CN112889834B - Preparation method and application of metalaxyl-M-pyraclostrobin microcapsule suspending agent - Google Patents

Preparation method and application of metalaxyl-M-pyraclostrobin microcapsule suspending agent Download PDFInfo

- Publication number

- CN112889834B CN112889834B CN202110078956.3A CN202110078956A CN112889834B CN 112889834 B CN112889834 B CN 112889834B CN 202110078956 A CN202110078956 A CN 202110078956A CN 112889834 B CN112889834 B CN 112889834B

- Authority

- CN

- China

- Prior art keywords

- metalaxyl

- pyraclostrobin

- value

- agent

- sodium

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Classifications

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01N—PRESERVATION OF BODIES OF HUMANS OR ANIMALS OR PLANTS OR PARTS THEREOF; BIOCIDES, e.g. AS DISINFECTANTS, AS PESTICIDES OR AS HERBICIDES; PEST REPELLANTS OR ATTRACTANTS; PLANT GROWTH REGULATORS

- A01N47/00—Biocides, pest repellants or attractants, or plant growth regulators containing organic compounds containing a carbon atom not being member of a ring and having no bond to a carbon or hydrogen atom, e.g. derivatives of carbonic acid

- A01N47/08—Biocides, pest repellants or attractants, or plant growth regulators containing organic compounds containing a carbon atom not being member of a ring and having no bond to a carbon or hydrogen atom, e.g. derivatives of carbonic acid the carbon atom having one or more single bonds to nitrogen atoms

- A01N47/10—Carbamic acid derivatives, i.e. containing the group —O—CO—N<; Thio analogues thereof

- A01N47/24—Carbamic acid derivatives, i.e. containing the group —O—CO—N<; Thio analogues thereof containing the groups, or; Thio analogues thereof

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01C—PLANTING; SOWING; FERTILISING

- A01C1/00—Apparatus, or methods of use thereof, for testing or treating seed, roots, or the like, prior to sowing or planting

- A01C1/06—Coating or dressing seed

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01C—PLANTING; SOWING; FERTILISING

- A01C1/00—Apparatus, or methods of use thereof, for testing or treating seed, roots, or the like, prior to sowing or planting

- A01C1/08—Immunising seed

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01N—PRESERVATION OF BODIES OF HUMANS OR ANIMALS OR PLANTS OR PARTS THEREOF; BIOCIDES, e.g. AS DISINFECTANTS, AS PESTICIDES OR AS HERBICIDES; PEST REPELLANTS OR ATTRACTANTS; PLANT GROWTH REGULATORS

- A01N25/00—Biocides, pest repellants or attractants, or plant growth regulators, characterised by their forms, or by their non-active ingredients or by their methods of application, e.g. seed treatment or sequential application; Substances for reducing the noxious effect of the active ingredients to organisms other than pests

- A01N25/02—Biocides, pest repellants or attractants, or plant growth regulators, characterised by their forms, or by their non-active ingredients or by their methods of application, e.g. seed treatment or sequential application; Substances for reducing the noxious effect of the active ingredients to organisms other than pests containing liquids as carriers, diluents or solvents

- A01N25/04—Dispersions, emulsions, suspoemulsions, suspension concentrates or gels

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01N—PRESERVATION OF BODIES OF HUMANS OR ANIMALS OR PLANTS OR PARTS THEREOF; BIOCIDES, e.g. AS DISINFECTANTS, AS PESTICIDES OR AS HERBICIDES; PEST REPELLANTS OR ATTRACTANTS; PLANT GROWTH REGULATORS

- A01N25/00—Biocides, pest repellants or attractants, or plant growth regulators, characterised by their forms, or by their non-active ingredients or by their methods of application, e.g. seed treatment or sequential application; Substances for reducing the noxious effect of the active ingredients to organisms other than pests

- A01N25/26—Biocides, pest repellants or attractants, or plant growth regulators, characterised by their forms, or by their non-active ingredients or by their methods of application, e.g. seed treatment or sequential application; Substances for reducing the noxious effect of the active ingredients to organisms other than pests in coated particulate form

- A01N25/28—Microcapsules or nanocapsules

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01N—PRESERVATION OF BODIES OF HUMANS OR ANIMALS OR PLANTS OR PARTS THEREOF; BIOCIDES, e.g. AS DISINFECTANTS, AS PESTICIDES OR AS HERBICIDES; PEST REPELLANTS OR ATTRACTANTS; PLANT GROWTH REGULATORS

- A01N37/00—Biocides, pest repellants or attractants, or plant growth regulators containing organic compounds containing a carbon atom having three bonds to hetero atoms with at the most two bonds to halogen, e.g. carboxylic acids

- A01N37/44—Biocides, pest repellants or attractants, or plant growth regulators containing organic compounds containing a carbon atom having three bonds to hetero atoms with at the most two bonds to halogen, e.g. carboxylic acids containing at least one carboxylic group or a thio analogue, or a derivative thereof, and a nitrogen atom attached to the same carbon skeleton by a single or double bond, this nitrogen atom not being a member of a derivative or of a thio analogue of a carboxylic group, e.g. amino-carboxylic acids

- A01N37/46—N-acyl derivatives

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Health & Medical Sciences (AREA)

- Environmental Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Dentistry (AREA)

- Agronomy & Crop Science (AREA)

- Pest Control & Pesticides (AREA)

- Plant Pathology (AREA)

- Engineering & Computer Science (AREA)

- Wood Science & Technology (AREA)

- Zoology (AREA)

- Toxicology (AREA)

- Soil Sciences (AREA)

- Dispersion Chemistry (AREA)

- Chemical & Material Sciences (AREA)

- Manufacturing Of Micro-Capsules (AREA)

- Agricultural Chemicals And Associated Chemicals (AREA)

Abstract

The invention relates to the field of pesticides, and discloses a preparation method of metalaxyl-M-pyraclostrobin microcapsule suspending agent, which comprises the following steps: a. uniformly mixing a urea-formaldehyde resin prepolymer aqueous solution and pyraclostrobin-metalaxyl-M dispersible oil suspension agent to obtain a first material; b. adjusting the pH value of the first material to 5.5-6.5 to obtain a second material; c. stirring the second material for 30-60 minutes, and adjusting the pH value to 3-5 to obtain a third material; d. carrying out curing polycondensation on the third material, adjusting the pH value of the material after curing polycondensation to be neutral, and then uniformly mixing the material with one or more of a dispersing agent, a thickening agent, a film-forming agent, color paste and an antifreezing agent; the preparation method can effectively reduce the usage amount of the organic solvent, improve the safety of seed emergence, reduce environmental pollution, remarkably improve the storage stability and the disease control effect of the microcapsule suspending agent containing metalaxyl-M and pyraclostrobin, prolong the lasting period and increase the crop yield.

Description

The application is a divisional application of an invention patent application with the application date of 2019, 7 and 2, and the application number of CN201910591357.4, wherein the invention name of the invention is 'a preparation method and application of metalaxyl-M-pyraclostrobin microcapsule suspending agent'.

Technical Field

The invention relates to the technical field of pesticides, and particularly relates to a preparation method and application of metalaxyl-M-pyraclostrobin microcapsule suspending agent.

Background

metalaxyl-M is an amide bactericide which is developed by a company of Ciba-Geigy of Switzerland in 1977 and takes a benzene ring as a matrix, and is characterized by having protection, treatment and systemic activities, namely a bactericide with higher systemic activity, and the action mechanism of the bactericide is similar to that of other bactericides of the same type, and can influence a protein compound II (succinate dehydrogenase) of a respiratory electron transfer chain of pathogenic bacteria, thereby achieving the bacteriostatic action. Can exert curative effect on pathogenic bacteria at each stage of plant diseases and insect pests, and has excellent effect of treating oomycete diseases and insect pests. Has good prevention and control effects on various plant diseases and insect pests caused by oomycetes, damping-off, seed rot and the like caused by phytophthora.

However, metalaxyl-M is easily degraded in soil, so that the rapid loss and deterioration of effective components can be generated when the metalaxyl-M is used as a seed treatment agent. Therefore, according to the market application situation, an environment-friendly, safe, efficient and stable metalaxyl-M seed treating agent needs to be researched.

Pyraclostrobin is a methoxy acrylate bactericide developed by BASF corporation, has the action mechanism of a mitochondrial respiration inhibitor, namely has the functions of protection, treatment and leaf permeation and conduction by preventing electron transfer in cytochrome synthesis, and has the advantages of wide bactericidal spectrum, high activity, low toxicity and the like.

However, it is susceptible to hydrolysis and photolysis, and many pyraclostrobin formulations result in loss of active ingredient and deterioration of the drug when applied. In addition, pyraclostrobin is highly toxic to fish, so that water body organisms can die when the pyraclostrobin is used in a place close to a water source. Therefore, an environment-friendly, safe and efficient pyraclostrobin dosage form needs to be researched according to market application conditions.

The existing binary compound microcapsule preparation has two effective components, but the two effective components need a large amount of organic solvents of different types to be dissolved by using the traditional method, so that the risk of seed emergence is high, and the environment is polluted.

Disclosure of Invention

In order to overcome the defects, the invention provides the pyraclostrobin-mefenoxam microcapsule suspending agent and the preparation method thereof. In addition, the method adopted by the invention does not add organic solvent in the preparation process, has good use safety, is environment-friendly, and is used for preparing methyl oleate, mineral oil, vegetable oil and the like, thereby improving the safety of seeds and reducing the pollution to the environment.

In order to realize the purpose, the invention provides a preparation method of metalaxyl-M-pyraclostrobin microcapsule suspending agent, which comprises the following steps:

(1) uniformly mixing the first solution and the second solution to obtain a first material; wherein the first solution contains urea-formaldehyde resin prepolymer aqueous solution; the second liquid contains pyraclostrobin-metalaxyl-M dispersible oil suspending agent; the weight ratio of the first solution to the second liquid is (1-5): 1;

(2) uniformly mixing the first material with a buffer solution to adjust the pH value to 5.5-6.5 to obtain a second material;

(3) stirring the second material for 30-60 minutes, and then uniformly mixing the second material with an acidic pH value regulator to regulate the pH value to 3-5 to obtain a third material;

(4) carrying out curing polycondensation on the third material to obtain a curing polycondensation product, and adjusting the pH value of the curing polycondensation product to 6.5-7.5;

(5) and uniformly mixing the cured polycondensation product after the pH value is adjusted with one or more of a dispersant, a thickening agent, a film-forming agent, color paste and an antifreezing agent to obtain the metalaxyl-M-pyraclostrobin microcapsule suspending seed treatment microcapsule suspending agent.

The invention also provides a metalaxyl-M-pyraclostrobin microcapsule suspending agent which is prepared by the method.

The invention adopts a new method to prepare the suspending agent containing metalaxyl-M and pyraclostrobin microcapsules, not only overcomes the defects of the original medicine and prolongs the effective period, but also increases the stability of the binary compound microcapsule prepared by the traditional dissolving-encapsulating method, and effectively enhances the storage stability of the suspending agent and the control effect on the seedling diseases of crops.

Additional features and advantages of the invention will be set forth in the detailed description which follows.

Detailed Description

The following describes in detail specific embodiments of the present invention. It should be understood that the detailed description and specific examples, while indicating the present invention, are given by way of illustration and explanation only, not limitation.

The invention provides a preparation method of metalaxyl-M-pyraclostrobin microcapsule suspending agent, which comprises the following steps:

(1) uniformly mixing the first solution and the second solution to obtain a first material; wherein the first solution contains urea-formaldehyde resin prepolymer aqueous solution; the second liquid contains pyraclostrobin-metalaxyl-M dispersible oil suspending agent; the weight ratio of the first solution to the second liquid is (1-5): 1;

(2) uniformly mixing the first material with a buffer solution to adjust the pH value to 5.5-6.5 to obtain a second material;

(3) stirring the second material for 30-60 minutes, and then uniformly mixing the second material with an acidic pH value regulator to regulate the pH value to 3-5 to obtain a third material;

(4) carrying out curing polycondensation on the third material to obtain a curing polycondensation product, and adjusting the pH value of the curing polycondensation product to 6.5-7.5;

(5) and uniformly mixing the cured polycondensation product after the pH value is adjusted with one or more of a dispersant, a thickening agent, a film-forming agent, color paste and an antifreezing agent to obtain the metalaxyl-M-pyraclostrobin microcapsule suspending agent.

In the invention, metalaxyl-M, also called high-efficiency metalaxyl, is an amide bactericide taking a benzene ring as a matrix, and is characterized by having high protection, treatment and systemic activity. Chemical name is N- (2, 6-xylyl) -N- (methoxyacetyl) -D-alanine methyl ester, CAS accession No. 70630-17-0, relative molecular weight: 279.33, having a formula as shown in formula (1):

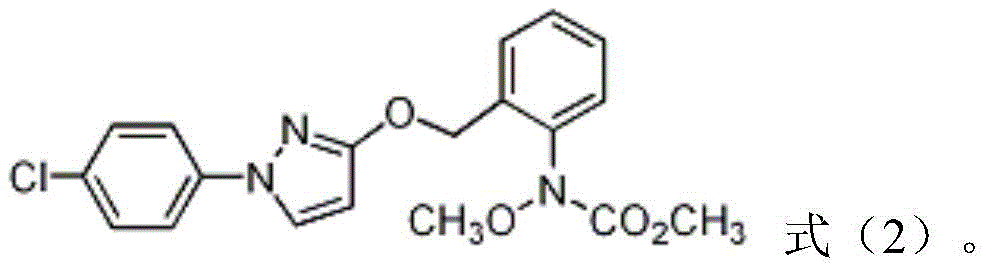

pyraclostrobin is compound N- [2- [1- (4-chlorophenyl) -1H-pyrazole-3-Oxomethyl radical]Phenyl radical]The trade name of methyl (N-methoxy) carbamate, Invitrogen, is pyraclostatin, formula C19H18ClN3O4Relative molecular mass 387.8, CAS No.: 175013-18-0, the structural formula is shown in formula (2):

according to the invention, the metalaxyl-M technical and the pyraclostrobin technical are prepared into dispersible oil suspending agents through steps of sanding and the like, the dispersible oil suspending agents and prepolymers are prepared into first materials, then the first materials are uniformly mixed with buffer solutions to adjust the pH value to be 5.5-6.5, and second materials are obtained; the second material and the acidic pH value regulator are uniformly mixed to regulate the pH value to 3-5, and when the third material is obtained, the prepared metalaxyl-M pyraclostrobin microcapsule suspending agent is stable in storage and not prone to agglomeration and solidification, the defect that the binary compound microcapsule prepared by a traditional method is overcome, and the effect of preventing and treating seedling diseases is good.

Further, in the step (1), the urea-formaldehyde resin prepolymer aqueous solution is preferably obtained by prepolymerization of a raw material solution containing urea, formaldehyde and water; preferably, the prepolymerization conditions comprise: the pH value is 8-10, the temperature is 70-75 ℃, and the reaction time is 1-2 hours.

More preferably, the aqueous solution of the urea-formaldehyde resin prepolymer can be obtained by pre-polymerizing a raw material solution containing urea, formaldehyde and water; more preferably, the urea-formaldehyde resin prepolymer aqueous solution can be obtained by pre-polymerizing urea, 35-45 wt% of formaldehyde aqueous solution and water, and the molar ratio of formaldehyde to urea can be 1: (0.5-1), the volume ratio of water to aqueous formaldehyde solution may be 1: (0.5-2).

According to the present invention, it is preferable that the aqueous solution of urea-formaldehyde resin prepolymer is prepared by prepolymerizing urea and 35 to 45 wt% aqueous solution of formaldehyde, and diluting the solution with water.

Further, in the step (1), the pyraclostrobin-mefenoxam dispersible oil suspension can be prepared by a preparation method well known to those skilled in the art, and the present invention is not particularly limited thereto. Preferably, the pyraclostrobin-metalaxyl-M dispersible oil suspension can contain pyraclostrobin original drug, metalaxyl-M original drug, emulsifier and oily medium; the emulsifier preferably comprises at least one of lauryl sodium sulfate, sodium dodecyl benzene sulfonate, a styrene-maleic anhydride copolymer, fatty alcohol polyoxyethylene ether, sorbitan polyoxyethylene polyoxypropylene ether, sorbitan monostearate polyoxyethylene ether, sodium lauryl sulfate, alkylphenol polyoxyethylene ether, castor oil polyoxyethylene ether and an EO-PO block copolymer; the oily medium preferably comprises at least one of methyl oleate, ethyl oleate, vegetable oil, mineral oil and paraffin oil; preferably, the weight ratio of the pyraclostrobin original drug to the metalaxyl-M original drug to the emulsifier to the oily medium is 1: (0.1-10): (1-10): (1-10).

The preparation method of the metalaxyl-M-pyraclostrobin dispersible oil suspending agent preferably comprises the following steps: and (2) mixing, dispersing and sanding the raw metalaxyl-M and the raw pyraclostrobin with an emulsifier and an oily medium in sequence to obtain the pyraclostrobin-metalaxyl-M dispersible oil suspending agent in the step (1).

According to the invention, in the pyraclostrobin-metalaxyl-M dispersible oil suspending agent, a raw metalaxyl-M and a raw pyraclostrobin exist in the form of suspended particles.

According to the invention, the average particle size of the suspended particles of metalaxyl-M technical and pyraclostrobin technical is preferably 1-5 microns.

Further, in order to improve the performance of the microcapsule suspension, it is preferable that in step (2), the buffer solution is a conjugate acid-base pair having a proper concentration and a proper ratio, and two substances in the conjugate acid-base pair are collectively called a buffer pair, for example, a buffer pair of citric acid-sodium citrate refers to citric acid and sodium citrate, and the total concentration of the citric acid-sodium citrate buffer pair is the sum of the concentrations of the citrate. The pH value of the buffer solution can be 3-5; the total concentration of the buffer pair in the buffer solution may be 1 to 5 wt%, wherein the buffer solution may be various buffer solutions conventionally used by those skilled in the art, and preferably, the buffer pair in the buffer solution may include at least one of citric acid-sodium citrate, citric acid-disodium hydrogen phosphate, and acetic acid-sodium acetate.

Further, in order to improve the coating rate, the uniformity and the tightness of the microcapsule shell, in step (3), the acidic pH adjusting agent may be various substances capable of lowering the pH value, which are conventionally used by those skilled in the art, and preferably, the concentration of the acidic pH adjusting agent may be 1 to 10 wt%; the solute of the acidic pH adjustor may include at least one of hydrogen chloride, sulfuric acid, acetic acid, ammonium chloride, and phosphoric acid.

Further, in order to further improve the particle size distribution and storage stability of the metalaxyl-M-p-azoxystrobin microcapsule suspending agent, in the step (5), the dispersing agent comprises at least one of sodium dodecyl benzene sulfonate, sodium methylene dinaphthalene sulfonate, a sodium 1-methyl naphthalene sulfonate formaldehyde condensate, a benzyl naphthalene sulfonate formaldehyde condensate, sodium lignosulfonate, desugared condensed sodium lignosulfonate, sodium succinate sulfonate, nekal, polyoxyethylene nonylphenol ether and polyoxyethylene fatty alcohol ether, polycarboxylate, naphthalenesulfonate, EO-PO block copolymer and nekal.

According to a preferred embodiment of the invention, the weight ratio of the cured polycondensation product to the dispersant, the film-forming agent and the color paste is 1: (0.01-0.05).

According to the present invention, the thickener and antifreeze may be agents conventionally used by those skilled in the art, and preferably, the thickener includes one or more of magnesium aluminum silicate, xanthan gum, polyethylene glycol, polyvinyl alcohol, carboxymethyl cellulose, bentonite, and white carbon.

Preferably according to the invention, the anti-freeze agent comprises one or more of ethylene glycol, 1, 2-propylene glycol, glycerol and urea.

According to a preferred embodiment of the present invention, the pH-adjusted cured polycondensation product is uniformly mixed with a dispersant, a thickener and an antifreeze, and preferably, the weight ratio of the cured polycondensation product, the dispersant, the thickener and the antifreeze may be 1: (0.01-0.05): (0.001-0.005): (0.05-0.1).

Further, in order to ensure the warning, slow release and film forming properties of the metalaxyl-M-pyraclostrobin microcapsule suspending agent used for seed treatment, in the step (5), the cured polycondensation product after the pH value is adjusted is uniformly mixed with a dispersing agent, a thickening agent, a film forming agent, color paste and an antifreezing agent, wherein the film forming agent and the color paste can be reagents conventionally used by a person skilled in the art.

Preferably, the film forming agent may include at least one of gum arabic, gum acacia, methyl cellulose, ethyl cellulose, sodium hydroxymethyl cellulose, polyvinyl alcohol, polyethylene glycol, polyacrylamide, sodium polyacrylate, homo vinyl acetate, polysaccharide high molecular compounds, and cellulose derivatives.

Preferably, the color paste comprises a red or blue water-soluble color paste.

The weight ratio of the curing polycondensation product to the film forming agent to the color paste can be 1: (0.01-0.1): (0.05-0.2).

Further, in order to improve the performance of the metalaxyl-M-pyraclostrobin microcapsule suspending agent, in the step (1), preferably, the mixing conditions include: the stirring speed can be 500-1000 rpm; in the preferred step (2), the mixing conditions may include: adding buffer solution at a constant speed of 200 and 300 revolutions per minute at 25-35 ℃ within 0.5-1 h; preferably, in step (3), the mixing conditions may include: adding the acid pH value regulator at a constant speed of 300-500 rpm within 1-2 hours at the temperature of 25-35 ℃.

Wherein, the uniform adding means that the adding amount in unit time is basically the same in the adding process.

According to the present invention, preferably, the curing polycondensation conditions include a curing temperature of 40 to 65 ℃ and a curing time of 2 to 6 hours, and the curing means may be mechanical stirring; after the solidification and polycondensation are finished, the pH value of the product after the solidification and polycondensation is adjusted to 6.5-7.5 by at least one pH regulator selected from triethylamine solution, triethanolamine solution, sodium hydroxide solution and potassium hydroxide solution.

The invention also provides metalaxyl-M-pyraclostrobin microcapsule suspending agent, wherein the suspending agent is obtained by the preparation method.

The invention provides an application of metalaxyl-M-pyraclostrobin microcapsule suspending agent in seed treatment.

According to the invention, the metalaxyl-M and pyraclostrobin seed treatment microcapsule suspending agent provided by the invention is stable in storage, is not easy to agglomerate and solidify, and has good control effects on diseases in seedling stage, such as rice seedling rot, seedling blight, corn stalk rot, wheat sharp eyespot and the like.

The present invention is further illustrated by the following examples. It should be understood that the embodiments described herein are only for illustrating and explaining the present invention and are not to be construed as limiting the present invention.

Example 1

Uniformly mixing urea and 37 wt% of formaldehyde aqueous solution, and reacting for 1.5h under the conditions that the pH value is 9 and the temperature is 72 ℃; adding water for dilution to obtain a urea-formaldehyde resin prepolymer aqueous solution, wherein the molar ratio of formaldehyde to urea is 1:0.5, and the volume ratio of water to the formaldehyde aqueous solution is 1: 1.

The metalaxyl-M and pyraclostrobin dispersible oil suspension agent is prepared by sequentially mixing, dispersing and sanding a metalaxyl-M technical, a pyraclostrobin technical, methyl oleate and sorbitan monooleate polyoxyethylene ether (Tween80), wherein the weight ratio of the metalaxyl-M technical, the pyraclostrobin technical, the methyl oleate to the sorbitan monostearate polyoxyethylene ether is 1:1:6: 2.

Uniformly mixing the obtained urea-formaldehyde resin prepolymer aqueous solution and metalaxyl-M-pyraclostrobin dispersible oil suspension agent at a stirring speed of 800 revolutions per minute to obtain a first material, wherein the weight ratio of the urea-formaldehyde resin prepolymer aqueous solution to the metalaxyl-M-pyraclostrobin dispersible oil suspension agent is 3: 1; under the condition of room temperature, adding a citric acid-sodium citrate buffer solution with the pH value of 4 and the total concentration of buffer pairs of 3 weight percent into the first material at a constant speed within 1 hour, uniformly mixing at a stirring speed of 250 revolutions per minute to adjust the pH value to 6.0 to obtain a second material; under the condition of room temperature, hydrochloric acid with the concentration of 5 weight percent is uniformly added into the second material within 1.5 hours, and is uniformly mixed at the stirring speed of 400 r/min to adjust the pH value to be 4.0, so as to obtain a third material; carrying out curing polycondensation on the third material for 2.5 hours at the temperature of 55 ℃ to obtain a curing polycondensation product; and adding triethanolamine to adjust the pH of the cured polycondensation product to 7.0; adding polycarboxylate Atlox-4913, magnesium aluminum silicate, glycol, sodium hydroxymethyl cellulose and red color paste, and uniformly mixing to obtain a fourth material, namely pyraclostrobin-mefenoxam microcapsule suspending agent; wherein the weight ratio of the cured polycondensation product to the polycarboxylate, the magnesium aluminum silicate, the glycol, the sodium hydroxymethyl cellulose and the red color paste is 1:0.02:0.003:0.05:0.05: 0.1.

Example 2

Uniformly mixing urea and 37 wt% of formaldehyde aqueous solution, and reacting for 2h under the conditions that the pH value is 10 and the temperature is 75 ℃; adding water for dilution to obtain a urea-formaldehyde resin prepolymer aqueous solution, wherein the molar ratio of formaldehyde to urea is 1:0.5, and the volume ratio of water to the formaldehyde aqueous solution is 1: 1.

Mixing, dispersing and sanding a metalaxyl-M technical raw material, a pyraclostrobin technical raw material, mineral oil and castor oil polyoxyethylene ether BY-125 in sequence to obtain the metalaxyl-M-pyraclostrobin dispersible oil suspending agent, wherein the weight ratio of the metalaxyl-M technical raw material, the pyraclostrobin technical raw material, the mineral oil and the styrene-maleic anhydride copolymer is 1:10:10: 10.

Uniformly mixing the obtained urea-formaldehyde resin prepolymer aqueous solution and metalaxyl-M-pyraclostrobin dispersible oil suspension agent at a stirring speed of 1000 revolutions per minute to obtain a first material, wherein the weight ratio of the urea-formaldehyde resin prepolymer aqueous solution to the metalaxyl-M-pyraclostrobin dispersible oil suspension agent is 5: 1; under the condition of room temperature, adding acetic acid-sodium acetate buffer solution with the pH value of 5 and the total concentration of a buffer pair of 5 weight percent into the first material at a constant speed within 1 hour, and uniformly mixing at a stirring speed of 300 r/min to adjust the pH value to 6.5 to obtain a second material; under the condition of room temperature, adding hydrochloric acid with the concentration of 10 weight percent into the second material at a constant speed within 2 hours, uniformly mixing at the stirring speed of 500 revolutions per minute to adjust the pH value to 3.0 to obtain a third material; carrying out curing polycondensation on the third material for 3 hours at the temperature of 60 ℃ to obtain a curing polycondensation product; and adding sodium hydroxide to adjust the pH of the cured polycondensation product to 7.5; adding sodium lignosulfonate, xanthan gum, glycerol, polyvinyl alcohol PVA-1799 and red color paste, and uniformly mixing to obtain a fourth material, namely pyraclostrobin-metalaxyl-M microcapsule suspending agent; wherein the weight ratio of the cured polycondensation product to the sodium lignosulfonate, the xanthan gum, the glycerol, the polyvinyl alcohol and the red color paste is 1:0.05:0.005:0.1:0.1: 0.2.

Example 3

Uniformly mixing urea and 37 wt% of formaldehyde aqueous solution, and reacting for 1.5h under the conditions that the pH value is 9 and the temperature is 72 ℃; adding water for dilution to obtain a urea-formaldehyde resin prepolymer aqueous solution, wherein the molar ratio of formaldehyde to urea is 1:0.5, and the volume ratio of water to the formaldehyde aqueous solution is 1: 1.

The metalaxyl-M and pyraclostrobin dispersible oil suspension agent is prepared by sequentially mixing, dispersing and sanding a metalaxyl-M technical material, a pyraclostrobin technical material, methyl oleate and sodium dodecyl benzene sulfonate, wherein the weight ratio of the metalaxyl-M technical material, the pyraclostrobin technical material, the methyl oleate to sorbitan monostearate polyoxyethylene ether is 1:1:6: 2.

Uniformly mixing the obtained urea-formaldehyde resin prepolymer aqueous solution and metalaxyl-M-pyraclostrobin dispersible oil suspension agent at a stirring speed of 800 revolutions per minute to obtain a first material, wherein the weight ratio of the urea-formaldehyde resin prepolymer aqueous solution to the metalaxyl-M-pyraclostrobin dispersible oil suspension agent is 3: 1; under the condition of room temperature, adding a citric acid-sodium citrate buffer solution with the pH value of 4 and the total concentration of buffer pairs of 3 weight percent into the first material at a constant speed within 1 hour, uniformly mixing at a stirring speed of 250 revolutions per minute to adjust the pH value to 6.0 to obtain a second material; under the condition of room temperature, hydrochloric acid with the concentration of 5 weight percent is uniformly added into the second material within 1.5 hours, and is uniformly mixed at the stirring speed of 400 r/min to adjust the pH value to be 4.0, so as to obtain a third material; carrying out curing polycondensation on the third material for 2.5 hours at the temperature of 55 ℃ to obtain a curing polycondensation product; and adding triethanolamine to adjust the pH of the cured polycondensation product to 7.0; adding polycarboxylate SD-816, magnesium aluminum silicate, ethylene glycol, sodium carboxymethylcellulose and red color paste, and uniformly mixing to obtain a fourth material, namely pyraclostrobin-metalaxyl-M microcapsule suspending agent; wherein the weight ratio of the cured polycondensation product to the polycarboxylate, the magnesium aluminum silicate, the glycol, the sodium hydroxymethyl cellulose and the red color paste is 1:0.02:0.003:0.05:0.05: 0.1.

Example 4

Uniformly mixing urea and 37 wt% of formaldehyde aqueous solution, and reacting for 2.5h under the conditions that the pH value is 7.5 and the temperature is 77 ℃; adding water for dilution to obtain a urea-formaldehyde resin prepolymer aqueous solution, wherein the molar ratio of formaldehyde to urea is 1:1, and the volume ratio of water to the formaldehyde aqueous solution is 1: 2.

Mixing, dispersing and sanding a metalaxyl-M technical raw material, a pyraclostrobin technical raw material, methyl oleate and castor oil polyoxyethylene ether BY-110 in sequence to obtain the metalaxyl-M-pyraclostrobin dispersible oil suspending agent, wherein the weight ratio of the metalaxyl-M technical raw material, the pyraclostrobin technical raw material, the methyl oleate and the castor oil polyoxyethylene ether is 1:1:10: 5.

Uniformly mixing the obtained urea-formaldehyde resin prepolymer aqueous solution and metalaxyl-M-pyraclostrobin dispersible oil suspension agent at a stirring speed of 500 revolutions per minute to obtain a first material, wherein the weight ratio of the urea-formaldehyde resin prepolymer aqueous solution to the metalaxyl-M-pyraclostrobin dispersible oil suspension agent is 5: 1; under the condition of room temperature, adding acetic acid-sodium acetate buffer solution with the pH value of 4 and the total concentration of buffer pairs of 3 weight percent into the first material at a constant speed within 1 hour, uniformly mixing at a stirring speed of 200 revolutions per minute to adjust the pH value to 6.2 to obtain a second material; under the condition of room temperature, adding acetic acid with the concentration of 5 weight percent into the second material at a constant speed within 1.5 hours, uniformly mixing at the stirring speed of 500 revolutions per minute to adjust the pH value to 3.0 to obtain a third material; carrying out curing polycondensation on the third material for 3 hours at the temperature of 60 ℃ to obtain a curing polycondensation product; and adding potassium hydroxide to adjust the pH of the cured polycondensation product to 7; adding sodium methylene dinaphthalenesulfonate, magnesium aluminum silicate, ethylene glycol, Arabic gum and red color paste, and uniformly mixing to obtain a fourth material, namely pyraclostrobin-metalaxyl-M microcapsule suspending agent; wherein the weight ratio of the cured polycondensation product to the methylene dinaphthalene sodium sulfonate, the magnesium aluminum silicate, the glycol, the Arabic gum and the red color paste is 1:0.02:0.001:0.05:0.01: 0.15.

Example 5

Uniformly mixing urea and 37 wt% of formaldehyde aqueous solution, and reacting for 1h under the conditions that the pH value is 10 and the temperature is 70 ℃; adding water for dilution to obtain a urea-formaldehyde resin prepolymer aqueous solution, wherein the molar ratio of formaldehyde to urea is 1:0.2, and the volume ratio of water to the formaldehyde aqueous solution is 1: 2.

Mixing, dispersing and sanding a metalaxyl-M technical raw material, a pyraclostrobin technical raw material, methyl oleate and sorbitan monostearate polyoxyethylene ether in sequence to obtain the metalaxyl-M-Z dispersible oil suspending agent, wherein the weight ratio of the metalaxyl-M technical raw material, the pyraclostrobin technical raw material, the methyl oleate and the sodium lauryl sulfate is 1:12:15: 0.5.

Uniformly mixing the obtained urea-formaldehyde resin prepolymer aqueous solution and metalaxyl-M-pyraclostrobin dispersible oil suspension agent at a stirring speed of 1000 revolutions per minute to obtain a first material, wherein the weight ratio of the urea-formaldehyde resin prepolymer aqueous solution to the metalaxyl-M-pyraclostrobin dispersible oil suspension agent is 2: 1; under the condition of room temperature, adding a citric acid-sodium citrate buffer solution with the pH value of 3 and the total concentration of buffer pairs of 2 weight percent into the first material at a constant speed within 1 hour, uniformly mixing at a stirring speed of 200 revolutions per minute to adjust the pH value to 5.8 to obtain a second material; under the condition of room temperature, adding acetic acid with the concentration of 5 weight percent into the second material at a constant speed within 2 hours, and uniformly mixing at a stirring speed of 400 r/min to adjust the pH value to 3.0 to obtain a third material; carrying out curing polycondensation on the third material for 3 hours at the temperature of 50 ℃ to obtain a curing polycondensation product; and adding potassium hydroxide to adjust the pH of the cured polycondensation product to 7; adding nekal, bentonite, glycol, sodium polyacrylate and red color paste, and uniformly mixing to obtain a fourth material, namely pyraclostrobin-metalaxyl-M microcapsule suspending agent; wherein the weight ratio of the cured polycondensation product to the nekal, the bentonite, the glycol, the sodium polyacrylate and the red color paste is 1:0.04:0.004:0.05:0.01: 0.15.

Example 6

Uniformly mixing urea and 37 wt% of formaldehyde aqueous solution, and reacting for 1h under the conditions that the pH value is 9 and the temperature is 70 ℃; adding water for dilution to obtain a urea-formaldehyde resin prepolymer aqueous solution, wherein the molar ratio of formaldehyde to urea is 1:1, and the volume ratio of water to the formaldehyde aqueous solution is 1: 1.

Mixing, dispersing and sanding a metalaxyl-M technical, a pyraclostrobin technical, methyl oleate and an EO-PO block copolymer Atlox G5000 in sequence to obtain the metalaxyl-M-pyraclostrobin dispersible oil suspension, wherein the weight ratio of the metalaxyl-M technical, the pyraclostrobin technical, the methyl oleate and the EO-PO block copolymer is 1:1:10: 5.

Uniformly mixing the obtained urea-formaldehyde resin prepolymer aqueous solution and metalaxyl-M-pyraclostrobin dispersible oil suspension agent at a stirring speed of 500 revolutions per minute to obtain a first material, wherein the weight ratio of the urea-formaldehyde resin prepolymer aqueous solution to the metalaxyl-M-pyraclostrobin dispersible oil suspension agent is 1: 1; under the condition of room temperature, adding a citric acid-sodium citrate buffer solution with the pH value of 2 and the total concentration of a buffer pair of 5.5 weight percent into the first material at a constant speed within 1 hour, and uniformly mixing at a stirring speed of 200 revolutions per minute to adjust the pH value to be 5.5 to obtain a second material; adding 1 wt% phosphoric acid solution into the second material at constant speed within 2 hr at room temperature, and mixing at 400 rpm to adjust pH to 4.0 to obtain a third material; carrying out curing polycondensation on the third material for 3 hours at the temperature of 50 ℃ to obtain a curing polycondensation product; and adding potassium hydroxide to adjust the pH of the cured polycondensation product to 7; adding nekal, xanthan gum, ethylene glycol, sodium polyacrylate and red color paste, and uniformly mixing to obtain a fourth material, namely pyraclostrobin-metalaxyl-M microcapsule suspending agent; wherein the weight ratio of the cured polycondensation product to the nekal, the xanthan gum, the glycol, the sodium polyacrylate and the red color paste is 1:0.04:0.002:0.05:0.01: 0.15.

Example 7

Uniformly mixing urea and 37 wt% of formaldehyde aqueous solution, and reacting for 1h under the conditions that the pH value is 9 and the temperature is 70 ℃; adding water for dilution to obtain a urea-formaldehyde resin prepolymer aqueous solution, wherein the molar ratio of formaldehyde to urea is 1:0.5, and the volume ratio of water to the formaldehyde aqueous solution is 1: 1.

Mixing, dispersing and sanding a metalaxyl-M technical, a pyraclostrobin technical, soybean oil and an EO-PO block copolymer D800 in sequence to obtain the metalaxyl-M-pyraclostrobin dispersible oil suspending agent, wherein the weight ratio of the metalaxyl-M technical, the pyraclostrobin technical, the vegetable oil and the EO-PO block copolymer is 1:0.1:10: 5.

Uniformly mixing the obtained urea-formaldehyde resin prepolymer aqueous solution and metalaxyl-M-pyraclostrobin dispersible oil suspension agent at a stirring speed of 500 revolutions per minute to obtain a first material, wherein the weight ratio of the urea-formaldehyde resin prepolymer aqueous solution to the metalaxyl-M-pyraclostrobin dispersible oil suspension agent is 1: 1; under the condition of room temperature, adding a citric acid-sodium citrate buffer solution with the pH value of 4 and the total concentration of a buffer pair of 4 weight percent into the first material at a constant speed within 1 hour, and uniformly mixing at a stirring speed of 200 revolutions per minute to adjust the pH value to 5.5 to obtain a second material; adding 0.5 wt% phosphoric acid solution into the second material at constant speed within 0.5 hr at room temperature, and mixing at 200 rpm to adjust pH to 4.0 to obtain a third material; carrying out curing polycondensation on the third material for 3 hours at the temperature of 50 ℃ to obtain a curing polycondensation product; and adding triethanolamine to adjust the pH of the cured polycondensation product to 6.5; adding naphthalenesulfonate Morwet-D425, bentonite, glycol, sodium polyacrylate and red color paste, and uniformly mixing to obtain a fourth material, namely pyraclostrobin-metalaxyl-M microcapsule suspending agent; wherein the weight ratio of the cured polycondensation product to the naphthalenesulfonate, the xanthan gum, the glycol, the sodium polyacrylate and the red color paste is 1:0.03:0.002:0.05:0.01: 0.15.

Example 8

Uniformly mixing urea and 37 wt% of formaldehyde aqueous solution, and reacting for 1h under the conditions that the pH value is 9 and the temperature is 70 ℃; adding water for dilution to obtain a urea-formaldehyde resin prepolymer aqueous solution, wherein the molar ratio of formaldehyde to urea is 1:0.5, and the volume ratio of water to the formaldehyde aqueous solution is 1: 2.

Mixing, dispersing and sanding a metalaxyl-M technical raw material, a pyraclostrobin technical raw material, paraffin oil and sodium lauryl sulfate in sequence to obtain the metalaxyl-M-pyraclostrobin dispersible oil suspension, wherein the weight ratio of the metalaxyl-M technical raw material, the pyraclostrobin technical raw material, the paraffin oil and the sodium lauryl sulfate is 1:5:5: 5.

Uniformly mixing the obtained urea-formaldehyde resin prepolymer aqueous solution and the metalaxyl-M-pyraclostrobin dispersible oil suspending agent at a stirring speed of 600 revolutions per minute to obtain a first material, wherein the weight ratio of the urea-formaldehyde resin prepolymer aqueous solution to the metalaxyl-M-pyraclostrobin dispersible oil suspending agent is 1: 1; under the condition of room temperature, adding a citric acid-sodium citrate buffer solution with the pH value of 3 and the total concentration of buffer pairs of 2 weight percent into the first material at a constant speed within 1 hour, and uniformly mixing at a stirring speed of 200 revolutions per minute to adjust the pH value to 5.5 to obtain a second material; under the condition of room temperature, adding hydrochloric acid with the concentration of 4 weight percent into the second material at a constant speed within 1 hour, uniformly mixing at the stirring speed of 200 revolutions per minute to adjust the pH value to 3.0 to obtain a third material; carrying out curing polycondensation on the third material for 4 hours at the temperature of 40 ℃ to obtain a curing polycondensation product; and adding triethanolamine to adjust the pH of the cured polycondensation product to 6.5; adding naphthalenesulfonate Morwet-D425, bentonite, urea, sodium polyacrylate and red color paste, and uniformly mixing to obtain a fourth material, namely pyraclostrobin-metalaxyl-M microcapsule suspending agent; wherein the weight ratio of the cured polycondensation product to the naphthalenesulfonate, the xanthan gum, the urea, the sodium polyacrylate and the red color paste is 1:0.03:0.002:0.1:0.01: 0.15.

Example 9

Uniformly mixing urea and 37 wt% of formaldehyde aqueous solution, and reacting for 1.5h under the conditions that the pH value is 9 and the temperature is 70 ℃; adding water for dilution to obtain a urea-formaldehyde resin prepolymer aqueous solution, wherein the molar ratio of formaldehyde to urea is 1:0.5, and the volume ratio of water to the formaldehyde aqueous solution is 1: 2.

Mixing, dispersing and sanding a metalaxyl-M technical raw material, a pyraclostrobin technical raw material, methyl oleate and sorbitan monostearate polyoxyethylene ether in sequence to obtain the metalaxyl-M-Z-M dispersible oil suspending agent, wherein the weight ratio of the metalaxyl-M technical raw material, the pyraclostrobin technical raw material, the methyl oleate and the sorbitan monostearate polyoxyethylene ether is 1:1:5: 4.

Uniformly mixing the obtained urea-formaldehyde resin prepolymer aqueous solution and metalaxyl-M-pyraclostrobin dispersible oil suspension agent at a stirring speed of 1000 r/min to obtain a first material, wherein the weight ratio of the urea-formaldehyde resin prepolymer aqueous solution to the metalaxyl-M-pyraclostrobin dispersible oil suspension agent is 4: 1; under the condition of room temperature, adding acetic acid-sodium acetate buffer solution with the pH value of 4 and the total concentration of buffer pairs of 2 weight percent into the first material at a constant speed within 1 hour, and uniformly mixing at a stirring speed of 200 revolutions per minute to adjust the pH value to 6.2 to obtain a second material; under the condition of room temperature, hydrochloric acid with the concentration of 5 weight percent is uniformly added into the second material within 1.5 hours, and is uniformly mixed at the stirring speed of 500 revolutions per minute to adjust the pH value to be 4.0, so as to obtain a third material; carrying out curing polycondensation on the third material for 2 hours at the temperature of 60 ℃ to obtain a curing polycondensation product; and adding 5% by weight triethanolamine to adjust the pH of the cured polycondensation product to 7; adding polycarboxylate Atlox 4913, magnesium aluminum silicate, ethylene glycol, vinyl acetate and red color paste, and uniformly mixing to obtain a fourth material, namely pyraclostrobin-metalaxyl-M microcapsule suspending agent; wherein the weight ratio of the cured polycondensation product to the polycarboxylate, the magnesium aluminum silicate, the glycol, the vinyl acetate and the red color paste is 1:0.005:0.006:0.15:0.15: 0.25.

Example 10

Uniformly mixing urea and 37 wt% of formaldehyde aqueous solution, and reacting for 1.5h under the conditions that the pH value is 9 and the temperature is 70 ℃; adding water for dilution to obtain a urea-formaldehyde resin prepolymer aqueous solution, wherein the molar ratio of formaldehyde to urea is 1:0.5, and the volume ratio of water to the formaldehyde aqueous solution is 1: 2.

Mixing, dispersing and sanding a metalaxyl-M technical raw material, a pyraclostrobin technical raw material, methyl oleate and sorbitan monostearate polyoxyethylene ether in sequence to obtain the metalaxyl-M-Z-M dispersible oil suspending agent, wherein the weight ratio of the metalaxyl-M technical raw material, the pyraclostrobin technical raw material, the methyl oleate and the sorbitan monostearate polyoxyethylene ether is 1:1:5: 4.

Uniformly mixing the obtained urea-formaldehyde resin prepolymer aqueous solution and metalaxyl-M-pyraclostrobin dispersible oil suspension agent at a stirring speed of 400 r/min to obtain a first material, wherein the weight ratio of the urea-formaldehyde resin prepolymer aqueous solution to the metalaxyl-M-pyraclostrobin dispersible oil suspension agent is 4: 1; under the condition of room temperature, adding an acetic acid-sodium acetate buffer solution with the pH value of 3 and the total concentration of buffer pairs of 3 weight percent into the first material at a constant speed within 2 hours, and uniformly mixing at a stirring speed of 100 revolutions per minute to adjust the pH value to 6.2 to obtain a second material; under the condition of room temperature, hydrochloric acid with the concentration of 5 weight percent is uniformly added into the second material within 2.5 hours, and is uniformly mixed at the stirring speed of 600 revolutions per minute to adjust the pH value to be 4.0, so as to obtain a third material; carrying out curing polycondensation on the third material for 2 hours at the temperature of 60 ℃ to obtain a curing polycondensation product; and adding 5% by weight triethanolamine to adjust the pH of the cured polycondensation product to 7; adding polycarboxylate, magnesium aluminum silicate, glycol, sodium carboxymethylcellulose and red color paste, and uniformly mixing to obtain a fourth material, namely the seed-treated pyraclostrobin-metalaxyl-M microcapsule suspending agent; wherein the weight ratio of the cured polycondensation product to the polycarboxylate, the magnesium aluminum silicate, the glycol, the sodium carboxymethyl cellulose and the red color paste is 1:0.02:0.02:0.1:0.05: 0.15.

Comparative example 1

The difference from example 1 is that after the first material was obtained, the pH of the material was adjusted to 4.0 directly with 5 wt% hydrochloric acid without adjusting the pH with a citric acid-sodium citrate buffer solution.

Comparative example 2

The difference from example 1 is that after the first material was obtained, the pH of the material was adjusted to 6 using a citric acid-sodium citrate buffer solution having a pH of 4 and a total concentration of buffer pairs of 2 wt%, and then the pH adjustment step was not performed for the second time.

Comparative example 3

The difference from the embodiment 1 is that the third material is directly mixed with the dispersant, the thickening agent, the antifreezing agent, the film forming agent and the color paste without a curing process of heating and stirring to obtain the metalaxyl-M pyraclostrobin microcapsule suspending agent.

Comparative example 4 common in-situ polymerization method was used to prepare metalaxyl-M-pyraclostrobin seed treatment microcapsule suspending agent.

An aqueous solution of a melamine-formaldehyde resin prepolymer was prepared according to the method described in example 1.

And uniformly mixing the obtained melamine-formaldehyde resin prepolymer aqueous solution and metalaxyl-M-pyraclostrobin missible oil at a stirring speed of 800 revolutions per minute to obtain a first material. Wherein the weight ratio of the melamine-formaldehyde resin prepolymer aqueous solution to metalaxyl-M-pyraclostrobin missible oil is 4: 1; the metalaxyl-M-pyraclostrobin missible oil consists of a metalaxyl-M original drug, a pyraclostrobin original drug, xylene and tristyrylphenol polyoxyethylene ether, wherein the weight ratio of the metalaxyl-M original drug to the pyraclostrobin original drug to the xylene to the tristyrylphenol polyoxyethylene ether is 1:1:10: 1.

Under the condition of room temperature, adding a citric acid-sodium citrate buffer solution with the pH value of 4 and the total concentration of buffer pairs of 3 weight percent into the first material at a constant speed within 1 hour, uniformly mixing at a stirring speed of 250 revolutions per minute to adjust the pH value to 6.0 to obtain a second material; under the condition of room temperature, hydrochloric acid with the concentration of 5 weight percent is uniformly added into the second material within 1.5 hours, and is uniformly mixed at the stirring speed of 400 r/min to adjust the pH value to be 4.0, so as to obtain a third material; carrying out curing polycondensation on the third material for 2.5 hours at the temperature of 55 ℃ to obtain a curing polycondensation product; and adding triethanolamine to adjust the pH of the cured polycondensation product to 7.0; adding polycarboxylate, magnesium aluminum silicate, glycol, sodium carboxymethylcellulose and red color paste, and uniformly mixing to obtain a fourth material, namely pyraclostrobin-metalaxyl-M microcapsule suspending agent; wherein the weight ratio of the cured polycondensation product to the polycarboxylate, the magnesium aluminum silicate, the glycol, the sodium hydroxymethyl cellulose and the red color paste is 1:0.02:0.003:0.05:0.05: 0.1.

Comparative example 5 preparation of metalaxyl-M-pyraclostrobin microcapsule suspending agent by interfacial polymerization method

Uniformly mixing metalaxyl-M technical, pyraclostrobin technical, dimethylbenzene and toluene diisocyanate to obtain an oil phase, wherein the weight ratio of the metalaxyl technical to the pyraclostrobin technical to the dimethylbenzene to the toluene diisocyanate is 1:1: 2: 0.05; and uniformly mixing water and calcium dodecyl benzene sulfonate to obtain a water phase, wherein the weight ratio of the water to the calcium dodecyl benzene sulfonate is 1: 0.05.

Shearing the oil phase and the water phase at a speed of 20000 revolutions per minute for 5 minutes to obtain an O/W emulsion, wherein the weight ratio of the oil phase to the water phase is 1: 1; adding ethylenediamine into the O/W emulsion, and stirring for 1 hour to obtain metalaxyl-M-pyraclostrobin microcapsule suspension; adding polycarboxylate, aluminum magnesium silicate, glycol, sodium hydroxymethyl cellulose and red color paste into the metalaxyl-M and pyraclostrobin microcapsule suspension to obtain the pyraclostrobin and metalaxyl-M seed treatment microcapsule suspension, wherein the weight ratio of the metalaxyl-M and pyraclostrobin microcapsule suspension to the polycarboxylate to the aluminum magnesium silicate to the glycol to the sodium hydroxymethyl cellulose to the red color paste is 1:0.02:0.003:0.05:0.05: 0.1.

Comparative example 6 metalaxyl-M.pyraclostrobin suspoemulsion

Uniformly mixing metalaxyl-M technical, pyraclostrobin technical, polycarboxylate, xanthan gum, ethylene glycol and water, and grinding the mixture by a sand mill until the particle size is less than 5 mu m to obtain the metalaxyl-M pyraclostrobin suspending emulsion, wherein the weight ratio of the metalaxyl technical, the pyraclostrobin technical, the polycarboxylate, the xanthan gum, the ethylene glycol and the water is 1:1:0.02:0.003:0.05: 15.

Comparative example 7 metalaxyl-M seed treatment microcapsule suspension

metalaxyl-M seed treatment microcapsule suspension was prepared according to the method of example 1.

Comparative example 8 pyraclostrobin seed treatment microcapsule suspending agent

Pyraclostrobin seed treatment microcapsule suspending agent was prepared according to the method of example 1.

Test example 1

This test example was used to test the heat storage stability and low temperature stability of the samples prepared in examples 1 to 10 and comparative examples 1 to 8.

Heat storage stability test: the samples prepared in examples 1 to 10 and comparative examples 1 to 8 were placed in a container, sealed and placed in a constant temperature oven at (54 ± 2) ° c, left to stand for 14 days and then taken out for observation, and the suspension percentage of the sample was measured according to the GB/T14825-2006 standard, and the results are shown in table 1.

And (3) low-temperature stability determination: the samples prepared in examples 1 to 10 and comparative examples 1 to 8 were placed in a container, sealed and placed in a freezer at (0. + -.2). degree.C.for 1 hour, stirred once every 15min for 15s, and observed for change in appearance, and after further standing at (0. + -.2). degree.C.for 7 days, the sample was taken out and placed at room temperature and allowed to stand for recovery, and the suspension percentage of the sample was measured according to GB/T14825-2006, the results of which are shown in Table 1.

TABLE 1

In table 1, it can be seen from comparison between examples 1 to 10 and comparative examples 1 to 8 that the metalaxyl-M-pyraclostrobin seed-treated microcapsule suspending agent prepared by the method provided by the invention has good heat storage stability and low-temperature storage stability.

Test example 2

The test example tests the control effect of the samples obtained in examples 1-10 and comparative examples 1-8 on rice seedling rot and the influence on the growth condition of rice, the test site is selected from Huaian city of Jiangsu province, the soil fertility of the selected test field is moderate, the management is fine, the variety of the rice to be planted is new-liangyou-98, the cultivation mode is direct sowing, seed dressing treatment before sowing, seed soaking and germination acceleration are carried out after air drying, the ratio of the pesticide to the liquid is 1:50, and the normal management is carried out after sowing.

In the test, samples obtained in examples 1 to 10 and comparative examples 1 to 8 were added with a proper amount of water and then respectively mixed with seeds, blank control was performed without mixing seeds, each treatment was repeated 3 times, 54 cells were counted, each cell was provided with 66.7 square meters, and the cells were randomly arranged.

And (5) investigating the emergence rate 10 days after sowing, investigating the growth vigor of seedlings and the disease degree of seedling rot 30 days after sowing, measuring the actual production in the harvest period, and calculating the average yield.

The investigation method comprises the following steps:

investigating the growth vigor of the seedlings: randomly taking 5 points in each cell, taking 10 rice seedlings at each point, and measuring the height of each seedling and the fresh weight of each seedling.

And (3) drug effect investigation: and randomly surveying 5 points in each cell, 100 plants in each point, digging the seedling to the depth of 30cm, surveying the morbidity by taking the pollution, the withered and green of the seedling and the dark color of the diseased root as indexes, and calculating the relative prevention effect.

And measuring actual yield of each cell in the harvest period, and estimating the yield per mu according to the area.

The results are shown in Table 2.

Relative preventing effect (%) of seedling rot (CK-PT)/CK x 100

In the formula: CK-placebo incidence;

PT-incidence in treatment area.

TABLE 2

In the test example 2, it can be known that the pyraclostrobin-metalaxyl-M seed treatment microcapsule suspending agent obtained by the technical scheme of the invention can improve the rate of emergence, promote the growth of crops in seedling stage, remarkably prolong the lasting period of diseases in seedling stage of crops, and achieve the effect of increasing yield after 30 days, wherein the effect of preventing and treating the seedling rot is still over 90%.

Test example 3

In the test example, the control effects and the effective periods of the samples obtained in the examples 1 to 10 and the comparative examples 1 to 8 on the sheath blight and take-all diseases of wheat are tested, the test site is selected from the province of Hebei province, the soil fertility of the selected test field is medium, the management is fine, the variety of the wheat to be planted is Mianmai 175, the seed is mixed before sowing, the seed is mixed with 30 to 50g (a.i.)/100kg of seeds, the ratio of the liquid medicine is 1:50, and the normal management is carried out after sowing.

In the test, samples obtained in examples 1 to 10 and comparative examples 1 to 8 were added with a proper amount of water and then respectively mixed with seeds, blank control was performed without mixing seeds, each treatment was repeated 3 times, 54 cells were counted, each cell was provided with 66.7 square meters, and the cells were randomly arranged.

And (3) investigating the incidence of sheath blight and take-all disease 10d, 20d, 30d and 60d after wheat seedling emergence, randomly sampling 5 points in each treatment area, investigating 30 plants in each cell, investigating the incidence of sheath blight and take-all disease, and calculating the relative prevention effect.

Relative control effect (%) of sheath blight/full rot ═ (CK-PT)/CK x 100

In the formula: CK-placebo incidence;

PT-treatment area morbidity;

the results are shown in Table 3.

TABLE 3

In the above test examples, it can be found from the results in tables 2 and 3 that, by comparing examples 1 to 10 with comparative examples 1 to 8, the dispersible oil suspending agent is used as an oil phase to prepare an emulsion, and the metalaxyl-pyraclostrobin microcapsule suspending agent prepared by the preparation method provided by the invention under specific reaction conditions of a buffer solution and an acidic pH regulator, a reaction system is adjusted step by step, and a corresponding emulsifier, a solvent and the like is selected, so that compared with metalaxyl-pyraclostrobin microcapsule suspending agents, non-microcapsule formulations and single-dose formulations prepared by other methods, the slow-release long-acting effect on preventing and treating seedling diseases can be achieved, the number of times and the amount of the drug use are reduced, the cost is saved, and the pollution to the environment is reduced.

The preferred embodiments of the present disclosure have been described in detail above, however, the present disclosure is not limited to the specific details of the above embodiments, and various simple modifications may be made to the technical solution of the present disclosure within the technical idea of the present disclosure, and these simple modifications all fall within the protection scope of the present disclosure.

It should be noted that the various features described in the above embodiments may be combined in any suitable manner without departing from the scope of the invention. In order to avoid unnecessary repetition, various possible combinations will not be separately described in this disclosure.

In addition, any combination of various embodiments of the present disclosure may be made, and the same should be considered as the disclosure of the present disclosure, as long as it does not depart from the spirit of the present disclosure.

Claims (4)

1. A preparation method of metalaxyl-M-pyraclostrobin microcapsule suspending agent is characterized by comprising the following steps:

(1) uniformly mixing the first solution and the second solution to obtain a first material; wherein the first solution contains urea-formaldehyde resin prepolymer aqueous solution; the second liquid contains pyraclostrobin-metalaxyl-M dispersible oil suspending agent; the weight ratio of the first solution to the second liquid is 3: 1;

wherein the urea-formaldehyde resin prepolymer aqueous solution is obtained by pre-polymerizing a raw material solution containing urea, formaldehyde and water; the prepolymerization conditions comprise: the pH value is 8-10, the temperature is 70-75 ℃, and the reaction time is 1-2 hours;

wherein the pyraclostrobin-metalaxyl-M dispersible oil suspension comprises pyraclostrobin original drug, metalaxyl-M original drug, emulsifier and oily medium; the emulsifier is sorbitan monostearate polyoxyethylene ether; the oily medium is methyl oleate; the weight ratio of the pyraclostrobin original drug to the metalaxyl-M original drug to the emulsifier to the oily medium is 1:1:6: 2; the preparation method of the pyraclostrobin-metalaxyl-M dispersible oil suspending agent comprises the following steps: mixing, dispersing and sanding a raw metalaxyl-M and a raw pyraclostrobin medicament with an emulsifier and an oily medium in sequence to obtain the pyraclostrobin-raw metalaxyl-M dispersible oil suspension; the average particle size of the suspended particles of the metalaxyl-M technical product and the pyraclostrobin technical product is 1-5 microns;

(2) uniformly mixing the first material with a buffer solution to adjust the pH value to 5.5-6.5 to obtain a second material;

wherein the pH value of the buffer solution is 3-5; the total concentration of buffer pairs in the buffer solution is 1-5 wt%; the buffer pair in the buffer solution comprises at least one of citric acid-sodium citrate, citric acid-disodium hydrogen phosphate and acetic acid-sodium acetate;

(3) stirring the second material for 30-60 minutes, and then uniformly mixing the second material with an acidic pH value regulator to regulate the pH value to 3-5 to obtain a third material; wherein the concentration of the acidic pH regulator is 1-10 wt%; the solute of the acidic pH regulator comprises at least one of hydrogen chloride, sulfuric acid, acetic acid, ammonium chloride and phosphoric acid;

(4) carrying out curing polycondensation on the third material to obtain a curing polycondensation product, and adjusting the pH value of the curing polycondensation product to 6.5-7.5; wherein, the curing polycondensation conditions comprise that the curing temperature is 40-65 ℃, the curing time is 2-6 hours, and the curing mode is mechanical stirring; after the solidification and polycondensation are finished, adjusting the pH value of a product after the solidification and polycondensation to 6.5-7.5 by at least one pH regulator selected from triethylamine solution, triethanolamine solution, sodium hydroxide solution and potassium hydroxide solution;

(5) uniformly mixing the cured polycondensation product after the pH value is adjusted with one or more of a dispersant, a thickening agent, a film-forming agent, color paste and an antifreezing agent to obtain the metalaxyl-M-pyraclostrobin microcapsule suspending agent; the dispersing agent comprises at least one of sodium dodecyl benzene sulfonate, sodium methylene dinaphthalene sulfonate, a 1-sodium methyl naphthalenesulfonate formaldehyde condensate, a benzyl naphthalenesulfonic acid formaldehyde condensate, sodium lignosulfonate, desugared condensed sodium lignosulfonate, sodium succinate sulfonate, nekal, nonylphenol polyoxyethylene ether and fatty alcohol polyoxyethylene ether, polycarboxylate, naphthalenesulfonate, EO-PO block copolymer and nekal; the thickening agent comprises one or more of magnesium aluminum silicate, xanthan gum, polyethylene glycol, polyvinyl alcohol, carboxymethyl cellulose, bentonite and white carbon black; the antifreezing agent comprises one or more of ethylene glycol, 1, 2-propylene glycol, glycerol and urea; the film forming agent can comprise at least one of Arabic gum, animal glue, methylcellulose, ethyl cellulose, sodium hydroxymethyl cellulose, polyvinyl alcohol, polyethylene glycol, polyacrylamide, sodium polyacrylate, homopolymerized vinyl acetate, polysaccharide high molecular compound and cellulose derivative; the color paste comprises red or blue water-soluble color paste; the weight ratio of the solidified polycondensation product to the dispersant, the thickener, the antifreezing agent, the film forming agent and the color paste is 1: (0.01-0.05): (0.001-0.005): (0.05-0.1): (0.01-0.1): (0.05-0.2).

2. The production method according to claim 1, wherein in the step (1), the mixing conditions include: the stirring speed is 500-1000 r/min; in the step (2), the mixing conditions include: adding buffer solution at a constant speed of 200 and 300 revolutions per minute at 25-35 ℃ within 0.5-1 h;

in the step (3), the mixing conditions include: adding the acid pH value regulator at a constant speed of 300-500 rpm within 1-2 hours at the temperature of 25-35 ℃.

3. metalaxyl-M pyraclostrobin microcapsule suspending agent, wherein the microcapsule suspending agent is obtained by the preparation method according to claim 1 or 2.

4. The metalaxyl-M pyraclostrobin microcapsule suspending agent obtained by the preparation method according to claim 1 or 2 is applied to seed treatment.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910492504 | 2019-06-06 | ||

| CN2019104925042 | 2019-06-06 | ||

| CN201910591357.4A CN110250170B (en) | 2019-06-06 | 2019-07-02 | Preparation method and application of metalaxyl-M-pyraclostrobin microcapsule suspending agent |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201910591357.4A Division CN110250170B (en) | 2019-06-06 | 2019-07-02 | Preparation method and application of metalaxyl-M-pyraclostrobin microcapsule suspending agent |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN112889834A CN112889834A (en) | 2021-06-04 |

| CN112889834B true CN112889834B (en) | 2021-12-14 |

Family

ID=67923973

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201910591357.4A Active CN110250170B (en) | 2019-06-06 | 2019-07-02 | Preparation method and application of metalaxyl-M-pyraclostrobin microcapsule suspending agent |

| CN202110078956.3A Active CN112889834B (en) | 2019-06-06 | 2019-07-02 | Preparation method and application of metalaxyl-M-pyraclostrobin microcapsule suspending agent |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201910591357.4A Active CN110250170B (en) | 2019-06-06 | 2019-07-02 | Preparation method and application of metalaxyl-M-pyraclostrobin microcapsule suspending agent |

Country Status (1)

| Country | Link |

|---|---|

| CN (2) | CN110250170B (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113402321A (en) * | 2021-06-23 | 2021-09-17 | 湖北富邦科技股份有限公司 | Method for preparing calcium-magnesium suspended fertilizer by using nanofiltration seawater to trap carbon dioxide product |

| CN114230395B (en) * | 2021-12-16 | 2022-12-06 | 河北安格诺农化有限公司 | Slow-release pesticide-fertilizer composition and application thereof |

| CN115414865B (en) * | 2022-09-27 | 2023-09-19 | 溢通环保科技(莆田)有限公司 | Anti-settling polymerization inhibitor for diesel exhaust treatment fluid and production process thereof |

| CN117441738B (en) * | 2023-12-26 | 2024-09-27 | 山东科赛基农生物工程有限公司 | Seed treatment suspending agent containing metalaxyl-M, pyraclostrobin and fluxapyroxad and application thereof |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102696645B (en) * | 2012-05-09 | 2015-10-21 | 广东中迅农科股份有限公司 | A kind of composition pesticide containing pyraclostrobin and Metalaxyl-M |

| CN103814923B (en) * | 2014-03-11 | 2015-09-09 | 陕西上格之路生物科学有限公司 | A kind of pyraclostrobin-containing dispersible oil-suspending agent |

| CN103975935B (en) * | 2014-05-28 | 2016-08-24 | 陕西上格之路生物科学有限公司 | A kind of bactericidal composition preventing and treating crops soil-borne disease |

| CN105409990A (en) * | 2015-12-19 | 2016-03-23 | 青岛奥迪斯生物科技有限公司 | Sterilization composition containing pyraclostrobin and efficient metalaxyl-M |

| CN107258777A (en) * | 2017-06-21 | 2017-10-20 | 北京明德立达农业科技有限公司 | A kind of seed treatment microcapsules suspension suspending agent of pyraclostrobin-containing and fluorine azoles bacterium aniline and preparation method thereof |

| CN108575993A (en) * | 2018-04-19 | 2018-09-28 | 河北威远生物化工有限公司 | A kind of dispersible micro-capsule oil-suspending agent of glufosinate-ammonium and preparation method thereof |

| CN108849990A (en) * | 2018-06-27 | 2018-11-23 | 四川福思达生物技术开发有限责任公司 | A kind of agricultural medicine fertilizer composition of pyraclostrobin-containing and its application |

-

2019

- 2019-07-02 CN CN201910591357.4A patent/CN110250170B/en active Active

- 2019-07-02 CN CN202110078956.3A patent/CN112889834B/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN110250170A (en) | 2019-09-20 |

| CN112889834A (en) | 2021-06-04 |

| CN110250170B (en) | 2021-03-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN112889834B (en) | Preparation method and application of metalaxyl-M-pyraclostrobin microcapsule suspending agent | |

| EP3385255B1 (en) | Fungicidal compound, fungicide composition and preparation and use thereof | |

| CN110140720A (en) | A kind of microcapsule suspension-suspendinagent agent and preparation method thereof for seed treatment | |

| CN105613500B (en) | A kind of plant growth regulator composition | |

| CN104381289A (en) | Safe and multi-effect seed treatment composition | |

| CN103109843A (en) | Insecticidal disease-preventing suspended seed coating containing thiamethoxam, thifluzamide and/or benzene kresoxim-methyl | |

| CN109197869B (en) | Pretilachlor microcapsule suspending agent and preparation method thereof | |

| CN113519546A (en) | Cabbage seed coating agent and using method thereof | |

| CN108184887A (en) | One kind resists cold type plant growth regulator and preparation method and application of keeping a full stand of seedings | |

| WO2020147277A1 (en) | Plant growth regulator composition | |

| CN106818839A (en) | A kind of corn seed coating agent and its application method | |

| CN103975935A (en) | Sterilization composition for preventing and treating soil-borne diseases of crops | |

| CN107258777A (en) | A kind of seed treatment microcapsules suspension suspending agent of pyraclostrobin-containing and fluorine azoles bacterium aniline and preparation method thereof | |

| CN106035363A (en) | Suspension seed coating agent containing fipronil and imidacloprid and its preparation method and use | |

| CN111149810A (en) | Bactericide composition and application thereof | |

| TW201029569A (en) | A method of improving growth damages of paddy rice | |

| CN110140728A (en) | Composition pesticide | |

| CN108576017A (en) | A kind of microcapsule suspension-suspendinagent agent and preparation method thereof containing benziothiazolinone and tiger glue adipic acid copper | |

| CN114847298A (en) | Seed treatment suspending agent containing thiamethoxam | |

| CN107467030A (en) | Seed treatment compositions containing fludioxonil, Metalaxyl-M and fluorine pyrrole furanone | |

| CN111034728B (en) | Tobacco axillary bud inhibitor and tobacco axillary bud inhibition method | |

| CN112167256A (en) | Compound granule containing thifluzamide and fluazinam and preparation method and application thereof | |

| CN114794114B (en) | Pesticide microcapsule suspending agent for preventing and treating rice diseases and preparation method thereof | |

| CN109645028A (en) | A kind of coating agent for seed and its application method containing OH11 | |

| CN109769846A (en) | A kind of seed treatment |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |