on first photovoltaic board, can restart motor 54 and accomplish the mucosa work of photovoltaic board.

Example 2

On the basis of embodiment 1, as shown in fig. 1, 2, 9, 10 and 11, the device further comprises a supporting mechanism 7, the supporting mechanism 7 comprises a return spring 71, a second fixing frame 72, a supporting block 73, a top rod 74, a handle 75, a compression spring 76 and a second supporting frame 77, the return spring 71 is connected between one side of each pushing block 4 away from each other and the chassis 1 on the same side, the two return springs 71 are sleeved on the sliding rod 3 on the same side, the first supporting frame 2 is welded with the second fixing frame 72, the second supporting frame 77 for preventing the film roll from falling is arranged on the upper side of the second fixing frame 72, a blanking groove is arranged in the middle of the second supporting frame 77, the supporting block 73 is slidably arranged on the lower side of the second fixing frame 72, the two pushing blocks 4 are in contact fit with the second supporting frame 77, the handle 75 is welded on the right side of the supporting block 73, the compression spring 76 is connected between the front side and the rear side of the right side of the bottom of the supporting block 73 and the second fixing frame 72, ejector rods 74 are arranged on the front side and the rear side of the top of the supporting block 73, the upper sides of the two ejector rods 74 are inclined planes, and the two ejector rods 74 are in contact fit with the pushing block 4 on the same side.

When the glue film roll is required to be fixed between the two pushing blocks 4, the handle 75 can be pulled downwards to drive the supporting block 73 to move downwards, the compression spring 76 is compressed accordingly, the supporting block 73 drives the ejector rod 74 to move downwards, the reset spring 71 is in a stretching state initially, the ejector rod 74 does not block the pushing blocks 4 when moving downwards, the two pushing blocks 4 can move outwards under the reset action of the reset spring 71, and further drive the sliding rod 3 to move outwards, at this time, people can place the glue film roll on the second supporting frame 77, then the handle 75 can be loosened, the supporting block 73 drives the handle 75 to move upwards and reset under the reset action of the compression spring 76, the supporting block 73 simultaneously drives the ejector rod 74 to move upwards and reset, so that the ejector rod 74 pushes the pushing block 4 to move inwards to reset by means of the inclined plane of the ejector rod 74, the reset spring 71 stretches along with the ejector rod, and further drives the sliding rod 3 to move inwards and reset, promote piece 4 inboard reset alright card advance in the glued membrane reel, and then it is spacing to glue membrane book, so it is more convenient when people place glued membrane book, need not artifical pulling slide bar 3 completion material loading work simultaneously, only leave the reel at glued membrane book end of use, people can repeat the downward pulling handle 75 of above-mentioned operation, and then make ejector pin 74 remove and no longer extrude promotion piece 4, promotion piece 4 alright outside move no longer spacing to the reel, make the reel drop to second carriage 77, and then down drop through the feed chute of second carriage 77, people alright directly place new glued membrane book on second carriage 77, repeat above-mentioned operation accomplish to the spacing of glued membrane book can.

Fig. 1, fig. 2, fig. 12, fig. 13 and fig. 14 show, still include unloading mechanism 8, unloading mechanism 8 is including guide bar 81, the connection frame 82, the sliding plate 83, gag lever post 84 and fixed frame 85, two upper portion right sides that promote piece 4 have all welded guide bar 81, the welding of first support frame 2 right side has connection frame 82, the symmetrical slidingtype is equipped with gag lever post 84 around connection frame 82 upper portion left side, be connected with sliding plate 83 between two gag lever post 84 right sides, sliding plate 83 and connection frame 82 sliding fit, sliding plate 83 bottom front and back symmetry is opened has the inclined groove, two guide bar 81 all with the inclined groove sliding fit of homonymy, connection frame 82 top is equipped with the fixed frame 85 that is used for depositing the glued membrane book.

When the photovoltaic panel needs to be laminated, a person can place the adhesive film roll in the fixing frame 85 to enable the adhesive film roll to contact with the sliding plate 83, when the adhesive film roll is replaced, the person pulls the handle 75 downwards to enable the ejector rod 74 to drive the pushing block 4 to move outwards, the pushing block 4 drives the guide rod 81 to move outwards at the same time, the guide rod 81 moves along the inclined groove on the sliding plate 83 to further drive the sliding plate 83 to move towards the right side, the adhesive film roll can fall into the supporting block 73 without being blocked by the sliding plate 83, at the moment, the person releases the handle 75 again to enable the ejector rod 74 to drive the pushing block 4 to move inwards to limit the adhesive film roll, the pushing block 4 moves inwards and drives the guide rod 81 to move inwards to enable the guide rod 81 to move inwards along the inclined groove on the sliding plate 83, the sliding plate 83 is driven to move towards the left side to reset, and the sliding plate 83 blocks other adhesive film rolls again, so under the effect of unloading mechanism 8, when the glued membrane book finishes using and changes, new glued membrane book will drop to second carriage 77 automatically in, need not the manual work and places the glued membrane book, only need the glued membrane book in fixed frame 85 be about to fill up when finishing using can.

Shown in fig. 1, fig. 2 and fig. 15, still include discharge mechanism 9, discharge mechanism 9 is including spacing frame 91, dwang 92, torsion spring 93 and rotation frame 94, supporting shoe 73 lower part is equipped with spacing frame 91, the equal rotary type in the anterior left and right sides of spacing frame 91 is equipped with dwang 92, all be connected with torsion spring 93 between two dwang 92 and the spacing frame 91, be connected with the rotation frame 94 that is convenient for the glued membrane to roll up the reel landing between the lower part of two dwang 92, rotation frame 94 and spacing frame 91 contact fit, paste the one deck cushion in the rotation frame 94, avoid the cylinder 56 to drop for a long time inside rotating frame 94, and then wearing and tearing rotate frame 94.

When changing the glued membrane book, promote piece 4 and no longer carry on spacingly to the reel to the outside removal, make the reel drop to rotating frame 94 through the lower silo, make rotating frame 94 rotate downwards under the effect of gravity, and then drive dwang 92 and rotate, torsion spring 93 takes place deformation thereupon, rotating frame 94 will be the tilt state, make the reel that rotates on the frame 94 landing downwards subaerially, and then break away from rotating frame 94, it is no longer the atress to rotate frame 94, make dwang 92 reset under torsion spring 93's reset action reverse rotation, and then drive and rotate frame 94 and upwards reverse rotation and reset and spacing frame 91 contact, and then be horizontal state again, so can avoid the reel directly to drop on conveyer belt 57 and then pound to the photovoltaic board under the effect of rotating frame 94, the fragile photovoltaic board.

As shown in fig. 1, 2, 16 and 17, the photovoltaic module further comprises a flattening mechanism 10, the flattening mechanism 10 comprises a connecting plate 101, a pressing block 102 and a tension spring 103, the connecting plate 101 is arranged at the top of the second supporting frame 59, the pressing block 102 capable of enabling the glue film to be pasted on the photovoltaic panel to be flatter is arranged at the bottom of the connecting plate 101 in a sliding mode, and the tension spring 103 is connected between the front side and the rear side of the top of the pressing block 102 and the connecting plate 101.

When people place the photovoltaic panels on the conveyor belt 57 in sequence, people need to push the pressing block 102 upwards to compress the tension spring 103, so that one photovoltaic panel can be placed on the conveyor belt 57 at a position below the pressing block 102, then one end of the adhesive film is adhered to the surface of the first photovoltaic panel counted from left to right, then people loosen the pressing block 102 to enable the pressing block 102 to move downwards under the reset action of the tension spring 103 to reset, the pressing block 102 is further pressed on the surface of the first photovoltaic panel, the tension spring 103 is still in a compressed state at the moment, the pressing block 102 presses the photovoltaic panel through the compressed force to enable the adhesive film to be tightly attached to the photovoltaic panel, when the film attaching work of the photovoltaic panel is carried out, the photovoltaic panel gradually moves the adhesive film to be attached to the left side, then the adhesive film is extruded by the pressing block 102 to further improve the flatness of the adhesive film attached to the photovoltaic panel, after the film attaching of the photovoltaic panels is completed, after the pressing block 102 flattens the last photovoltaic panel on the conveyor belt 57, the pressing block 102 is reset upwards to an initial state under the reset action of the tension spring 103, so that the tension spring 103 returns to a natural state.

It should be understood that the above description is for exemplary purposes only and is not meant to limit the present invention. Those skilled in the art will appreciate that variations of the present invention are intended to be included within the scope of the claims herein.

Claims (8)

1. The utility model provides a pad pasting device for solar PV modules encapsulation POE photovoltaic glued membrane, including chassis (1), first support frame (2), slide bar (3) and promotion piece (4), chassis (1) totally two, be connected with first support frame (2) between two chassis (1) upsides, two chassis (1) upsides all slidingtype are equipped with slide bar (3), one side that two slide bar (3) are close to each other all is connected with promotes piece (4), it is used for spacing glued membrane book to promote piece (4), characterized by: still including transport mechanism (5) and cutting mechanism (6), be connected with transport mechanism (5) that need not the manual work and carry out the conveying to the photovoltaic board between two chassis (1), be equipped with on transport mechanism (5) and need not the manual work and carry out cutting mechanism (6) of cuting to the glued membrane.

2. The film sticking device for the POE (polyolefin elastomer) photovoltaic film for packaging the solar photovoltaic module as claimed in claim 1, which is characterized in that: the conveying mechanism (5) comprises first fixing frames (51), first connecting frames (52), mounting frames (53), motors (54), rotating frames (55), rollers (56), conveying belts (57), connecting blocks (58), second supporting frames (59), rollers (510) and first supporting frames (511), wherein the first fixing frames (51) are arranged on the left sides of the tops of the two bottom frames (1), the first connecting frames (52) are connected between the two first fixing frames (51), the mounting frames (53) are arranged on the right sides of the lower portions of the two bottom frames (1), the motors (54) are arranged on the front mounting frames (53), the rotating frames (55) are rotatably arranged on the rear mounting frames (53) and the left sides of the upper portions of the two bottom frames (1), the rotating frames (55) are also connected to the front sides of output shafts of the motors (54), the rollers (56) are connected between the two rotating frames (55) on the left side and the right side, the conveying belt (57) is sleeved between the two rollers (56), five connecting blocks (58) are uniformly arranged on the upper side and the lower side of the conveying belt (57), the second supporting frame (59) is arranged on the left side of the top of the first connecting frame (52), the roller (510) is rotatably arranged on the second supporting frame (59), and the first supporting frame (511) is arranged on the right side of the upper portion of the first connecting frame (52).

3. The film sticking device for the POE (polyolefin elastomer) photovoltaic film for packaging the solar photovoltaic module as claimed in claim 2, which is characterized in that: the cutting mechanism (6) comprises a top frame (61), second connecting frames (62), limiting frames (63), lifting blocks (64), cutters (65), return springs (66) and fixing rods (67), the top frame (61) is arranged on the front side and the rear side of each connecting block (58), the left side wall of the upper top frame (61) is provided with a certain radian, the right side of the upper top frame (61) is provided with a reset groove, the top frame (61) on the lower portion and the top frame (61) on the upper portion are in a mirror image relationship, the left side of the top portion of the first connecting frame (52) is connected with the second connecting frame (62), the tops of the second connecting frames (62) are provided with the limiting frames (63), the lifting blocks (64) are symmetrically arranged on the front side and the rear side of the limiting frames (63) in a sliding manner, the return springs (66) are respectively connected between the right sides of the tops of the two lifting blocks (64) and the limiting frames (63), the cutters (65) are connected between the bottoms of the two lifting blocks (64), cutter (65) and connecting block (58) contact cooperation, and one side that two elevator blocks (64) kept away from each other all is connected with dead lever (67), and two dead levers (67) all cooperate with roof-rack (61) contact.

4. The film sticking device for the POE (polyolefin elastomer) photovoltaic film for packaging the solar photovoltaic module as claimed in claim 3, which is characterized in that: the glue film replacing device further comprises a supporting mechanism (7) convenient for people to replace glue films, the supporting mechanism (7) comprises a reset spring (71), a second fixing frame (72), a supporting block (73), an ejector rod (74), a handle (75), a compression spring (76) and a second supporting frame (77), the reset spring (71) is connected between one side, away from each other, of the two pushing blocks (4) and the chassis (1) on the same side, the two reset springs (71) are sleeved on the sliding rod (3) on the same side, the second fixing frame (72) is arranged on the first supporting frame (2), the second supporting frame (77) is arranged on the upper side of the second fixing frame (72), a blanking groove is formed in the middle of the second supporting frame (77), the supporting block (73) is arranged on the lower side of the second fixing frame (72) in a sliding mode, the two pushing blocks (4) are in contact fit with the second supporting frame (77), the handle (75) is arranged on the right side of the supporting block (73), compression springs (76) are connected between the front side and the rear side of the right side of the bottom of the supporting block (73) and the second fixing frame (72), ejector rods (74) are arranged on the front side and the rear side of the top of the supporting block (73), the upper sides of the two ejector rods (74) are inclined planes, and the two ejector rods (74) are in contact fit with the pushing block (4) on the same side.

5. The film sticking device for the POE (polyolefin elastomer) photovoltaic film for packaging the solar photovoltaic module as claimed in claim 4, which is characterized in that: still including unloading mechanism (8) that can carry out the unloading to the glued membrane automatically, unloading mechanism (8) are including guide bar (81), carriage (82), sliding plate (83), gag lever post (84) and fixed frame (85), two upper portion right sides that promote piece (4) all are equipped with guide bar (81), first carriage (2) right side is equipped with carriage (82), symmetrical slidingtype is equipped with gag lever post (84) around carriage (82) upper portion left side, be connected with sliding plate (83) between two gag lever posts (84) right sides, sliding plate (83) and carriage (82) sliding fit, symmetrical division has the inclined groove around sliding plate (83) bottom, two guide bar (81) all with the inclined groove sliding fit of homonymy, carriage (82) top is equipped with fixed frame (85).

6. The film sticking device for the POE (polyolefin elastomer) photovoltaic film for packaging the solar photovoltaic module as claimed in claim 5, which is characterized in that: still including avoiding the reel directly to drop discharge mechanism (9) on conveyer belt (57), discharge mechanism (9) are including spacing frame (91), dwang (92), torque spring (93) and rotation frame (94), supporting shoe (73) lower part is equipped with spacing frame (91), the equal rotary type in the anterior left and right sides of spacing frame (91) is equipped with dwang (92), all be connected with torque spring (93) between two dwang (92) and spacing frame (91), be connected with between two dwang (92) lower parts and rotate frame (94), rotate frame (94) and spacing frame (91) contact fit, it has the one deck cushion to paste in rotation frame (94), avoid cylinder (56) to drop for a long time inside rotating frame (94), and then wearing and tearing rotate frame (94).

7. The film sticking device for the POE (polyolefin elastomer) photovoltaic film for packaging the solar photovoltaic module as claimed in claim 6, which is characterized in that: the glue film pasting machine is characterized by further comprising a flattening mechanism (10) capable of enabling a glue film to be pasted more flatly, wherein the flattening mechanism (10) comprises a connecting plate (101), a pressing block (102) and an extension spring (103), the connecting plate (101) is arranged at the top of the second supporting frame (59), the pressing block (102) is arranged at the bottom of the connecting plate (101) in a sliding mode, and the extension spring (103) is connected between the front side and the rear side of the top of the pressing block (102) and the connecting plate (101).

8. The film sticking device for the POE (polyolefin elastomer) photovoltaic film for packaging the solar photovoltaic module as claimed in claim 6, which is characterized in that: a layer of soft cushion is stuck in the rotating frame (94).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210136513.XA CN114368508B (en) | 2022-02-15 | 2022-02-15 | Film pasting device for packaging POE photovoltaic adhesive film by solar photovoltaic module |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210136513.XA CN114368508B (en) | 2022-02-15 | 2022-02-15 | Film pasting device for packaging POE photovoltaic adhesive film by solar photovoltaic module |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN114368508A true CN114368508A (en) | 2022-04-19 |

| CN114368508B CN114368508B (en) | 2023-05-23 |

Family

ID=81145705

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210136513.XA Active CN114368508B (en) | 2022-02-15 | 2022-02-15 | Film pasting device for packaging POE photovoltaic adhesive film by solar photovoltaic module |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114368508B (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115057021A (en) * | 2022-06-01 | 2022-09-16 | 瑞昌市金宇铜业制造有限公司 | Water-proof film covering device of lifting rod for bathroom |

| CN117842443A (en) * | 2024-03-08 | 2024-04-09 | 淮安杰海新材料有限公司 | Photovoltaic backboard film sticking device |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000272786A (en) * | 1999-03-25 | 2000-10-03 | Seiko Epson Corp | Paper roll storage device |

| CN207367989U (en) * | 2017-09-11 | 2018-05-15 | 东方日升新能源股份有限公司 | A kind of solar panel automatic film applicator |

| CN210480346U (en) * | 2019-08-12 | 2020-05-08 | 浙江台华新材料股份有限公司 | Automatic cloth feeding and shaft unloading device |

| CN112830009A (en) * | 2019-11-22 | 2021-05-25 | 江门市雅枫纸业有限公司 | Film discharging mechanism for tissue processing |

| CN214566747U (en) * | 2021-03-10 | 2021-11-02 | 张深云 | Medicine box label sealing and pasting equipment for pharmaceutical industry |

| CN113734509A (en) * | 2021-11-05 | 2021-12-03 | 山东龙光天旭太阳能有限公司 | Photovoltaic solar energy component laminating machine |

| CN113844906A (en) * | 2021-09-30 | 2021-12-28 | 王聪 | Auxiliary device for processing photovoltaic module |

-

2022

- 2022-02-15 CN CN202210136513.XA patent/CN114368508B/en active Active

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000272786A (en) * | 1999-03-25 | 2000-10-03 | Seiko Epson Corp | Paper roll storage device |

| CN207367989U (en) * | 2017-09-11 | 2018-05-15 | 东方日升新能源股份有限公司 | A kind of solar panel automatic film applicator |

| CN210480346U (en) * | 2019-08-12 | 2020-05-08 | 浙江台华新材料股份有限公司 | Automatic cloth feeding and shaft unloading device |

| CN112830009A (en) * | 2019-11-22 | 2021-05-25 | 江门市雅枫纸业有限公司 | Film discharging mechanism for tissue processing |

| CN214566747U (en) * | 2021-03-10 | 2021-11-02 | 张深云 | Medicine box label sealing and pasting equipment for pharmaceutical industry |

| CN113844906A (en) * | 2021-09-30 | 2021-12-28 | 王聪 | Auxiliary device for processing photovoltaic module |

| CN113734509A (en) * | 2021-11-05 | 2021-12-03 | 山东龙光天旭太阳能有限公司 | Photovoltaic solar energy component laminating machine |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115057021A (en) * | 2022-06-01 | 2022-09-16 | 瑞昌市金宇铜业制造有限公司 | Water-proof film covering device of lifting rod for bathroom |

| CN115057021B (en) * | 2022-06-01 | 2023-11-03 | 瑞昌市金宇铜业制造有限公司 | Waterproof tectorial membrane device of lifting rod for bathroom |

| CN117842443A (en) * | 2024-03-08 | 2024-04-09 | 淮安杰海新材料有限公司 | Photovoltaic backboard film sticking device |

| CN117842443B (en) * | 2024-03-08 | 2024-05-24 | 淮安杰海新材料有限公司 | Photovoltaic backboard film sticking device |

Also Published As

| Publication number | Publication date |

|---|---|

| CN114368508B (en) | 2023-05-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109368339B (en) | Full-automatic material collecting machine for continuous semiconductor chip belt | |

| CN107994263B (en) | Battery tab rubberizing folding all-in-one | |

| CN114368508A (en) | A pad pasting device that is used for solar PV modules to encapsulate POE photovoltaic glued membrane | |

| CN110137576B (en) | Full-automatic sticking film machine of lithium cell | |

| CN111591836B (en) | Full-automatic adhesive tape sticking machine and full-automatic rewinding machine | |

| CN216734942U (en) | Laminating device is used in touch-sensitive screen production | |

| CN113327878A (en) | Wafer loading device and wafer film pasting device | |

| CN114889323B (en) | High-efficient thermoprint tectorial membrane device | |

| CN110802911A (en) | Automatic film tearing machine for middle frame of mobile phone | |

| CN205526959U (en) | Equipment of pasting of two -sided non -setting adhesive sticky tape of paper extraction package | |

| CN106364133B (en) | The automatic change of lap adhering devices of EVA | |

| CN115763314B (en) | High-power rectifier bridge packaging production line | |

| CN113371417B (en) | Automatic conveying, extruding and packaging production equipment and production method for silicone rubber | |

| CN115390313B (en) | MNT shows backlight unit equipment with multi-functional rigging machine | |

| CN212501446U (en) | Three-side labeling machine | |

| CN212097910U (en) | Automatic film tearing machine for middle frame of mobile phone | |

| CN112009838B (en) | Three-dimensional metal label sticking equipment and sticking method thereof | |

| CN115743812A (en) | Raw ceramic sheet film tearing equipment and raw ceramic sheet film tearing method | |

| CN219238795U (en) | Full-automatic ten-axis stationery slitting machine | |

| CN210911153U (en) | Film tape laminating machine with laminating function | |

| CN113428714B (en) | Film separation conveying line and film separation conveying method | |

| CN112777073A (en) | Film pastes mark device | |

| CN219858031U (en) | Automatic large gummed paper pasting device and equipment for square battery cell | |

| CN218827289U (en) | Light-weight rubberizing system | |

| CN219771190U (en) | Multifunctional automatic label removing machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |