CN112131760B - CBAM model-based prediction method for residual life of aircraft engine - Google Patents

CBAM model-based prediction method for residual life of aircraft engine Download PDFInfo

- Publication number

- CN112131760B CN112131760B CN202011206202.3A CN202011206202A CN112131760B CN 112131760 B CN112131760 B CN 112131760B CN 202011206202 A CN202011206202 A CN 202011206202A CN 112131760 B CN112131760 B CN 112131760B

- Authority

- CN

- China

- Prior art keywords

- data

- aircraft engine

- engine

- representing

- attention

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 title claims abstract description 37

- 238000012544 monitoring process Methods 0.000 claims abstract description 32

- 238000006731 degradation reaction Methods 0.000 claims abstract description 27

- 230000015556 catabolic process Effects 0.000 claims abstract description 21

- 238000012360 testing method Methods 0.000 claims abstract description 17

- 238000004364 calculation method Methods 0.000 claims abstract description 14

- 238000013507 mapping Methods 0.000 claims abstract description 8

- 230000008569 process Effects 0.000 claims abstract description 7

- 238000010586 diagram Methods 0.000 claims description 23

- 238000011176 pooling Methods 0.000 claims description 21

- 238000012549 training Methods 0.000 claims description 14

- 230000004913 activation Effects 0.000 claims description 11

- 238000012886 linear function Methods 0.000 claims description 7

- 239000011159 matrix material Substances 0.000 claims description 7

- 230000014509 gene expression Effects 0.000 claims description 4

- 230000009467 reduction Effects 0.000 claims description 3

- 238000012935 Averaging Methods 0.000 claims 1

- 230000036541 health Effects 0.000 abstract description 6

- 230000006870 function Effects 0.000 description 9

- 230000007246 mechanism Effects 0.000 description 8

- 238000004088 simulation Methods 0.000 description 7

- 238000005516 engineering process Methods 0.000 description 5

- 230000008901 benefit Effects 0.000 description 2

- 238000004422 calculation algorithm Methods 0.000 description 2

- 238000013135 deep learning Methods 0.000 description 2

- 238000007781 pre-processing Methods 0.000 description 2

- 230000009471 action Effects 0.000 description 1

- 230000002776 aggregation Effects 0.000 description 1

- 238000004220 aggregation Methods 0.000 description 1

- 238000013528 artificial neural network Methods 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000013527 convolutional neural network Methods 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000012800 visualization Methods 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06N—COMPUTING ARRANGEMENTS BASED ON SPECIFIC COMPUTATIONAL MODELS

- G06N3/00—Computing arrangements based on biological models

- G06N3/02—Neural networks

- G06N3/04—Architecture, e.g. interconnection topology

- G06N3/045—Combinations of networks

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06N—COMPUTING ARRANGEMENTS BASED ON SPECIFIC COMPUTATIONAL MODELS

- G06N3/00—Computing arrangements based on biological models

- G06N3/02—Neural networks

- G06N3/04—Architecture, e.g. interconnection topology

- G06N3/049—Temporal neural networks, e.g. delay elements, oscillating neurons or pulsed inputs

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06N—COMPUTING ARRANGEMENTS BASED ON SPECIFIC COMPUTATIONAL MODELS

- G06N3/00—Computing arrangements based on biological models

- G06N3/02—Neural networks

- G06N3/08—Learning methods

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T90/00—Enabling technologies or technologies with a potential or indirect contribution to GHG emissions mitigation

Landscapes

- Engineering & Computer Science (AREA)

- Theoretical Computer Science (AREA)

- Physics & Mathematics (AREA)

- General Health & Medical Sciences (AREA)

- Computing Systems (AREA)

- Biomedical Technology (AREA)

- Biophysics (AREA)

- Computational Linguistics (AREA)

- Data Mining & Analysis (AREA)

- Evolutionary Computation (AREA)

- Life Sciences & Earth Sciences (AREA)

- Molecular Biology (AREA)

- Artificial Intelligence (AREA)

- General Engineering & Computer Science (AREA)

- General Physics & Mathematics (AREA)

- Mathematical Physics (AREA)

- Software Systems (AREA)

- Health & Medical Sciences (AREA)

- Management, Administration, Business Operations System, And Electronic Commerce (AREA)

- Feedback Control In General (AREA)

Abstract

The invention provides a CBAM model-based prediction method for the residual life of an aircraft engine, belonging to the field of fault Prediction and Health Management (PHM). First order difference calculation is performed on the original monitored variable of the engine to obtain a (new) difference characteristic, and the difference characteristic and the original characteristic are used together for representing degradation of the engine. Then, a residual life prediction model of the parallel CNN network embedded into a CBAM module is provided, and the feature map obtained by conventional convolution calculation further highlights valuable feature information and weakens useless or noise information from two dimensions of channel attention and space attention. And constructing input and output of the sample according to the mapping relation between the monitoring variable and the residual life, and using the input and output to train the model. And finally, constructing a test sample for the in-service aircraft engine, and inputting the test sample into the trained prediction model to obtain a predicted value of the residual service life of the in-service aircraft engine. The method provided by the invention is simple and effective in calculation process and high in prediction precision.

Description

Technical Field

The invention relates to a prediction method of residual Life (RUL) of an aircraft engine, in particular to a CNN (conditional Neural network) network of a CBAM (conditional block attachment) module which generates new characteristics by a difference technology and simultaneously considers a space and channel attention mechanism, wherein a parallel CNN model of the integrated CBAM module constructed on the basis is used for predicting the residual Life of the aircraft engine, and belongs to the field of fault Prediction and Health Management (PHM).

Background

As the heart of the aircraft, the health condition of an aircraft engine directly determines the safety of flight and passengers, but the performance condition of the aircraft is continuously challenged by the extreme working environment of high temperature, high pressure, extreme cold and the like for a long time. Therefore, how to perform health management on the aircraft engine, and ensure the reliability and safety of the aircraft engine is always the focus of attention in the industry, wherein the residual life prediction is the most challenging core key technology in the health management. However, as a high-precision technical device, an aircraft engine has an intricate internal structure, self-coupling action and an extreme external environment, and it is difficult to characterize the performance state of the engine through a simple univariate degradation process or an accurate mathematical prediction model.

With the rapid development of sensors and storage technologies, massive monitoring data of the aircraft engine and parts can be collected, recorded and stored, and a new solution is provided for predicting the residual service life of the aircraft engine. In recent years, deep learning methods have been increasingly gaining importance in data-driven prediction of remaining life. As a popular deep learning, CNN has been successfully applied to a plurality of fields such as image recognition. In order to improve the performance of CNN, besides improving the network structure in terms of its depth, width and base, the introduction of attention mechanism is another implementation way to improve its performance. Wherein the SE (Squeeze-and-Excitation) module gives different weights to different convolution characteristics from the perspective of the channel attention mechanism. The CBAM module is an architecture which considers a space attention mechanism and a channel attention mechanism at the same time, and not only weights are given to the characteristics of different channels, but also weight calculation is carried out on different areas of the same characteristic diagram.

Disclosure of Invention

The technical problem to be solved by the invention is as follows: when the residual life of the aircraft engine is predicted, the difference features are obtained by adopting first-order difference calculation on the original features, so that degradation information can be enriched on a data level; the CNN model has the advantage of extracting high-quality degradation information from the multi-dimensional monitoring variables with noise. In order to further identify strong degradation features and weaken the influence of invalid features or noise, the invention introduces an attention mechanism, namely a CBAM (Convergence amplitude modulation) module on the basis of a CNN (convolutional neural network) model, and highlights valuable feature information and weakens useless or noise information in a mode of weighting a feature map obtained by conventional convolution operation in two dimensions of channel attention and space attention. Therefore, the invention provides a CBAM model-based prediction method for the residual life of an aircraft engine.

In order to realize the purpose of the invention, the following technical scheme is adopted for realizing the purpose:

the prediction method of the residual life of the aeroengine based on the CBAM model comprises the following steps:

step one, acquiring historical aeroengine failure data to form a training set X L×V Wherein L is L 1 +L 2 +…+L N Represents the total running track length of N aeroengine samples, and N represents the number of the aeroengine samples, L n The monitoring track length of the nth aircraft engine sample is shown, wherein N is 1,2, …, N and V is the number of sensors in the aircraft engine;

step two, performing feature selection on the V monitoring variables to obtain F monitoring variables, and reducing the dimension of the original training set to X L×F . F monitoring variables are standardized according to a 'minimum-maximum' method, and the calculation formula is as follows:

wherein,raw data representing the ith instant of the nth engine signal j,is thatNormalized value, andandrespectively representing the maximum value and the minimum value of the signal j;

then, carrying out differential operation on the standardized variables to generate new variables, and forming a data matrix X of the aircraft engine performance degradation together with the original characteristics L×2F And the calculation formula of the d-order difference operation is as follows:

in the invention, the default value of d is 1, namely, first-order difference operation is carried out, and a new variable generated through the first-order difference operation is used for depicting the system degradation speed;

step three, constructing a parallel CNN network architecture embedded with CBAM module

First, a mapping relationship between the monitoring variable X and the remaining lifetime RUL is established, which is expressed as follows:

f:X→RUL i.e.,RUL(t)=f(X t-s+1 ,X t-s+2 ,…,X t )。

wherein t represents time, s represents time step, X i T-s +1, …, where t represents the monitoring data corresponding to time i and is in the form of a vector with a length of 2F;

when the residual service life of the aircraft engine is predicted, a CBAM module is embedded in a basic CNN network, valuable characteristic information is highlighted and useless or noise information is weakened in a mode of weighting a characteristic diagram obtained by conventional convolution operation in two angles of channel attention and space attention. Because the collected data is from time sequence data monitored by a plurality of different sensors, and the difference of different characteristics is considered, the convolution operation in the CNN adopts one-dimensional convolution operation to aggregate data on the same characteristic, and the specific explanation is as follows:

determining that the input 1-dimensional sequence data is x ═ x 1 ,x 2 ,…,x N ]Where N represents the sequence length, the convolution operation in the convolution layer is defined as the filter kernel w,and concatenation vectorIs expressed as follows

Wherein the output z i Is a feature learned by the convolution kernel w,denotes a nonlinear activation function, b denotes a bias T It is shown that the transpose operation,indicates a window length F starting from the ith data point L Sequence data of (2) fromThe following data connection operations are represented:

representing the characteristic diagram obtained after the operation of the jth convolution kernel as follows:

wherein,i=1,2,…,N-F L +1 denotes the jth convolutional parityPerforming non-linear operationsThe output of the latter vector form;

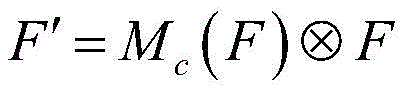

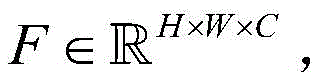

the CBAM module, which is followed by the base CNN, includes two dimensions, channel attention and spatial attention. Characteristic diagram for an intermediate layerCBAM will sequentially get 1-dimensional channel attention mapAnd 2-dimensional spatial attention mapThe whole process is as follows:

wherein,for point multiplication, the channel attention diagram is firstly multiplied with the input feature diagram to obtain F ', then F ' space attention diagram is calculated, and the two are multiplied to obtain the final output F '.

Specifically, the operation of the channel attention module is: firstly, the feature maps are respectively used in the spatial dimensionCompression of mean pooling (AvgPool) and maximum pooling (MaxPool); then, inputting the obtained two different spatial descriptions into a shared network formed by a multilayer perceptron (MLP); finally, the results obtained from MLP are summedAnd performing nonlinear activationObtaining a channel attention map M c 。

Wherein, W 0 ∈R C/r×C ,W 1 ∈R C×C/r R represents a reduction rate, W 0 Followed by a ReLU function;the result of average pooling and maximum pooling on the feature map F in the spatial dimension is shown; sigma represents a sigmoid activation function; m c Representing the resulting channel attention map.

The operation of the spatial attention module is: performing average pooling (AvgPool) and maximum pooling (Maxpool) on the feature map in channel dimension respectively to obtain two different feature descriptionsAndthen, the two features are combined and subjected to convolution operation (f) conv ) (ii) a Finally, the result of the convolution operation is activated in a non-linear wayGet a spatial attention map M s 。

Wherein,representing the result of average pooling and maximum pooling on the feature map F in the channel dimension; f. of conv Represents a convolution operation; sigma represents a sigmoid activation function; m s Representing the resulting spatial attention map.

Constructing the input and output of the sample, pair X L×2F The degradation track data of each engine is respectively constructed by adopting a window sliding method to input a training sample, and a label corresponding to the output, namely the residual life RUL, is corrected according to a hierarchical linear function, and finally the input and the output of paired samples are obtained, wherein the window sliding method is described as follows:

for X L×2F Degradation trajectory data of the nth engineExpressed in the form of a two-dimensional matrix

Further, the kth sample of the nth engine is obtained according to the step s being 1 as follows:

wherein N is t Representing the length of the constructed sample time window.

Wherein the order linear function expression is as follows:

wherein Label represents a constructed sampleA label for the data, RUL, representing the actual remaining life in the acquired historical aircraft engine failure data, R early Indicates a threshold value set according to circumstances, which is set to 125 as a default value in the present invention;

and step four, constructing the input of a test sample for the monitoring data of the in-service aircraft engine to be subjected to the residual life prediction, and forming a test set. And inputting the constructed test set into a trained prediction model of the residual life of the aircraft engine to obtain a predicted value of the residual life of the in-service aircraft engine.

The invention has the advantages that:

taking the residual service life RUL of the aircraft engine as a prediction target, firstly, establishing a mapping relation between a characteristic variable for representing a system degradation process and the prediction target, and further adopting a difference technology to generate a new characteristic variable so as to provide more degradation information; secondly, attention mechanisms on two dimensions of space and channels are considered by embedding a CBAM module in the CNN network, so that the importance of different channel characteristics and the importance of different areas of the same channel are considered. Therefore, under the idea of using the channel-space attention mechanism, a parallel CNN network model embedded in CBAM is constructed for the original features and the differential features to learn the mapping relationship.

Drawings

In order to more clearly illustrate the technical solutions in the embodiments or the prior art of the present invention, the drawings used in the description of the embodiments or the prior art will be briefly described below, and it is obvious that the drawings in the following description are only some embodiments of the present invention, and for the ordinary skill in the art, other drawings can be obtained according to these drawings without creative efforts.

FIG. 1 is a flow chart of a CBAM model-based method for predicting the remaining life of an aircraft engine according to an embodiment of the present invention;

FIG. 2 is a schematic diagram of a parallel CNN network architecture with embedded CBAM modules;

FIG. 3 is a diagram illustrating a one-dimensional convolution operation;

FIG. 4 is a schematic diagram of a CBAM module;

FIG. 5 is a diagram of an aircraft engine architecture and simulation module logic in accordance with an embodiment of the present invention;

FIG. 6 is a scatter plot of 21 sensor signals for an aircraft engine, according to an embodiment of the present disclosure;

FIG. 7 is a diagram of a CBAM-based network architecture;

FIG. 8 is a comparison of predicted results for 100 tested engines sorted by RUL.

Detailed Description

The technical solution in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. It is to be understood that the described embodiments are merely exemplary of the invention, and not restrictive of the full scope of the invention. All other embodiments, which can be obtained by a person skilled in the art without making any creative effort based on the embodiments of the present invention, belong to the protection scope of the present invention.

Referring to fig. 1, fig. 1 is a flowchart of a CBAM model-based method for predicting remaining life of an aircraft engine according to an embodiment of the present invention, including the following steps:

the prediction method of the residual life of the aeroengine based on the CBAM model comprises the following steps:

step one, obtaining historical aeroengine failure data to form training data X L×V Wherein L is L 1 +L 2 +…+L N Representing the total length of the running track of N aero-engine samples, wherein N represents the number of aero-engine samples, L n The monitoring track length of the nth aircraft engine sample is shown, wherein N is 1,2, …, N and V is the number of sensors in the aircraft engine;

step two, performing feature selection on the V monitoring variables to obtain F monitoring variables, and reducing the dimension of the original training set to X L×F . F monitoring variables are standardized according to a 'minimum-maximum' method, and the calculation formula is as follows:

wherein,raw data representing the ith instant of the nth engine signal j,is thatNormalized value, andandrespectively representing the maximum value and the minimum value of the signal j;

then, the normalized variables are subjected to differential operation to generate new variables, and the new variables and the original characteristics jointly form a data matrix form X of the engine performance degradation L×2F And the calculation formula of the d-order difference operation is as follows:

in the invention, the default value of d is 1, namely, first-order difference operation is carried out, and a new variable generated through the first-order difference operation is used for depicting the system degradation speed;

step three, constructing a parallel CNN network architecture embedded into a CBAM module

First, a mapping relationship between the monitoring variable X and the remaining lifetime RUL is established, which is expressed as follows:

f:X→RUL i.e.,RUL(t)=f(X t-s+1 ,X t-s+2 ,…,X t )。

wherein t represents time, s represents time step, X i T-s +1, …, where t represents the monitoring data corresponding to time i and is in the form of a vector with a length of 2F;

when the residual life of the aircraft engine is predicted, a schematic diagram of the proposed CBAM model is shown in FIG. 2, a CBAM module is embedded in a basic CNN network, and valuable feature information is highlighted and useless or noise information is weakened in a mode of weighting a feature map obtained by conventional convolution operation in two angles of channel attention and space attention. Because the collected data is from time series data monitored by a plurality of different sensors, and in consideration of differences of different characteristics, the convolution operation in the CNN adopts the one-dimensional convolution operation in fig. 3 to perform aggregation operation on data on the same characteristic, which is specifically set forth as follows:

determining that the input 1-dimensional sequence data is x ═ x 1 ,x 2 ,…,x N ]Where N represents the sequence length, the convolution operation in the convolution layer is defined as the filter kernel w,and concatenation vectorIs expressed as follows

Wherein the output z i Is a feature learned by the convolution kernel w,representing a non-linear activation function, b representing a bias T It is shown that the transpose operation,indicates a window length F starting from the ith data point L The following data join operation, denoted by [ ]:

representing the characteristic diagram obtained after the jth convolution kernel operation as follows:

wherein,i=1,2,…,N-F L +1 denotes the jth convolutional parityPerforming non-linear operationThe output of the latter vector form;

the CBAM module followed by the base CNN is shown in fig. 4, and includes two dimensions, channel attention and spatial attention. Feature map for an intermediate layerCBAM will sequentially get 1-dimensional channel attention mapAnd 2-dimensional spatial attention mapThe whole process is as follows:

wherein,to dot-multiply, first pay attention to the channelThe graph is multiplied by the input feature graph to obtain F ', then the spatial attention graph of F ' is calculated, and the two are multiplied to obtain the final output F '.

Specifically, the operation of the channel attention module is: firstly, compressing the feature map in spatial dimension by using average pooling (AvgPool) and maximum pooling (MaxPool) respectively; then, inputting the obtained two different spatial descriptions into a shared multilayer perceptron network (MLP); finally, the results obtained from MLP are summedAnd performing nonlinear activationObtaining a channel attention map M c 。

Wherein, W 0 ∈R C/r×C ,W 1 ∈R C×C/r R represents a reduction rate, W 0 Followed by a ReLU function;the result of average pooling and maximum pooling on the feature map F in the spatial dimension is shown; sigma represents a sigmoid activation function; m c Representing the resulting channel attention map.

The operation of the spatial attention module is: performing mean pooling (AvgPool) and maximum pooling (Maxpool) on the feature map in the channel dimension separately yields two different feature descriptionsAndthen, the two features are combined and subjected to convolution operation (f) conv ) (ii) a Finally, the result of the convolution operation is activated in a non-linear wayObtaining a spatial attention map M s 。

Wherein,representing the result of performing average pooling and maximum pooling on the feature graph F in the channel dimension; f. of conv Represents a convolution operation; sigma represents a sigmoid activation function; m s Representing the resulting spatial attention map.

Construct the input and output of the sample, for X L×2F The degradation track data of each engine is respectively constructed by adopting a window sliding method to input a training sample, and a label corresponding to the output, namely the residual life RUL, is corrected according to a hierarchical linear function, and finally the input and the output of paired samples are obtained, wherein the window sliding method is described as follows:

for X L×2F Degradation trajectory data of the nth engineExpressed in the form of a two-dimensional matrix

Further, the kth sample of the nth engine is obtained according to the step s being 1 as follows:

wherein N is t Representing the length of the constructed sample time window.

Wherein the order linear function expression is as follows:

wherein Label represents a Label for constructing sample data, RUL represents the actual residual life in the acquired historical aeroengine failure data, and R early Indicates a threshold value set according to circumstances, which is set to 125 as a default value in the present invention;

and step four, constructing the input of a test sample for the monitoring data of the in-service aircraft engine to be subjected to the residual life prediction, and forming a test set. And inputting the constructed test set into a trained prediction model of the residual life of the aircraft engine to obtain a predicted value of the residual life of the in-service aircraft engine.

The following describes the implementation and prediction effect of the present invention with reference to a specific application example:

in this implementation, NASA is used to provide a CMAPSS simulation data set for an aircraft engine. The CMAPSS is modular aviation propulsion system simulation software developed by Green research center of NASA (national aeronautical service), and aims to simulate the whole degradation process of an airplane from normal to fault and provide a data base for a prediction model. Simulation experiments were created under the Matlab Simulink tool, simulating an engine model with 90000 pounds of thrust, and the program included an atmospheric model and an electrical management system involving five component modules of a fan, a Low Pressure Compressor (LPC), a High Pressure Compressor (HPC), a high pressure turbine (HPC), and a Low Pressure Turbine (LPT). The logical structural relationship of the five modules in the aircraft engine simulation experiment is shown in fig. 5.

The open source data comprises four groups of simulation data in total, the specific implementation process of the invention selects 'train _ FD 001' and 'test _ FD 001' as a training set and a test set respectively, wherein each subdata set comprises 26 columns, namely, a number, an operation period, an environment setting 1, an environment setting 2, an environment setting 3 and 21 monitoring indexes, 21 monitoring data are used for outputting signal data in the engine degradation process in the simulation experiment, and the specific meaning represented by the data is described as shown in Table 1.

TABLE 1 Engine monitoring index description

Step one, obtaining aeroengine failure data X from train _ FD001.txt files in a first group of simulation data sets 20631×26 It refers to the data of the whole process from a certain starting moment of the engine to the final failure. Row 20631 is the total duration of 100 engine operating cycles, and column 26 includes the number, operating cycle, environment setting 1, environment setting 2, environment setting 3, and 21 monitoring indicators. The visualization results of the 21 monitoring indexes are shown in fig. 6.

Step two, the trend of the change of the 21 monitoring variables in the whole life cycle in fig. 6 roughly divides the sensor data into two types: constant and changing (i.e., increasing or decreasing trend). The constant signal is clearly not functional in characterizing the engine degradation process and is therefore not considered in the input variables of the later model. In addition, Sensor 6 is also believed to not contribute to characterizing engine degradation phenomena. Therefore, 14 indexes are selected as the original input features of the RUL prediction model, and the numbers of the indexes are 2, 3, 4, 7, 8, 9, 11, 12, 13, 14, 15, 17, 20 and 21.

Then, the selected 14 monitoring variables are normalized according to a method of 'min-max', and the calculation formula is as follows:

wherein,indicates the nth hairThe raw data at the ith time of motive signal j,is thatNormalized value, andandrespectively representing the maximum value and the minimum value of the signal j;

then, the normalized variables are subjected to first order difference operation to generate new variables, and the new variables and the original characteristics jointly form a data matrix form X of the engine performance degradation 20631×28 The calculation formula of the first order difference operation is as follows:

step three, drawing a network structure diagram based on the CBAM model as shown in FIG. 7. And inputting a sample constructed by a training set into the network architecture, wherein the training round epoch is 200 and the loss function cost is RMSE + alpha Score (alpha is 0.025), and obtaining a well-trained aircraft engine residual life prediction model. Wherein the expressions for RMSE and Score are as follows:

wherein n represents the number of samples, d i =RUL′ i -RUL i Representing the error between the predicted value and the true value of the ith sample.

For training setThe size of each engine data in the (1) is constructed to be N according to a time window method t ×N f Is input of samples of (1), wherein N t =30,N f 28; resetting the real residual life by using a step linear function method to form a sample output, and assuming that the sample output has a constant RUL value R in the initial stage early =125。

And step four, preprocessing the data in the test set test _ FD001.txt through the data in the step two, and constructing a sample input of the prediction model according to the method in the step three. And inputting samples of 100 test engines into the trained prediction model of the residual life of the aircraft engine to obtain a prediction result, as shown in fig. 8.

In conclusion, the invention establishes the mapping relation between the characteristic variables for representing the system degradation process and the prediction target (RUL); the method comprises the steps of obtaining newly generated features according to a difference technology to depict speed information of system degradation, wherein a CBAM module is embedded in a CNN network to highlight valuable feature information and weaken useless or noise information in a mode of weighting a feature diagram obtained by conventional convolution operation in two angles of channel attention and space attention, not only the importance of different channel features but also the importance of different degradation features of the same channel are considered, and a constructed network model is used for learning the proposed mapping relation. Preprocessing original monitoring data, constructing a sample for inputting the proposed model, inputting the constructed sample into a set model, and training to obtain a final prediction model; and finally, inputting the test sample into the trained model to obtain a prediction result and a prediction performance index. The method well solves the problem of predicting the residual service life of the data-driven aircraft engine through the steps, and is beneficial to building the bridge connected with big data and intelligent system health management. Compared with the existing method, the algorithm provided by the invention is simple and effective in calculation process. According to the specific embodiment, the algorithm provided by the invention has high prediction precision.

Although the present invention has been described with reference to the preferred embodiments, it will be understood by those skilled in the art that various changes in form and details may be made therein without departing from the spirit and scope of the invention as defined by the appended claims.

Claims (3)

1. The prediction method of the residual life of the aeroengine based on the CBAM model is characterized by comprising the following steps:

step one, obtaining historical aircraft engine failure data to form a training set X L×V Wherein L ═ L 1 +L 2 +…+L N Representing the total running track length of N aero-engine samples, N representing the number of aero-engine samples, L n The monitoring track length of the nth aircraft engine sample is shown, wherein N is 1,2, …, N and V is the number of sensors in the aircraft engine;

step two, performing feature selection on the V monitoring variables to obtain F monitoring variables, and reducing the corresponding training set dimension to X L×F (ii) a F monitoring variables are standardized according to a 'minimum-maximum' method, and the calculation formula is as follows:

wherein,raw data representing the ith instant of the nth engine signal j,is thatNormalized value, andandrespectively representing the maxima of the signal jA large value and a minimum value;

then, carrying out differential operation on the standardized variables to generate new variables, and forming a data matrix X of the aircraft engine performance degradation together with the original characteristics L×2F And the calculation formula of the d-order difference operation is as follows:

step three, constructing a parallel CNN network architecture embedded with CBAM module

First, a mapping relationship between the monitoring variable X and the remaining lifetime RUL is established, which is expressed as follows:

f:X→RULi.e.,RUL(t)=f(X t-s+1 ,X t-s+2 ,…,X t );

wherein t represents time, s represents time step, X i T-s +1, …, where t represents the monitoring data corresponding to time i and is in the form of a vector with a length of 2F;

when the residual service life of the aircraft engine is predicted, a CBAM module is embedded into a basic CNN network, and valuable characteristic information is highlighted and useless or noise information is weakened in a mode of weighting a characteristic diagram obtained by conventional convolution operation in two angles of channel attention and space attention; because the collected data is from time sequence data monitored by a plurality of different sensors, and the difference of different characteristics is considered, the convolution operation in the CNN adopts one-dimensional convolution operation to aggregate data on the same characteristic, and the specific explanation is as follows:

determining that the input 1-dimensional sequence data is x ═ x 1 ,x 2 ,…,x N ]Where N represents the sequence length, the convolution operation in the convolution layer is defined as the filter kernel w,and concatenation vectorIs expressed as follows

Wherein the output z i Is a feature learned by the convolution kernel w,representing a non-linear activation function, b representing a bias T It is shown that the transpose operation,indicates a window length F starting from the ith data point L Sequence data of (2) fromThe following data connection operations are represented:

representing the characteristic diagram obtained after the operation of the jth convolution kernel as follows:

wherein,representing the jth convolutional checkup sequencePerforming non-linear operationThe output of the latter vector form;

at the baseA CBAM module is connected behind the base CNN and comprises two dimensions of channel attention and space attention; feature map for an intermediate layerCBAM will sequentially get 1-dimensional channel attention mapAnd 2-dimensional spatial attention mapThe whole process is as follows:

wherein,for point multiplication, firstly multiplying the channel attention diagram with the input feature diagram to obtain F ', then calculating an F' space attention diagram, and multiplying the F 'space attention diagram with the space attention diagram to obtain a final output F';

specifically, the operation of the channel attention module is: firstly, compressing a feature map by respectively using average pooled AvgPool and maximum pooled MaxPool on a spatial dimension; secondly, inputting the obtained two different space descriptions into a shared multilayer perceptron network (MLP); finally, the results obtained by MLP are summed and nonlinear activation is carried out to obtain a channel attention map M c ;

Wherein, W 0 ∈R C/r×C ,W 1 ∈R C×C/r R represents a reduction rate, W 0 Followed by a ReLU function; the result of average pooling and maximum pooling on the feature map F in the spatial dimension is shown; sigma represents a sigmoid activation function; m c Representing the resulting channel attention map;

the operation of the spatial attention module is: averaging pooling AvgPool and Maxpool MaxPool separately on the feature map in channel dimension yields two different feature descriptionsAndthese two features are then combined and subjected to a convolution operation f conv (ii) a Finally, nonlinear activation is carried out on the convolution operation result to obtain a space attention map M s ;

Wherein,representing the result of average pooling and maximum pooling on the feature map F in the channel dimension; f. of conv Representing a convolution operation; sigma represents a sigmoid activation function; m s Representing the resulting spatial attention map;

constructing the input and output of the sample, pair X L×2F The degradation track data of each engine is respectively input by adopting a window sliding method to construct a training sample, and the input isAnd modifying the corresponding output label, namely the residual service life RUL according to a step linear function, and finally obtaining input and output of paired samples, wherein the window sliding method is described as follows:

for X L×2F Degradation trajectory data of the nth engineExpressed in the form of a two-dimensional matrix as follows

Further, the kth sample of the nth engine is obtained according to the step s being 1 as follows:

wherein N is t Represents the length of the constructed sample time window;

wherein the order linear function expression is as follows:

wherein Label represents a Label for constructing sample data, RUL represents the actual residual life in the acquired historical aeroengine failure data, and R early Indicates a threshold value set according to the situation;

fourthly, building input of a test sample for monitoring data of the in-service aircraft engine to be subjected to residual life prediction to form a test set; and inputting the constructed test set into a trained aircraft engine residual life prediction model to obtain a predicted value of the residual life of the in-service aircraft engine.

2. The CBAM model-based prediction method for the residual life of the aircraft engine, as defined in claim 1, wherein in the second step, the value d is 1, i.e. a first-order difference operation is performed, and a new variable generated through the first-order difference operation is used for depicting the degradation speed of the system.

3. The CBAM model-based prediction method for the remaining life of an aircraft engine as claimed in claim 1, wherein R in the third step early The value is 125.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911064237.5A CN110807257A (en) | 2019-11-04 | 2019-11-04 | Method for predicting residual life of aircraft engine |

| CN2019110642375 | 2019-11-04 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN112131760A CN112131760A (en) | 2020-12-25 |

| CN112131760B true CN112131760B (en) | 2022-08-23 |

Family

ID=69500993

Family Applications (4)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201911064237.5A Pending CN110807257A (en) | 2019-11-04 | 2019-11-04 | Method for predicting residual life of aircraft engine |

| CN202011205350.3A Active CN112149316B (en) | 2019-11-04 | 2020-11-02 | Aero-engine residual life prediction method based on improved CNN model |

| CN202011205335.9A Active CN112100865B (en) | 2019-11-04 | 2020-11-02 | Method for predicting remaining life of aircraft engine based on parallel CNN model |

| CN202011206202.3A Active CN112131760B (en) | 2019-11-04 | 2020-11-02 | CBAM model-based prediction method for residual life of aircraft engine |

Family Applications Before (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201911064237.5A Pending CN110807257A (en) | 2019-11-04 | 2019-11-04 | Method for predicting residual life of aircraft engine |

| CN202011205350.3A Active CN112149316B (en) | 2019-11-04 | 2020-11-02 | Aero-engine residual life prediction method based on improved CNN model |

| CN202011205335.9A Active CN112100865B (en) | 2019-11-04 | 2020-11-02 | Method for predicting remaining life of aircraft engine based on parallel CNN model |

Country Status (1)

| Country | Link |

|---|---|

| CN (4) | CN110807257A (en) |

Families Citing this family (36)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111361759B (en) * | 2020-03-02 | 2023-02-03 | 哈尔滨工业大学 | Airplane auxiliary power device on-wing residual life prediction method based on hybrid model |

| CN111460728B (en) * | 2020-03-09 | 2022-08-12 | 华南理工大学 | Method and device for predicting residual life of industrial equipment, storage medium and equipment |

| CN111507046B (en) * | 2020-04-16 | 2022-09-06 | 哈尔滨工程大学 | Method and system for predicting remaining service life of electric gate valve |

| CN111639467B (en) * | 2020-06-08 | 2024-04-16 | 长安大学 | Aero-engine service life prediction method based on long-term and short-term memory network |

| CN111695521B (en) * | 2020-06-15 | 2022-06-10 | 哈尔滨理工大学 | Attention-LSTM-based rolling bearing performance degradation prediction method |

| CN111597663B (en) * | 2020-07-27 | 2020-10-27 | 中国人民解放军国防科技大学 | Momentum wheel residual life prediction method fusing residual life empirical data |

| CN112115643B (en) * | 2020-09-15 | 2022-06-10 | 中南大学 | Smart train service life non-invasive prediction method |

| CN112131673B (en) * | 2020-09-30 | 2021-09-28 | 西南石油大学 | Engine surge fault prediction system and method based on fusion neural network model |

| CN112231980B (en) * | 2020-10-19 | 2024-06-07 | 西安建筑科技大学 | Engine life prediction method, storage medium and computing device |

| CN112560252B (en) * | 2020-12-07 | 2023-09-15 | 厦门大学 | Method for predicting residual life of aeroengine |

| CN112613226B (en) * | 2020-12-10 | 2022-11-18 | 大连理工大学 | Feature enhancement method for residual life prediction |

| CN112613227B (en) * | 2020-12-15 | 2022-09-30 | 大连理工大学 | Model for predicting remaining service life of aero-engine based on hybrid machine learning |

| CN112881518B (en) * | 2021-01-08 | 2022-07-12 | 东冶及策河北能源技术有限公司 | Method for predicting residual life of dynamic filter compensator |

| CN113158445B (en) * | 2021-04-06 | 2022-10-21 | 中国人民解放军战略支援部队航天工程大学 | Prediction algorithm for residual service life of aero-engine with convolution memory residual error self-attention mechanism |

| CN113139278A (en) * | 2021-04-08 | 2021-07-20 | 上海工程技术大学 | Deep learning-based bearing residual life prediction method and system |

| CN113076913A (en) * | 2021-04-16 | 2021-07-06 | 嘉兴毕格智能科技有限公司 | Aircraft engine fault prediction method |

| CN113297787B (en) * | 2021-05-12 | 2021-12-17 | 北京航空航天大学 | Method for predicting remaining life of aircraft engine based on transfer learning |

| CN113344281B (en) * | 2021-06-22 | 2022-02-11 | 太仓比泰科自动化设备有限公司 | Probe performance prediction method, system, device and storage medium |

| CN113722989B (en) * | 2021-08-23 | 2023-04-28 | 南京航空航天大学 | CPS-DP model-based aeroengine service life prediction method |

| CN113602526B (en) * | 2021-08-27 | 2023-05-23 | 中国航空工业集团公司上海航空测控技术研究所 | Verification test method and system for electromechanical fault prediction and health management system of airplane |

| CN114048762B (en) * | 2021-09-26 | 2024-07-02 | 东南大学 | Double-attention-guided rotary machine health assessment method |

| CN113987704B (en) * | 2021-10-28 | 2024-09-13 | 重庆大学 | Aero-engine service life prediction method based on automatic multi-differential learning deep network |

| CN114266278B (en) * | 2021-12-29 | 2024-02-20 | 合肥工业大学 | Dual-attention network-based equipment residual service life prediction method |

| CN114510870B (en) * | 2022-01-07 | 2024-04-16 | 华东交通大学 | Method and device for predicting residual life of underground structure of urban rail transit |

| CN114707257A (en) * | 2022-02-18 | 2022-07-05 | 江苏赛德力制药机械制造有限公司 | Mechanical residual service life prediction method based on all-state attention and BiLSTM |

| CN114528662A (en) * | 2022-02-22 | 2022-05-24 | 上海三一重机股份有限公司 | Method and device for predicting residual life of structural part and operating machine |

| CN114880767B (en) * | 2022-04-24 | 2024-03-08 | 西北工业大学 | Aero-engine residual service life prediction method based on attention mechanism Dense-GRU network |

| CN114971052A (en) * | 2022-06-07 | 2022-08-30 | 南京理工大学 | Engine remaining service life prediction method based on improved HRHN |

| CN115510740A (en) * | 2022-09-02 | 2022-12-23 | 同济大学 | Aero-engine residual life prediction method based on deep learning |

| CN115982942B (en) * | 2022-11-25 | 2023-07-14 | 浙江长龙航空有限公司 | Method, device, equipment and storage medium for predicting residual life of aviation precooler |

| CN116502516B (en) * | 2023-01-15 | 2023-12-01 | 北京控制工程研究所 | Identification method and device for degradation stage of spacecraft component |

| CN116561528B (en) * | 2023-05-08 | 2024-03-01 | 重庆市荣冠科技有限公司 | RUL prediction method of rotary machine |

| CN117113843B (en) * | 2023-08-29 | 2024-06-07 | 太原理工大学 | Method for predicting residual life of aeroengine |

| CN117556261B (en) * | 2024-01-08 | 2024-05-14 | 浙江大学 | MCNN-based diaphragm pump check valve service life prediction method and system |

| CN118133690B (en) * | 2024-05-07 | 2024-07-26 | 深圳市安保医疗科技股份有限公司 | Sample construction method, turbine performance prediction method, device, equipment and medium |

| CN118656595A (en) * | 2024-08-09 | 2024-09-17 | 中国人民解放军国防科技大学 | Engine residual life prediction method and device based on digital-real combined data |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20170116552A1 (en) * | 2010-06-04 | 2017-04-27 | Sapience Analytics Private Limited | System and Method to Measure, Aggregate and Analyze Exact Effort and Time Productivity |

| CN103336908B (en) * | 2013-07-23 | 2016-01-20 | 哈尔滨工业大学 | The method for predicting residual useful life of dull echo state network |

| CN106169001B (en) * | 2016-07-11 | 2019-06-21 | 北京航空航天大学 | A kind of aero-engine complete machine method for predicting residual useful life based on gas circuit performance parameter Graphic Pattern Matching |

| CN107153759B (en) * | 2017-04-27 | 2019-10-15 | 西安交通大学 | A kind of aviation turbofan engine method for predicting residual useful life of multisource data fusion |

| CN108959778B (en) * | 2018-07-06 | 2020-09-15 | 南京航空航天大学 | Method for predicting residual life of aircraft engine based on consistency of degradation modes |

| CN109272114A (en) * | 2018-08-08 | 2019-01-25 | 西安交通大学 | The deep learning method that mechanized equipment remaining life is quickly and effectively predicted |

| CN109460574A (en) * | 2018-10-09 | 2019-03-12 | 南京航空航天大学 | A kind of prediction technique of aero-engine remaining life |

| CN109472110B (en) * | 2018-11-29 | 2023-06-27 | 南京航空航天大学 | Method for predicting residual service life of aeroengine based on LSTM network and ARIMA model |

| CN109766583B (en) * | 2018-12-14 | 2023-06-20 | 南京航空航天大学 | Aircraft engine life prediction method based on unlabeled, unbalanced and initial value uncertain data |

| CN109783906B (en) * | 2018-12-29 | 2023-07-07 | 东北大学 | Intelligent analysis system and method for detecting magnetic flux leakage data in pipeline |

| CN109829136B (en) * | 2019-01-22 | 2022-10-04 | 中国人民解放军火箭军工程大学 | Method and system for predicting residual life of degradation equipment with random jump |

| CN109992872B (en) * | 2019-03-27 | 2020-07-28 | 西安交通大学 | Mechanical equipment residual life prediction method based on stacked separation convolution module |

-

2019

- 2019-11-04 CN CN201911064237.5A patent/CN110807257A/en active Pending

-

2020

- 2020-11-02 CN CN202011205350.3A patent/CN112149316B/en active Active

- 2020-11-02 CN CN202011205335.9A patent/CN112100865B/en active Active

- 2020-11-02 CN CN202011206202.3A patent/CN112131760B/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN112100865B (en) | 2022-08-23 |

| CN112131760A (en) | 2020-12-25 |

| CN112149316A (en) | 2020-12-29 |

| CN110807257A (en) | 2020-02-18 |

| CN112149316B (en) | 2022-04-19 |

| CN112100865A (en) | 2020-12-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN112131760B (en) | CBAM model-based prediction method for residual life of aircraft engine | |

| CN112580263B (en) | Turbofan engine residual service life prediction method based on space-time feature fusion | |

| CN108960303B (en) | Unmanned aerial vehicle flight data anomaly detection method based on LSTM | |

| CN108256173B (en) | Gas circuit fault diagnosis method and system for dynamic process of aircraft engine | |

| CN110609524B (en) | Industrial equipment residual life prediction model and construction method and application thereof | |

| CN115758212B (en) | Mechanical equipment fault diagnosis method based on parallel network and transfer learning | |

| CN114329826A (en) | Plane cascade steady flow prediction method based on generative confrontation network | |

| CN114266278B (en) | Dual-attention network-based equipment residual service life prediction method | |

| CN112859898B (en) | Aircraft trajectory prediction method based on two-channel bidirectional neural network | |

| CN105606914A (en) | IWO-ELM-based Aviation power converter fault diagnosis method | |

| CN116434777B (en) | Transformer fault diagnosis method and system based on multistage attention and feature fusion | |

| CN111523081A (en) | Aircraft engine fault diagnosis method based on enhanced gated cyclic neural network | |

| CN114169091A (en) | Method for establishing prediction model of residual life of engineering mechanical part and prediction method | |

| CN110516391A (en) | A kind of aero-engine dynamic model modeling method neural network based | |

| CN116662743A (en) | Engine residual life prediction method based on multi-mode deep learning | |

| CN115577748A (en) | Dual-channel wind power prediction method integrated with extrusion excitation attention mechanism | |

| CN114357372A (en) | Aircraft fault diagnosis model generation method based on multi-sensor data driving | |

| CN112560252A (en) | Prediction method for residual life of aircraft engine | |

| CN115048873B (en) | Residual service life prediction system for aircraft engine | |

| CN114841063A (en) | Aero-engine residual life prediction method based on deep learning | |

| CN115017984A (en) | Early warning method and system for failure risk of aircraft engine | |

| Cui et al. | Prediction of Aeroengine Remaining Useful Life Based on SE-BiLSTM | |

| CN114880767A (en) | Aero-engine remaining service life prediction method based on attention mechanism Dense-GRU network | |

| CN112883656B (en) | Power cabin failure risk evaluation method based on normal operation data | |

| CN118094343B (en) | Attention mechanism-based LSTM machine residual service life prediction method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |