CN112583066A - 一种叉车磷酸铁锂电池充电方法 - Google Patents

一种叉车磷酸铁锂电池充电方法 Download PDFInfo

- Publication number

- CN112583066A CN112583066A CN202010906372.6A CN202010906372A CN112583066A CN 112583066 A CN112583066 A CN 112583066A CN 202010906372 A CN202010906372 A CN 202010906372A CN 112583066 A CN112583066 A CN 112583066A

- Authority

- CN

- China

- Prior art keywords

- charging

- battery

- iron phosphate

- lithium iron

- bms

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- GELKBWJHTRAYNV-UHFFFAOYSA-K lithium iron phosphate Chemical compound [Li+].[Fe+2].[O-]P([O-])([O-])=O GELKBWJHTRAYNV-UHFFFAOYSA-K 0.000 title claims abstract description 55

- 238000000034 method Methods 0.000 title claims abstract description 22

- 239000000178 monomer Substances 0.000 claims description 8

- 230000002035 prolonged effect Effects 0.000 abstract description 5

- 238000004891 communication Methods 0.000 description 11

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 description 7

- 229910052744 lithium Inorganic materials 0.000 description 7

- 230000008569 process Effects 0.000 description 3

- 239000002253 acid Substances 0.000 description 2

- 238000007599 discharging Methods 0.000 description 2

- 238000012544 monitoring process Methods 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- 230000002159 abnormal effect Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000002788 crimping Methods 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000003792 electrolyte Substances 0.000 description 1

- 238000005265 energy consumption Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 238000003912 environmental pollution Methods 0.000 description 1

- 238000004880 explosion Methods 0.000 description 1

- 238000007689 inspection Methods 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 230000002427 irreversible effect Effects 0.000 description 1

- 230000003446 memory effect Effects 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J7/00—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries

- H02J7/007—Regulation of charging or discharging current or voltage

- H02J7/00712—Regulation of charging or discharging current or voltage the cycle being controlled or terminated in response to electric parameters

- H02J7/007182—Regulation of charging or discharging current or voltage the cycle being controlled or terminated in response to electric parameters in response to battery voltage

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L53/00—Methods of charging batteries, specially adapted for electric vehicles; Charging stations or on-board charging equipment therefor; Exchange of energy storage elements in electric vehicles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L58/00—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles

- B60L58/10—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries

- B60L58/12—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries responding to state of charge [SoC]

- B60L58/15—Preventing overcharging

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L58/00—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles

- B60L58/10—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries

- B60L58/18—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries of two or more battery modules

- B60L58/20—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries of two or more battery modules having different nominal voltages

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/42—Methods or arrangements for servicing or maintenance of secondary cells or secondary half-cells

- H01M10/44—Methods for charging or discharging

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J7/00—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries

- H02J7/0029—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries with safety or protection devices or circuits

- H02J7/00302—Overcharge protection

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J7/00—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries

- H02J7/0029—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries with safety or protection devices or circuits

- H02J7/00308—Overvoltage protection

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J7/00—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries

- H02J7/0029—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries with safety or protection devices or circuits

- H02J7/00309—Overheat or overtemperature protection

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L2200/00—Type of vehicles

- B60L2200/40—Working vehicles

- B60L2200/42—Fork lift trucks

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/70—Energy storage systems for electromobility, e.g. batteries

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/7072—Electromobility specific charging systems or methods for batteries, ultracapacitors, supercapacitors or double-layer capacitors

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T90/00—Enabling technologies or technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02T90/10—Technologies relating to charging of electric vehicles

- Y02T90/14—Plug-in electric vehicles

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Mechanical Engineering (AREA)

- Transportation (AREA)

- Life Sciences & Earth Sciences (AREA)

- Sustainable Development (AREA)

- Sustainable Energy (AREA)

- General Chemical & Material Sciences (AREA)

- Electrochemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Chemical & Material Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Secondary Cells (AREA)

- Charge And Discharge Circuits For Batteries Or The Like (AREA)

Abstract

一种叉车磷酸铁锂电池充电方法,本发明通过实测电芯在不同温度不同荷电状态SOC的充电数据,根据充电数据确定制定BMS电池系统在电池荷电状态S0C 0‑80%充电策略,而在电池充电末端90%‑100%,为满足整车工作时间及电芯使用寿命,执行本发明描述的末端充电策略。本发明增加叉车正常工作运行时间。增加充电容量:按照恒流的方式,充电容量为电池组额定容量95%左右,按照本发明描述方法,充电容量为电池组额定容量的100%;这将增加叉车工作时间30‑40min,根据不同温度下电池的充电性能,合理的调整充电电流比恒流方式充电能更好的符合电池的充电曲线,有利于电池使用寿命的增加,大概在延长使用寿命1‑3年。

Description

技术领域

本发明涉及对于使用锂电的叉车充电技术领域,具体涉及一种锂电池叉车充电策略。

背景技术

随着电动叉车的推广和普及,越来越多的叉车采用锂电池作为动力源,摒弃了之前铅酸电池作为动力源的做法。锂电池对比铅酸电池其优势明显,如放电效率高、比能量大、环境污染小、可快速充电及无记忆效应等。由于锂电池叉车具有环保要求高、使用频率高、作业时间长等严苛工况特点,目前行业中多采用快充充电方式对叉车电池进行充电,以满足叉车正常工作所需的能耗,但采用恒流快速充电的方法不仅会对电池寿命造成影响,而且容量达不到电池的额定容量,大大降低了叉车的工作时间。

发明内容

本发明的目的主要用于解决锂电池叉车快速充电容量不达标技术问题,而提供一种叉车磷酸铁锂电池充电方法,提升了电池的充电容量,增加了叉车的工作运行时间。

本发明的技术方案是:一种叉车磷酸铁锂电池充电方法,其特征在于:包括:

1)、BMS电池系统根据磷酸铁锂电池模组的温度状态、荷电状态SOC下的充放电表动态调节请求电流,磷酸铁锂电池模组进入动态充电阶段;

2)、若步骤1)中BMS电池系统检测到磷酸铁锂电池模组电压达到保护阈值三级告警Ut3,BMS电池系统切断充电继电器,结束充电;

3)、在动态充电阶段BMS电池系统检测到磷酸铁锂电池模组充电至荷电状态SOC为90%时,执行末端充电阶段,末端充电阶段包括:

a. BMS电池系统检测磷酸铁锂电池模组的电池单体电压,当电池单体最高电压每次达到第一次阈值电压U1时, BMS电池系统发送第一次请求电流I1降电流,充电电流Ic降流至Icc1,以充电电流Ic为Icc1为磷酸铁锂电池模组充电;

b. BMS电池系统检测磷酸铁锂电池模组的电池单体电压,当电池单体最高电压每次达到第二次阈值电压U2时, BMS电池系统发送第二次请求电流I2降电流,充电电流Ic降流至Icc2,以充电电流Ic为Icc2为磷酸铁锂电池模组充电;

c. 以充电电流Ic为Icc2为磷酸铁锂电池模组充电至电池单体最高电压每次达到第三次阈值电压U3时,磷酸铁锂电池模组电压达到荷电状态SOC为100%, BMS电池系统切断充电继电器,结束充电;

d.在步骤a-c中:当磷酸铁锂电池模组电池单体电压≥3.65V时,BMS电池系统切断充电继电器,停止充电;当磷酸铁锂电池模组最高温度>55℃,BMS电池系统切断充电继电器,停止充电。

保护阈值设置三级,分别为一级告警Ut1、二级告警Ut2、三级告警Ut3,当BMS电池系统检测到磷酸铁锂电池模组电压达到一级告警Ut1、二级告警Ut2时,BMS电池系统发送请求电流使得充电桩调整输出电流来降低充电功率;当BMS电池系统检测到磷酸铁锂电池模组电压达到保护阈值三级告警时,停止充电,BMS电池系统切断充电继电器。荷电状态SOC设置100%的条件:只有以正常充电完成为标识来设置荷电状态SOC为100%,充电未完成荷电状态SOC最高只能到99%。

所述末端充电阶段:

步骤a中U1=3500mV,0.1 C≤Icc1≤0.2C;当电池电压达到3500mv时SOC为80~90%之间,此时温度在30-40℃之间,查表可得充电电流为0.4C;

步骤b中U2=3600mV,0.05C≤Icc2<0.1 C;

步骤c中U3=3650mV。

所述末端充电阶段:

步骤a中U1=3500mV, Icc1=0.2C;

步骤b中U2=3600mV, Icc2=0.05C。

所述末端充电阶段的步骤a、b中充电桩调整时间均为Tcc1,Tcc1≤5s,充电桩调整时间期间不下调充电电流Ic。

一种叉车磷酸铁锂电池充电电路,包括磷酸铁锂电池模组、充电系统、BMS电池系统、用于提供辅助电源给BMS电池系统供电的DC/DC模块,磷酸铁锂电池模组置于电池箱内,磷酸铁锂电池模组由多个串联的电池单体采用激光焊接方式组成,充电系统包括直流充电桩、直流充电插座,磷酸铁锂电池模组串联继电器、分流器、熔断器,直流充电插座并联在磷酸铁锂电池模组两端,BMS电池系统、DC/DC模块分别与磷酸铁锂电池模组并联,继电器、分流器、熔断器、直流充电插座分别与BMS电池系统连接。本发明充电电路适用于快充充电,快充输出的是直流DC无需经过转换器。

通讯接插件安装于电池箱上,通讯接插件一端与BMS电池系统相连,通讯接插件另一端通过通讯插头对插后与整车进行通讯,可使电池SOC、电压、温度等信息显示在整车仪表上。继电器、分流器、熔断器、直流充电插座、通讯接插件采用螺栓连接方式固定在电池箱上。

继电器:继电器起控制断路作用,通过BMS电池系统实现对继电器的控制,当充电电压、电流、温度等达到BMS电池系统设定的极限阈值后,BMS电池系统会发出指令,断开继电器,停止充电,若未设置,则可能导致电池过充,过温等严重情况,造成电池不可逆损伤,影响使用寿命。分流器:分流器为电流检测元件,BMS电池系统通过采集分流器两端电势差变化转换为具体充电电流值,若无分流器,则无法检测充电电流。熔断器:熔断器设置目的是为防止电池由于某些原因短路造成过大电流后发生起火、爆炸等危害,发生短路时可及时熔断,将电池回路断开,若未设置则可能会出现上述风险。

本发明为一种叉车磷酸铁锂电池充电方法,通过实测电芯在不同温度不同荷电状态SOC的充电数据,根据充电数据确定制定BMS电池系统在电池荷电状态S0C 0-80%充电策略,而在电池充电末端90%-100%,为满足整车工作时间及电芯使用寿命,执行本发明描述的末端充电策略。

本发明提出一种充电策略满足快充充电容量,增加叉车正常工作运行时间。增加充电容量:按照恒流的方式,充电容量为电池组额定容量95%左右,按照本发明描述方法,充电容量为电池组额定容量的100%;这将增加叉车工作时间30-40min,根据不同温度下电池的充电性能,合理的调整充电电流比恒流方式充电能更好的符合电池的充电曲线,有利于电池使用寿命的增加,大概在延长使用寿命1-3年。

本发明的充电策略相比于现有技术具有如下优点:

1、在电池不同温度不同荷电状态SOC下不再采用恒流方式充电,而是采用动态的方式通过BMS根据不同状况改变充电电流大小,有利于电池使用寿命的提升。

2、在充电末端时,执行末端策略,较以往提升了电池的充电容量,增加了叉车的工作运行时间。

附图说明

图1为本发明磷酸铁锂电池模组的充电电路。

具体实施方式

下面将对本发明实施例中的技术方案进行完整地描述,实施例仅是本发明的一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其它实施例,都属于本发明保护的范围。

如1所示,本发明的充电电路包括直流充电插座2,磷酸铁锂电池模组1、熔断器3、DC/DC模块、BMS电池系统5、分流器4、继电器7。磷酸铁锂电池模组1、熔断器3、分流器4、继电器7及直流充电插座2串联在一起,BMS电池系统5并联在DC/DC模块后,不需要外接的单独电源给其供电,BMS电池系统5可直接通过DC/DC从电池端转接的12V电源工作, BMS电池系统5、DC/DC模块与磷酸铁锂电池模组1并联。BMS电池系统5与磷酸铁锂电池模组1连接用于监控电池电压、电流、温度、SOC、SOH信息,BMS电池系统5与继电器7连接用于控制继电器闭合和断开, BMS电池系统5与分流器4连接用于监控充放电电流,BMS电池系统5与继电器7、分流器4、直流充电插座2电气件均为低压连接,BMS电池系统5与继电器7通过线对线接插件对插连接,与分流器通过M4采集端子压接,与直流充电插座2通过线对线接插件对插连接,BMS电池系统5与直流充电插座2连接用于充电时对外通讯。直流充电插座2上面有低压连接线束,直接与BMS连接用于充电通讯,通讯端口6用于对整车通讯。直流充电桩采用国标GBT27930-2015通讯协议。充电插座采用直流快充插座。磷酸铁锂单个电池采用激光焊接方式组成电池模组,其余零部件采用螺栓连接方式固定在电池箱内。

本发明的充电策略:

一种叉车磷酸铁锂电池充电方法:直流充电插座插入充电枪后,BMS电池系统检测到CC2信号被唤醒,BMS电池系统唤醒后自检,检验BMS自身有无异常,无异常则执行充电程序,输出12V使能信号控制闭合总负继电器(总负继电器即指继电器7)、充电继电器,完成控制闭合继电器并和直流充电桩进行信号交互,握手成功后进入充电阶段。充电过程中,BMS电池系统通过CAN线随时调节充电电流大小,根据不同电芯型号(主要是容量不同)不同温度不同荷电状态SOC下的充放电表,不同温度不同荷电状态SOC下电池的充电电流不同,BMS可根据电池厂家提供的数据表表一进行动态调节充电电流,不采用恒流方式进行充电,防止电芯过充,对电芯寿命造成影响。由于磷酸铁锂的特性,电池的工作电压范围为2.5-3.65V,BMS保护阈值应设置三级告警,其中一、二级告警降低充电功率,三级告警断开继电器,阈值分别设置为3.55V/3.60V/3.65V。当磷酸铁锂电池模组充电至荷电状态SOC90%时,

此时执行末端充电策略:

1.电池单体最高电压每次达到3500mV时,通过BMS电池系统发送请求电流至充电桩,充电桩调整输出电流,降充电电流,降流至0.2C,5S时间给充电桩调整,期间不下调充电电流;

2. 电池单体最高电压达到3600mV时,通过BMS电池系统发送请求电流至充电桩,充电桩调整输出电流,降充电电流,降流为0.05C;

3.以0.05C充到电池单体最高电压3650mV后, BMS电池系统向充电桩发送充电完成报文,控制充电桩停止充电,收到充电桩中止报文指令号断开充电接触器,具体为:BMS电池系统标定电池荷电状态SOC100%并通过CAN通讯发送电池荷电状态SOC状态,标定荷电状态SOC为100%,当BMS电池系统检测到电池状态100%时,触发设定阈值,断开充电继电器,充电桩检测电池无外总压后自动断开。

4. 荷电状态SOC设置100%的条件:只有以正常充电完成为标识来设置荷电状态SOC为100%,充电未完成荷电状态SOC最高只能到99%;

5.充电过程中,当单体电压≥3.65V时,BMS电池系统向充电机发送充电完成报文,充电机应立即停止充电,断开充电继电器;

6.上电后或充电过程中, BMS电池系统检测电池模组的最高温度,根据电芯使用及实测数据,一般当电芯大于55℃后,充电性能急速下降,且强行进行充电可能造成电池电解液析出,即通常讲的析锂,会发生安全风险,一般充电的范围0-55℃,BMS电池系统控制断开充电继电器,使充电回路断开实现停充。

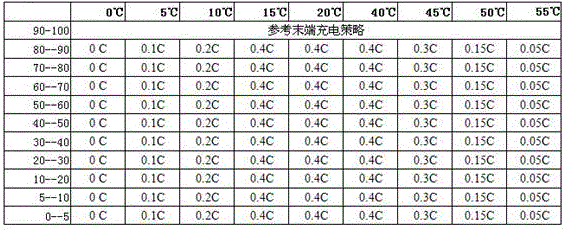

表一:

综上所述,本发明一种叉车的充电策略,不仅节省了叉车充电时间,有利于提高充电效率。同时还增加了电池的充电容量,提高叉车工作运行时间,且延长了电池的使用寿命。

Claims (5)

1.一种叉车磷酸铁锂电池充电方法,其特征在于:包括:

1)、BMS电池系统根据磷酸铁锂电池模组的温度状态、荷电状态SOC下的充放电表动态调节请求电流,磷酸铁锂电池模组进入动态充电阶段;

2)、若步骤1)中BMS电池系统检测到磷酸铁锂电池模组电压达到保护阈值三级告警Ut3,停止充电;

3)、在动态充电阶段BMS电池系统检测到磷酸铁锂电池模组充电至荷电状态SOC为90%时,执行末端充电阶段,末端充电阶段包括:

a. BMS电池系统检测磷酸铁锂电池模组的电池单体电压,当电池单体最高电压每次达到第一次阈值电压U1时, BMS电池系统发送第一次请求电流I1降电流,充电电流Ic降流至Icc1,以充电电流Ic为Icc1为磷酸铁锂电池模组充电;

b. BMS电池系统检测磷酸铁锂电池模组的电池单体电压,当电池单体最高电压每次达到第二次阈值电压U2时, BMS电池系统发送第二次请求电流I2降电流,充电电流Ic降流至Icc2,以充电电流Ic为Icc2为磷酸铁锂电池模组充电;

c. 以充电电流Ic为Icc2为磷酸铁锂电池模组充电至电池单体最高电压每次达到第三次阈值电压U3时,磷酸铁锂电池模组电压达到荷电状态SOC为100%, BMS电池系统切断充电继电器,结束充电;

d.在步骤a-c中:当磷酸铁锂电池模组电池单体电压≥3.65V时,BMS电池系统切断充电继电器,停止充电;当磷酸铁锂电池模组最高温度>55℃,BMS电池系统切断充电继电器,停止充电。

2.根据权利要求1所述的叉车磷酸铁锂电池充电方法,其特征在于:保护阈值设置三级,分别为一级告警Ut1、二级告警Ut2、三级告警Ut3,当BMS电池系统检测到磷酸铁锂电池模组电压达到一级告警Ut1、二级告警Ut2时,BMS电池系统发送请求电流使得充电桩调整输出电流来降低充电功率;当BMS电池系统检测到磷酸铁锂电池模组电压达到保护阈值三级告警Ut3时,停止充电,BMS电池系统切断充电继电器。

3.根据权利要求1所述的叉车磷酸铁锂电池充电方法,其特征在于:所述末端充电阶段:

步骤a中U1=3500mV,0.1 C≤Icc1≤0.2C;

步骤b中U2=3600mV,0.05C≤Icc2<0.1 C;

步骤c中U3=3650mV。

4.根据权利要求1或3中所述的叉车磷酸铁锂电池充电方法,其特征在于:所述末端充电阶段:

步骤a中U1=3500mV, Icc1=0.2C;

步骤b中U2=3600mV, Icc2=0.05C。

5.根据权利要求1中所述的叉车磷酸铁锂电池充电方法,其特征在于:所述末端充电阶段的步骤a、b中充电桩调整时间均为Tcc1,Tcc1≤5s,充电桩调整时间期间不下调充电电流Ic。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010906372.6A CN112583066A (zh) | 2020-09-01 | 2020-09-01 | 一种叉车磷酸铁锂电池充电方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010906372.6A CN112583066A (zh) | 2020-09-01 | 2020-09-01 | 一种叉车磷酸铁锂电池充电方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN112583066A true CN112583066A (zh) | 2021-03-30 |

Family

ID=75119436

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010906372.6A Pending CN112583066A (zh) | 2020-09-01 | 2020-09-01 | 一种叉车磷酸铁锂电池充电方法 |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN112583066A (zh) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114207909A (zh) * | 2021-10-26 | 2022-03-18 | 东莞新能安科技有限公司 | 电化学装置管理方法、系统、电化学装置及电子设备 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101345432A (zh) * | 2007-07-13 | 2009-01-14 | 三洋电机株式会社 | 电池组的充电方法 |

| US20170234934A1 (en) * | 2013-06-20 | 2017-08-17 | University Of Electronic Science And Technology Of China | Power system and state of charge estimation |

| CN111525201A (zh) * | 2020-04-28 | 2020-08-11 | 江西凯马百路佳客车有限公司 | 一种装配磷酸铁锂电池新能源车辆的充电控制方法 |

-

2020

- 2020-09-01 CN CN202010906372.6A patent/CN112583066A/zh active Pending

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101345432A (zh) * | 2007-07-13 | 2009-01-14 | 三洋电机株式会社 | 电池组的充电方法 |

| US20170234934A1 (en) * | 2013-06-20 | 2017-08-17 | University Of Electronic Science And Technology Of China | Power system and state of charge estimation |

| CN111525201A (zh) * | 2020-04-28 | 2020-08-11 | 江西凯马百路佳客车有限公司 | 一种装配磷酸铁锂电池新能源车辆的充电控制方法 |

Non-Patent Citations (4)

| Title |

|---|

| 于海东: "《电动汽车结构原理与维修》", 31 January 2019 * |

| 何黎明: "《中国物流技术发展报告 2017》", 30 November 2017 * |

| 徐寅秀: "《无线充电技术和电力传输的未来》", 30 June 2018 * |

| 鲁植雄: "《新能源汽车》", 30 November 2019 * |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114207909A (zh) * | 2021-10-26 | 2022-03-18 | 东莞新能安科技有限公司 | 电化学装置管理方法、系统、电化学装置及电子设备 |

| WO2023070323A1 (zh) * | 2021-10-26 | 2023-05-04 | 东莞新能安科技有限公司 | 电化学装置管理方法、系统、电化学装置及电子设备 |

| CN114207909B (zh) * | 2021-10-26 | 2024-02-27 | 东莞新能安科技有限公司 | 电化学装置管理方法、系统、电化学装置及电子设备 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN108099685B (zh) | 电动车用锂离子电池系统和充电加热方法 | |

| CN110768330B (zh) | 一种充放电控制方法、装置及ups系统 | |

| CN103855748A (zh) | 一种车辆的充电系统及其充电方法 | |

| CN112009246A (zh) | 一种汽车辅助电源管理系统及控制方法 | |

| CN216389527U (zh) | 电池加热系统、电池包和用电装置 | |

| CN107618397A (zh) | 电池管理系统 | |

| CN101917045B (zh) | 带过压保护电路的城轨车辆铅酸蓄电池及其过压保护方法 | |

| WO2022160186A1 (zh) | 充电的方法和功率转换设备 | |

| CN206412814U (zh) | 一种蓄电池组充放电管理装置和系统 | |

| CN205211873U (zh) | 一种汽车启动锂离子蓄电池组装置 | |

| CN112583066A (zh) | 一种叉车磷酸铁锂电池充电方法 | |

| CN203456930U (zh) | 复合能源系统 | |

| US11973364B2 (en) | Circuit control method, battery and its controller and management system, and electrical apparatus | |

| CN212162855U (zh) | 一种储能系统用高压配电箱 | |

| CN116653606A (zh) | 一种铅酸电池保护系统及车辆 | |

| CN112477694B (zh) | 车辆充电控制方法、装置及电路、车辆和计算机设备 | |

| CN115714441A (zh) | 一种充放电控制系统和控制方法 | |

| CN106877456B (zh) | 一种电动车电源系统 | |

| CN115800456B (zh) | 一种锂离子电池模组充放电防反接智能保护控制系统 | |

| CN112134323A (zh) | 一种工业电车用锂电池快速充电方法 | |

| CN218161896U (zh) | 一种锂电池充放电保护装置 | |

| CN218940723U (zh) | Bms防二次过充保护电路 | |

| CN216783304U (zh) | 电池包及电动汽车 | |

| CN212676916U (zh) | 一种电池充电管理系统 | |

| CN214543668U (zh) | 一种改进型直流电源系统 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication |

Application publication date: 20210330 |