CN112524623A - Air mixing device and chimney system comprising same - Google Patents

Air mixing device and chimney system comprising same Download PDFInfo

- Publication number

- CN112524623A CN112524623A CN202011496086.3A CN202011496086A CN112524623A CN 112524623 A CN112524623 A CN 112524623A CN 202011496086 A CN202011496086 A CN 202011496086A CN 112524623 A CN112524623 A CN 112524623A

- Authority

- CN

- China

- Prior art keywords

- ring flange

- inner cylinder

- chimney

- mixing device

- small ring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000000779 smoke Substances 0.000 abstract description 19

- 230000000630 rising effect Effects 0.000 abstract description 6

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 abstract description 5

- 239000003546 flue gas Substances 0.000 abstract description 5

- 230000002087 whitening effect Effects 0.000 abstract description 5

- 238000000034 method Methods 0.000 abstract description 4

- 230000002093 peripheral effect Effects 0.000 abstract description 4

- 230000000694 effects Effects 0.000 abstract description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 8

- 230000008030 elimination Effects 0.000 description 6

- 238000003379 elimination reaction Methods 0.000 description 6

- 238000001816 cooling Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000011084 recovery Methods 0.000 description 2

- 239000002699 waste material Substances 0.000 description 2

- 230000000750 progressive effect Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23J—REMOVAL OR TREATMENT OF COMBUSTION PRODUCTS OR COMBUSTION RESIDUES; FLUES

- F23J11/00—Devices for conducting smoke or fumes, e.g. flues

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/26—Drying gases or vapours

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23J—REMOVAL OR TREATMENT OF COMBUSTION PRODUCTS OR COMBUSTION RESIDUES; FLUES

- F23J13/00—Fittings for chimneys or flues

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23J—REMOVAL OR TREATMENT OF COMBUSTION PRODUCTS OR COMBUSTION RESIDUES; FLUES

- F23J15/00—Arrangements of devices for treating smoke or fumes

- F23J15/006—Layout of treatment plant

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Chemical Kinetics & Catalysis (AREA)

Abstract

The invention discloses a wind mixing device which comprises a small ring flange, a large ring flange and an inner cylinder, wherein the lower caliber of the inner cylinder is smaller than the inner diameter of the small ring flange, and the upper caliber of the inner cylinder is smaller than the inner diameter of the large ring flange; and the blades are wound on the outer side of the inner cylinder and are connected with the small ring flange and the large ring flange. In the process of smoke rising, the high-speed airflow is gradually expanded and reduced at the inner side and the outer side of the inner cylinder, negative pressure is formed locally, and external cold air can be drawn in. The high-temperature and high-humidity flue gas discharged from the chimney forms white fog when being cooled, and the white fog is collected and whitened by the whitening device after entering the whitening device. The mode of staggered entrainment of the central part and the peripheral part of the smoke has simple structure and low cost, can obviously improve the integral entrainment effect, and lays a foundation for obtaining better chimney whitening effect in the next step. The invention also provides a chimney system with corresponding advantages.

Description

Technical Field

The invention relates to the technical field of flue gas emission, in particular to an air mixing device and a chimney system comprising the same.

Background

In the thermal power industry and other industries, the overall level of water resource utilization efficiency is still low, and considerable space is saved. Effective measures are actively taken, the comprehensive utilization rate of water is improved, water is saved, the water-saving water-.

At present, the chimney of various industries often discharges 'white smoke', 'white smoke' is actually water, and 'white smoke' discharge is actually waste of water resources.

Besides the waste of resources, the 'white smoke' also affects the visibility of surrounding residential areas and traffic roads and destroys the urban environment; in addition, the humidity in the downwind area can be increased, and the fog falls on the ground to cause the road surface around the cooling tower to be wet, slippery or frozen, thereby bringing great potential safety hazard to surrounding traffic, influencing the safety production of factories and influencing the safe operation of production equipment around the cooling tower.

How to recover water resources discharged from a chimney with high efficiency and low cost is a problem which needs to be continuously researched.

Disclosure of Invention

The invention aims to provide an air mixing device and a chimney system, which can efficiently and inexpensively complete air mixing and further realize the recovery of water resources in a chimney.

In order to achieve the purpose, the air mixing device provided by the invention comprises a small ring flange for butting the outlet end of a chimney, a large ring flange coaxially arranged above the small ring flange, and an inner cylinder arranged in the central position between the small ring flange and the large ring flange, wherein the lower caliber of the inner cylinder is smaller than the inner diameter of the small ring flange, and the upper caliber of the inner cylinder is smaller than the inner diameter of the large ring flange; and the blades are wound on the outer side of the inner cylinder and are connected with the small ring flange and the large ring flange.

Preferably, the inner cylinder is a circular truncated cone cylinder with a smaller lower caliber and a larger upper caliber, and is coaxial with the small ring flange and the large ring flange.

Preferably, the lower opening edge of the inner cylinder is higher than the small ring flange, and the upper opening edge of the inner cylinder is lower than the large ring flange.

Preferably, the lower side of the blade is flush with the small ring flange, and the upper side of the blade is flush with the large ring flange.

Preferably, each blade is uniformly wound on the outer side of the inner cylinder in the circumferential direction.

The invention also provides a chimney system, which comprises a chimney body, a wet plasma generator and a dry plasma generator, wherein the wet plasma generator is arranged in the outlet end of the chimney body; the air mixing device is arranged between the outlet end of the chimney body and the dry plasma generator.

Preferably, the air mixing device, the wet plasma generator, and the dry plasma generator are all supported by the chimney body through a support member.

The invention provides a wind mixing device, which comprises a small ring flange for butting the outlet end of a chimney, a large ring flange coaxially arranged above the small ring flange, and an inner cylinder arranged in the central position between the small ring flange and the large ring flange, wherein the lower aperture of the inner cylinder is smaller than the inner diameter of the small ring flange, and the upper aperture of the inner cylinder is smaller than the inner diameter of the large ring flange; and the blades are wound on the outer side of the inner cylinder and are connected with the small ring flange and the large ring flange. In the smoke rising process, the high-speed airflow is gradually enlarged and reduced on the inner side and the outer side of the inner cylinder, the flowing cross section is increased, the flow speed is reduced, and according to the Bernoulli principle, negative pressure is locally formed, so that the external cold air can be involved. Along with the mixing of the cold air, the high-temperature and high-humidity flue gas discharged by the chimney forms white fog when meeting cold, and after the white fog enters the white elimination device, the white fog is collected by the white elimination device, so that the white elimination of the chimney is realized.

The inner cylinder divides the smoke at the discharge end of the chimney into a center part and a periphery part, the smoke at the periphery part can be well involved in cold air at the initial stage of removing the chimney, the smoke at the center part can be well involved in the cold air at the higher position at the next stage after rising along with the inner cylinder, and the smoke staggered entrainment mode of the center part and the periphery part has the advantages of simple structure and low cost, can obviously improve the integral entrainment effect, and lays a foundation for obtaining the better chimney whitening effect at the next step.

The chimney system provided by the invention has corresponding advantages and is not described in detail.

Drawings

In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the drawings used in the description of the embodiments or the prior art will be briefly described below, it is obvious that the drawings in the following description are only embodiments of the present invention, and for those skilled in the art, other drawings can be obtained according to the provided drawings without creative efforts.

FIG. 1 is a schematic structural diagram of a chimney system according to an embodiment of the present invention;

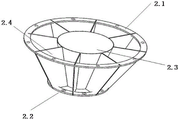

fig. 2 is a schematic structural view of the wind mixing device in fig. 1.

Detailed Description

The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only a part of the embodiments of the present invention, and not all of the embodiments. All other embodiments, which can be derived by a person skilled in the art from the embodiments given herein without making any creative effort, shall fall within the protection scope of the present invention.

The core of the invention is to provide the air mixing device and the chimney system, which can complete air mixing with high efficiency and low cost so as to realize the recovery of water resources in the chimney.

Referring to fig. 1 and fig. 2, fig. 1 is a schematic structural diagram of a chimney system according to an embodiment of the present invention; fig. 2 is a schematic structural view of the wind mixing device in fig. 1.

In a first embodiment, the chimney system provided by the invention mainly comprises a chimney body 1, a wind mixing device 2, a wet plasma generator 3, a dry plasma generator 4, a support member 5 and the like.

Wherein, the wet plasma generator 3 is disposed in the outlet end of the chimney body 1, and the wet plasma generator 3 is not exposed normally. The dry plasma generator 4 is provided in addition to the chimney body 1, and the dry plasma generator 4 is usually kept at an appropriate height distance from the outlet end of the chimney body 1.

And an air mixing device 2 is also arranged between the outlet end of the chimney body 1 and the dry plasma generator 4. The air mixing device 2, the wet plasma generator 3, the dry plasma generator 4, etc. can be supported on the chimney body 1 through the supporting component 5, and for the specific shape and structure of the supporting component 5, please refer to the prior art, which is not described herein again.

A detailed description of a specific embodiment of the air mixing device 2 is given below.

The wind mixing device 2 mainly comprises a large ring flange 2.1, a small ring flange 2.2, an inner cylinder 2.3, blades 2.4 and the like.

Wherein, the small ring flange 2.2 is positioned at a relatively lower position and can be butted with the outlet end of the chimney body 1; the large ring flange 2.1 is dimensioned to be significantly larger than the small ring flange 2.2, is located at a relatively high position and is arranged coaxially with the small ring flange 2.2.

The inner cylinder 2.3 is arranged at the center of the flange ring, can be a circular truncated cone with smaller lower caliber and larger upper caliber, and can be coaxially arranged with the large ring flange 2.1 and the small ring flange 2.2; the lower caliber of the inner cylinder 2.3 is smaller than the inner diameter of the small ring flange 2.2, and the upper caliber is smaller than the inner diameter of the large ring flange 2.1.

The lower opening edge of the inner cylinder 2.3 can be equal to or slightly higher than the small ring flange 2.2, and the upper opening edge can be equal to or slightly lower than the large ring flange 2.1.

Therefore, the smoke at the outlet of the chimney is divided into the middle part positioned in the central area and the peripheral part positioned in the peripheral area, the smoke at the peripheral part can be used for sucking the external cold air after flowing out of the chimney, and the smoke at the central part starts to suck the external cold air after rising for a certain height, so that the staggered sucking is realized.

The number of the blades 2.4 can be selected according to the actual situation of the specific occasion, and each blade 2.4 is wound on the outer side of the inner cylinder 2.3 and is connected with the small ring flange 2.2 and the large ring flange 2.1, so that the flue gas at the periphery of the outlet of the chimney is further divided into a plurality of strands distributed in the circumferential direction.

The lower side of the blade 2.4 can be flush with the small ring flange 2.2, and the upper side can be flush with the large ring flange 2.1.

Each blade 2.4 can be uniformly wound on the outer side of the inner cylinder 2.3 in the circumferential direction.

The invention provides a wind mixing device, which comprises a small ring flange for butting the outlet end of a chimney, a large ring flange coaxially arranged above the small ring flange, and an inner cylinder arranged in the central position between the small ring flange and the large ring flange, wherein the lower aperture of the inner cylinder is smaller than the inner diameter of the small ring flange, and the upper aperture of the inner cylinder is smaller than the inner diameter of the large ring flange; and the blades are wound on the outer side of the inner cylinder and are connected with the small ring flange and the large ring flange. In the smoke rising process, the high-speed airflow is gradually enlarged and reduced on the inner side and the outer side of the inner cylinder, the flowing cross section is increased, the flow speed is reduced, and according to the Bernoulli principle, negative pressure is locally formed, so that the external cold air can be involved. Along with the mixing of the cold air, the high-temperature and high-humidity flue gas discharged by the chimney forms white fog when meeting cold, and after the white fog enters the white elimination device, the white fog is collected by the white elimination device, so that the white elimination of the chimney is realized.

The inner cylinder divides the smoke at the discharge end of the chimney into a center part and a periphery part, the smoke at the periphery part can be well involved in cold air at the initial stage of removing the chimney, the smoke at the center part can be well involved in the cold air at the higher position at the next stage after rising along with the inner cylinder, and the smoke staggered entrainment mode of the center part and the periphery part has the advantages of simple structure and low cost, can obviously improve the integral entrainment effect, and lays a foundation for obtaining the better chimney whitening effect at the next step.

The chimney system provided by the invention has corresponding advantages and is not described in detail.

The embodiments in the present description are described in a progressive manner, each embodiment focuses on differences from other embodiments, and the same and similar parts among the embodiments are referred to each other.

The air mixing device and the chimney system provided by the invention are described in detail above. The principles and embodiments of the present invention are explained herein using specific examples, which are presented only to assist in understanding the method and its core concepts. It should be noted that, for those skilled in the art, it is possible to make various improvements and modifications to the present invention without departing from the principle of the present invention, and those improvements and modifications also fall within the scope of the claims of the present invention.

Claims (7)

1. The air mixing device is characterized by comprising a small ring flange (2.2) used for butting the outlet end of a chimney, a large ring flange (2.1) coaxially arranged above the small ring flange (2.2), and an inner cylinder (2.3) arranged in the central position between the small ring flange and the large ring flange, wherein the lower caliber of the inner cylinder (2.3) is smaller than the inner diameter of the small ring flange (2.2), and the upper caliber of the inner cylinder is smaller than the inner diameter of the large ring flange (2.1); a plurality of blades (2.4) are wound on the outer side of the inner cylinder (2.3) and are connected with the small ring flange (2.2) and the large ring flange (2.1).

2. The wind mixing device according to claim 1, characterized in that the inner cylinder (2.3) is a circular truncated cone with a smaller lower caliber and a larger upper caliber, and is coaxial with both the small ring flange (2.2) and the large ring flange (2.1).

3. The wind mixing device according to claim 1 or 2, characterized in that the lower mouth edge of the inner cylinder (2.3) is higher than the small ring flange (2.2), and the upper mouth edge is lower than the large ring flange (2.1).

4. A wind mixing device according to claim 3, characterised in that the lower side of the blades (2.4) is flush with the small ring flange (2.2) and the upper side is flush with the large ring flange (2.1).

5. The wind mixing device according to claim 4, characterized in that each of the blades (2.4) is circumferentially and uniformly wound around the outer side of the inner cylinder (2.3).

6. A chimney system comprises a chimney body (1), a wet plasma generator (3) arranged in the outlet end of the chimney body (1), and a dry plasma generator (4) arranged outside the outlet end of the chimney body (1); characterized in that a wind mixing device (2) according to any one of claims 1-5 is installed between the outlet end of the chimney body (1) and the dry plasma generator (4).

7. The chimney system according to claim 6, characterized in that the wind mixing device (2), the wet plasma generator (3), the dry plasma generator (4) are supported to the chimney body (1) by a support member (5).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011496086.3A CN112524623A (en) | 2020-12-17 | 2020-12-17 | Air mixing device and chimney system comprising same |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011496086.3A CN112524623A (en) | 2020-12-17 | 2020-12-17 | Air mixing device and chimney system comprising same |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN112524623A true CN112524623A (en) | 2021-03-19 |

Family

ID=75001034

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202011496086.3A Pending CN112524623A (en) | 2020-12-17 | 2020-12-17 | Air mixing device and chimney system comprising same |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN112524623A (en) |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN206838310U (en) * | 2017-06-29 | 2018-01-05 | 江苏景南环保科技有限公司 | Plasma eliminating white smoke device |

| CN108692323A (en) * | 2017-04-12 | 2018-10-23 | 中国石油化工股份有限公司 | A kind of chimney structure |

| CN109224786A (en) * | 2018-11-02 | 2019-01-18 | 昊姆(上海)节能科技有限公司 | Flue gas injection mixes wind and disappears white system and eliminating white smoke method |

| CN210916124U (en) * | 2019-10-28 | 2020-07-03 | 秦皇岛中青冶金阀门有限公司 | Compact smoke white eliminating device |

| CN214332760U (en) * | 2020-12-17 | 2021-10-01 | 江苏双良低碳产业技术研究院有限公司 | Air mixing device and chimney system comprising same |

-

2020

- 2020-12-17 CN CN202011496086.3A patent/CN112524623A/en active Pending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108692323A (en) * | 2017-04-12 | 2018-10-23 | 中国石油化工股份有限公司 | A kind of chimney structure |

| CN206838310U (en) * | 2017-06-29 | 2018-01-05 | 江苏景南环保科技有限公司 | Plasma eliminating white smoke device |

| CN109224786A (en) * | 2018-11-02 | 2019-01-18 | 昊姆(上海)节能科技有限公司 | Flue gas injection mixes wind and disappears white system and eliminating white smoke method |

| CN210916124U (en) * | 2019-10-28 | 2020-07-03 | 秦皇岛中青冶金阀门有限公司 | Compact smoke white eliminating device |

| CN214332760U (en) * | 2020-12-17 | 2021-10-01 | 江苏双良低碳产业技术研究院有限公司 | Air mixing device and chimney system comprising same |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN214332760U (en) | Air mixing device and chimney system comprising same | |

| TWI683956B (en) | Wind collector | |

| CN106194591B (en) | Energy-capturing type wind generating set | |

| CN112524623A (en) | Air mixing device and chimney system comprising same | |

| CN108499239B (en) | High-efficient multistage defroster | |

| CN214332767U (en) | Electrode air mixing device of chimney white elimination system | |

| CN112524624A (en) | Electrode air mixing device of chimney white elimination system | |

| CN107816684A (en) | A kind of electric car illumination device based on wind power generation | |

| WO2023188263A1 (en) | Vertical wind speed-accelerating windmill | |

| CN214320518U (en) | Wet-type electrostatic precipitator negative pole fixing device's whirl protection device | |

| CN102966602B (en) | The energy-conservation water conservancy diversion air duct of a kind of cooling tower | |

| CN209781300U (en) | Centrifugal fan | |

| CN2038958U (en) | Axial flow type electric fan | |

| CN221388024U (en) | Air curtain dust hood | |

| CN216062381U (en) | Novel high-efficient liquid drop separation device | |

| CN213899043U (en) | Low-concentration gas discharging and diffusing device | |

| CN105509080B (en) | Hyperboloid chimney cowl | |

| CN210905435U (en) | Dust collector for construction | |

| KR100535525B1 (en) | Water saparator of air duct | |

| CN216950459U (en) | Spiral-flow type gas washing machine | |

| CN219045453U (en) | Nitrogen making machine air compressor unit parallel pipeline flow stabilizer capable of reducing pressure loss bias current | |

| CN1287903C (en) | Guide rectifier for circulating-current cycle dust-removing system | |

| CN219701372U (en) | Mechanical coagulation centrifugal diversion dust removal defogging device | |

| CN213452177U (en) | Noise reduction pipe with excellent noise reduction effect | |

| CN110566409B (en) | Wind power generation device and wind power generation method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |